Enamel kettle stirring baffle structure

A technology of baffle plate structure and enamel kettle, which is applied in the field of enamel kettle mixing, can solve the problems that the full baffle condition cannot be achieved, the stirring effect is poor, and no baffle is added, so as to improve the mixing efficiency of enamel kettle, convenient layout, and guarantee The effect of corrosion resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the technical solutions of the present invention clearer and clearer to those skilled in the art, the present invention will be further described in detail below in conjunction with the examples and accompanying drawings, but the embodiments of the present invention are not limited thereto.

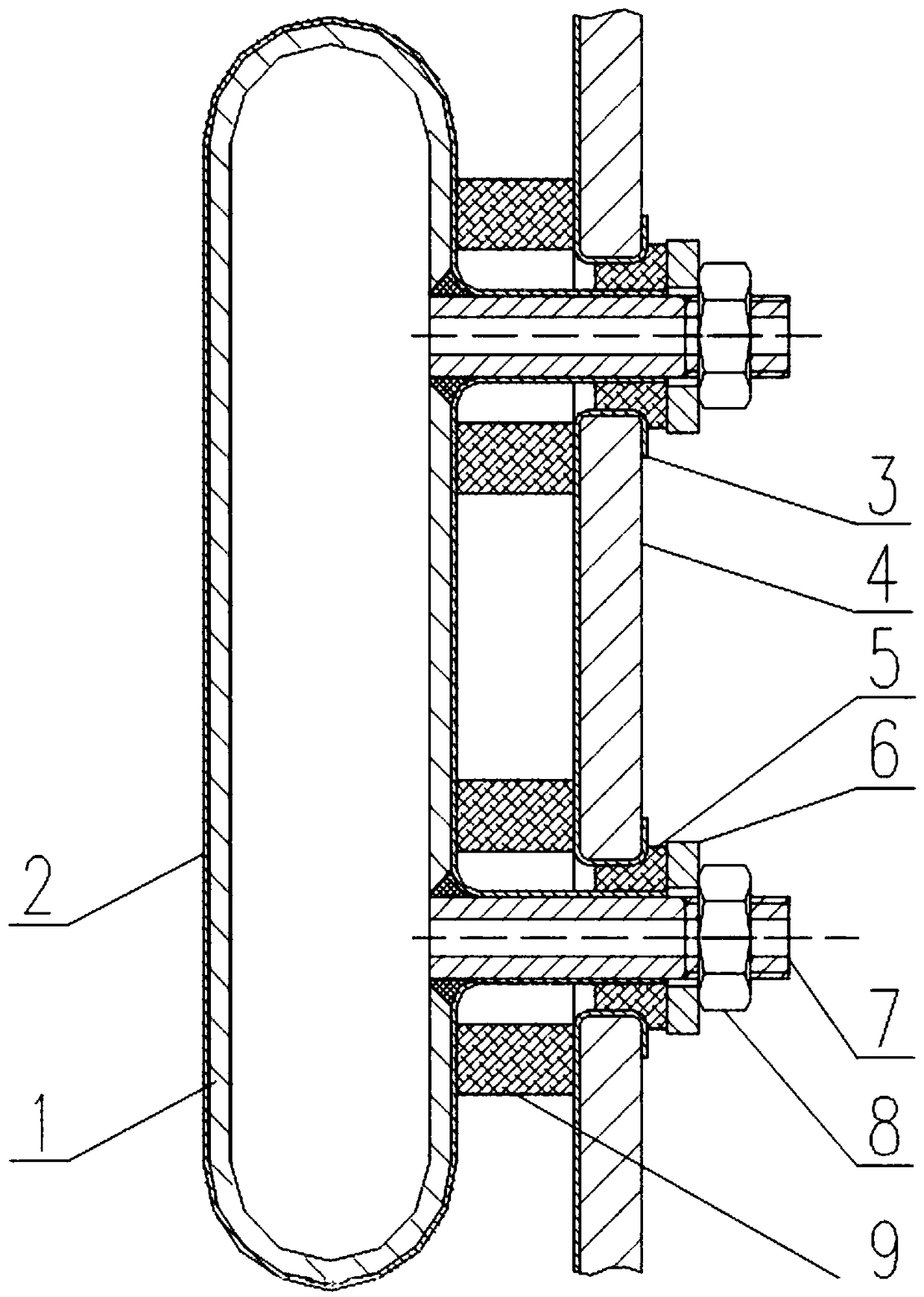

[0023] Such as figure 1 As shown, a kind of enamel kettle stirring baffle structure provided in this embodiment includes a hollow baffle 1 and at least one support tube 7 arranged on the baffle 1, and the surfaces of the baffle 1 and the support tube 7 are provided with baffles and The surface of the support tube is enamel 2, and the baffle plate 1 is installed on the cylinder body 4 of the enamel kettle through the support tube 7. 7 is provided with a positioning block 9, and after the supporting tube 7 is covered with a positioning block 9, it protrudes from the cylinder 4, and a filling material 5 and a compression ring 6 are sequentially sleeved at its protrudi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com