Waterborne fireproof coating for ultrathin expanded steel structure and preparation method thereof

A technology for fire-resistant coatings and section steel, applied in the direction of fire-resistant coatings, coatings, etc., can solve the problems of reducing the effective performance of the coating film, poor water resistance and durability, and easy wrinkling of the surface coating film, and achieve good water resistance and UV resistance properties, dense coating structure, and improved hydrolytic stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

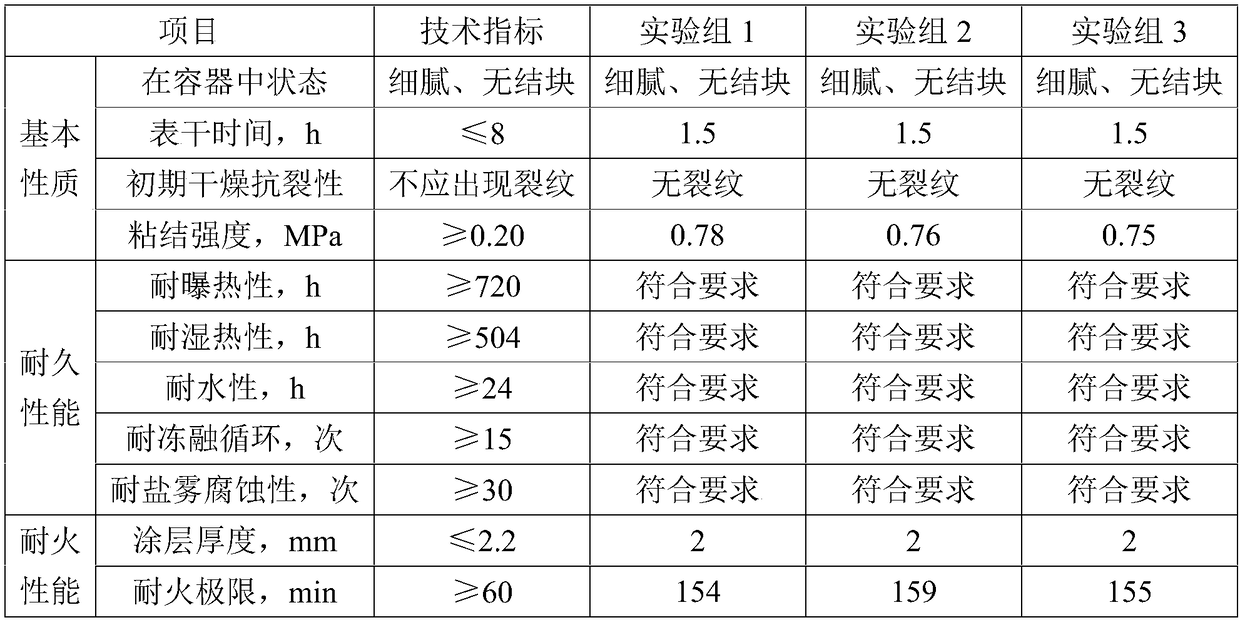

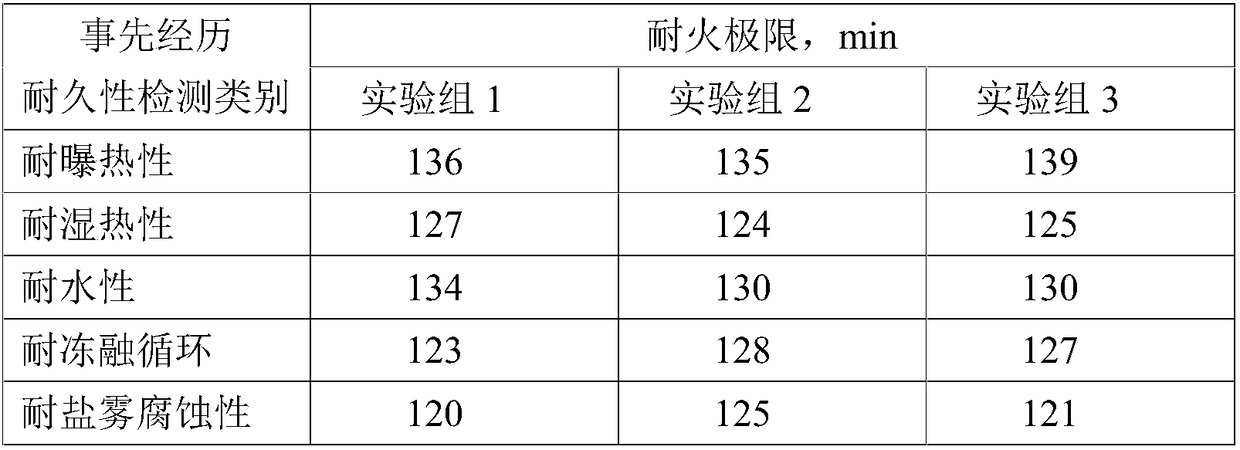

Embodiment 1

[0045] The ultra-thin intumescent water-based fireproof coating for steel structures of this embodiment includes water and the following components in parts by weight: 12 parts of silicon acrylic emulsion, 18 parts of vinegar tert-emulsion, 2.0 parts of expanded perlite, 1.5 parts of hollow glass microspheres, micro 39 parts of encapsulated intumescent flame retardant based on core material, 4.0 parts of microencapsulated synergistic flame retardant based on core material, 5.0 parts of filler, 1.8 parts of preservative, and 4.2 parts of coating aid; the solid content of the fireproof coating 55%;

[0046] Wherein, the microencapsulated intumescent flame retardant is made of silica gel-coated core material intumescent flame retardant, the intumescent flame retardant is composed of ammonium polyphosphate, melamine and pentaerythritol, ammonium polyphosphate, melamine and The mass ratio of pentaerythritol is 18:9:12;

[0047] The microencapsulated synergistic flame retardant is ...

Embodiment 2

[0063] The ultra-thin intumescent steel structure water-based fireproof coating of this embodiment includes water and the following components in parts by weight: 13 parts of silicon acrylic emulsion, 17 parts of vinegar tert-emulsion, 2.2 parts of expanded perlite, 1.3 parts of hollow glass microspheres, micro 40 parts of encapsulated intumescent flame retardant based on core material, 3.8 parts of microencapsulated synergistic flame retardant based on core material, 4.7 parts of filler, 1.6 parts of preservative, and 4.0 parts of coating aid; the solid content of the fireproof coating 55%;

[0064] Wherein, the microencapsulated intumescent flame retardant is made of silica gel-coated core material intumescent flame retardant, the intumescent flame retardant is composed of ammonium polyphosphate, melamine and pentaerythritol, ammonium polyphosphate, melamine and The mass ratio of pentaerythritol is 18:10:12;

[0065] The microencapsulated synergistic flame retardant is made o...

Embodiment 3

[0081] The ultra-thin intumescent steel structure water-based fireproof coating of this embodiment includes water and the following components in parts by weight: 14 parts of silicon acrylic emulsion, 16 parts of tert-acetic acid emulsion, 2.5 parts of expanded perlite, 1.0 part of hollow glass microspheres, micro 42 parts of encapsulated intumescent flame retardant based on core material, 3.5 parts of microencapsulated synergistic flame retardant based on core material, 4.5 parts of filler, 1.5 parts of preservative, and 3.5 parts of coating aid; the solid content of the fireproof coating 55%;

[0082] Wherein, the microencapsulated intumescent flame retardant is made of silica gel-coated core material intumescent flame retardant, the intumescent flame retardant is composed of ammonium polyphosphate, melamine and pentaerythritol, ammonium polyphosphate, melamine and The mass ratio of pentaerythritol is 20:10:12;

[0083] The microencapsulated synergistic flame retardant is m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| critical temperature | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com