Metal surface enamel layer, processing technology of interface thereof and use of technique

A metal surface and interface treatment technology, which is applied in the direction of metal layered products, metal material coating technology, coating, etc., can solve the problems of high sintering temperature, difficulty and short time of metal enamel sintering, and achieve high degree of bonding, High-temperature gas erosion resistance and the effect of expanding the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The interface treatment technology of metal surface enamel, which consists of: surface treatment, enamel treatment, the surface treatment is to use arc spraying or oxyacetylene spraying to treat the surface of metal material products, and the enamel treatment adopts electric induction heating method high temperature Sintering, the temperature range is 850°C--1100°C, and the sintering time is 3-8 minutes.

Embodiment 2

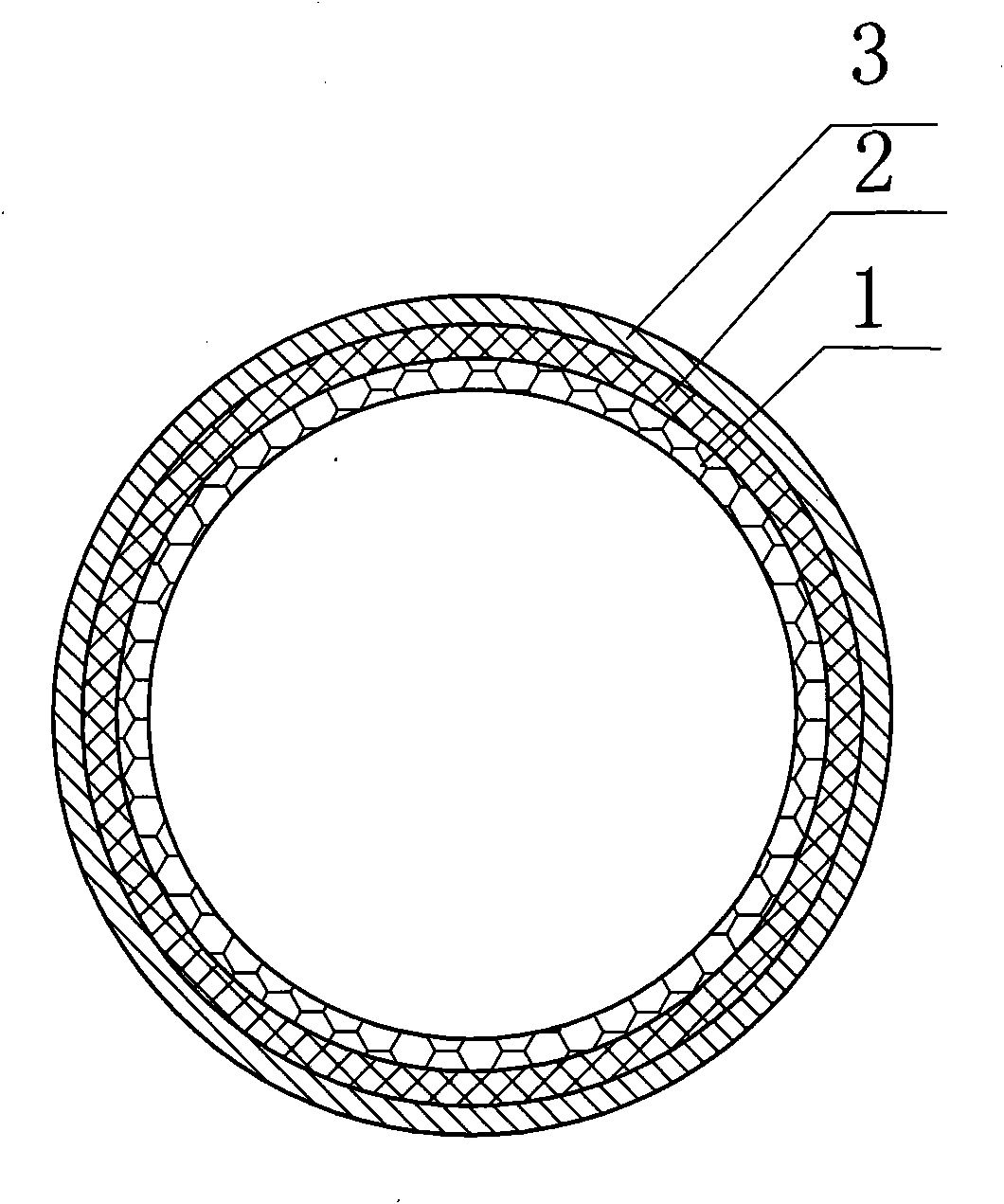

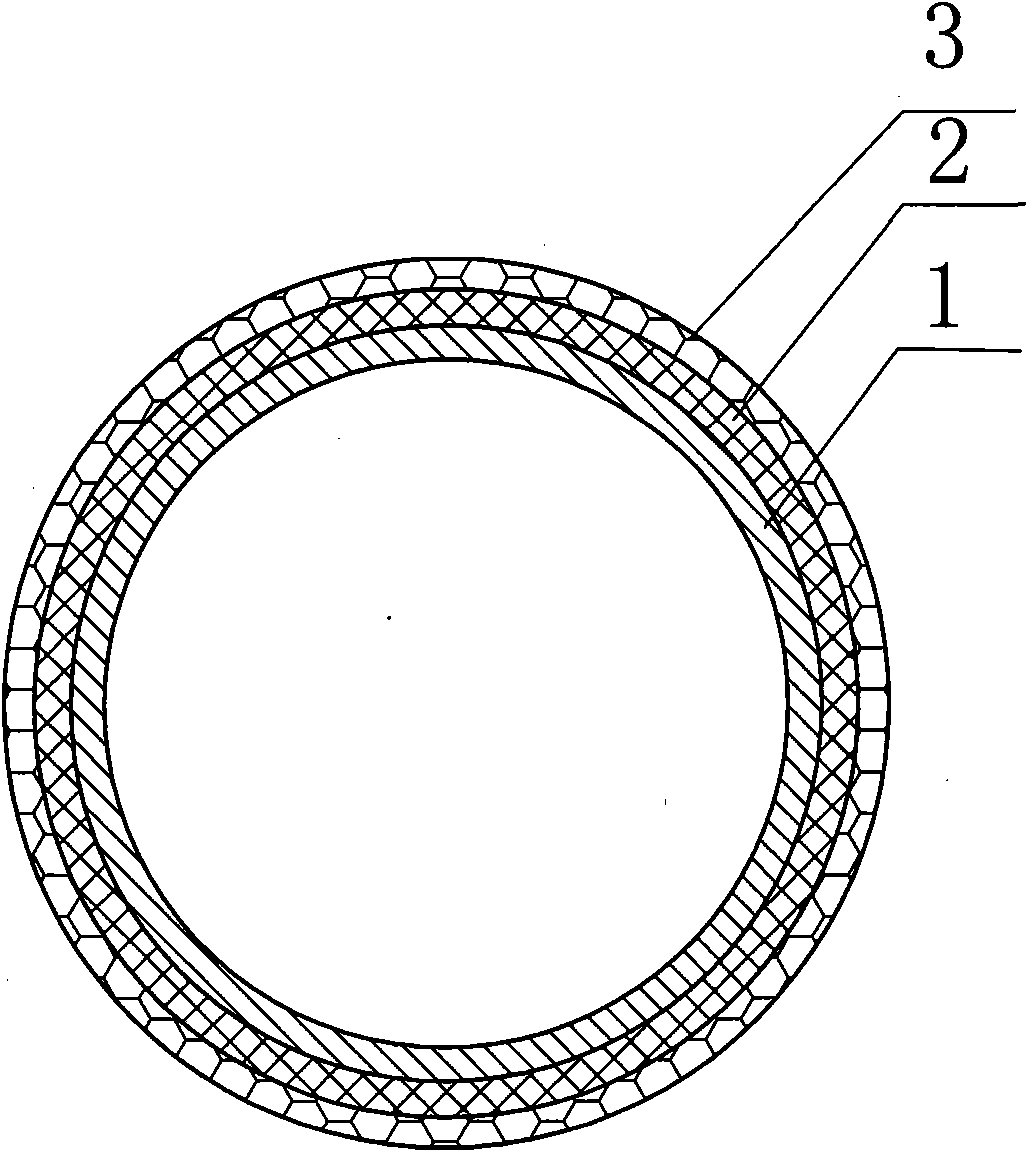

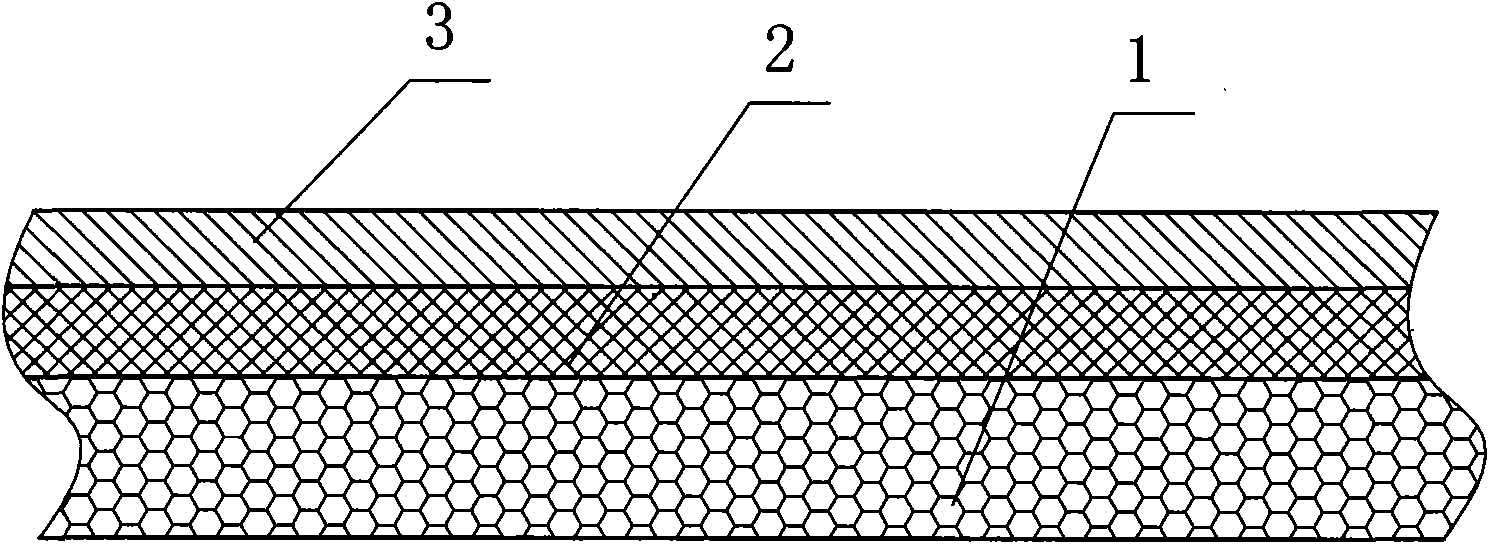

[0023] Arc spraying or oxyacetylene spraying is used to spray the surface of metal material products to obtain a metal coating with a certain roughness, and then enamel treatment is performed on the surface of the coating to form a metal matrix with a certain gradient - thermal spray coating --- Composite coating of enamel layer.

[0024] The metal substrate is processed by thermal spray coating and enamel layer to form a composite coating, which needs to be sintered at a high temperature of 850°C--1100°C. The sintering is completed by the electric induction heating process.

[0025] Among them, the metal enamel product is a cylinder with a diameter of 30mm-1000mm and a length of 1m-12m. And sintering is carried out in complex parts of various geometric shapes.

Embodiment 3

[0027] The enamel layer on the metal surface comprises: a thermal spray coating and an enamel layer. There is a thermal spray coating between the metal substrate and the enamel layer. The thermal spray coating includes a nickel base and an iron base.

[0028] The enamel layer on the metal surface, the nickel-based material includes Cr, B, Si, C, Fe, wherein the content of Cr is 15%, the content of B is 3.5%, and the content of Si content of 3.5%, the content of C is 0.8%, the content of Fe is 13%, the iron-based material includes Cr, Ni, Ti, C, and the content of Cr is 18% %, the Ni content is 8%, the Ti content is 0.8%, and the C content is 0.01%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com