Efficient wood peeling machine with cutting mechanism

A technology of cutting mechanism and peeling machine, which is applied in the direction of wood processing equipment, bark, manufacturing tools, etc. It can solve the problems of not being able to clamp and fix the wood, easy to damage the wood, and low peeling quality, so as to ensure the peeling effect and avoid damage to the wood , The effect of saving equipment resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

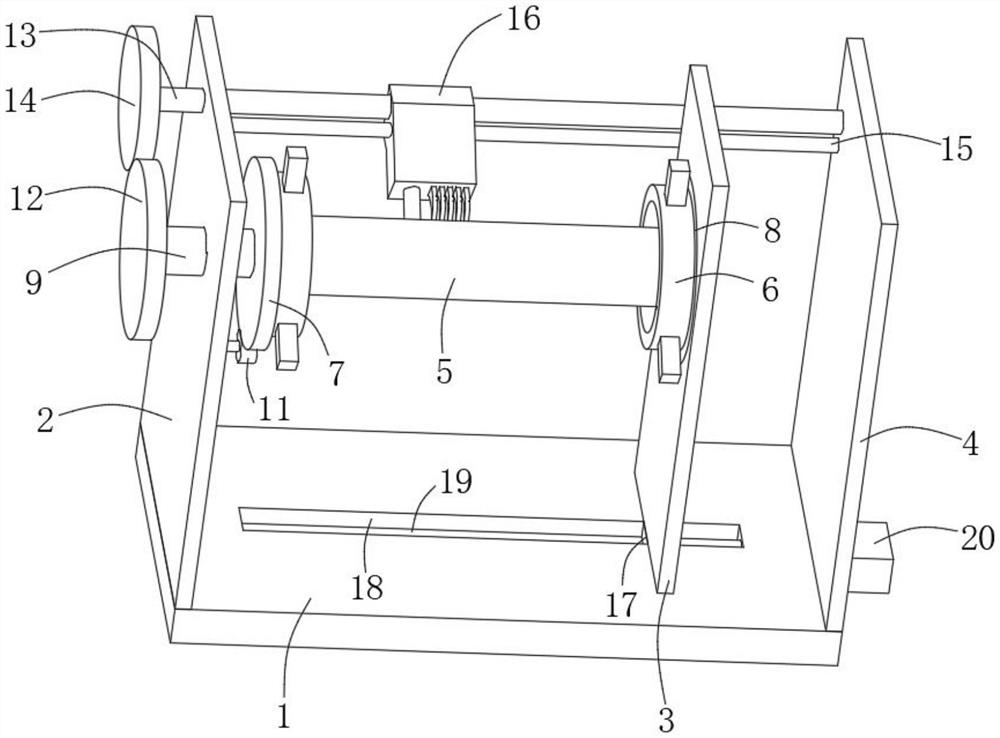

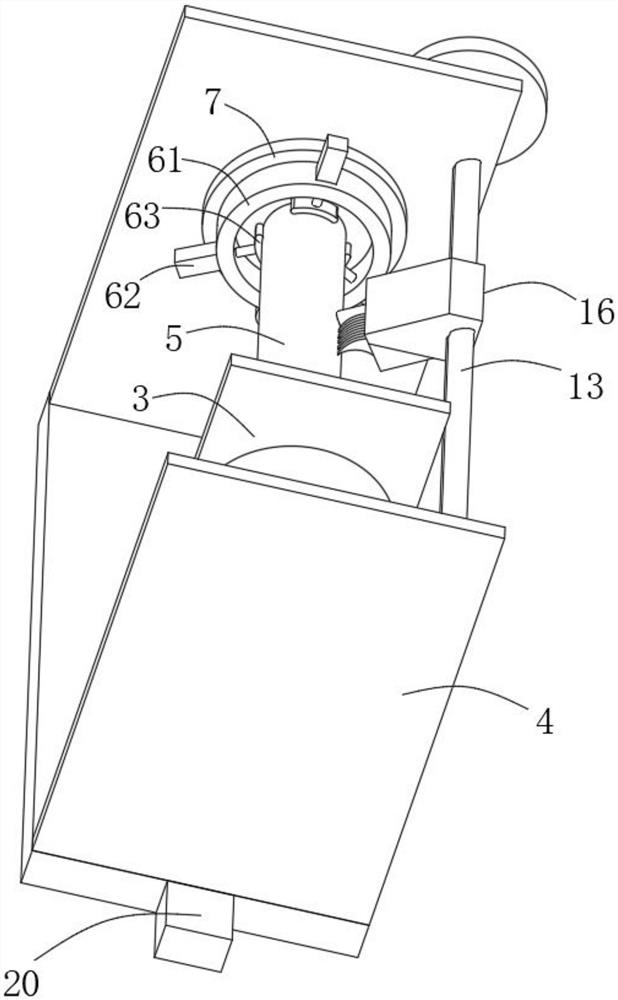

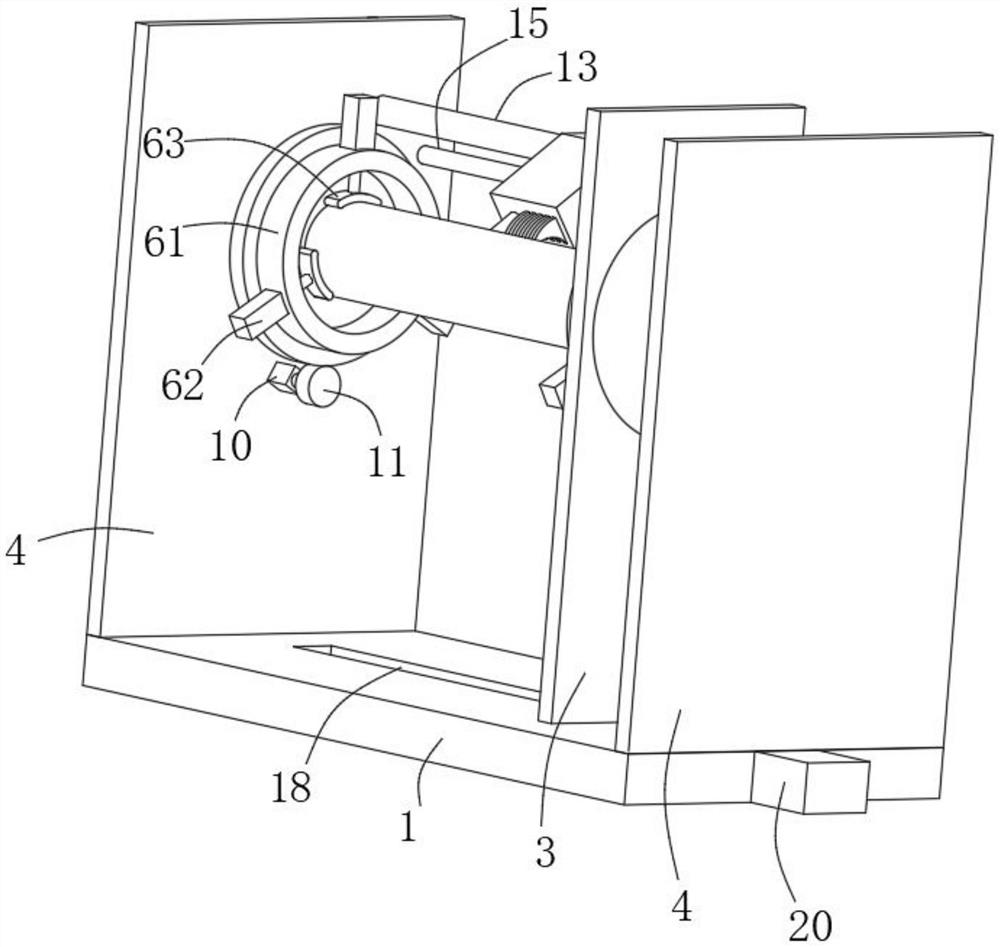

[0025] refer to Figure 1-5 , a high-efficiency wood peeling machine provided with a cutting mechanism, comprising a bottom plate 1, the upper end of the bottom plate 1 is symmetrically fixedly connected with a first support plate 2 and a second support plate 4, between the first support plate 2 and the second support plate 4 A clamping plate 3 is arranged in parallel, the width of the first support plate 2 and the second support plate 4 are equal, the width of the clamping plate 3 is smaller than the width of the first support plate 2, and the first threaded rod 13 and the guide rod 15 are located at On one side of the clamping plate 3 , the clamping plate 3 will not interfere with the rotation of the first threaded rod 13 .

[0026] An axial displacement device is connected between the clamping plate 3 and the base plate 1. Specifically, the axial displacement device includes a slider 17 fixed on the lower end of the clamping plate 3. The upper end of the base plate 1 is pro...

Embodiment 2

[0035] In this embodiment, the following improvements are made on the basis of Embodiment 1: one end of the rotating rod 9 passes through the third gear 12 and is coaxially fixedly connected with a cutting knife.

[0036] In the process of peeling the wood 5 to be peeled, in order to save power, the rotating rod 9 can cut other woods in the process of driving the cutting knife to rotate, so as to prepare for the next peeling and improve the efficiency of cutting and peeling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com