Enamel removing device for enamelled wire

A technology of enameled wire paint and lacquer leather, which is applied to circuit/collector parts, equipment for dismantling/armored cables, electrical components, etc., can solve the problems of low production efficiency, poor reliability of manual welding or socketing, etc., and achieve production efficiency. High, good peeling effect, long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

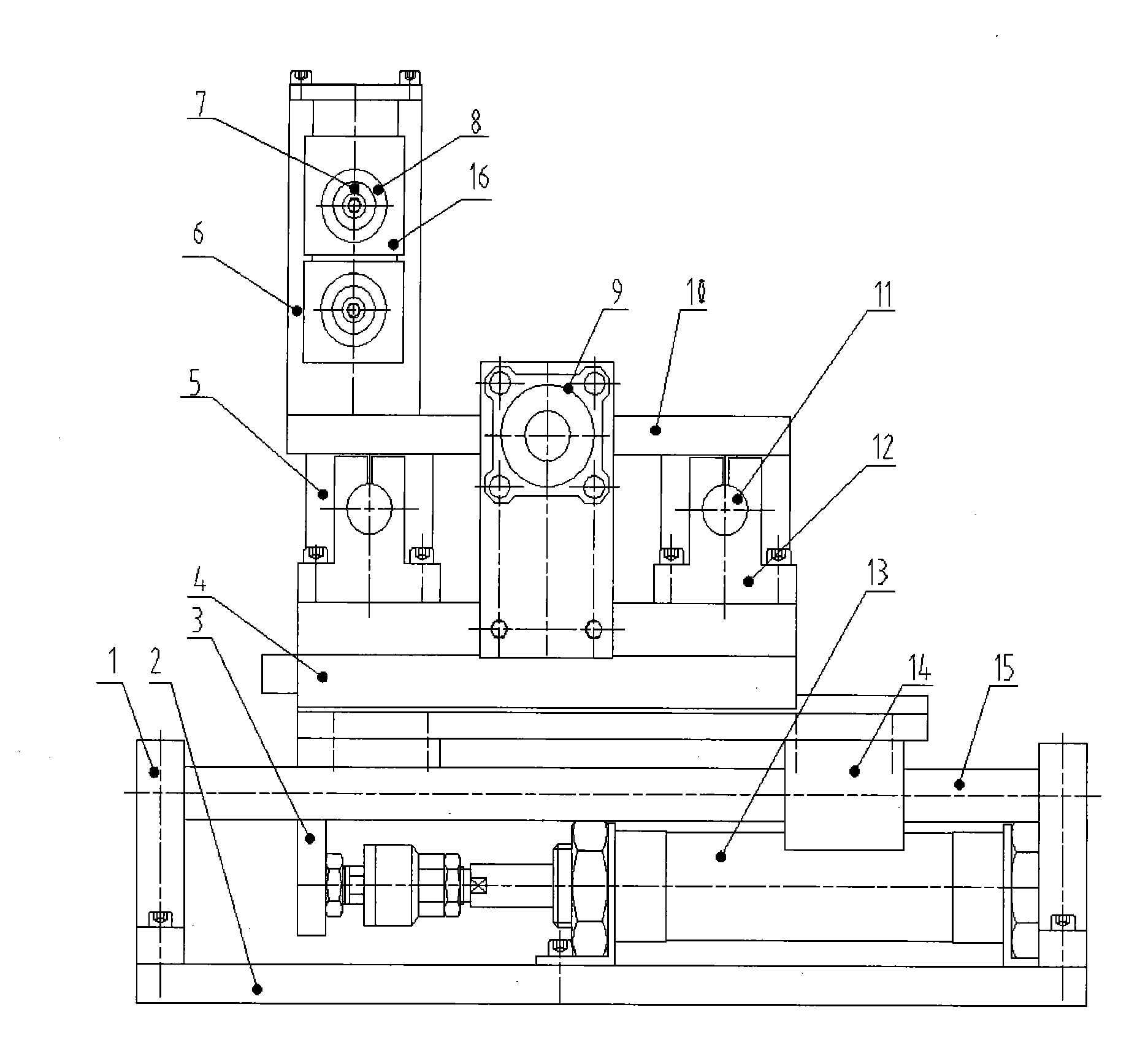

[0011] Refer to attached picture. An enameled wire paint stripping device is provided with a longitudinal movement mechanism on the base plate 2, a transverse movement mechanism on the middle fixed plate 4 of the longitudinal movement mechanism, and a paint peeling mechanism on the upper fixed plate 10 of the transverse movement mechanism. The longitudinal movement mechanism is supported and fixed by four supporting bases 1 on the base plate 2, and two longitudinal guide rods 15 are supported and fixed. The plate 4 is fixedly connected with the piston rod of the longitudinally moving cylinder 13 on the base plate 2 through the push-pull seat plate 3 . The lateral movement mechanism is provided with four support seats 12 on the middle fixed plate 4 to support and fix two lateral guide rods 11, the slider 5 is set on the two lateral guide rods 11, and the upper fixed plate 10 is also provided on the slider 5. It is fixedly connected with the lateral movement cylinder 9 on the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com