Multifunctional aluminum profile anodic oxidation hanging tool

A technology for anodizing hangers and aluminum profiles, applied in anodizing, electrolytic components, electrolytic processes, etc., can solve problems such as easy shaking of aluminum profiles, and achieve the effect of reducing shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

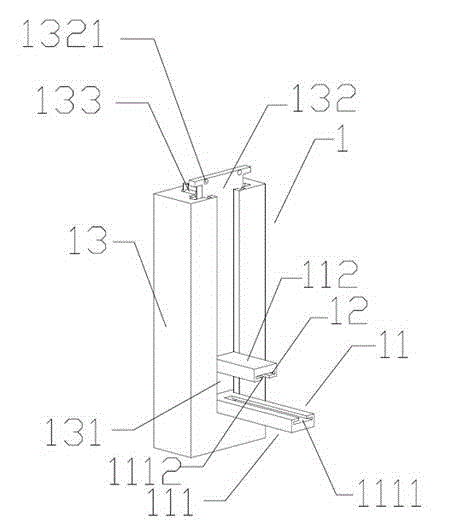

[0021] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings. A multi-functional aluminum profile anodized hanger, comprising a hanger main body 1 and a hanger insert 2.

[0022] The hanger main body 1 includes a power supply part 12 for supplying power to the hanger insert 2 , a main body installation part 11 for installing the hanger insert, and a base 13 for an external drive device and a power supply. The main body mounting part is fixedly connected to the base 13, and the power supply part 12 is electrically connected to a power source. The main body mounting part comprises the main body upper mounting part 111 and the main body lower mounting part 112 arranged in parallel up and down; one end of the main body lower mounting part 112 is fixedly connected with the base 13, and the main body upper mounting part 111 is slidably connected with the base 13 so that the main body upper mounting part 111 can slide up a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com