Film structure of 316L alloy steel surface enamel coating

A technology of film layer structure and alloy steel, applied in the direction of metal layered products, layered products, chemical instruments and methods, etc., to achieve the effects of wide application range, superior adhesion performance, and good heat and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below through the description of specific embodiments in conjunction with the accompanying drawings.

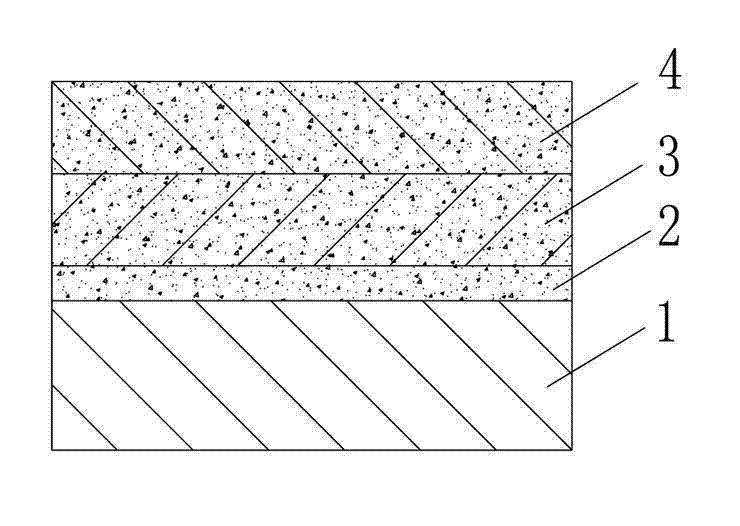

[0023] One of the specific implementation modes, as attached figure 1 shown.

[0024] A film layer structure of an enamel layer on the surface of a 316L alloy steel, comprising a 316L alloy steel substrate 1, and an enamel layer coated on the surface of the 316L alloy steel substrate 1, and its film structure is formed by the alloy steel substrate 1 The physical reconstruction superficial layer 2 on the surface of the 316L alloy steel substrate 1, the intermediate layer 3 coated on the surface of the reconstructed superficial layer 2, and the surface layer 4 coated on the surface of the intermediate layer 3 constitute 4 Layer composite film structure, and its:

[0025] The reconstructed superficial layer 2 is a superficial rough adhesion layer reconstructed by steel shots (including steel grit) impacting the surface of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com