Flange pipeline butt joint design method and system

A design method and design system technology, applied in computing, computer parts, image data processing, etc., can solve the problems of low information utilization, inconvenient mold operation, long design cycle, etc., to improve design accuracy and reduce life safety. Risks and equipment safety risks, the effect of improving the utilization of spatial information

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

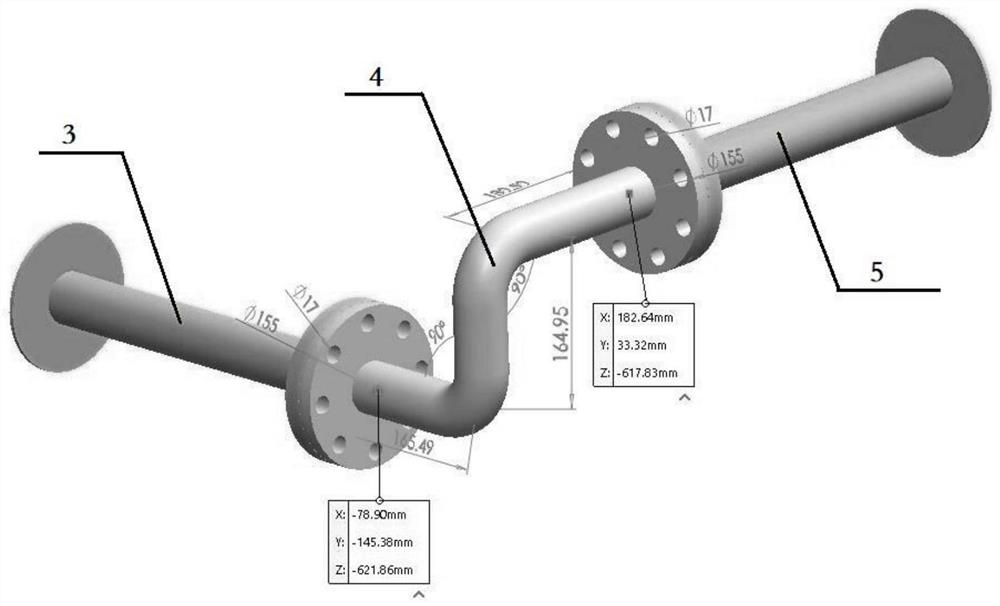

[0033] The method and system for butt joint design of flanged pipes of the present invention will be further described below in conjunction with the accompanying drawings:

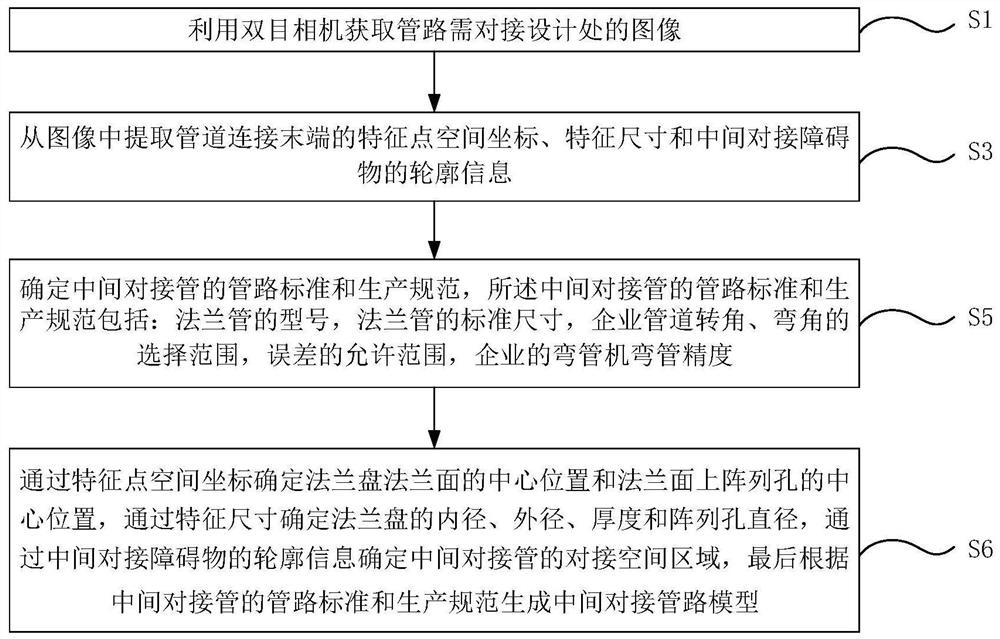

[0034] The flange pipe pipeline butt joint design method of the embodiment of the present invention, such as figure 1 shown, including the following steps:

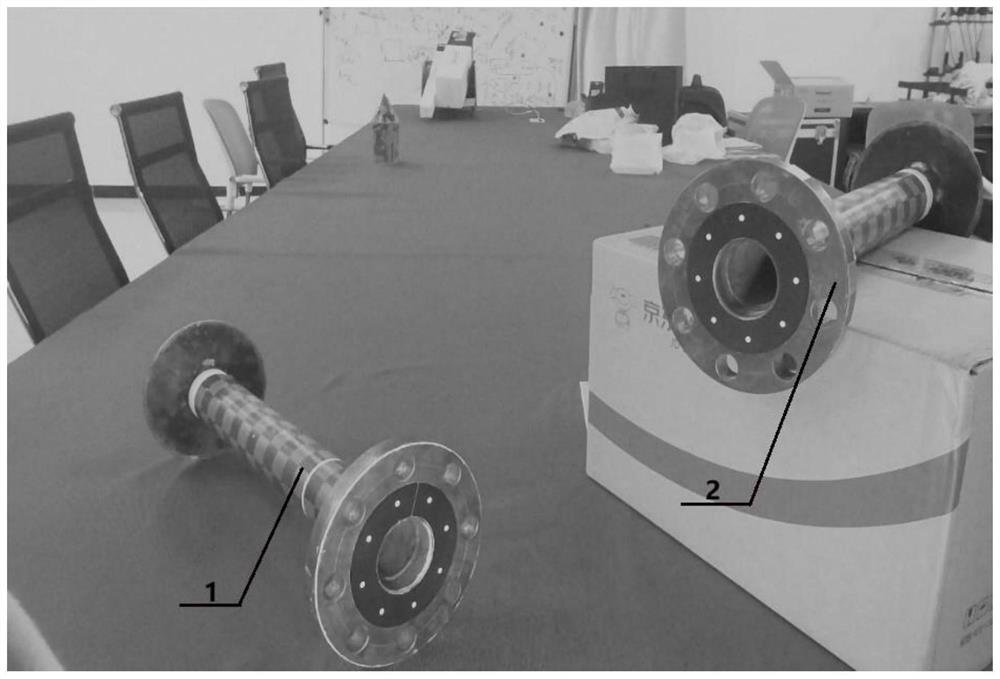

[0035] S1. Use the binocular camera to obtain the image of the place where the pipeline needs to be connected to the design. Such as figure 2 As shown, the binocular camera is used to take pictures of the design where the pipeline needs to be connected, mainly to take pictures of the connecting ends of the first sampling tube 1 and the second sampling tube 2, and then obtain the local image of the binocular camera. In order to improve the accuracy of the design, after the image is acquired, it can be manually or automatically screened through the human-computer interaction interface to obtain a better quality image.

[0036] S3. Extracting from th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com