In addition, the types of cleaning systems designed herein specifically exclude machines that use blast-cleaning as part of a manufacturing operation.

(1) The types of cleaning systems used for

manufacturing operations typically operate in a

stationary mode, and the pieces or components that are being cleaned will be passed through (or otherwise temporarily inserted into) a high-tech cleaning

machine. By contrast, the vast majority of blast-cleaning machines that are designed for non-manufacturing use, such as for removing paint or

rust from buildings or bridges, need to be portable, so that they can be moved to a series of different work sites at a series of different locations.

(2) The economic and operating requirements for fixed cleaning systems that are designed and used for high-tech manufacturing, versus systems designed to remove old paint or

rust from buildings or similar structures, are totally different. The types of systems and methods that have been developed for sophisticated cleaning of

electronics or other sensitive devices use very expensive machines that often require installation, debugging, and optimization for days or even weeks, by

highly skilled engineers and technicians. By contrast, the types of blast-cleaning machines used to remove old paint or

rust from buildings or other structures must be designed for rapid setup and operation, by semi-skilled laborers.

In particular, because of the power levels involves, the volumes of grit or other

particulates, and the frequent need for using dry ice as

particulate material, the types of machines disclosed and claimed herein are not suited for medical, veterinary, or dental work.

However, those types of units are very expensive high-precision medical devices, which are designed to

handle only very small quantities of extremely small

abrasive particulates which have very uniform sizes (the range of differences between particle diameters must be kept very low, and tightly controlled).

When used as a blast-cleaning media, sand suffers from various problems, including the creation of very small “free

silicate” particles that become airborne and that can create severe

lung problems among workers and others.

(1) When particles of

water ice are used for blast cleaning, the particles immediately melt, when they

impact against a surface at high speed. Therefore, whenever

water ice is used, it creates a heavy and wet form of waste, containing water mixed with dust, specks, chips, flakes, and other particles of paint, rust, charred wood, or any other material being removed from a surface by blast-cleaning. That type of wet and heavy waste (which can be referred to as a mud,

slurry, etc.) creates substantial and potentially severe problems of hazardous and potentially

toxic waste that must somehow be washed away or otherwise disposed of.

(2) If a wet

slurry accumulates on a floor or other surface where workers must move around and walk, the floor likely will become slippery and dangerous, especially since the workers will be handling and maneuvering hoses that are blowing materials out through pressurized high-speed nozzles.

(3) Water from melted ice poses a substantial danger of permeating into and damaging or degrading various types of surfaces that may need to be blast-cleaned (such as wood, as one example).

(4) Water also tends to evaporate slowly, especially in cool or

cold weather, and it clings to wood and many other surfaces in ways that can impede a refinishing operation. For example, many types of paint and other coatings should not be applied to a surfaces that has become wet, unless the surface has dried out for at least a full day or two. Accordingly, the use of

water ice can interfere with a repainting or similar operation that could be carried out immediately, if the blast cleaning operation uses only dry ice, or dry particulates.

However, the Ichinoseki process was never been widely adopted or used, because of several reasons.

First, the inclusion of water in a blast-cleaning mixture will create increased quantities of waste, compared to blast-

cleaning methods that use dry particles only.

Although it is only a relatively mild acid, it is nevertheless classified as corrosive, and if added to

radioactive waste, it would require an additional set of requirements and safeguards.

The third major problem with any blast-cleaning

system that uses particles of water ice is that the ice particles encounter a highly-compressed and fast-moving air

stream, while still in a pressurized hose.

This will create some quantity of melting and water, within the hose and

nozzle system.

If dry ice particles are also being carried by the same hose and nozzle system, the

liquid water droplets can trigger a highly undesirable type of agglomeration and clumping of the dry ice particles, which can create or severely aggravate problems of clogging and loss of flow.

Indeed, because of the increased risks and problems of clogging, to the best of the Applicant's knowledge and belief, mixtures of water ice and dry ice are not used or recommended by any companies that provide equipment or supplies for blast cleaning.

Most blast-cleaning operations are done by two-man crews, partly because of safety reasons (

carbon dioxide is a dangerous gas that can quickly asphyxiate and kill someone, if a

respirator malfunctions), and partly because holding and moving around a hose with a high-speed nozzle at the end, for hours at a time, is a physically difficult and tiring operation, which can be performed best by alternating periods of hose work and support work.

Smaller hoppers could be made if desired, but they would require more frequent reloading, which would disrupt and

delay a cleaning operation.

For example, very large hoppers often can hold several tons of particulate blasting media.

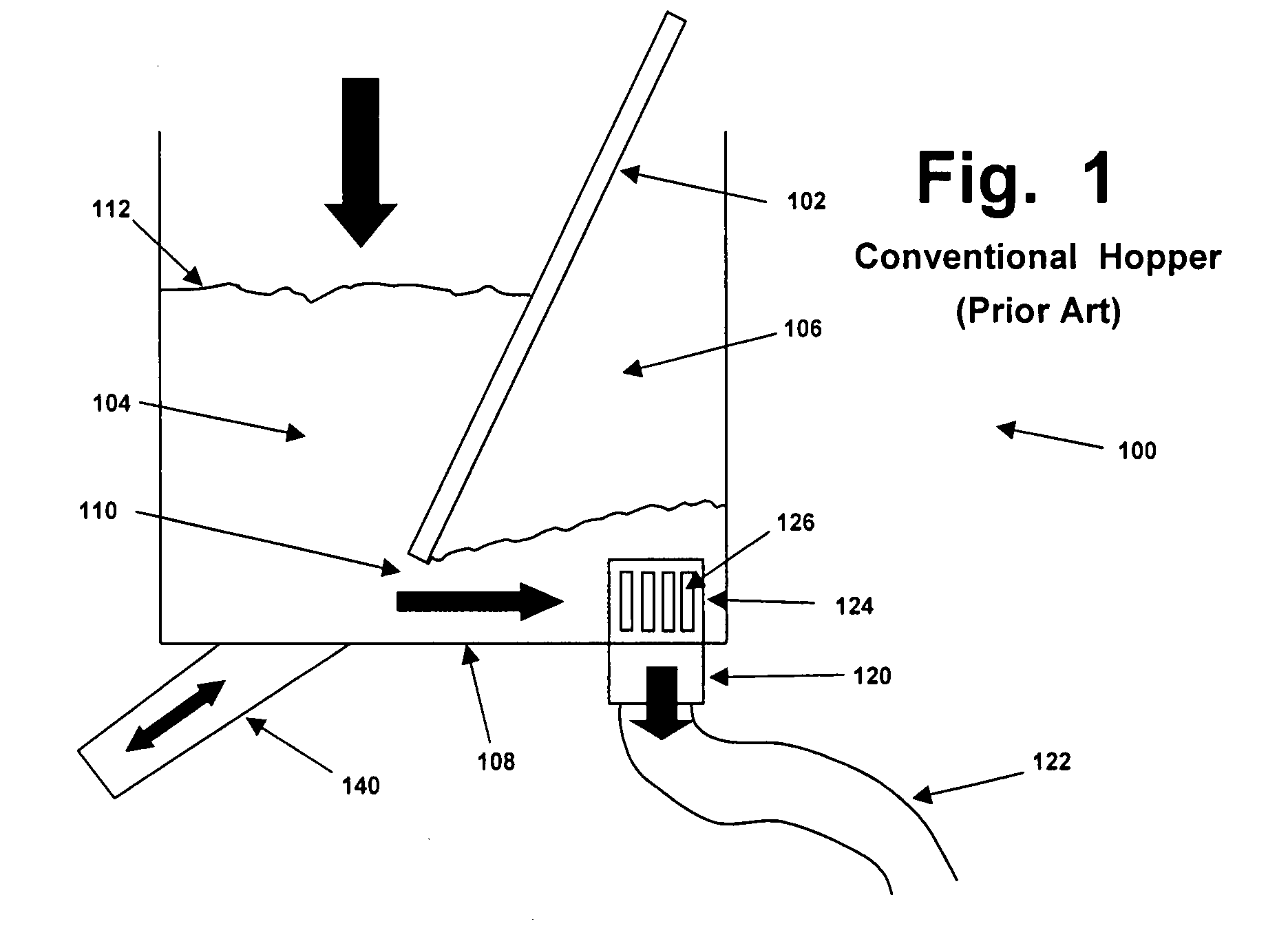

However, those terms are not always used consistently, and some people refer to the complete device or

assembly as a bin.

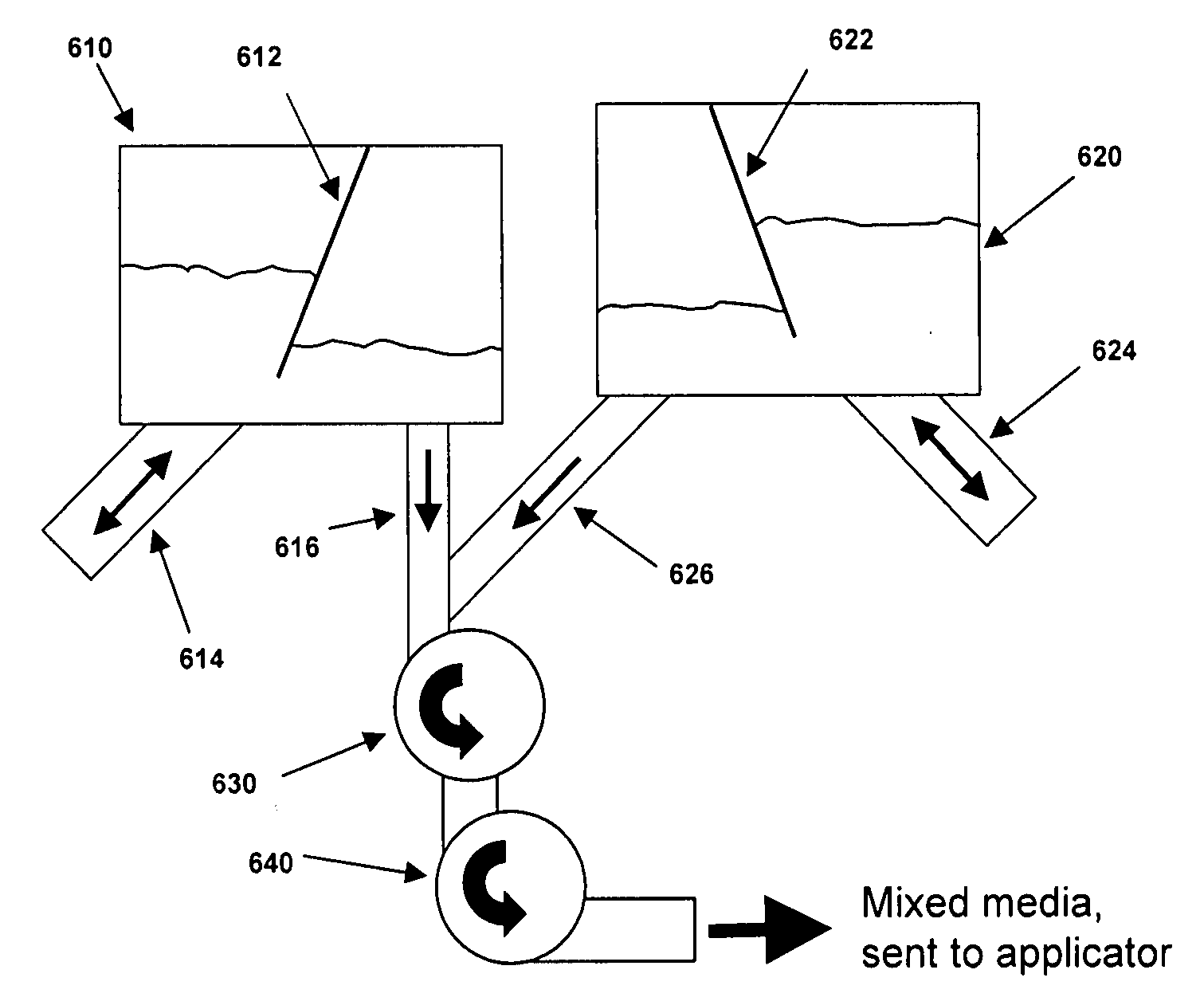

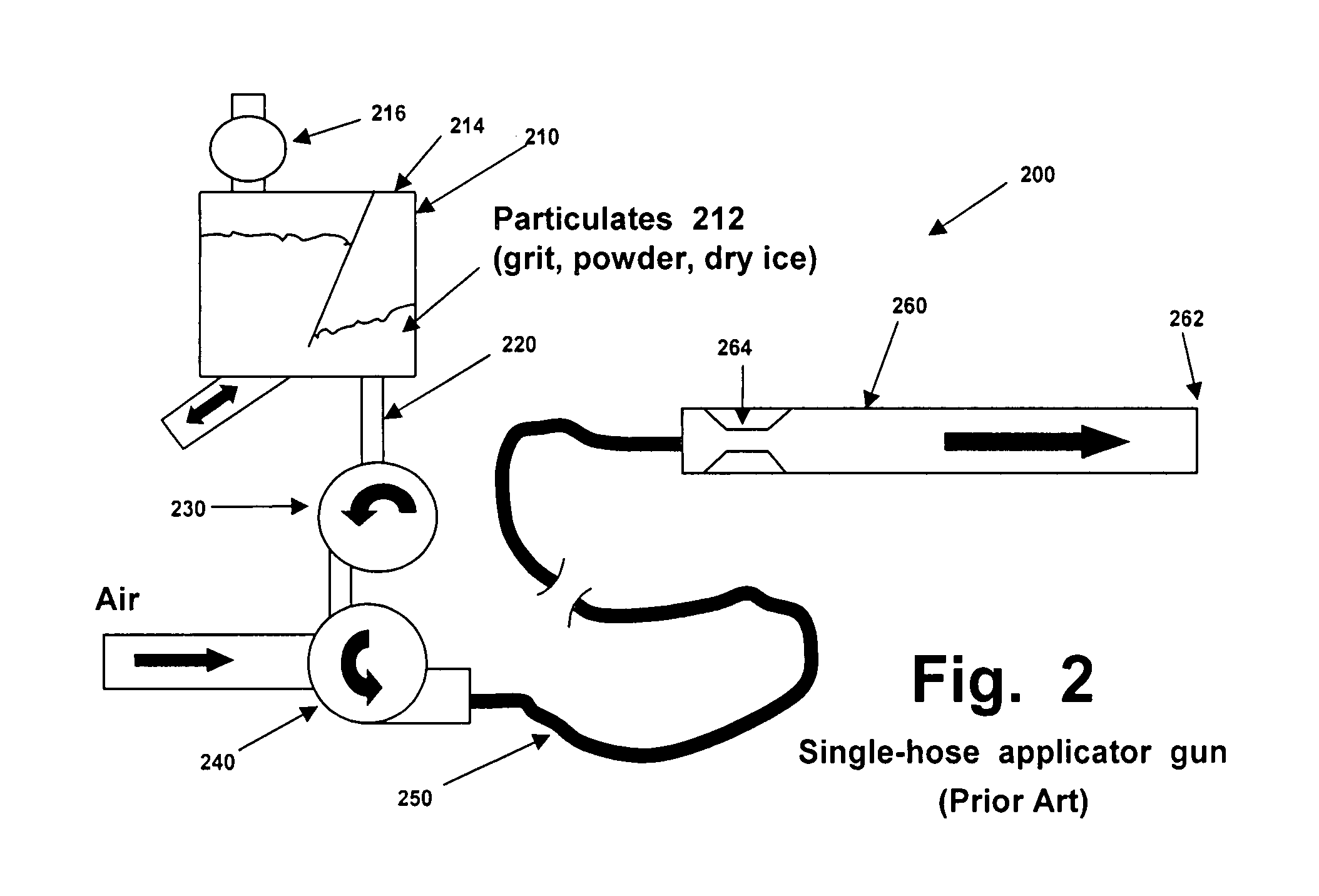

As explained below, single hose systems are more powerful and efficient, when they are working properly; however, they also are much more prone to clogging, in ways that can be difficult and even dangerous to unclog.

The advantages of

higher power, greater efficiency, and reduced working times, in single-hose systems, quickly become apparent to anyone who has worked with both types of systems; however, the higher frequency of clogging problems in single-hose systems, and the time-consuming and potentially dangerous chore of unclogging a single-hose system (under the prior art) also becomes apparent to anyone who has used single-hose systems on multiple occasions.

This is where clogging commonly occurs.

Clogging is a major problem in single-hose systems, and it can grow worse as an applicator gun ages, due to two factors.

First, even though

extremely hard metal alloys are used to make critical orifices, the entry ramp that leads into the constricted orifice tends to become pitted and scarred, over time, as highly

abrasive particles are blasted through the orifice for hours at a time.

Second, the

diameter of the critical orifice can be widened, over time, by the abrasive particles, creating a mismatch between the orifice traits and the outlet nozzle traits.

Either of those types of gradual developments can create problems, and any such applicator gun eventually will need to be replaced.

However, as an offsetting

disadvantage, dual-hose systems suffer from problems of reduced output velocity, which leads to reduced power and efficiency.

That mixing operation unavoidably creates some level of turbulence in the

mixing zone, and the turbulence creates interference and disruption that prevent the mixture from passing through the applicator in an efficient “laminar flow” manner that could sustain higher velocities.

However, experienced operators also will report that single-hose systems do indeed suffer from much more frequent clogging than double-hose systems.

However, sandblasting suffers from several problems and shortcomings that have limited its use.

(1) sandblasting cannot discriminate between the

surface layer or contaminant that should be removed (such as old paint, etc.), and underlying material that should not be altered. Because sandblasting is so powerful and abrasive, it often “

scars” the surface of the underlying material, creating problems such as an undesired roughened appearance, weakening of the material, and increased susceptibility to

corrosion;

(2) high-velocity sand generates heat, when the sand smashes against a surface and bounces off. In some cases, heat production can be very undesirable; for example, paint that is being removed may soften and melt, forming a sticky mess rather a clean surface;

(3) if sand is used to clean a surface, any sand that remains scattered around the work area, after the blasting operation has been completed, can

pose serious problems; and,

(4) when

natural sand is used for blast-cleaning, it can generate microscopic airborne “free

silicate” particles, which

pose a serious risk of

health problems among workers who do this type of work.

These constraints

pose not just one but two complicated and potentially competing challenges, because of two important factors: (i) compressors will heat up any air they

handle; but, (ii) if a conventional cooling device is used to chill heated air that emerges from a compressor, the cooling action can increase the

relative humidity of the air, in ways that can create

moisture problems.

First, the very cold particles of dry ice prevent any heating of the surface, and in many cases can render surface

layers or contaminants brittle (also called friable, which indicates that something can be easily broken).

However, the freezing effects of

dry ice blasting will render the sap-laden material hard and brittle, so it can be efficiently removed from the sanding belt or planing drum.

The cost of the machinery and power to run a

dry ice blasting system is relatively high, since dry ice is more expensive to obtain (or create) and store, compared to

inert particulate materials.

Also, since dry ice

pellets are softer than sand or other mineral particulates, it takes a larger quantity of dry ice, applied for a longer period of time, to completely clean some surfaces; indeed, due to its lower levels of abrasiveness, dry ice blasting simply cannot clean some types of coatings, from some types of surfaces that need to be cleaned.

Under the prior art, no one adequately figured out how to create and provide a blasting system that can reliably handle a “wide variety” of different media types.

People who work with sand or dry ice blasting have known and recognized, for years or even decades, that each

media type has only a limited range of effective uses.

At the hardest, most abrasive end of the spectrum, sand and other grit media are very powerful, but they have several major problems and limitations, including: (i) they will scar and damage most underlying materials; (ii) they generate levels of heat that can interfere seriously with some uses; and, (iii) they leave behind large quantities of gritty residues, which can create problems that range from annoying, to unacceptable.

In the center of the spectrum, powders tend to be more expensive than sand; they tend to suffer from clumping and

caking problems; and, because they are less abrasive than grit, they usually require longer blasting times, and greater volumes.

At the softest end of the spectrum, dry ice creates no heat and leaves no residue, but it is the most expensive blasting media, and it is not strong enough or abrasive enough to remove some types of coatings that need to be removed.

In such uses, sand or other hard grit would rapidly degrade the undamaged

soft materials, and should not be used.

Similarly, blasting using dry ice or some powders can be used to remove mold from

soft materials such as

pine wood, dry wall, and sheetrock, without damaging the soft supporting material; however, grit cannot be used for such purposes, since it would rapidly destroy soft wood,

drywall material, etc.

Finally, it must be noted that various problems mentioned above are often aggravated by the working conditions encountered in blasting operations.

If any equipment breaks or supplies run out, the operation often comes to a halt until a specialist can fix the problem, or until new equipment or supplies are delivered.

These requirements lead to additional

clutter and complications, and the plastic lenses used in goggles often become: (i) spattered with paint or other material that is being removed from a surface, and / or (ii) pitted and degraded, if grit is used as a blasting media.

Because the blasting media emerge from the nozzle at very high speed, the hose pushes against the holder with considerable force, and it is tiring on the arms, chest,

abdomen and legs to have to hold a heavy reinforced hose and point the nozzle in carefully controlled directions, for long periods of time.

In view of all of these factors, it tends to be difficult and uncomfortable work, and laborers who do this kind of work usually just want to get finished as quickly as possible, and then get cleaned up and leave.

Login to View More

Login to View More