Golf club head with increased radius of gyration and face reinforcement

a golf club head and radius technology, applied in the field of golf club head radius gyration and face reinforcement, can solve the problems of difficult to increase the perimeter weighting effect of the clubhead, unfavorable face depth, high cost of forging technology, etc., and achieve the effect of increasing the radius of gyration and high impa

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

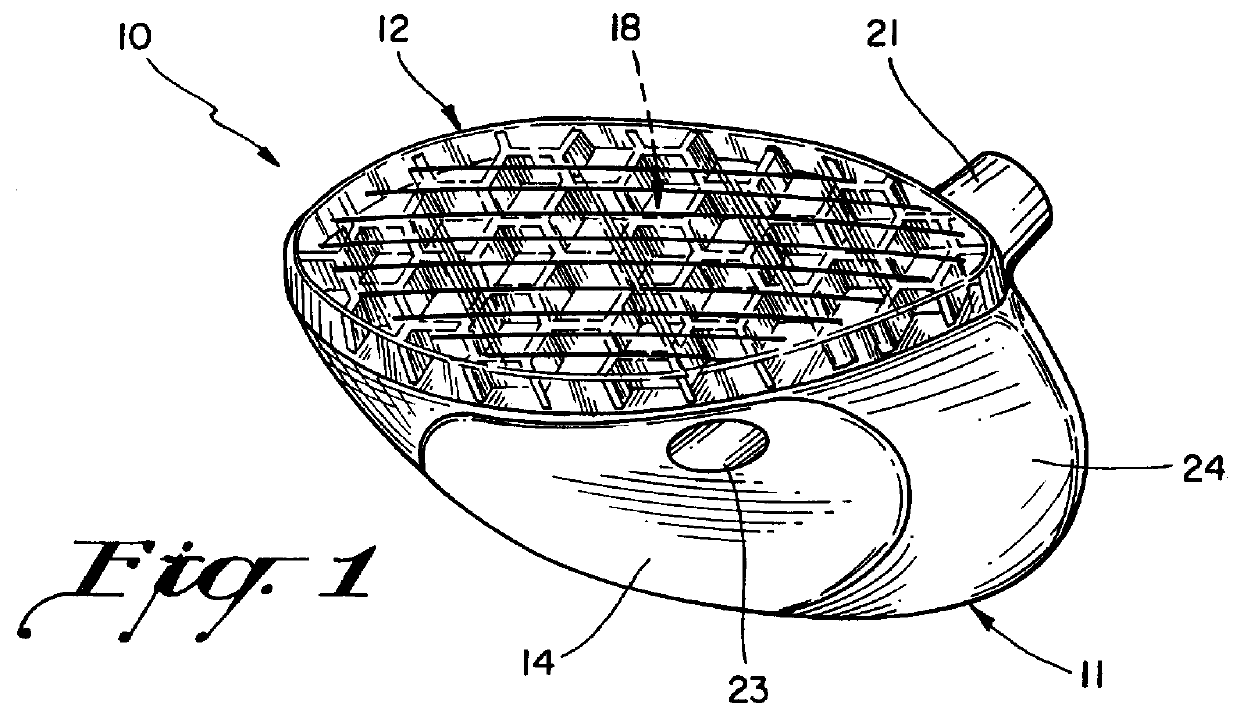

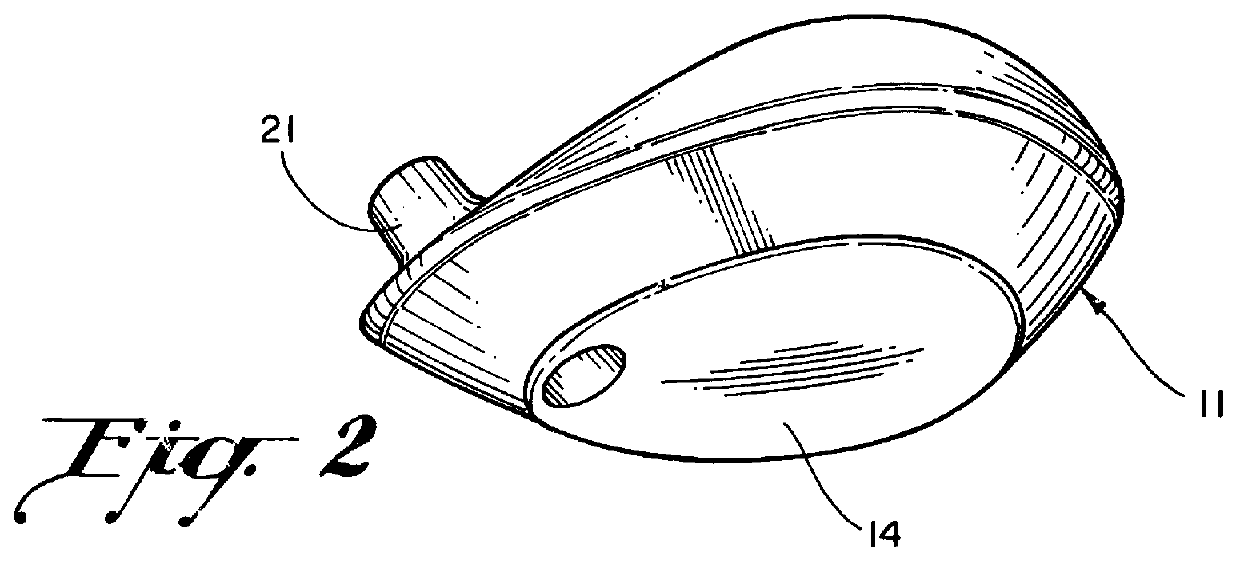

Referring to the drawings and particularly FIGS. 1 to 8, a clubhead 10 is illustrated consisting of an investment cast clubhead body 12 with its forward wall covered by an in situ molded plastic insert 12 thereover.

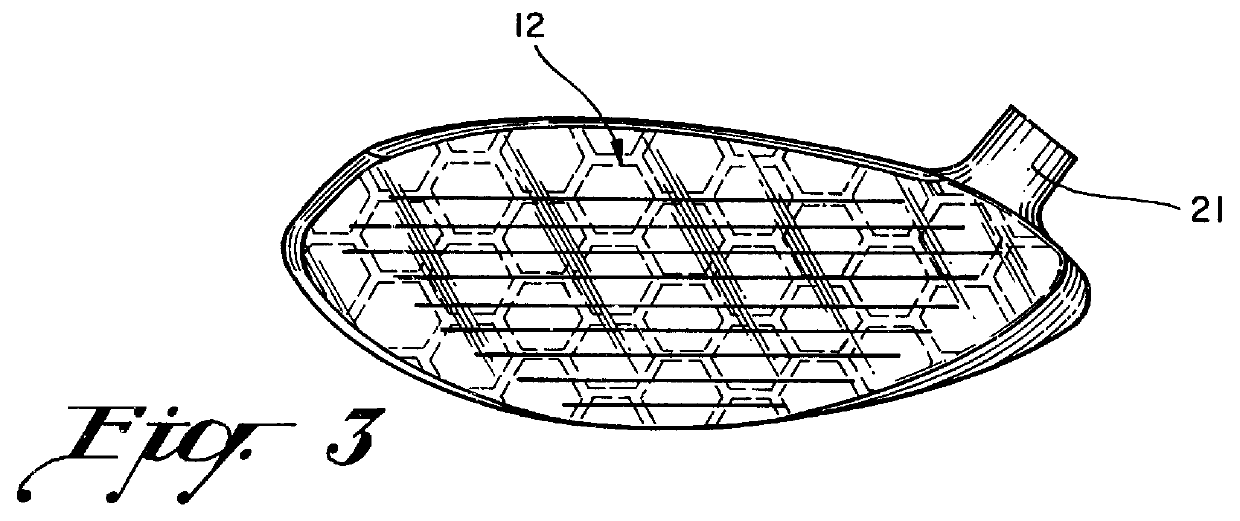

The clubhead 10 is preferably a thin walled investment cast head constructed of a high strength metal alloy such as 17-4 stainless steel or a high titanium content alloy with aluminum but certain aspects of the present invention can be utilized in clubheads constructed of other materials. The clubhead 10 is a hollow casting that is enclosed by a sole plate 14 constructed of the same material as the clubhead body 11. Sole plate 14 is also investment cast and connected to the clubhead body 11 by heliarc welding around its perimeter. The investment casting techniques for the clubhead body 11, the sole plate 14, and the welding of the sole plate 14 to the body 11 have been well known for at least the past eight years although the unique shape of the clubhead body 11 requires ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com