Monocell, packaging film, solar cell module and manufacturing method thereof

A solar cell and packaging film technology, applied in the field of solar cells, to achieve the effects of ensuring peeling performance, solving metal wire offset, and ensuring electrical contact

- Summary

- Abstract

- Description

- Claims

- Application Information

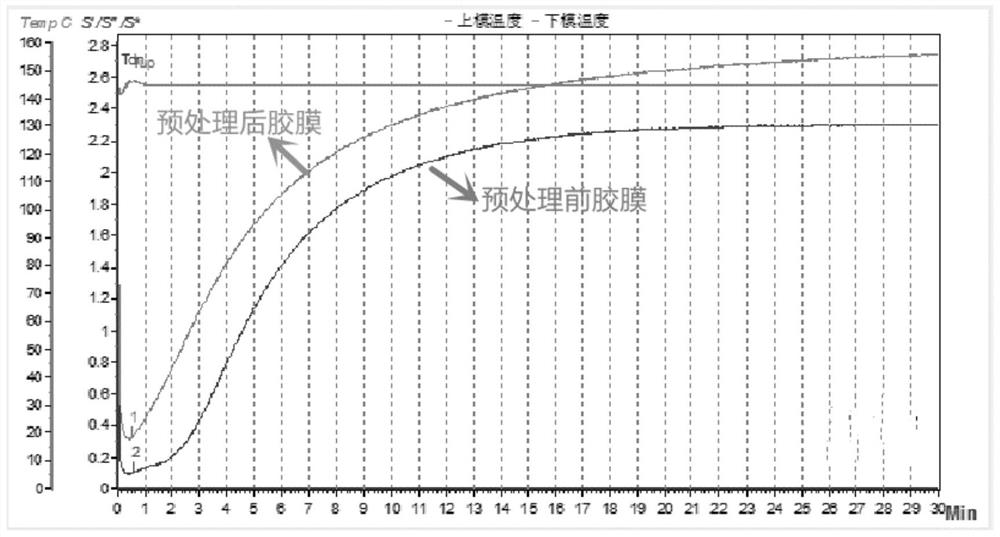

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

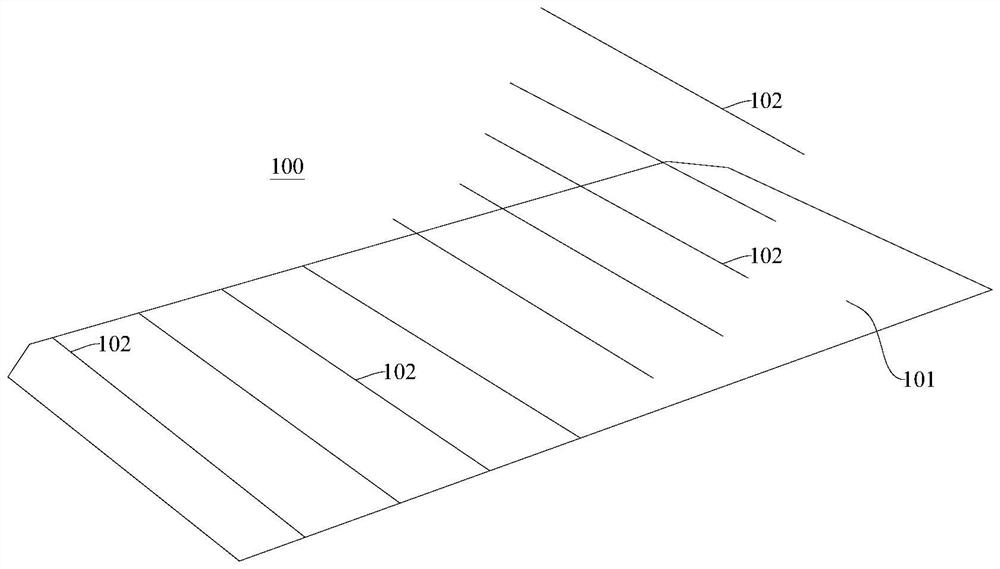

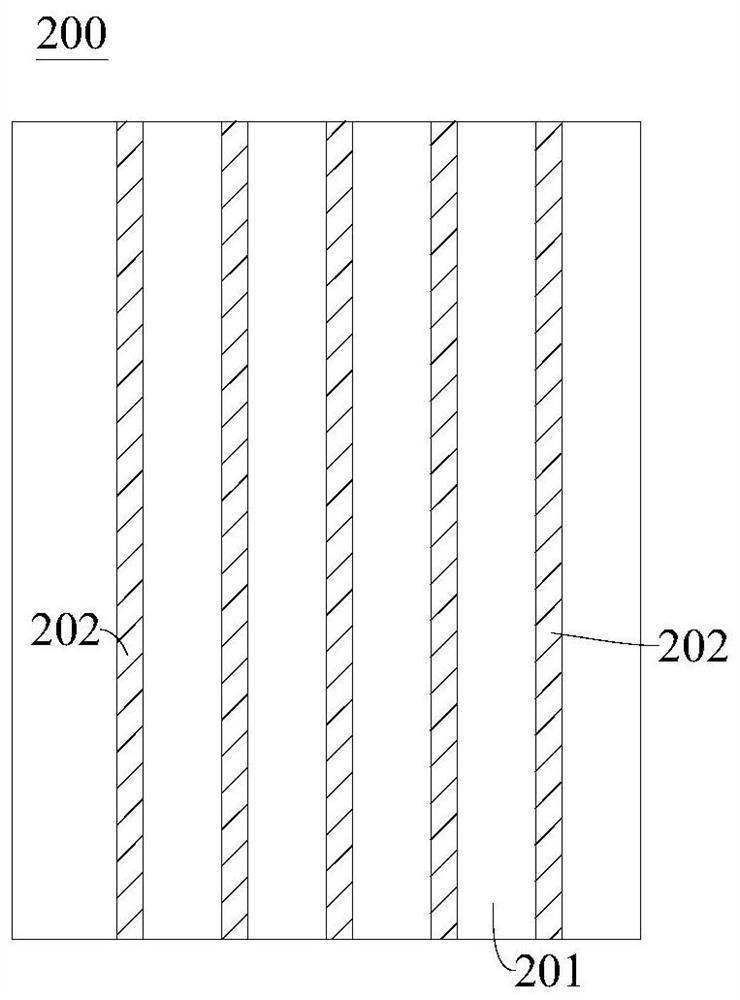

[0046] A single solar cell is usually not directly used as a power source due to factors such as its output voltage. Therefore, when used as a power source, several single cells need to be connected in series or in parallel, and then tightly packaged into components.

[0047] In addition, due to the difference in the electrical performance of individual solar cells, and considering the need to output power stably as a whole, in addition to connecting multiple single cells in series and parallel, other electrical devices can also be installed as required.

[0048] Among them, the quality of packaging is directly related to the final performance of the battery module. An important step in the packaging process is to connect individual cells in series and parallel.

[0049] At present, the production process of solar modules is to connect the "solder ribbon" with multiple "single-chip cells" according to the positive and negative electrodes. That is, one end of the ribbon is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com