Method for making bagged fermented preserved pickled vegetables

A technology of pickled mustard and kimchi, which is applied in the field of biotechnology and food, and can solve the problems of difficulty in realizing large-scale standardized production, high production cost of fermented mustard and kimchi, and large discharge of high-salt and high-acid wastewater, so as to inhibit the infection of pathogenic bacteria , prevent oxidation and discoloration, and promote the normal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

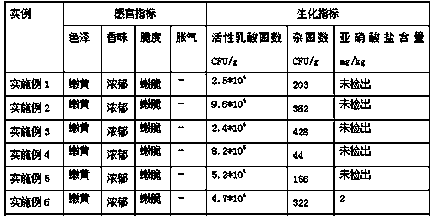

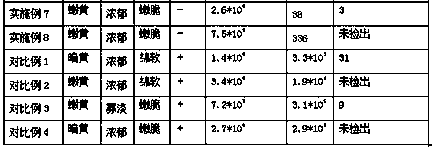

Examples

Embodiment 1

[0097] This embodiment is described by taking 100 kg of pickled mustard to make fermented pickled mustard as an example after pretreatment.

[0098] Pretreatment: Pretreatment the pickled mustard to remove impurities and inedible parts, then process the pickled mustard into knots, wash and set aside.

[0099] Disinfection and cleaning: Take 100kg of the pretreated pickled mustard, treat it with trichloroisocyanuric acid with a mass concentration of 0.01g / ㎏ for 3 minutes, rinse it with water for 3 minutes, and drain it for later use.

[0100] Dehydration: put the washed pickled mustard into a blender, add 2kg of iodine-free salt, leave it for 5 hours after stirring, and then use a three-legged centrifuge to centrifuge for 3 minutes at a speed of 1000r / min; The mustard mustard after dehydration is 78kg, and total yield is 78%. The pickled mustard of 78kg is put into the mixer again.

[0101] Raw materials: take 78kg of dehydrated pickled mustard as the benchmark, and weigh the...

Embodiment 2

[0119] The difference between this example and Example 1 is that this example uses chlorine dioxide with a mass concentration of 0.10 g / kg for 5 minutes, then rinses with water for 5 minutes, and drains for later use.

Embodiment 3

[0121] This embodiment is described by taking 200 kg of pickled mustard to make fermented pickled mustard as an example after pretreatment.

[0122] Pretreatment: Pretreatment the pickled mustard to remove impurities and inedible parts, then process the pickled mustard into blocks, wash and set aside.

[0123] Disinfection and cleaning: Take 200kg of the pretreated pickled mustard, treat it with trichloroisocyanuric acid with a mass concentration of 0.05g / ㎏ for 5 minutes, rinse it with water for 5 minutes, and drain it for later use.

[0124] Dehydration: put the washed pickled mustard into a mixer, add 16kg of iodine-free salt, stir for 19 hours, and then use a three-legged centrifuge for centrifugal dehydration. The three-legged centrifuge is centrifuged at a speed of 2000r / min for 10 minutes; Mustard mustard after dehydration is 110kg, and total yield is 55%. The pickled mustard of 110kg is put into the mixer again.

[0125] Raw materials: take 110kg of dehydrated pickled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com