Patents

Literature

50results about How to "Advanced and reasonable structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

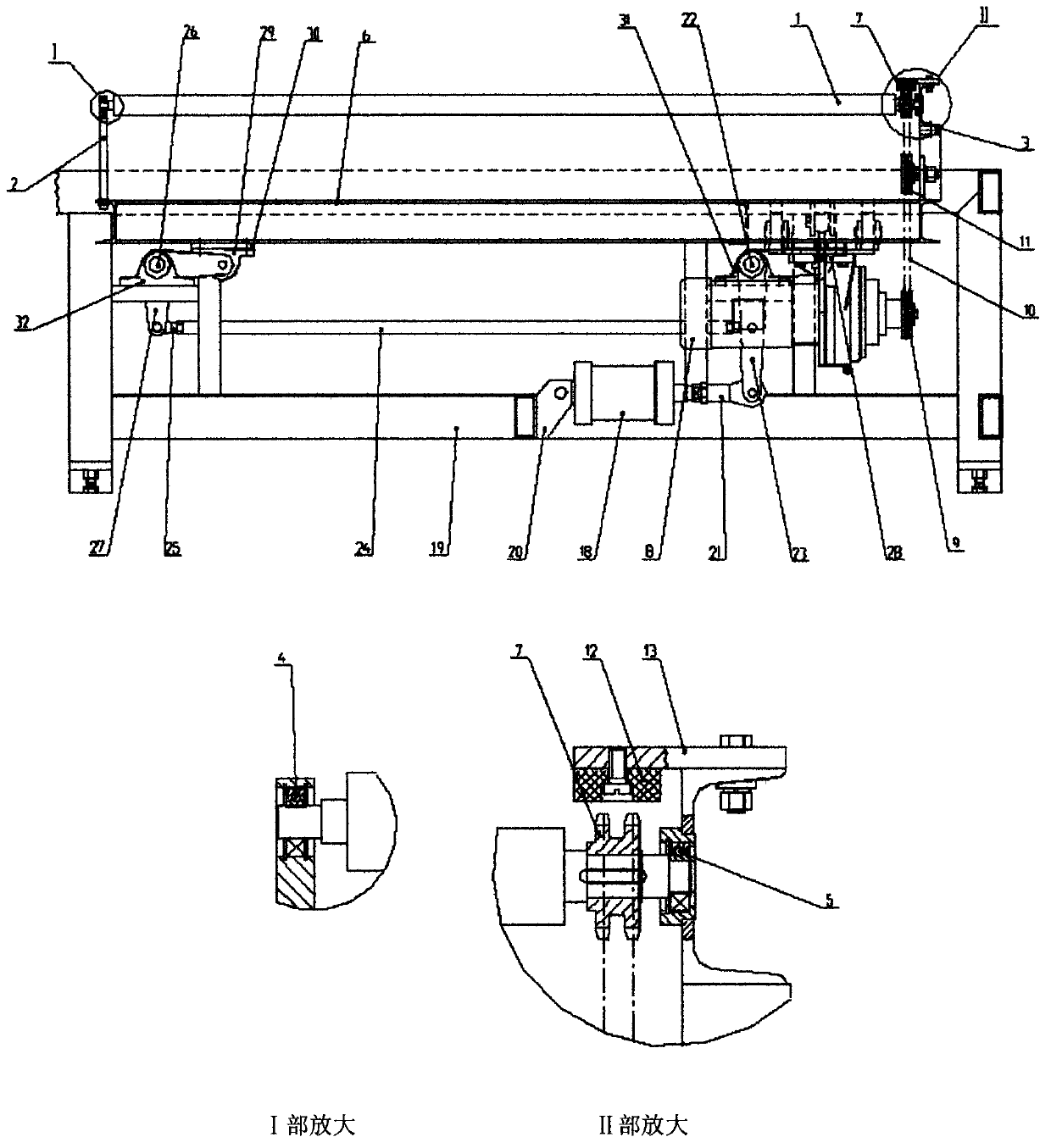

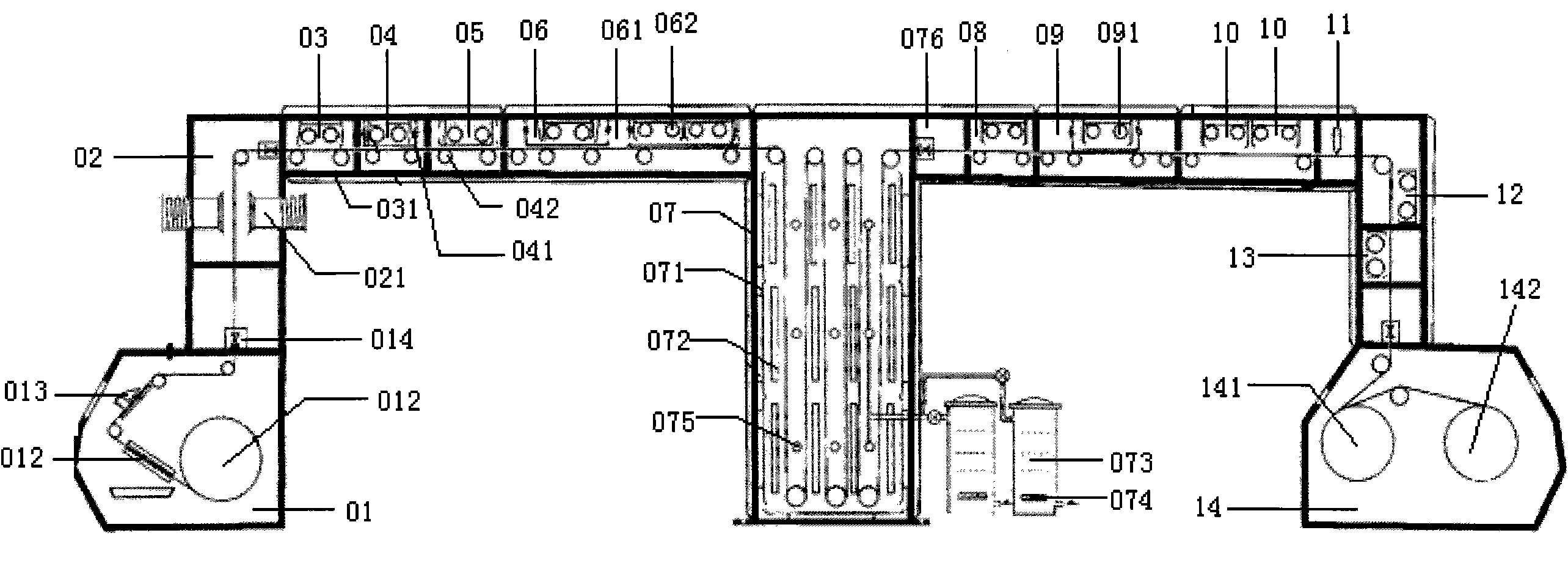

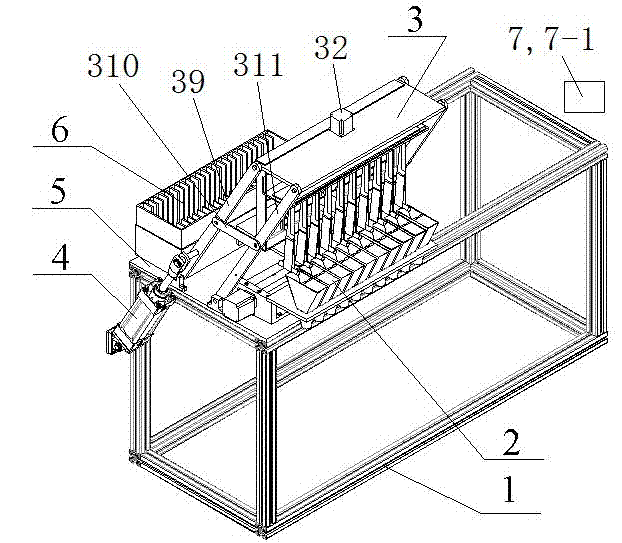

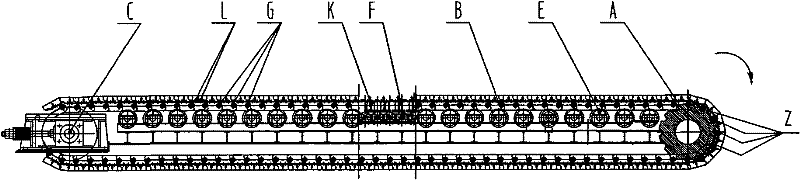

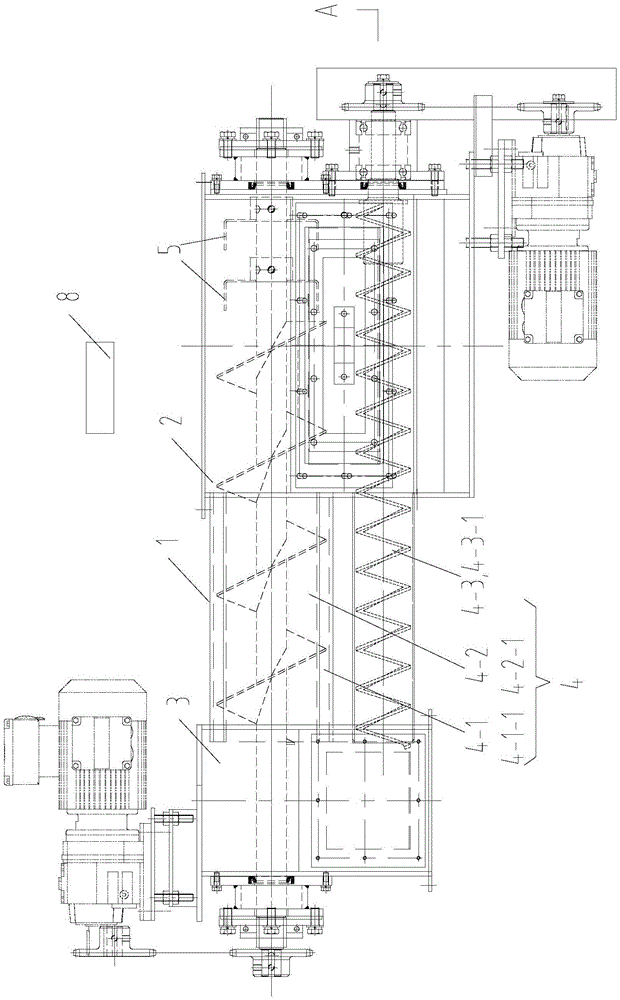

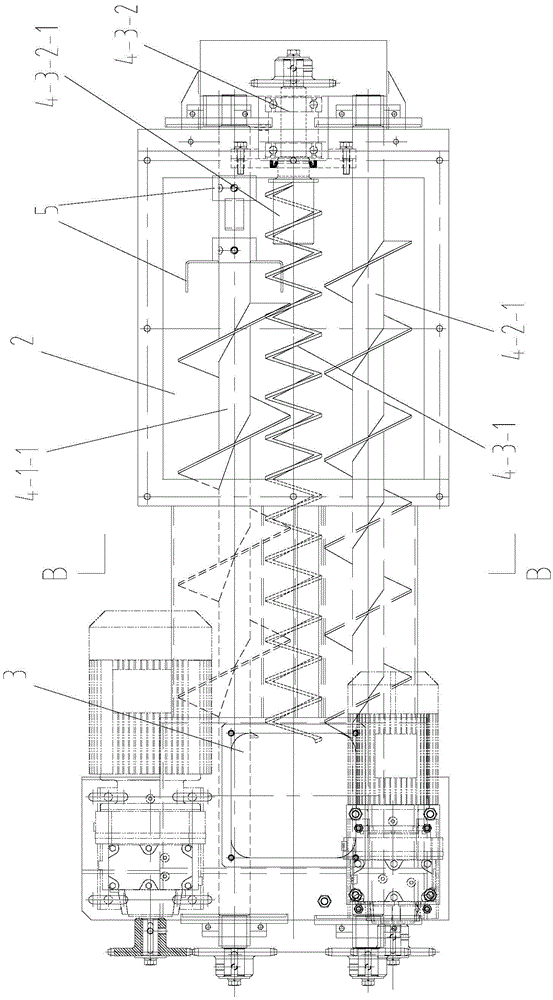

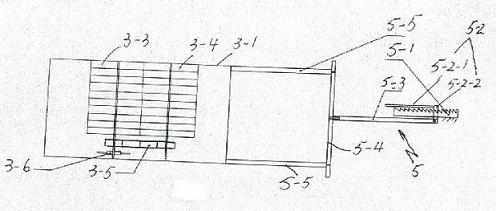

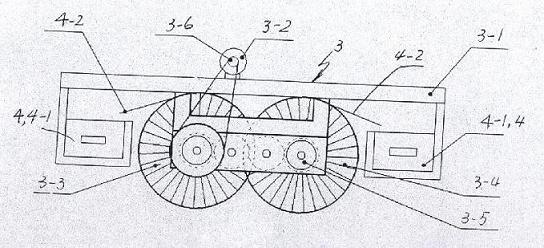

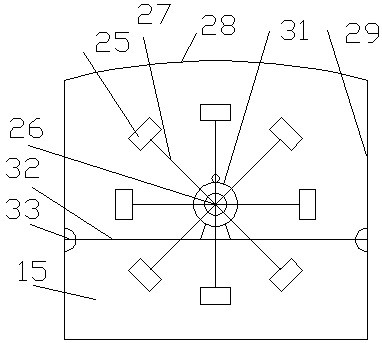

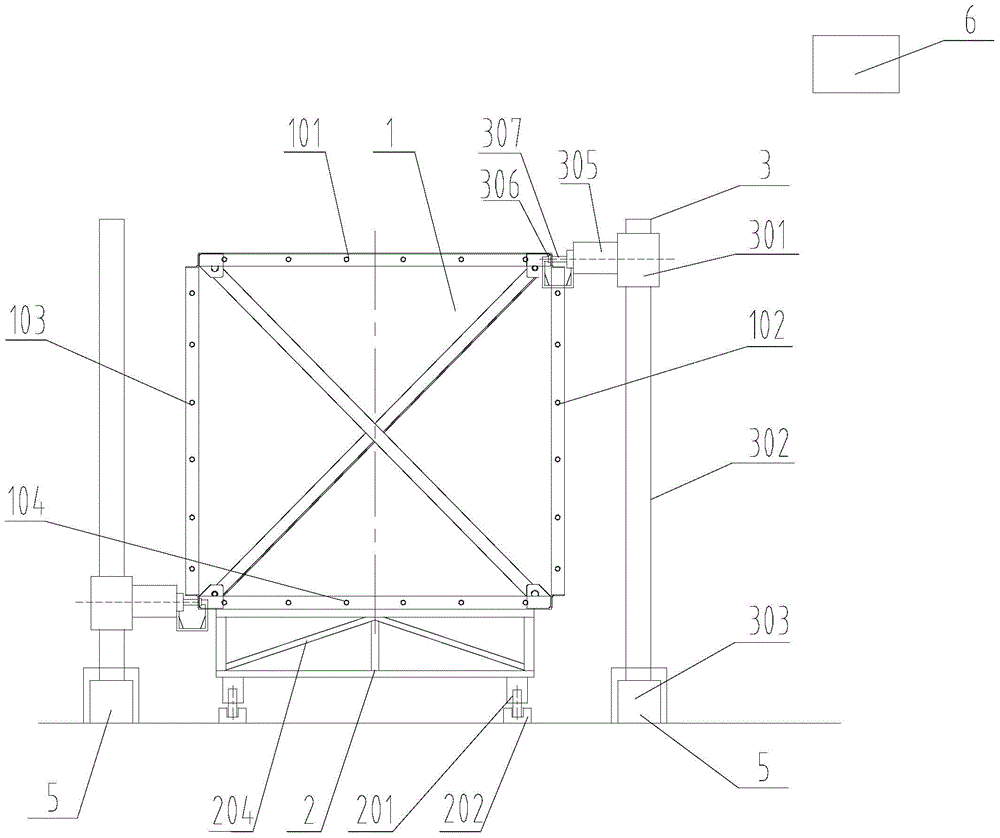

Automatic braiding machine

InactiveCN102774635ARealize the whole stackAdvanced and reasonable structureDischarging arrangementConveyor partsState of artRoller chain

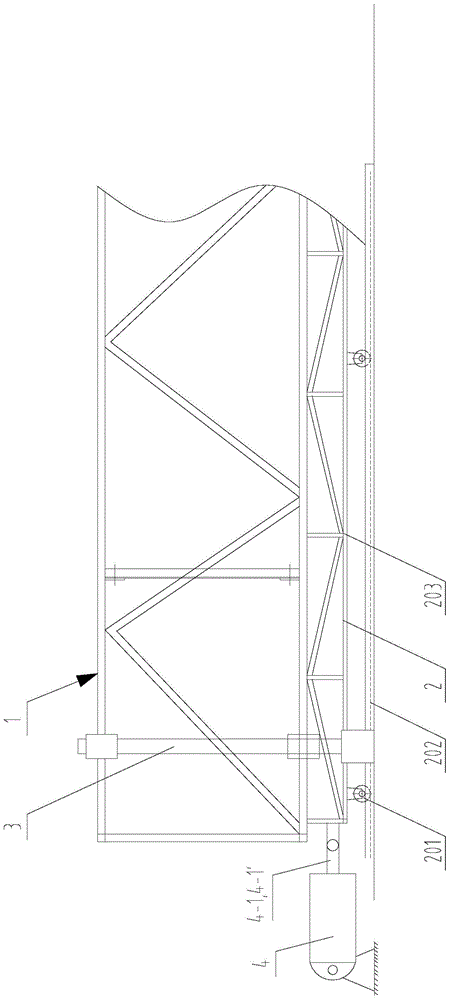

The invention provides a novel automatic braiding machine, aims at improving technical levels of wet green or dry green braiding processes in novel domestic wall material production lines and overcomes defects existing in prior art. The technical scheme includes that the automatic braiding machine is mainly composed of a green feeding carrier roller mechanism, a turning mechanism, a horizontal parting mechanism, a longitudinal parting mechanism and a cover band roller chain conveying mechanism. The automatic braiding machine has scientific and reasonable structures and automatic braiding and automatic parting functions and is capable of automatically finishing braiding, horizontal parting and longitudinal parting in sequence, sequential stacking of green bodies is achieved, gaps among the green bodies are even, green body square matrixes are orderly, the novel automatic braiding machine is stably operated, and the yield is high.

Owner:中节能东方双鸭山建材设备有限公司 +1

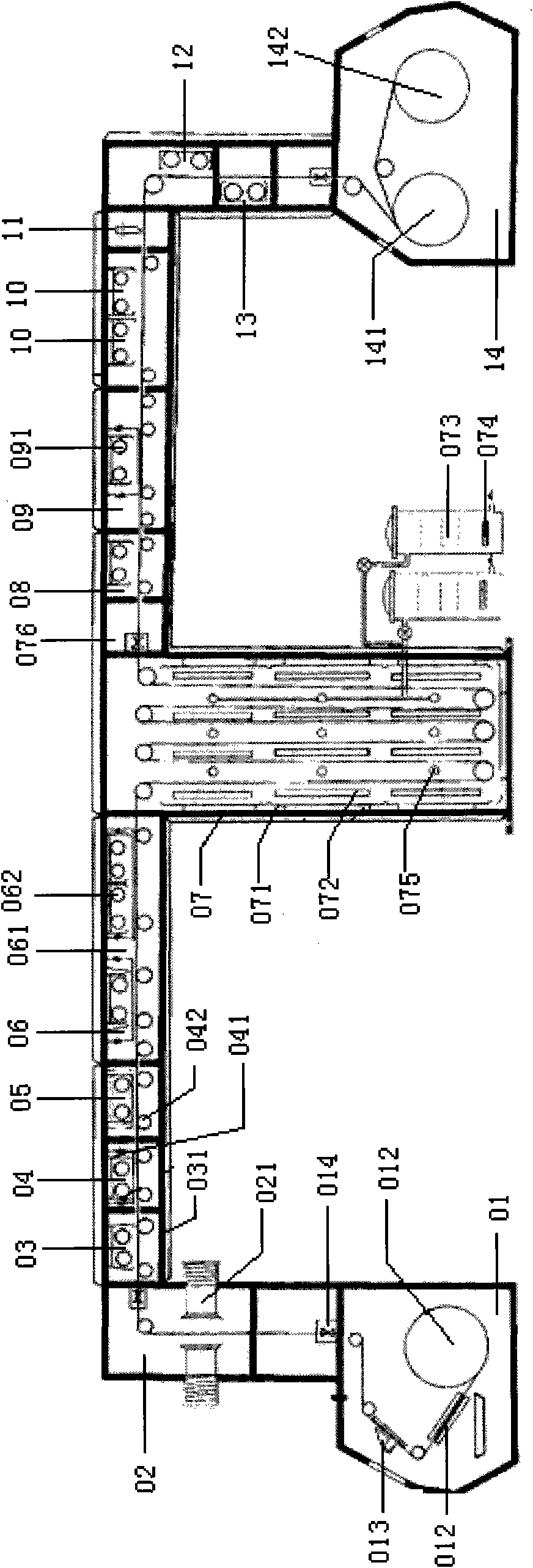

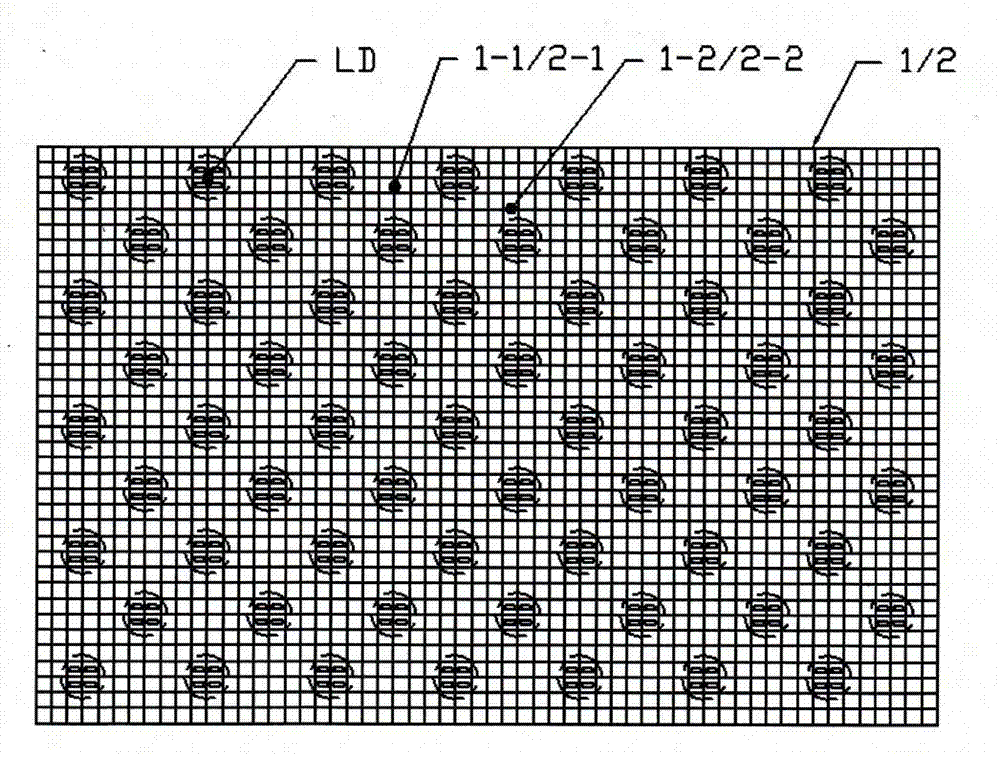

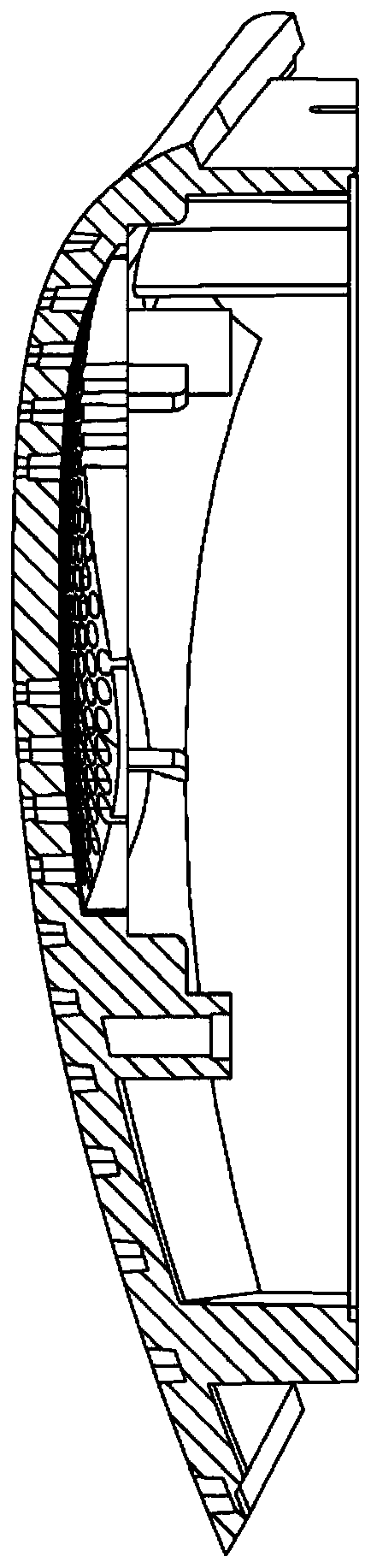

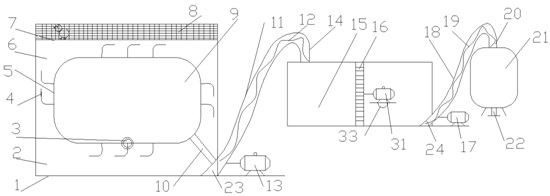

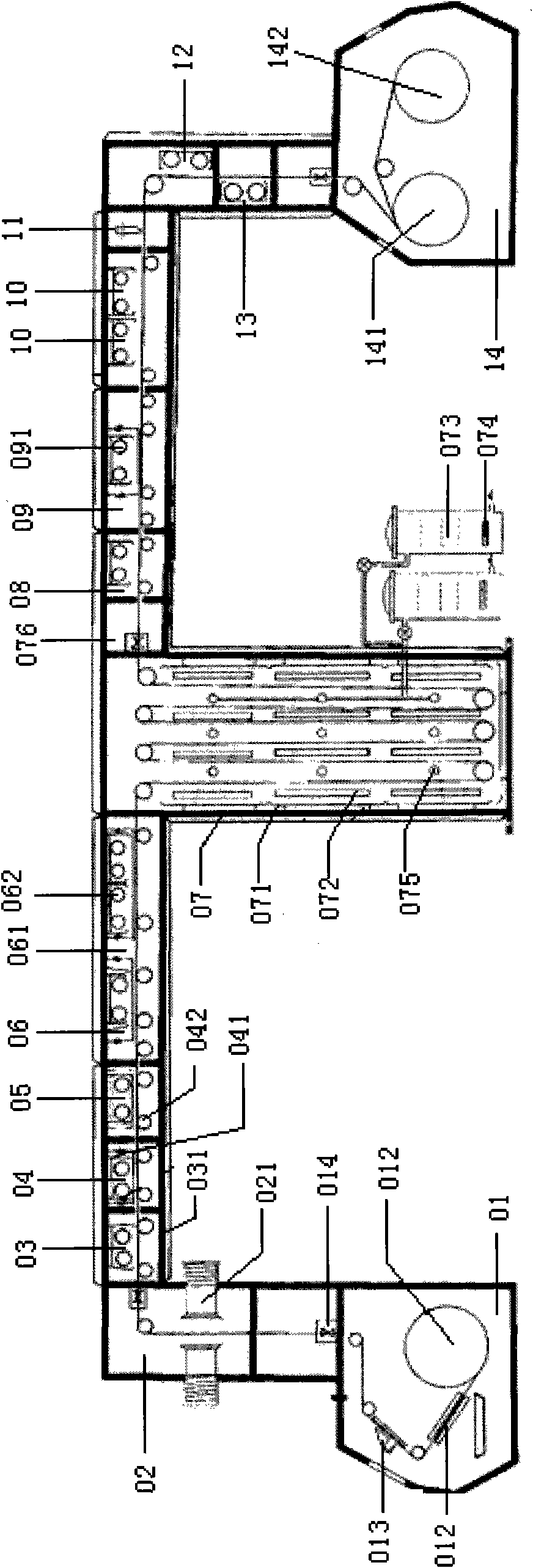

Flexible thin-film solar photoelectric cell and large-scale continuous automatic production method thereof

ActiveCN102110732AQuality improvementIncrease conversion rateFinal product manufactureVacuum evaporation coatingIndiumTitanium oxide

The invention provides a flexible thin-film solar photoelectric cell and a large-scale continuous automatic production method thereof. The solar photoelectric cell comprises an antireflection layer, a transparent upper electrode layer, an isolating layer, a window layer, a protective layer, an absorbing layer, a reflecting layer, a metal back electrode layer, an insulating layer, a substrate layer and a solder flux layer in sequence. The material of the antireflection layer is magnesium fluoride, the material of the transparent upper electrode layer is aluminum zinc oxide, the material of the isolating layer is intrinsic zinc oxide, the material of the window layer is zinc sulfide, the material of the protective layer is sulfur or zinc, the material of the absorbing layer is CIGS (copper indium gallium diselenide) or CIAS (copper indium aluminum diselenide), the material of the reflecting layer is aluminum, the material of the metal back electrode layer is copper-molybdenum-sodium alloy, the material of the insulating layer is titanium oxide, and the material of the substrate layer is stainless steel, copper, aluminum foil or polyimide film. The production method of the flexible thin-film solar photoelectric cell comprises sputtering layer by layer in a closed environment on a continuous automatic production line through a plurality of sputtering methods to form a multilayer structure. The large-scale continuous automatic production method provided by the invention has the advantages of high efficiency, high quality, and low cost.

Owner:江苏航天之光新能源装备有限公司

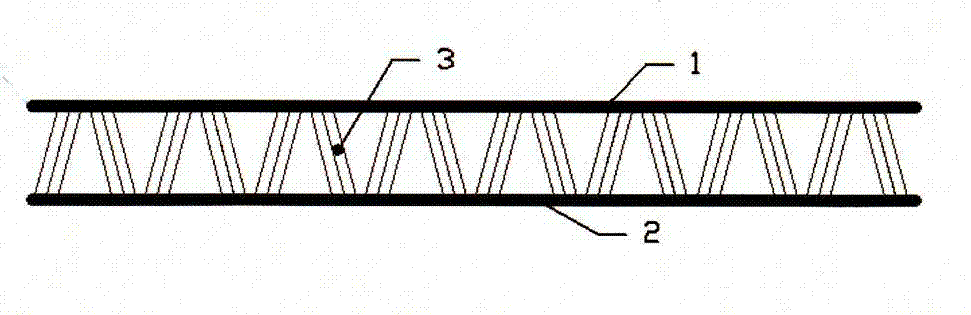

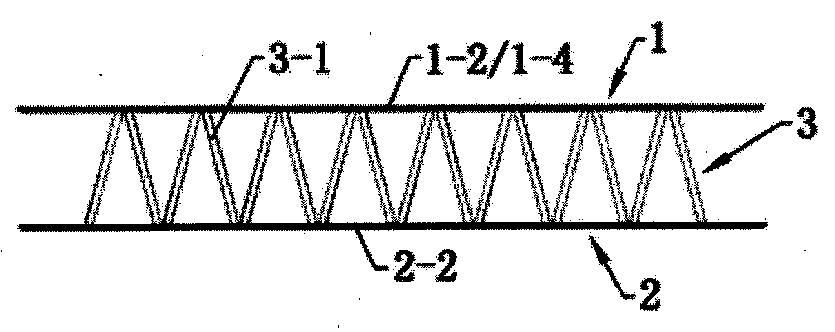

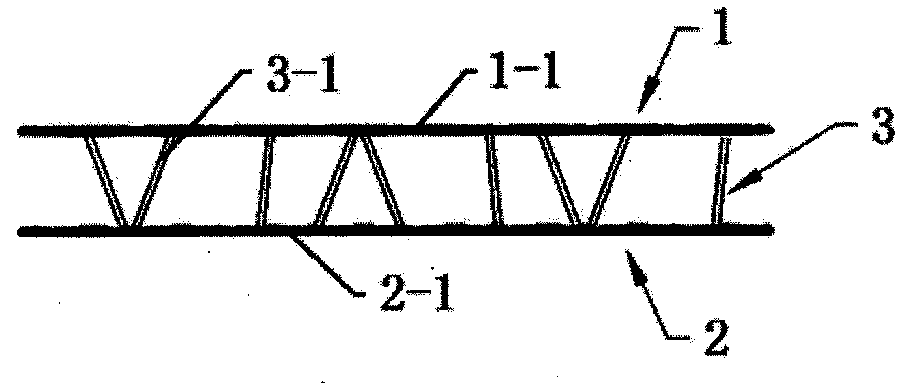

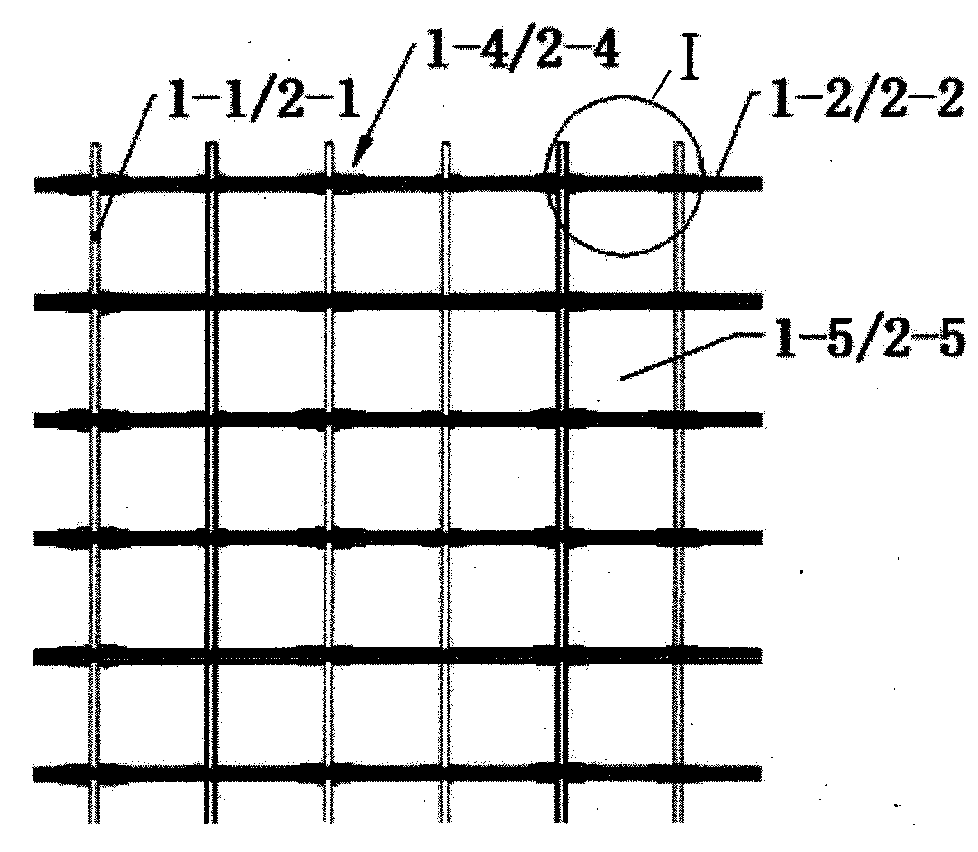

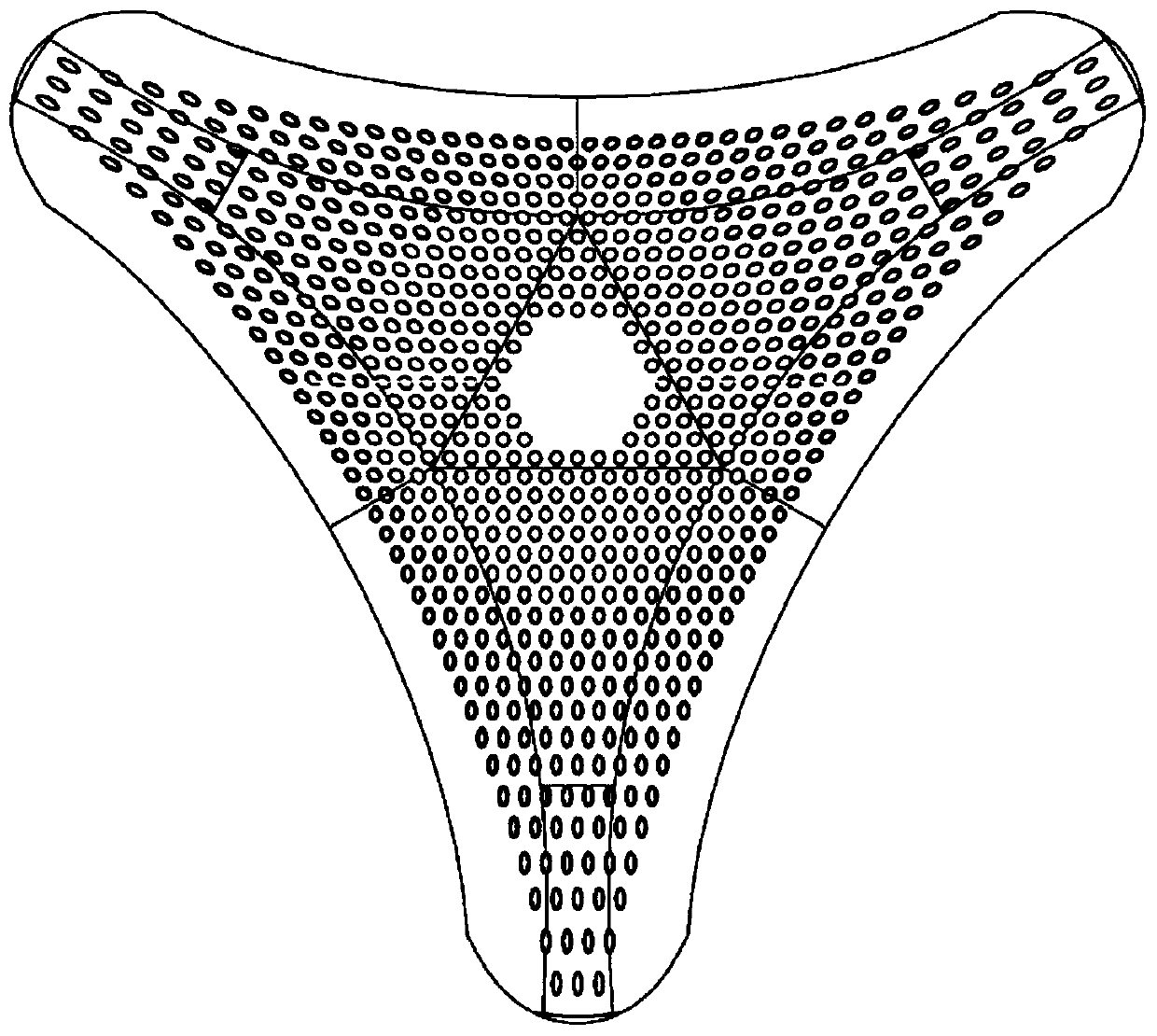

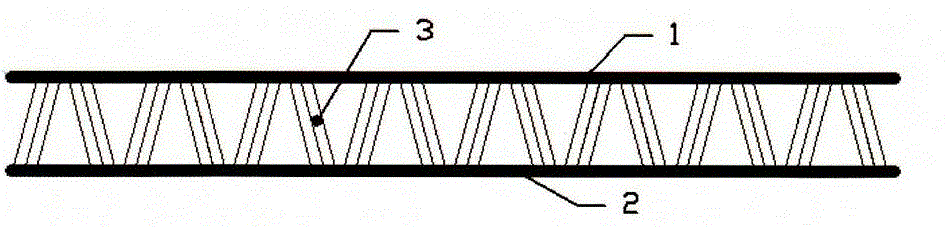

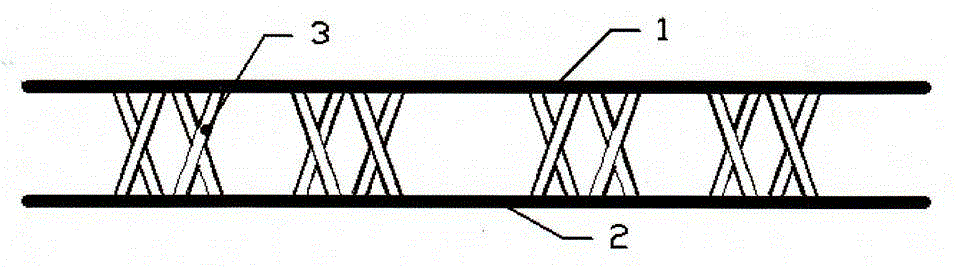

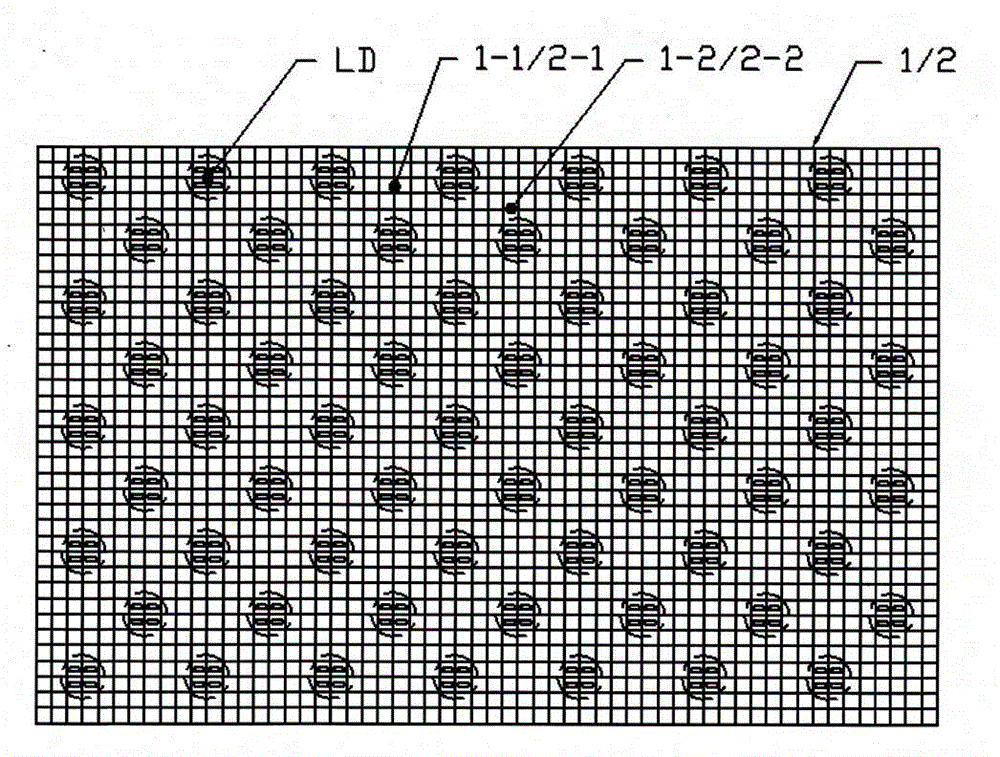

Vertical core material woven fabric

ActiveCN103789905ASimple processIncrease production capacitySynthetic resin layered productsWoven fabricsGlass fiberMetallic materials

The invention discloses a vertical core material woven fabric which is formed by connecting a first fabric layer and a second fabric layer through stand supporting core column filaments, wherein the first fabric layer and the second fabric layer are woven through warps and wefts made of inorganic nonmetallic materials. The stand supporting core column filaments for connecting the first fabric layer and a second fabric layer are connected in continuous W shapes along the weft direction and are connected in a staggered and intersected mode and in double X shapes along the warp direction. The stand supporting core column filaments and warp-wise connection points and weft-wise connection points of the first fabric layer and the second fabric layer respectively form a plurality of connection nodes nearby, and the plurality of connection nodes are positioned on the planes of the first fabric layer and the second fabric layer in staggered queue type distribution vertically and correspondingly. The vertical core material woven fabric has the advantages of being reasonable and advanced in structure, capable of serving as the core material to manufacture hollow glass fiber reinforced plastic products, relatively simple in process, high in production efficiency, good in quality of manufactured goods and the like.

Owner:CHANGZHOU YUECHENG NEW MATERIAL

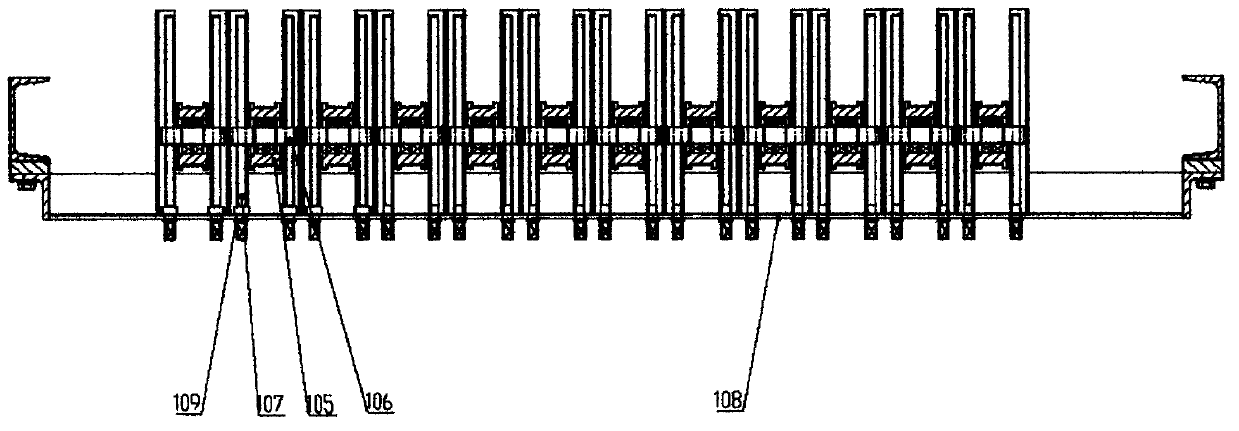

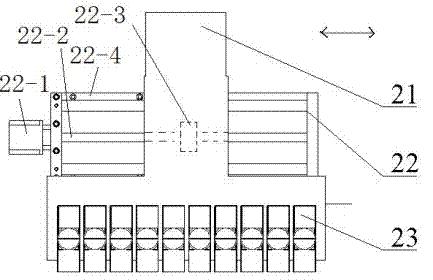

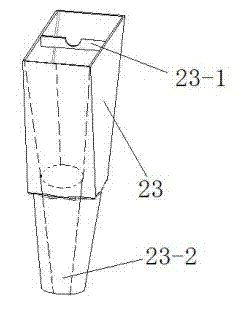

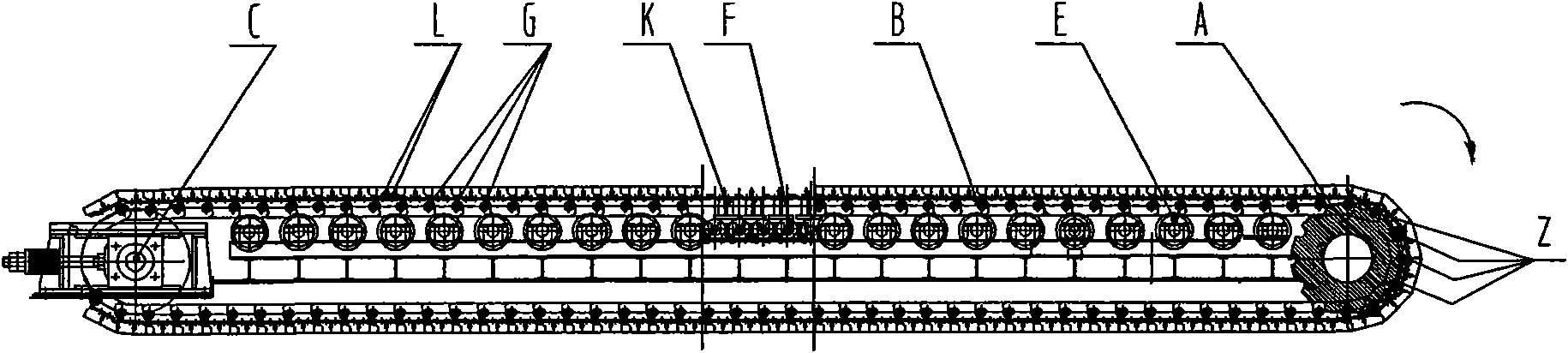

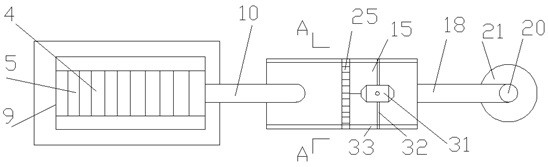

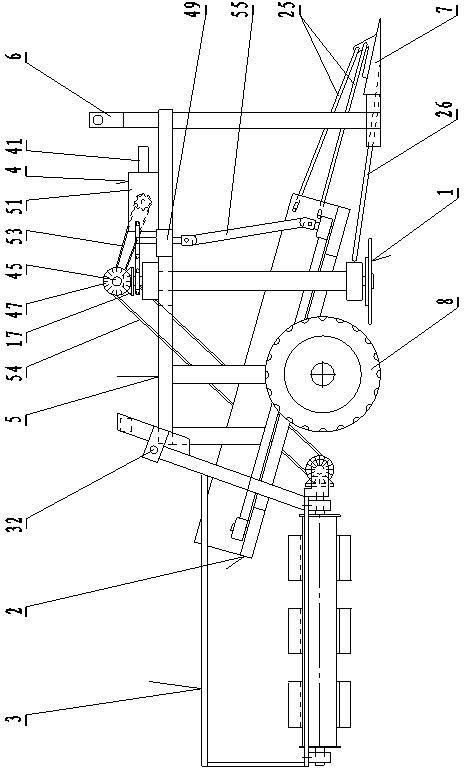

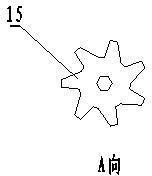

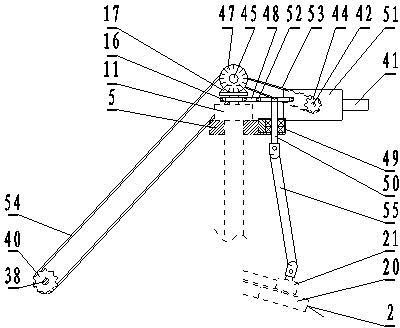

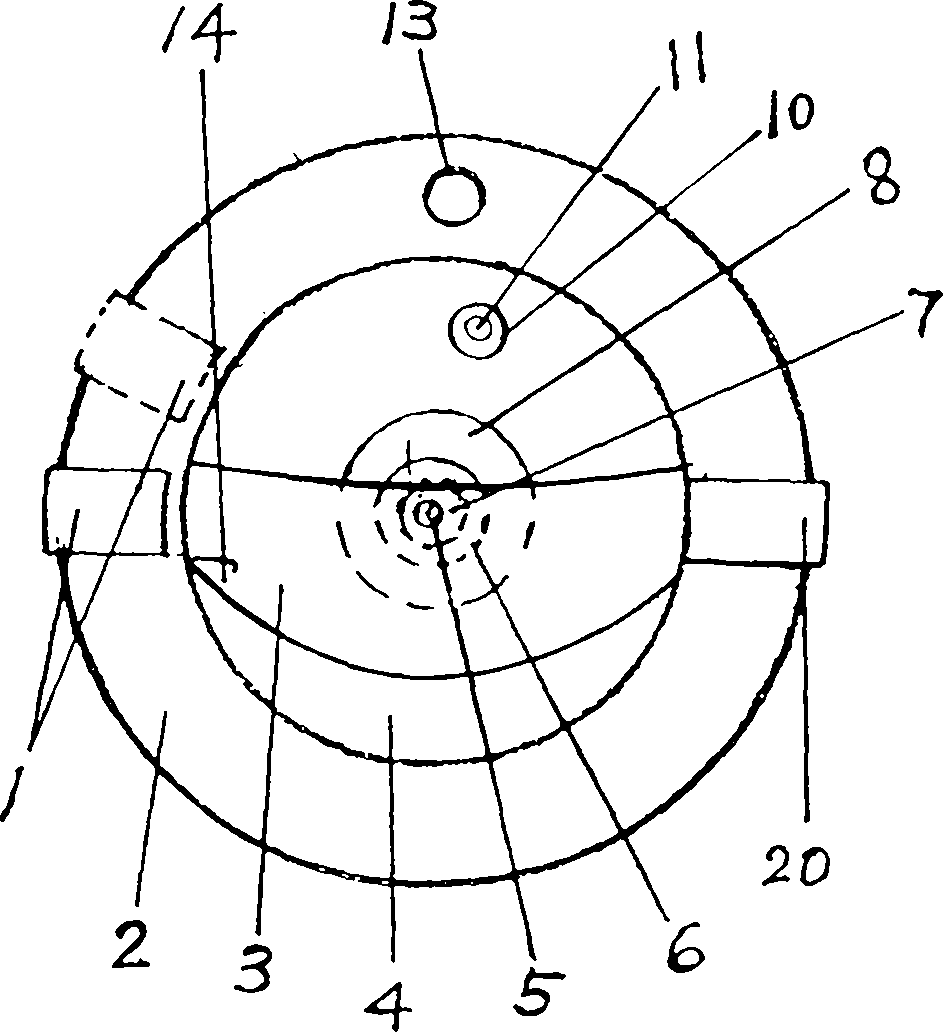

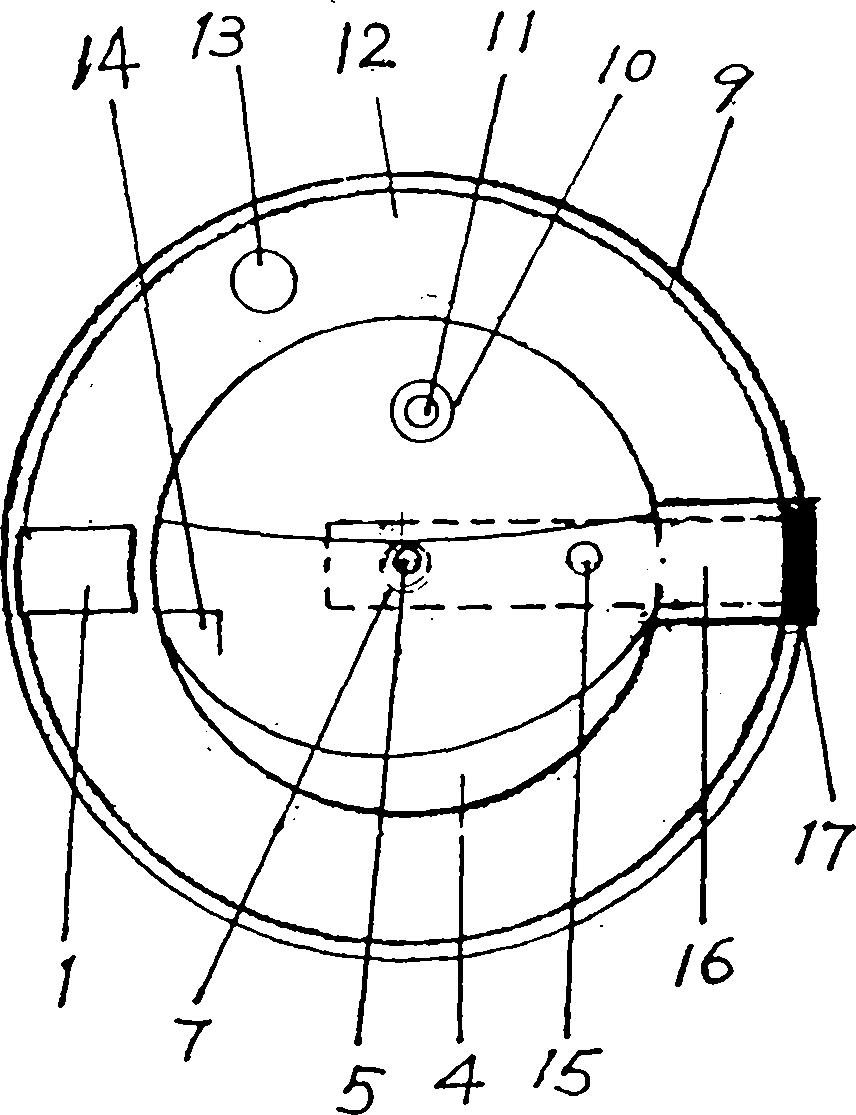

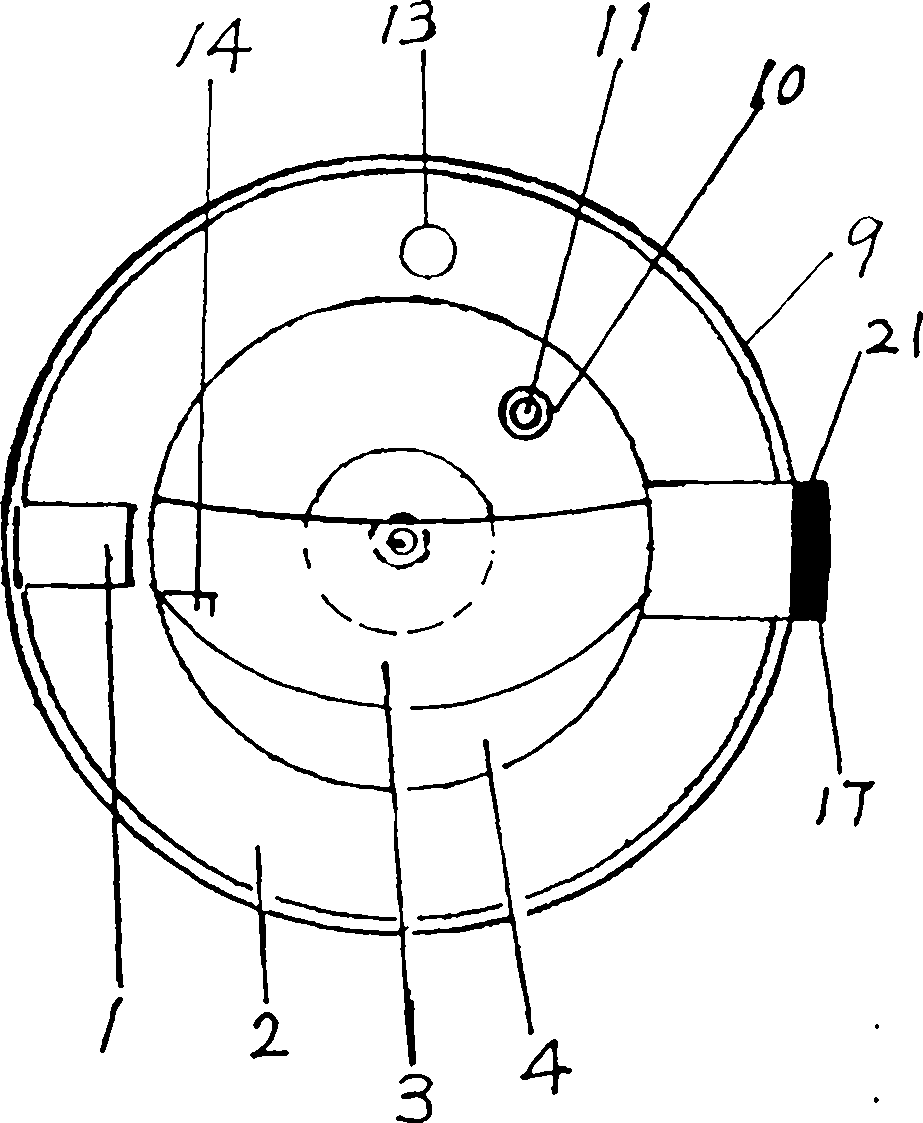

Automatic-batching pipe inserting machine for doffing of spinning frame

ActiveCN102851800AAdvanced and reasonable structureImprove work efficiencyTextiles and paperEngineeringBobbin

The invention discloses an automatic-batching pipe inserting machine for doffing of a spinning frame. The automatic-batching pipe inserting machine is mainly characterized by comprising an electric control device, a rack, a bobbin box, a pipe taking device and a pipe inserting device. The automatic-batching pipe inserting machine disclosed by the invention is installed on a traveling type automatic doffing machine, and has the advantages of advanced and reasonable structure, high working efficiency, in-place and accurate pipe insertion and high automation degree and the like.

Owner:CHANGZHOU INST OF ADVANCED MFG TECH

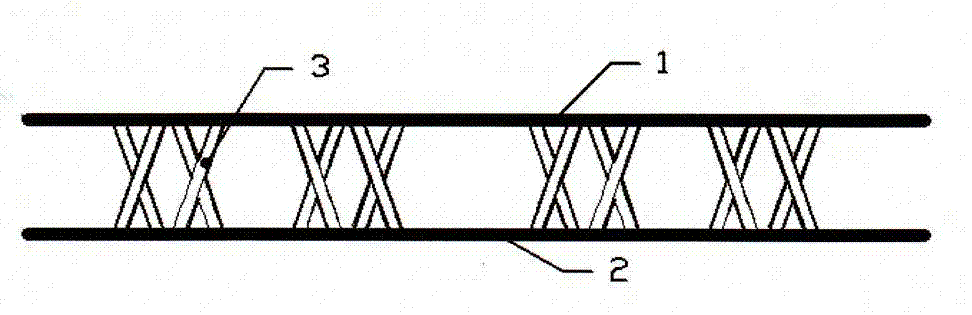

Three-dimensional grid core material woven fabric

The invention discloses a three-dimensional grid core material woven fabric. The three-dimensional grid core material woven fabric is composed of a first face layer fabric, a second face layer fabric and a core layer, wherein the first face layer fabric and the second face layer fabric are woven through weft and warp made of inorganic nonmetallic materials, and the core layer is used for connecting the first face layer fabric and the second face layer fabric. The low-density weft and warp of the first face layer fabric are interwoven in a tabby structure mode, a plurality of pieces of warp in adjacent sections are tied respectively to form stranding warp through wrap-directional filaments in a twisted-woven mode, and therefore the first face layer fabric which is of a continuous mesh grating-shaped structure is formed. Core layer filaments are distributed in a continuous V-shaped structure mode in the warp direction and are continuously and alternately distributed in an I-shaped or V-shaped mode in the weft direction, corresponding warp and weft of the first face layer fabric and the second face layer fabric are vertically connected at intervals, and the three-dimensional grid core material woven fabric is formed. The three-dimensional grid core material woven fabric has the advantages that the structure is advanced and reasonable, when used as core materials for manufacturing light building members, the three-dimensional grid core material woven fabric is good in compatibility for foaming cement or gypsum or other else, pouring is convenient, tamping is easy, and the strength of a produced product is high.

Owner:CHANGZHOU YUECHENG NEW MATERIAL

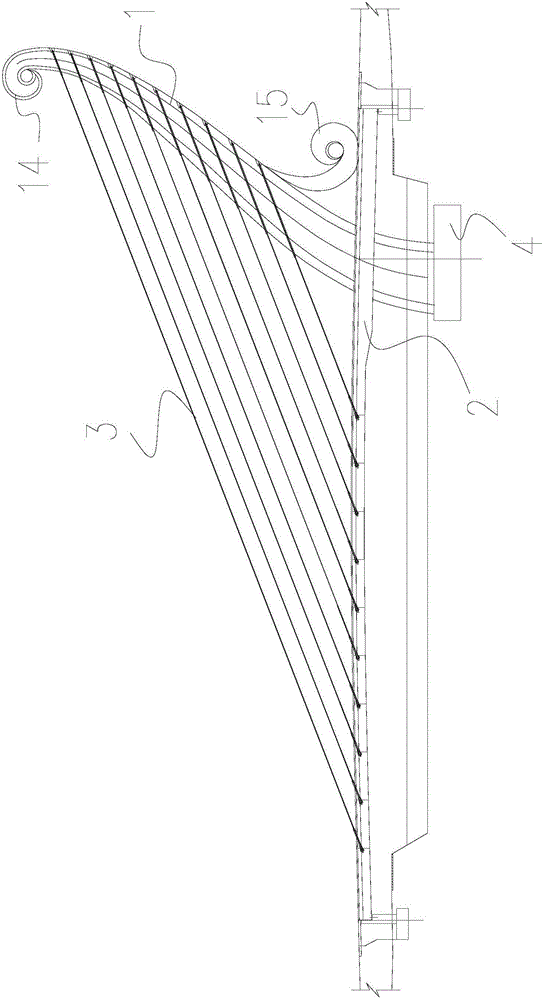

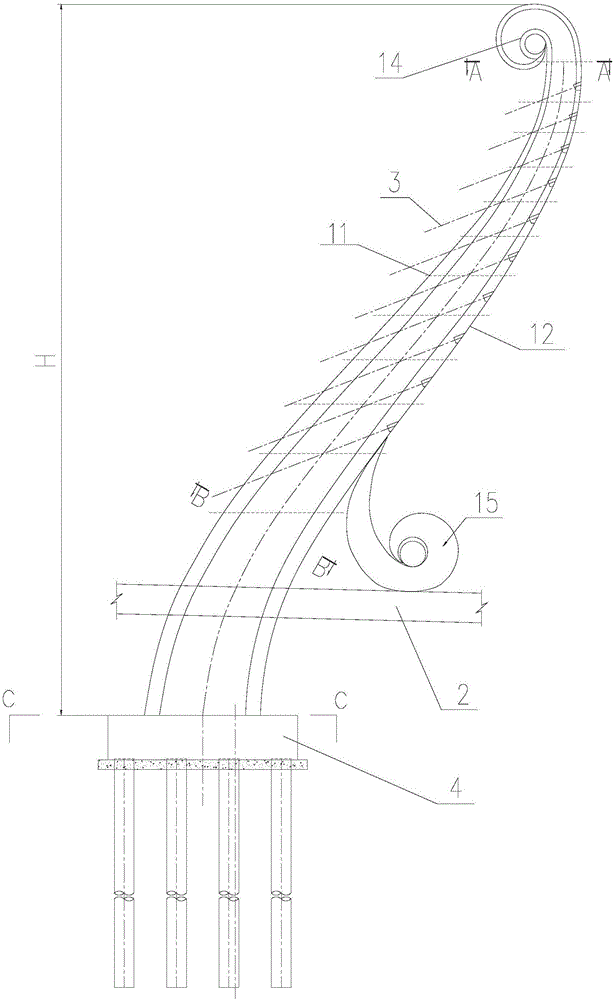

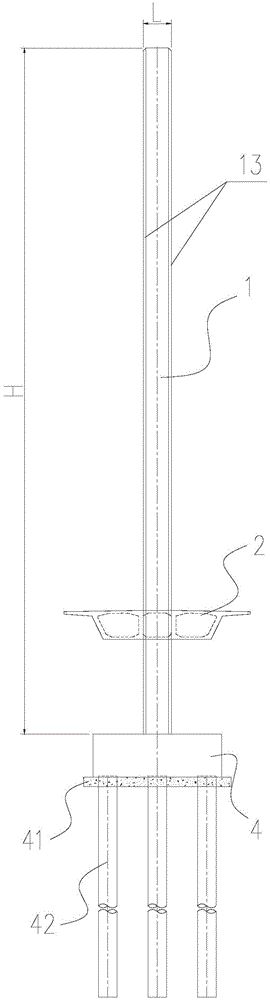

Cable-stayed bridge provided with curved single pylon with double cable planes

ActiveCN105839511AImprove carrying capacityImprove construction convenienceCable-stayed bridgeBridge structural detailsCable stayedSlant angle

The invention discloses a cable-stayed bridge provided with curved single pylon with double cable planes. The bridge comprises a main pylon, a main beam, stay cables and a cushion cap, wherein the cable facing plane and the cable backing plane of the main pylon are cambered surfaces with variable curvature and unchangeable width, longitudinal slant angles are different and change section by section along with construction of the main pylon, the longitudinal slant angle in the middle section of the main pylon is at least 50 degrees, and the longitudinal slant angles at the bottom and the top of the pylon are about 90 degrees; two side surfaces of the main pylon are planes, the widths of the two sides surface of the main pylon gradually get smaller from bottom to top, and accordingly, the cross sections of the main pylon gradually linearly get smaller from the bottom to the top of the pylon in the height direction; the main pylon is a solid section with four chamfered sides, the lengths of chamfers of the main pylon are gradually linearly changed from 150 cm to 50 cm from the bottom to the top of the pylon in height direction, and the widths of the chamfers are all 30 cm; the main beam and the main pylon are integrated through concrete pouring; ten pairs of stay cables are arranged between the main pylon and the main beam. The cable-stayed bridge is reasonable in structure, attractive in appearance and strong in stress sense and gives people a unique visual feeling.

Owner:CCCC THIRD HARBOR ENG +2

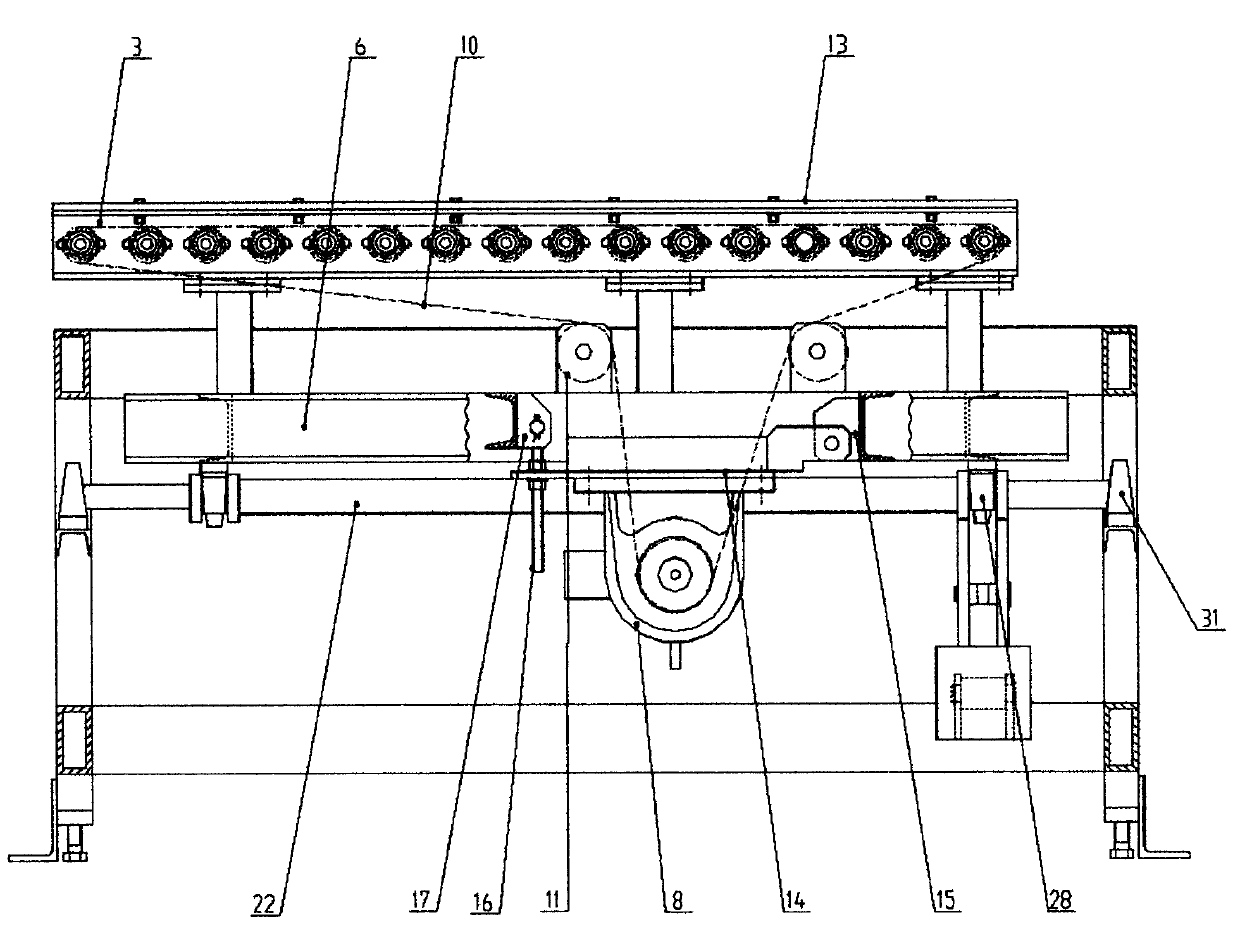

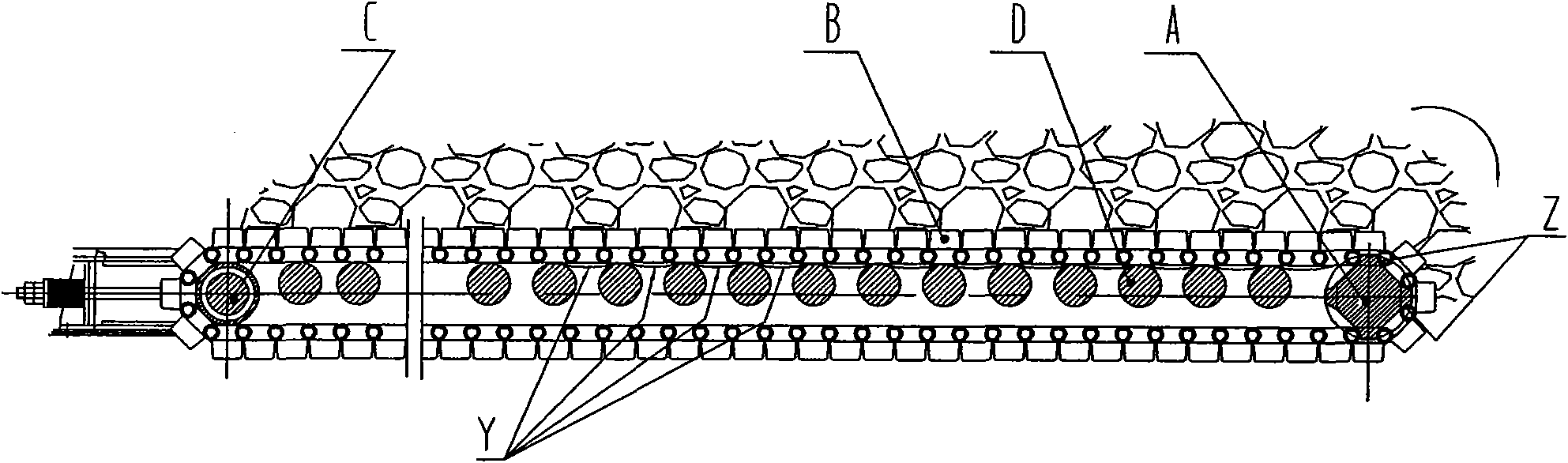

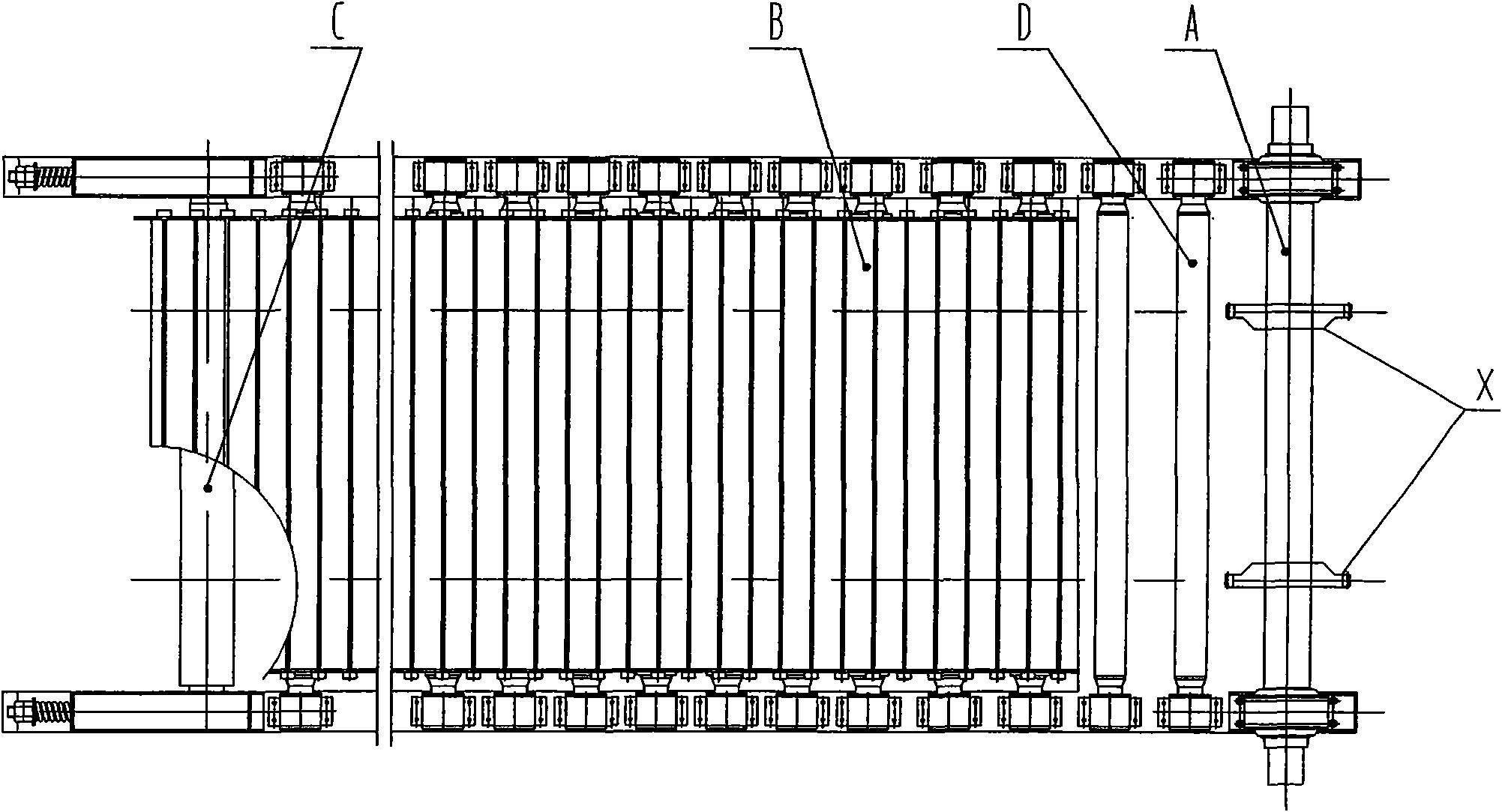

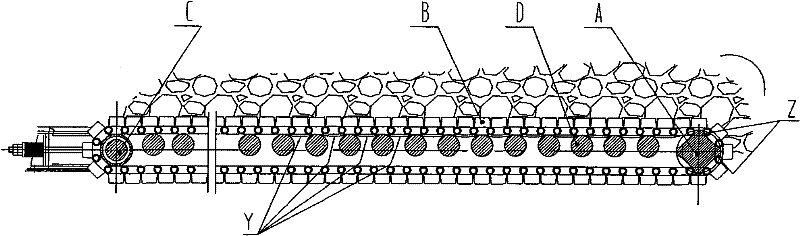

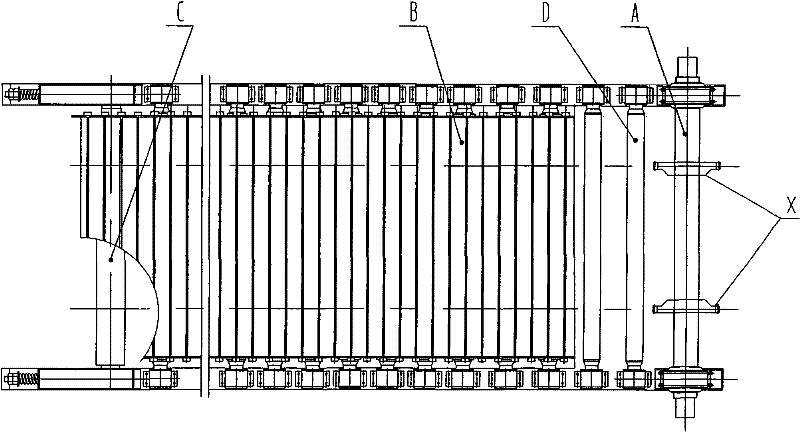

Heavy duty plate feeder capable of realizing smooth transmission

The invention discloses a heavy duty plate feeder capable of realizing smooth transmission, and relates to material transportation and transshipment equipment. The heavy duty plate feeder comprises a drive shaft, a sealed chain belt wound on the drive shaft and a tension shaft, and chain supporting rollers for supporting the chain belt, wherein a drive chain unit is arranged on two sides of each chain unit component of the chain belt; a transverse H-shaped bearing plate is fixed in the middle; the drive chain unit is connected with the transverse H-shaped bearing plate; the sealed chain belt is engaged with a chain wheel of the drive shaft by the drive chain unit; guide wheels engaged with the chain belt are arranged at the position, corresponding to the chain wheel, of two ends of the tension shaft; the chain supporting rollers are arranged along equipment longitudinally in five lines; the chain supporting rollers in the two outer lines are chain belt driving rollers which are provided with ribs and arranged below the drive chain unit; and the chain supporting rollers in the three inner lines are chain belt bearing rollers arranged below the transverse H-shaped bearing plate. The heavy duty plate feeder has the advantages of effectively solving the problems of shock vibration and deviation of the chain belt in the transmission process, reducing wearing of the chain belt, prolonging operation period and improving production efficiency of equipment.

Owner:TAIYUAN HEAVY IND

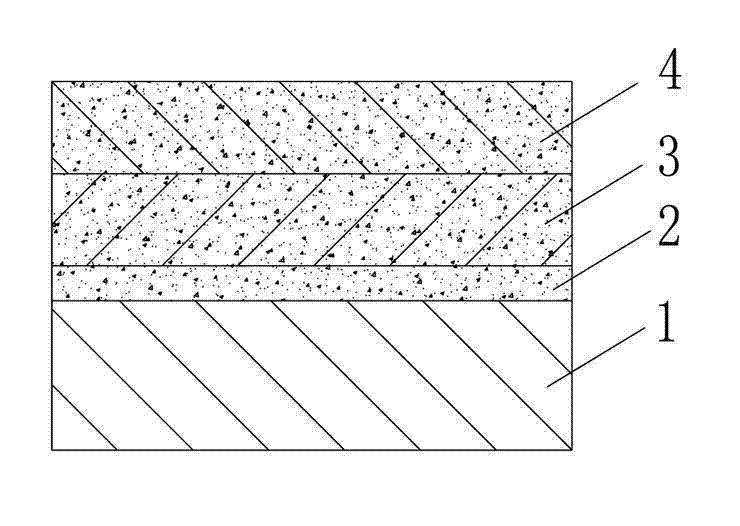

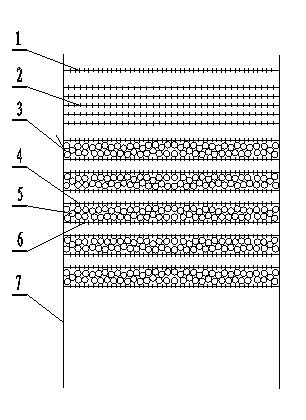

Film structure of 316L alloy steel surface enamel coating

InactiveCN104496181AExcellent adhesionAccelerated corrosionMetal layered productsSurface layerFilm structure

The invention discloses a film structure of a 316L alloy steel surface enamel coating. The film structure of the 316L alloy steel surface enamel coating is mainly characterized in that a 316L alloy steel substrate (1), a reconstruction shallow surface layer (2), an intermediate layer (3) and a surface layer (4) forms a four-layer complex enamel film, and components of an enamel material for the intermediate layer (3) and the surface layer (4) and weight percentage of each component are also disclosed. The film structure of the 316L alloy steel surface enamel coating has the characteristics of reasoned and advanced structure, good corrosion resistance, strong friction pull and the like, and the obtained 316L alloy steel surface enamel coating part can be widely applied to various fields.

Owner:常州宣纳尔新能源科技有限公司

Heavy duty plate feeder capable of realizing smooth transmission

The invention discloses a heavy duty plate feeder capable of realizing smooth transmission, and relates to material transportation and transshipment equipment. The heavy duty plate feeder comprises a drive shaft, a sealed chain belt wound on the drive shaft and a tension shaft, and chain supporting rollers for supporting the chain belt, wherein a drive chain unit is arranged on two sides of each chain unit component of the chain belt; a transverse H-shaped bearing plate is fixed in the middle; the drive chain unit is connected with the transverse H-shaped bearing plate; the sealed chain belt is engaged with a chain wheel of the drive shaft by the drive chain unit; guide wheels engaged with the chain belt are arranged at the position, corresponding to the chain wheel, of two ends of the tension shaft; the chain supporting rollers are arranged along equipment longitudinally in five lines; the chain supporting rollers in the two outer lines are chain belt driving rollers which are provided with ribs and arranged below the drive chain unit; and the chain supporting rollers in the three inner lines are chain belt bearing rollers arranged below the transverse H-shaped bearing plate. Theheavy duty plate feeder has the advantages of effectively solving the problems of shock vibration and deviation of the chain belt in the transmission process, reducing wearing of the chain belt, prolonging operation period and improving production efficiency of equipment.

Owner:TAIYUAN HEAVY IND

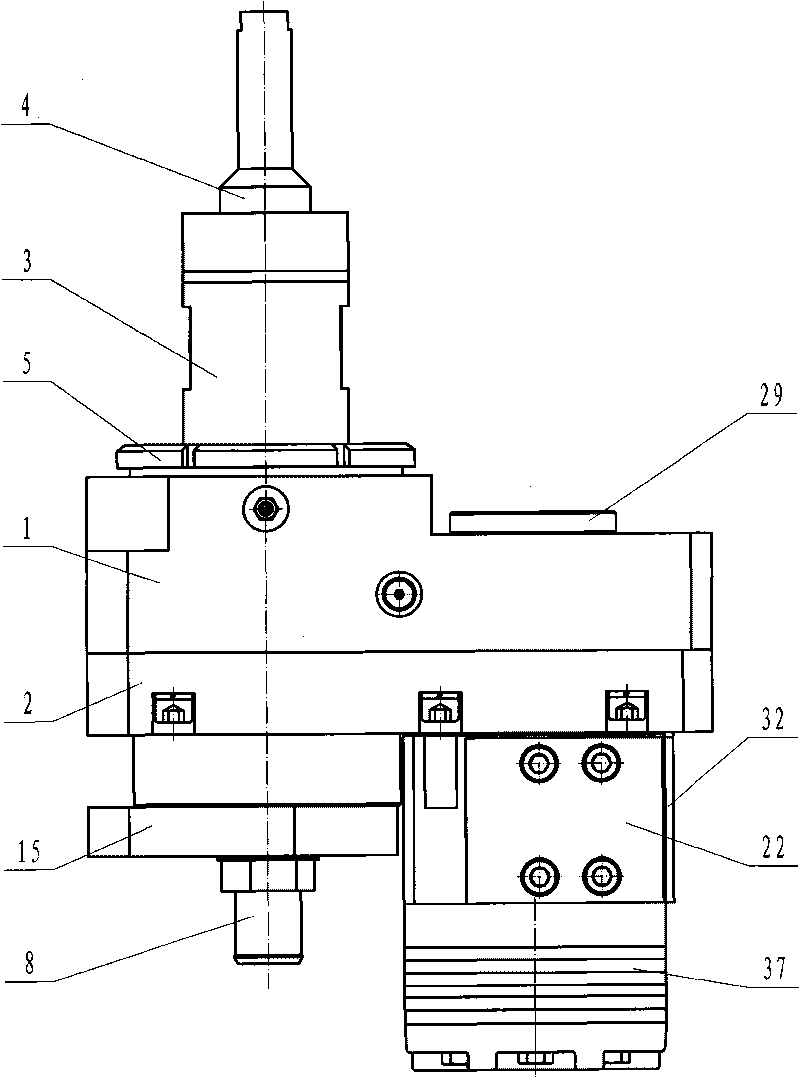

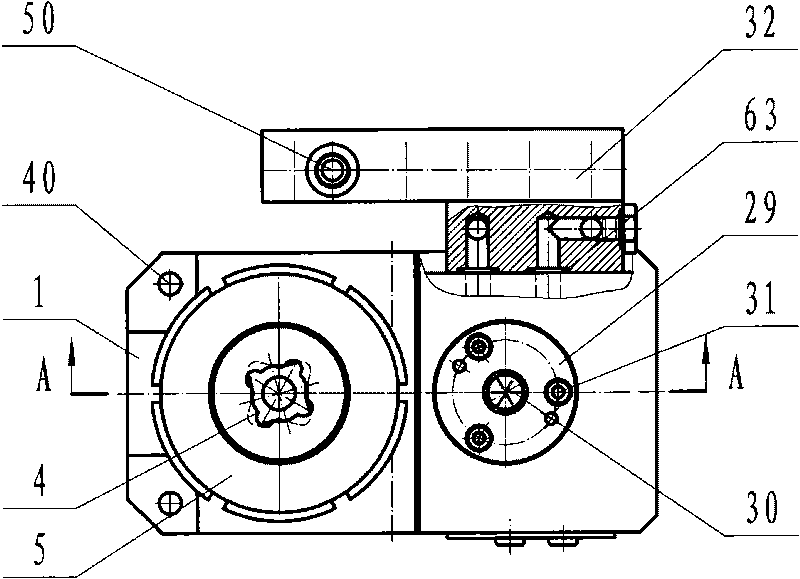

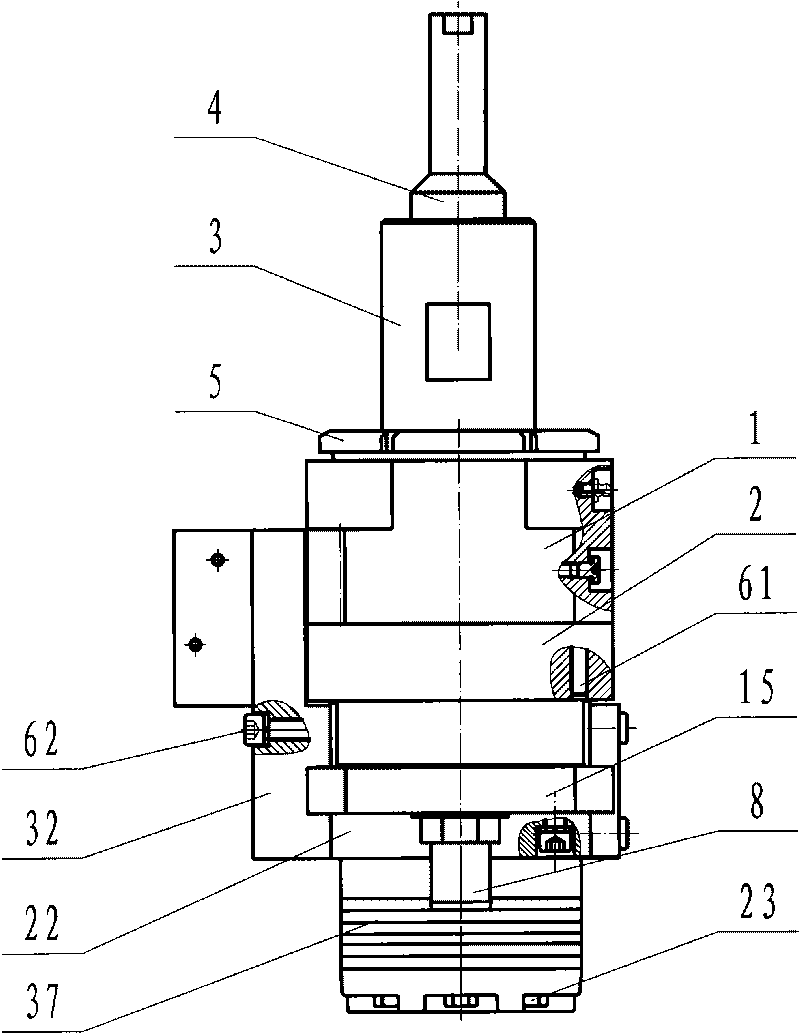

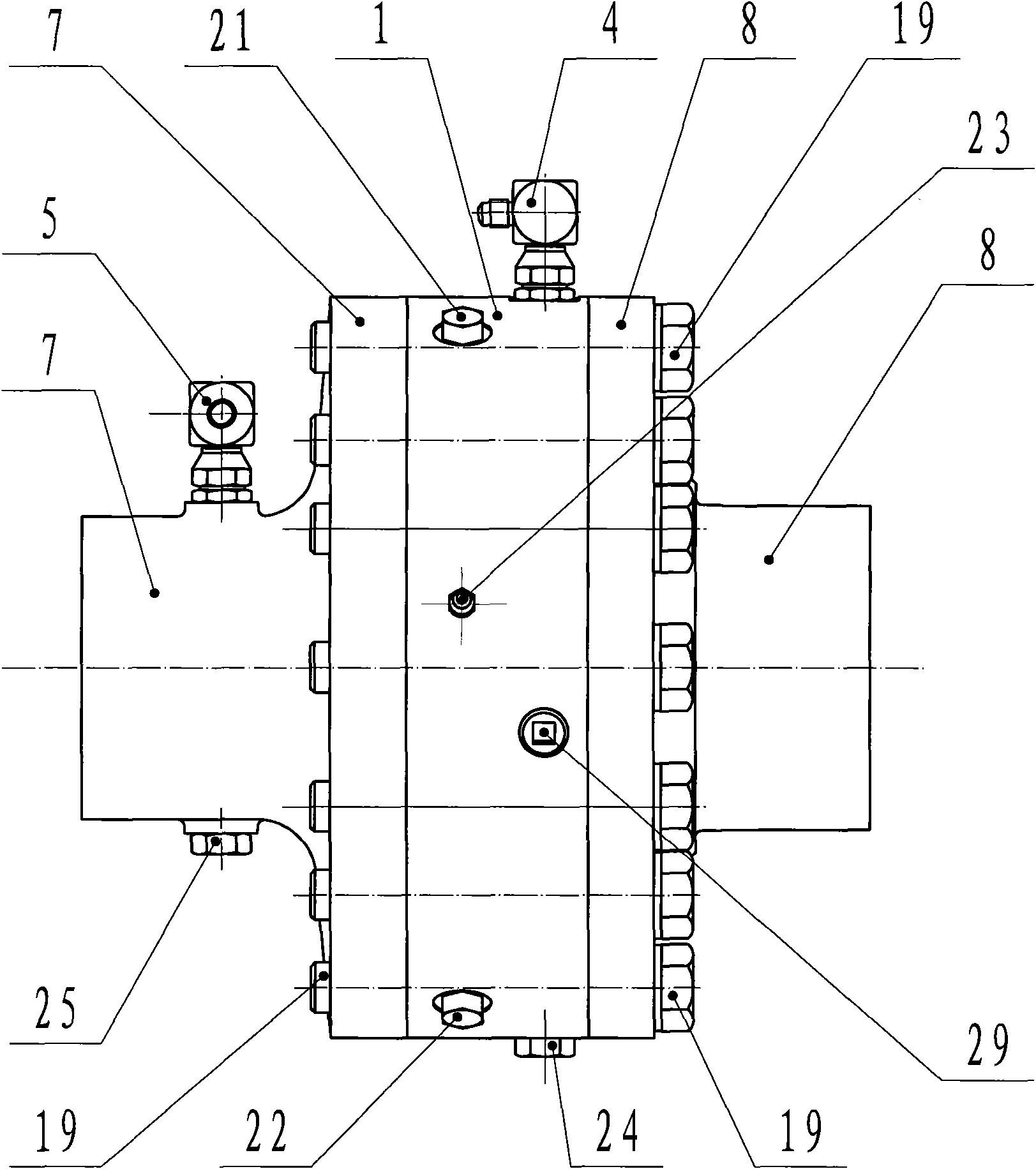

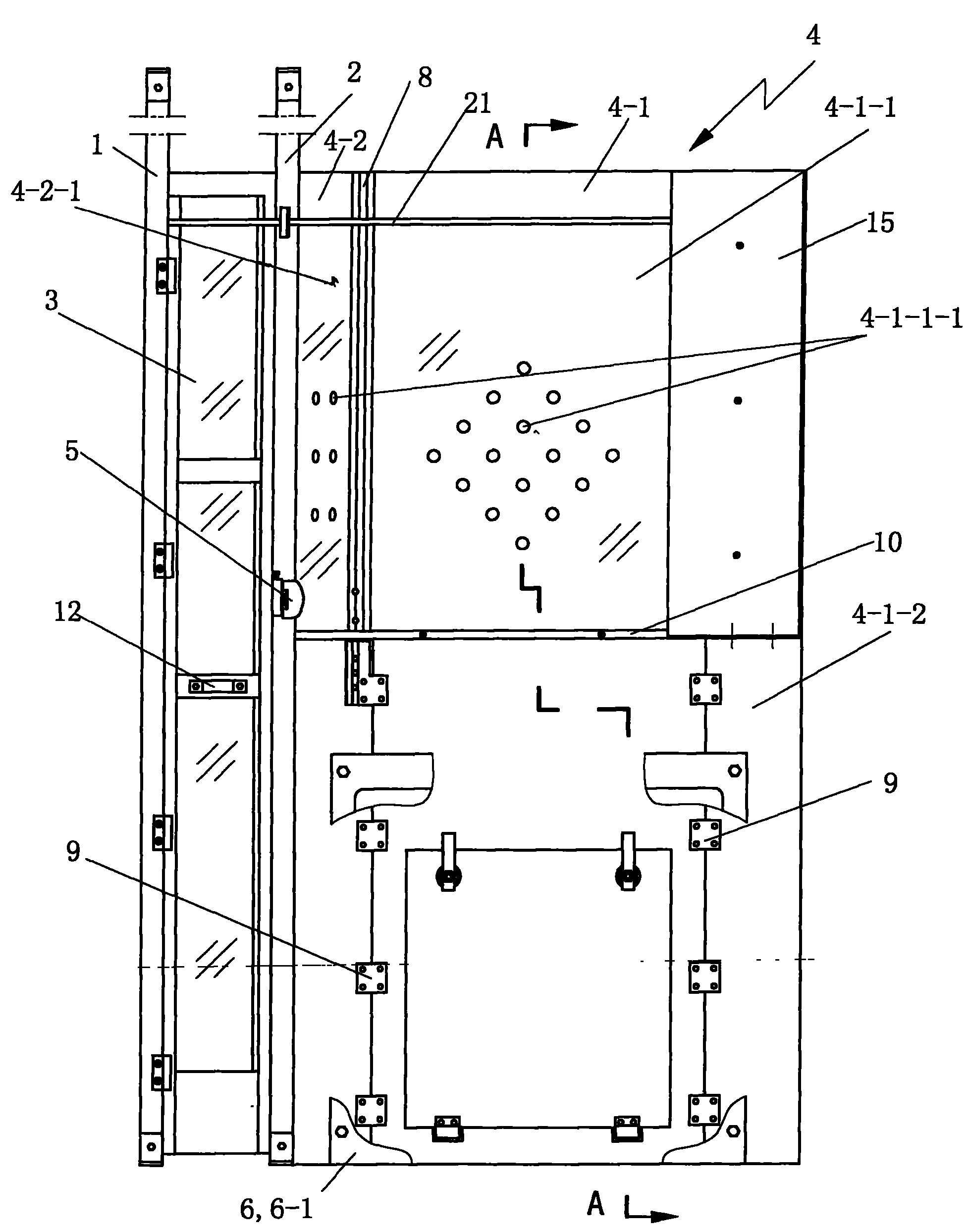

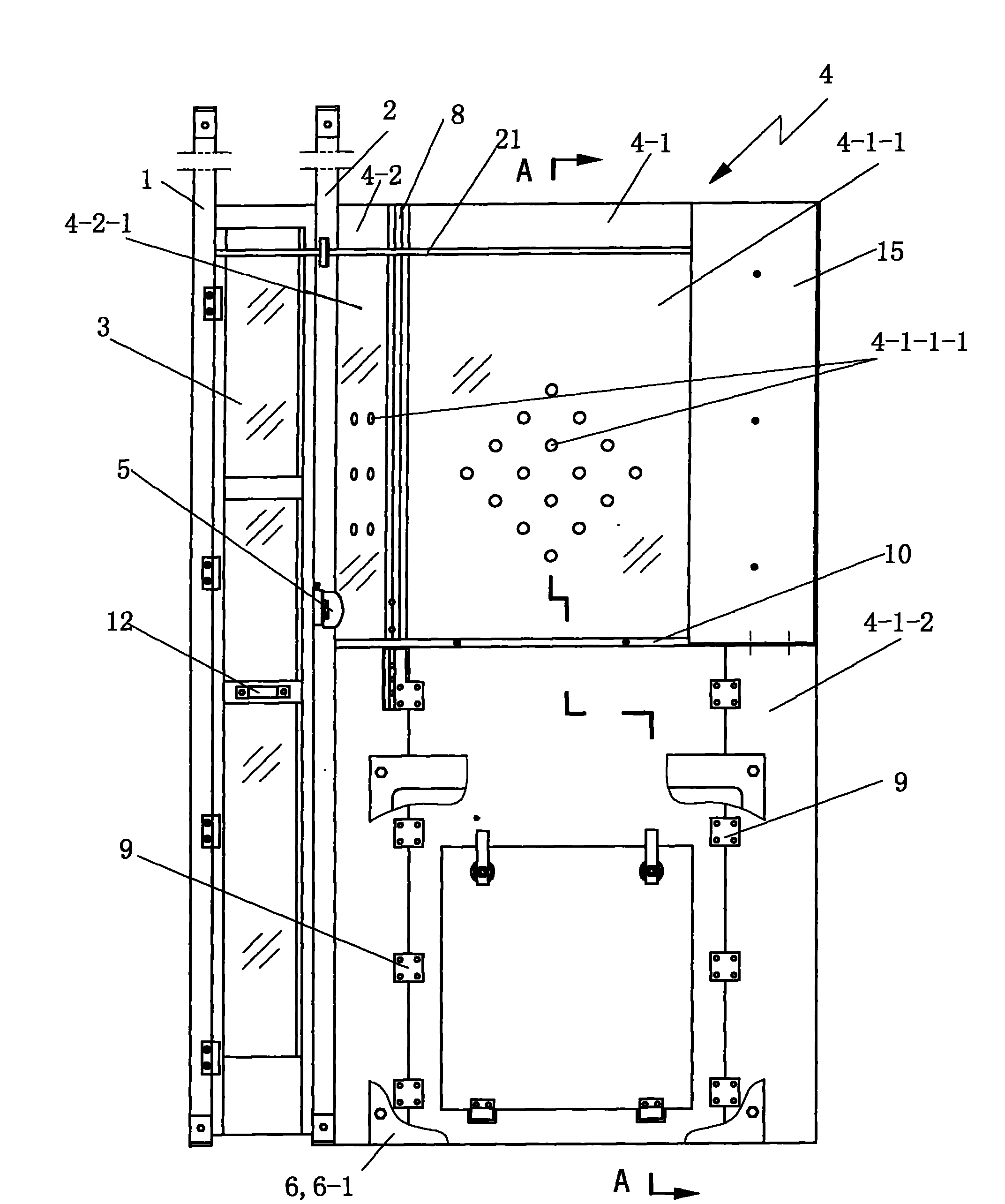

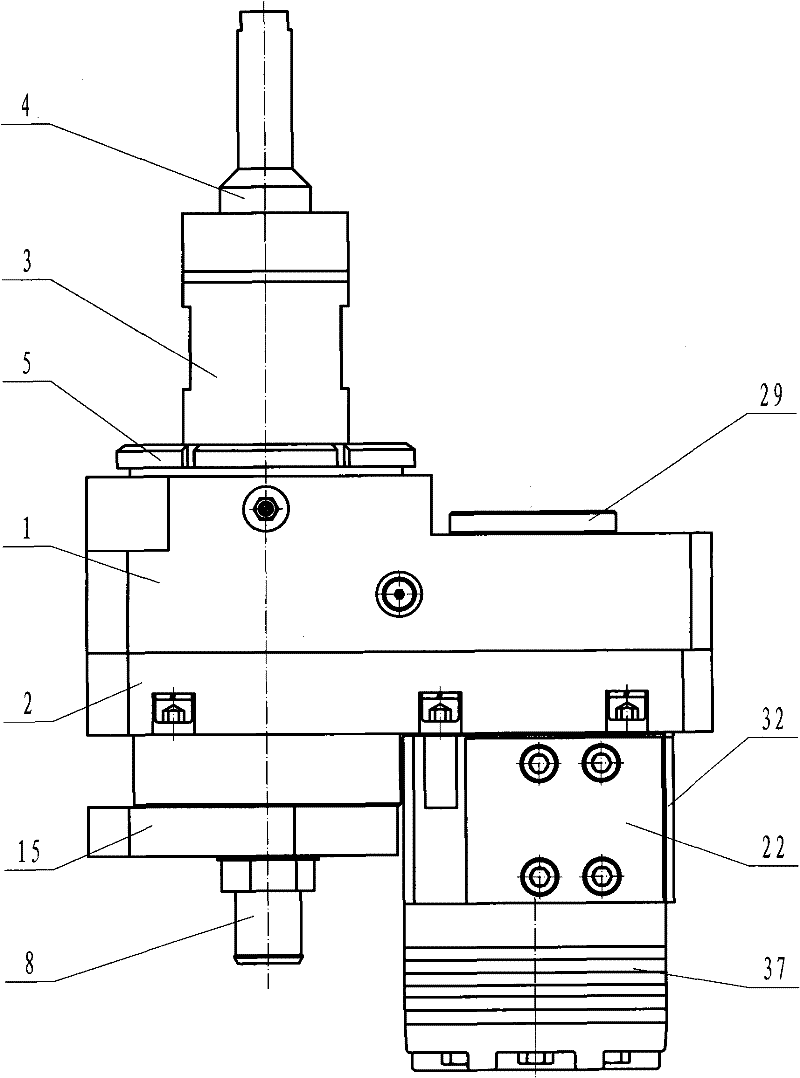

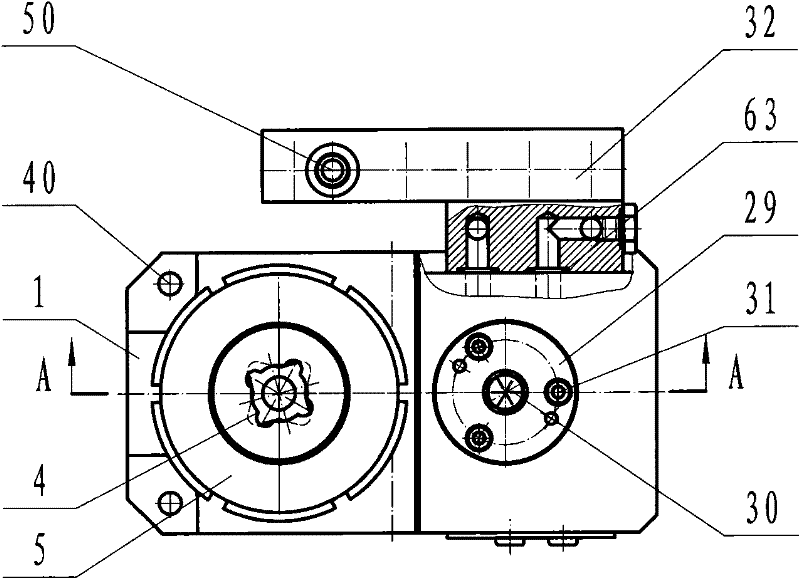

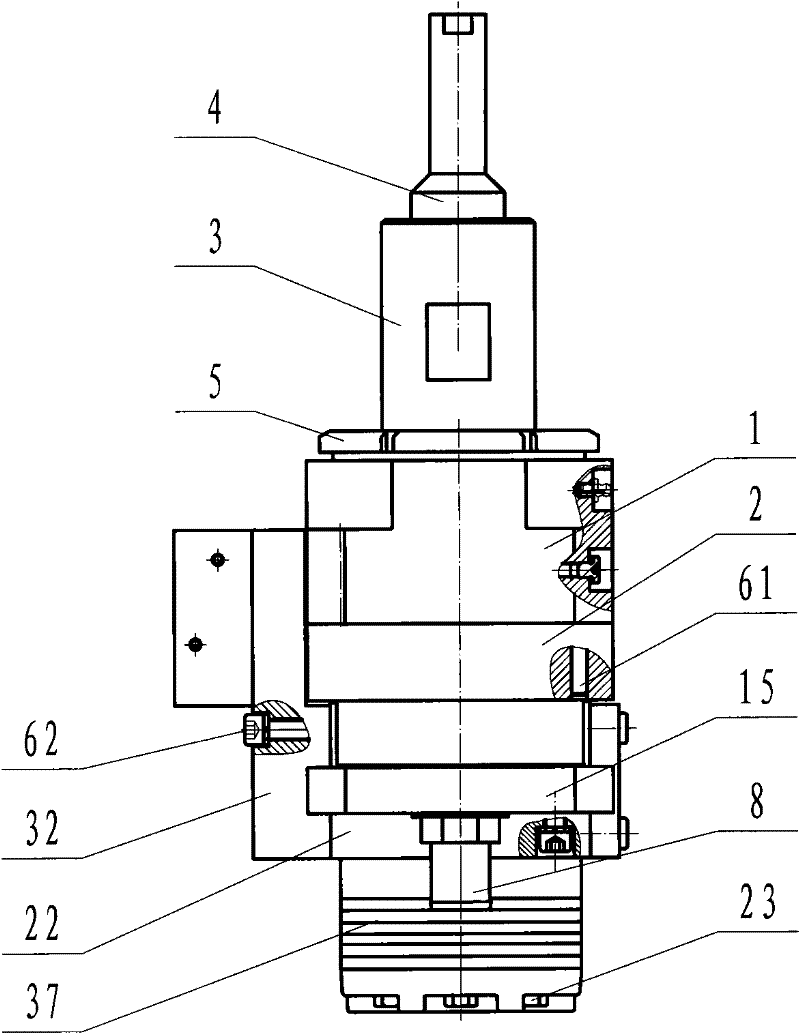

Dry wet-type drill box of anchor rod drill carriage

ActiveCN101737006AAvoid enteringAdvanced and reasonable structureGear lubrication/coolingAnchoring boltsHydraulic motorDrive shaft

The invention relates to a dry wet-type drill box of an anchor rod drill carriage, which mainly consists of an upper box body, a lower box body, a transmission shaft, a drill bushing, a drill rod, a water seal, a locking disc, a lower end cover, a framework sealing seat, a floating seal, a hydraulic motor, a hydraulic motor connecting block, a liquid preparing plate, a hydraulic motor shaft gear, a transmission shaft gear and a bearing; wherein the drill box can be used in both a dry dedusting state and a wet dedusting state of the anchor rod drill carriage, and takes the cycloid hydraulic motor as power to drive the hydraulic motor shaft gear and the transmission shaft gear to rotate, thus driving the drill bushing and the drill rod to drill holes. By adopting full-sealing structure and combining framework seal, the floating seal, a sealing ring and the water seal, the drill box prevents dry-type boring dust from entering and prevents dust-containing water of wet-type atomizing boring dust removal from entering, thus leading the drill box to have drilling operation in a full-closed state. The drill box is advanced and reasonable in design, compact in structure, convenient in use and installation, safe, stable and reliable, and has dual purposes of dry and wet dust removal and good universality, thus being an ideal drill box of the anchor rod drill carriage and used on similar equipment.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

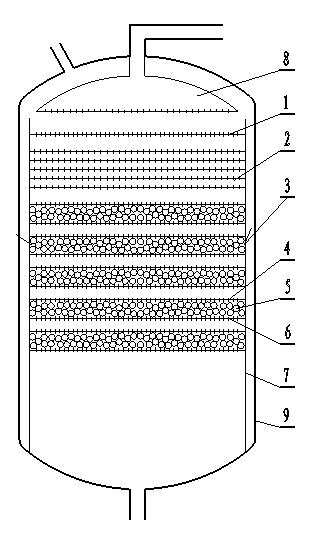

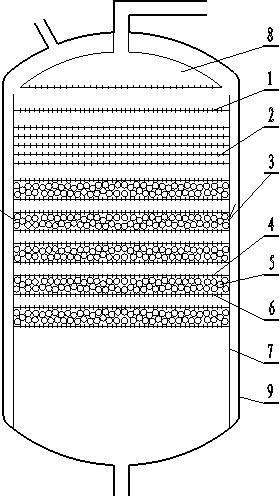

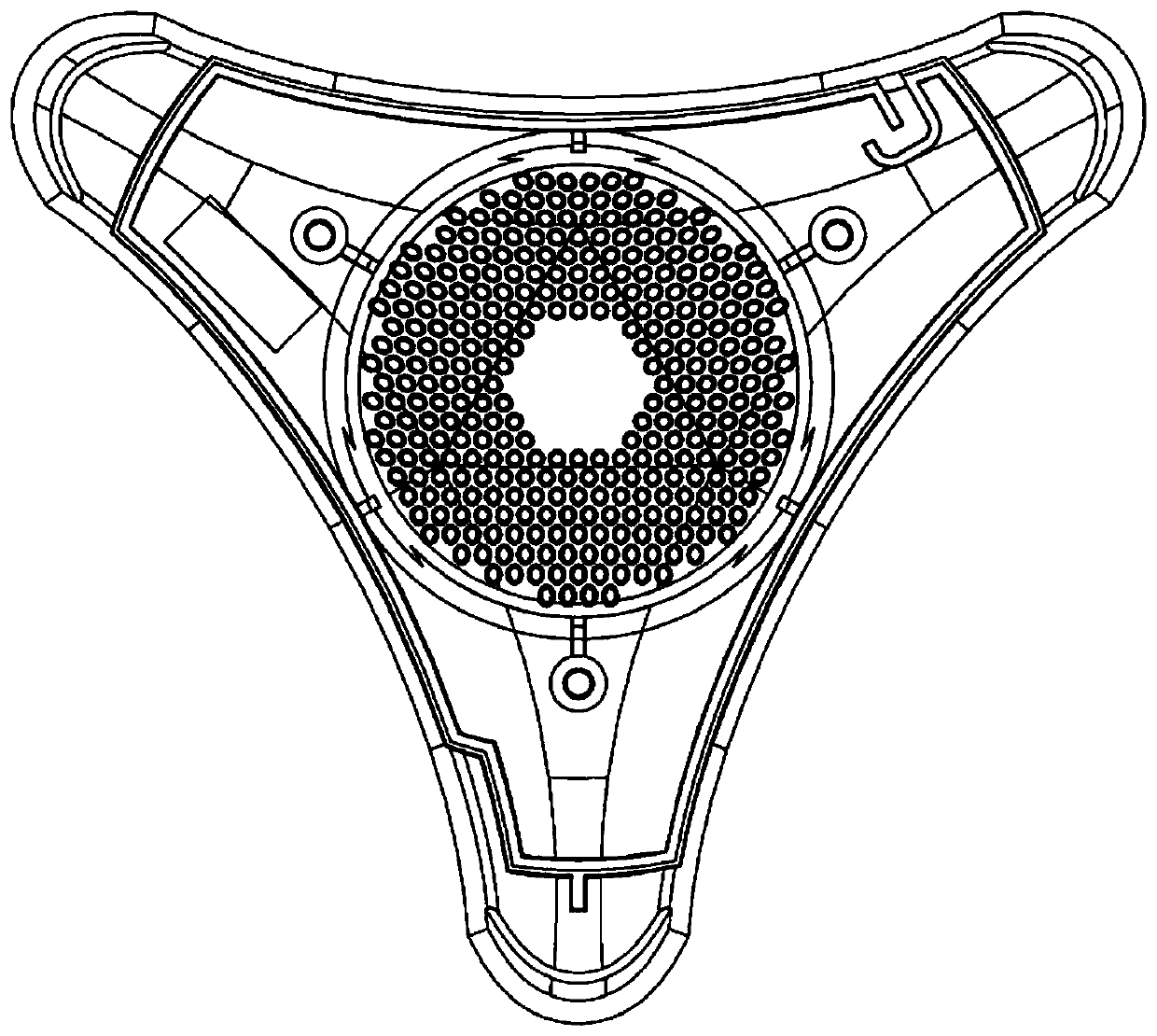

Foam elimination device for vacuum oil purification

ActiveCN102641610AEliminate generationImprove securityFoam dispersion/preventionElastic fiberChromatography detector

The invention discloses a foam elimination device for vacuum oil purification, which comprises guide plates, stainless steel meshes, chromatography devices and a bracket, wherein the bracket is successively connected with the guide plates, five layers of stainless steel meshes and five sets of chromatography devices from top to bottom; the guide plate is made of a stainless steel plate of which the thickness is 1.5mm; a plurality of holes of which the diameter is 3mm are processed in the plate; the diameter of holes in the stainless steel meshes is 1mm; space between every two layers of stainless steel meshes is 10mm; each chromatography device is formed by successively connecting an upper guide plate, a high-elastic fiber ball and a lower guide plate; the space between the upper guide plate and the lower guide plate is 30mm; the middle is provided with a high-elastic fiber ball of which the diameter is 10mm; and the space between every two layers of chromatography devices is 20mm. The foam elimination device for vacuum oil purification has the advantages of reasonable and advanced structure, foam generated in a vacuum tank in the vacuum oil purification processing process can be effectively eliminated, and the safety and the environment protection in the vacuum oil purification processing process are greatly improved.

Owner:高存兴

Intelligent secondary fixed die releasing injection molding die structure

PendingCN109968609AAdvanced and reasonable structureNovel and practical structureDomestic articlesHot runnerEngineering

The invention relates to the technical field of dies, and particularly relates to an intelligent secondary fixed die releasing injection molding die structure. The intelligent secondary fixed die releasing injection molding die structure comprises a heat insulation board, a panel, a pushing rod bottom plate, a fixed die pushing rod fixing plate, a supporting plate, a fixed die plate and a movabledie plate which are sequentially arranged from top to bottom, wherein a fixed die embedding part and a fixed die mold core are mounted in the fixed die plate; a movable die embedding part is mounted in the movable die plate; the fixed die mold core is sleeved with the fixed die embedding part; a movable mold core which is fixedly connected to the supporting plate sleeves the fixed die mold core; and a plurality of pushing rods are mounted at the bottom part of the pushing rod bottom plate and penetrate the fixed die pushing rod fixing plate, the supporting plate, the fixed die plate and the fixed die mold core. The intelligent secondary fixed die releasing injection molding die structure further comprises a hot runner pouring system. The intelligent secondary fixed die releasing injectionmolding die structure is simple and novel; the hot runner pouring system and the pushing rods are arranged at the fixed die side, such structure is opposite to a general die structure; and the outer surface of a loudspeaker-shaped cover is prevented form pushing rod and pouring port marks.

Owner:GUANGDONG UNIV OF SCI & TECH

Self guiding type mechanical powder product finishing machine

InactiveCN101862835AAdvanced and reasonable structureSimple structurePunchingAgricultural engineering

The invention discloses a self guiding type mechanical powder product finishing machine. An upper slide block of the finishing machine does up and down reciprocating movement via a guide rail arranged on a machine frame through being driven by a crank shaft, an upper connecting plate is connected with the bottom of the upper slide block, an upper punching fixed plate is arranged under the upper connecting plate, a middle mold is arranged under the upper punching fixed plate and is connected with a work table of the machine frame, the middle part of the middle mold is provided with a hole, a core rod is arranged in the middle part of the upper connecting plate and passes through an upper punching inner hole arranged under the upper punching fixed plate, a guide post is arranged at the bottom of the upper connecting plate and passes through the upper punching fixed plate and the middle mold, an upper punching fixed plate reset spring is surrounded on the periphery of the guide post, a female mold cover with a hole formed in the middle part is fixedly connected with the middle part of the middle mold, the hole formed in the middle part of the female mold cover corresponds to the hole at the middle part of the middle mold, a female mold is arranged in the hole of the middle part of the female mold cover, a lower punching device is arranged in the hole of the middle mold and passes through the female mold, and a pressure regulation screw rod is arranged at the bottom of the middle mold and is used for regulating the height of the lower punching device. Compared with the existing structure, the structure of the invention is simpler, and the invention is particularly suitable for finishing ball type products.

Owner:YANGZHOU HAILI PRECISION MACHINERY MFG

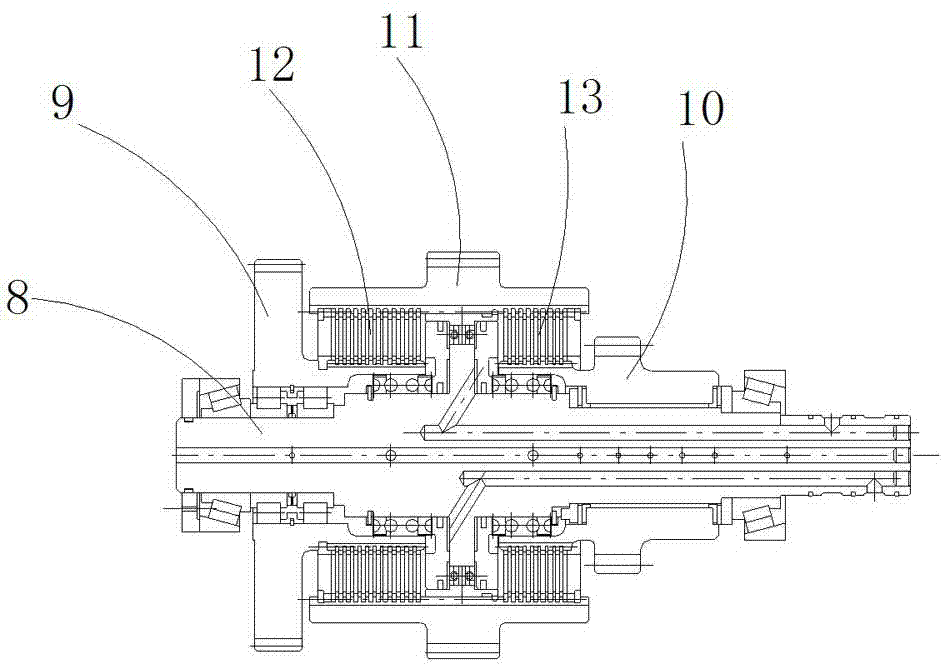

Brake with cooling in driving axle of battery forklift

ActiveCN101659252AAvoid stickingAdvancedBrake coolingFluid braking transmissionStatic frictionFuel tank

The invention relates to a brake with cooling in a driving axle of a battery forklift, which mainly comprises a piston shell body, a piston body, a piston cavity, a cooling inlet and outlet oil valve,a left axle body and a right axle body, a transmission shaft, a spline shaft, a spline sleeve, a braking spring, a dynamic friction plate and a static friction plate, a braking inlet and outlet oil port, a lubricating inlet and outlet oil port and screws. A wet-type brake in the driving axle is provided with double circuits for braking and cooling and a double-cycle and synchronous structure anduses the same hydraulic oil tank, the cooling inlet and outlet oil valve is started synchronously while braking to carry out cooling external circulation, and the braking spring ensures clearance to generate between the dynamic friction plate and the static friction plate, thus eliminating the friction force, avoiding heating bonding and solving the problem of synchronous braking and cooling well.The device has advanced and reasonable design, compact structure, safe, steady and reliable properties and convenient installation and use and is an ideal brake with cooling for the battery forklift,and the device can also be used in other similar vehicle types.

Owner:TAIYUAN INST OF COAL SCI RES INST +1

Feeding machine

ActiveCN105599926AAvoid sticky positionsReduce inaction lossSolid materialEngineeringMaterial storage

The invention provides a feeding machine which can be configured with a weighing packing machine. The feeding machine comprises a rack, a material storage bin, a discharging hopper and helicoid conveyer assemblies, wherein the helicoid conveyer assemblies comprise a big helicoid conveyer assembly, a medium helicoid conveyer assembly and a small helicoid conveyer assembly which are different in diameter; the connecting lines of the axial centers of the three helicoid conveyer assemblies with different diameters are in the shape of a reversed isosceles triangle, which is a main characteristic. The feeding machine has the characteristics that the structure is reasonable and advanced, the discharging speed of packing is quick, the precision is high, and the requirements of discharging for different sizes of packing and different specifications and weights are met.

Owner:CHANGZHOU REITRON AUTOMATIC EQUIP

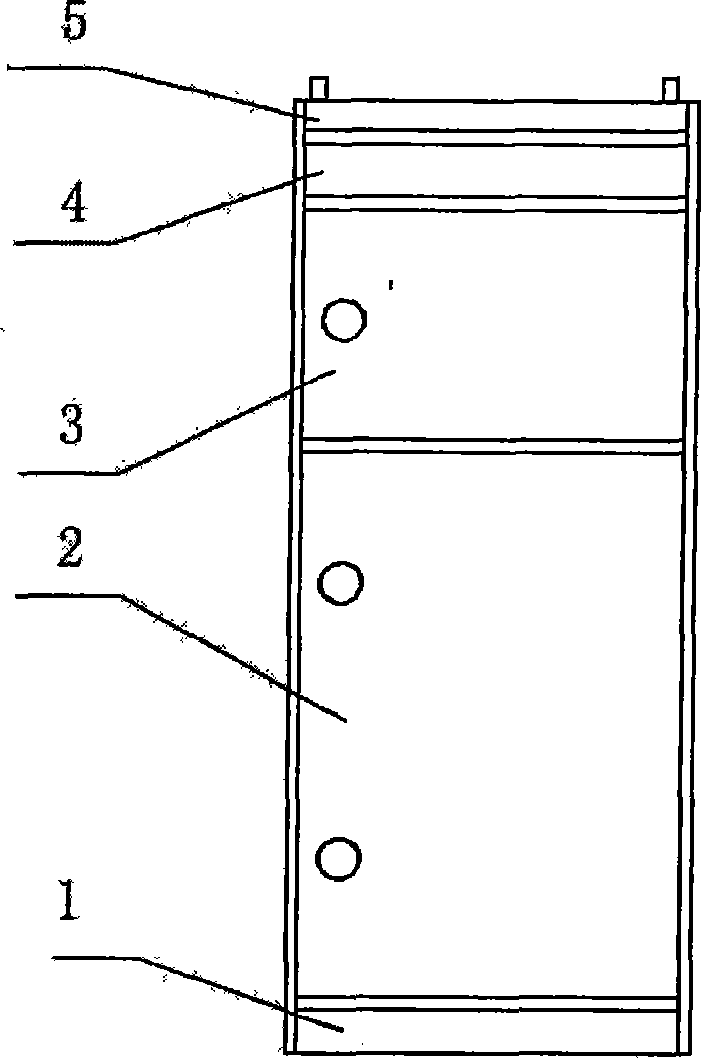

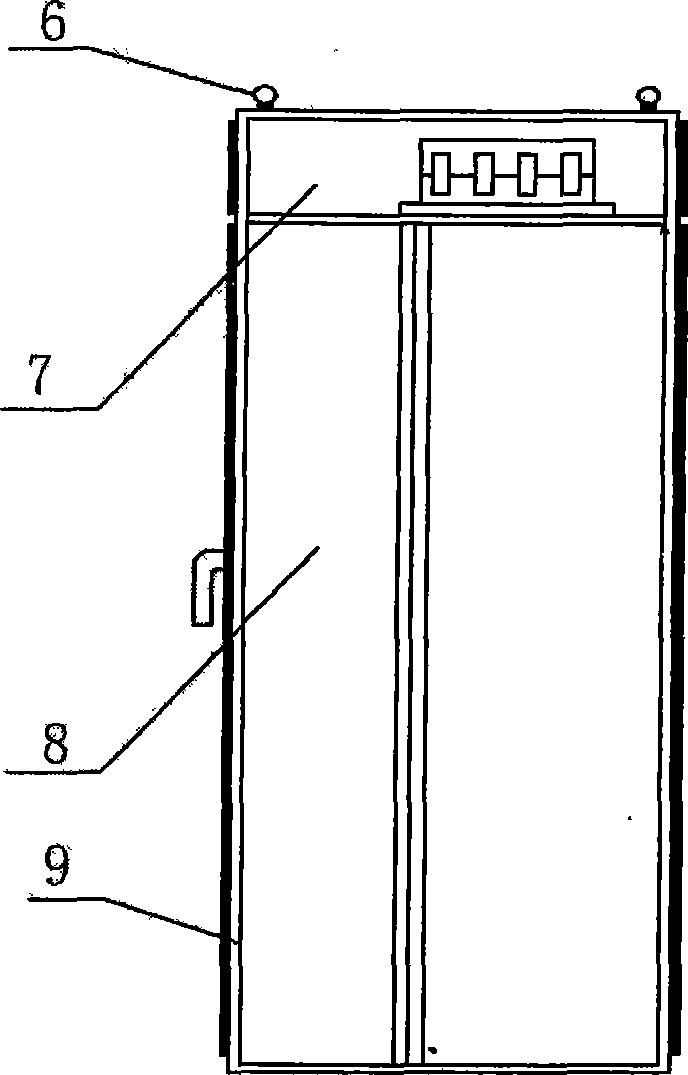

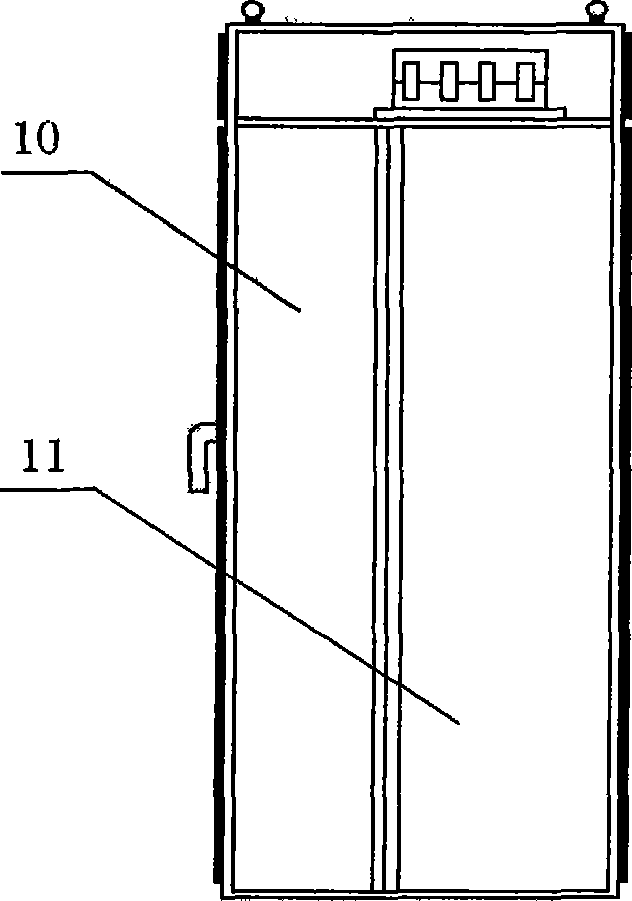

Combined low-voltage switch cabinet and working method thereof

InactiveCN101521358AReduce volumeCompact structureBoards/switchyards circuit arrangementsSubstation/switching arrangement cooling/ventilationLow voltageSwitchgear

The invention relates to a combined low-voltage switch cabinet and a working method thereof. The combined low-voltage switch cabinet is characterized by consisting of a cabinet body of the switch cabinet, an upper ventilation plate, a lower ventilation plate, a bus, an instrument, a cable and a unit room with a functional switch circuit. The working method comprises the steps of: 1) the installation of the cabinet body, 2) the selection of a circuit proposal, 3) the internal connection of the switch cabinet, 4) the external connection of the switch cabinet, 5) the running of the switch cabinet and 6) the operation of a user. The invention has the advantages of compact structure, ability of saving the volume of the cabinet body, strong seriation and universality, high breaking ability, good dynamic thermal stability, advanced and reasonable structure, economic layout of a power distribution circuit and arbitrary combination of various proposals and units; a functional unit adopts a fixed structure, thereby facilitating the safe running, facilitating the overhaul, shortening the accident power outage time and ensuring the reliable power use; an electrical appliance element can select a domestic element or an imported element arbitrarily according to the different user demands, thereby being capable of meeting the market demands to the maximum extent; furthermore, the combined low-voltage switch cabinet has beautiful appearance, high protection level, high operation continuity and reliability and convenient installation and maintenance.

Owner:TIANJIN HAIYANG SWITCHGEAR PLANT

Flame-retardant modified bitumen waterproof coiled material coating material and flame-retardant self-adhesive bitumen waterproof coiled material and preparation method thereof

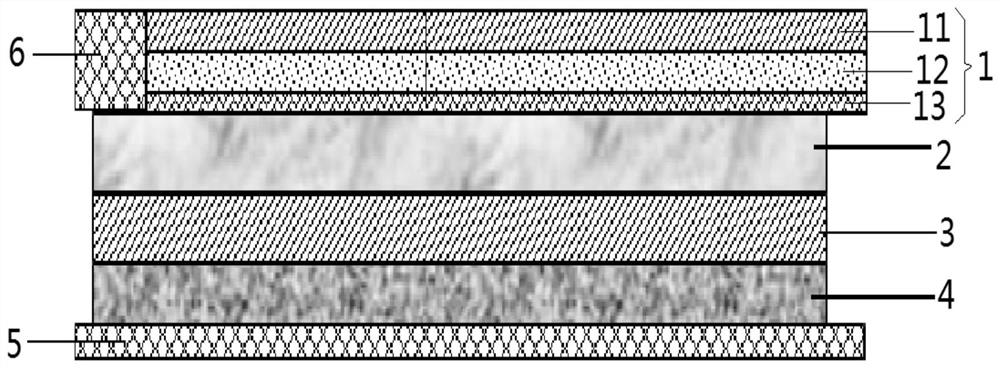

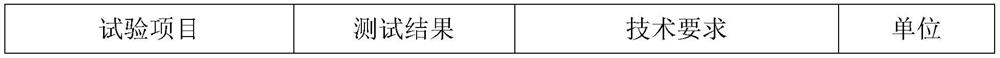

InactiveCN112236303AThinHigh bonding strengthRoof covering using flexible materialsSynthetic resin layered productsBituminous waterproofingFlame resistance

Disclosed are a flame-retardant modified bitumen waterproof coiled material coating material and a flame-retardant self-adhesive bitumen waterproof coiled material and preparation method thereof. Thewaterproof coiled material includes a metal glass fiber grid composite flame-retardant layer, a flame-retardant modified asphalt layer, a glass fiber tire flame-retardant layer, a flame-retardant self-adhesive asphalt layer, and an isolation layer that are sequentially arranged from top to bottom. The invention is thin and adapts to the trend of building energy saving and carries out cold self-adhesive construction, and has high bonding strength and good heat resistance. There is no need to use open flame for construction. Construction is convenient, safe and environmentally friendly. The invention has excellent waterproof and flame-retardant performance, is multi-layer synergistic flame-retardant, has fire-proof grade B1, and stops burning after leaving the fire source. The invention is especially suitable for building waterproofing with high waterproof requirements and can be flame-retardant from the inside to the outside and from the outside to the inside. It has excellent flame retardant performance and wide application prospects.

Owner:HUIZHOU ORIENTAL YUHONG BUILDING MATERIALS

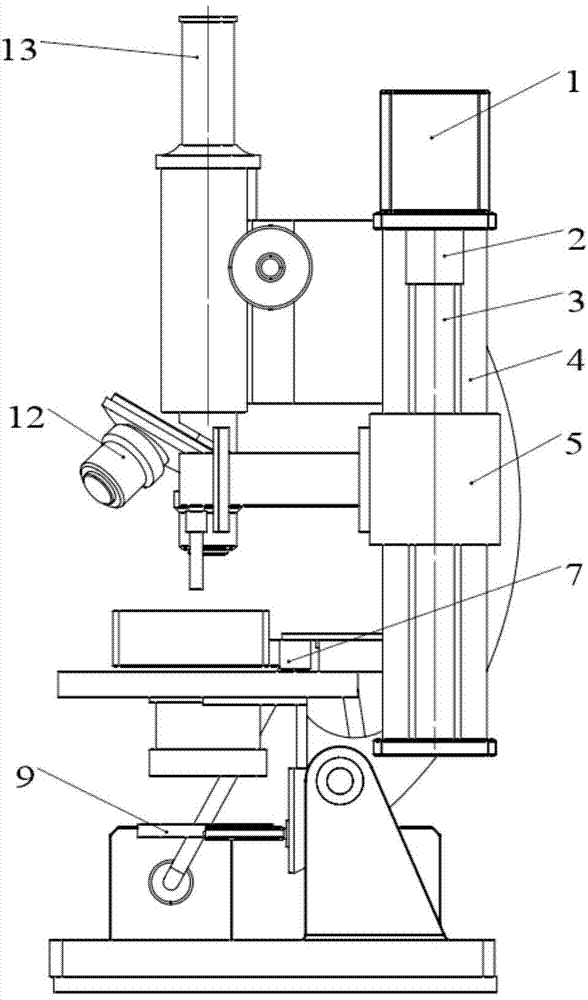

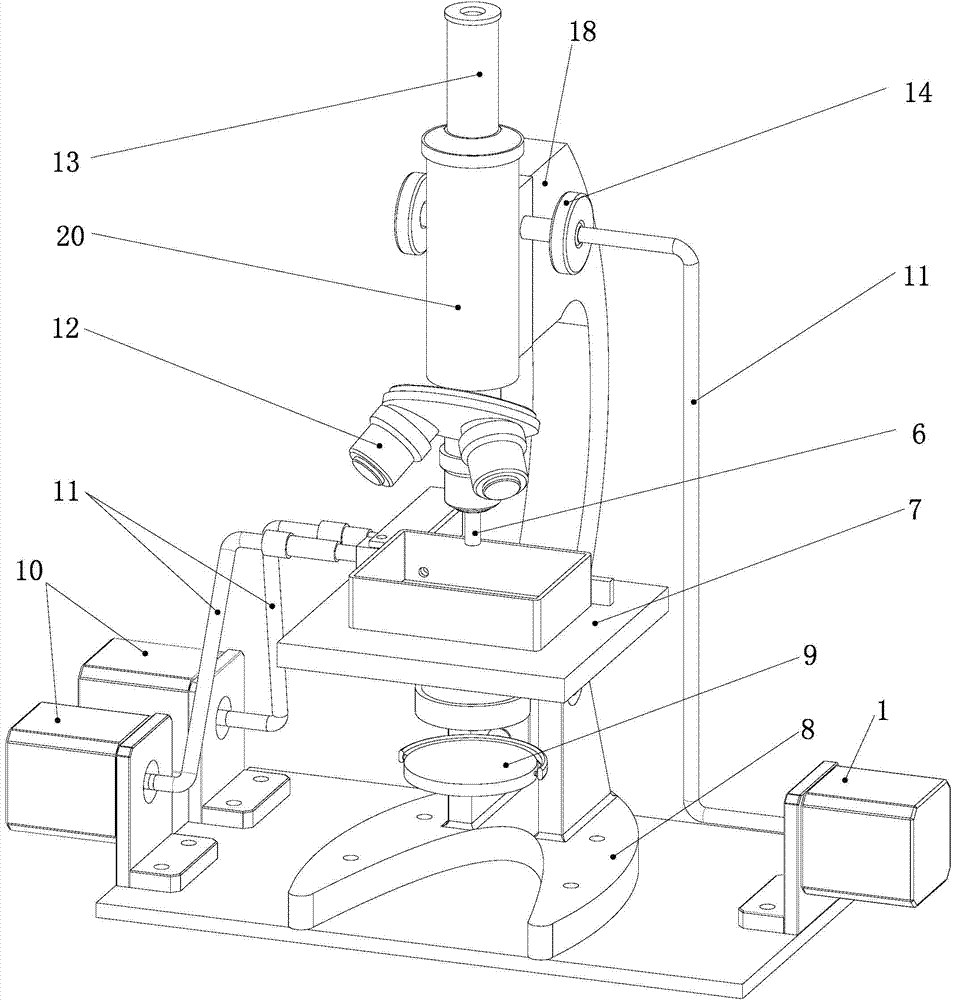

Biological microscope based hand-held type electro spark processing machine tool integrated with processing and measuring

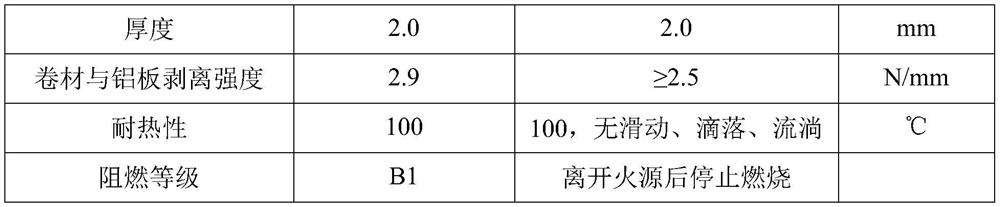

InactiveCN104741710AAdvanced structureReasonable structureElectrical-based auxillary apparatusMicroscopeEngineering

The invention relates to a biological microscope based hand-held type electro spark processing machine tool integrated with processing and measuring. The problems in an existing electro spark processing machine tool that the numerical control resolution ratio is fixed and unchangeable, measuring cannot be carried out during the processing process, and the machine tool is complex in structure and high in cost are solved. The biological microscope based hand-held type electro spark processing machine tool integrated with processing and measuring comprises a biological microscope, a main shaft head, a transverse driving mechanism and a longitudinal driving mechanism. The main shaft head comprises a first stepping motor, a ball screw rod, a guide rail, a sliding block and a rotary main shaft. The guide rail is connected with an arm, the upper portion of the guide rail is provided with the first stepping motor, the sliding block is embedded into the guide rail and can slide upward and downward, an output shaft of the first stepping motor is connected with one end of the ball screw rod which is vertically arranged, and the other end of the ball screw rod penetrates through a threaded through hole of the sliding block and is connected with the threaded through hole in a threaded mode. The transverse driving mechanism and the longitudinal driving mechanism comprise two stepping motors and two flexible shafts. The biological microscope based hand-held type electro spark processing machine tool integrated with processing and measuring is used for electro sparking processing.

Owner:HARBIN INST OF TECH

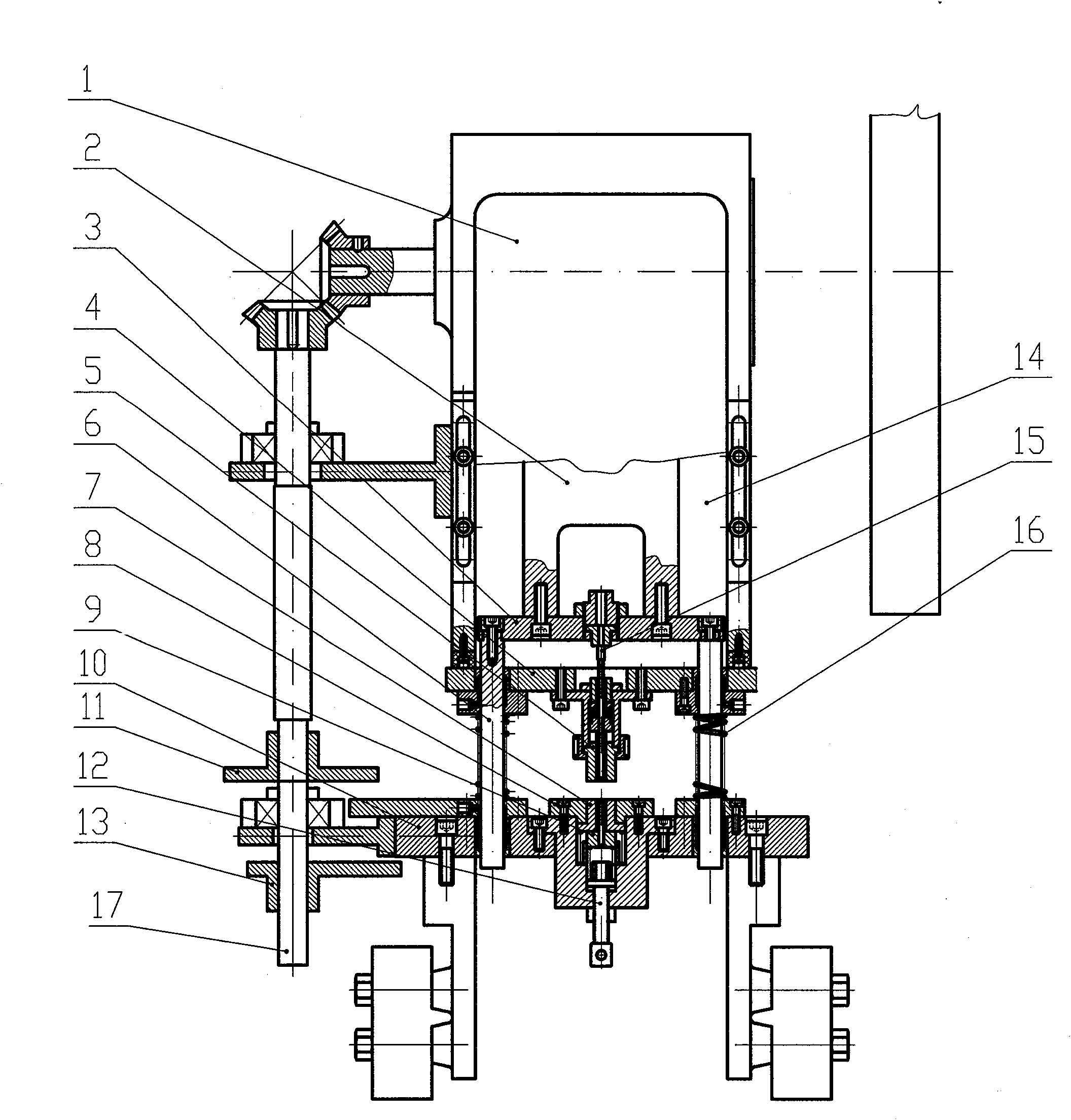

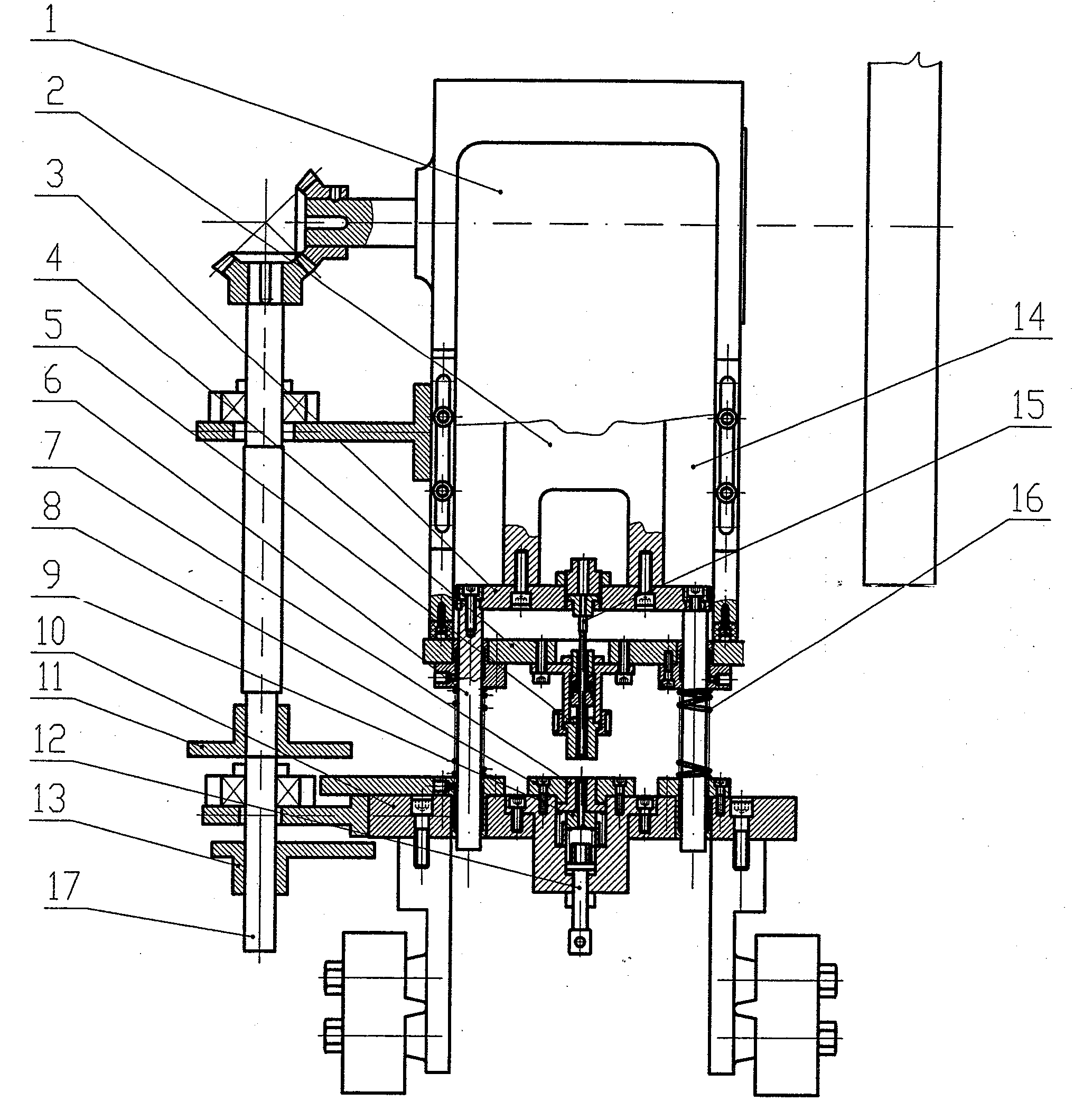

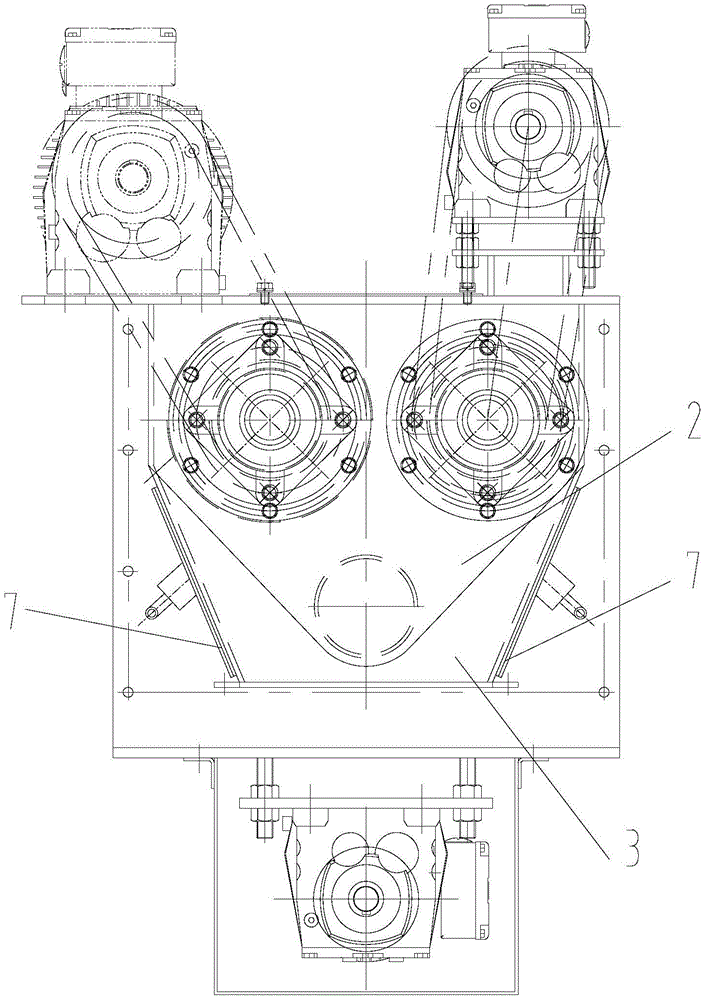

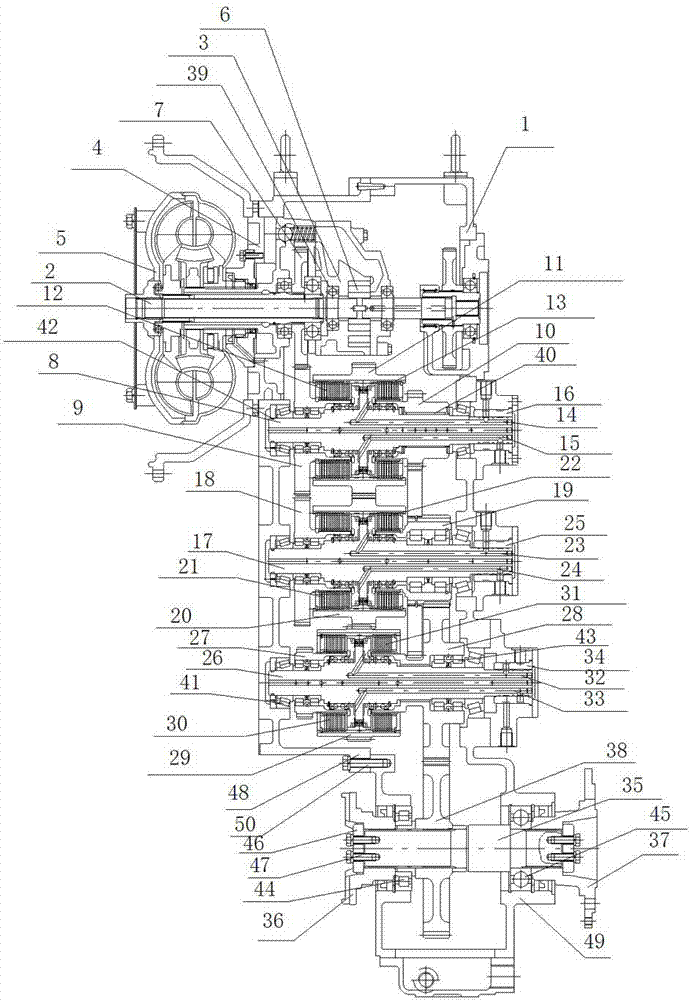

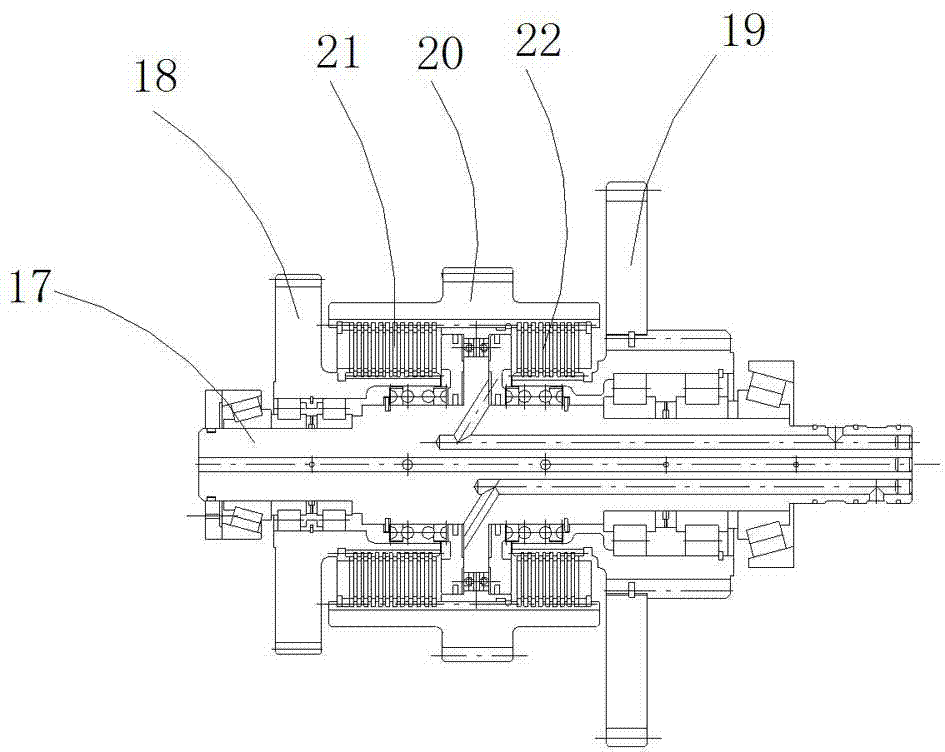

Multi-gear multivariant movable axis type semi-automatic control speed changing box

ActiveCN102889356AAdvanced and reasonable structureSmall idle powerGearboxesFluid gearingsAutomatic controlSemi automatic

The invention relates to a control speed changing box, and particularly relates to a multi-gear multivariant movable axis type semi-automatic control speed changing box. A variable pump driving mechanism, a forward gear transmission mechanism, a reverse gear transmission mechanism, a fast gear transmission mechanism and an output transmission mechanism are respectively arranged in the speed changing box; wherein the variable pump driving mechanism is mutually in engaging transmission with the forward gear transmission mechanism and the reverse gear transmission mechanism respectively, the forward gear transmission mechanism is mutually respectively in engaging transmission with the reverse gear transmission mechanism, the reverse gear transmission mechanism is mutually respectively in engaging transmission with the fast gear transmission mechanism; the fast gear transmission mechanism is mutually respectively in engaging transmission with the output transmission mechanism, the variable pump driving mechanism is arranged at an upper end in a speed changing box body, the forward gear transmission mechanism, the reverse gear transmission mechanism and the fast gear transmission mechanism are respectively arranged at a middle end in the speed changing box body, and the output transmission mechanism is arranged at a lower end of the speed changing box body. The multi-gear multivariant movable axis type semi-automatic control speed changing box has an advanced and reasonable structure, power consumption is small, transmission efficiency is high, and the control speed changing box can be matched with a high-speed engine, thereby realizing continuous gear shifting of power.

Owner:HANGZHOU FADA GEARBOX GROUP

Road public traffic vehicle driver fence

Owner:常州金源汽车内饰有限公司

Garbage sweeper

InactiveCN101985828AAdvanced and reasonable structureEasy to operateRoad cleaningLitterCentrifugal force

The invention discloses a garbage sweeper, comprising a frame, a sweeping device and a garbage storage tank assembly; wherein the cleaning device is of two-brush rolling type. Garbage is collected by the way that the garbage is thrown out by centrifugal force of the rolling brush and enters into the garbage storage tank by virtue of a garbage guide plate. The invention has the advantages that: structure is reasonable and advanced, operation is easy, cleaning effect is good, and manufacturing cost is relatively low.

Owner:HOHAI UNIV CHANGZHOU

Automatic chicken manure organic fertilizer production equipment and process method thereof

PendingCN112374925AHigh degree of mechanizationIncrease productivityClimate change adaptationExcrement fertilisersAgricultural engineeringEnvironmental engineering

The invention discloses automatic chicken manure organic fertilizer production equipment and a process method thereof, and is characterized in that a transmission device consisting of a belt, a scraper and a first motor is arranged in a manure pit; when chicken manure in a coop body falls into the belt and the scraper in the pit, the chicken manure is conveyed to an unloading belt and is conveyedto a plowing and stirring wheel in a first lifting stirring bin through a first lifting screw shaft; the chicken manure is stirred by the plowing and stirring wheel, conveyed to an anaerobic drying tank through a second lifting screw shaft to be dried, and then, discharged from a discharge port to obtain the organic chicken manure. The chicken manure organic fertilizer has the advantages of simplestructure, easiness in manufacturing, convenience in installation and use, low cost and no secondary environmental pollution, and the prepared chicken manure organic fertilizer is high in fertilizerefficiency, safe and quick-acting.

Owner:广西贺州农贝贝农牧科技有限公司

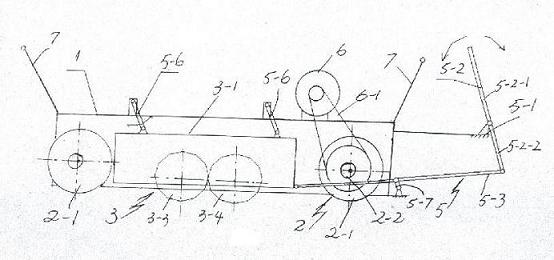

Swather for kidney beans

The invention discloses a swather for kidney beans. The swather comprises ridging devices, seedling gathering and carrying devices, turnable conveying devices, a driving device, a frame, a suspension bracket, shares with angle irons and land wheels, wherein the suspension bracket is connected to the middle of a cross beam above the front end of the frame and is connected with a tractor in a suspension manner; three shares with the angle irons are connected onto three vertical beams below the front end of the frame; and the land wheels are connected with the lower end of an L-shaped vertical beam between two sides of the frame; two sets of ridging devices are respectively connected between the frame and two cross beams; two sets of seedling gathering and carrying devices are respectively connected to eight vertical beams of the frame; the upper parts at the rear ends of two side frames of the frame are connected with the turnable conveying devices through pin roll assemblies; and a transmission case is fixedly arranged at the middle above the front end of the frame and is respectively in driving connection with the ridging devices, the seedling gathering and carrying devices and the turnable conveying devices through transverse transmission shafts. Due to the adoption of the firm ridging devices, the seedling gathering and carrying devices formed by reliable compound elevating conveyor belts and the turnable conveying devices, the swathing quality and efficiency are greatly increased.

Owner:夏元海 +1

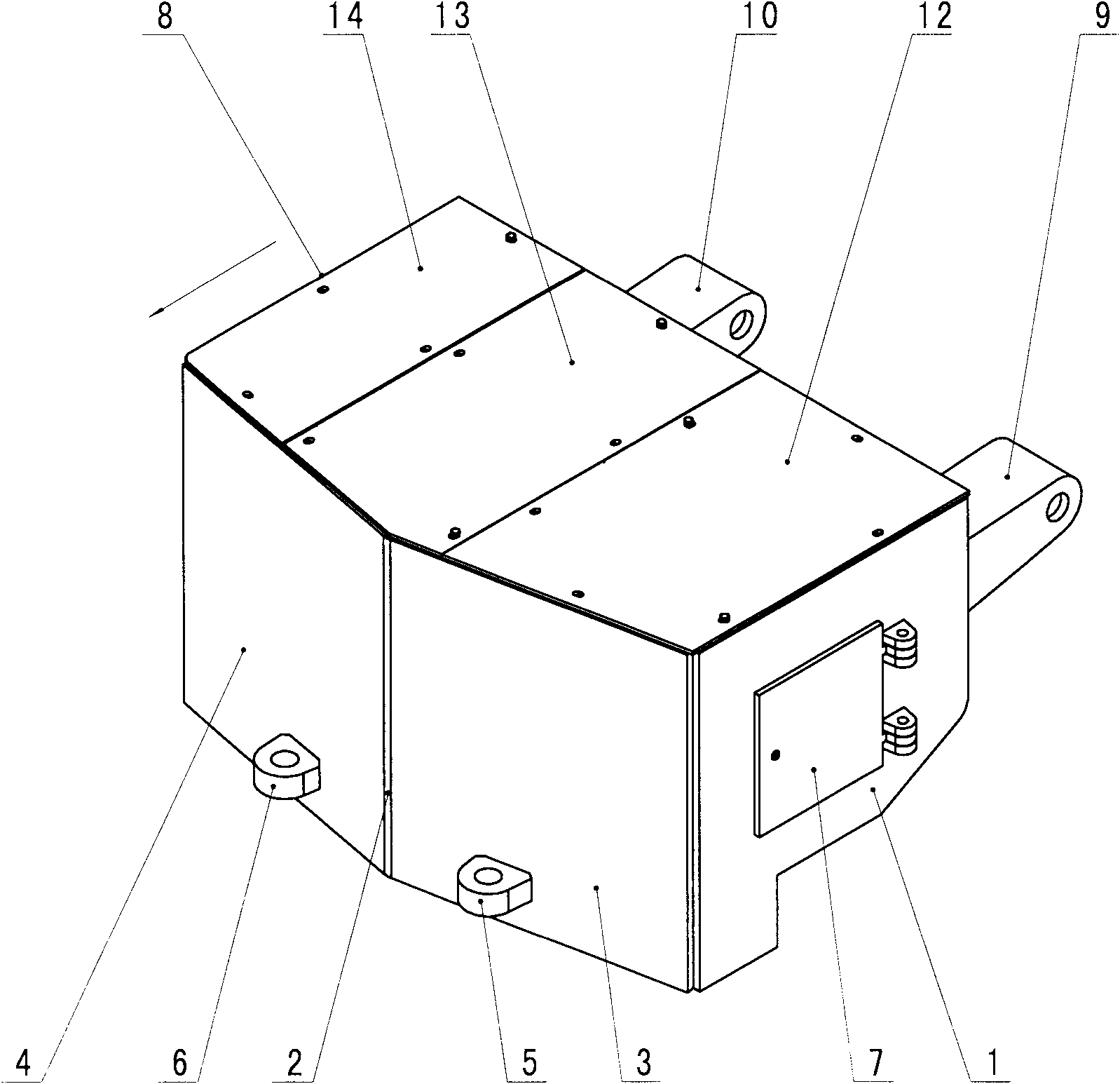

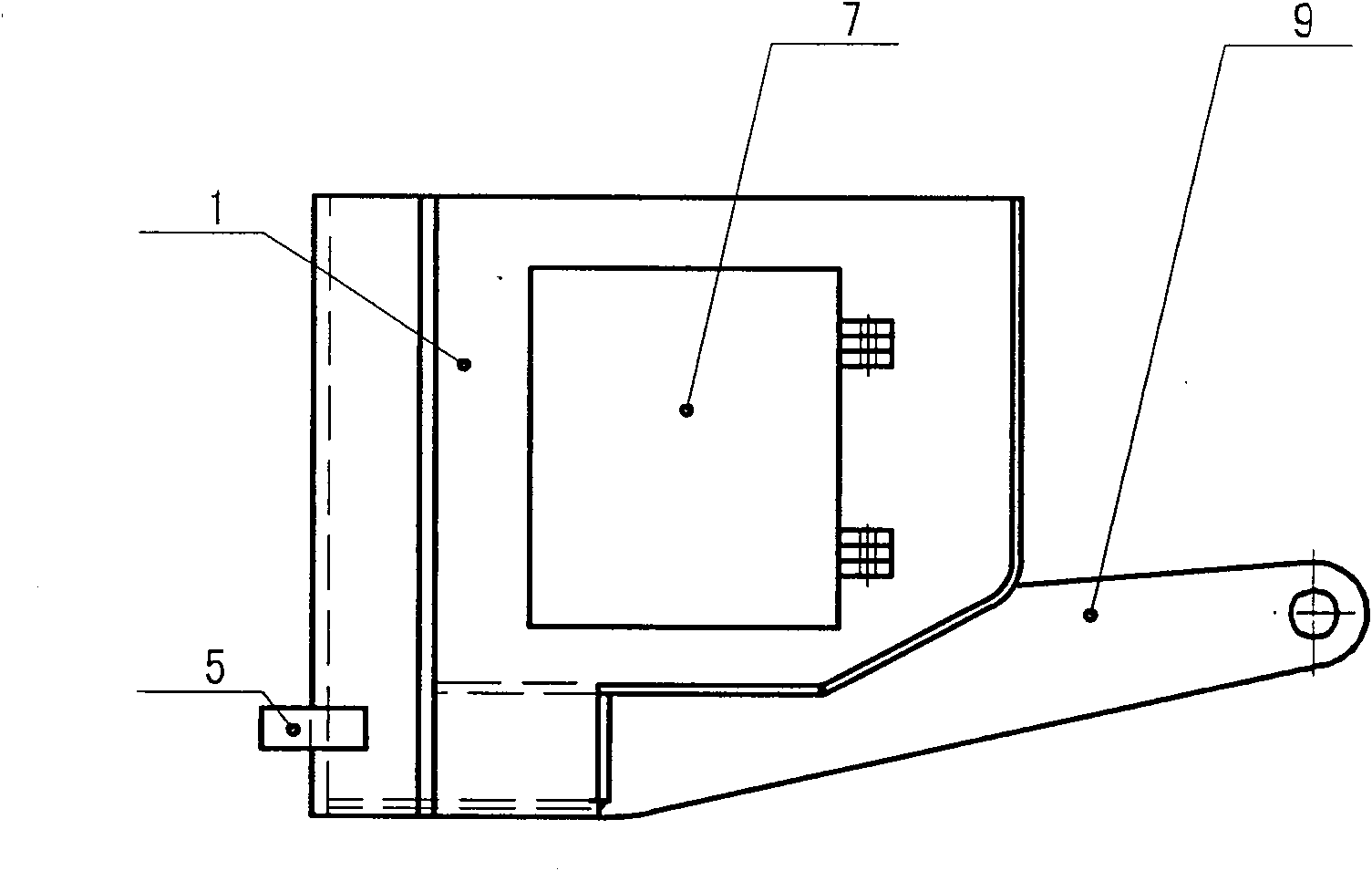

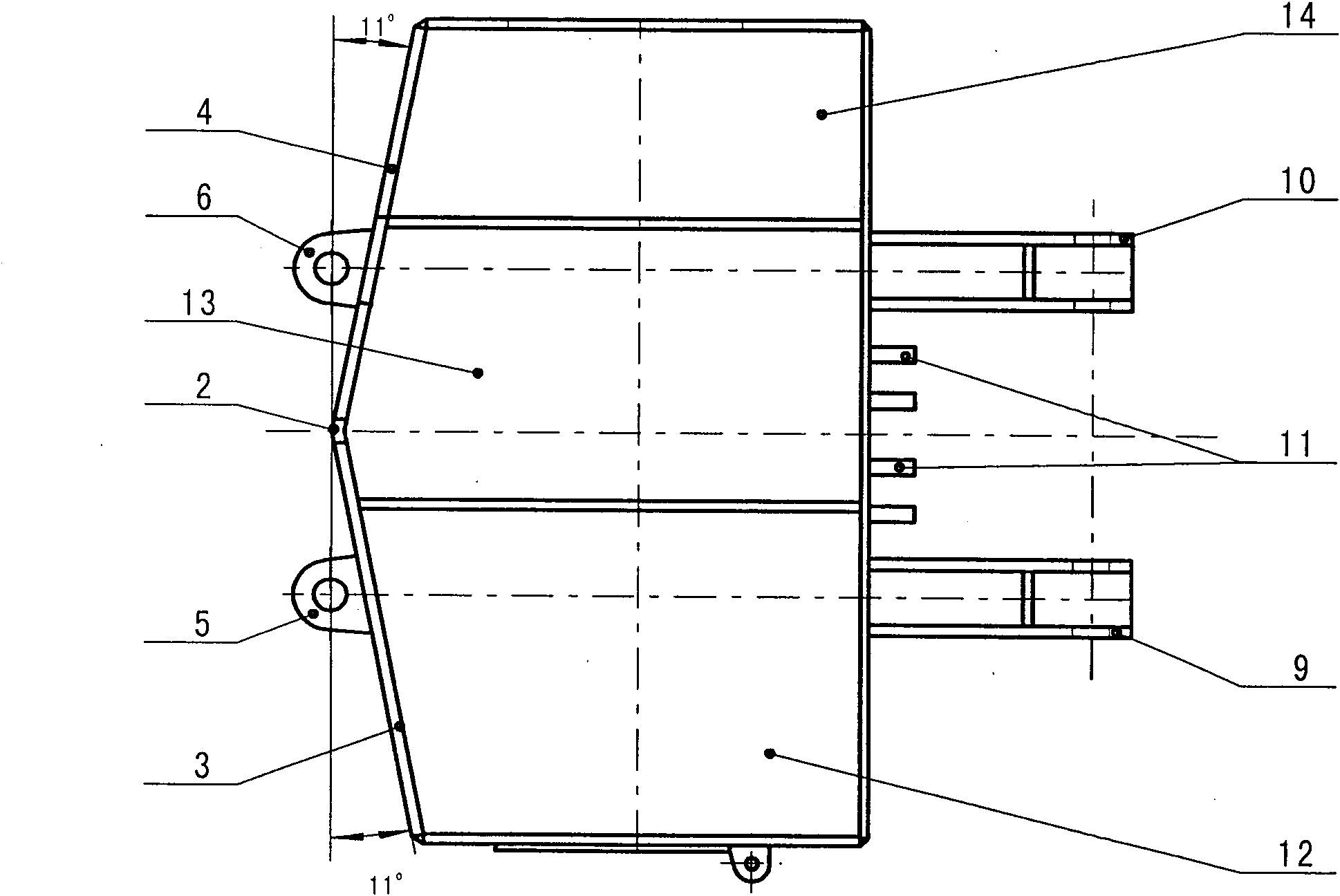

Coal removal device of crawler walking hydraulic support

The invention relates to a coal removal device of crawler walking hydraulic support. The main structure of the coal removal device comprises a case, a flow distribution plate, left and right push plates, a case door, a cover plate, a connecting plate, a positioning plate, a traction ear, a clapboard, left and right case cavities, an electrical control mechanism, a cable rolling mechanism, a cable frame, a hydraulic mechanism and pin bores. The device is designed according to the actual situation of shortwall coal mining under the coal mine and the structural features of the hydraulic support and makes full use of limited space of the support; the coal removal device is provided at the front part of the support base; meanwhile, the electrical control mechanism, the cable rolling mechanism and the hydraulic mechanism are arranged in the case of the coal removal device. Therefore, float coal, coal gangue and rock can be removed by the coal removal device at the front part during walking, and all mechanisms in the case run normally; and thus, ground obstacles in alleys can be removed and all mechanisms are not damaged. The device has advanced and reasonable design, compact structure, and is safe, stable and reliable, and also has a multi-use case; and the device removes obstacles fast and conveniently, rolls cables automatically and lays cables fast and thus is an ideal coal removal device of the hydraulic support.

Owner:TAIYUAN INST OF COAL SCI RES INST +1

Torsion frame punching-riveting connecting device and punching-riveting forming structure of machining piece of torsion frame punching-riveting connecting device

ActiveCN104858317APrecise location of punching riveting connection pointsNo looseningMetal-working feeding devicesPositioning devicesPunchingEngineering

The invention discloses a torsion frame punching-riveting connecting device and a punching-riveting forming structure of a machining piece of the torsion frame punching-riveting connecting device. The punching-riveting connecting device is mainly characterized in that the punching-riveting connecting device comprises a transmission component and punching-riveting components and has the advantages that the structure is advanced; the punching-riveting quality is good; the production efficiency is high. According to the punching-riveting forming structure of the machining piece of the torsion frame punching-riveting connecting device, a punching head and a bottom forming die are driven by punching-riveting liquid / a pneumatic assembly, and the punching-riveting forming structure is formed through one-time punching-riveting and has the advantages that rivets are not needed, and riveting is firm.

Owner:常州龙腾光热科技股份有限公司

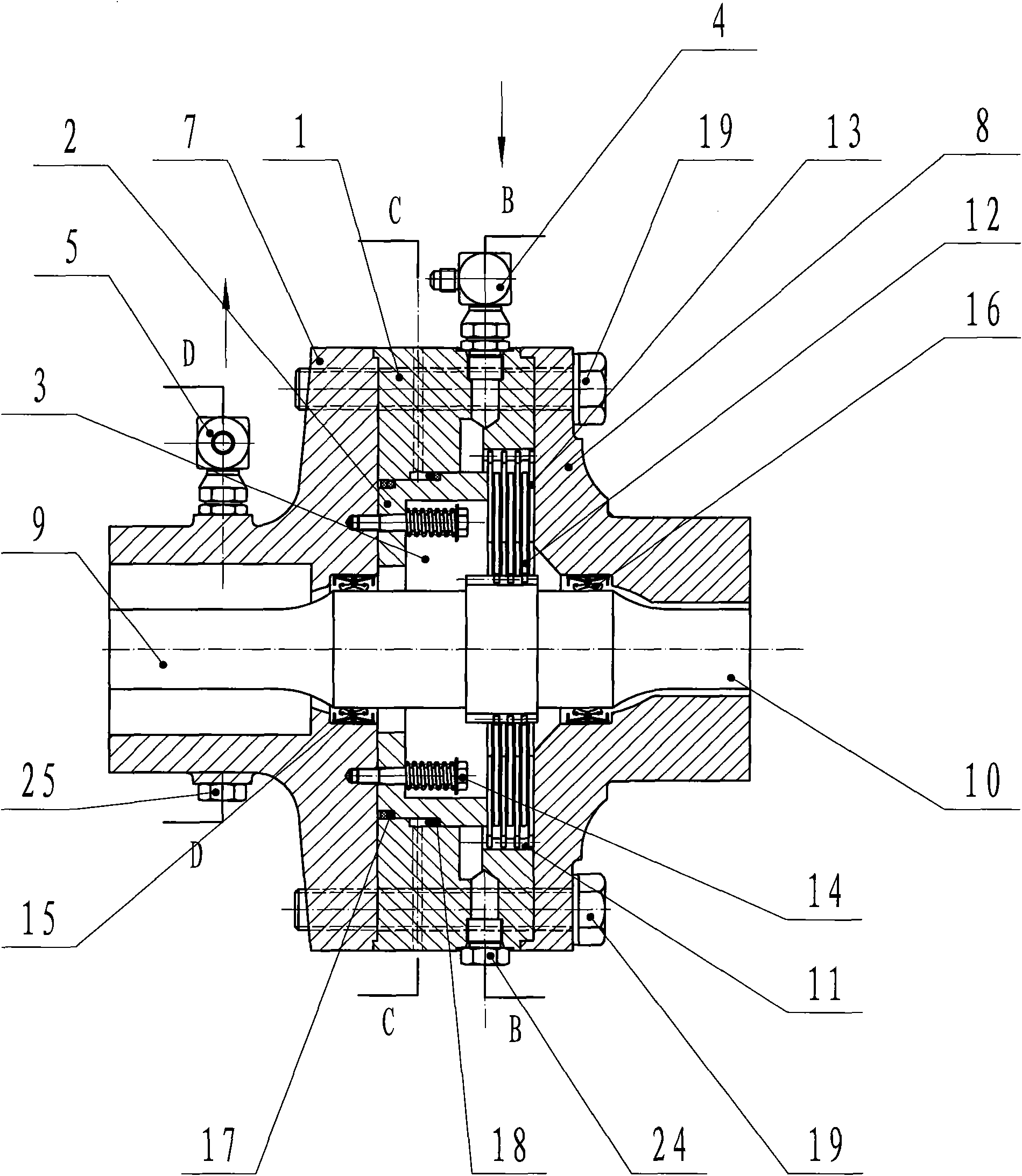

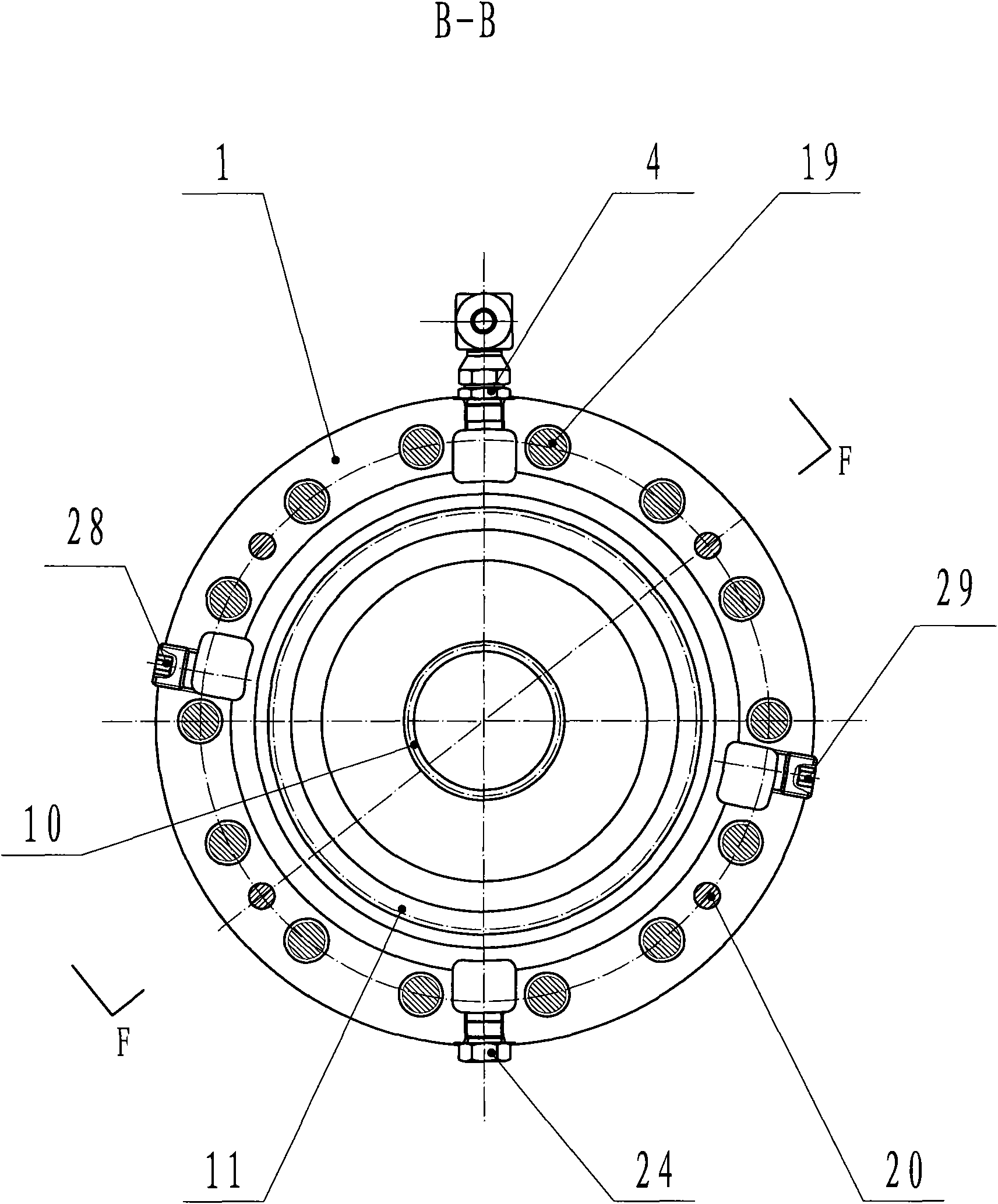

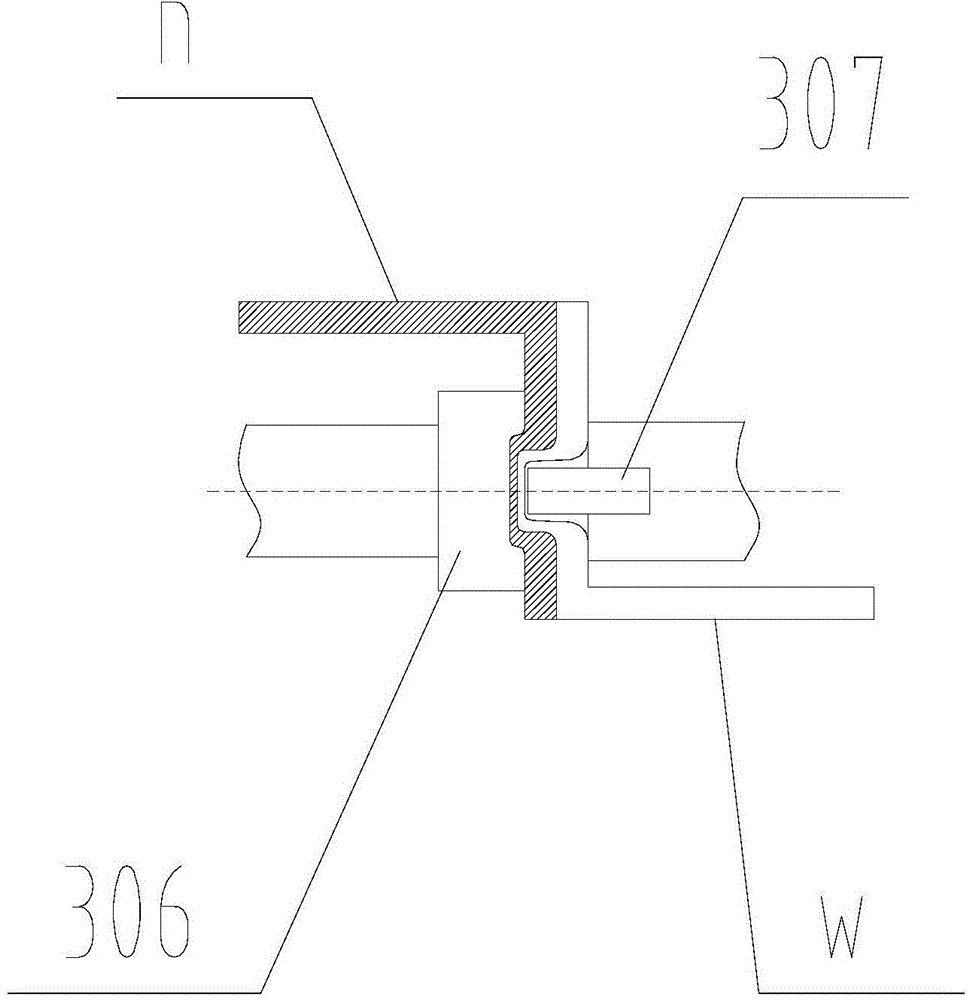

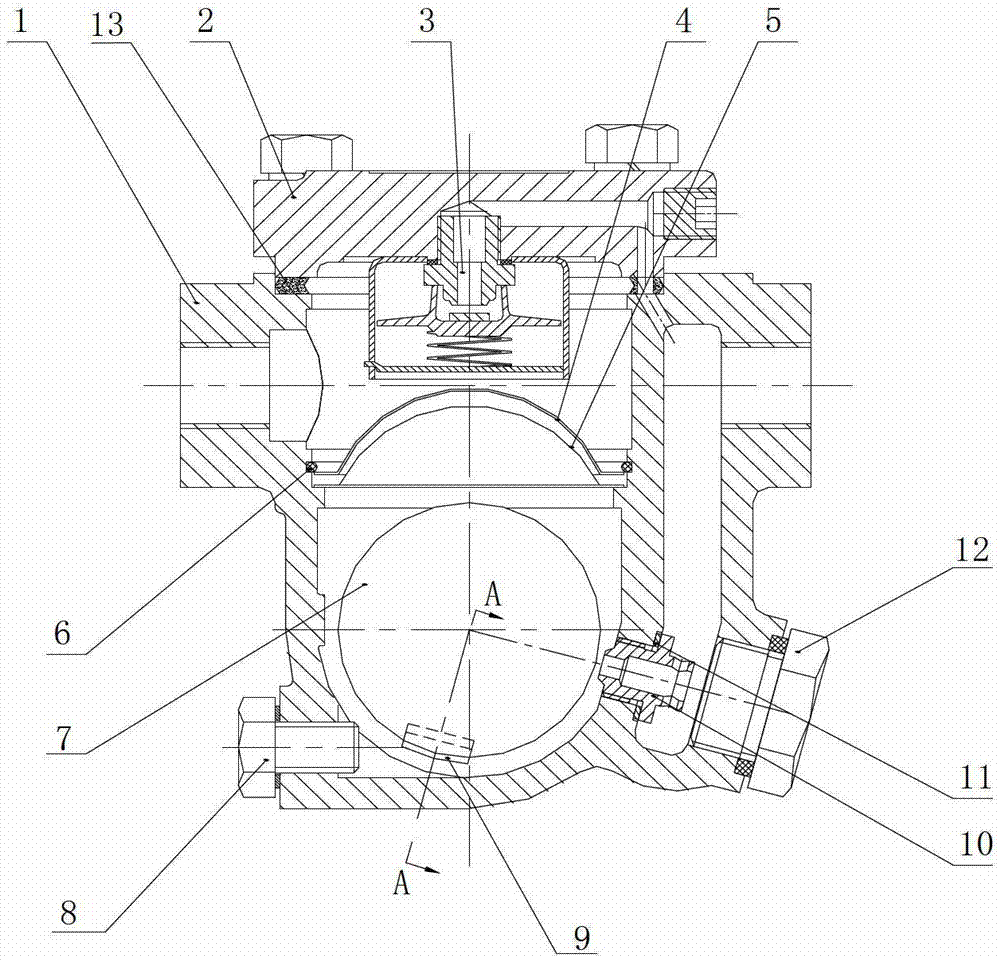

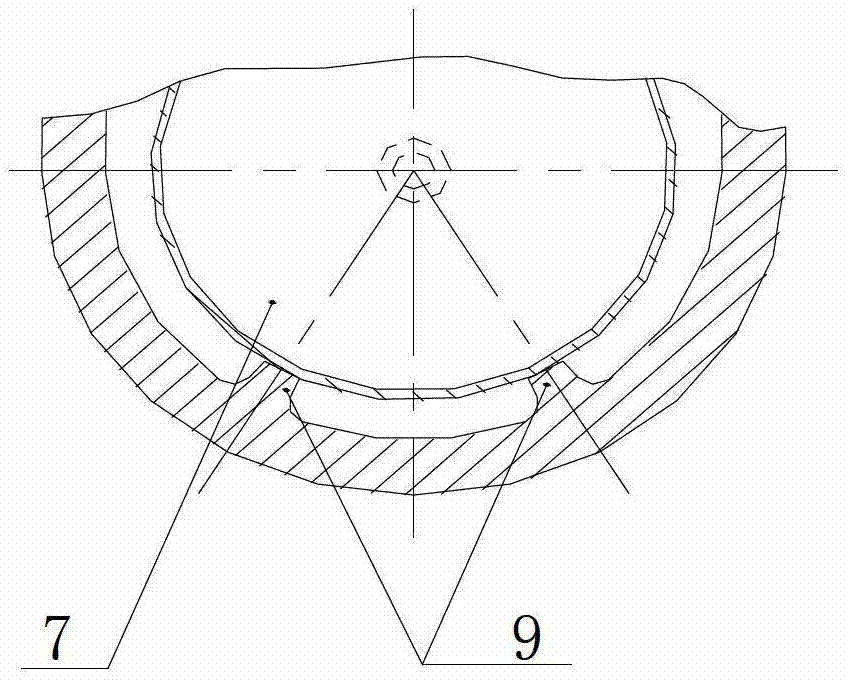

Guild rail type free float drain valve

The invention relates to a drain valve and provides a guild rail type free float drain valve which uses a three-point positioning sealing mode. The valve comprises a valve body, a valve cover, an air exhaust device, a filtering screen, a separating cover, a snap spring, a floating ball, a sewage draining bolt, a guild rail, a main valve seat, a main valve seat gasket and an outer plug, wherein the valve cover is installed at the upper end of the valve body, a wound gasket is arranged between the valve body and the valve cover, the air exhaust device is connected with a threaded hole of the lower end face of the valve cover, the floating ball is arranged in the inner cavity of the valve body, the separating cover and the filtering screen are respectively installed on a boss of the inner cavity of the valve body, the snap spring is pressed on the filtering screen and is arranged in a groove of the snap spring, the sewage draining bolt is sleeved in the wound gasket and is installed in a sewage draining threaded hole of the side lower end of the valve body, the guild rail is arranged on the two side surfaces of the bottom of a valve cavity and is connected with the valve body into a whole, an axle center of the guild rail and a main valve seat hole are coaxial, the cambered surface of the guild rail is the same as the radian of the outer diameter of the floating ball, the main valve seat is sleeved in the main valve seat gasket and is connected with the main valve seat threaded hole of the valve body, and the outer plug is sleeved in the wound gasket and is in threaded connection with the lower side end of the valve body.

Owner:洪新强

Dry wet-type drill box of anchor rod drill carriage

ActiveCN101737006BAvoid enteringAdvanced and reasonable structureGear lubrication/coolingAnchoring boltsHydraulic motorGear wheel

The invention relates to a dry wet-type drill box of an anchor rod drill carriage, which mainly consists of an upper box body, a lower box body, a transmission shaft, a drill bushing, a drill rod, a water seal, a locking disc, a lower end cover, a framework sealing seat, a floating seal, a hydraulic motor, a hydraulic motor connecting block, a liquid preparing plate, a hydraulic motor shaft gear,a transmission shaft gear and a bearing; wherein the drill box can be used in both a dry dedusting state and a wet dedusting state of the anchor rod drill carriage, and takes the cycloid hydraulic motor as power to drive the hydraulic motor shaft gear and the transmission shaft gear to rotate, thus driving the drill bushing and the drill rod to drill holes. By adopting full-sealing structure and combining framework seal, the floating seal, a sealing ring and the water seal, the drill box prevents dry-type boring dust from entering and prevents dust-containing water of wet-type atomizing boring dust removal from entering, thus leading the drill box to have drilling operation in a full-closed state. The drill box is advanced and reasonable in design, compact in structure, convenient in use and installation, safe, stable and reliable, and has dual purposes of dry and wet dust removal and good universality, thus being an ideal drill box of the anchor rod drill carriage and used on similarequipment.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

Vertical core material woven fabric

ActiveCN103789905BSimple processIncrease production capacitySynthetic resin layered productsWoven fabricsGlass fiberType distribution

Owner:CHANGZHOU YUECHENG NEW MATERIAL

Flexible thin-film solar photoelectric cell and large-scale continuous automatic production method thereof

ActiveCN102110732BQuality improvementIncrease conversion rateFinal product manufactureVacuum evaporation coatingIndiumTitanium oxide

The invention provides a flexible thin-film solar photoelectric cell and a large-scale continuous automatic production method thereof. The solar photoelectric cell comprises an antireflection layer, a transparent upper electrode layer, an isolating layer, a window layer, a protective layer, an absorbing layer, a reflecting layer, a metal back electrode layer, an insulating layer, a substrate layer and a solder flux layer in sequence. The material of the antireflection layer is magnesium fluoride, the material of the transparent upper electrode layer is aluminum zinc oxide, the material of the isolating layer is intrinsic zinc oxide, the material of the window layer is zinc sulfide, the material of the protective layer is sulfur or zinc, the material of the absorbing layer is CIGS (copper indium gallium diselenide) or CIAS (copper indium aluminum diselenide), the material of the reflecting layer is aluminum, the material of the metal back electrode layer is copper-molybdenum-sodium alloy, the material of the insulating layer is titanium oxide, and the material of the substrate layer is stainless steel, copper, aluminum foil or polyimide film. The production method of the flexible thin-film solar photoelectric cell comprises sputtering layer by layer in a closed environment on a continuous automatic production line through a plurality of sputtering methods to form a multilayer structure. The large-scale continuous automatic production method provided by the invention has the advantages of high efficiency, high quality, and low cost.

Owner:江苏航天之光新能源装备有限公司

Pressure pot cover opened through cooperation of fingers of one hand

ActiveCN101961205BAdvanced and reasonable structureBeautiful shapePressure-cookersRight thumbEngineering

The invention relates to a pressure pot cover opened through the cooperation of fingers of one hand, belonging to the field of pressure pots. The pressure pot cover is divided into a pot and cover separated type or a pot and cover connected type. The pressure pot cover comprises a push block (1) and a pull block (3) made into a crab shell shape or a strip shape, one of the push block or the pull block is fixed on the edge of a metal cover (2), and the other one can relatively rotate around the center of the metal cover. When the push block is fixed on the metal cover, the push block jacked with the right thumb, the pull block is pressed with other fingers, the metal cover is clockwise rotated by the cooperation of the fingers, and the pot cover is simultaneously taken out or turned and hung onto the pot body incidentally. When the pull block is fixed on the metal cover, the push block is jacked with the right thumb, the pull block is pressed with other fingers, the metal cover is anticlockwise rotated by the cooperation of the fingers, and the pot cover is simultaneously taken out or turned and hung onto the pot body incidentally. The structure and the operating method of the pressure pot cover are reasonable and advanced.

Owner:方展崇

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com