Patents

Literature

96results about How to "Hard surface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Implantable joint prosthesis

InactiveUS20020035400A1Improve wear resistanceImprove tribological propertiesDiagnosticsJoint implantsRange of motionIntervertebral disc

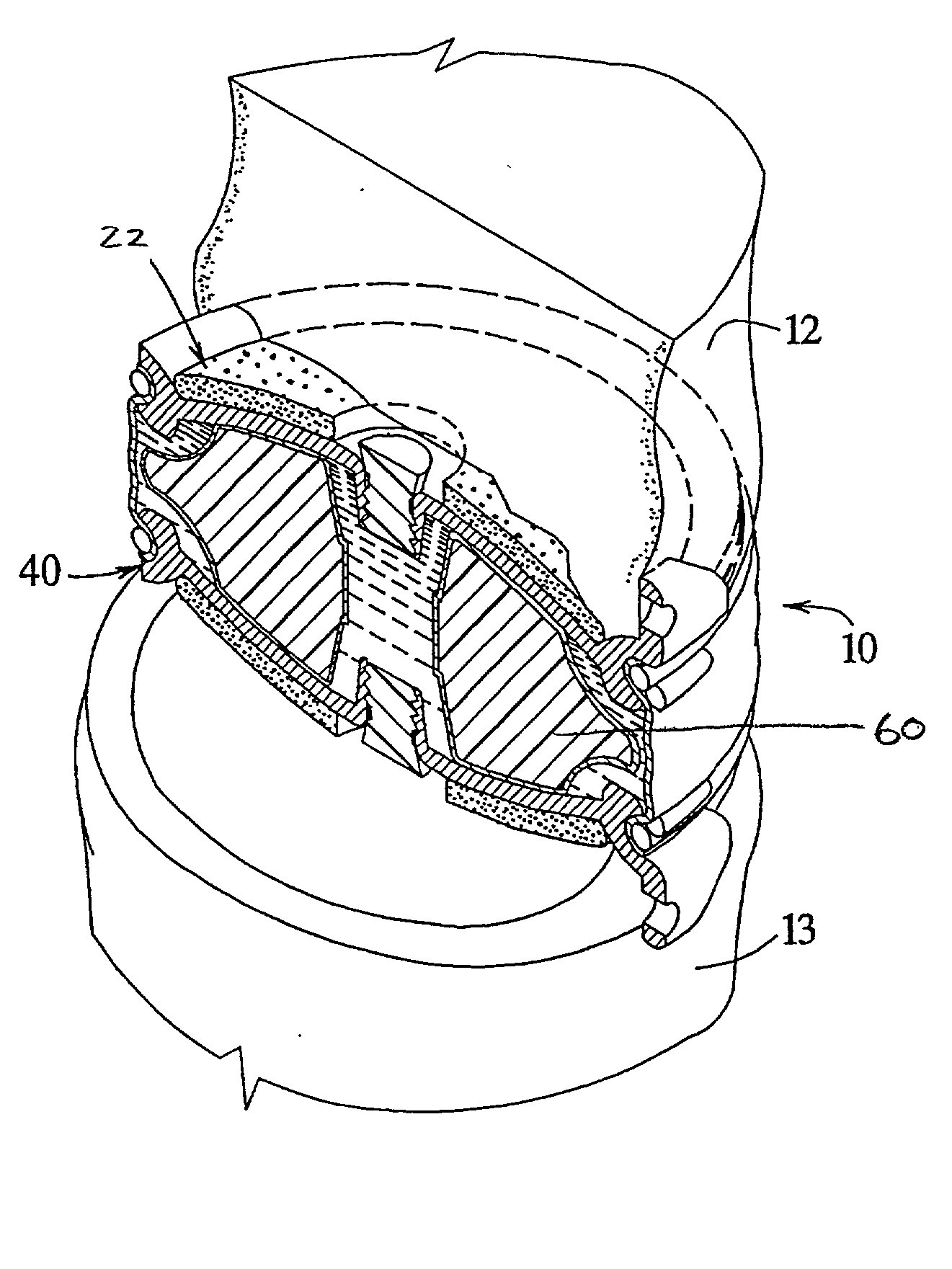

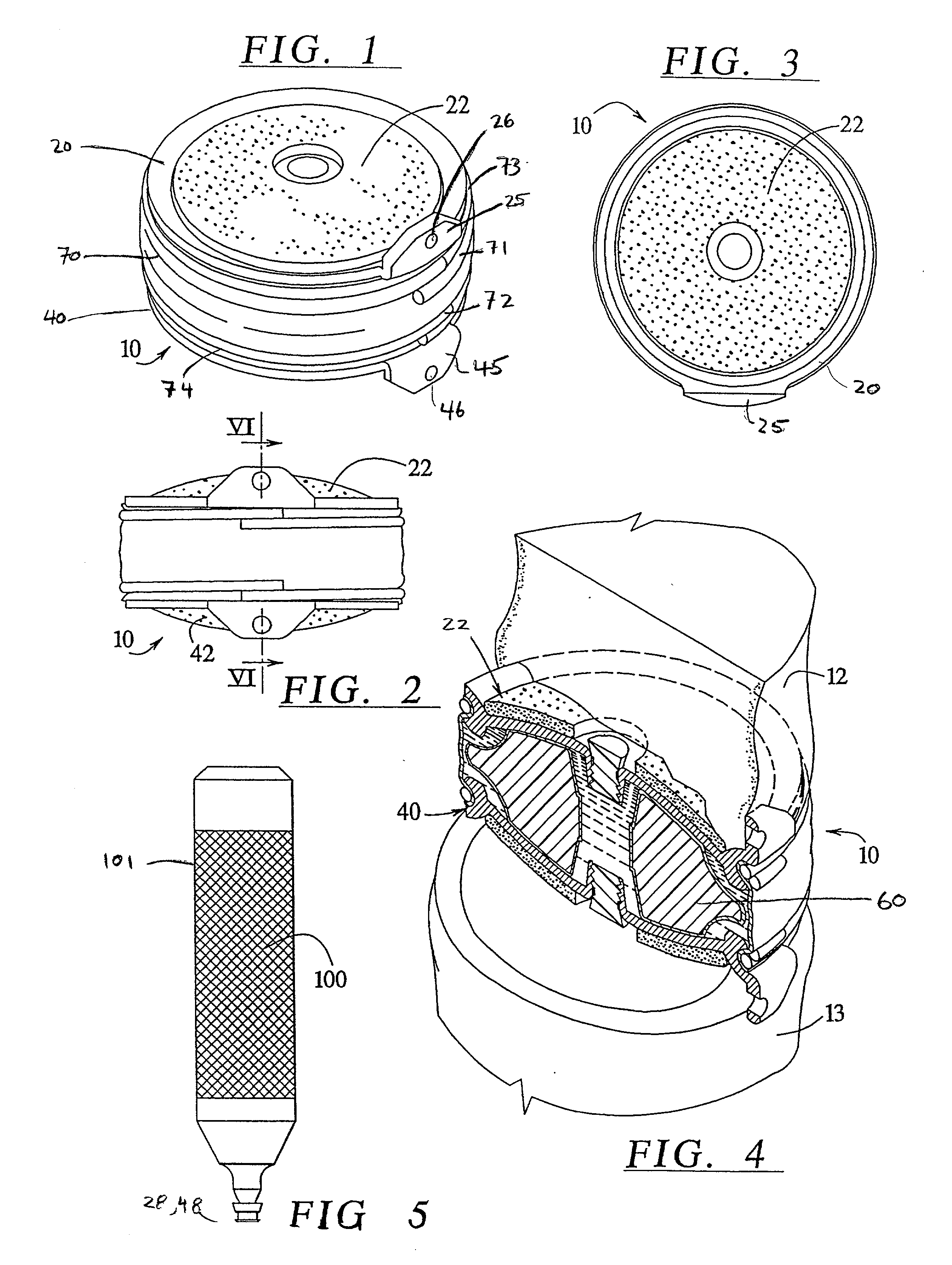

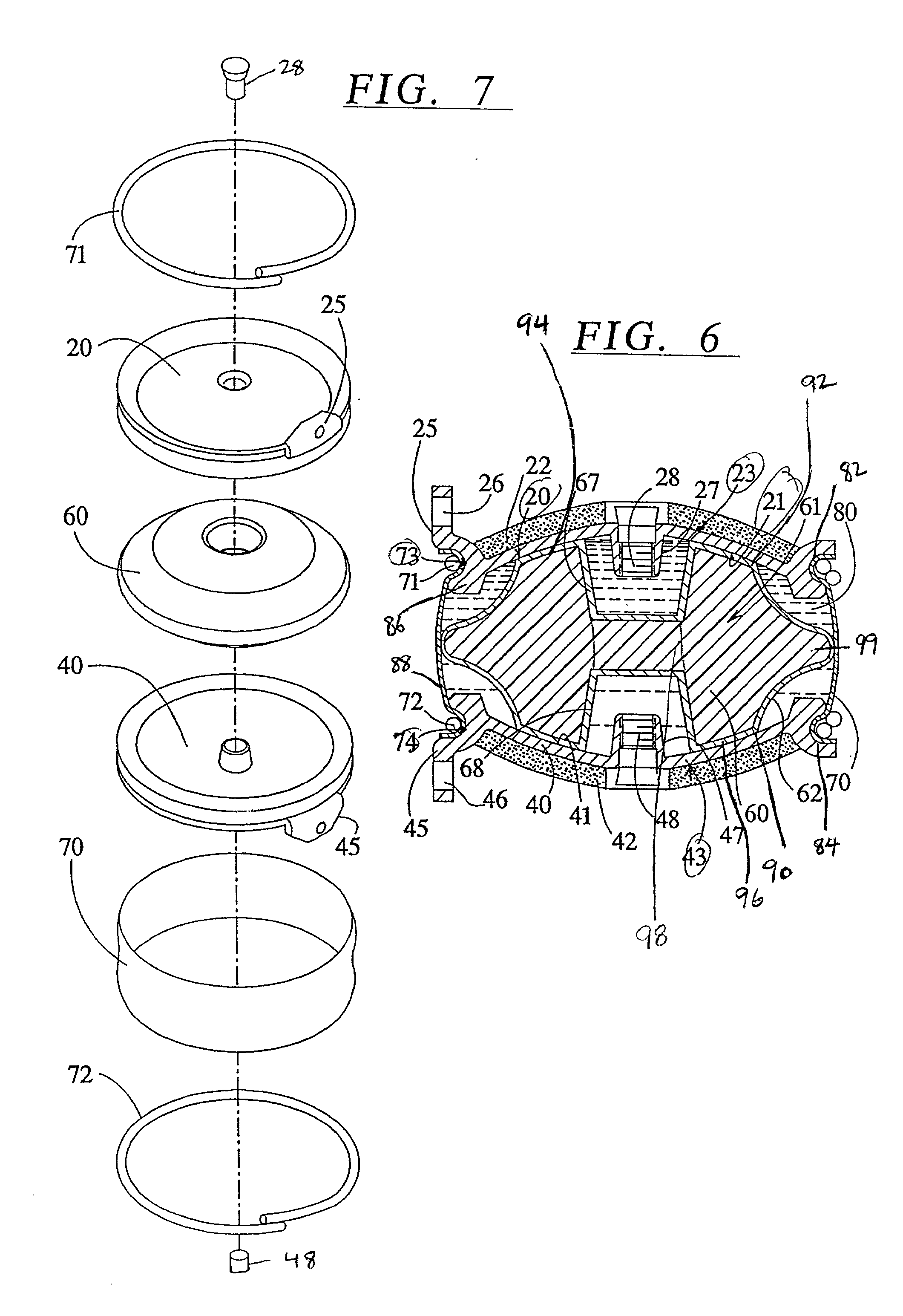

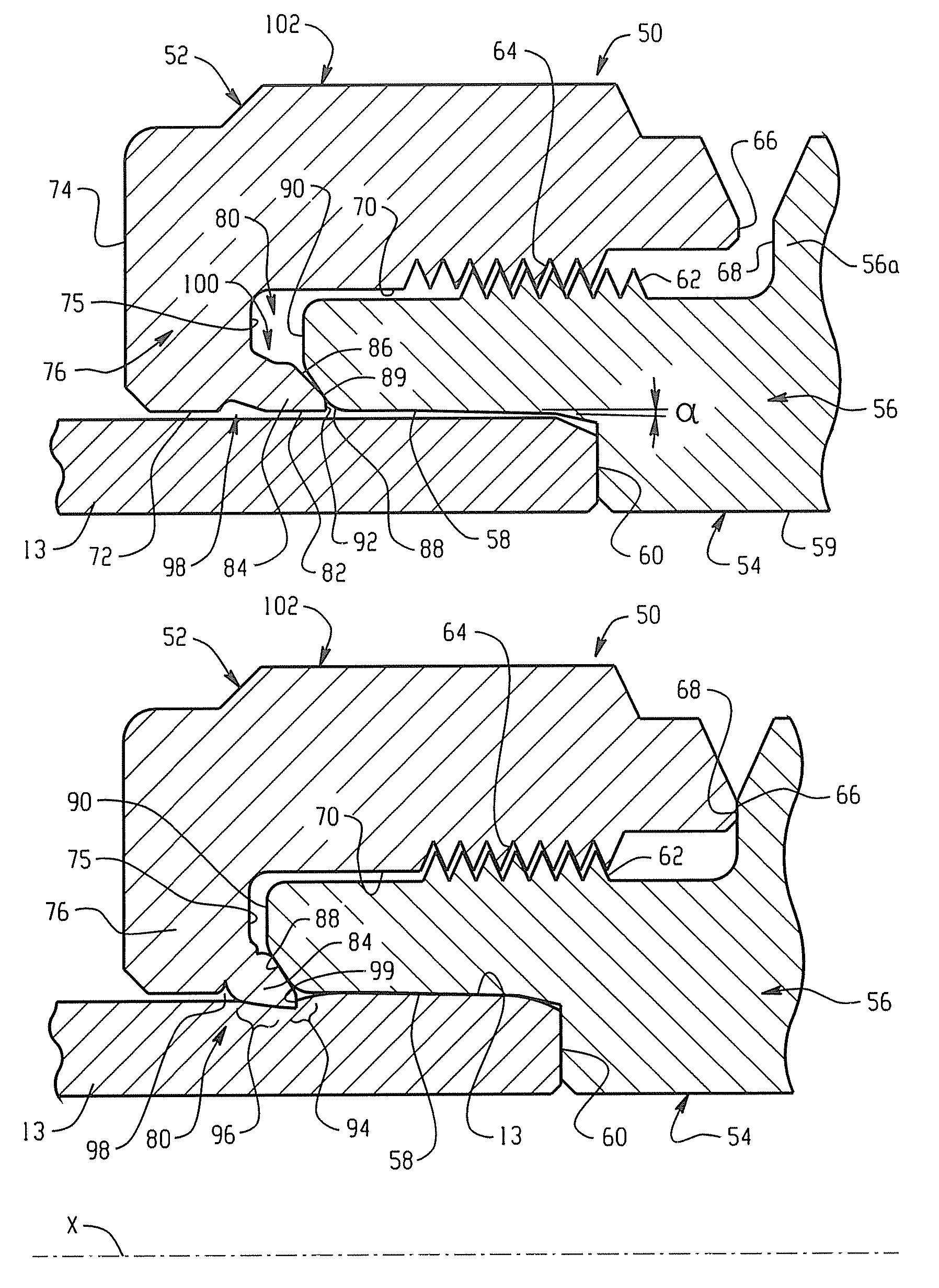

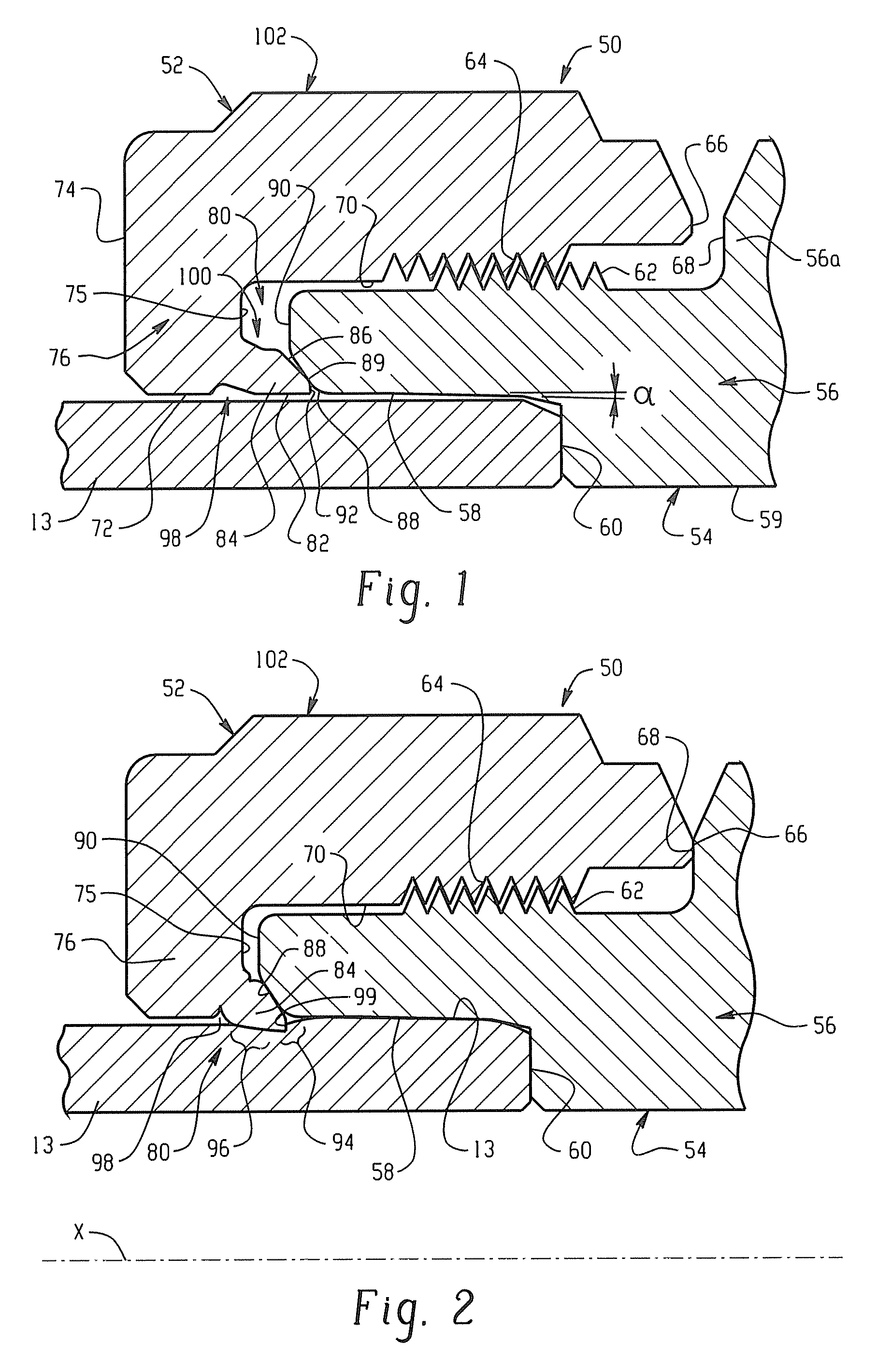

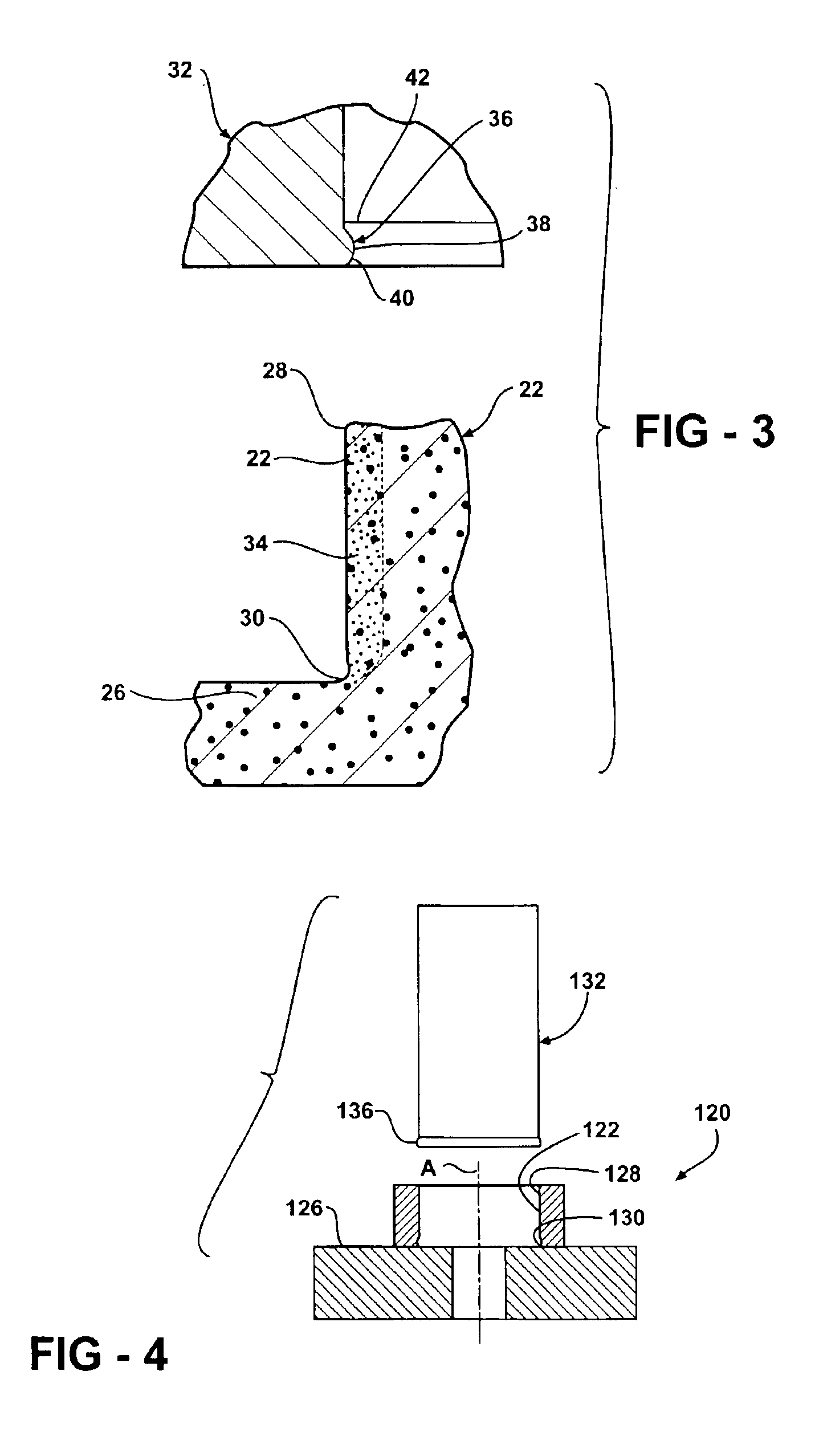

The invention relates to a surgical implant that provides an artificial diarthroidal-like joint, suitable for use in replacing any joint, but particularly suitable for use as an intervertebral disc endoprosthesis. The invention contains two rigid opposing shells, each having an outer surface adapted to engage the surfaces of the bones of a joint in such a way that the shells are immobilized by friction between their outer surfaces and the surfaces of the bone. These outer surfaces are sufficiently rough that large frictional forces strongly resist any slippage between the outer surface and the bone surfaces in the joint. They may be convex, and when inserted into a milled concavity, are immediately mechanically stable. Desirably, the outer surfaces of the shells are adapted to allow for bony ingrowth, which further stabilizes the shells in place. The inner surfaces of the shells are relatively smooth, and adapted to slide easily across a portion of the outer surface of a central body disposed between the shells. The central body has a shape that cooperates with the shape of the inner surface of the shell so as to provide a range of motion similar to that provided by a healthy joint. A flexible sheath extends between edges of the opposing shells. The inner surface of this sheath, together with the inner surfaces of the rigid shells, defines a cavity encasing the central body. At least a portion of this cavity is filled with a fluid lubricant, further decreasing the frictional force between inner surfaces of the shell and the surface of the central body.

Owner:SPINAL DYNAMICS CORP

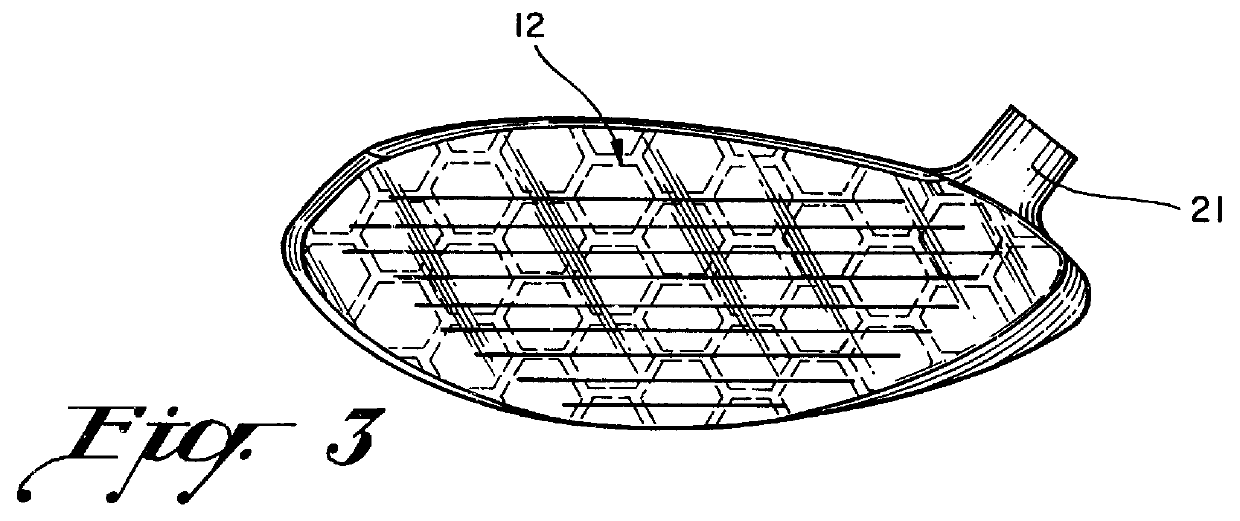

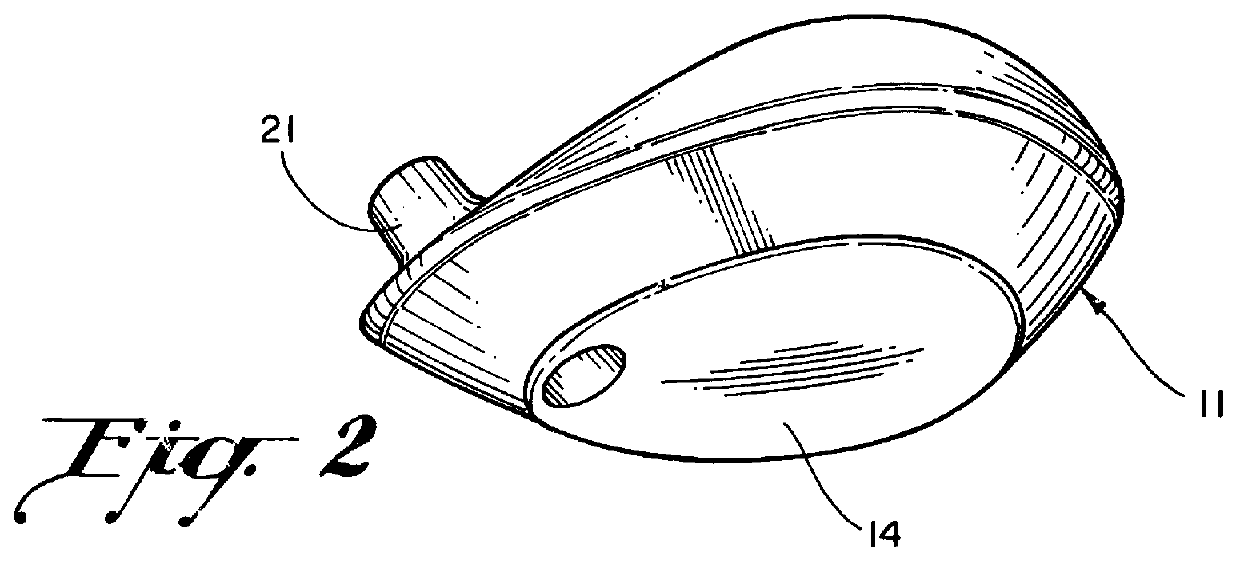

Golf club head with increased radius of gyration and face reinforcement

InactiveUSRE36950E1Increased radius of gyrationImprove impact performanceFoundry mouldsFoundry coresHeel-and-toeVertical plane

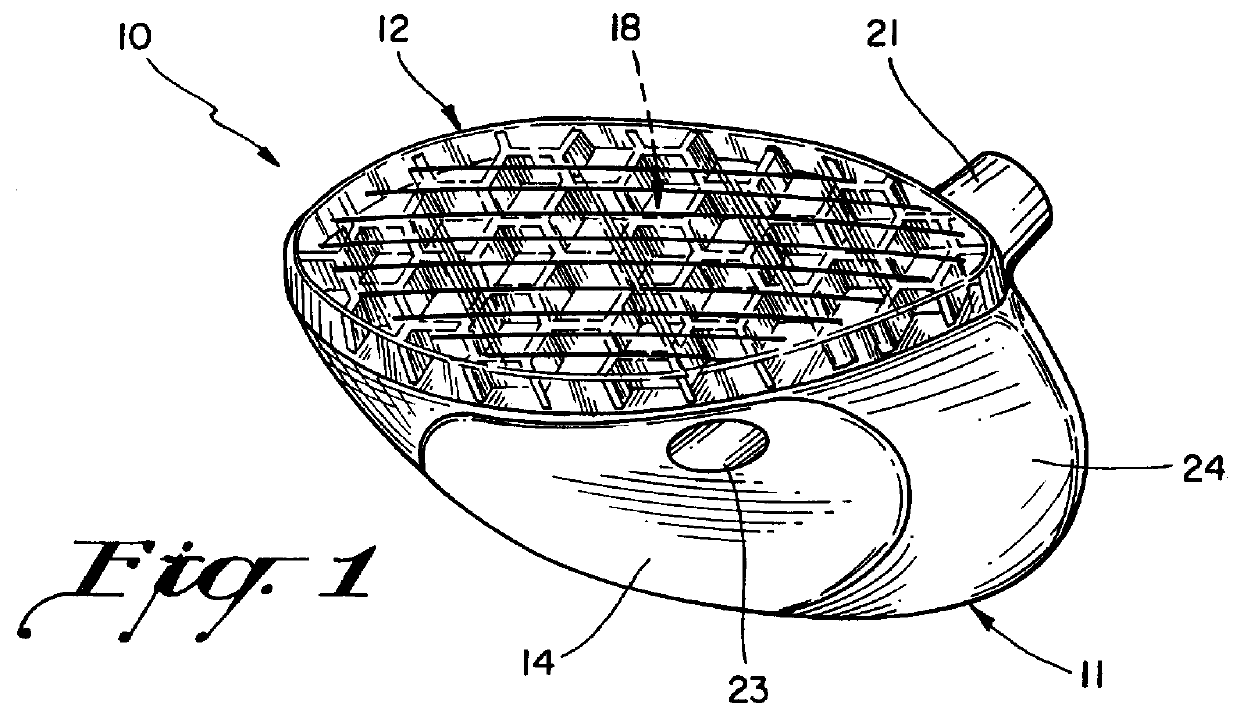

An improved high impact metal clubhead with a unique reinforced composite face wall, increased radius of gyration, and a positive lift air foil surface contour. The composite face wall includes an impact supporting wall rigidified by a pattern of integrally cast reinforcing bars that extend forwardly, rather than rearwardly, from the supporting wall. The reinforced supporting wall is covered by a very hard plastic ball striking insert that is cast in situ over the supporting wall. The increase in radius of gyration is accomplished by extending the heel and toe portions of the clubhead along the face wall further from the geometric center of the head, beyond present day parameters for high impact clubheads. And the positive lift is effected by contouring the top wall of the clubhead downwardly and rearwardly from the base wall more severely almost to the plane of the sole plate, and flattening the rear wall so it is almost co-planar with the sole plate. This configuration results in the top wall being equal to or greater in length than the combined length of the sole plate and rear wall in a vertical plane extending through the clubhead along the target line. The laws of continuity of matter and the air foil shape of the top wall eliminate the negative lift or drag in today's "woods" and offer the possibility of some positive lift to increase ball overspin.

Owner:KARSTEN MFG CORP

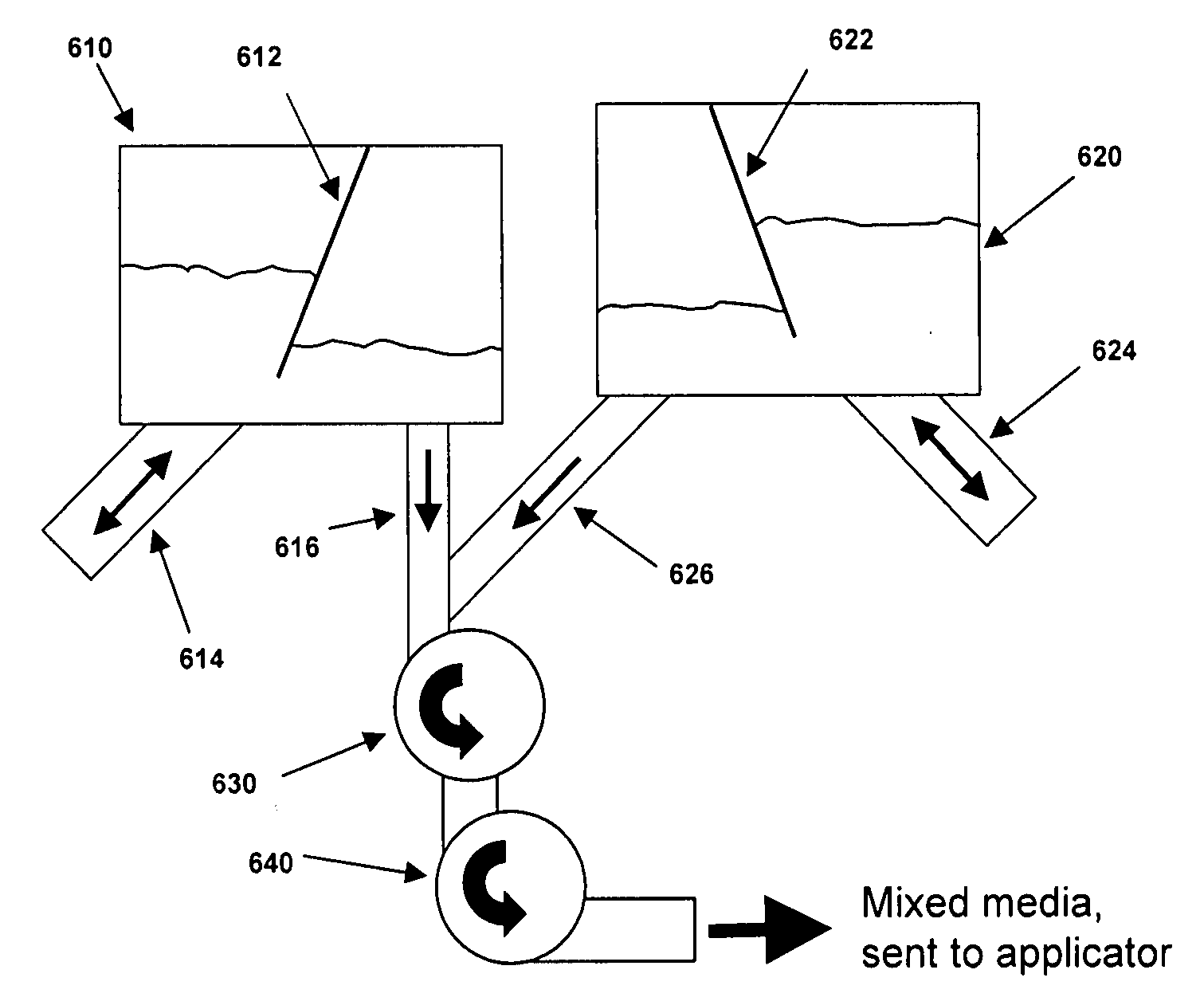

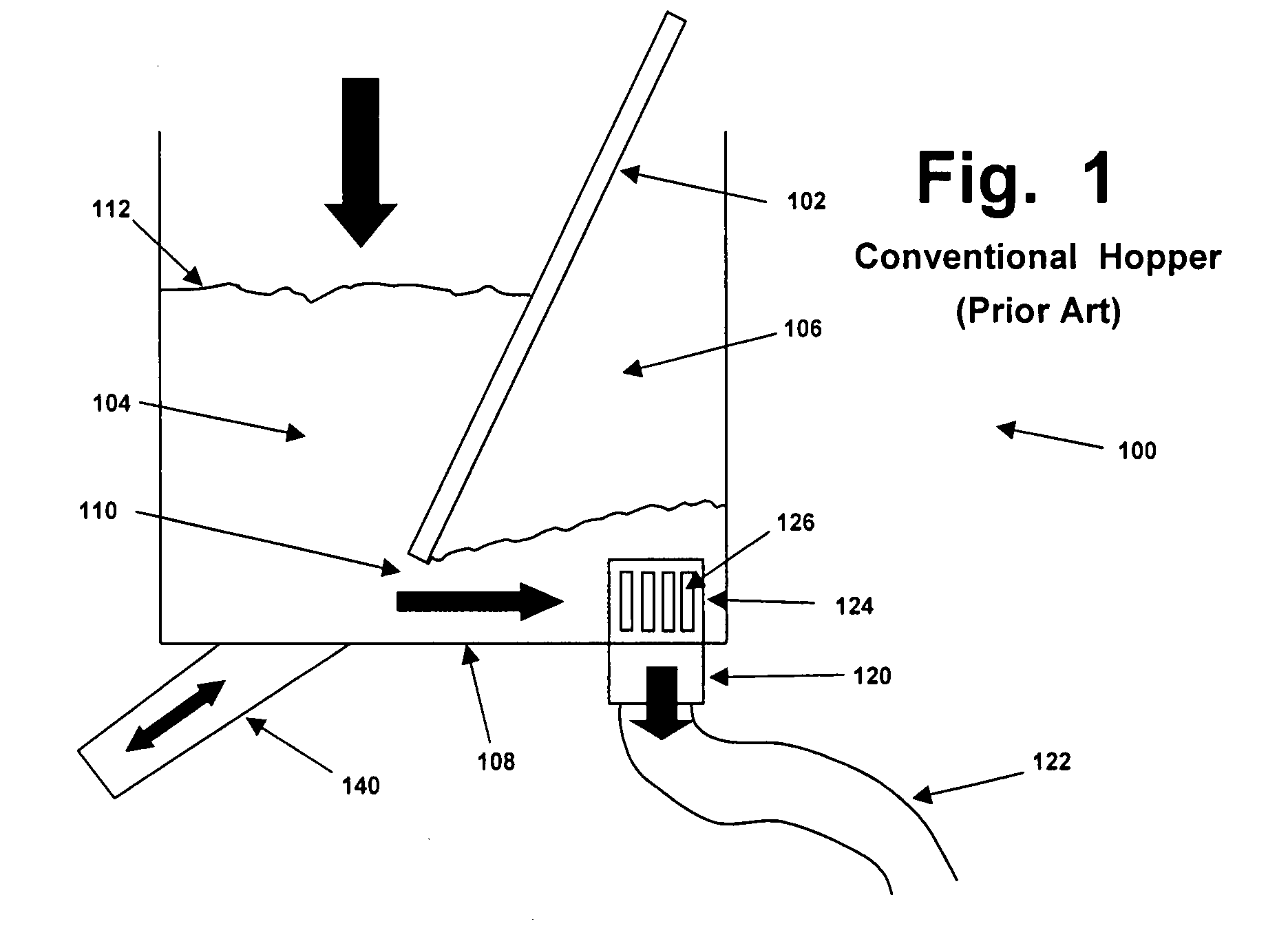

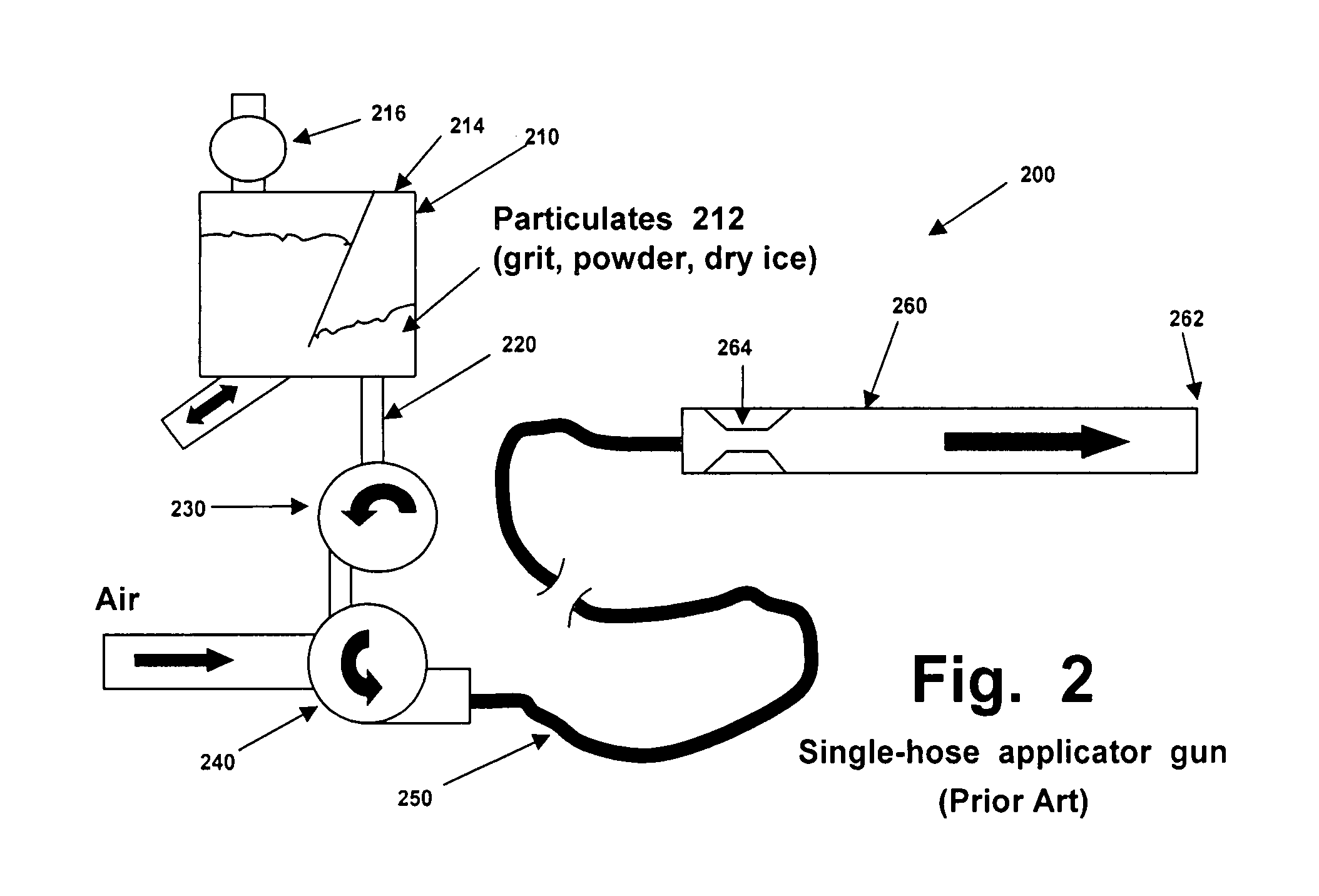

Portable cleaning and blasting system for multiple media types, including dry ice and grit

InactiveUS20080176487A1Promote resultsMaximum flexibilityAbrasive feedersAbrasive machine appurtenancesParticulatesDry ice

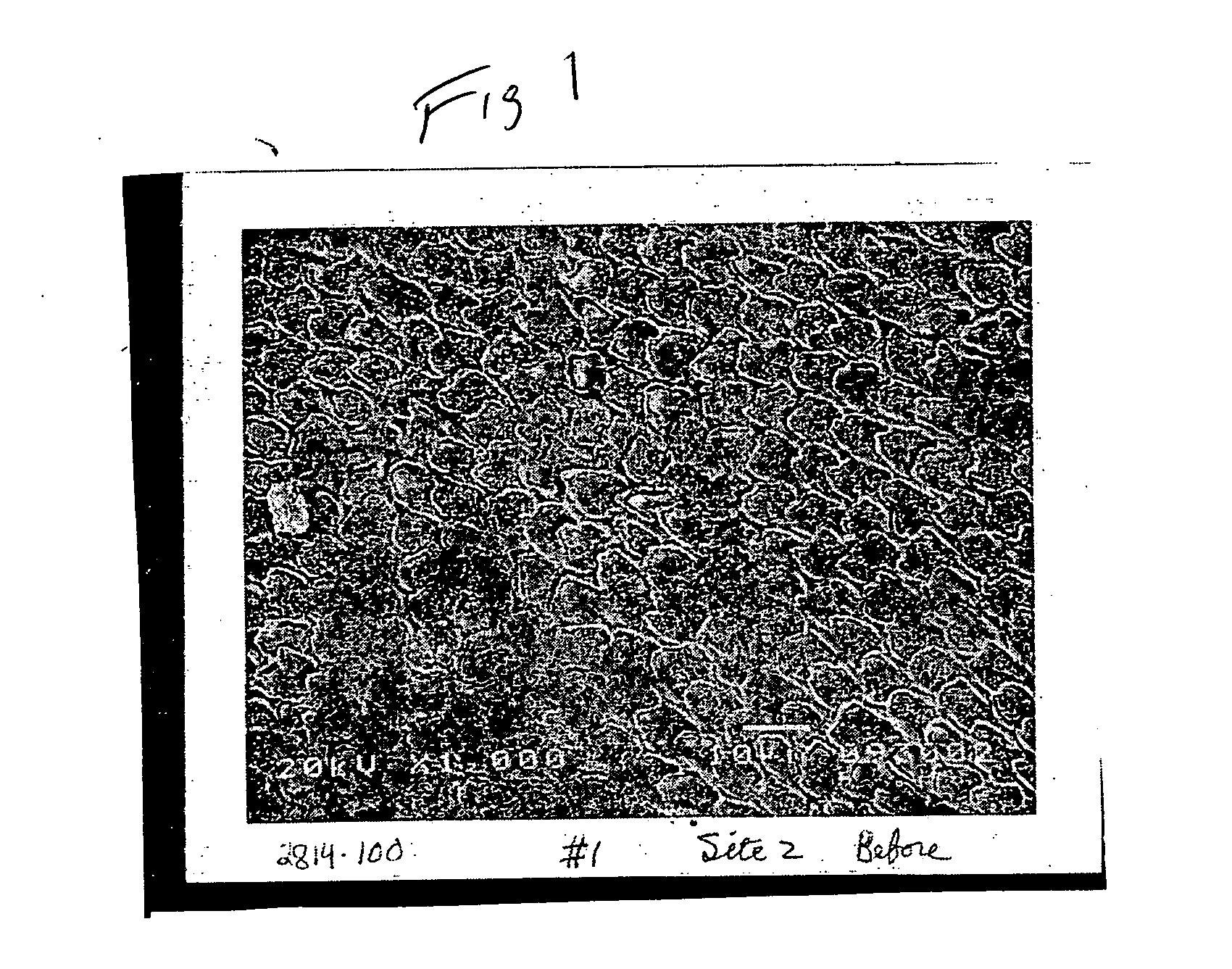

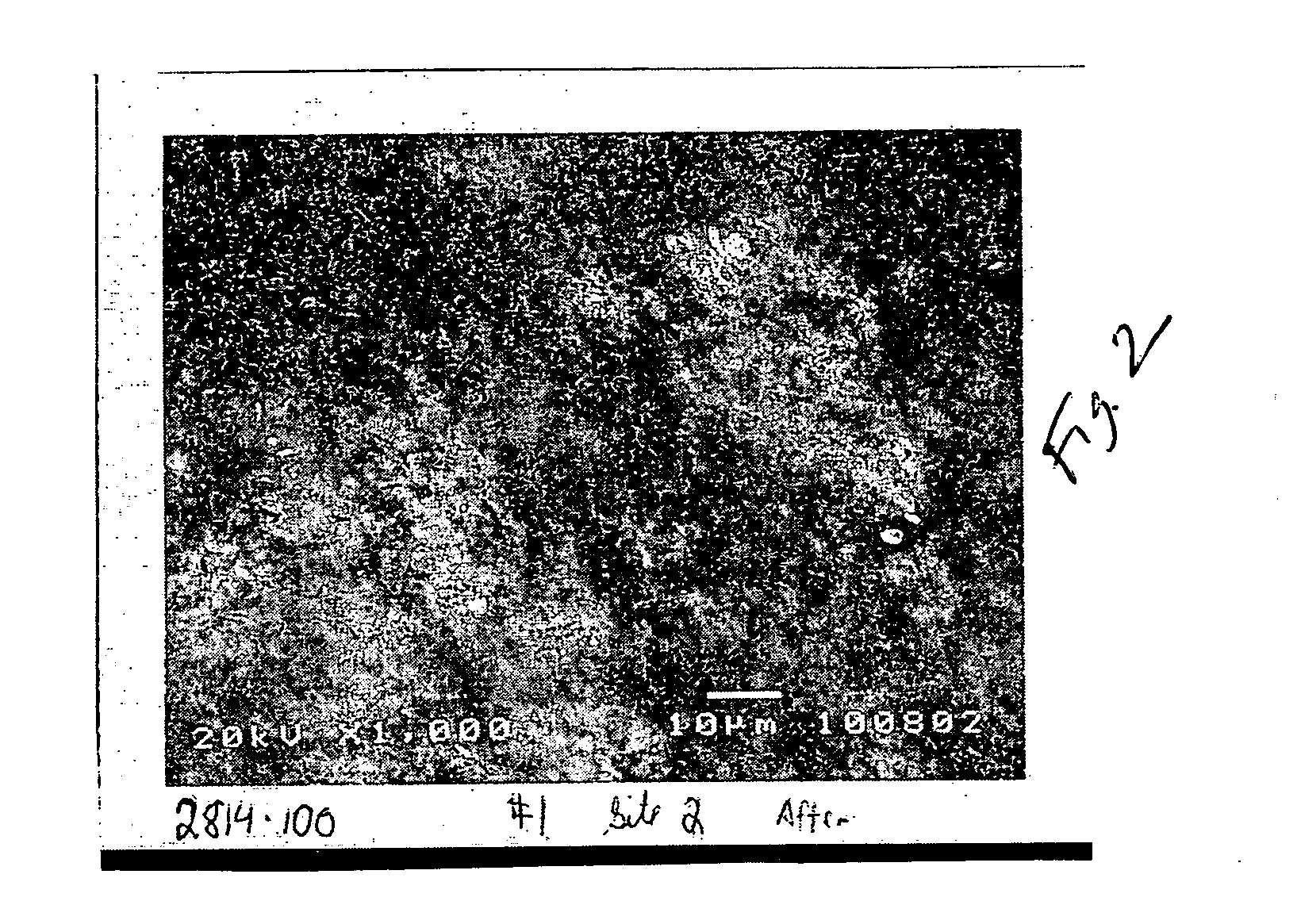

Blast-cleaning systems are disclosed, which enable a single system to handle different classes of particulate blasting media, such as grit, powder, and dry ice, and to deliver controllable mixtures of different media types during a blasting operation. This “multi-media” system includes a hopper having two chambers or other supply assemblies that are isolated from each other, for holding two different types of blasting media. Both chambers provide their particulates to a metering control device, which supplies a compressor. For example, by combining grit with dry ice, extremely efficient cleaning can be accomplished, with greatly reduced production of solid waste. Tests have shown that combinations of dry ice (at roughly 90%) with a grit or powder can provide far greater cleaning efficiency than either media type by itself.

Owner:ARMSTRONG JAY T

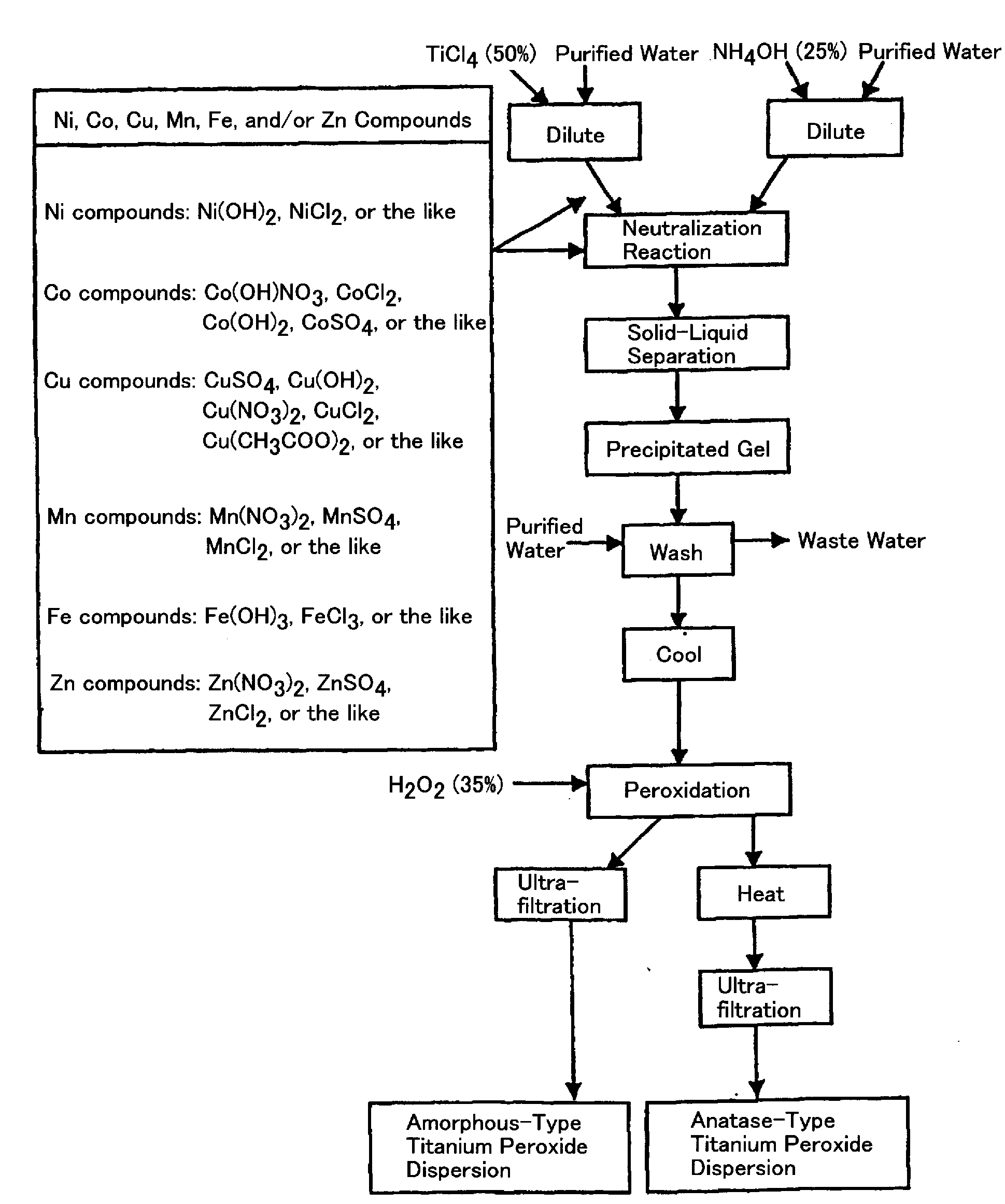

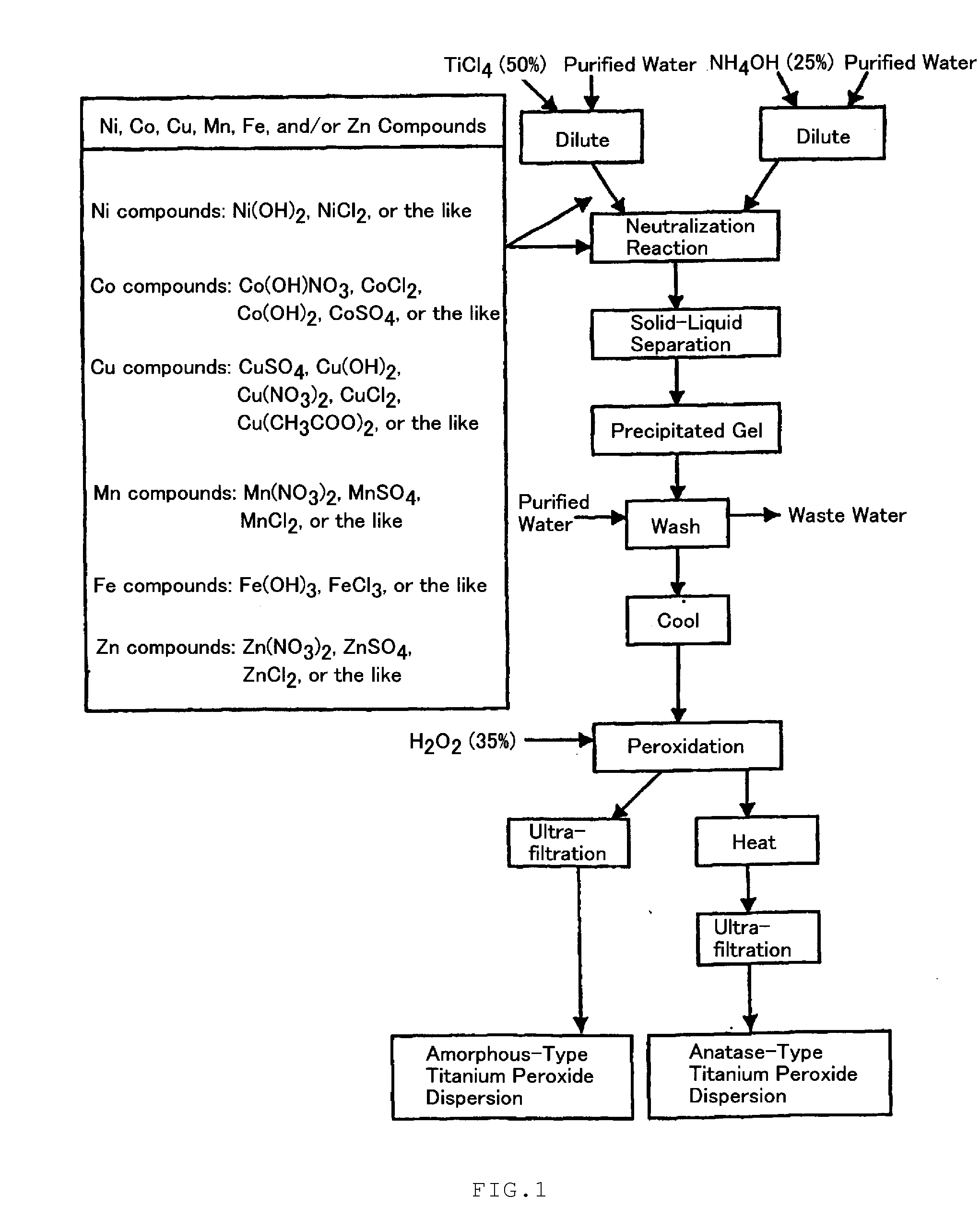

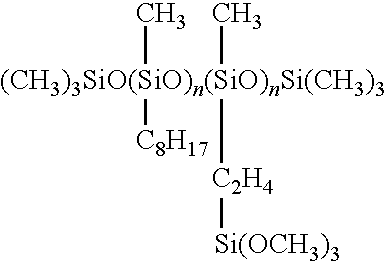

Solution Or Dispersion For Base Surface Treatment Containing Titanium Oxide Doped With Metal Element, Method Of Treating Base Surface With The Liquid, And Surface-Treated Material Obtained By the Method

InactiveUS20090211491A1Reduce fadingHard surfacePigmenting treatmentOther chemical processesSurface layerSilanes

A surface-treating agent for imparting both water repellency or unsusceptibility to water absorption and excellent antifouling properties to a surface of a material, especially a material for outdoor use; and a material whose surface has been treated with the surface-treating agent. A solution or dispersion which contains a water repellent or water absorption inhibitor, preferably a water repellent or water absorption inhibitor of the silane, siliconate, silicone, silicone / silane composite, and / or fluorochemical type, and a titanium oxide doped with at least one metal element selected from the group consisting of copper, manganese, nickel, cobalt, iron, and zinc, preferably an amorphous titanium oxide or an amorphous titanium oxide which has been peroxidized at least partly, is used to form, on a surface of a base material and / or in a surface layer thereof, a layer comprising the water repellent or water absorption inhibitor and the titanium oxide doped with at least one metal element selected from the group consisting of copper, manganese, nickel, cobalt, iron, and zinc.

Owner:DOW CORNING TORAY CO LTD

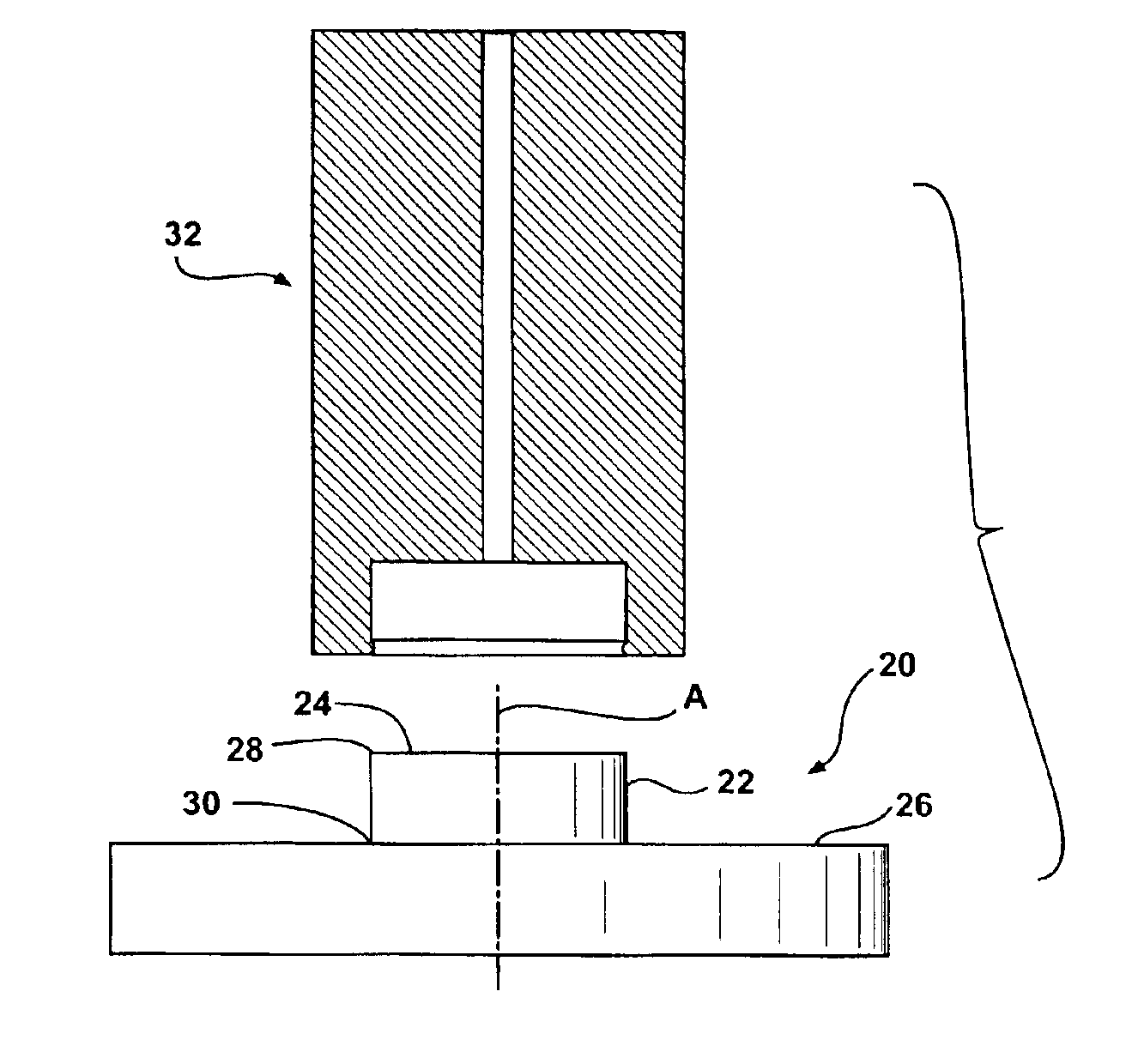

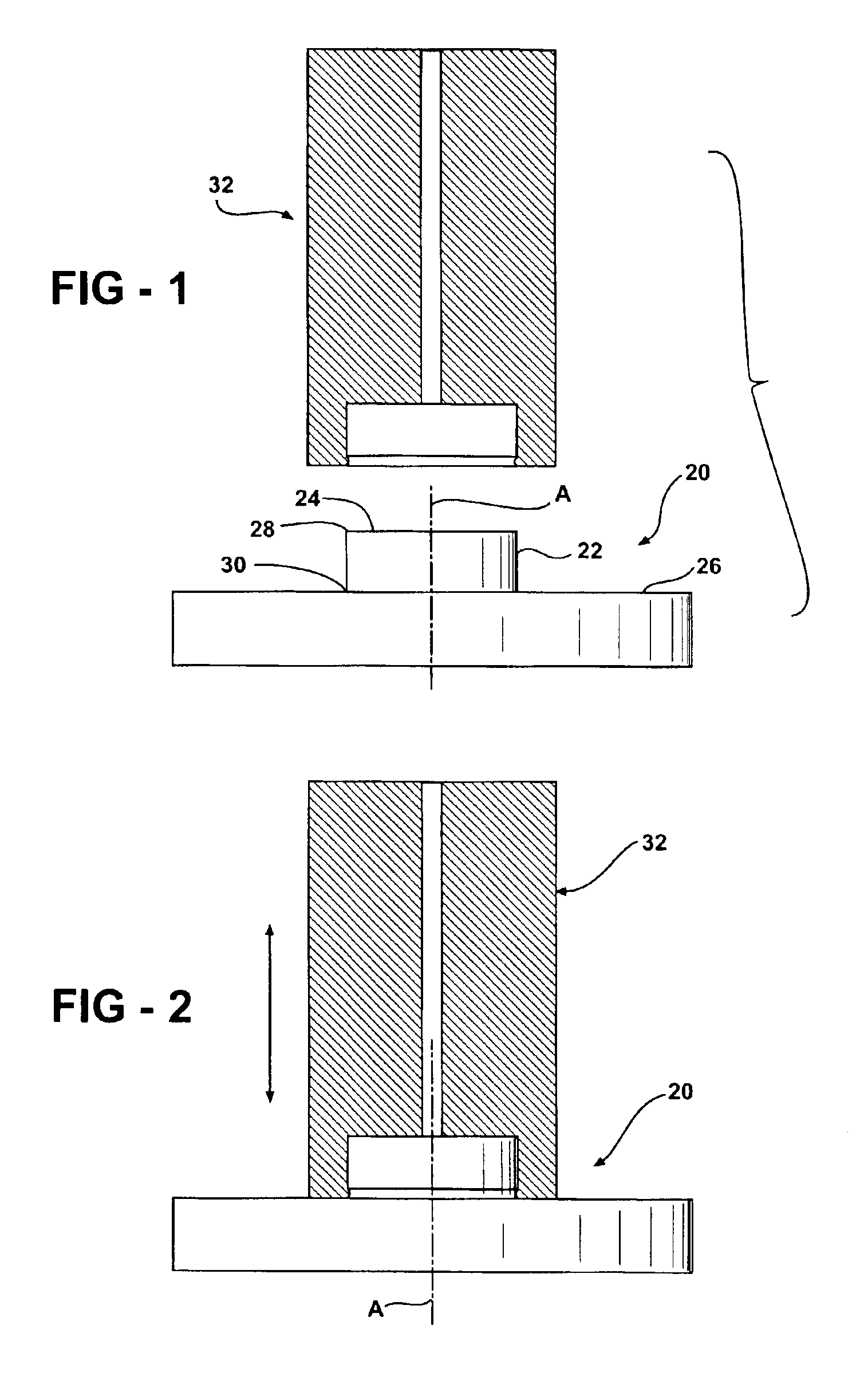

Tube fitting for stainless steel tubing

InactiveUS7393018B2Improve sealingFunction increaseSleeve/socket jointsJoints with sealing surfacesEngineeringCase hardening

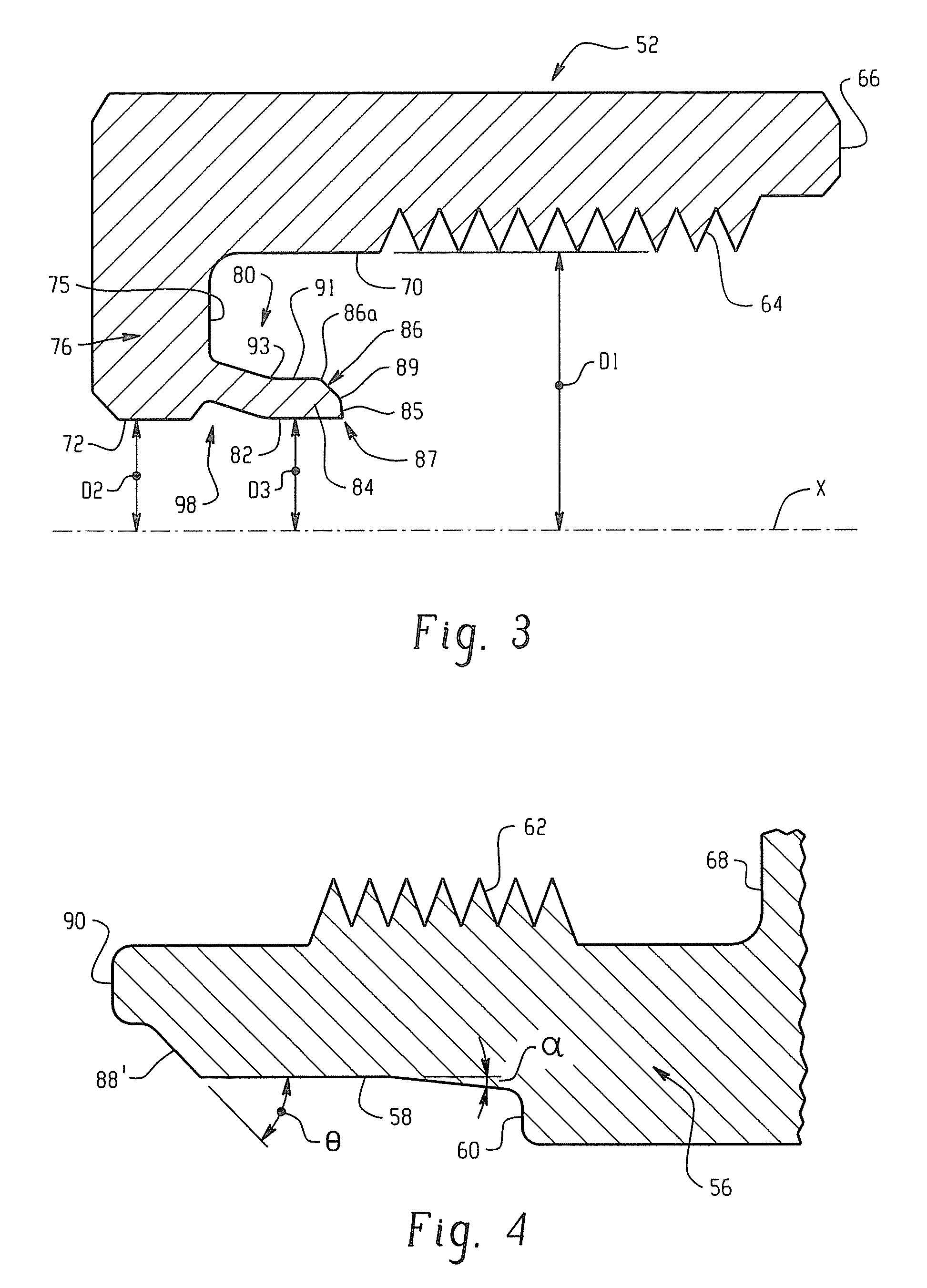

A tube fitting that uses only two components, namely a fitting body and a fitting nut. The nut and body are adapted to be threadably coupled together by relative rotation therebetween. The nut includes an integral tube gripping ring that cooperates with a camming surface on the body when the fitting is made-up. The camming surface preferably has a steep camming angle. The ring is radially compressed against the tube outer wall to form a seal and a tight tube grip. The ring also forms a line contact-type seal against the camming surface. The ring is designed to have a hinging action and to plastically deform during pull-up to embed into the tubing for excellent tube grip, and an axially adjacent swage or collet zone that isolates any stress riser resulting from the embedding action from vibration effects. The fitting components, and particularly the ring, may be case hardened, the fitting may include a self-gauging feature to indicate sufficient pull-up to prevent excessive pull-up. Also provided is a single ferrule tube fitting that uses a steep camming surface and is at least about 3.3 times harder than the stainless steel tube end.

Owner:SWAGELOK CO

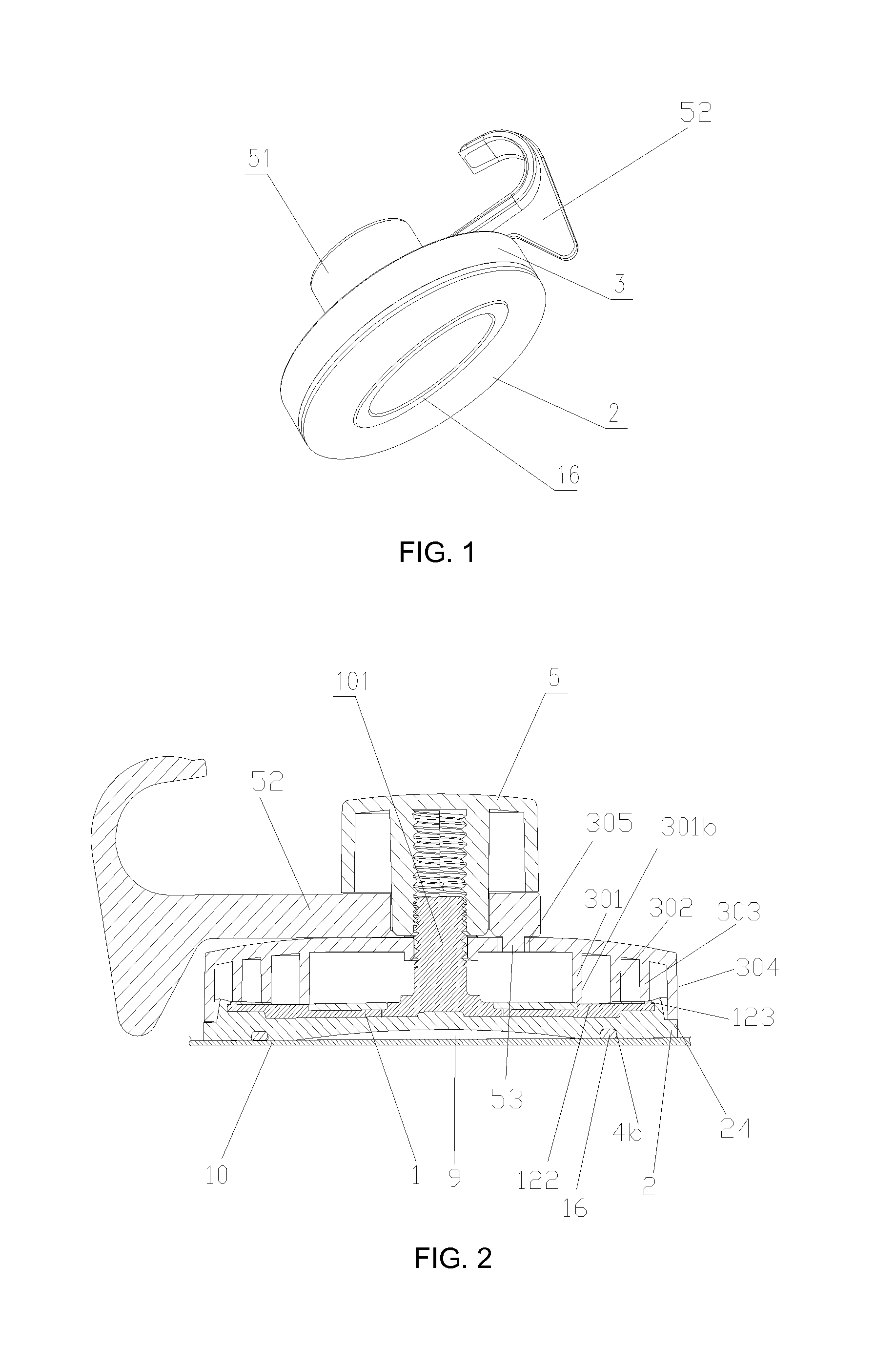

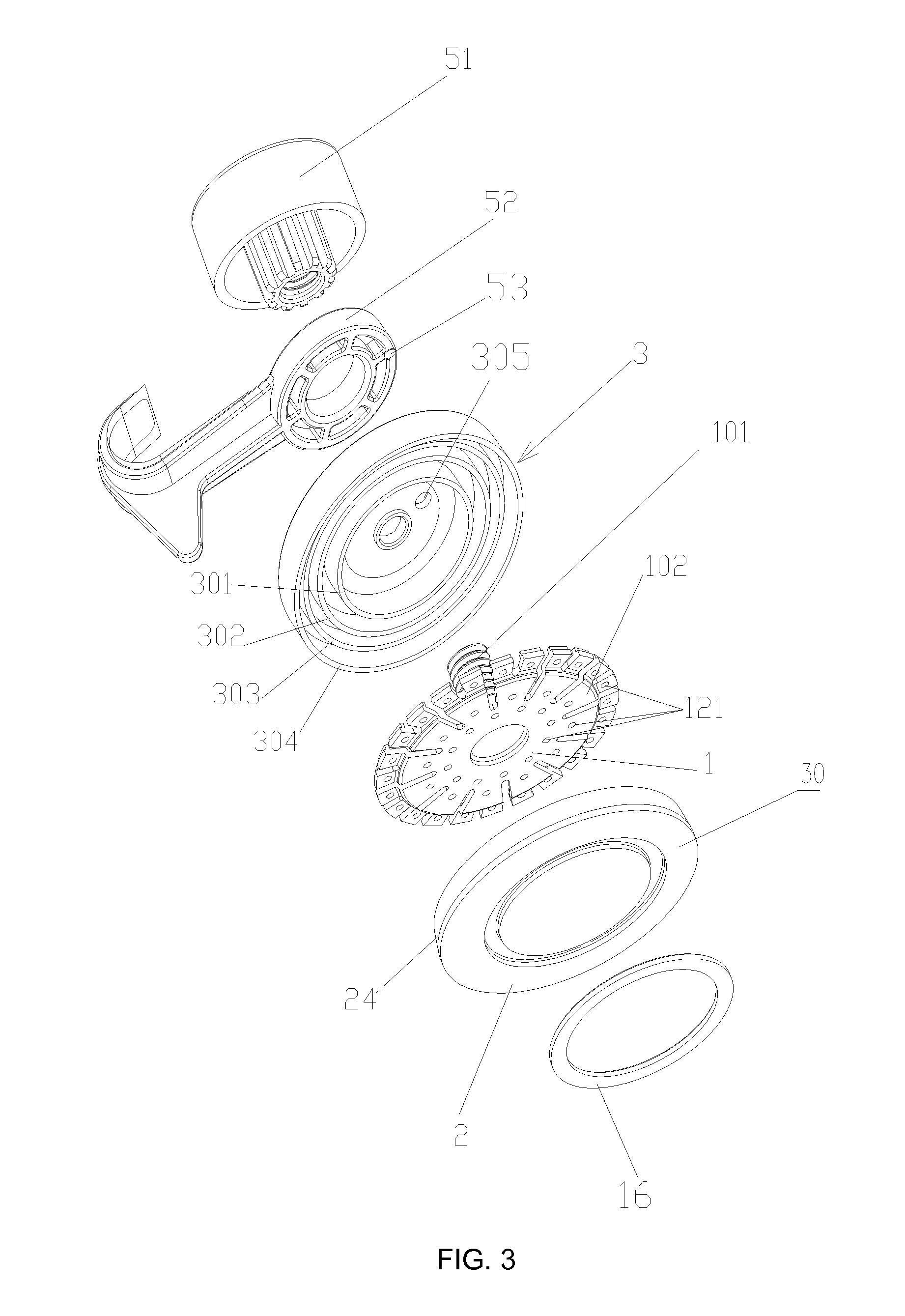

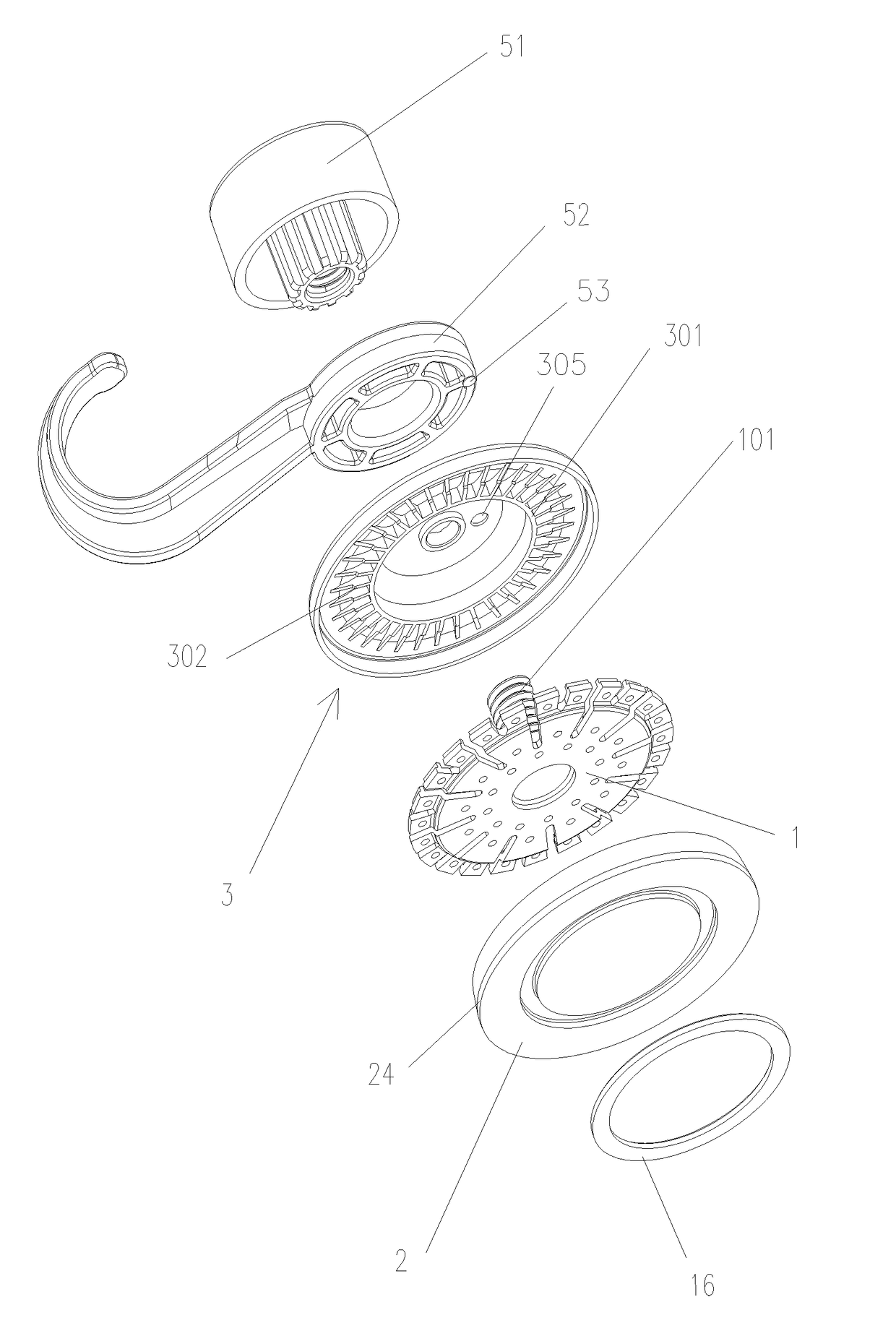

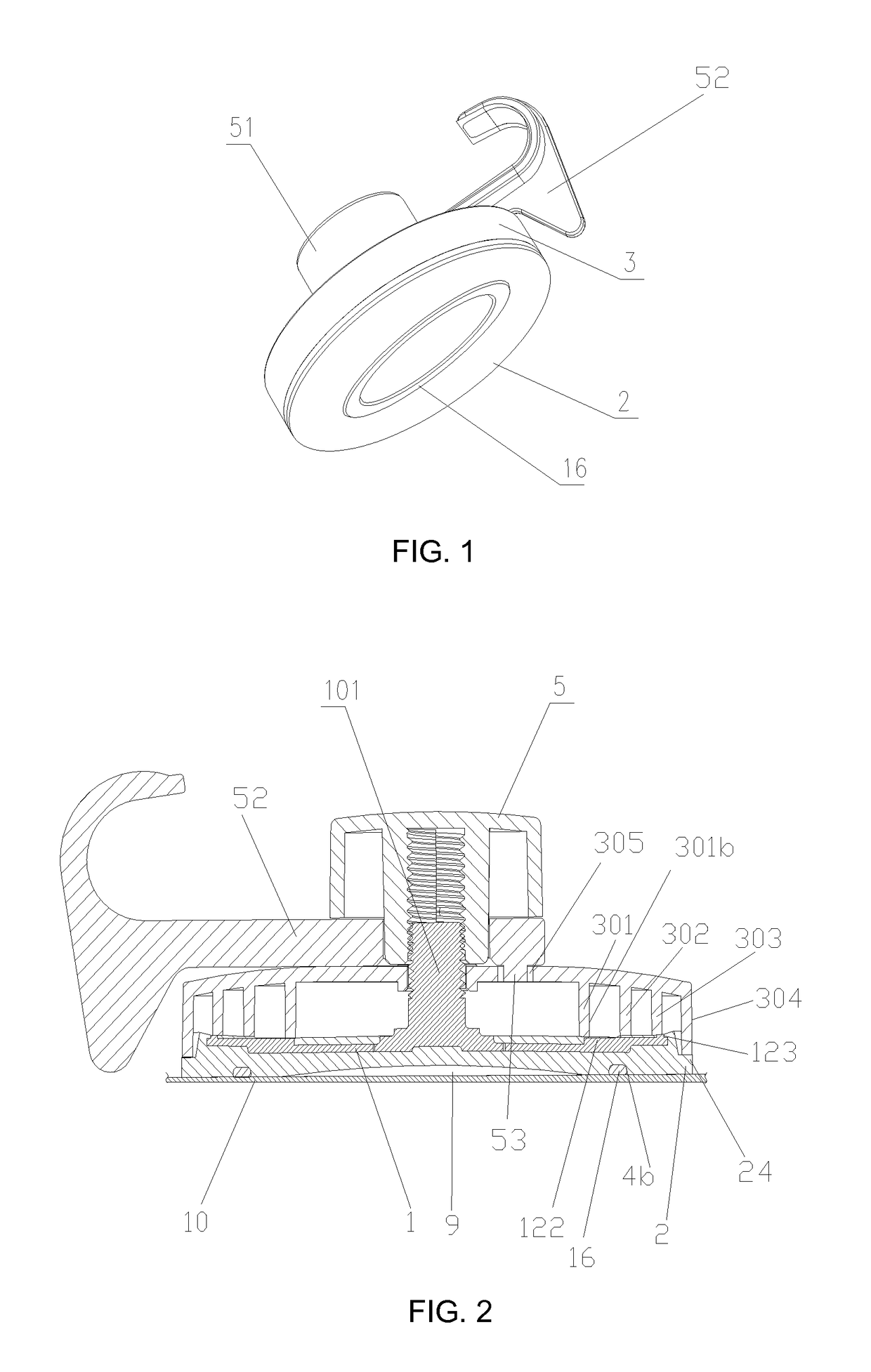

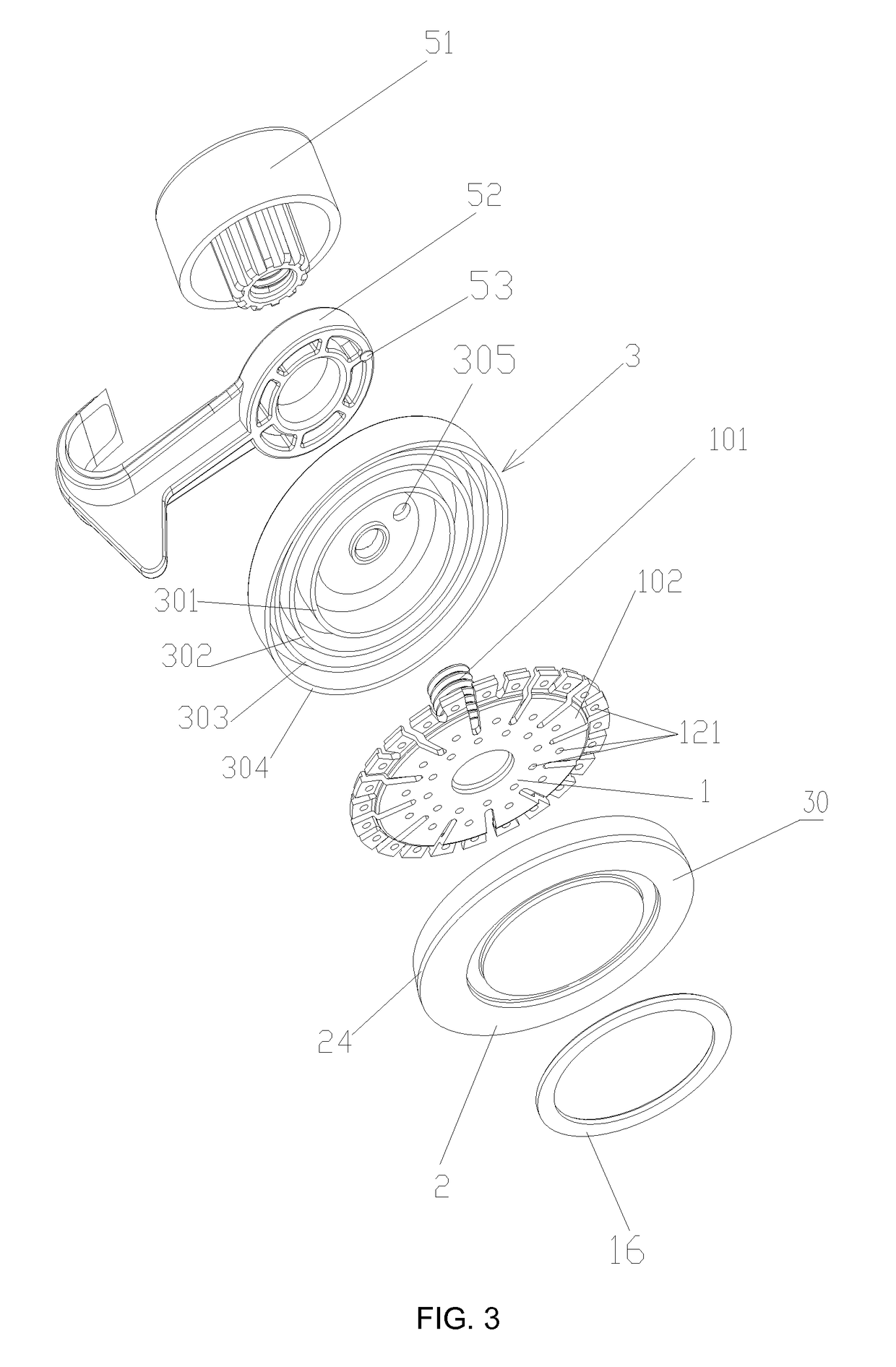

Suction Cup with Flat Framework

ActiveUS20150240862A1Simple structureEffectively transfer pressing forceStands/trestlesKitchen equipmentAir tightnessSupport surface

Owner:ZHONGSHAN TAILI HOUSEHOLD PROD MFG

Method of producing surface densified metal articles

A method of producing powder metal articles includes compacting and sintering powder metal to produce a shaped powder metal preform having at least one exposed surface to be surface densified which extends parallel to an axis of the preform between a free end and a blind end adjacent a transverse portion of the preform. The blind surface is cold worked by forcing a shaped densifying tool axially along the surface in a direction from the free end toward the blind end, and then reversing the direction of the tool toward the free end to densify a layer of the material at the exposed surface. In addition to the blind surface, the article can include one or more additional surfaces that can be densified in the same manner in a simultaneous operation.

Owner:PMG INDIANA CORP

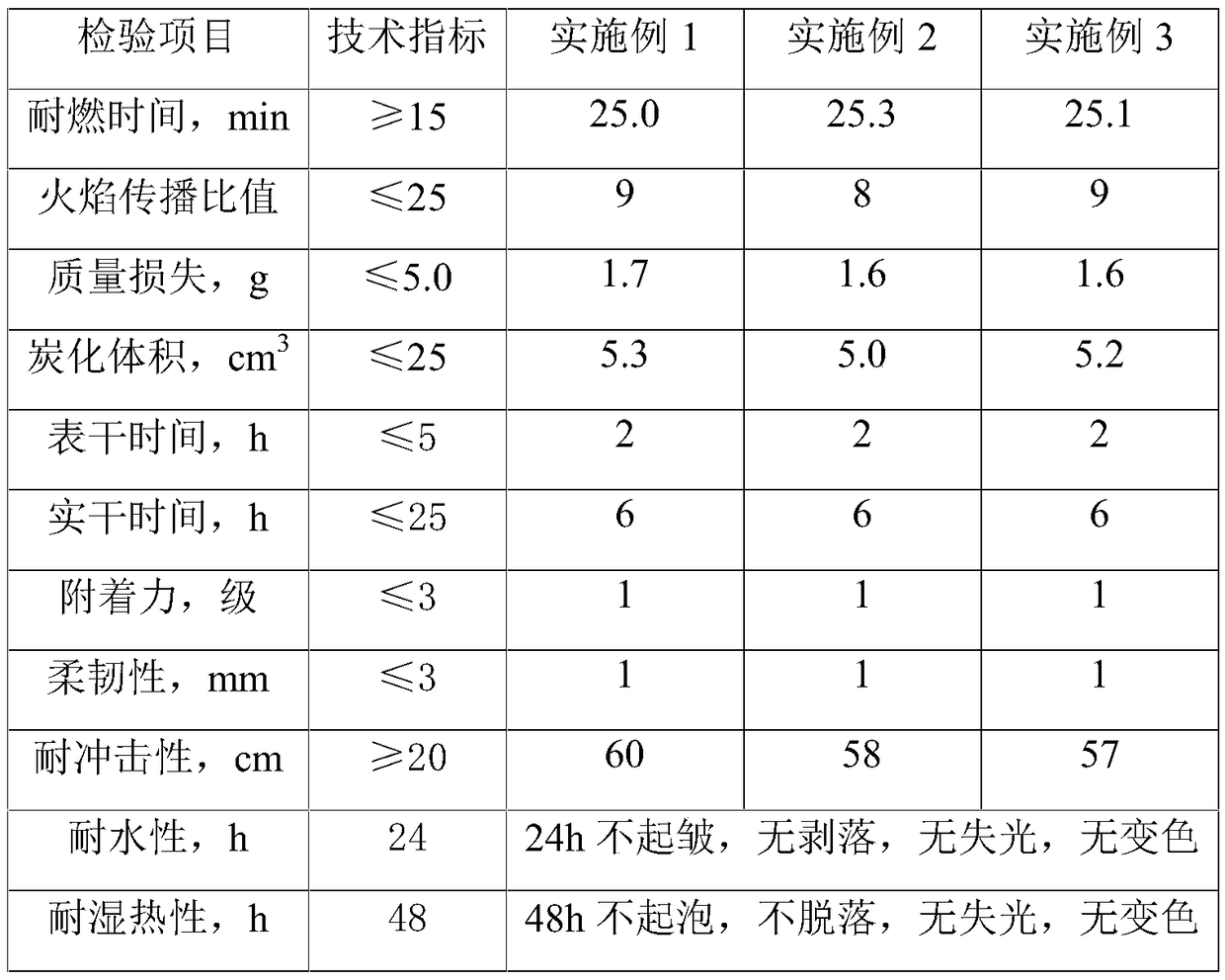

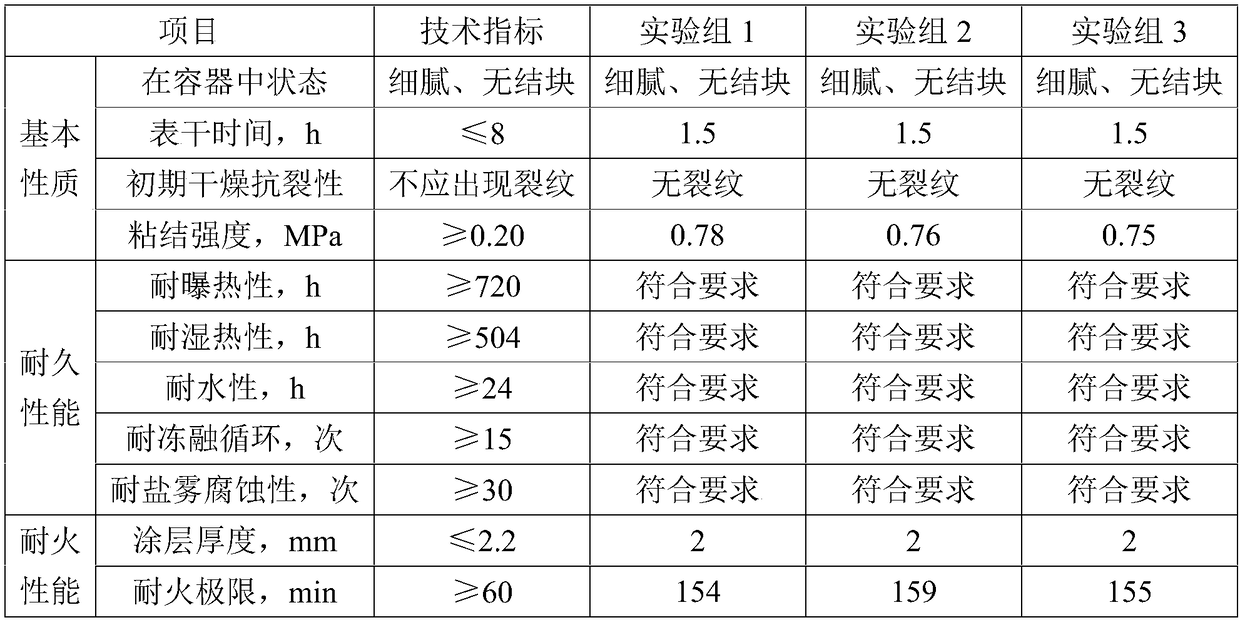

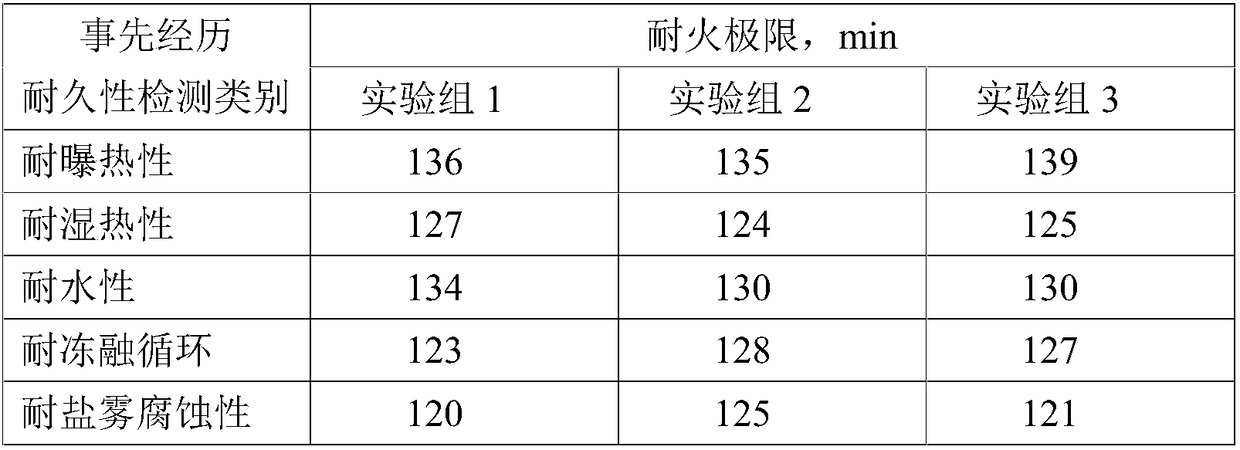

Expansive waterborne fireproof and flame-retardant coating for wood material and preparation method of expansive waterborne fireproof and flame-retardant coating

The invention relates to an expansive waterborne fireproof and flame-retardant coating for a wood material and a preparation method of the expansive waterborne fireproof and flame-retardant coating. The coating comprises water and the following components in parts by weight: 200 parts of melamine-modified urea resin emulsion, 110-120 parts of ethylene-vinyl acetate copolymer emulsion, 20-24 partsof boric acid, 36-38 parts of ammonium polyphosphate, 20-24 parts of guanylurea phosphate, 36-40 parts of pentaerythritol, 30-34 parts of melamine, 1.0-1.4 parts of sulfonated carbon, 3.6-4.0 parts ofzinc borate, 2.0-2.4 parts of ammonium octamolybdate, 16-20 parts of coating auxiliaries and 0-44 parts of pigment and filler. When heated, the expansive waterborne fireproof and flame-retardant coating is capable of greatly retarding the combustion of the wood material so as to prevent fire spreading; and the expansive waterborne fireproof and flame-retardant coating has good smoke inhibiting property and is capable of delaying the smoke generation time, reducing the release amount of smoke and the generation of poisonous gases and providing more safety time and space for escape and rescue of personnel under the condition of a fire hazard.

Owner:湘诚新材料科技有限公司

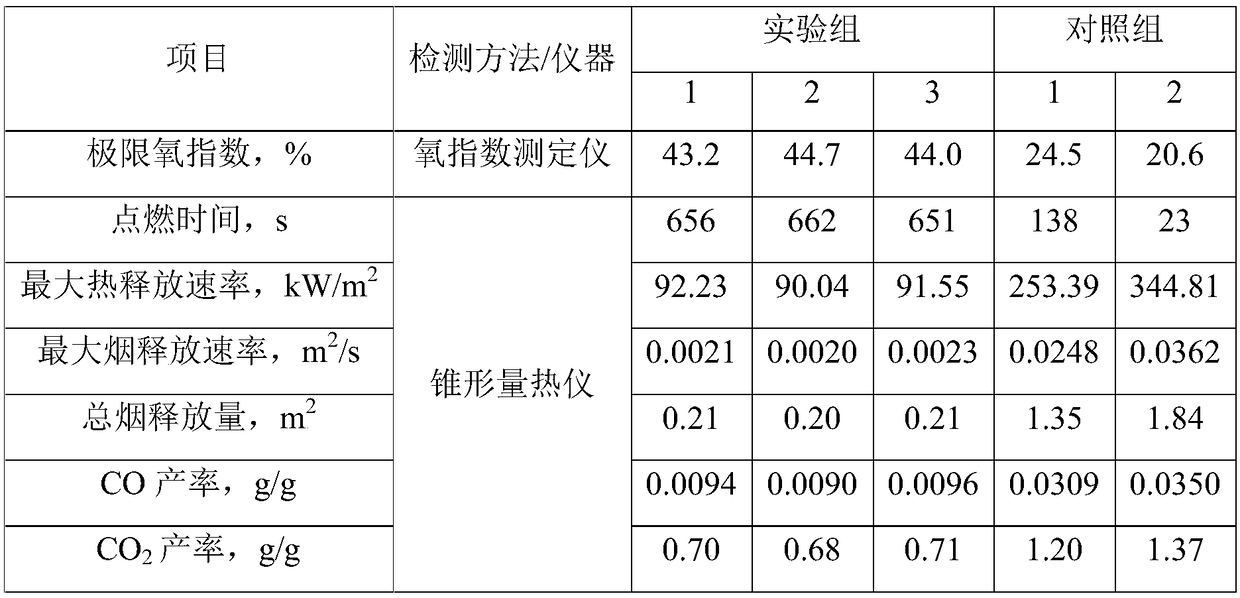

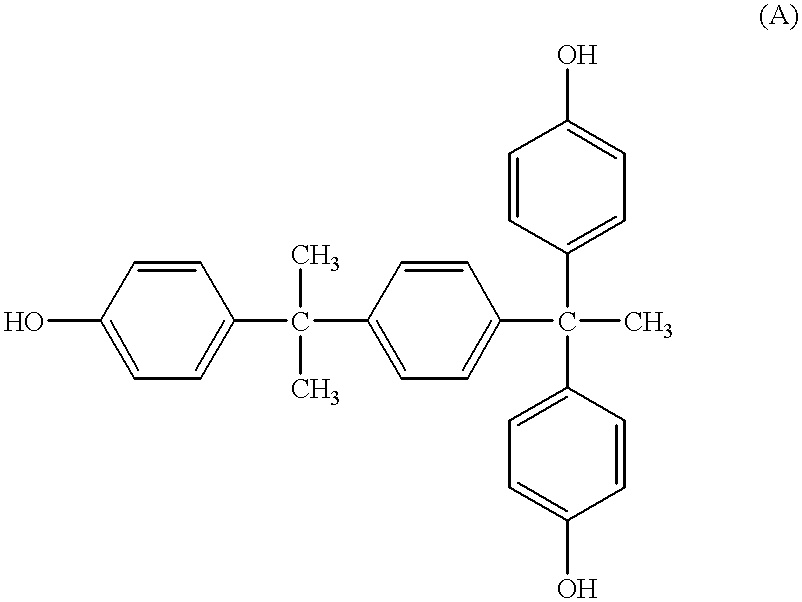

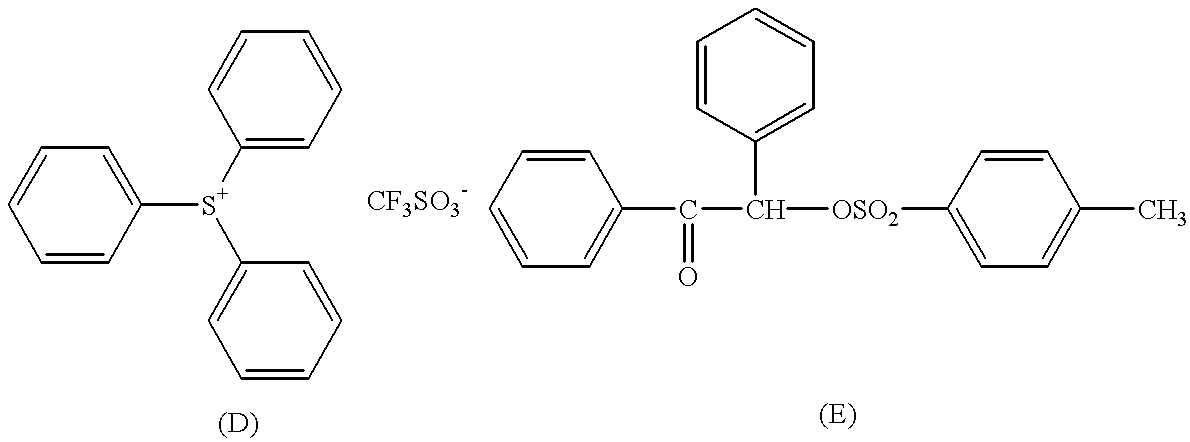

Photosensitive resin composition and process for producing the same

InactiveUS6440632B2Promote absorptionHard surfaceSemiconductor/solid-state device manufacturingDiazo compound compositionsImage resolutionLength wave

A photosensitive resin composition comprises a base resin (e.g., novolak resins, polyvinylphenol-series polymers), a first photoactive ingredient (e.g., diazobenzoquinone derivatives, diazonaphthoquinone derivatives) and a second photoactive ingredient (e.g., mixtures with azide compounds) each having an absorption range at wavelength lambd1 or lambd2, the wavelengths thereof being different from each other. Between the first and second photoactive ingredients, at least one photoactive ingredient is substantially inert at the absorption wavelength of the other. After exposing the photosensitive resin composition to a light to form a pattern, the whole surface of the photosensitive layer is exposed to a light of the other wavelength to make the surface hardly soluble (in the case a positive pattern is formed) or readily soluble (in the case a negative pattern is formed) in a developer, and developed, thereby forming a pattern of high resolution. Utilizing an existing exposure system, there can be obtained photosensitive resin compositions (especially, resists for semiconductor production) having improved sensitivity and resolution.

Owner:KRI INC

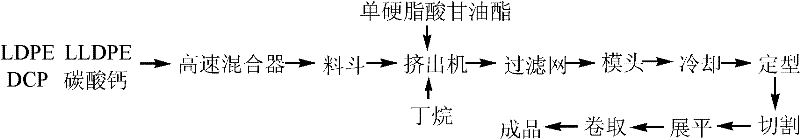

Preparation method of high performance expanded polyethylene product

ActiveCN102558647AHigh densityHigh surface hardnessLow-density polyethyleneLinear low-density polyethylene

The invention relates to a preparation method of a high performance expanded polyethylene product. The material of the invention comprises the following component in parts by weight: 50 parts of LDPE (low-density polyethylene) and LLDPE (linear low-density polyethylene), 0.01-1 parts of peroxide, 0.3-2 parts of talcum powder and / or calcium carbonate, 0.02-0.06 parts of antishrinking agent and 0.1-0.4 parts of foaming agent. In the invention, butane is used as the foaming agent, and the LDPE and the LLDPE are used as resin raw materials. The expanded polyethylene prepared by the preparation method of the invention has the advantages of high density and high surface hardness, the density of the expanded polyethylene is 60-400g / m<3> and the surface hardness is 40-70 degrees. The high performance expanded polyethylene product has good anti-scraping performance and puncture resistance as well as good rebound resilience and anti-quake effect. The high performance expanded polyethylene product meets the requirements of high performance of current packaging materials and fully protecting the substances being packaged. In addition, the high performance expanded polyethylene product has theadvantage of long sustainable using time as a panel and good market potential.

Owner:XIAMEN SANDEXIN SCI&TECH CO LTD

Flame retarding thermoplastic alloy and its preparation method

The present invention discloses a thermoplastic flame-retardant alloy and a method for preparing it, composed of the following components by the shares and weights as below: 5-94 shares of ABS resin, 3-94 shares of polyester or co-polyester or the mixture of both, 1-50 shares of brominated flame retardant, 1-10 shares of synergistic flame-retardant, 0.001-30 shares of chlorinated polyethylene (CPE), 0.001-2 shares of anti-dripping agent and 0.1-6 shares of processing aid. Comparing with the ABS flame retardant presenting the prior art, the thermoplastic flame-retardant alloy features better glossness, scratch resistance, stronger ultraviolet radiation resistance and better mechanical property, thus making up for the disadvantage that the flame-retardant ABS is prone to become yellow on some occasions with high weatherability requirements. Furthermore, the preparation method of the thermoplastic flame-retardant alloy for the present invention is successive, stable and feasible.

Owner:KINGFA SCI & TECH CO LTD +1

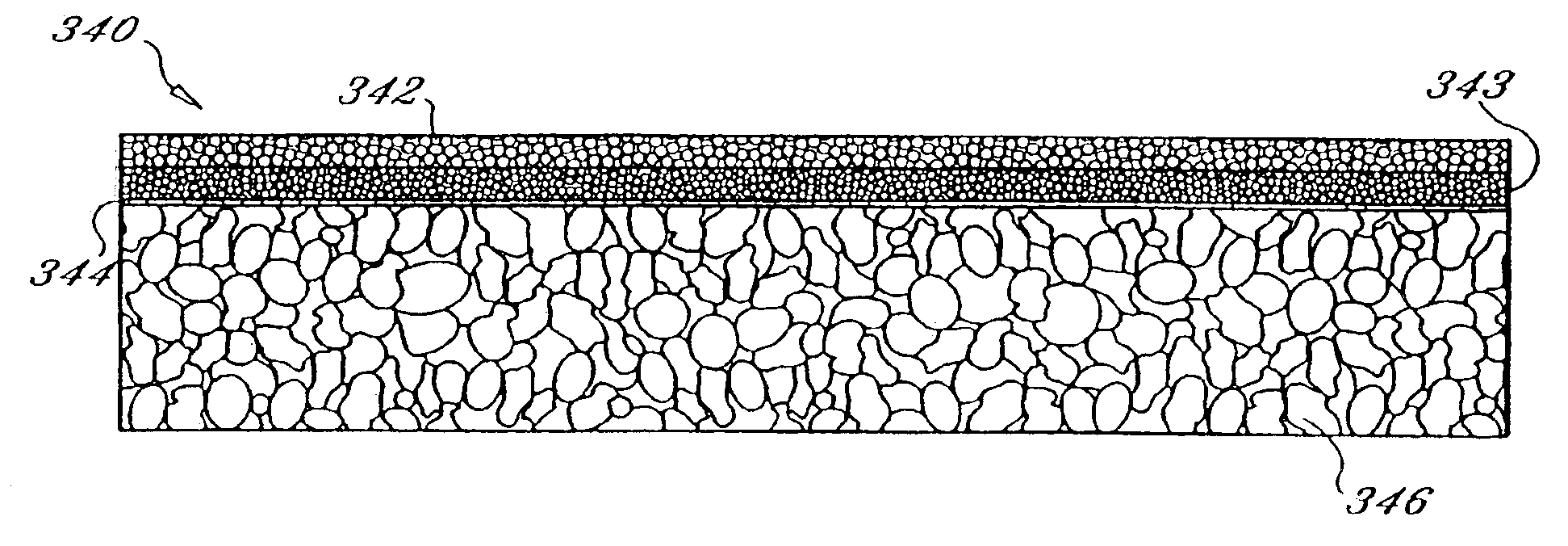

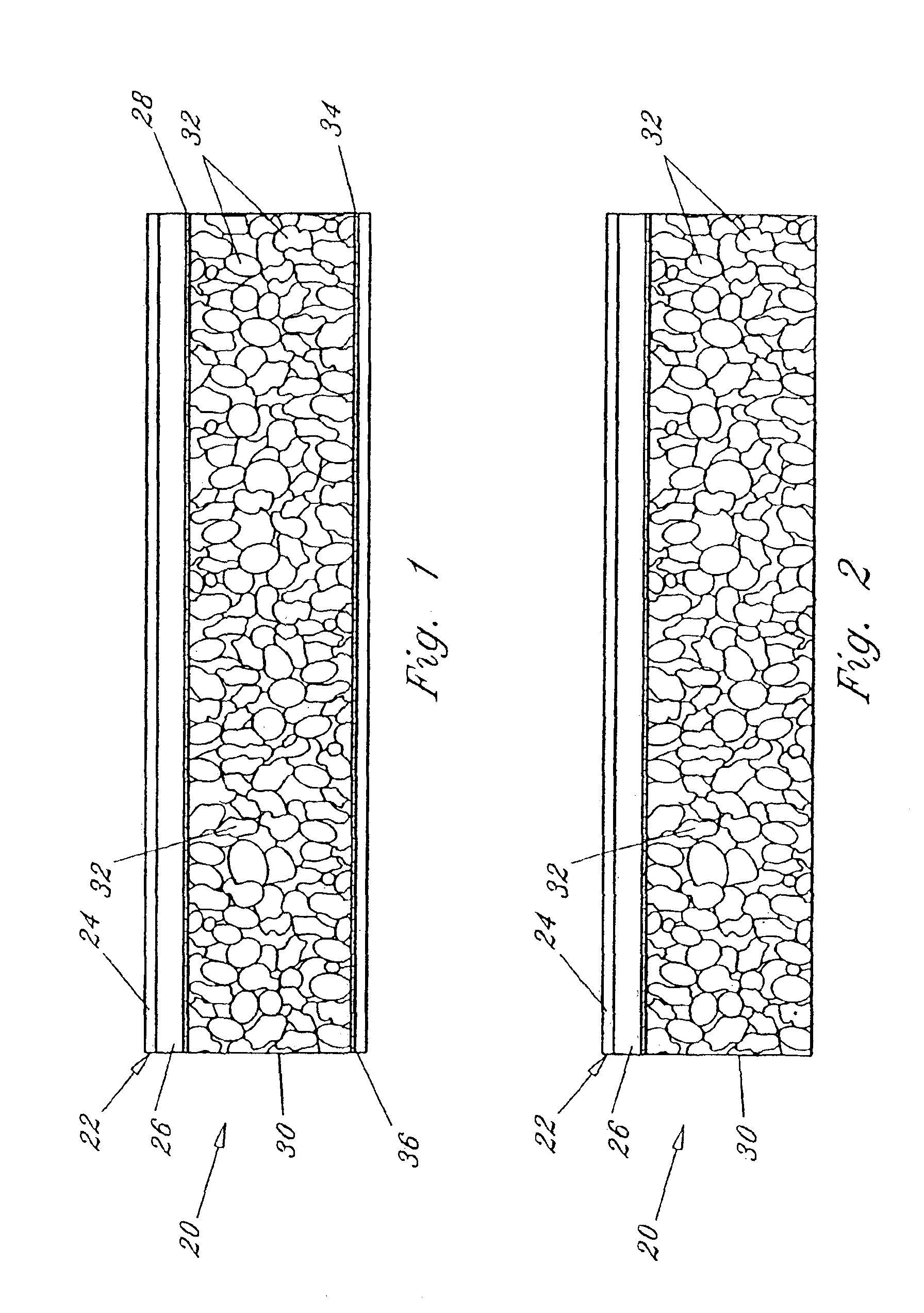

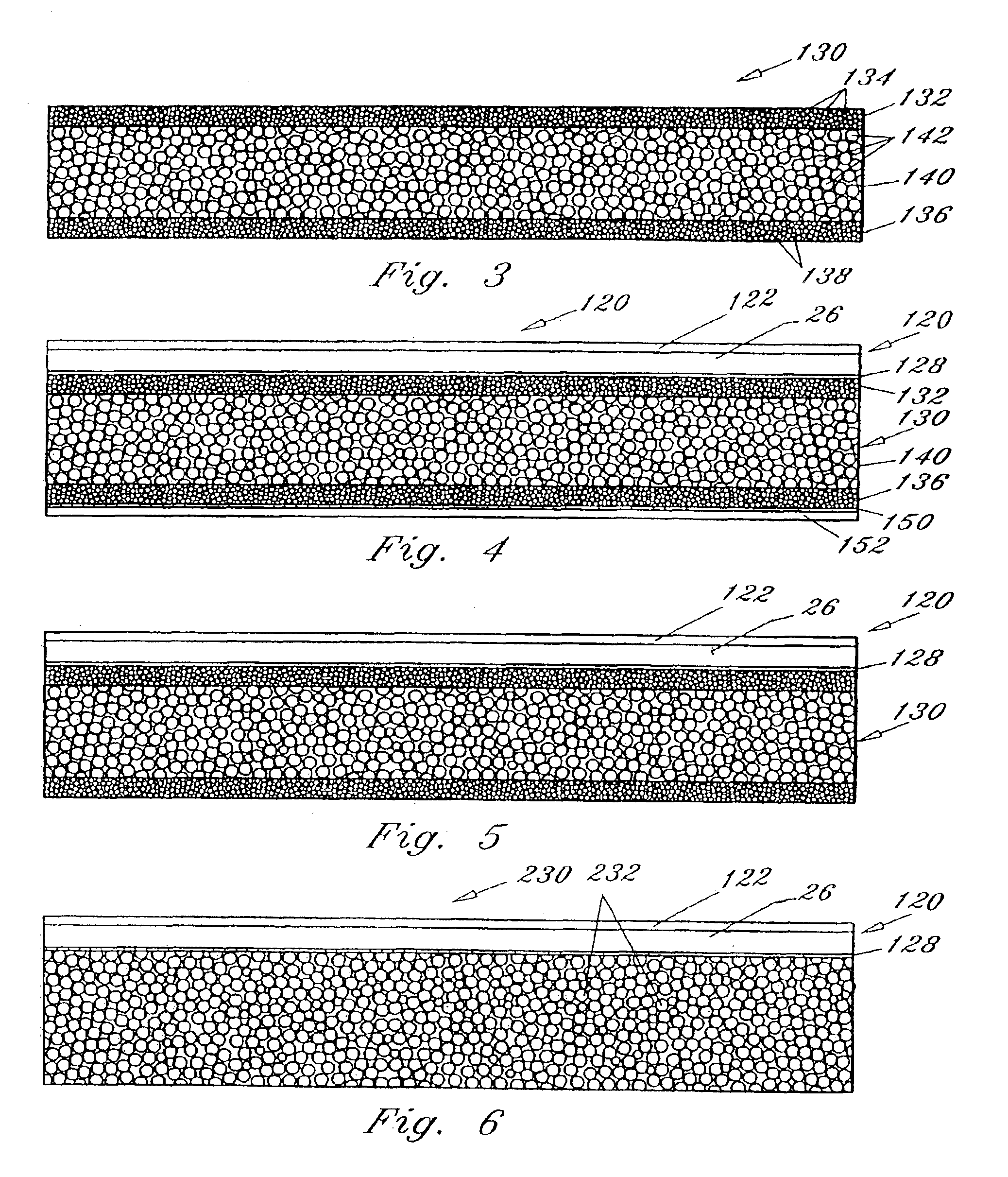

Thermoplastic multi-layer composite structure

InactiveUS6878437B1High energyReduce maintenanceSynthetic resin layered productsLaminationAdhesiveEngineering

A thermoplastic multi-layer composite structure is disclosed and in a first embodiment as a co-extruded acrylic polypropylene outer skin and high melt strength polypropylene substrate which is attracted to a first surface of a polypropylene foam core. An inner polypropylene skin is attached to a second surface of the foamed core, which can either be constructed from an expanded polypropylene or an extruded polypropylene and is attached to the outer and inner skin through the use of an adhesive. Where an extruded polypropylene foam core is provided, the skins can be attached to the foam core by adhesives or through a welding or bonding process in lieu of adhesives. Additionally, the extruded foam core can vary in density to provide a composite foam core. An all acrylic composite multi-layered structure is also provided.

Owner:BRUNSWICK CORPORATION

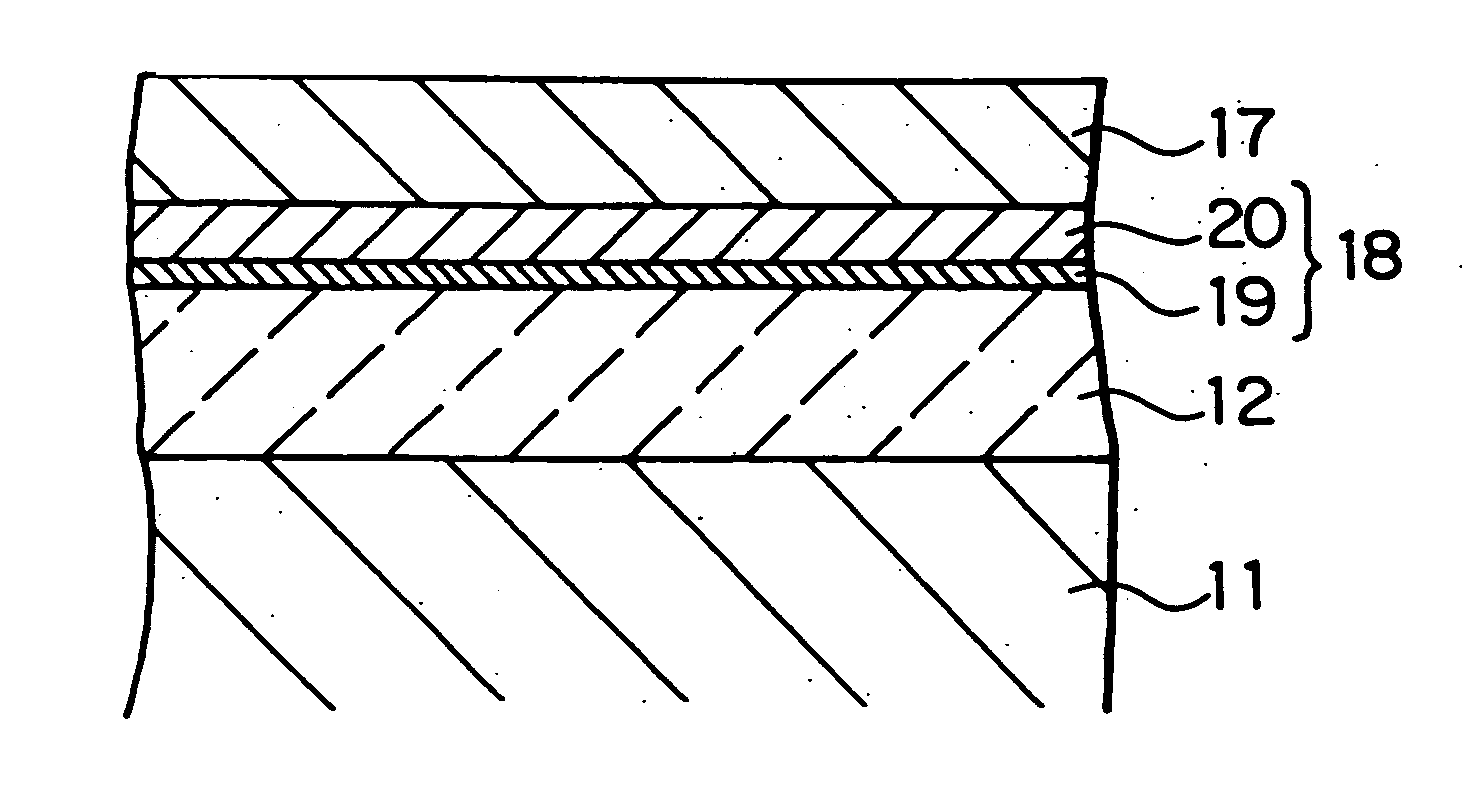

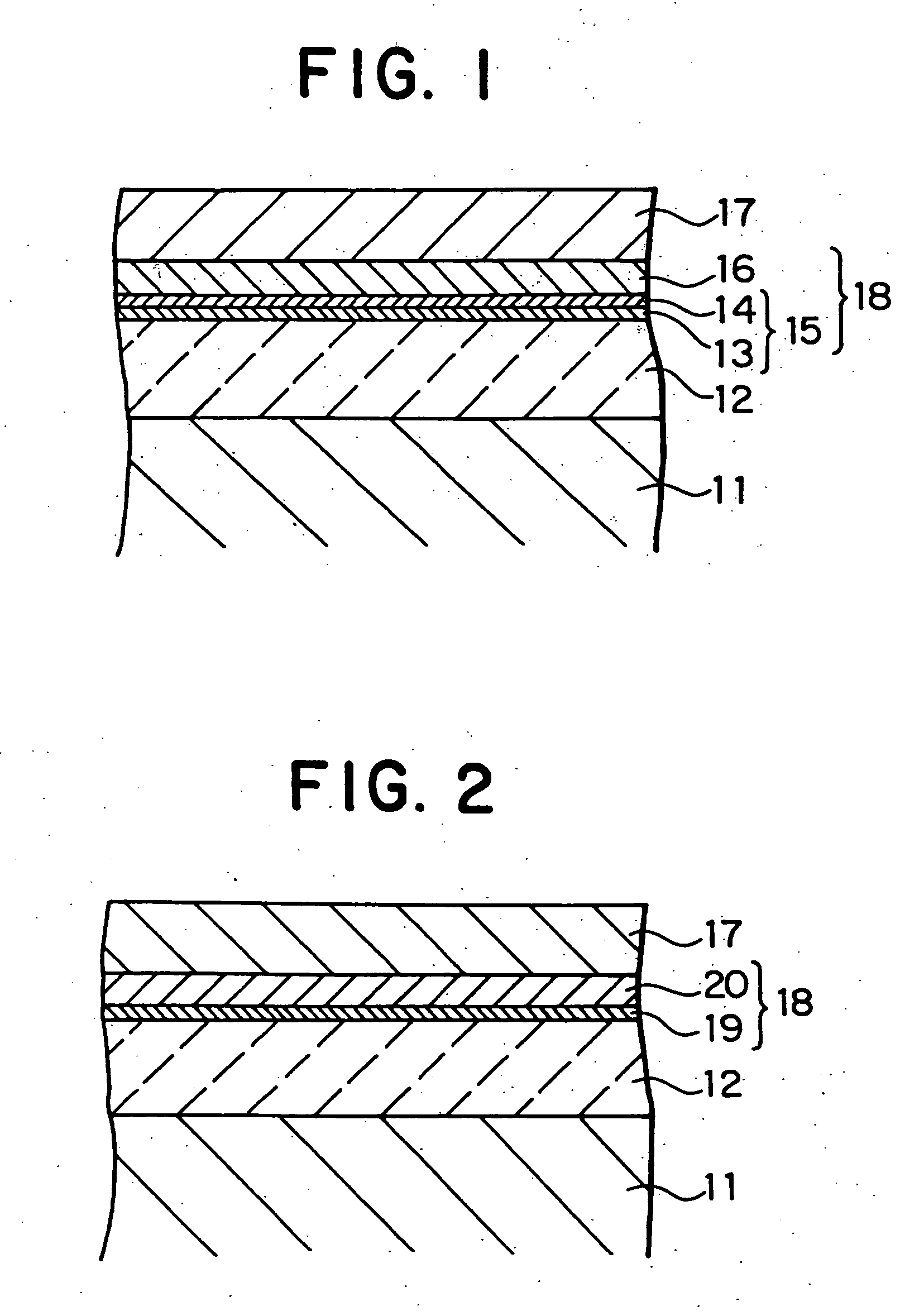

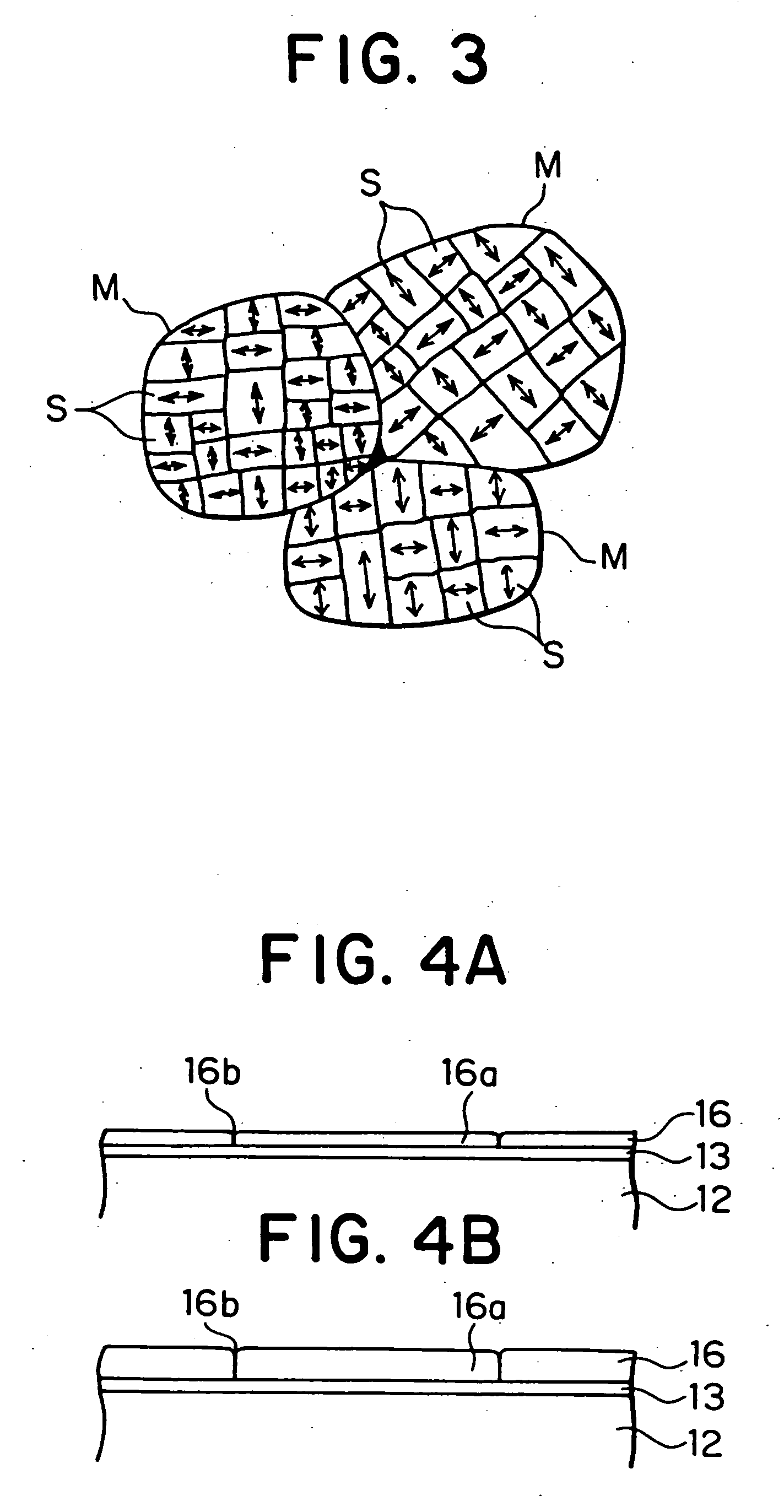

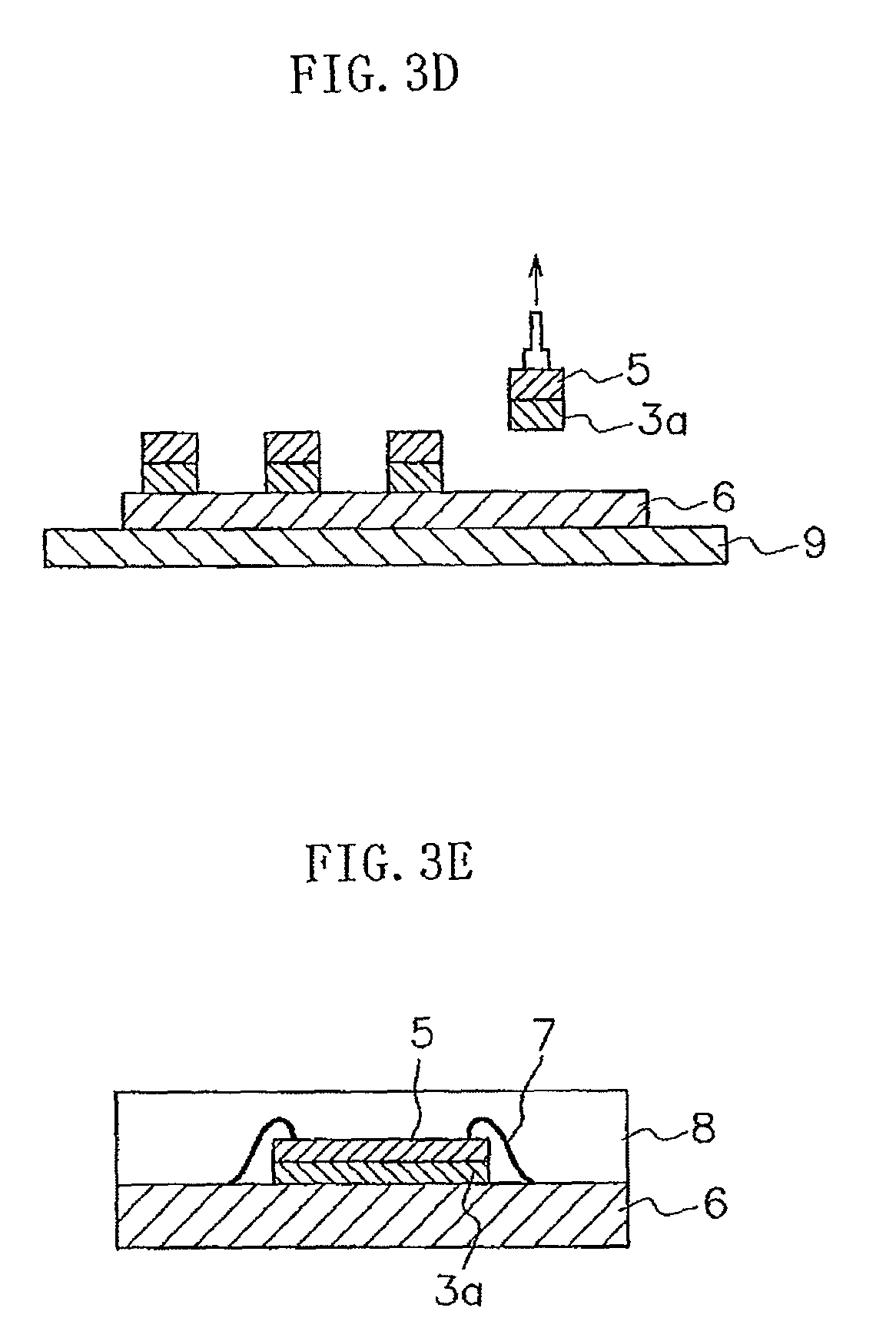

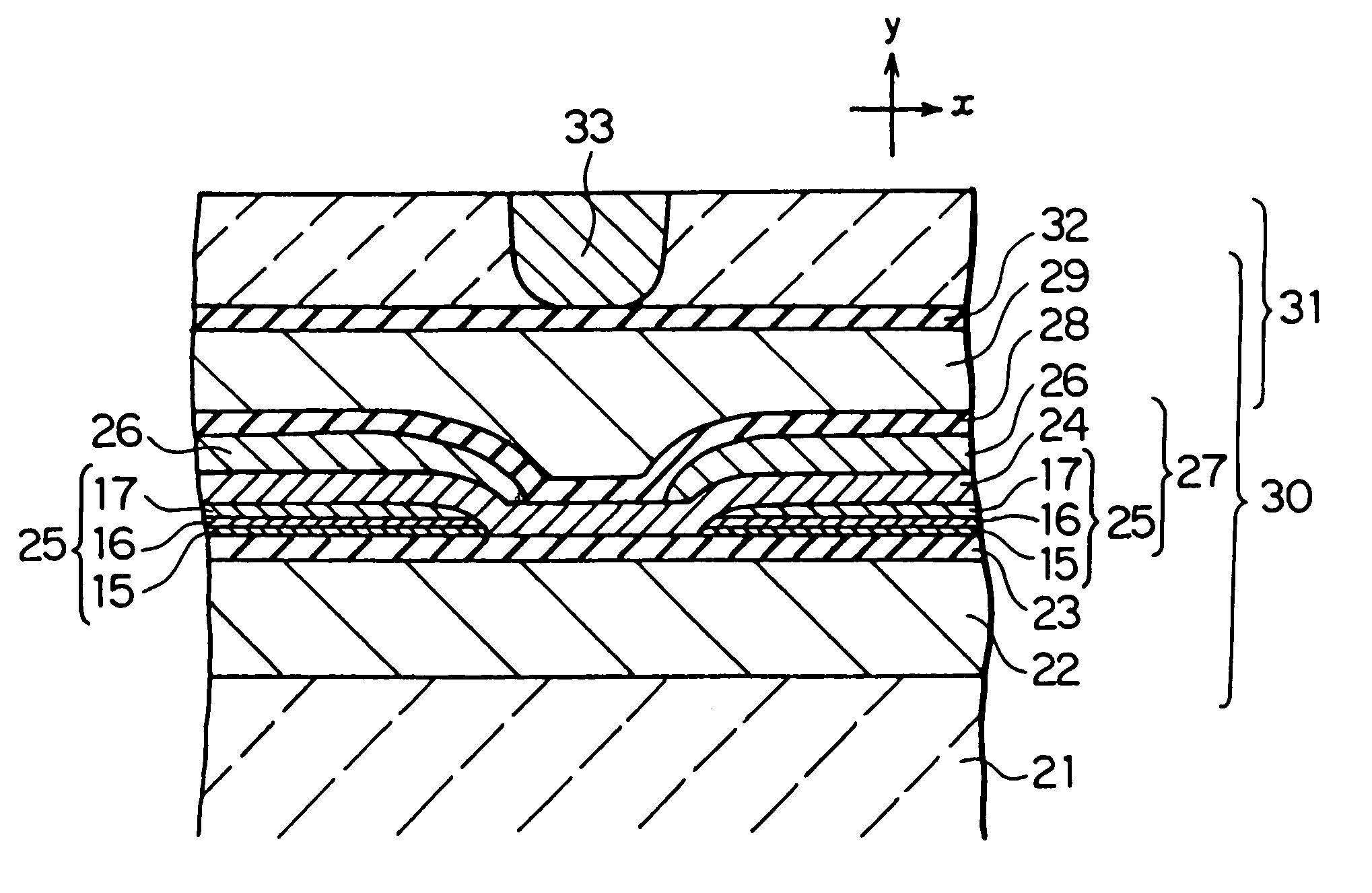

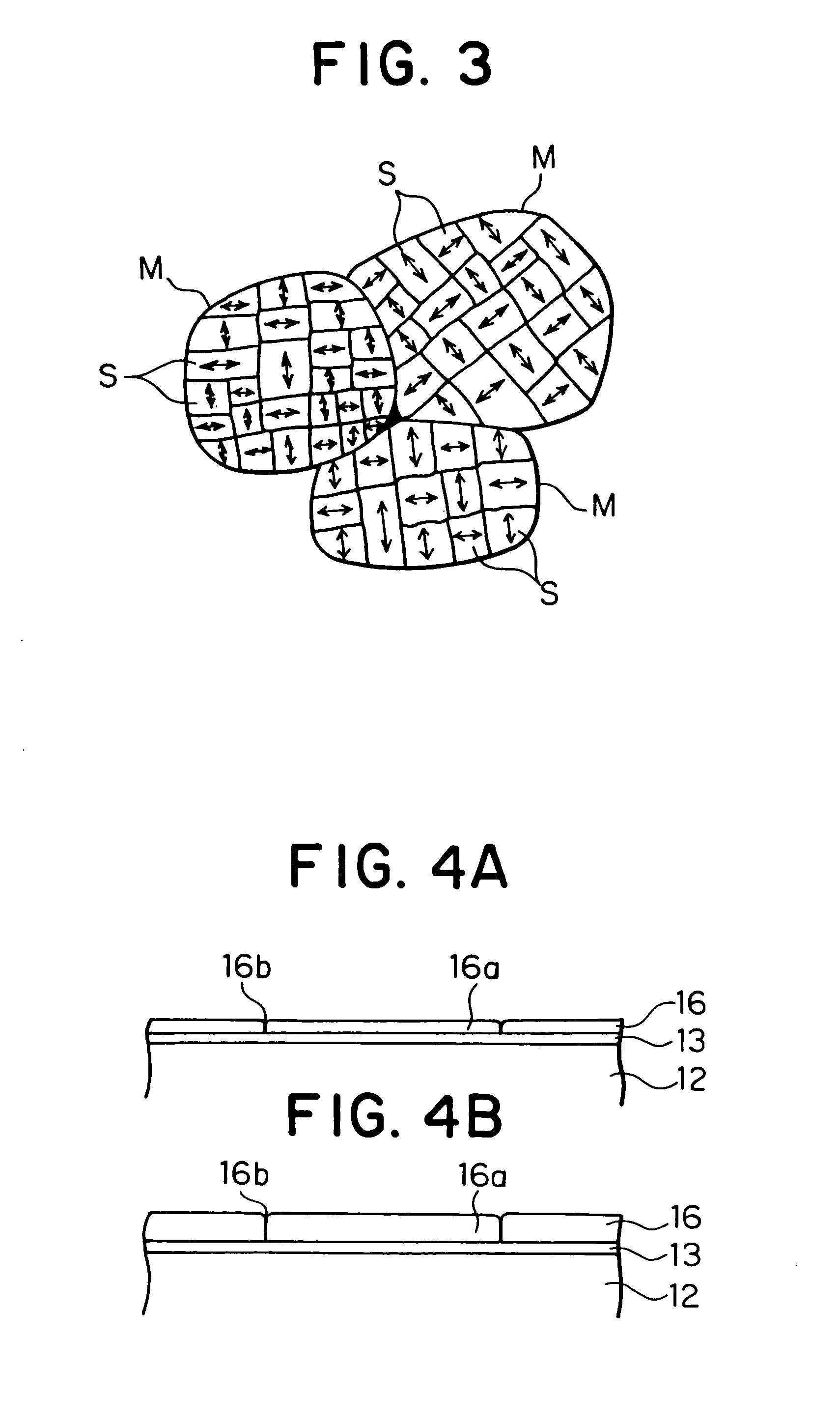

Hard magnetic film structural body, magnetoresistance effect device thereof, magnetic head, magnetic recording/reproducing head thereof, and magnetic record medium thereof, and magnetic storing apparatus thereof

InactiveUS20060198063A1Excellent magnetic propertiesGood reproducibilityNanomagnetismMagnetic-field-controlled resistorsMetallurgyCrystal structure

A base film of a hard magnetic film containing Co as a structural element has a crystal metal base film such as a Cr film formed on the main surface of a substrate and a reactive base film (mixing layer) formed between the substrate and the crystal metal base film and having a reactive amorphous layer containing a structural element of the substrate and a structural element of the crystal metal base film. A hard magnetic film containing Co as a structural element is formed on the crystal metal base film. With the crystal metal base film such as the Cr film formed on an amorphous layer, a hard magnetic film with a bi-crystal structure can be obtained with high reproducibility. With the hard magnetic film, magnetic characteristics such as coercive force Hc, residual magnetization Mr, saturated magnetization Ms, and square ratio S can be improved without need to use a thick base film. The hard magnetic film containing Co as a structural element is applied to a bias magnetic field applying film of a magnetoresistance effect device and a record layer of a magnetic record medium.

Owner:KK TOSHIBA

Waterborne fireproof coating for ultrathin expanded steel structure and preparation method thereof

The invention relates to a waterborne fireproof coating for an ultrathin expanded steel structure and a preparation method thereof. The fireproof coating is prepared from the following components in parts by weight: 12 to 14 parts of silicone acrylic emulsion, 16 to 18 parts of vac-veova emulsion, 2.0 to 2.5 parts of expanded perlite, 1.0 to 1.5 parts of hollow glass micro-beads, 39 to 42 parts ofa microencapsulated flame retardant measured by a core material, 3.5 to 4.0 parts of a microencapsulated synergistic flame retardant measured by the core material, 4.5 to 5.0 parts of filler, 1.5 to1.8 parts of a preservative and 3.5 to 4.2 parts of a coating additive, wherein the microencapsulated flame retardant is prepared from a silica gel coated intumescent flame retardant, and the microencapsulated synergistic flame retardant is prepared from silica gel coated synergistic flame retardant. The fireproof coating is high in fire endurance and excellent in durability and water resistance;the effective fireproof material and flame retardant compositions of the fireproof coating loss slowly along with external environmental factors; the effective fireproof service life is long; the fireproof flame retarding effect is good; and the fireproof coating is particularly suitable for an outdoor steel structural building.

Owner:奔腾漆业(上海)有限公司

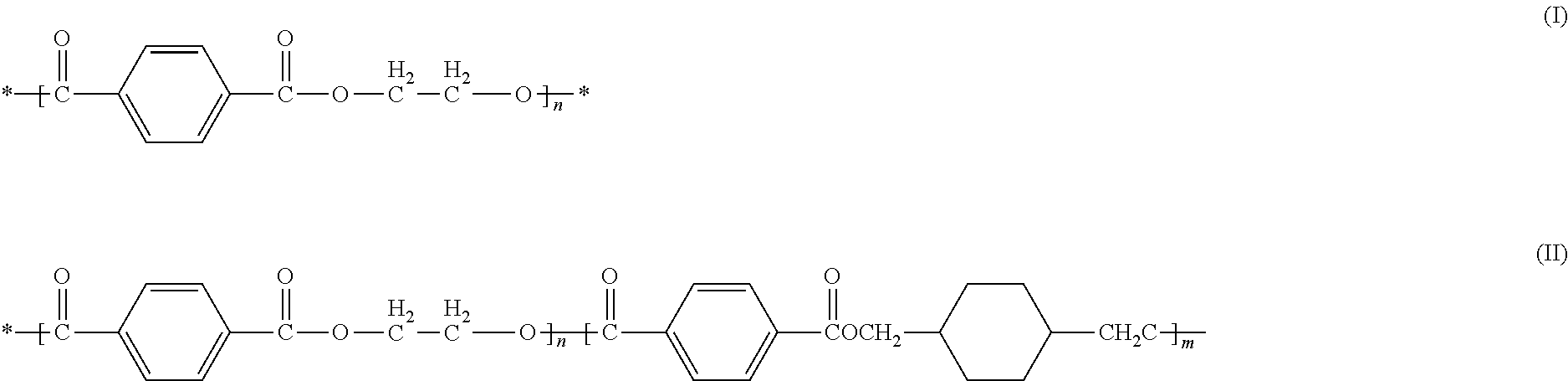

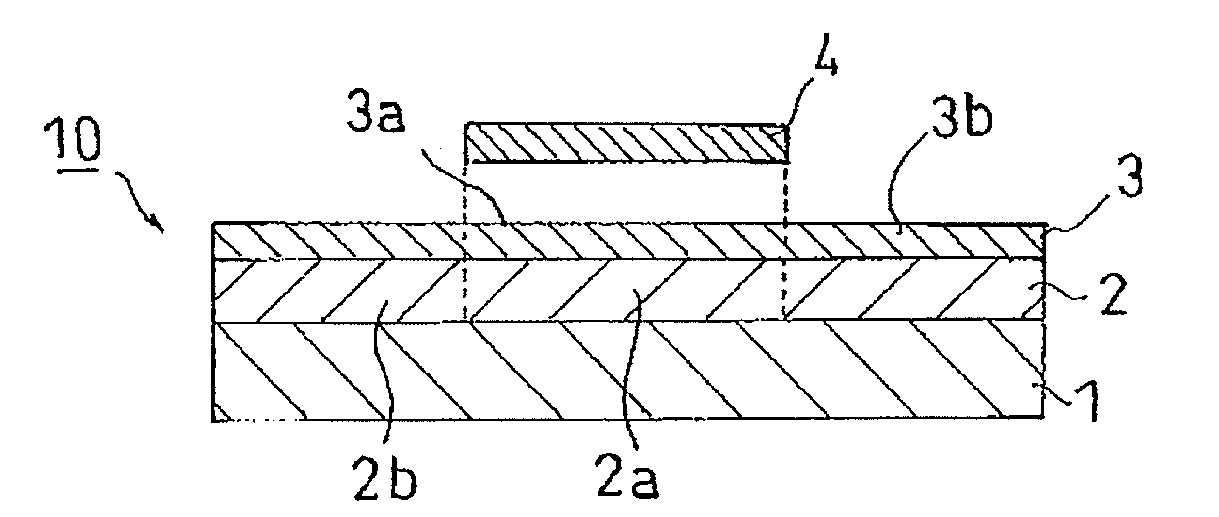

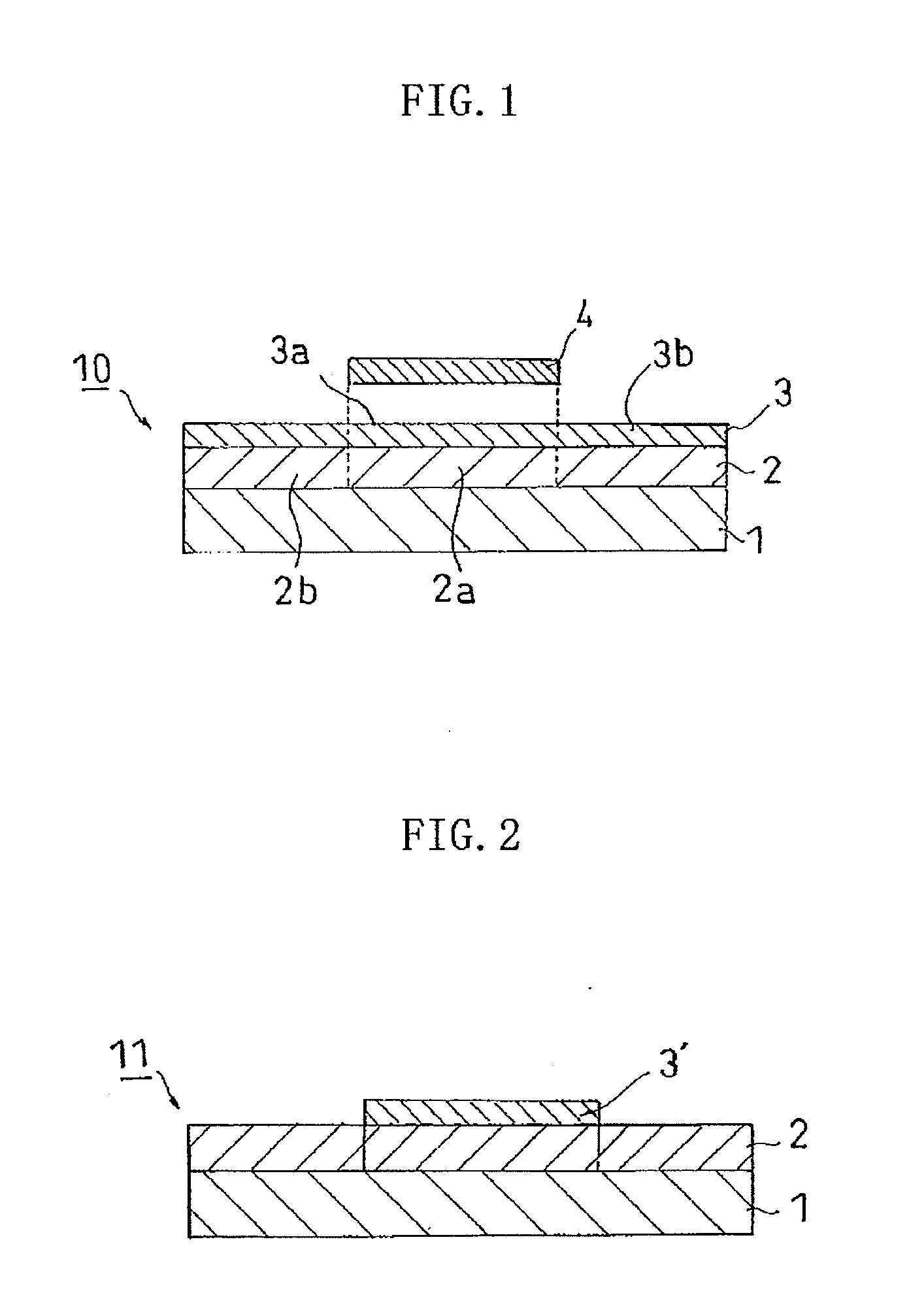

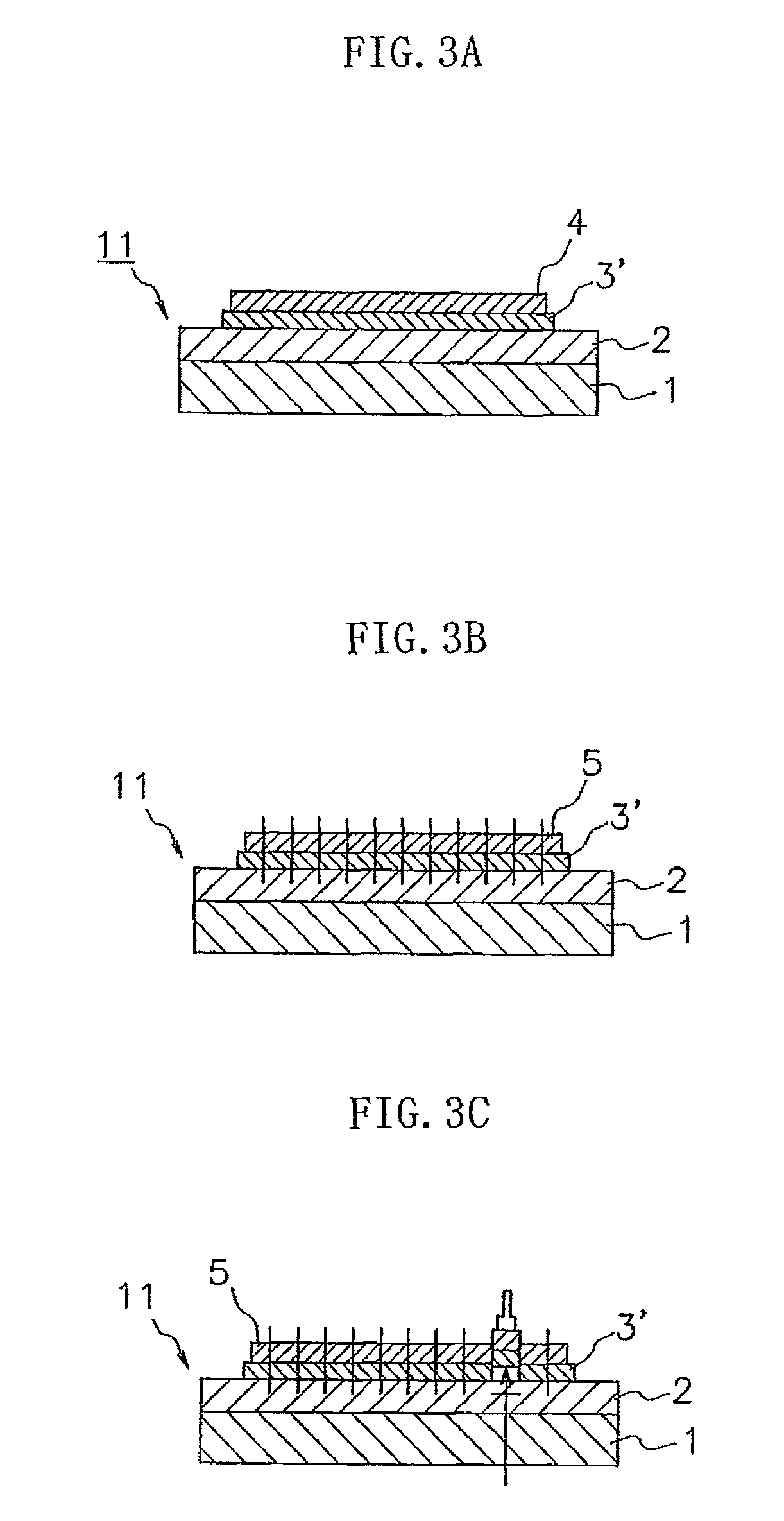

Dicing die-bonding film

InactiveUS20100029060A1Preventing chip flyExcellent in pickup propertyLamination ancillary operationsFilm/foil adhesivesFree-radical reactionPressure sensitive

A dicing die-bonding film having a pressure-sensitive adhesive layer on a base and a die-bonding film on the pressure-sensitive adhesive layer, the pressure-sensitive adhesive layer comprising an acrylic polymer comprising acrylic ester A represented by CH2═CHCOOR1 (where R1 is an alkyl group having 6-10 carbon atoms), acrylic ester B represented by CH2═CHCOOR2 (where R2 is an alkyl group having 11 carbon atoms or more), a hydroxyl group-containing monomer, and an isocyanate compound having a radical reactive carbon-carbon double bond, where the ratios of components are 40-10 mol % of the acrylic ester B with respect to 60-90 mol % of the acrylic ester A, 10-30 mol % hydroxyl group-containing monomer with respect to 100 mol % of the total of the acrylic ester A and the acrylic ester B, and 70-90 mol % isocyanate compound with respect to 100 mol % of the monomer containing a hydroxl group.

Owner:NITTO DENKO CORP

Oral compositions and uses thereof

ActiveUS20120100193A1Superior cleaning abilityHard surfaceCosmetic preparationsToilet preparationsChemistryHardness

The present invention is directed to oral compositions comprising an orally-acceptable carrier and a silica abrasive comprising a precipitated amorphous silica compound having an average particle size of from 5 μm to 20 μm, oil absorption of from 60 cc / 100 g to 120 cc / 100 g, and an Einlehner hardness of from 4 to 11, and methods of use thereof

Owner:COLGATE PALMOLIVE CO

Tooth enamel rejuvenating toothpaste

InactiveUS20050084461A1Reduced tendency to pick up stainHard surfaceCosmetic preparationsToilet preparationsTooth enamelToothpaste

An oral composition is provided which is effective for mineralization of surface enamel comprising a first part containing a partially water soluble calcium salt and a second part containing a fluoride salt and a bicarbonate salt. The oral composition can be a toothpaste and wherein the second part preferably contains sufficient bicarbonate salt to provide a fresh, clean feeling to the oral cavity.

Owner:CHURCH & DWIGHT CO INC

Novel water-based polyamido polyurethane wood paint and preparation method thereof

InactiveCN104530947AHigh hardnessHard surfacePolyurea/polyurethane coatingsWater basedTemperature resistance

The invention belongs to the field of paints, and discloses a novel water-based polyamido polyurethane wood paint and a preparation method thereof. The wood paint is prepared from 25-35% of polyamide resin polyalcohol, 10-20% of high-molecular polyalcohol, 30-40% of isocyanate, 3-5% of dibasic alcohol chain extender, 2-4% of tribasic alcohol chain extender, 5-8% of dimethylolpropionic acid, 3-5% of triethylamine, 2-4% of post chain extender, 0.1-0.4% of organic bismuth, 0.2-0.5% of organosilicon coupling agent, 0.1-0.3% of thickener and 0.1-0.3% of leveling agent. The product water-based paint has the advantages of no odor, energy saving, environmental protection, high hardness, hard surface, favorable wear resistance, flexible, clear and transparent coated film, favorable yellowing resistance, favorable heat resistance, favorable high-temperature resistance, favorable hydrolysis resistance, high adhesive force and wet and greaseless coated film, and is simple and convenient for construction.

Owner:ANQING HAOYE WATER PAINT

Ganoderma lucidum pictographic miniascape and cultivation method of pictographic works of art

InactiveCN103081722AUnique shapeBright colorSpecial ornamental structuresHorticultureBiotechnologySpore

The invention discloses a ganoderma lucidum pictographic miniascape and a cultivation method of pictographic works of art. Through shape constraint, a red cheese culture medium and sporocarps are shaped to needed shapes. Films are covered after hypha grows full of a bag and feels hard. After mycoderma is cultivated to turn to brown, the covered films are opened, and ganoderma lucidum outlet is covered by the films and ganoderma lucidum outlet cultivation is conducted. After a white growth circle on the edge of the ganoderma lucidum fungus lid turns to light brown and spores are not sent out, a ventral side of the ganoderma lucidum is stuck by film pieces until the ventral side becomes thick and hard. After process, viewing works of art are formed through combination of the ganoderma lucidum culture medium and the sporocarps. The product appearance of the ganoderma lucidum pictographic miniascape is peculiar, color and luster is bright, and longer vigor of life can be maintained. Hypha in a culture medium with a thin wax coating surface can have vigor of life for a long time and a viewing effect can be further improved. The processed sporocarps and culture medium is hard in surface, attractive in color and luster and can be stored for a long time.

Owner:吴辰

Travertine-like arabesquitic vat and production technology thereof

The invention discloses a travertine-like arabesquitic vat. The forming material of the travertine-like arabesquitic vat mainly comprises a solid material, a blended solution and staple, wherein the solid material comprises the following components in percentage by weight: 30-45% of rapid-hardening sulphoaluminate cement, 45-65% of fine river sand, 1-3% of titanium dioxide, 1-3% of yellow powder and 0.01-0.15% of red powder; the blended solution comprises the following components in percentage by weight: 99-99.9% of water and 0.01-0.1% of polyacrylamide; and the staple is glass fiber of which the length is 5-10cm. The invention also discloses a production technology for the travertine-like arabesquitic vat, which comprises the following steps of: burdening, mixing, cleaning a mold, installing a material mold, installing the staple, demolding, nursing, trimming, repairing, brushing to be smooth, applying a surface coating and the like. The travertine-like arabesquitic vat disclosed by the invention has the advantages of clear and natural texture, good product intensity, light weight, hard surface layer, abrasion resistance, small possibility of delaminating and falling powder, low cost and good decoration effect, is convenient to produce on a large scale and is easy for stable control of product chromatic aberration, natural travertine in the natural world can be prevented from being mined on a large scale, and mine waste can be utilized to protect the ecological environment.

Owner:泉州市嘉利来石材工艺有限公司

Composite ground prepared from anti static, spark failure concrete

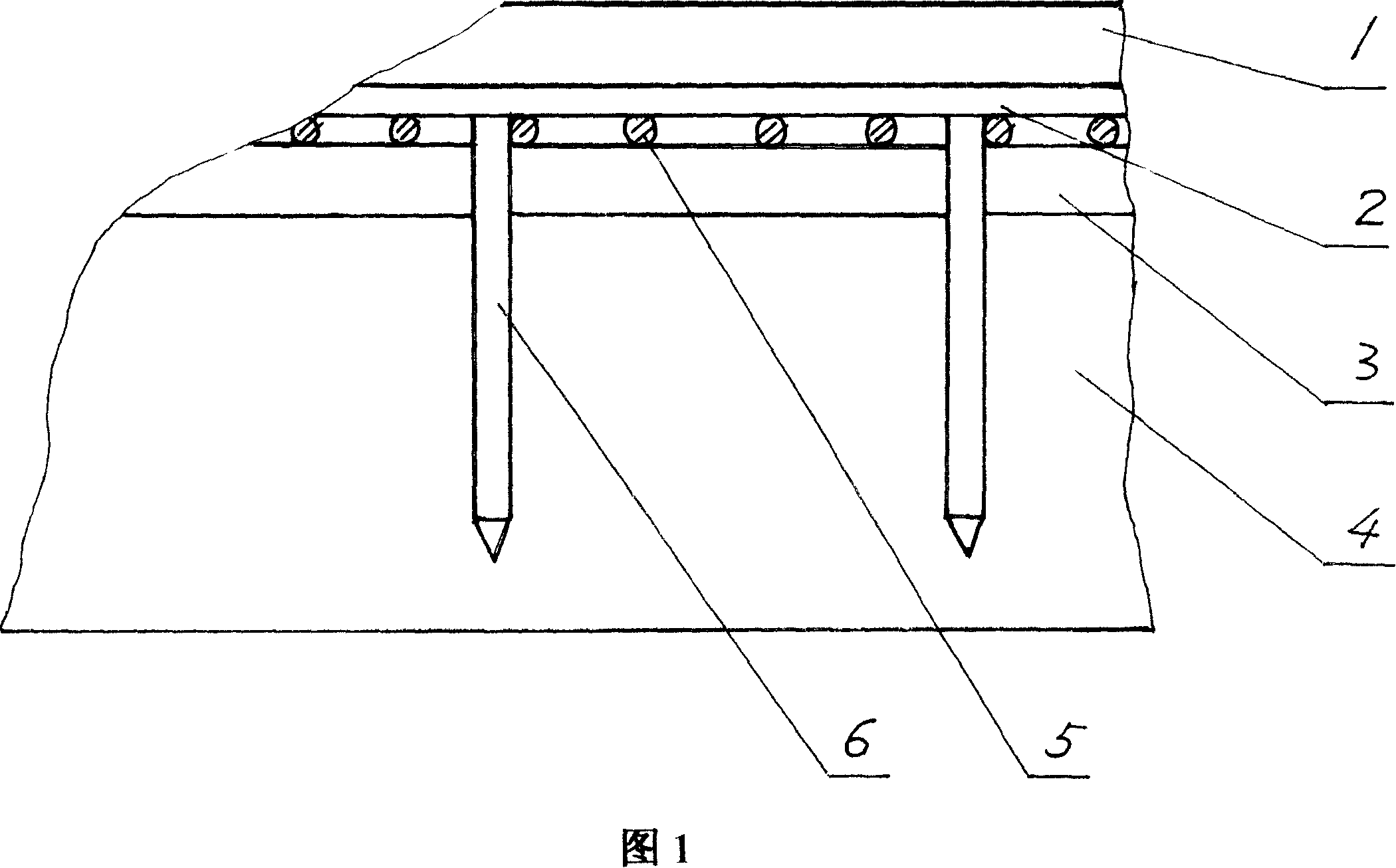

This invention relates to anti-static and misfire concrete compound ground including a surface layer and a base layer characterizing that the surface layer is a mixed material layer of 10-30mm ordinary Portland cement and water, misfire broken stone materials and an agent reducing resistance rate, a static discharge net woven with metal wires is set between the base layer and the surface layer with a combined layer, earth metal rods are set at the crunodes of the metal wires and connected by leads then accessed to the public earth pole.

Owner:罗辉

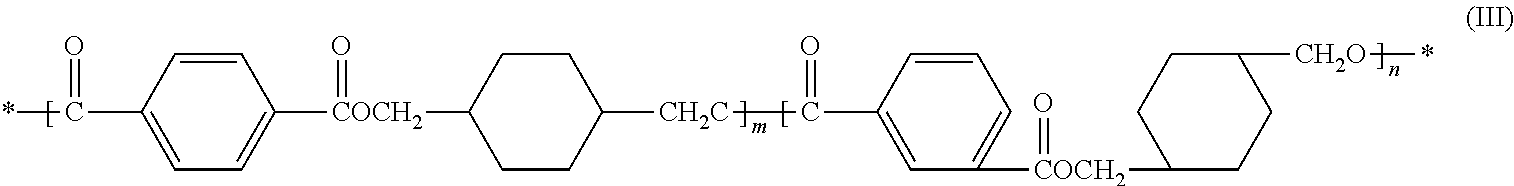

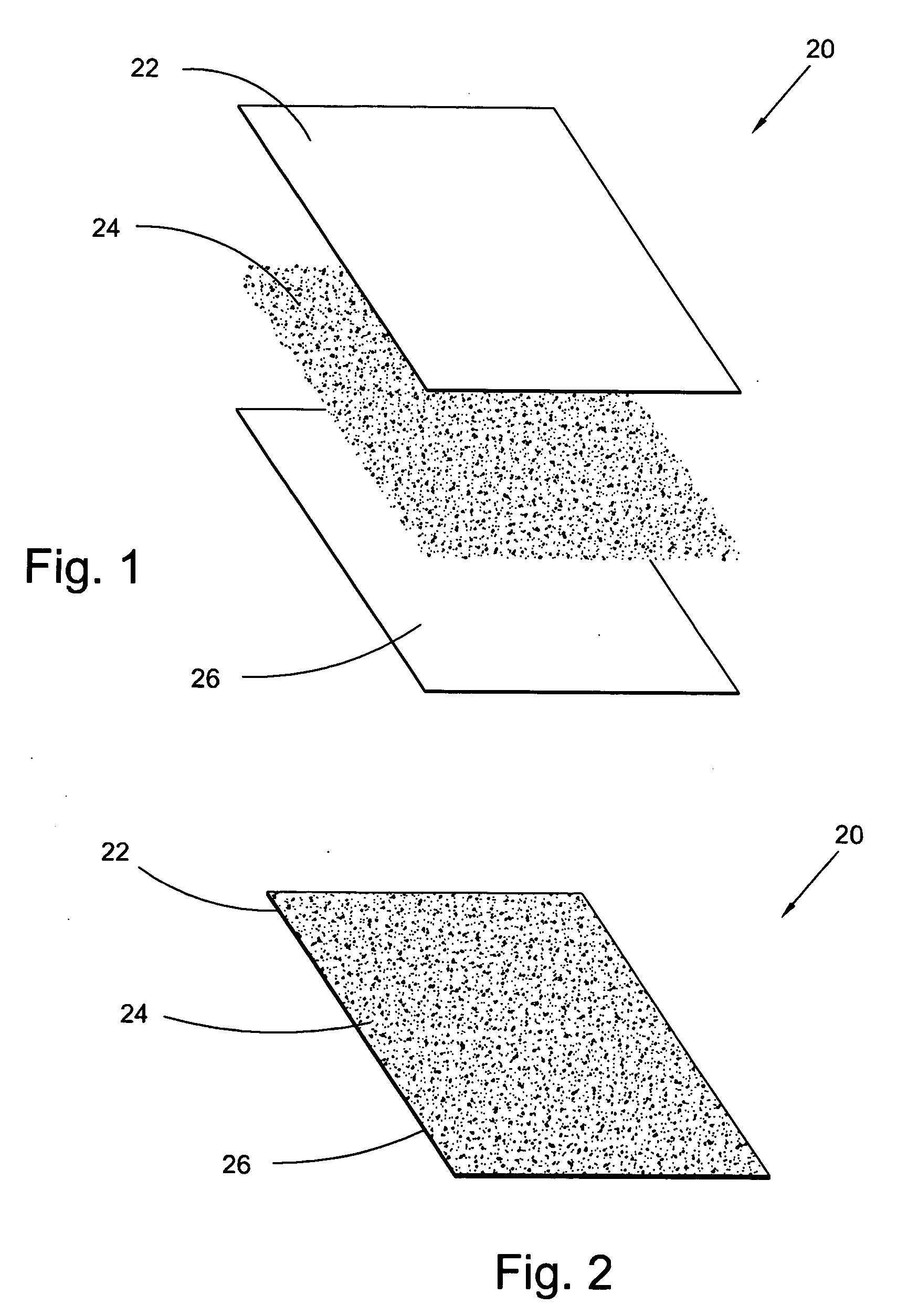

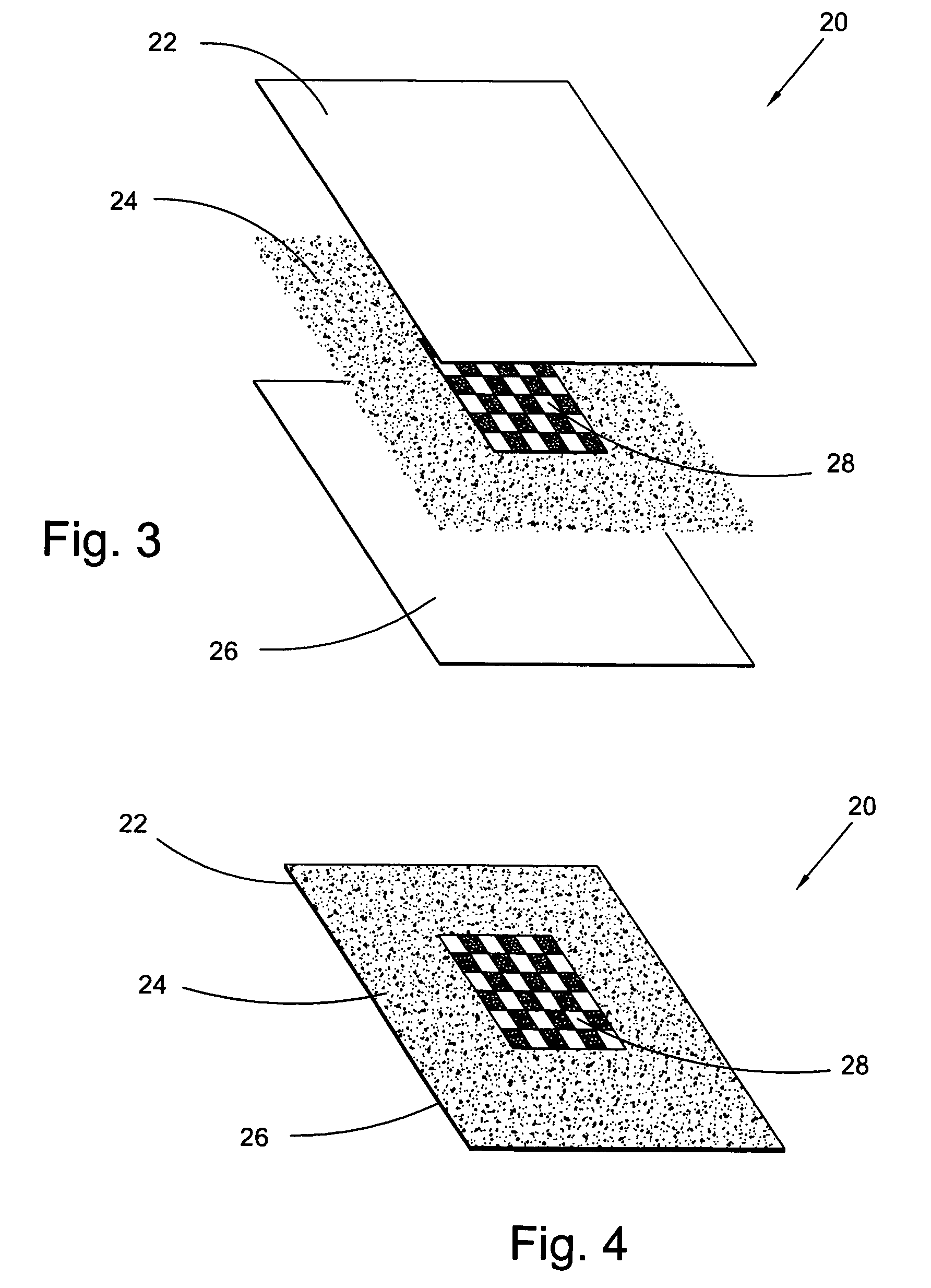

Quartz/solid surface laminate

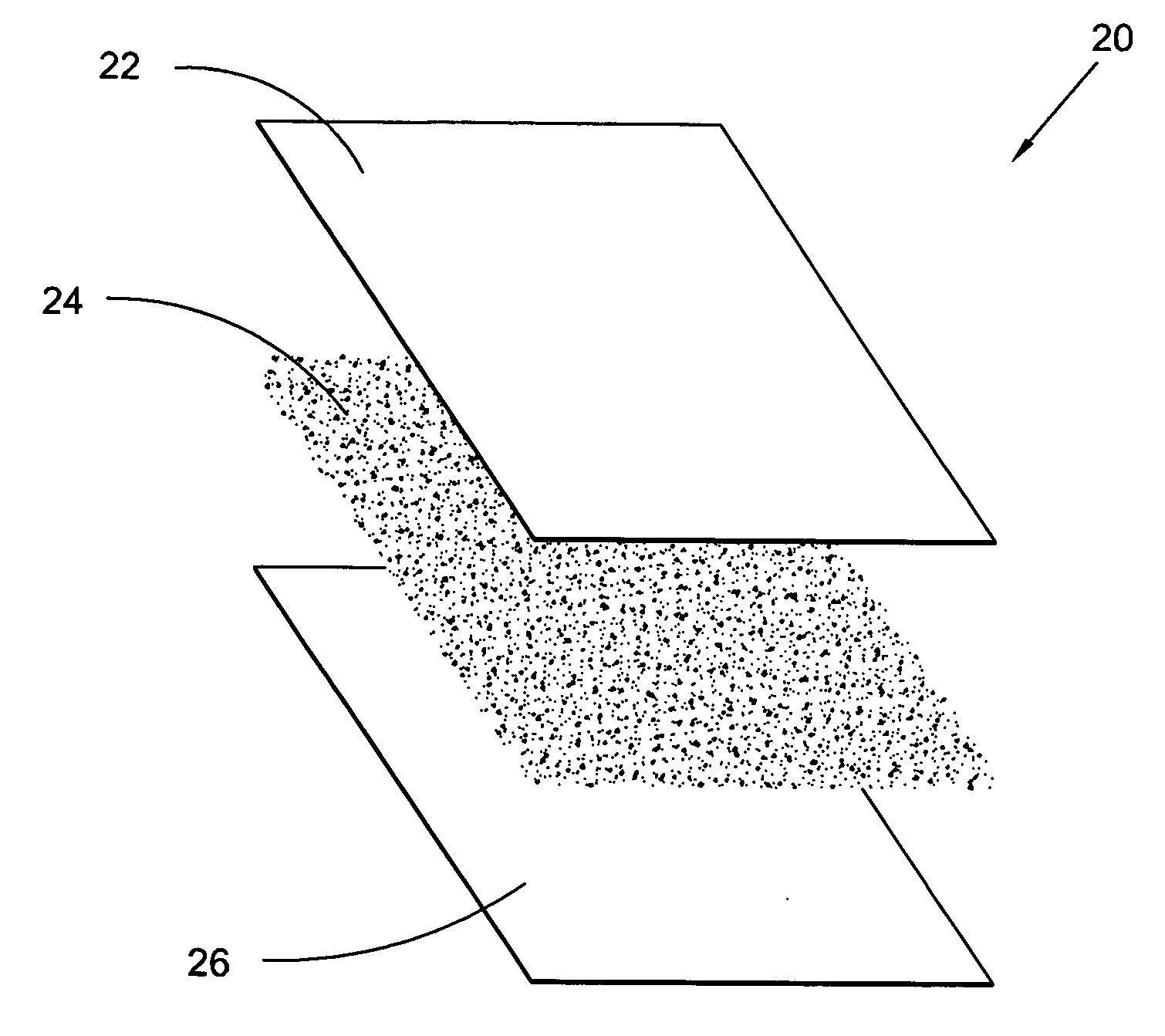

InactiveUS20070248836A1Functional performanceFaster laminating timeSynthetic resin layered productsAbrasion apparatusParticulatesPolyester

The present invention relates to a method of fabricating a laminate sheet product by using heat and pressure to form thermoformable particulates, such as acrylics and / or non-thermoformable particulates, such as polyester granules, quartz, or silica, into a sheet product. The invention also includes a particulate laminate sheet product comprising a melamine or phenolic backer sheets and a layer of one or more particulates. In preferred embodiments, melamine overlay sheets are also included in the laminate sheet. The invention also includes a particulate laminate sheet product made by the method of fabricating a laminate sheet product using heat and pressure to form thermoformable particulates, such as acrylics and / or non-thermoformable particulates, such as polyester granules, quartz, or silica, into a sheet product.

Owner:LINDE JOHN

Magnetic garnet material and faraday rotator using the same

InactiveUS6309557B1Hard surfaceReduced growth ratePolycrystalline material growthLiquid-phase epitaxial-layer growthChemical elementNon magnetic

An object is to provide a magnetic garnet material, even if a thickness of an element is made thin, in which a sufficient Faraday rotation capacity can be obtained, a magnetic field for saturation can be controlled to be less than 200 (Oe), and a magnetic compensation temperature can be controlled to be less than 0° C. as well as to provide a Faraday rotator which can be made thin, suppresses a manufacturing cost and achieves a high yielding. The above object can be achieved by a magnetic garnet material known as the general chemical formula BixYbyGdzM13-x-y-zFewM2uM35-w-uO12 and the Faraday rotator using the above material. However, M1 is more than one kind of chemical elements which can replace Bi, Yb or Gd, M2 is more than one kind of non-magnetic chemical elements which can replace Fe, and M3 is more than one kind of chemical elements which can replace Fe and M2. Further, x, y, z, w and u respectively satisfies 1.0<=x<=1.6, 0.3<=y<=0.7, 0.9<=z<=1.6, 4.0<=w<=4.3 and 0.7<=u<=1.0.

Owner:TDK CORPARATION

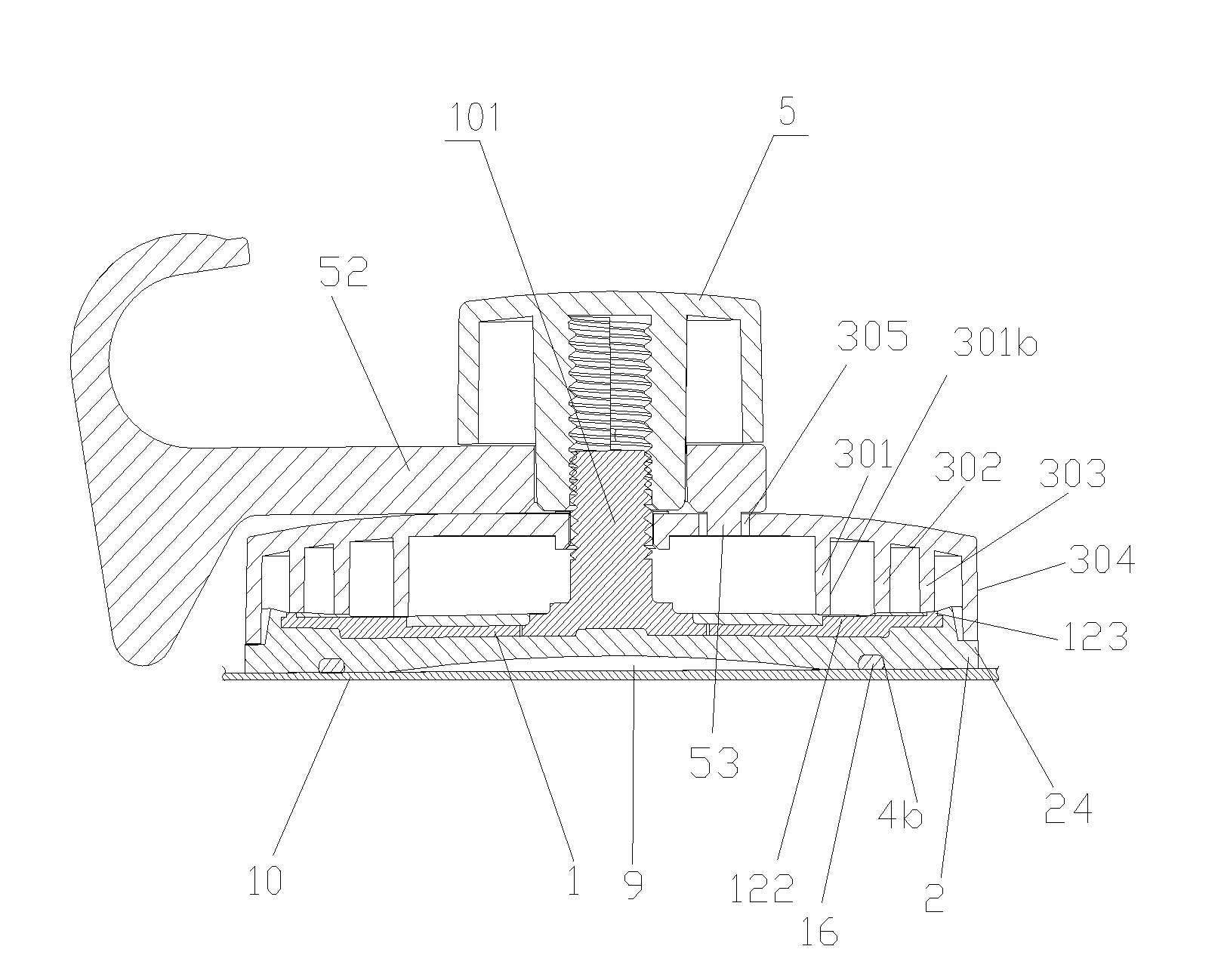

Suction cup with flat framework

ActiveUS9746022B2Simple structureEffectively transfer pressing forceMachine supportsSuction cupsEngineeringAir tightness

Owner:ZHONGSHAN TAILI HOUSEHOLD PROD MFG

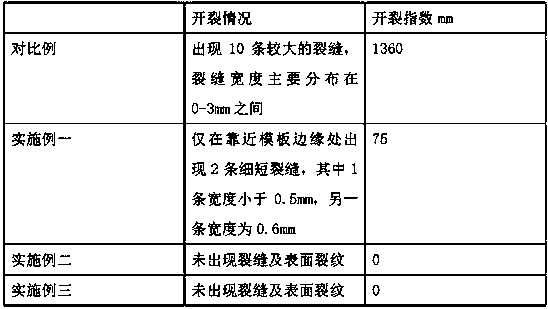

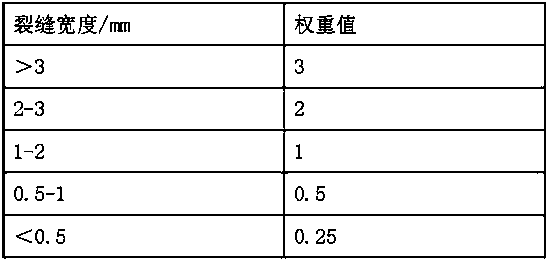

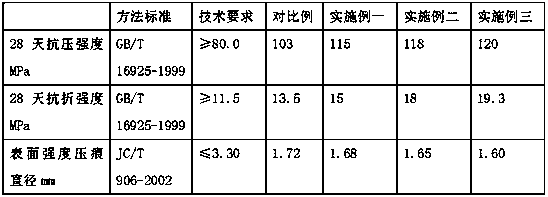

High-crack-resistance wear-resistant terrace material and preparation method thereof

The invention relates to the technical field of building materials. The invention relates to a terrace material, in particular to a high-crack-resistance wear-resistant terrace material and a preparation method thereof. The high-strength concrete comprises the following components in parts by weight: 250-550 parts of Portland cement, 300-800 parts of an aggregate, 0.1-50 parts of an admixture, 0.1-5 parts of a water reducing agent, 0.1-8 parts of redispersible latex powder, 0.05-5 parts of fibers and 0.1-5 parts of an early strength agent. The terrace material has the advantages of being resistant to cracking and cracking, high in abrasion resistance, high in pressure resistance, hard in surface, economical, durable, good in impact resistance, long in service life and the like; by adding the fiber material, the internal structure of the terrace material can be obviously improved, the micro-crack condition is avoided, and the extension of cracks is reduced, so that the toughness, the impermeability and the wear resistance of the terrace material are enhanced.

Owner:广州康磊建材有限公司

Mechanical parts having increased wear resistance

InactiveUS20080233428A1Extended service lifeHigh hardnessSolid state diffusion coatingThin material handlingWear resistantWear resistance

Owner:SKAFF OF AMERICA

Dicing die-bonding film

InactiveUS8119236B2Relieve stressReduce adhesionFilm/foil adhesivesPolyureas/polyurethane adhesivesPolymer scienceDouble bond

A dicing die-bonding film having a pressure-sensitive adhesive layer on a base and a die-bonding film on the pressure-sensitive adhesive layer, the pressure-sensitive adhesive layer comprising an acrylic polymer comprising acrylic ester A represented by CH2═CHCOOR1 (where R1 is an alkyl group having 6-10 carbon atoms), acrylic ester B represented by CH2═CHCOOR2 (where R2 is an alkyl group having 11 carbon atoms or more), a hydroxyl group-containing monomer, and an isocyanate compound having a radical reactive carbon-carbon double bond where the ratios of components are 40-10 mol % of the acrylic ester B with respect to 60-90 mol % of the acrylic ester A, 10-30 mol % hydroxyl group-containing monomer with respect to 100 mol % of the total of the acrylic ester A and the acrylic ester B, and 70-90 mol % isocyanate compound with respect to 100 mol % of the monomer containing a hydroxl group.

Owner:NITTO DENKO CORP

Magnetoresistance effect device having hard magnetic film structural body

InactiveUS7116527B1Excellent magnetic propertiesGood reproducibilityNanomagnetismMagnetic-field-controlled resistorsMetallurgyCrystal structure

Owner:KK TOSHIBA

Multilayer film for use in simultaneous injection molding-lamination method

InactiveUS20090252935A1High surface hardnessImprove heat resistanceDecorative surface effectsDuplicating/marking methodsPolymer scienceHeat resistance

A multilayer film for use in a simultaneous injection molding-lamination method comprising a layer (A) formed of a polycarbonate resin and a layer (B) formed of a methacrylic resin and acrylic rubber particles, which is laminated on at least one surface of the layer (A). The multilayer film is preferably used as a decorative film having high heat resistance and high surface hardness.

Owner:SUMITOMO CHEM CO LTD

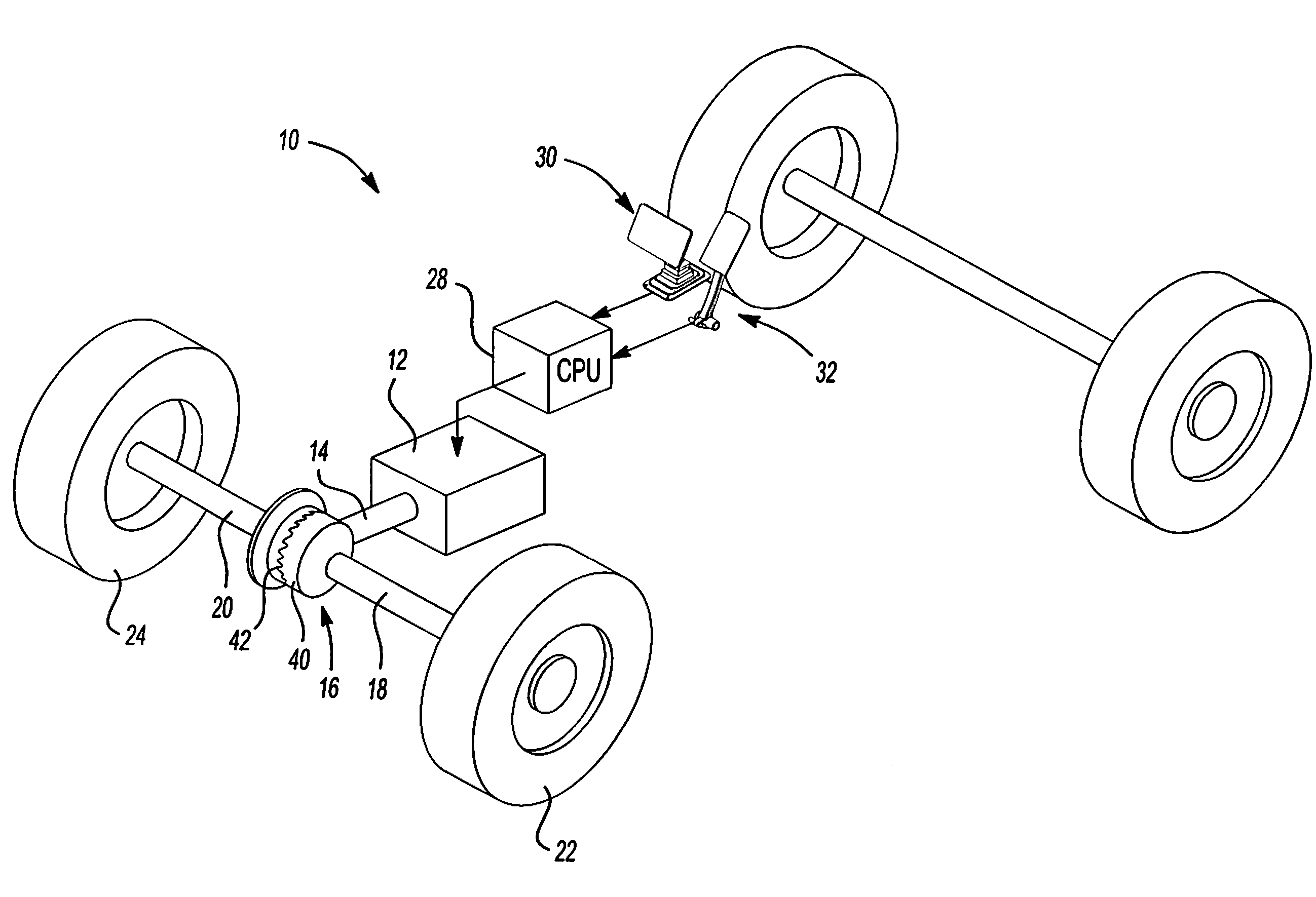

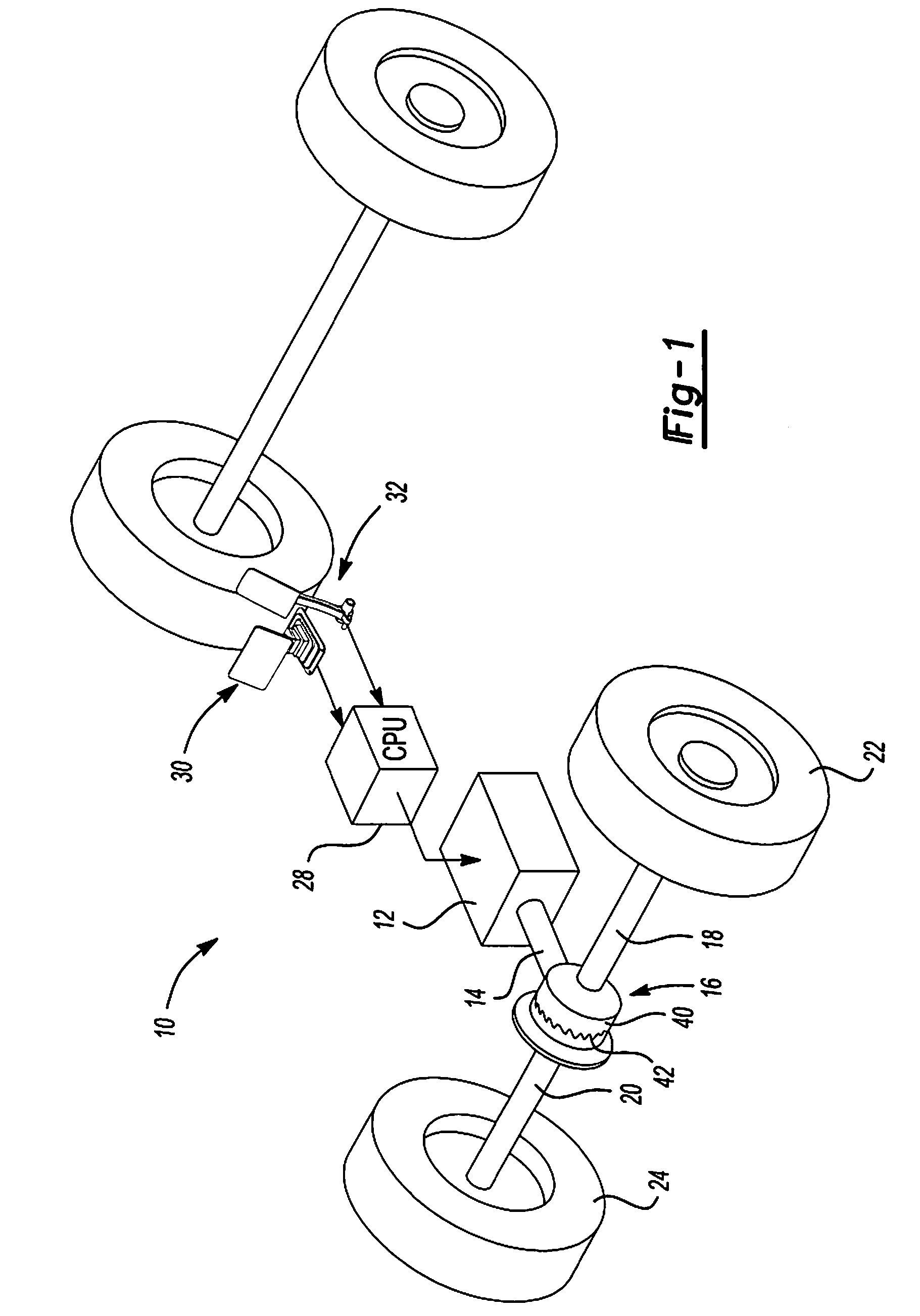

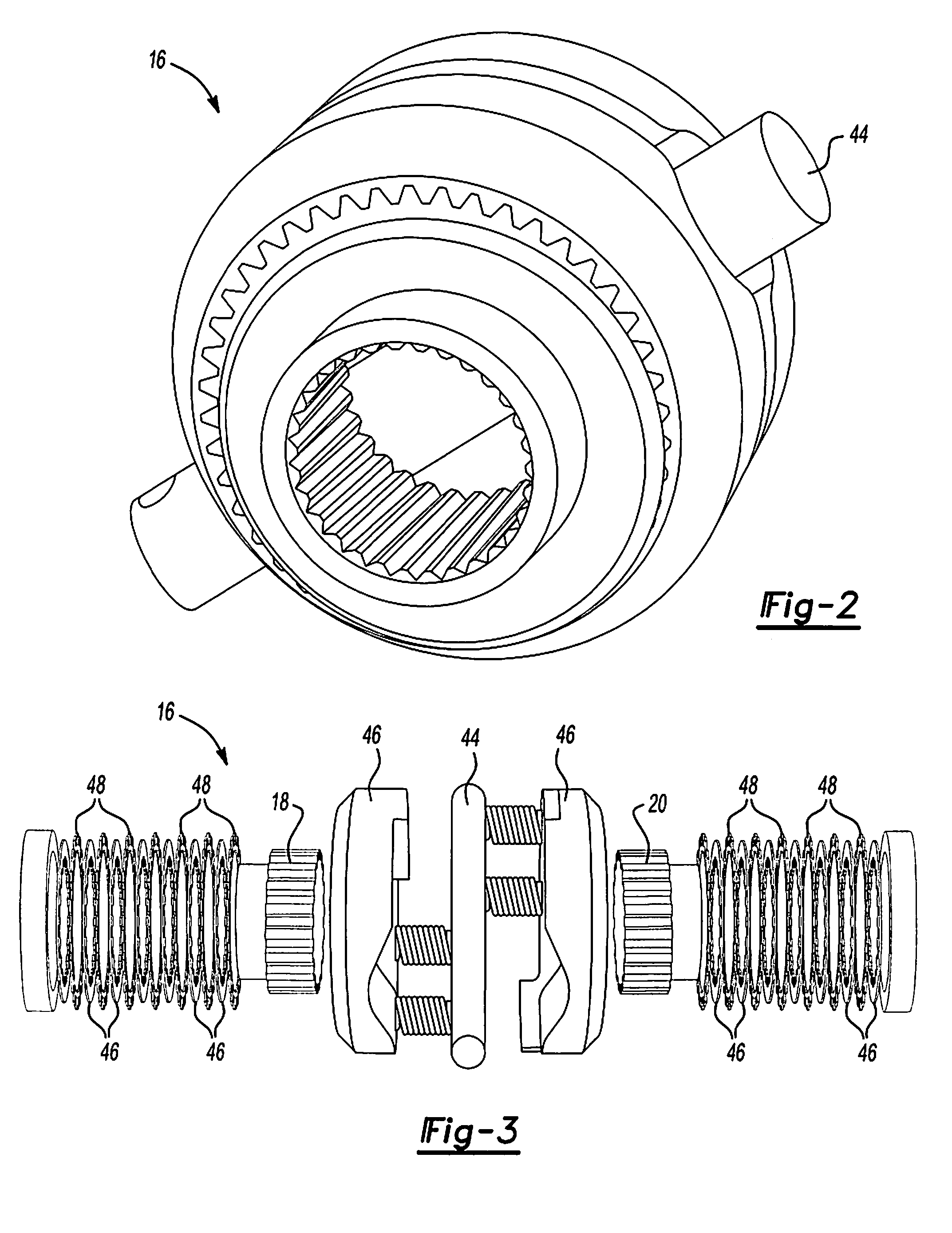

Limited Slip Differential For Electric Vehicle

InactiveUS20090107741A1Slippery surface can be difficultPrevent rotationElectrodynamic brake systemsElectric propulsion mountingLimited-slip differentialDrivetrain

An electric vehicle, such as a golf car or utility vehicle, is provided with an electric motor that provides dynamic braking for the vehicle. The vehicle drivetrain is provided with a limited slip differential in order to prevent the wheels from turning freely when traction is lost.

Owner:TEXTRON INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com