Patents

Literature

33 results about "Swather" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A swather, or windrower, is a farm implement that cuts hay or small grain crops and forms them into a windrow. "Swather" is predominantly the North American term for these machines. In Australia and other parts of the world, they are called "windrowers". They aid harvesting by speeding up the process of drying the crop down to a moisture content suitable for harvesting and storage.

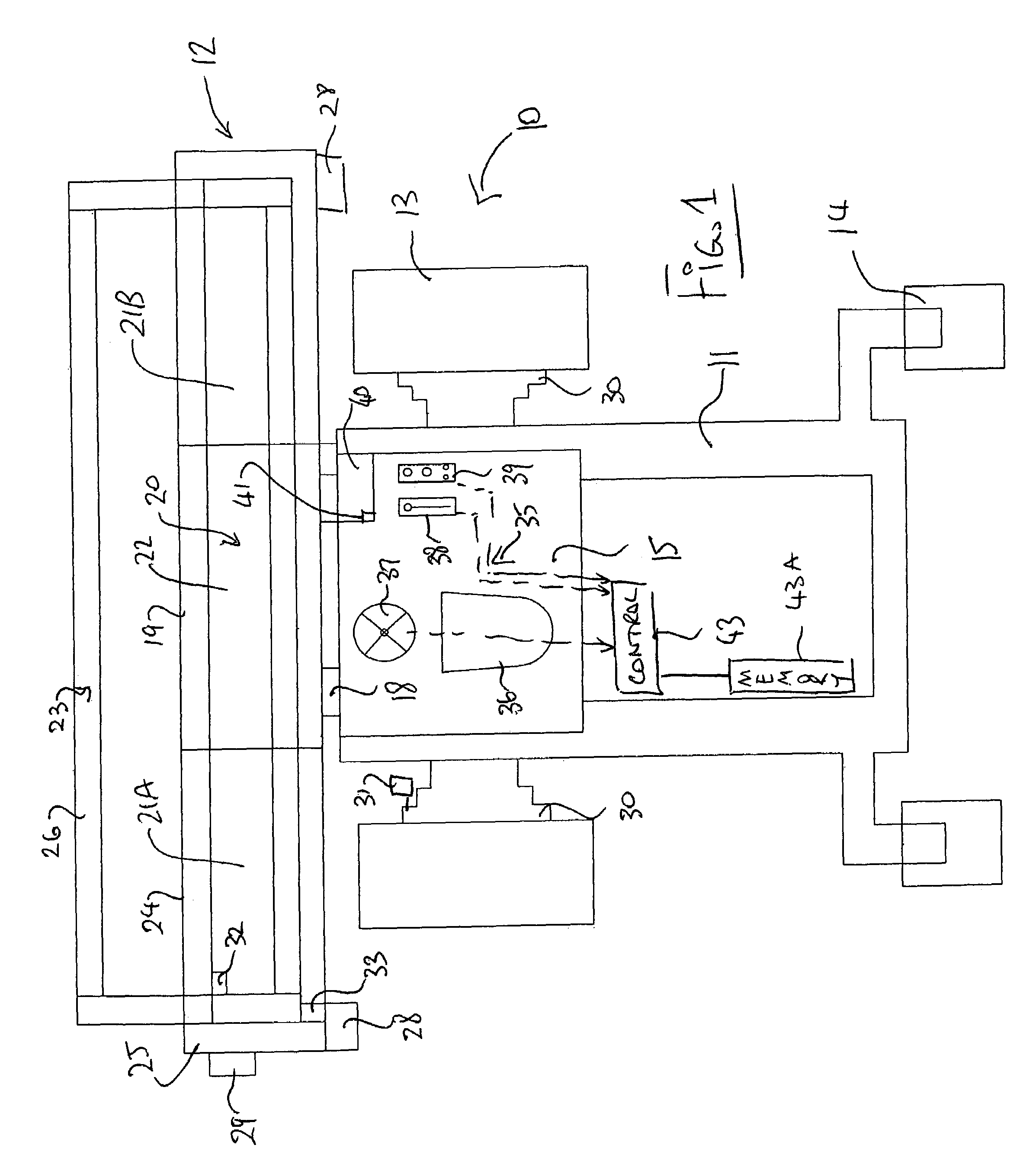

Crop cutting header with speed control of driven element using valve profiling

In a swather formed by a tractor and attached header for cutting standing crop to form a swath, reel speed and optionally draper speed are controlled relative to ground speed by a control system including a manually operable input and display available to the operator. The control system acts to calibrate” the control output so that the control module has a secondary reference point as to how the PWM valve should function in the event of a speed sensor failure. Instead of using the speed sensor signal as a reference, the control system now compares the set point with the stored table (which may in one example provide 256 values) containing the PWM voltage / current values. These values correspond to a set of actual speed sensor values taken during the profiling procedure, plus extrapolated values equalling 256 points.

Owner:MACDON INDS

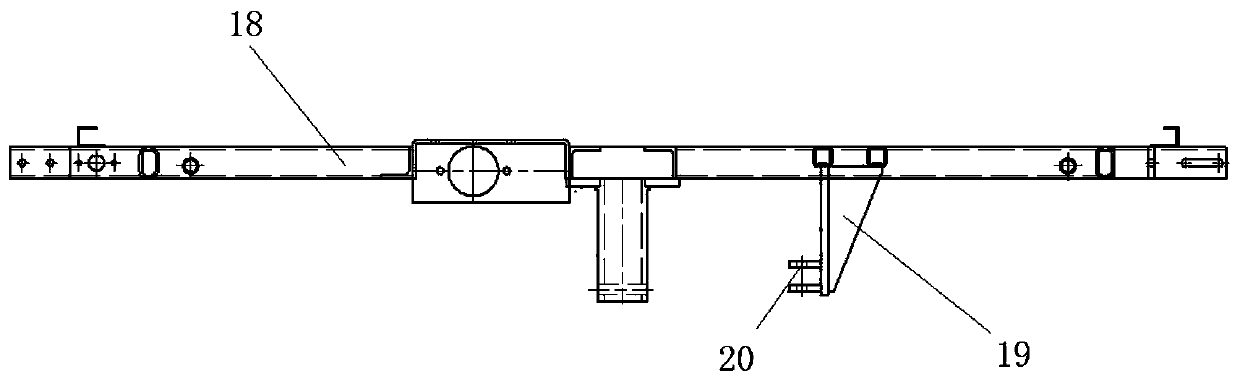

Header transport

Owner:MACDON INDS

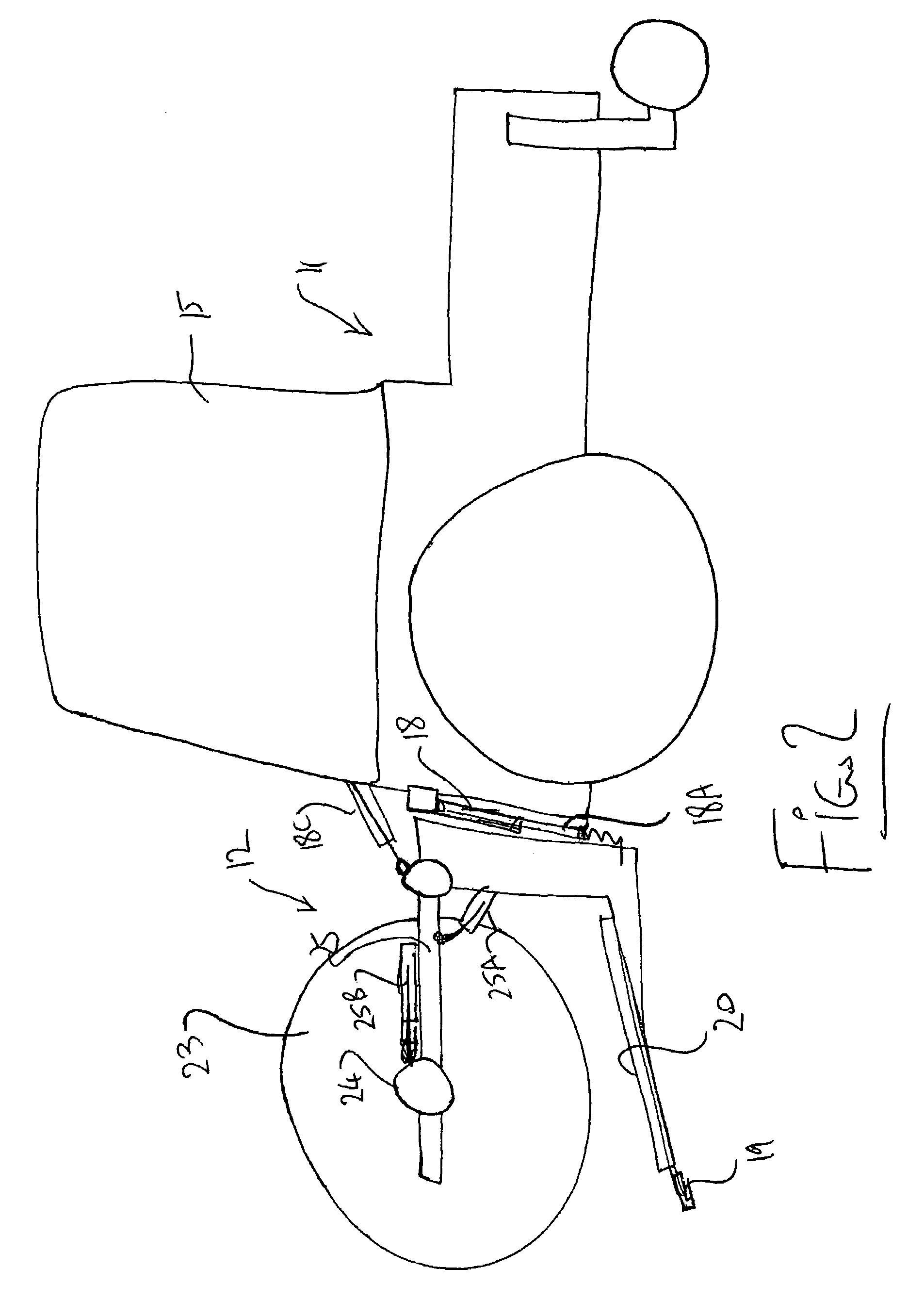

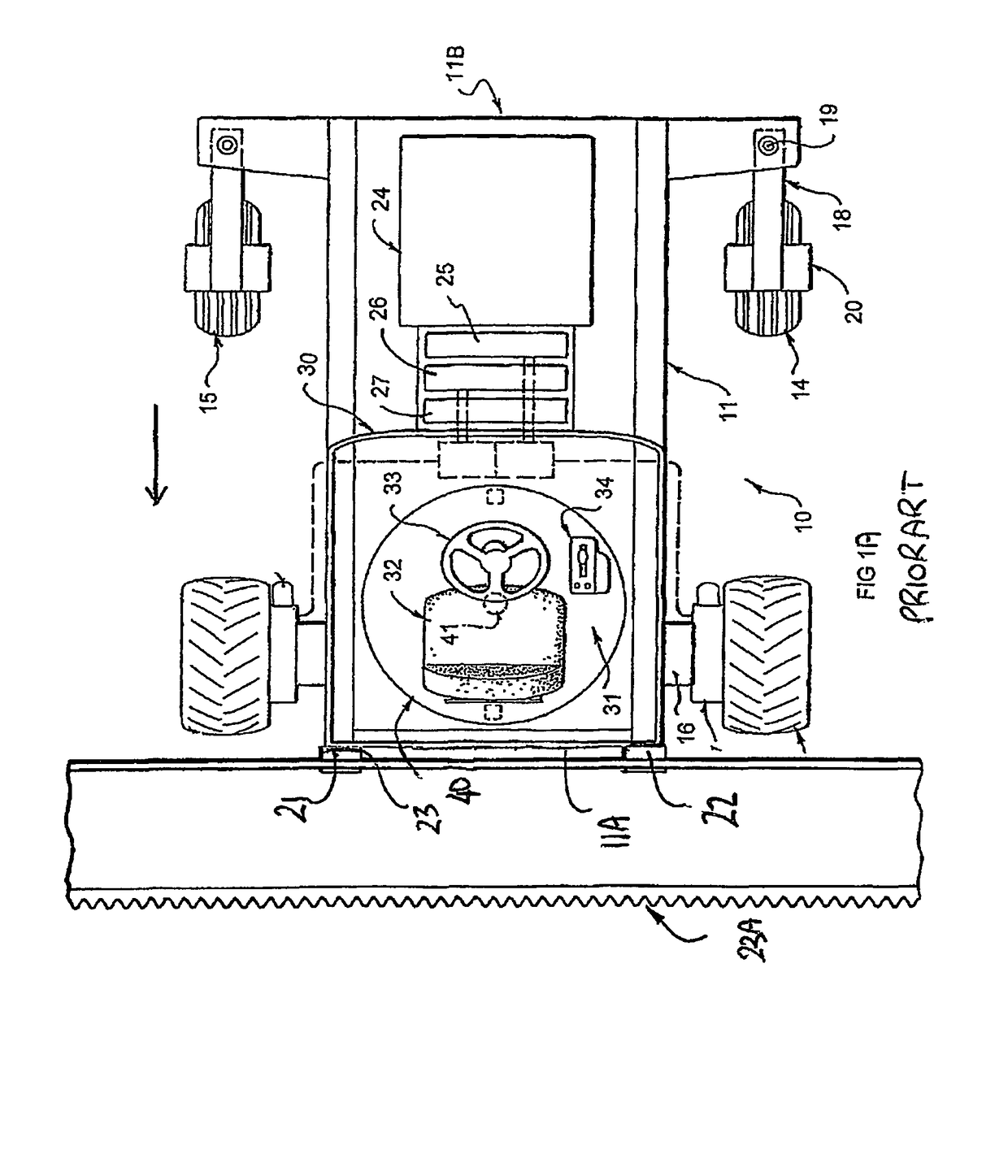

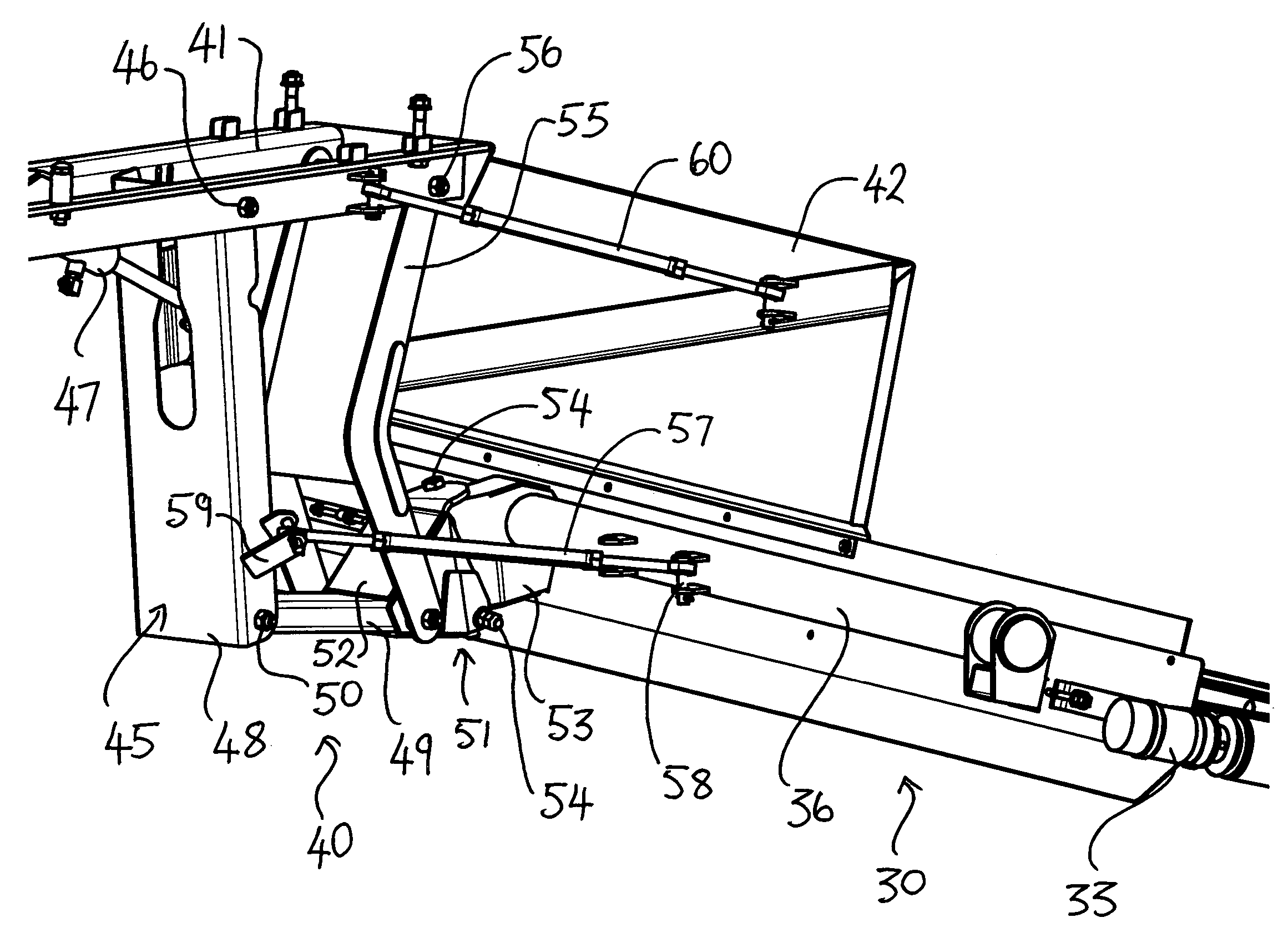

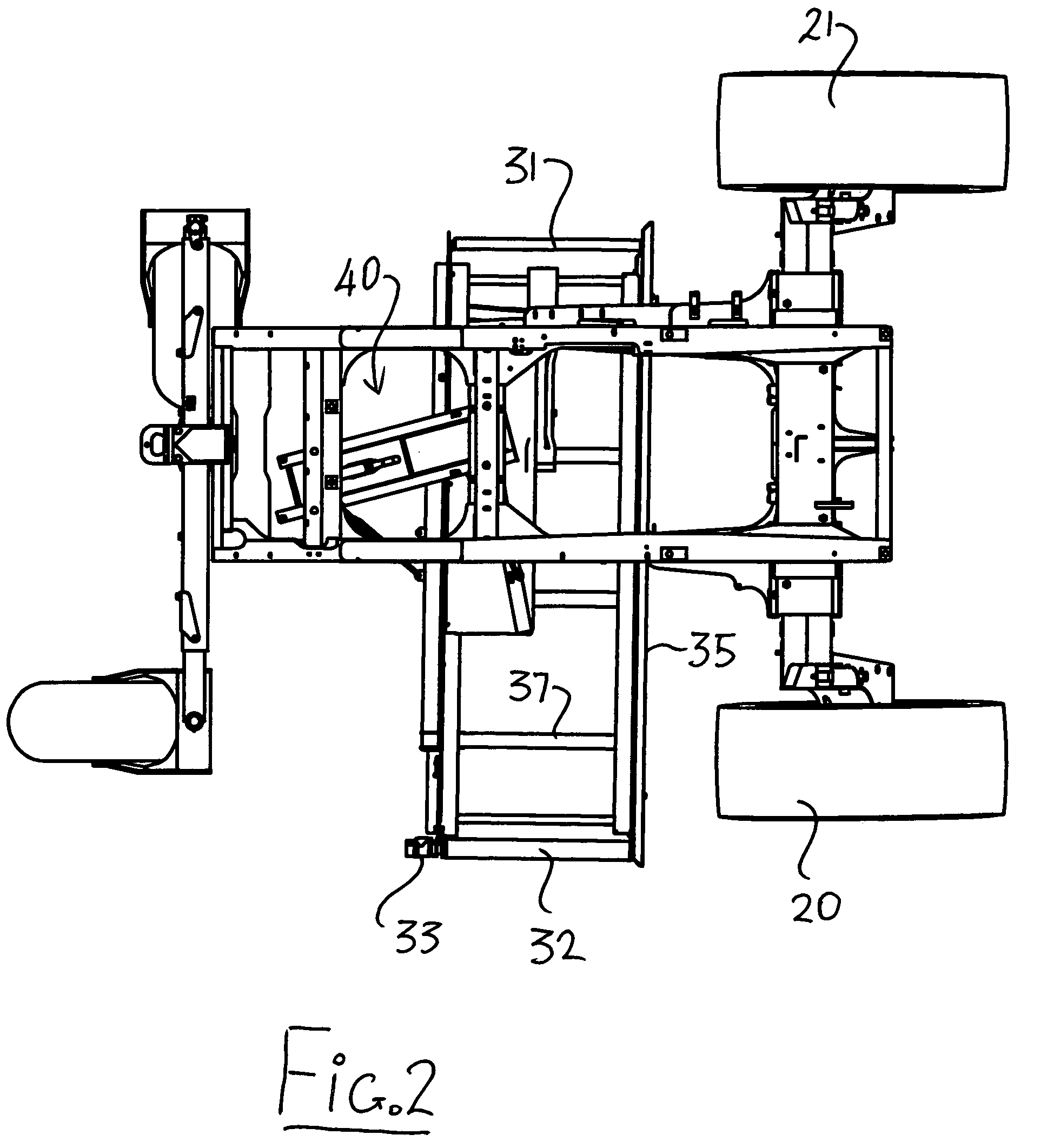

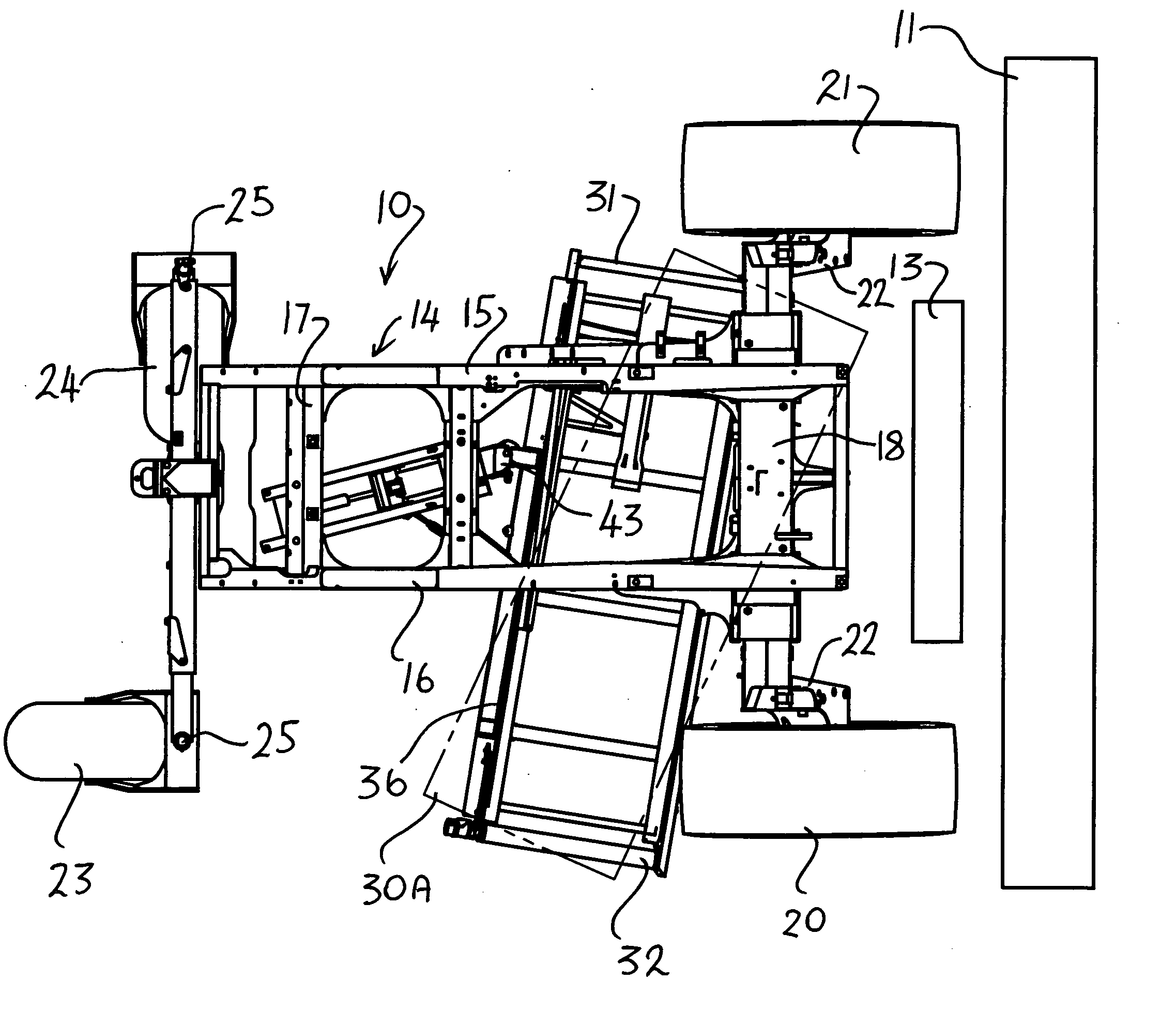

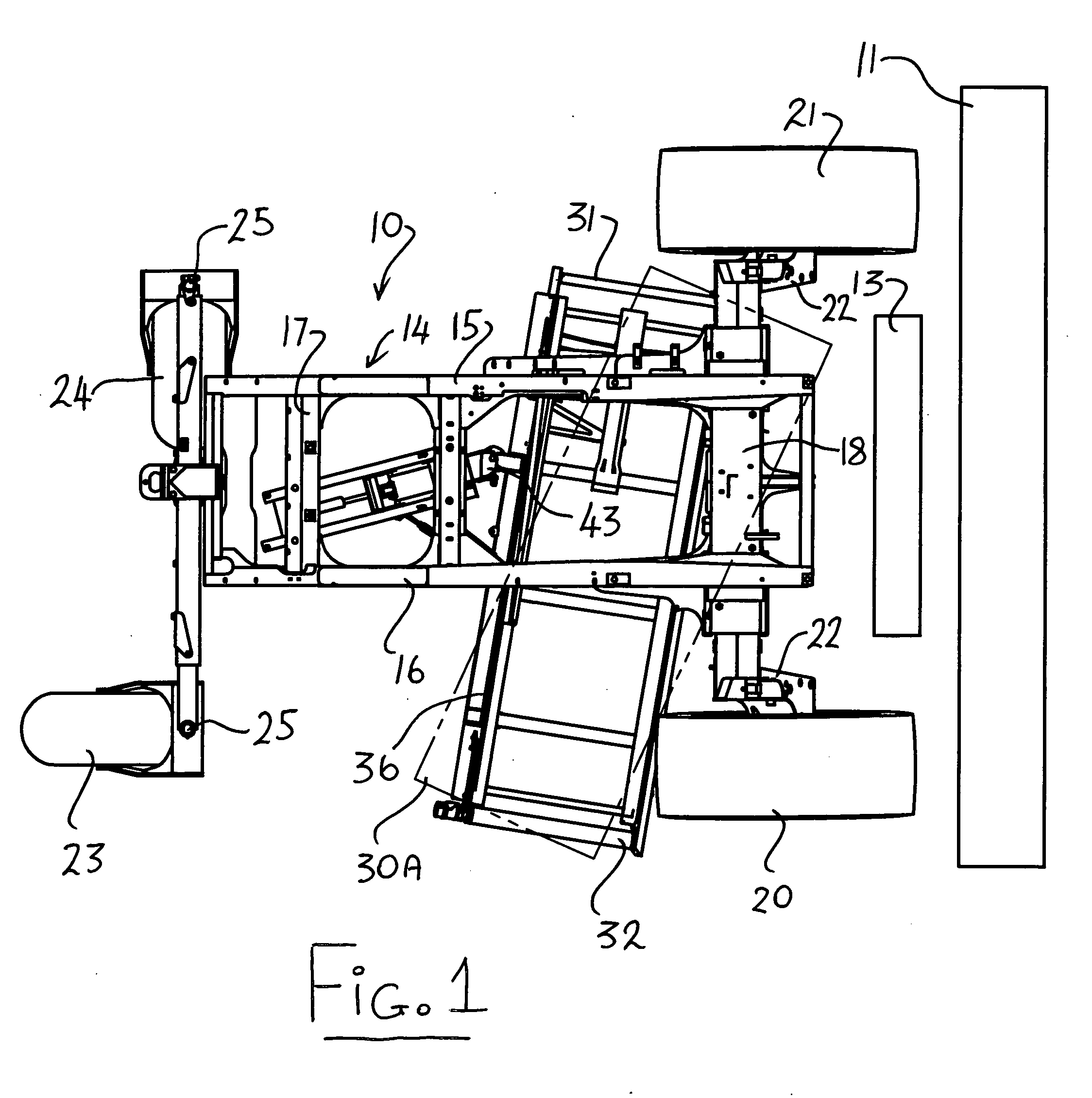

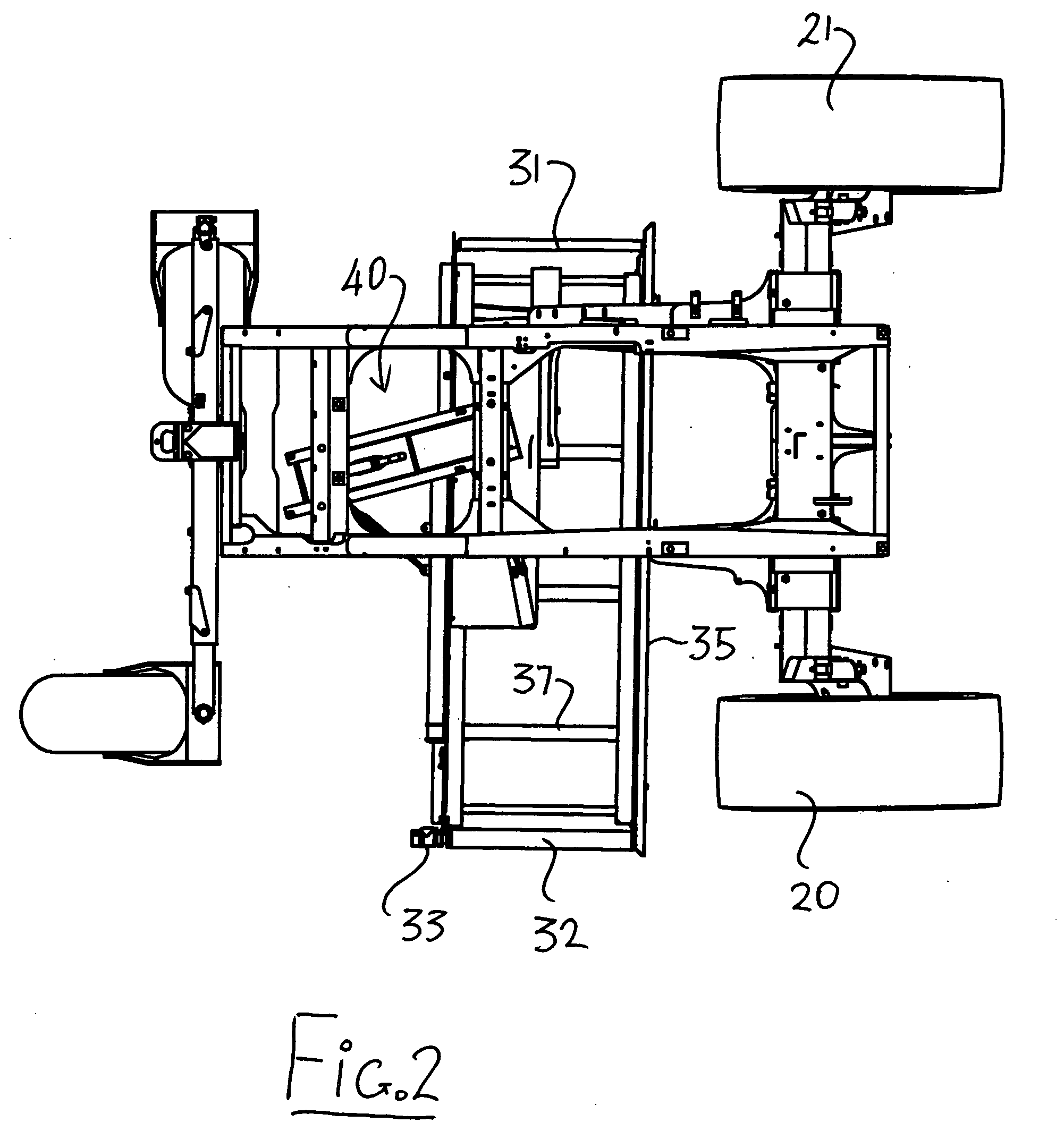

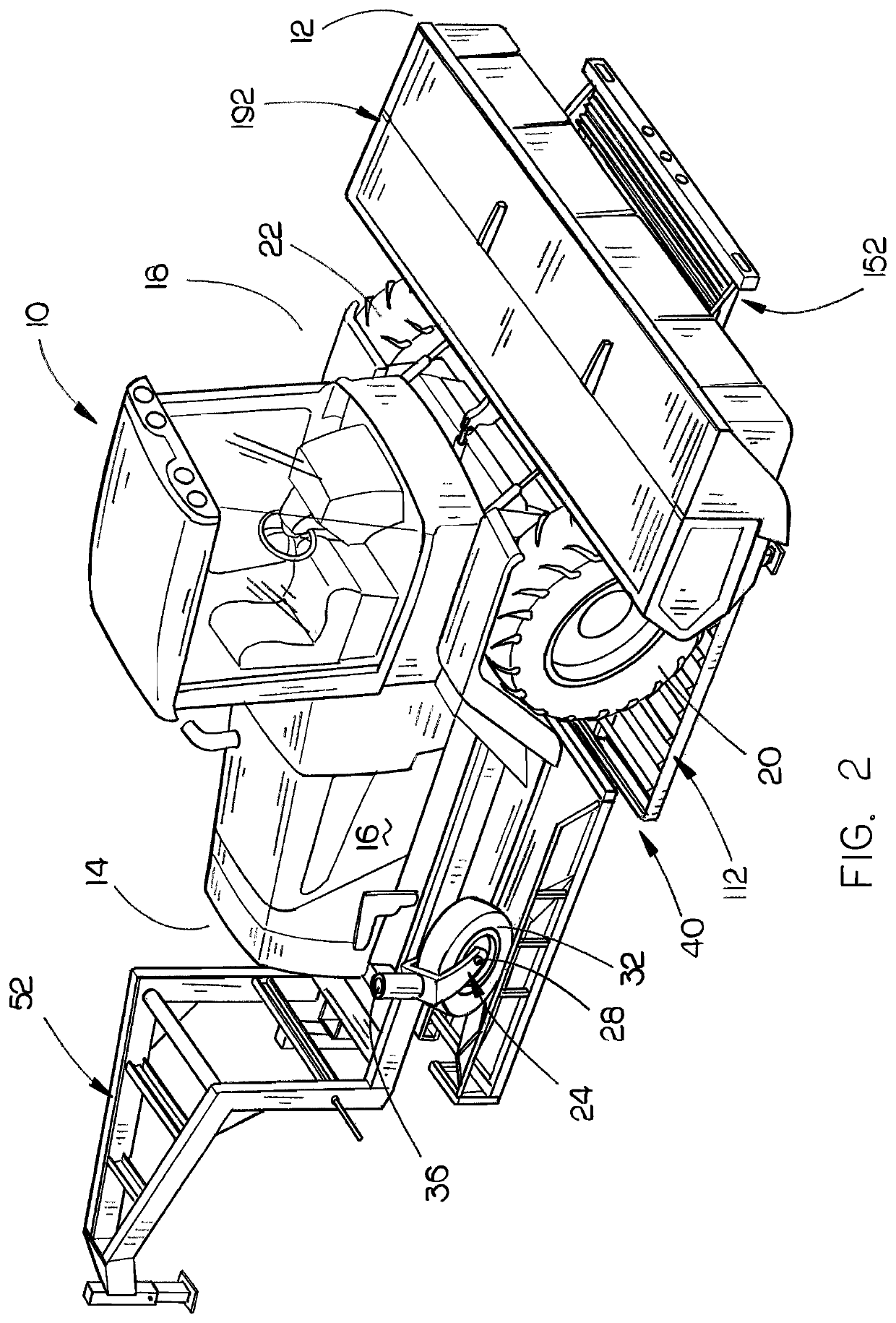

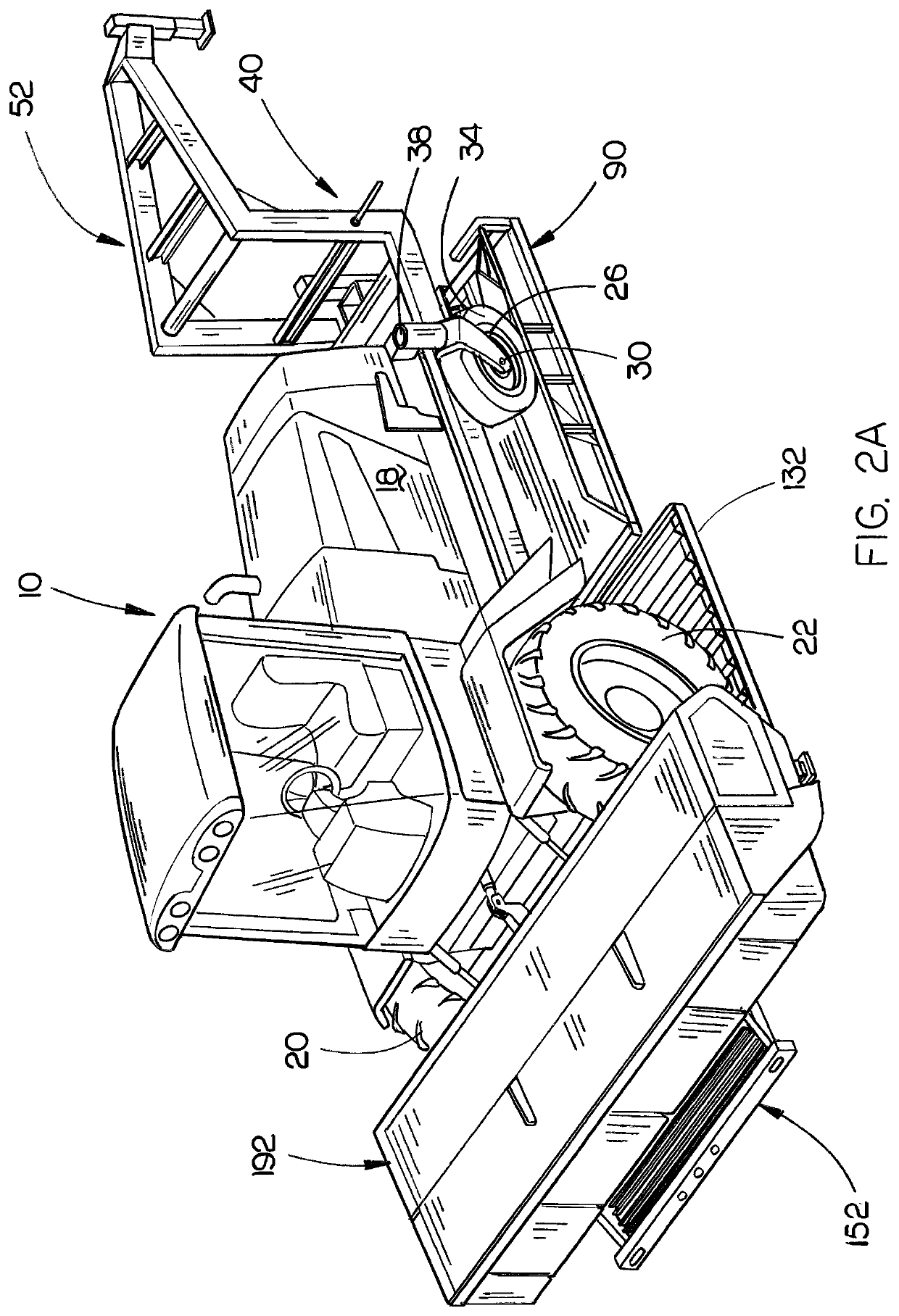

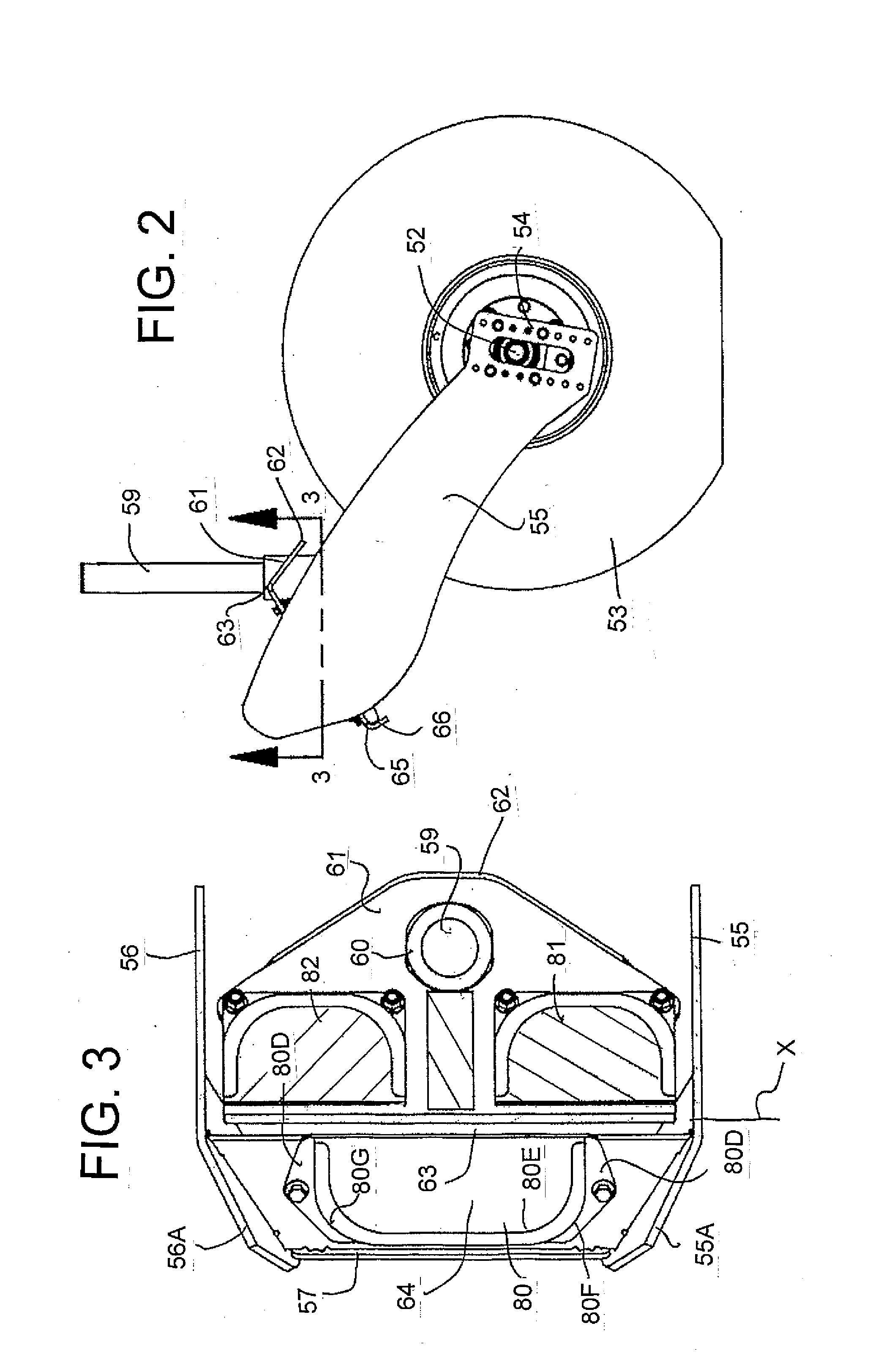

Operating and storage positions of a swather conveyor

A self-propelled swather has a frame mounted on ground wheels with a header in front which discharges between the wheels. A swath conveyor belt is located underneath the frame and arranged to convey the cut crop across the frame to a first discharge side of the frame. A mounting assembly including a beam across the belt and a lift arm mounts the swath conveyor for movement between a raised storage position in which the belt is horizontal underneath the frame and a lowered operating position in which the belt is inclined forwardly and downwardly while at the same time causing the beam to twist to cause the inlet end of the belt to move forwardly further than the discharge end to a forwardly inclined position between the front wheels.

Owner:MACDON INDS

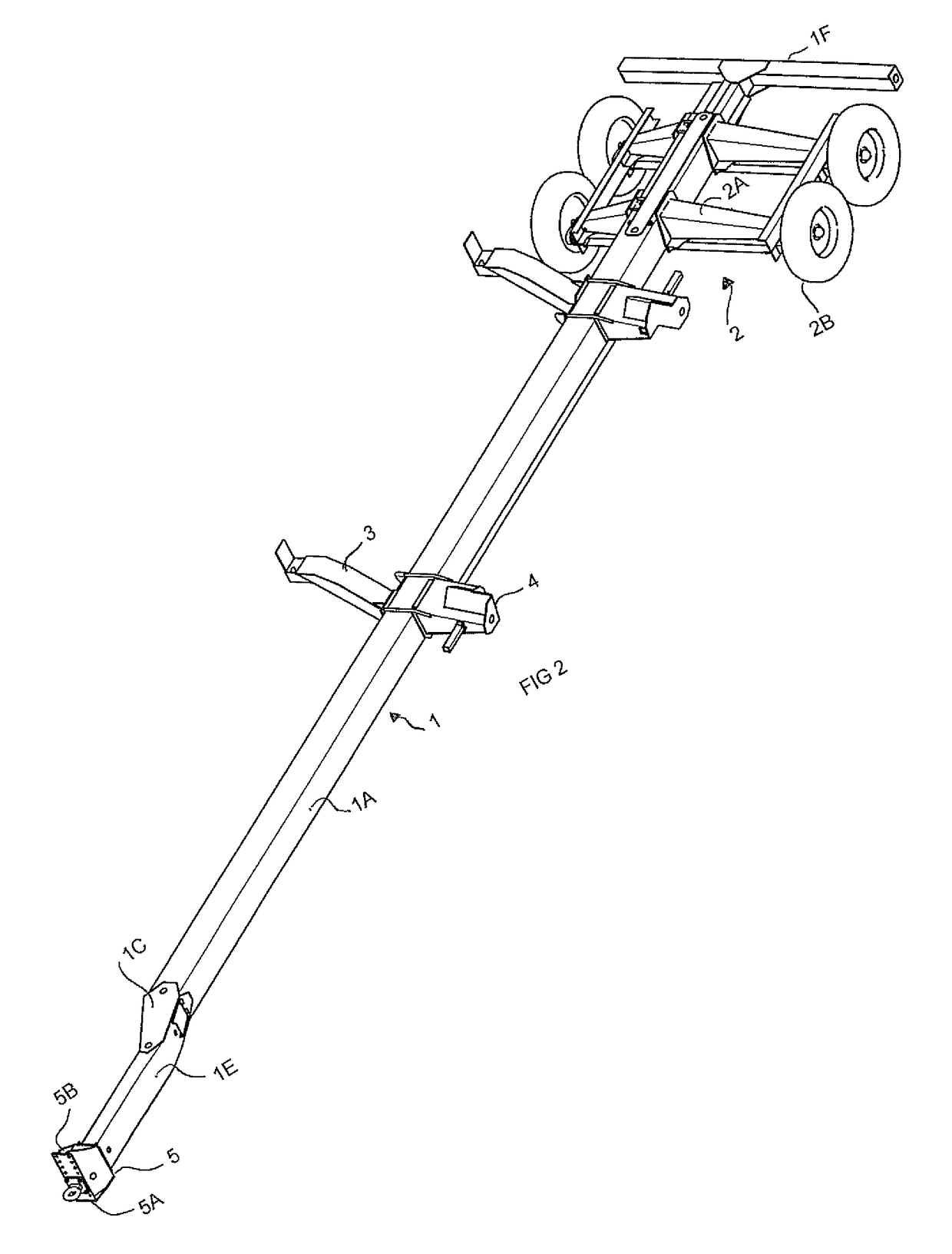

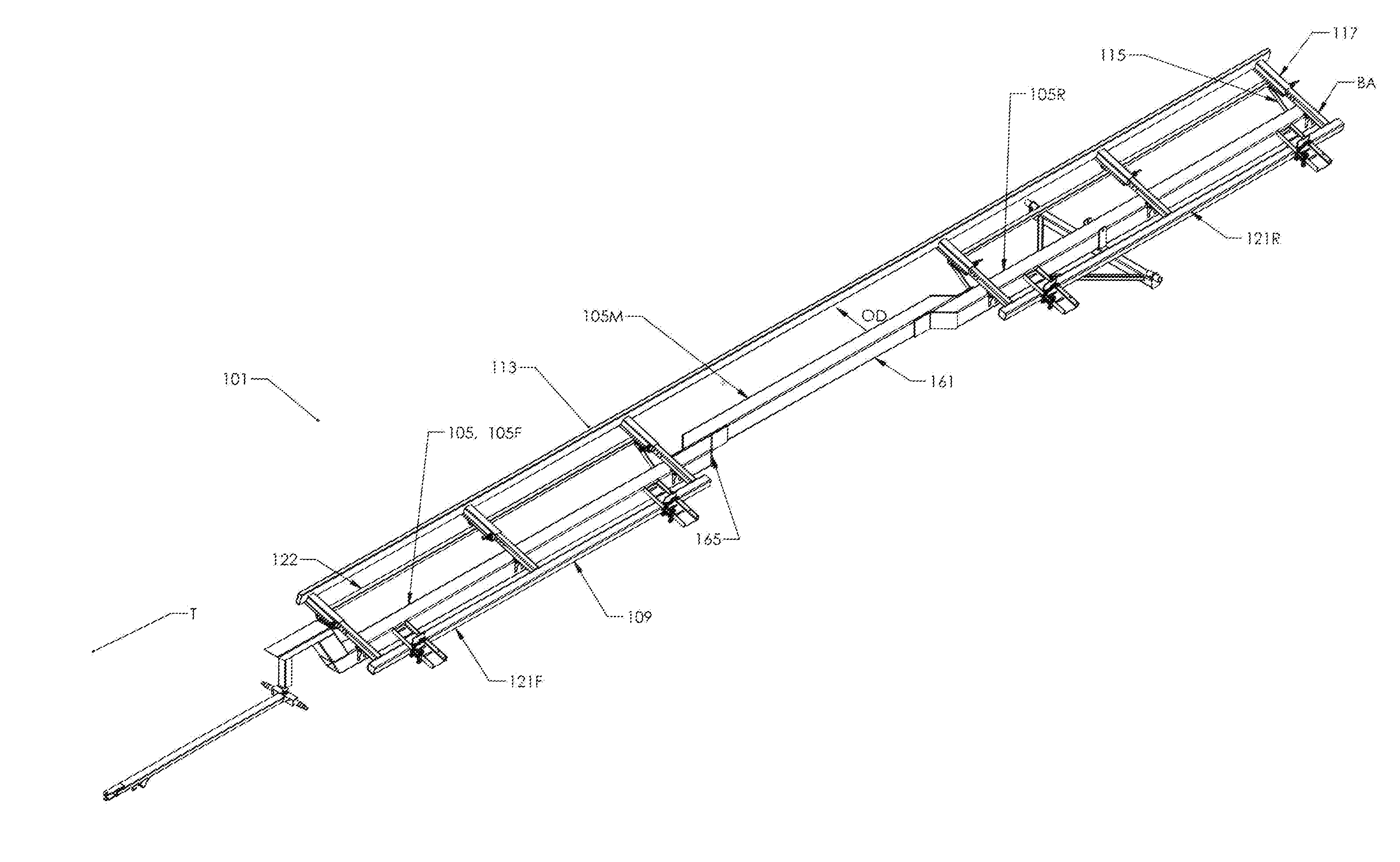

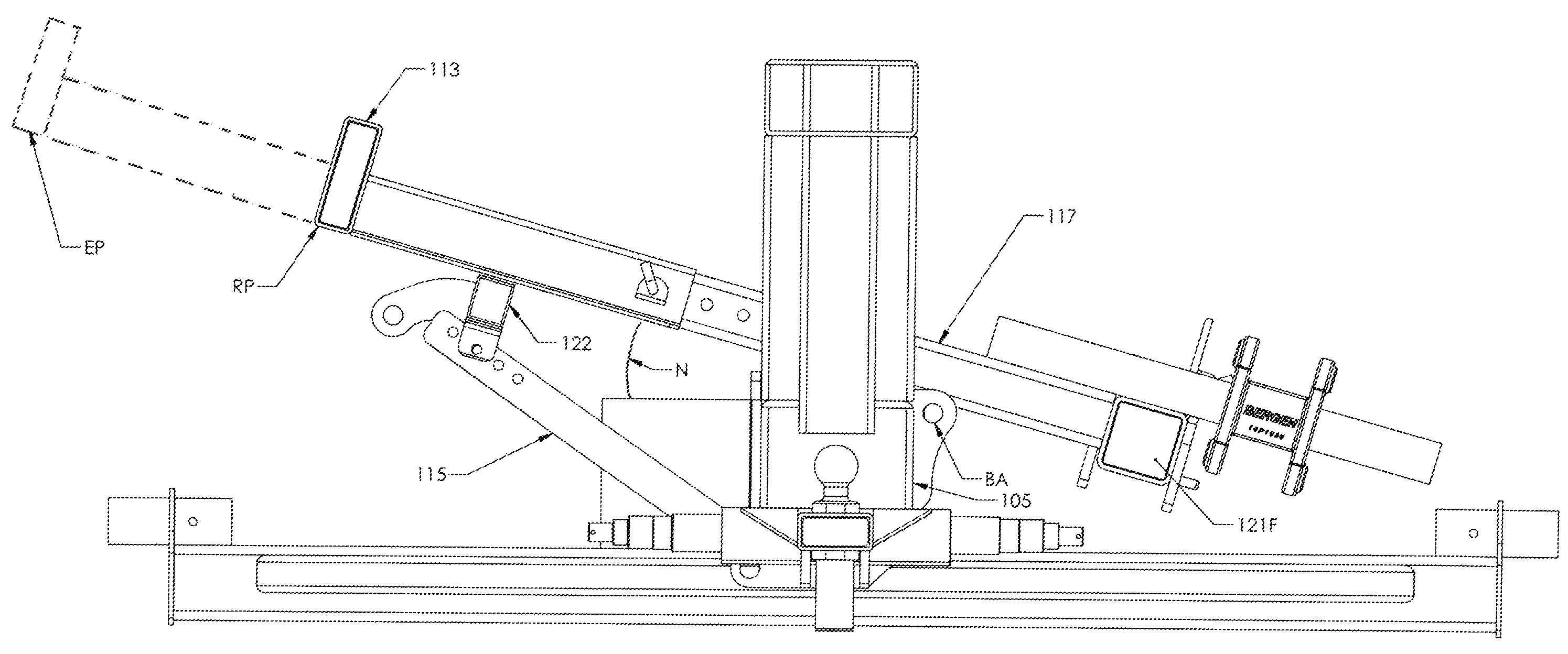

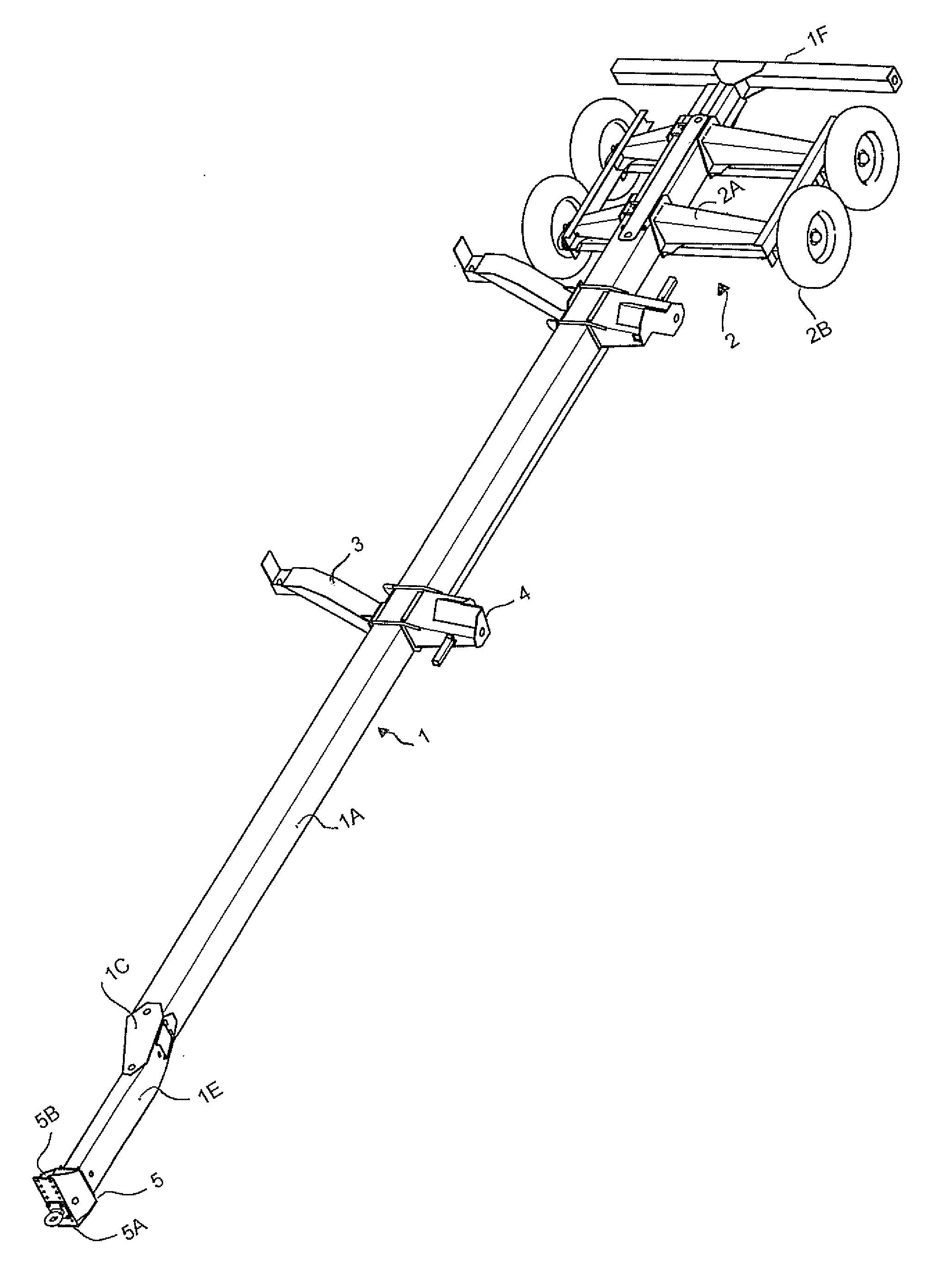

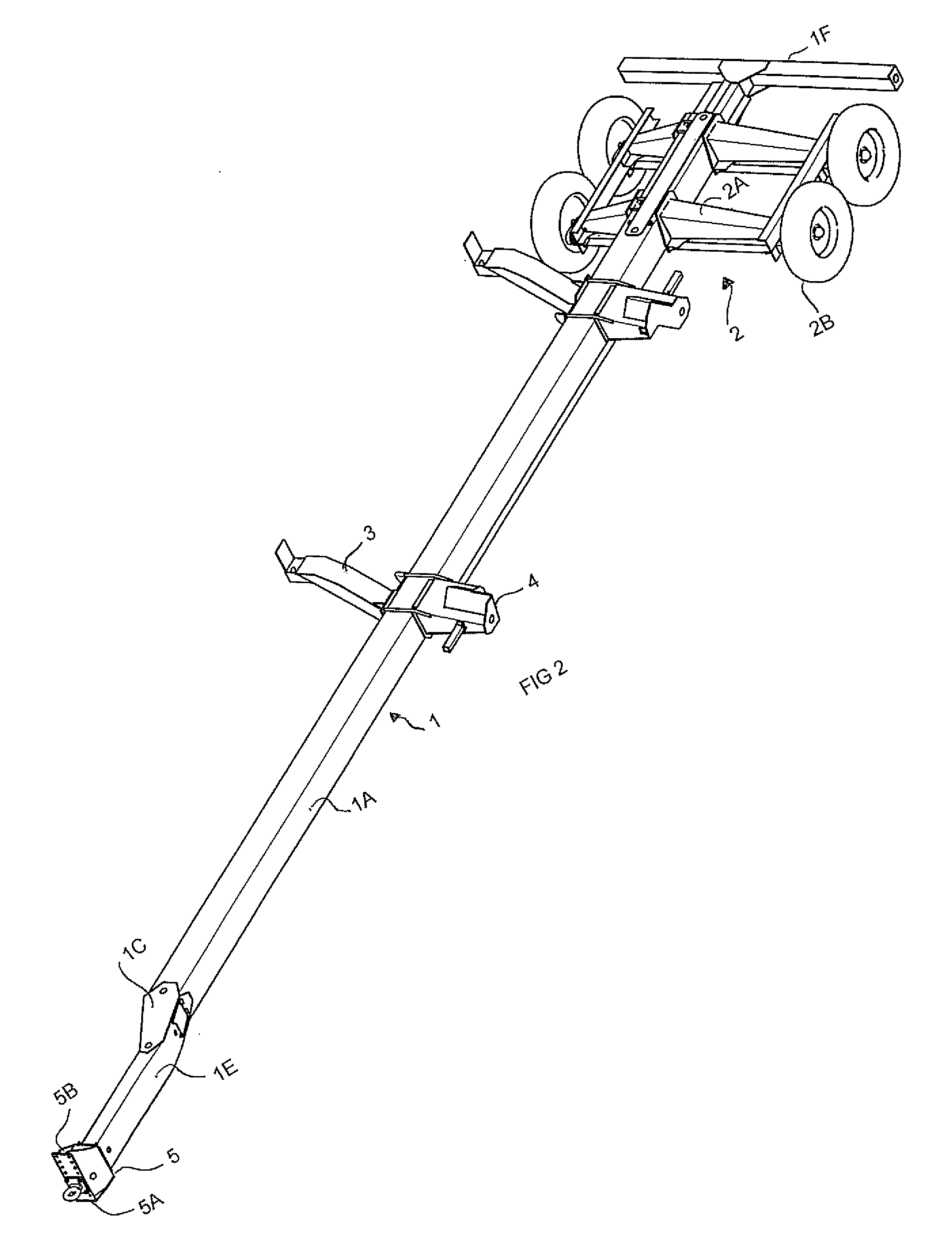

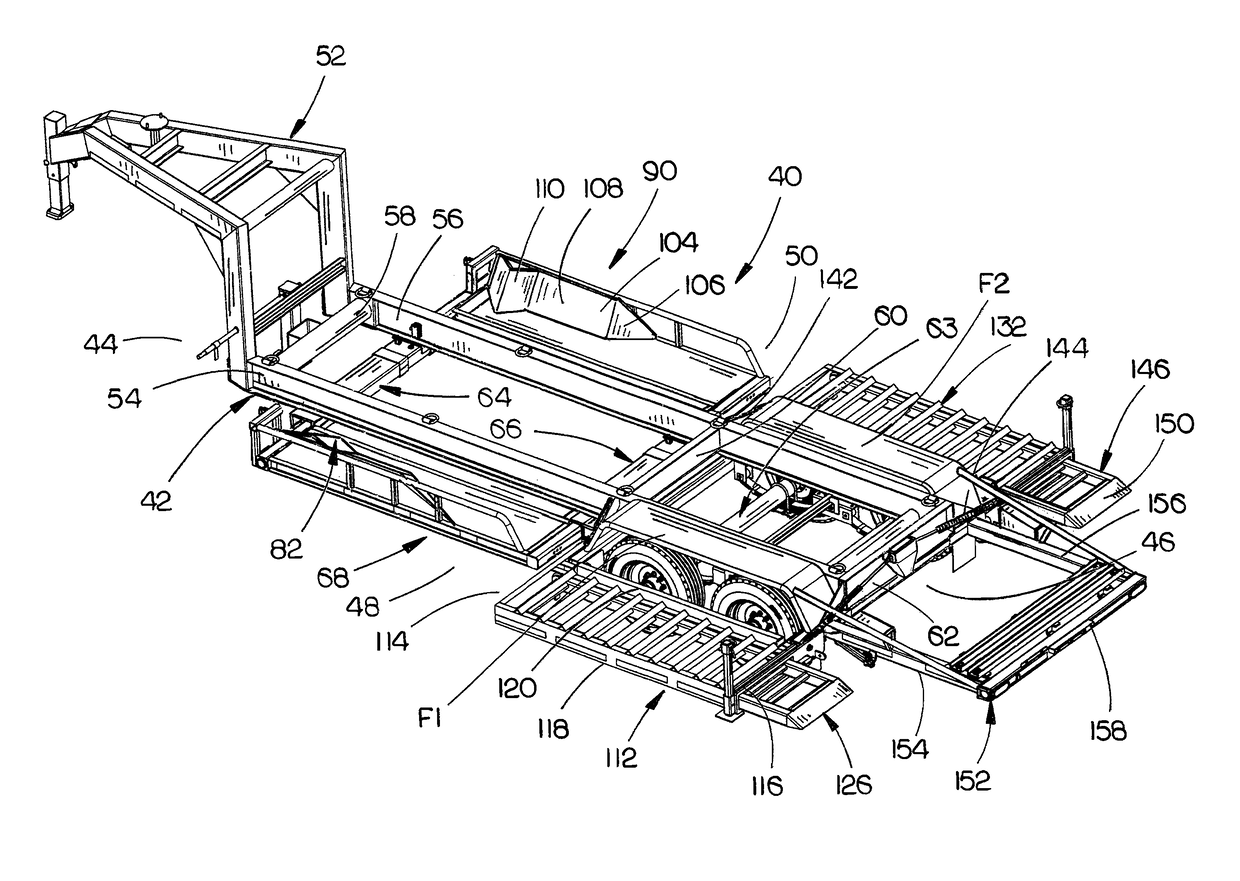

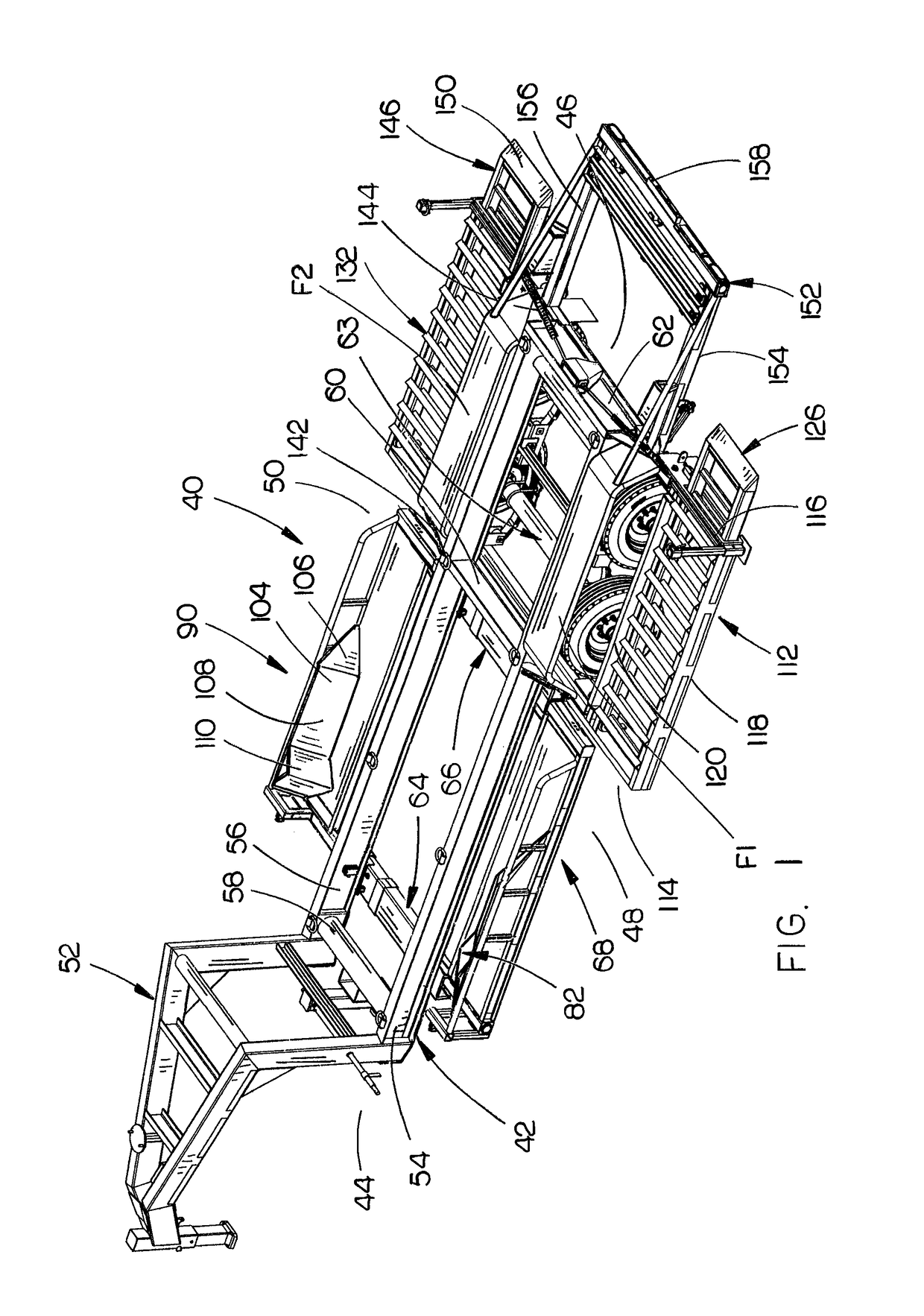

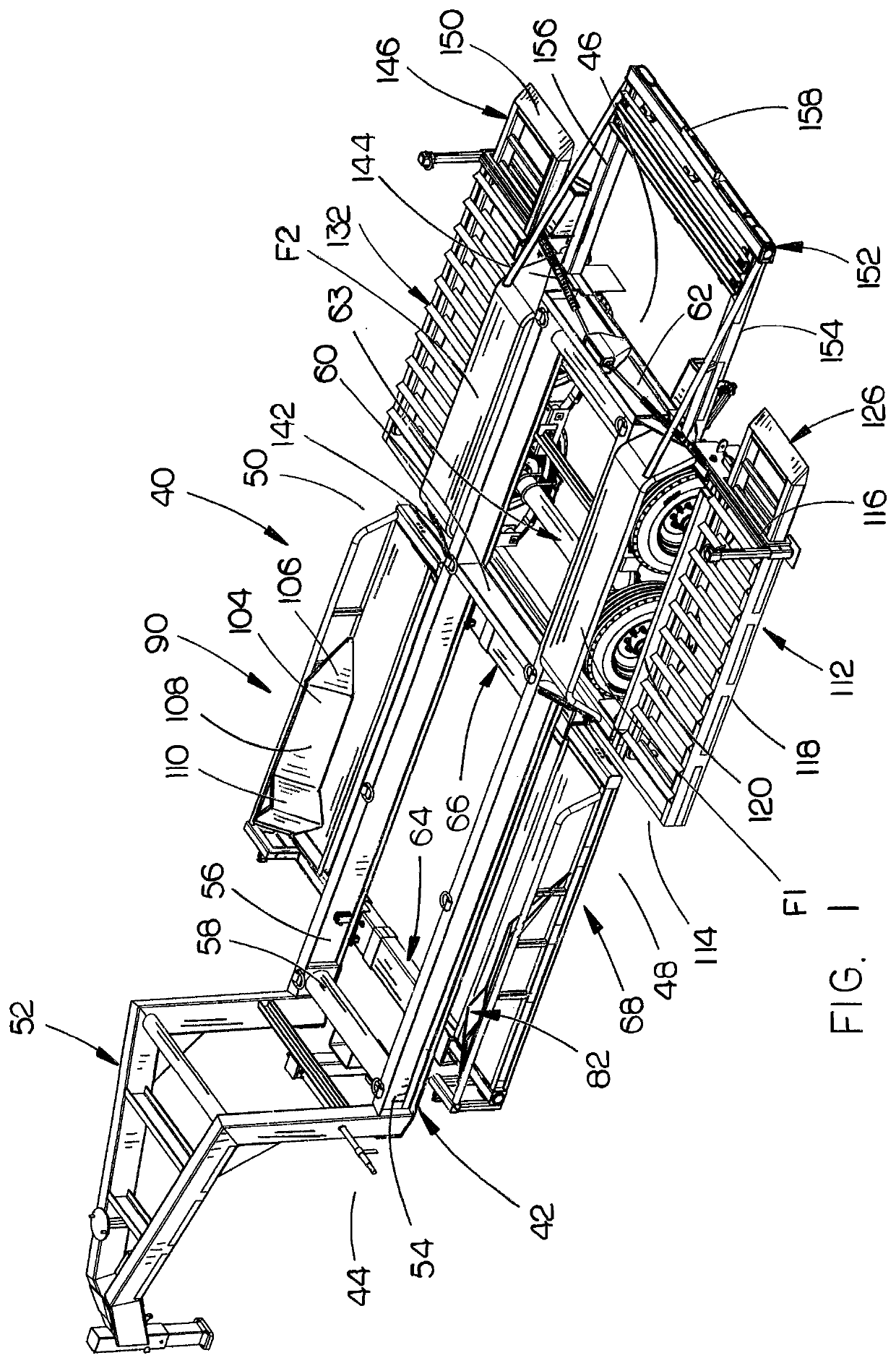

Header trailer

InactiveUS20110176882A1Reduce distanceEasy loading and unloadingHarvestersVehicle to carry long loadsEngineeringTroffer

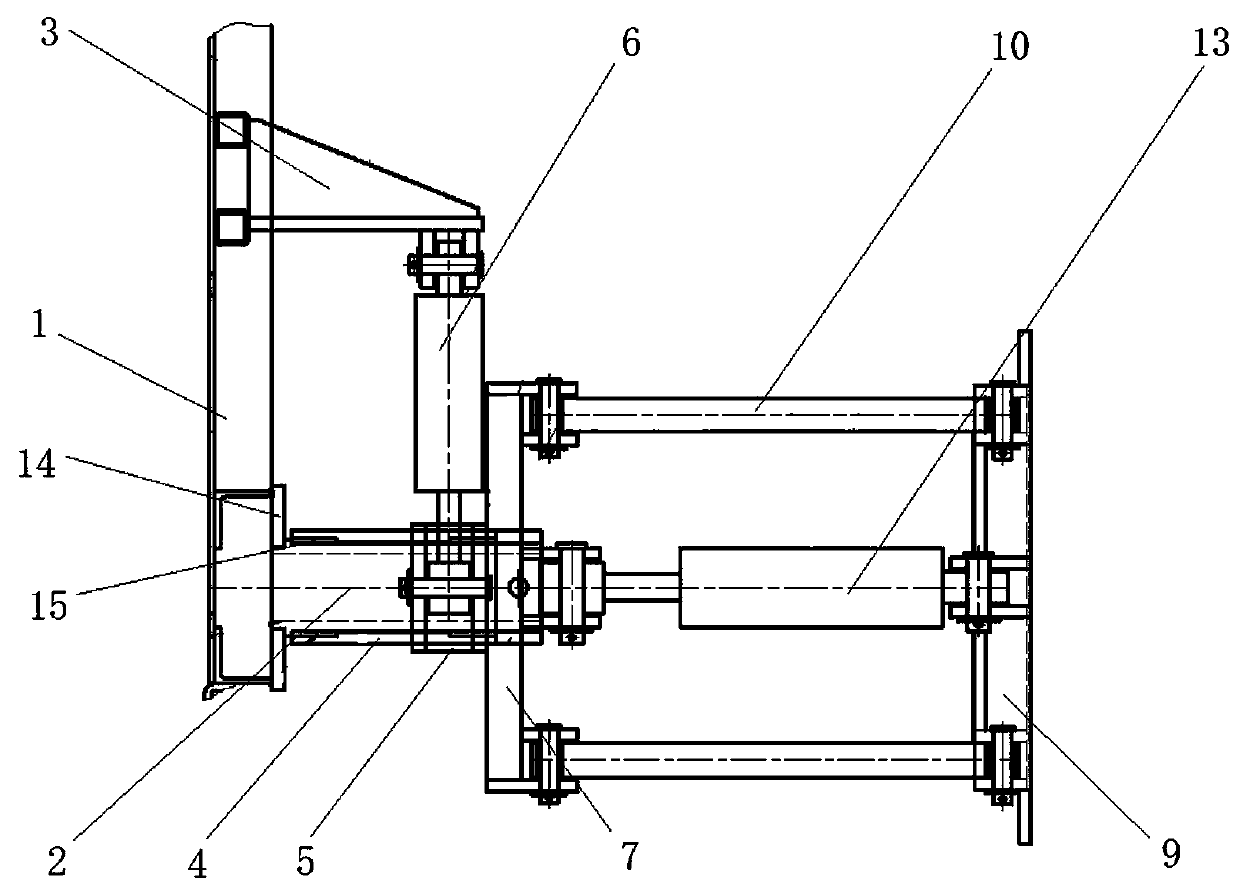

A trailer apparatus for transporting a harvest header has a main beam on wheels. A bed assembly is pivotally attached to the main beam above the main beam such that when one side of the bed assembly moves up, an opposite side moves down. The bed assembly is supported at a desired tilt angle by adjustable tilt. The bed assembly includes a movable side extension along one side that is movable through a range from an extended position to a retracted position and can be releasably locked in the range. The tilt angle can be adjusted independently of the position of the side extension. A middle portion of the main beam and bed assembly can be laterally offset to form a recess to accommodate lift arms of a self propelled swather when the swather header is loaded on the bed assembly.

Owner:PETER BERGEN IND INC

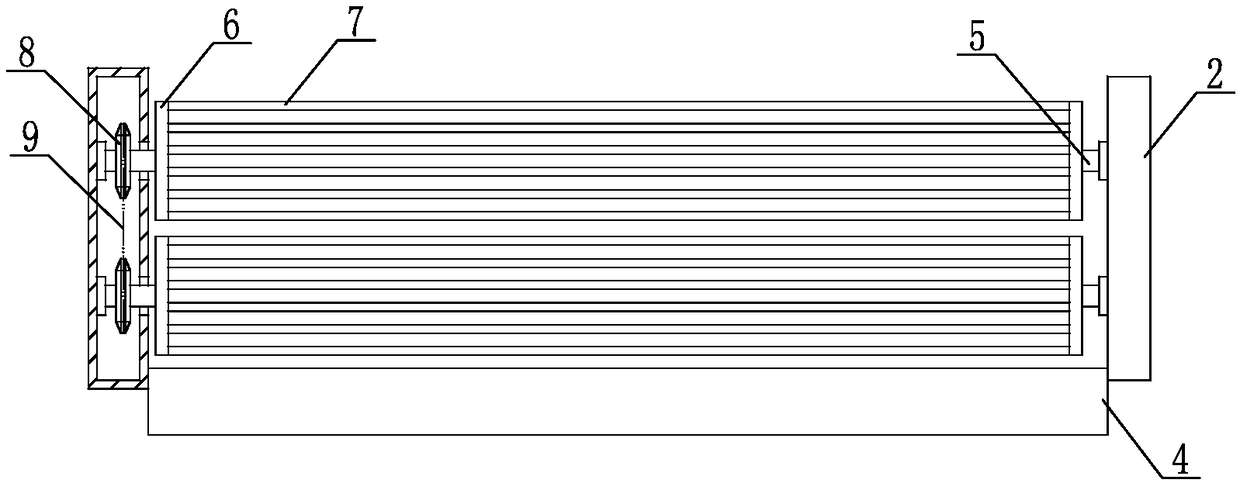

Conveyor for a windrower

A self-propelled swather has a frame mounted on ground wheels with a header in front which discharges between the wheels. A swath conveyor belt is located underneath the frame and arranged to convey the cut crop across the frame to a first discharge side of the frame. A mounting assembly including a beam across the belt and a lift arm mounts the swath conveyor for movement between a raised storage position in which the belt is horizontal underneath the frame and a lowered operating position in which the belt is inclined forwardly and downwardly while at the same time causing the beam to twist to cause the inlet end of the belt to move forwardly further than the discharge end to a forwardly inclined position between the front wheels.

Owner:MACDON INDS

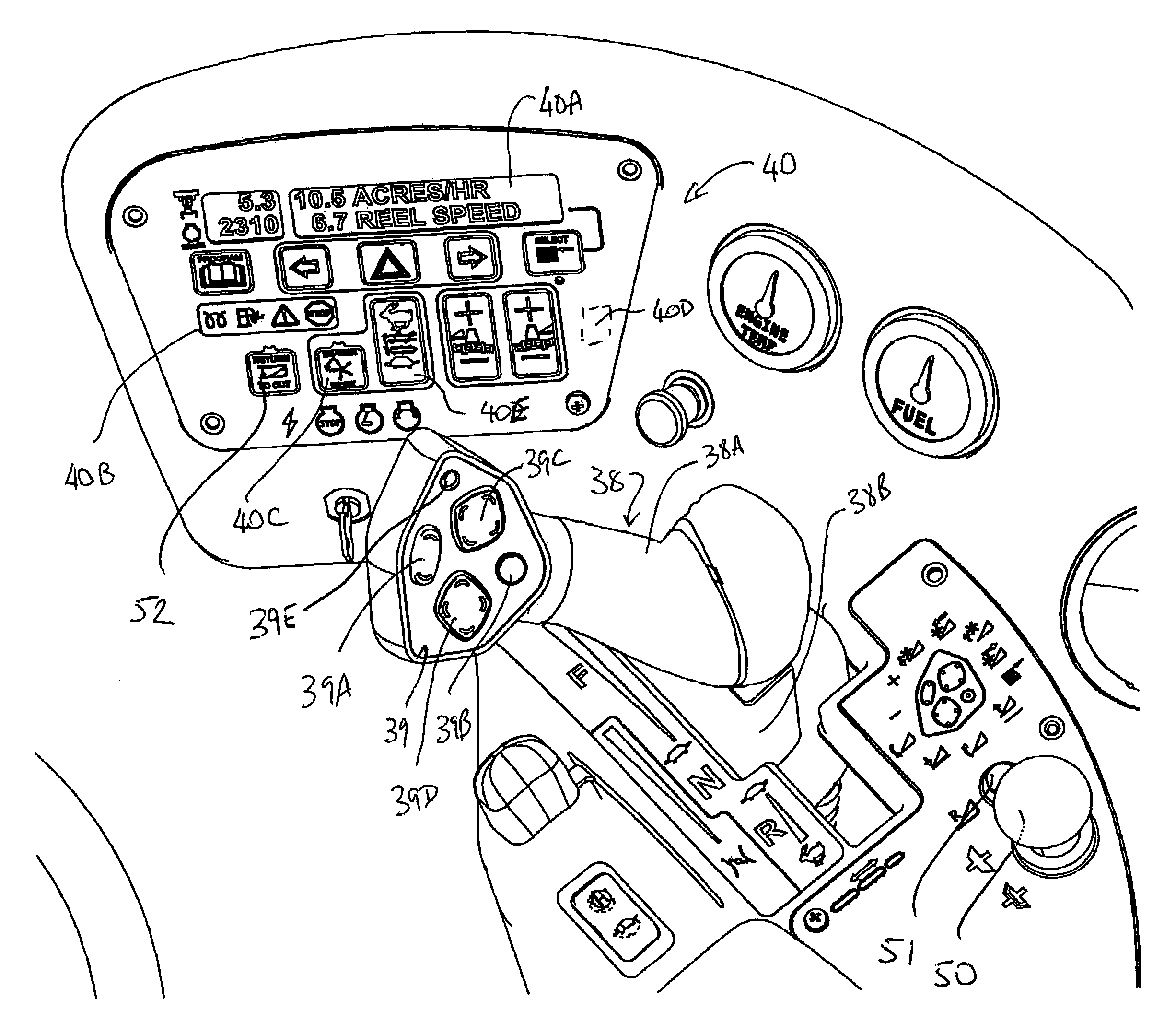

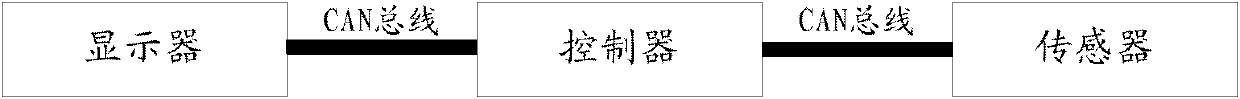

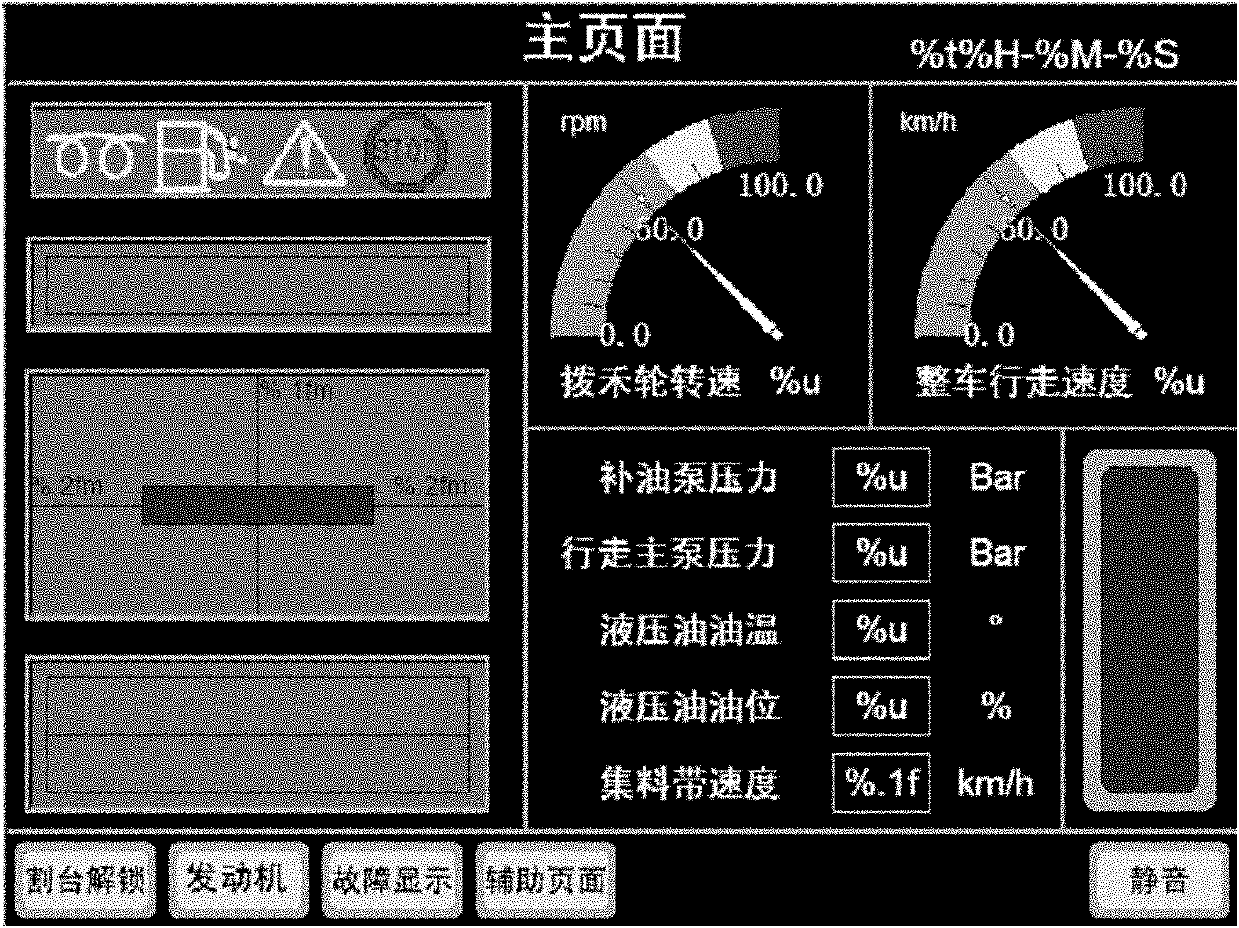

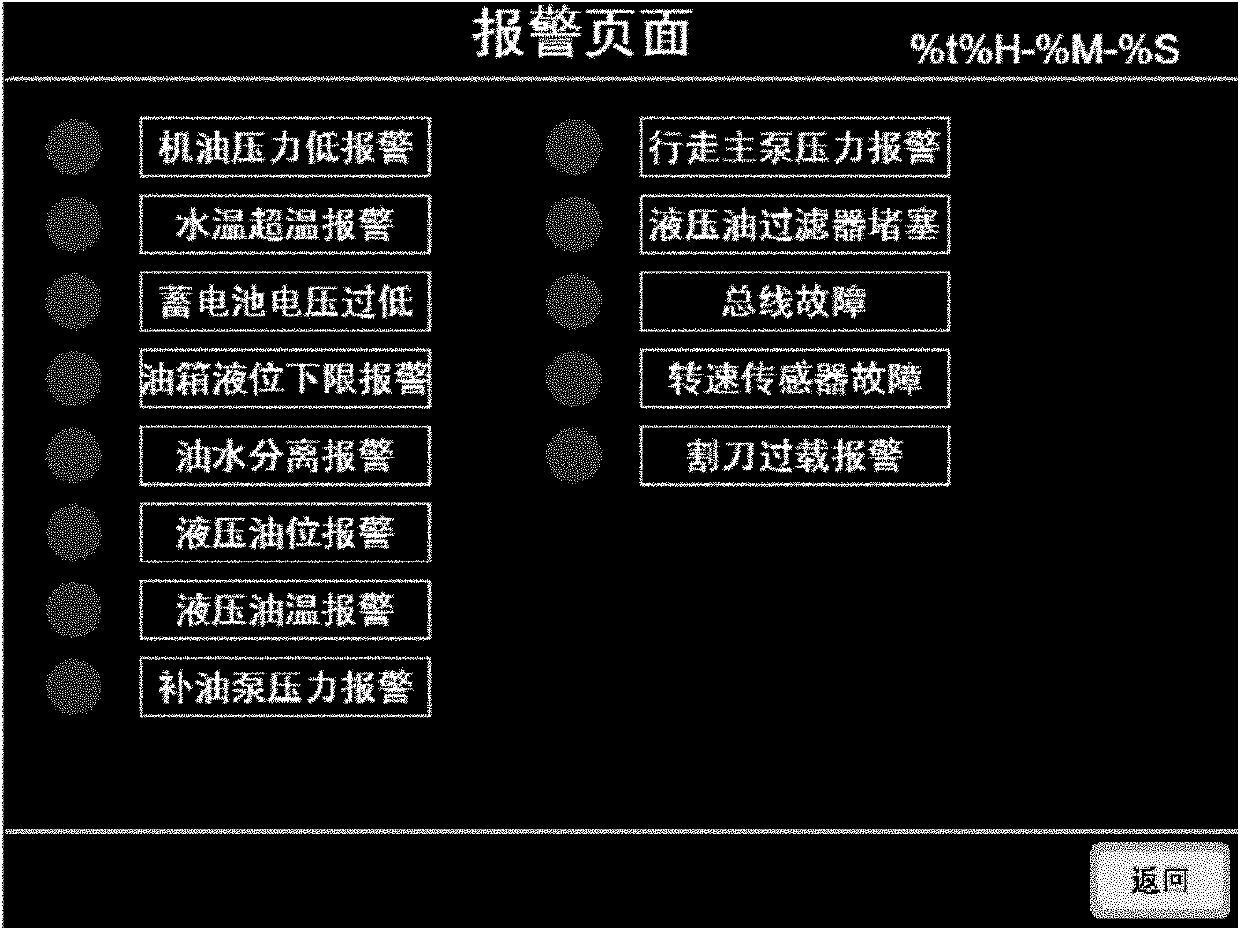

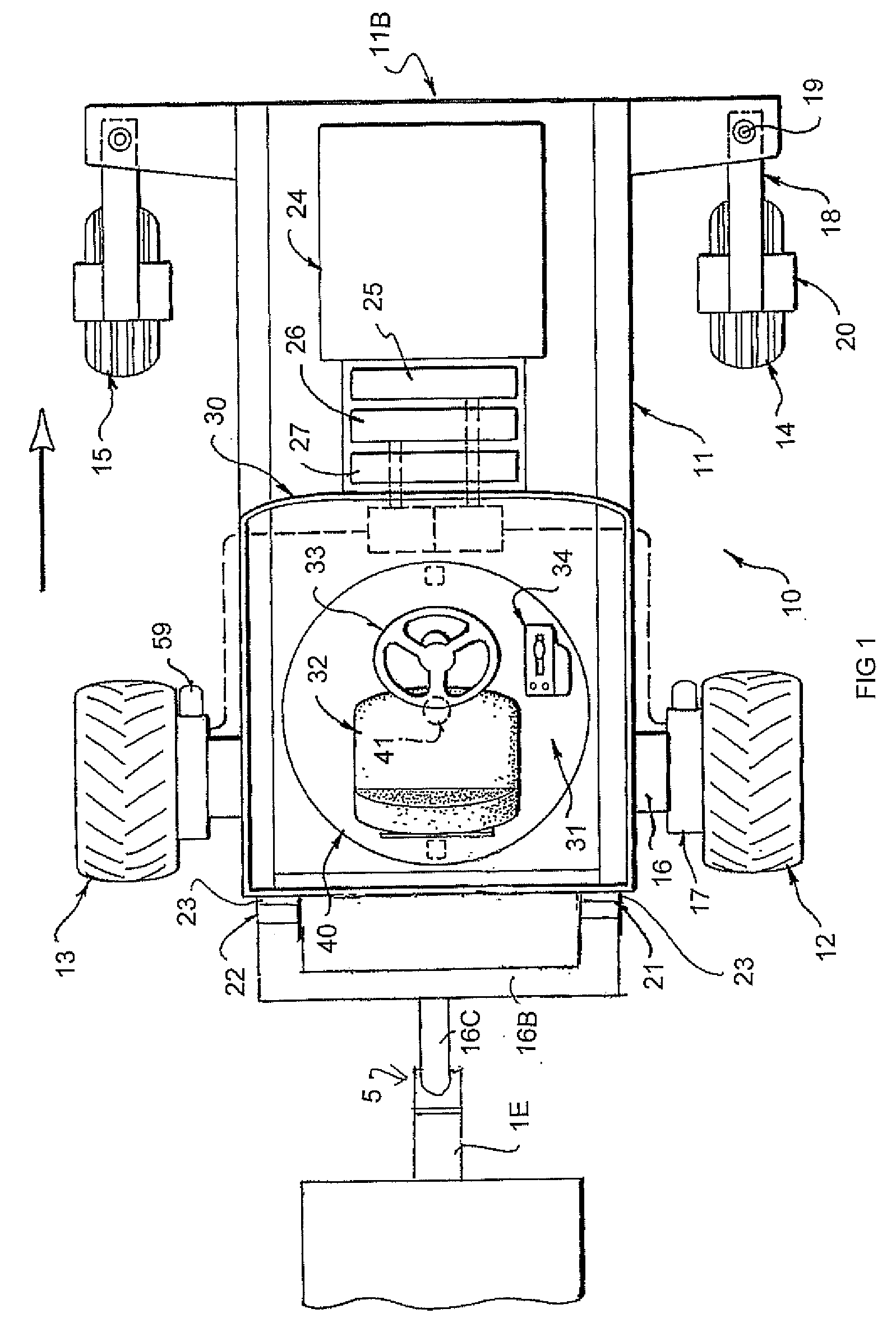

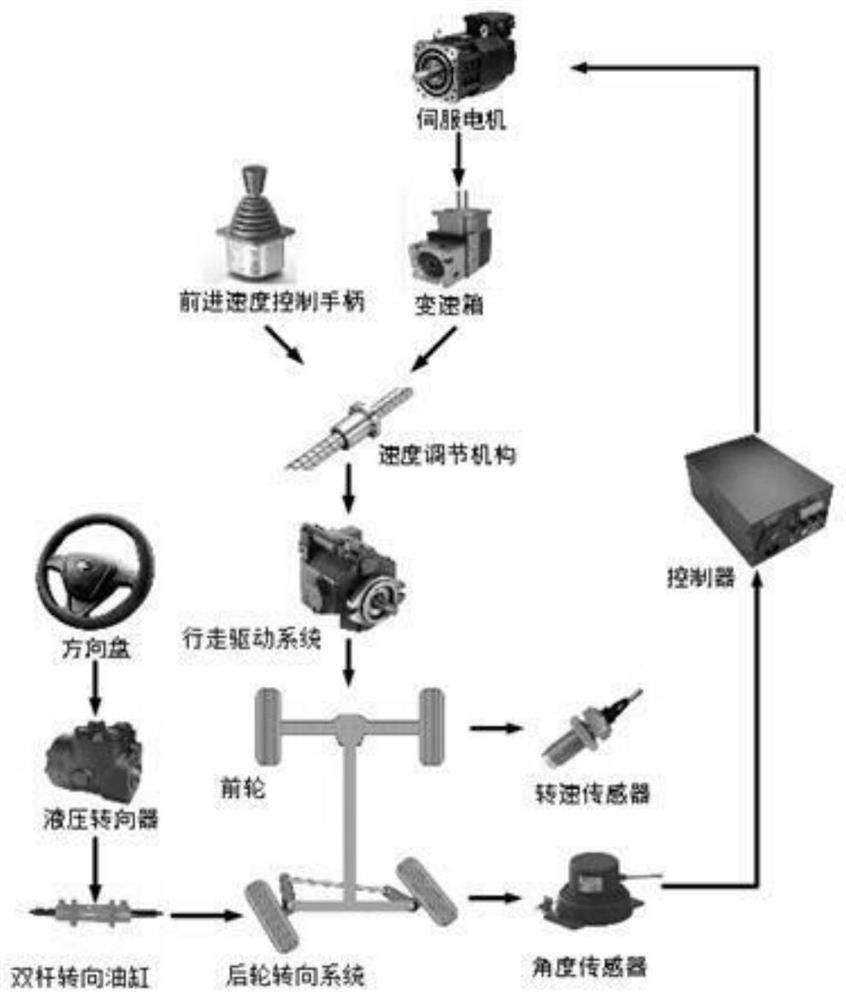

Human-computer interface control system and control method for self-propelled swather

InactiveCN102566516AEasy to operateIncrease the level of automationHarvestersProgramme total factory controlTime efficientHuman–machine interface

The invention discloses a human-computer interface control system and a control method for a self-propelled swather. The control system comprises sensors, a controller and a display, wherein the controller is connected with the sensors; the display is connected with the controller; the sensors are used for sensing a real-time working state of each part of the swather; the controller is used for receiving information sensed by the sensors and controlling each action of the swather; and the display is used for inputting a control command of a user and displaying an obtained real-time working state parameter of each part of the swather. According to the invention, the control system and a human-computer interface are like the brain of the swather, the control system has the advantages of safety, reliability, easiness for operation and humanization and the automatic level of the swather is improved, so that the swather has higher working efficiency and higher reliability and time, labor and materials can be saved.

Owner:SHANGHAI PAL FIN AUTOMATIC CONTROL TECH

Header trailer

InactiveUS8616812B2Reduce distanceEasy loading and unloadingHarvestersVehicle to carry long loadsTrofferSwather

A trailer apparatus for transporting a harvest header has a main beam on wheels. A bed assembly is pivotally attached to the main beam above the main beam such that when one side of the bed assembly moves up, an opposite side moves down. The bed assembly is supported at a desired tilt angle by adjustable tilt. The bed assembly includes a movable side extension along one side that is movable through a range from an extended position to a retracted position and can be releasably locked in the range. The tilt angle can be adjusted independently of the position of the side extension. A middle portion of the main beam and bed assembly can be laterally offset to form a recess to accommodate lift arms of a self propelled swather when the swather header is loaded on the bed assembly.

Owner:PETER BERGEN IND INC

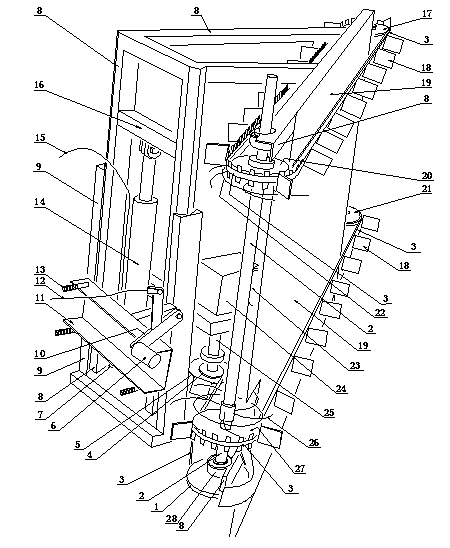

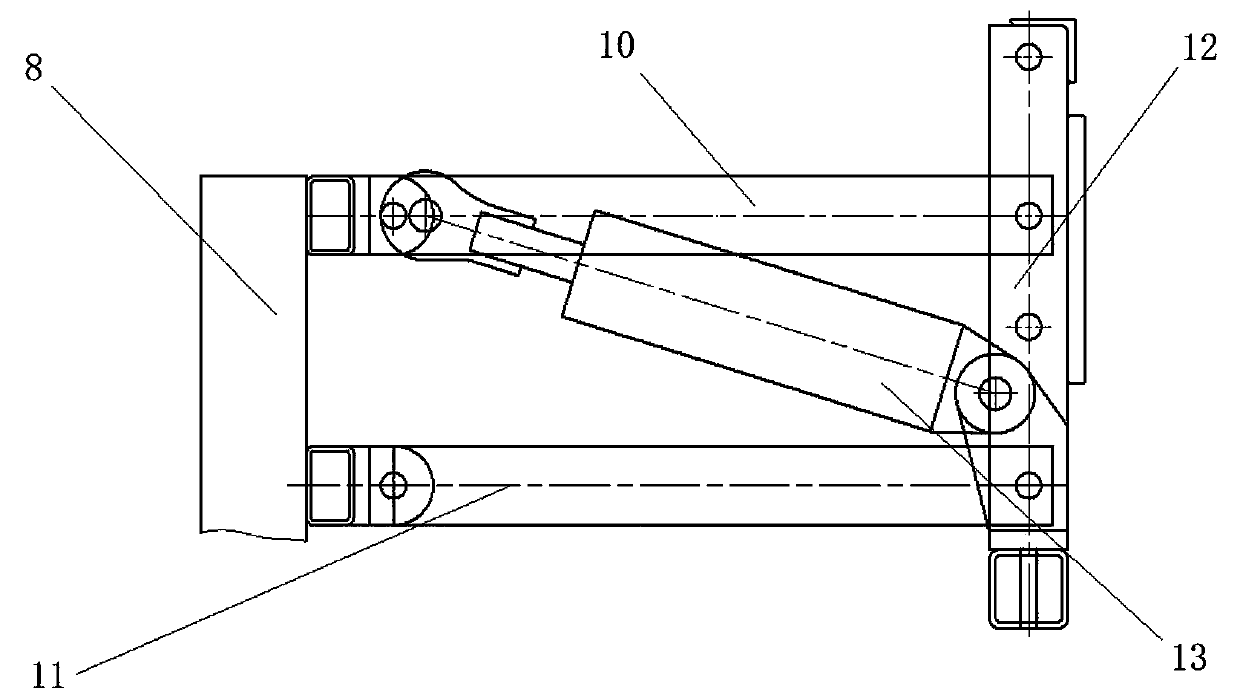

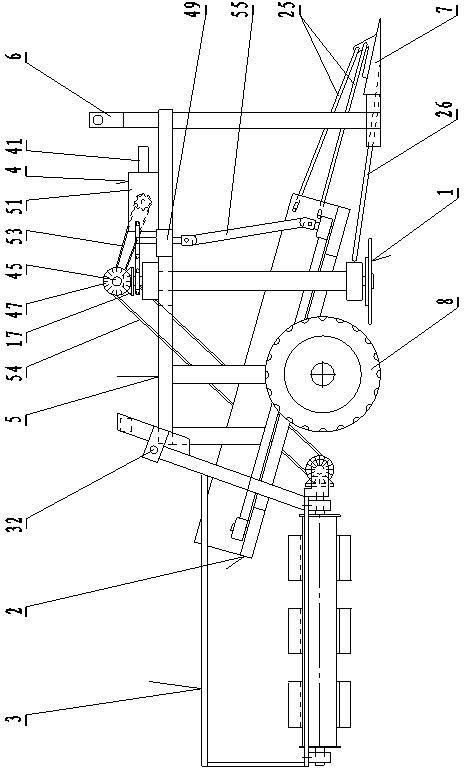

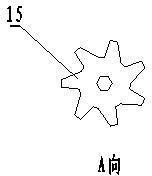

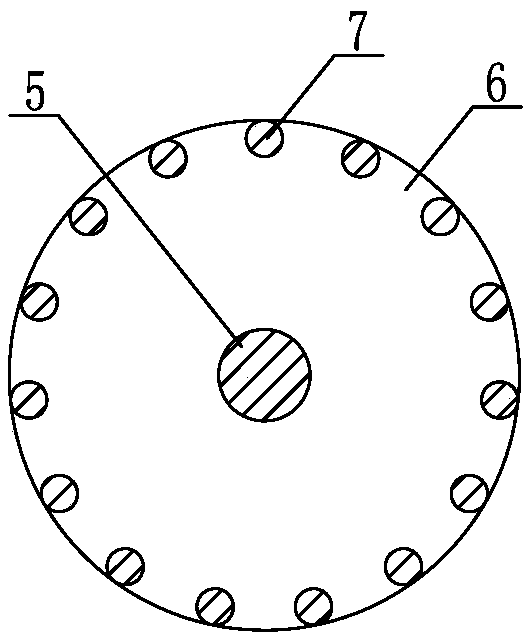

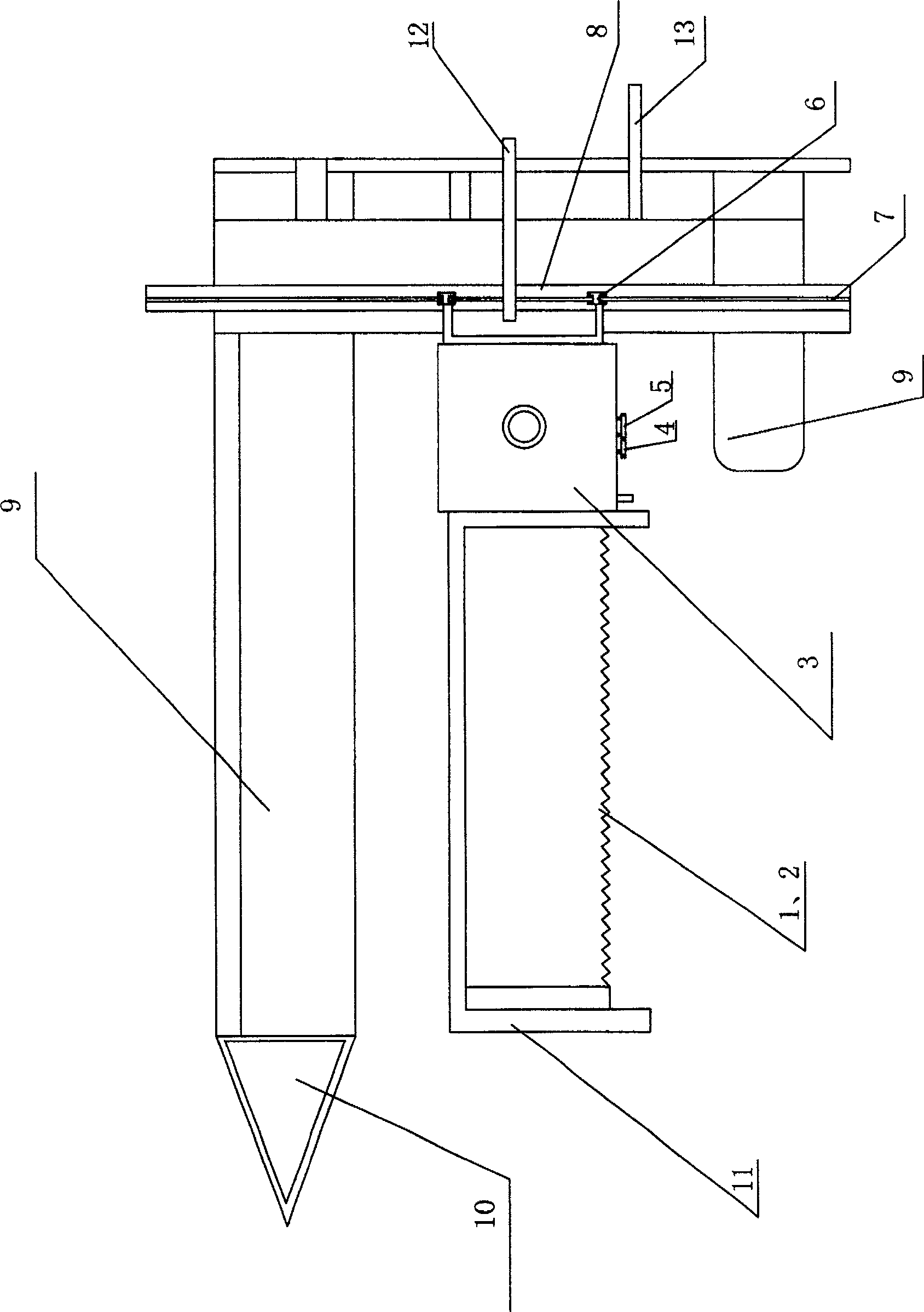

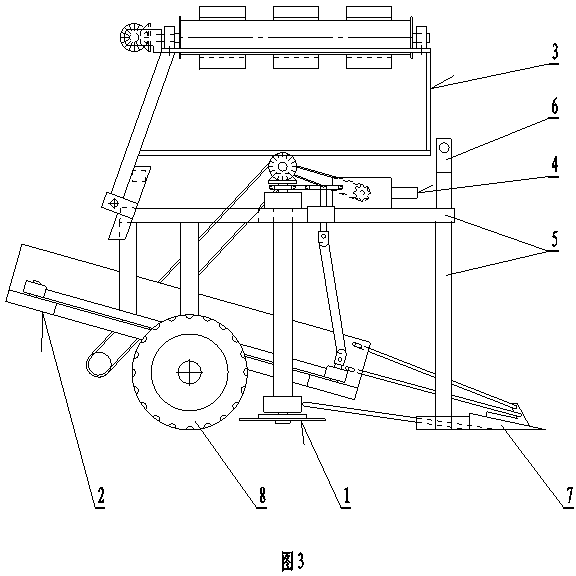

Crop straw swather

InactiveCN103404302AIncreased tidy placement rateSimple structureHarvestersAgricultural engineeringSprocket

The invention belongs to the field of agricultural machinery, in particular to a crop straw swather. According to the crop straw swather, a panel is connected between an upper frame and a lower frame of a vertical face of a triangular pyramid rack, an upper right chain wheel and a lower right chain wheel are installed at the right ends of the two frames in a connecting mode, bearing pedestals are installed at the left ends of the two frames in a connecting mode, a vertical shaft penetrates through the position between the pedestals, and a lower chain wheel is installed at the lower end of the shaft in a connecting mode. An upper left chain wheel, an upper right chain wheel, an upper straw prodding rod disk and a lower straw prodding rod disk are installed on the vertical shaft from top to bottom respectively in a connecting mode, and a double-lug chain is connected between the left chain wheel and the right chain wheel of each group, and vertical straw supporting plates are installed on the double-lug chains at intervals in a connecting mode. The lower portions of two vertical frames on the other face of the rack are respectively arranged in a V-shaped slide rail in a sleeved mode. A hydraulic oil cylinder is installed between a horizontal frame and a beam in a connecting mode, wherein the horizontal frame is arranged between the two vertical frames, and the beam is arranged between the two slide rails. A speed reducer is erected on a horizontal support between the two vertical faces, and the lower end of a shaft of the speed reducer is connected with an upper chain wheel and a lower chain wheel which are coaxial. Straw cutting disks are arranged on the lower portion of the inner wall of the panel at intervals in a connecting mode. The upper chain wheel and the lower chain wheel which are coaxial are connected with the lower chain wheels and the straw cutting disks through chains respectively. The crop straw swather can cut straw smoothly, the straw is laid orderly, and the work efficiency is promoted obviously.

Owner:克孜勒苏柯尔克孜自治州农牧业机械技术推广站

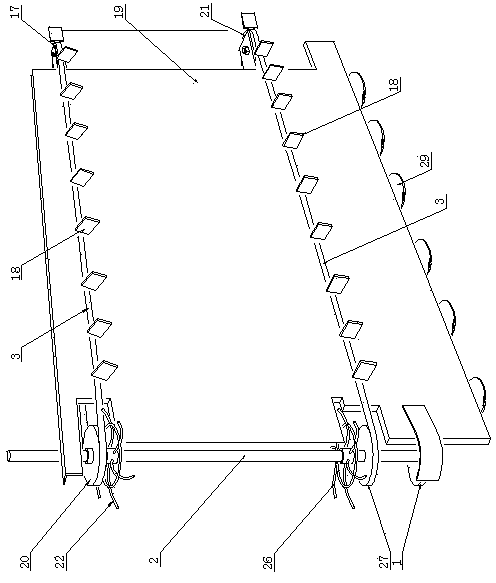

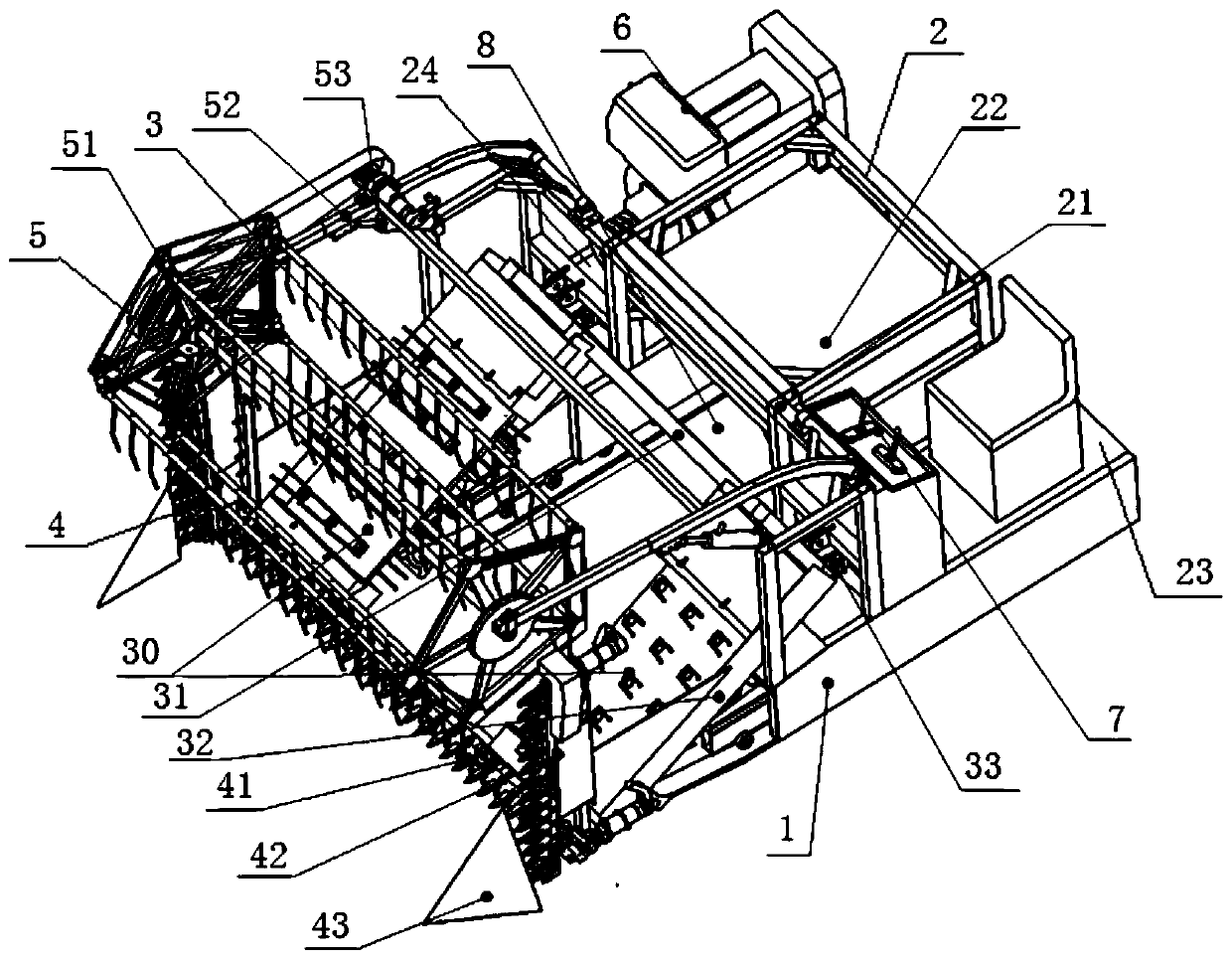

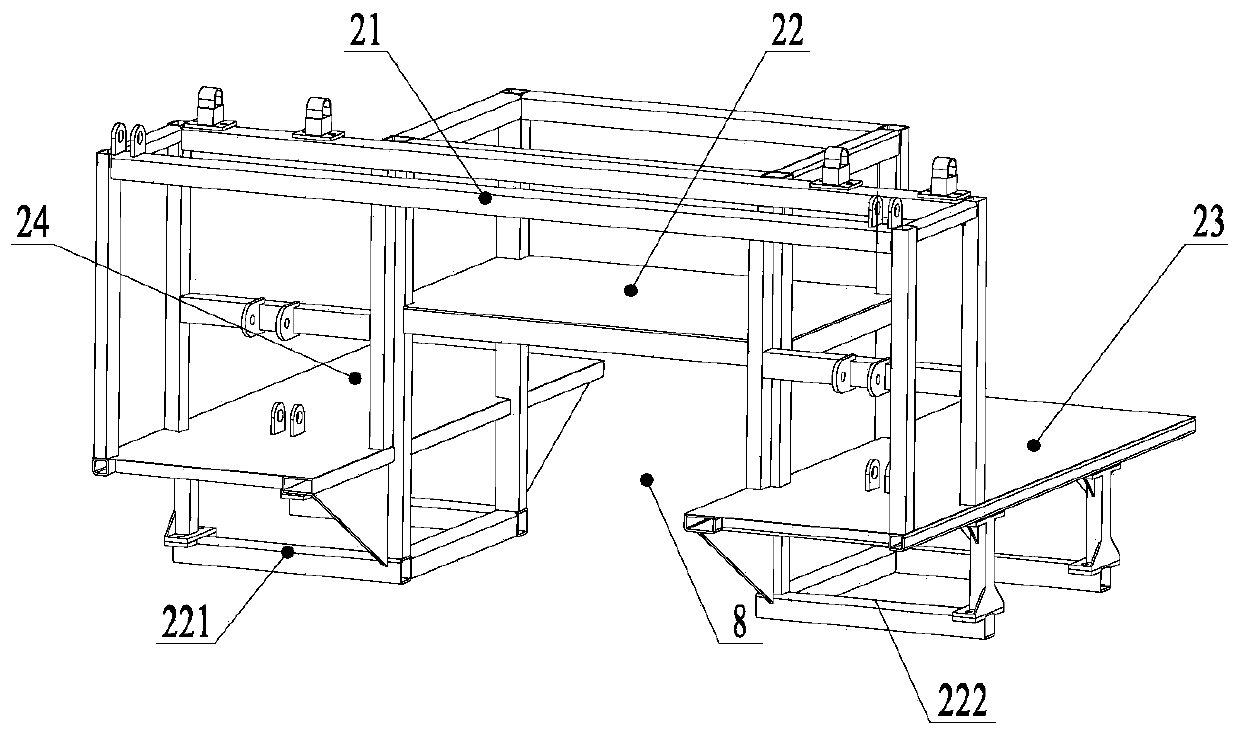

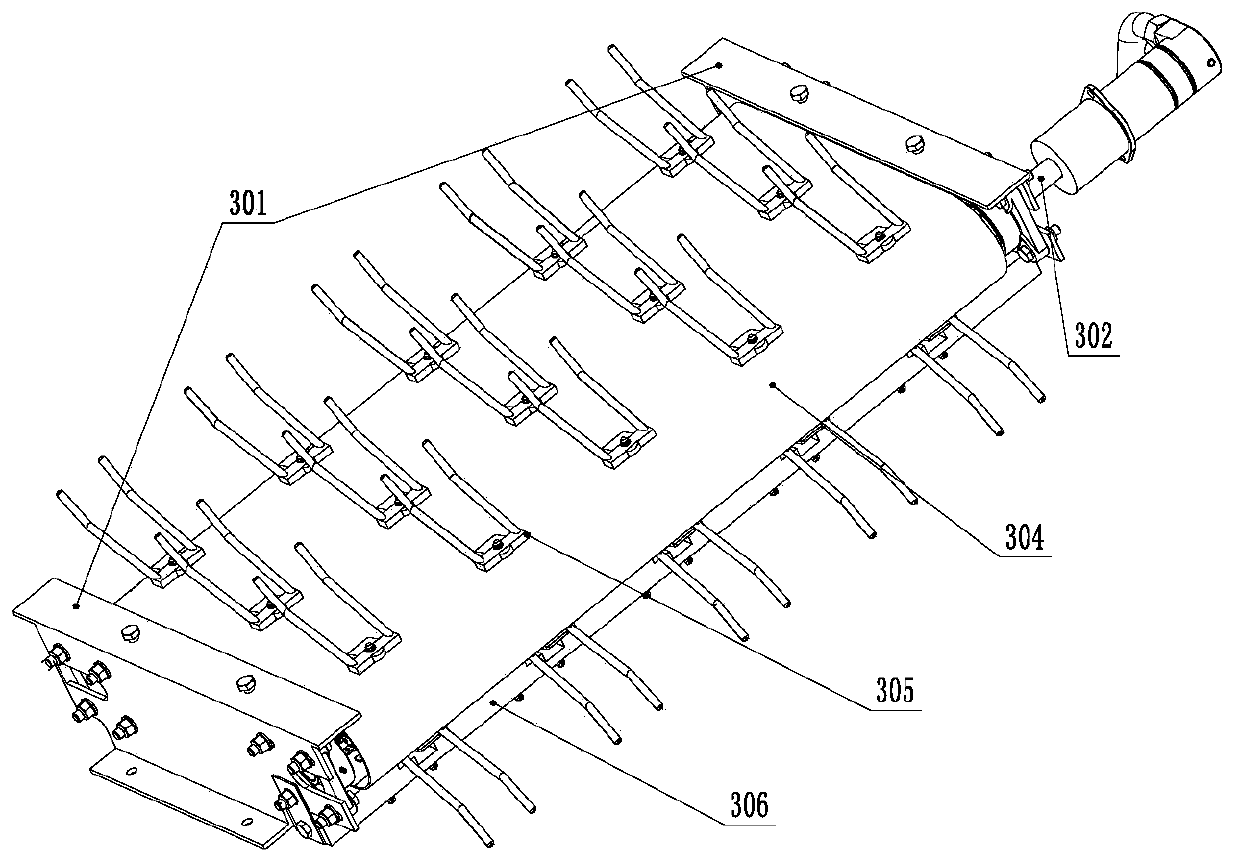

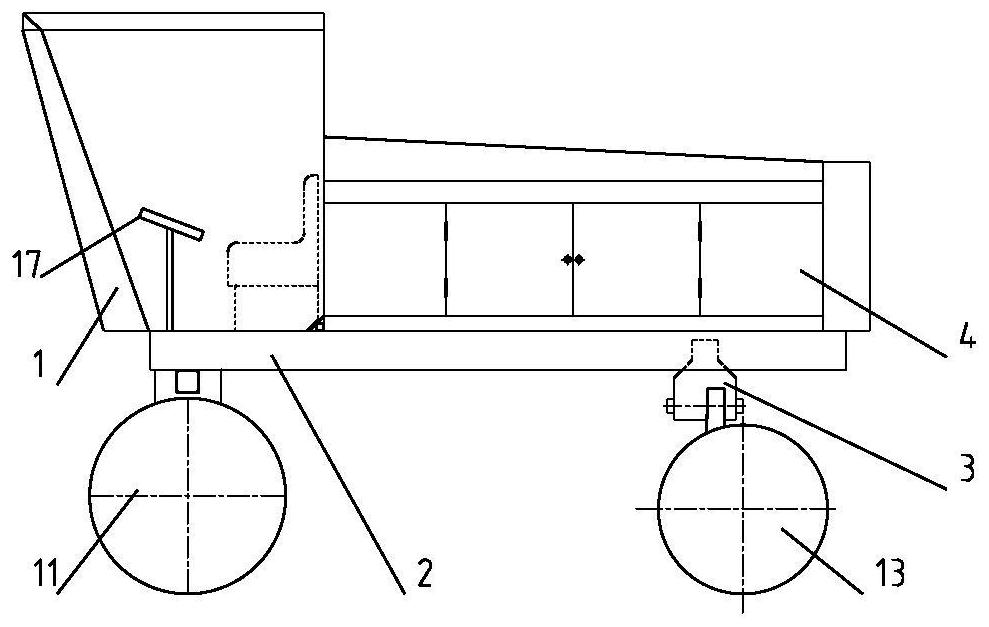

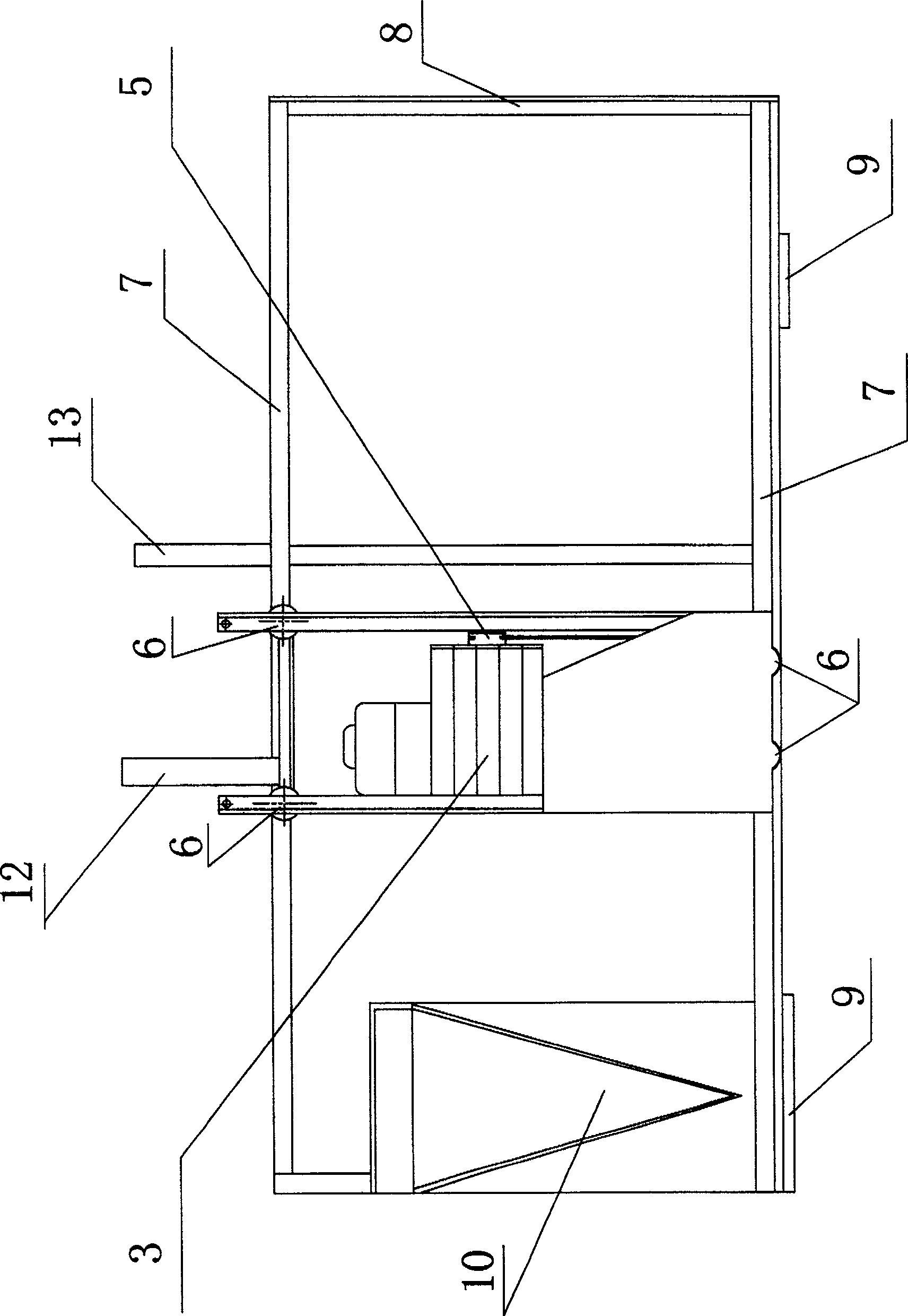

Multifunctional lateral laying swather

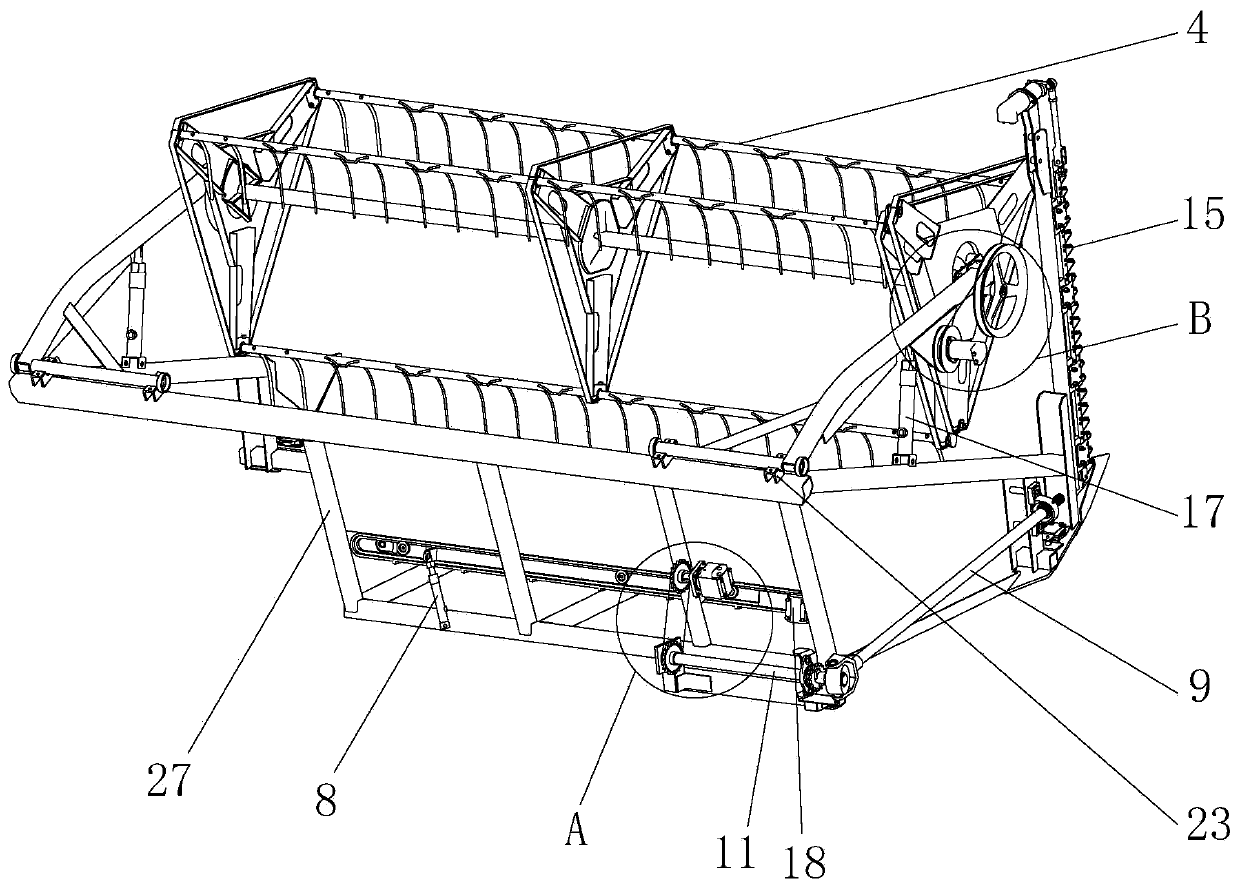

PendingCN110199668AElevate lateral conveyingImprove placement performanceMowersHeadersHydraulic cylinderEngineering

The invention discloses a multifunctional lateral laying swather which comprises a conveying groove, a swathing table frame, a cross cutter and a harvester body. Hooking connectors are vertically andparallelly formed in the back of the swathing table frame, the swathing table frame are hooked on the conveying groove through the hooking connectors, the conveying groove is formed in a chassis of the harvester body, supporting arms are arranged at two ends of the swathing table frame, the ends of the supporting arms are hinged to the swathing table frame through supporting seats, the middles ofthe supporting arms are hinged to the top ends of reel hydraulic cylinders, the reel hydraulic cylinders are fixed onto the swathing table frame, and reels are arranged between the two supporting arms. As the swather is provided with pin holes, conveying belt hydraulic cylinders, laying openings and the hooking connectors, and the swather solves the problems that a working object of a traditionalswather is single, the traditional swather cannot meet requirements of various crops and difficultly adapts to harvesting of high and large crops, and laying effects are poor after harvesting.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

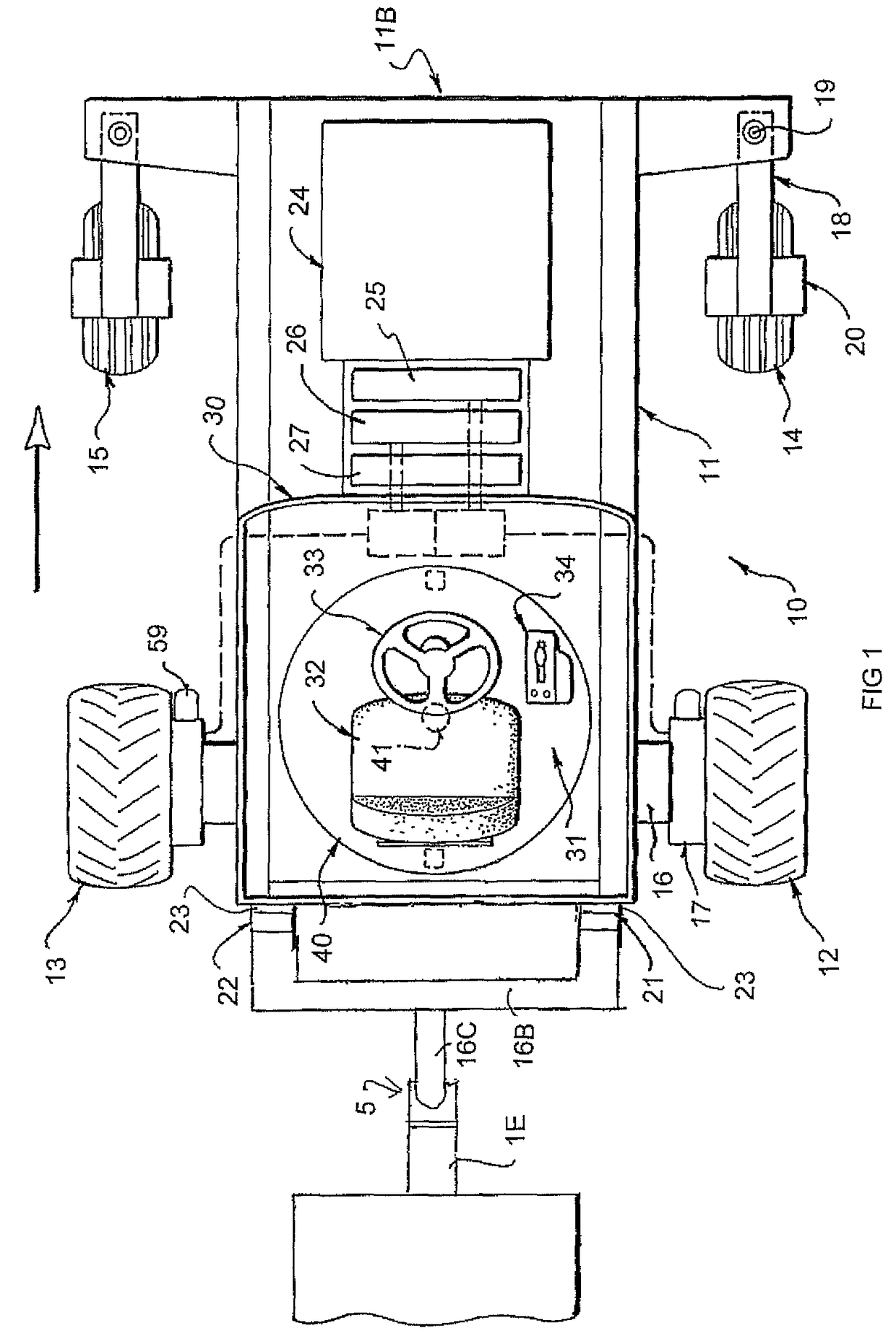

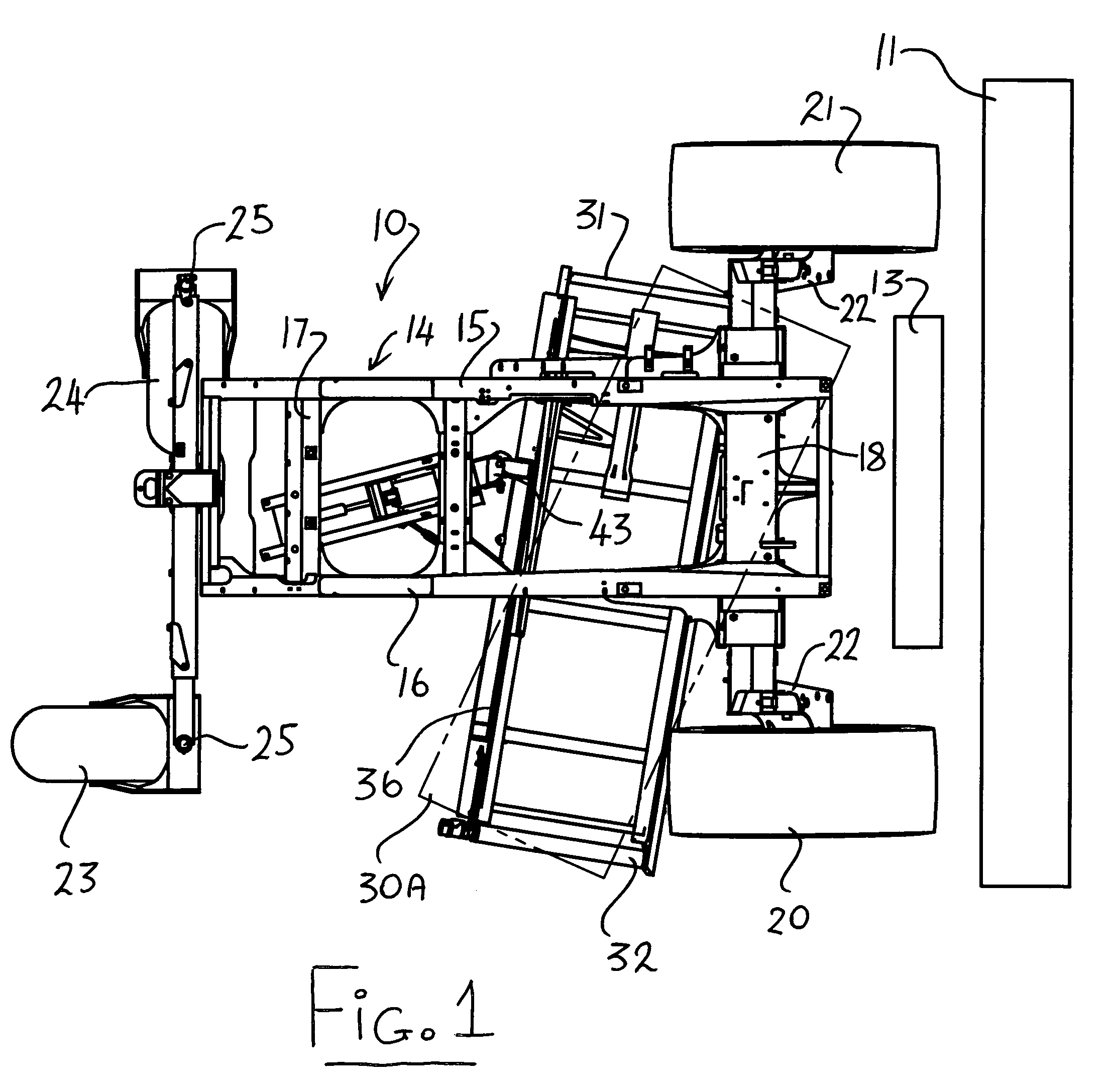

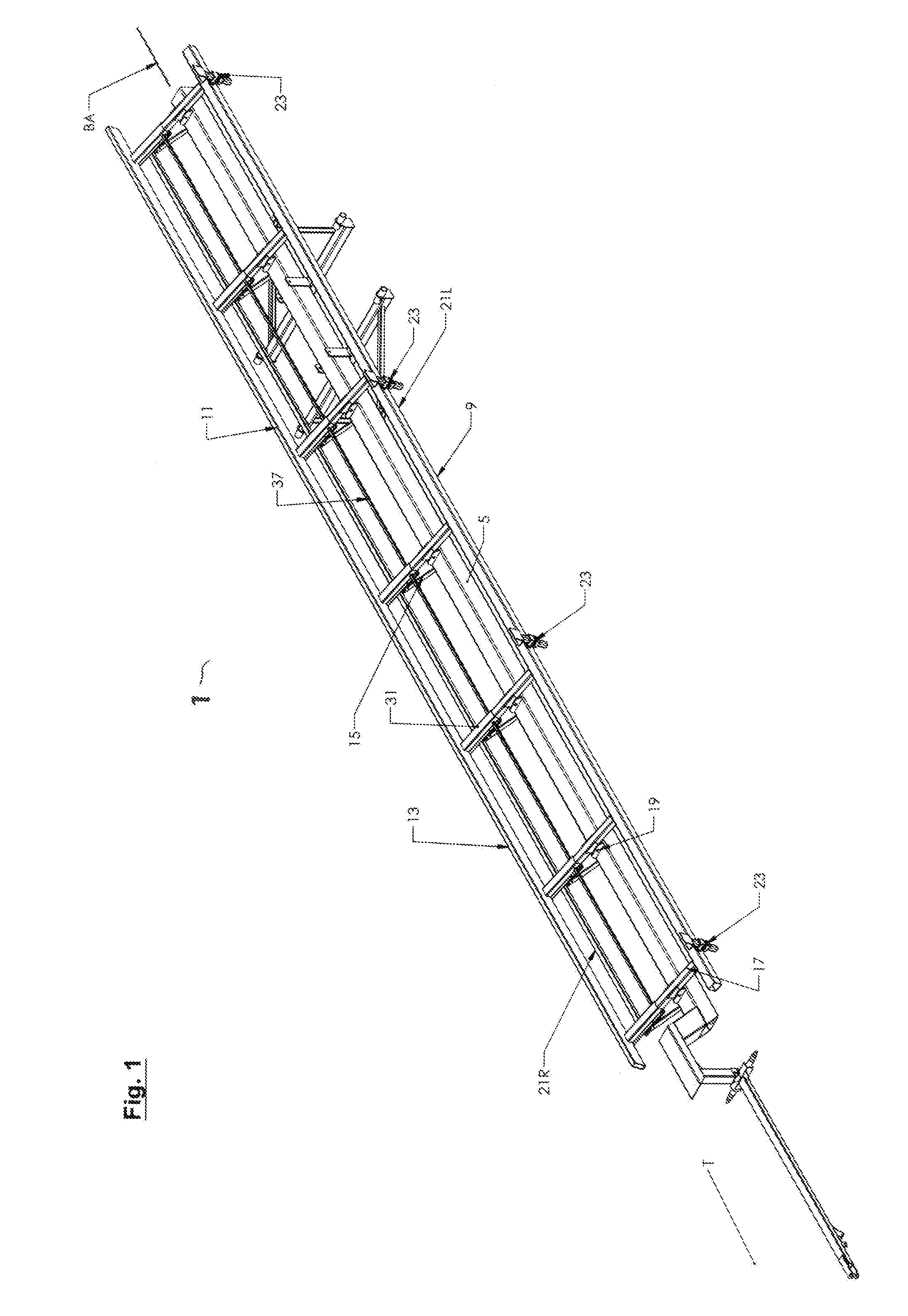

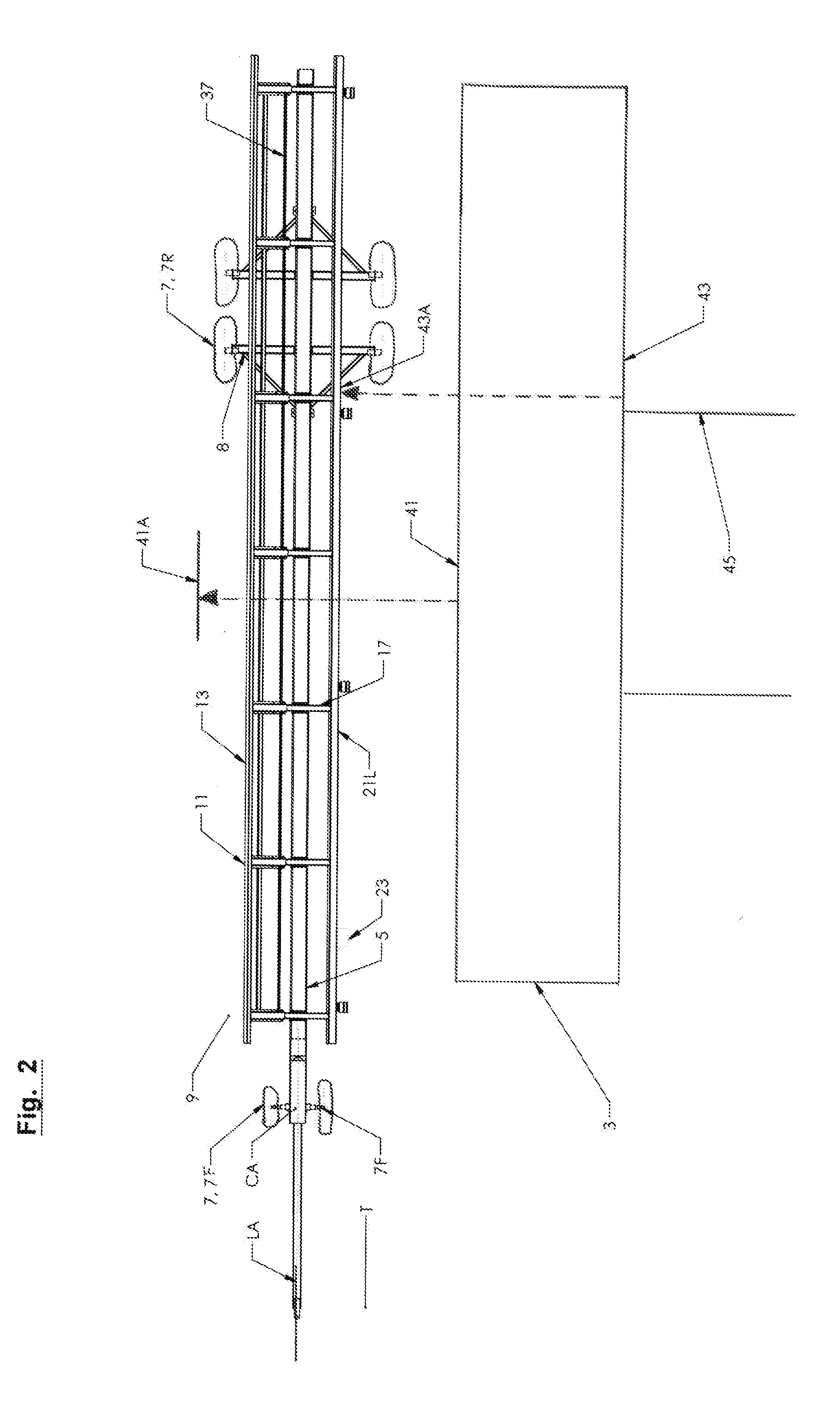

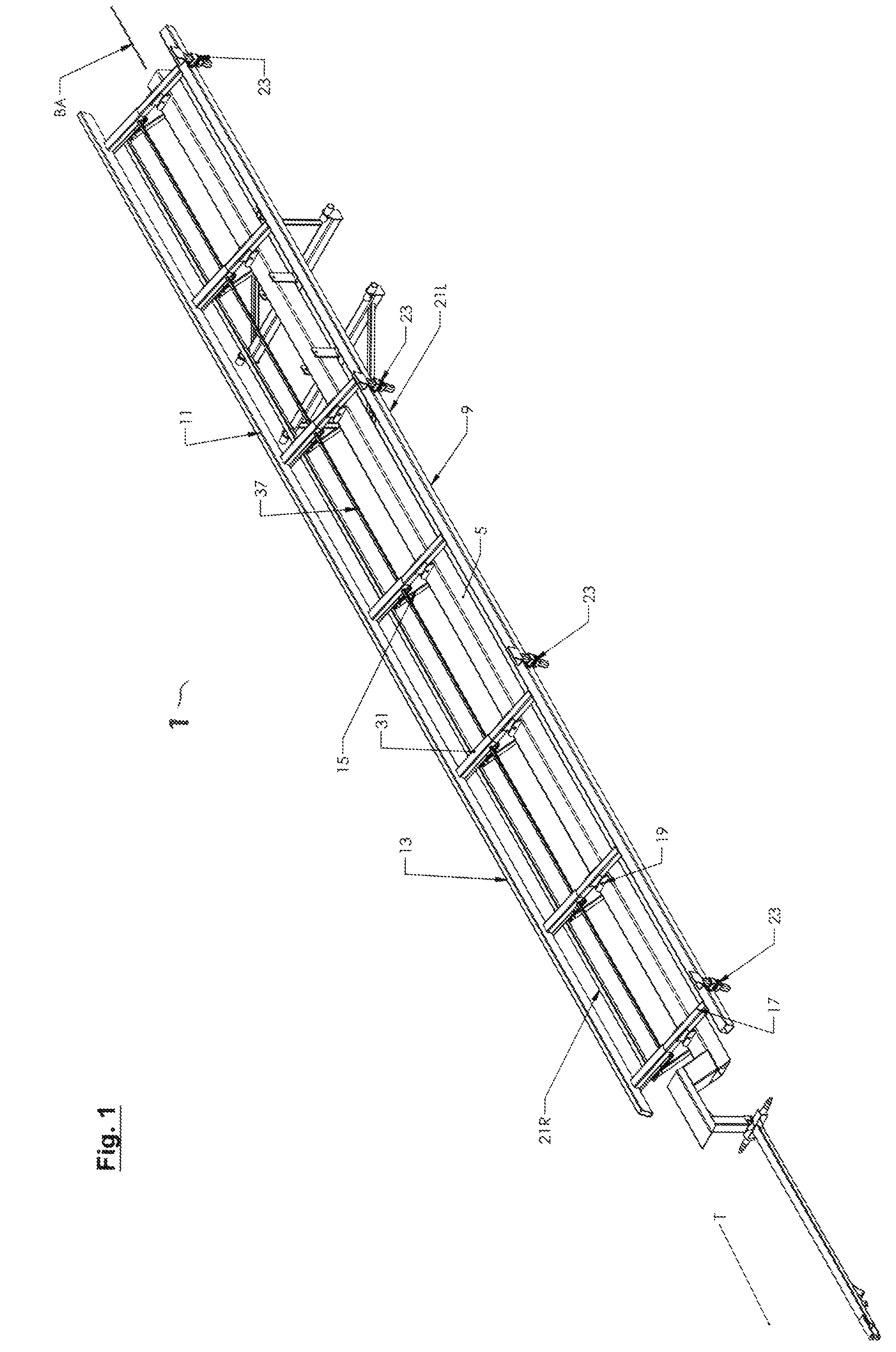

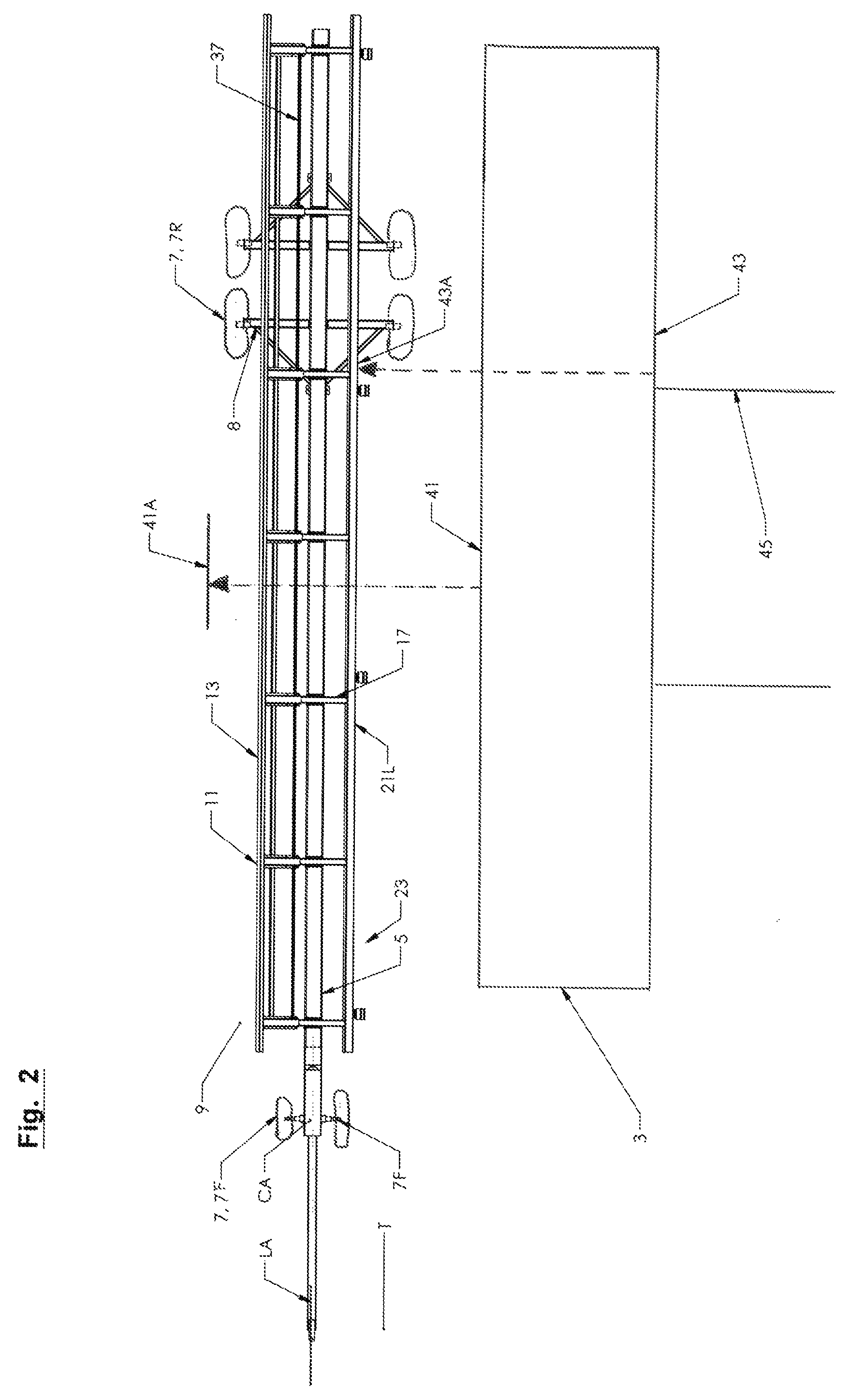

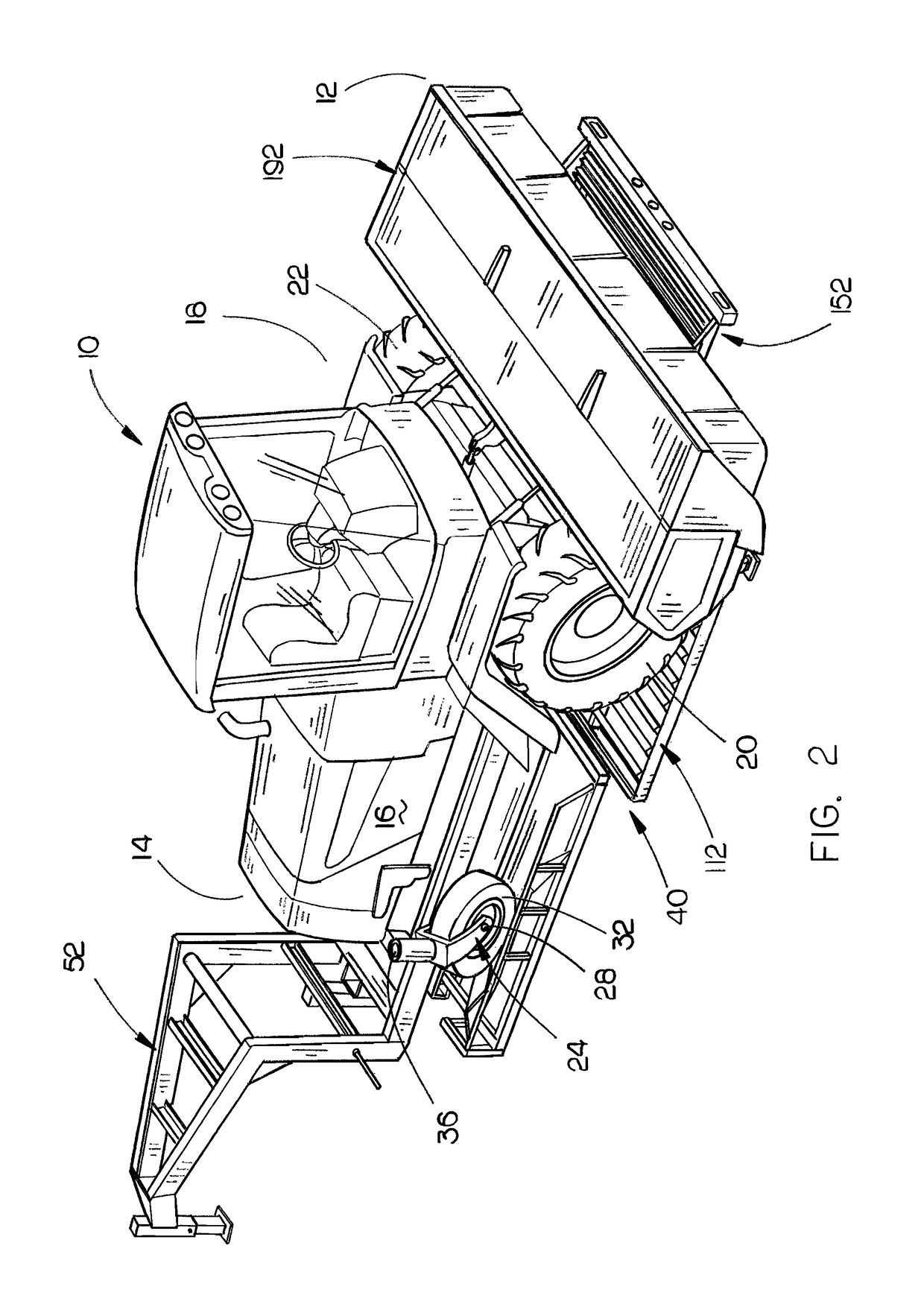

Header transport

A swather tractor has ground drive wheels at a first end, castor wheels at a second end and a header lift arms at the first end and can be driven with the first end forward for harvesting and with the first end rearward for towing. A transport for the header includes a longitudinal beam with a plurality of transverse support arms along the beam. The beam is kinked adjacent the front so that a main portion of the beam is offset to one side relative to the hitch assembly and the rear wheels. A yoke engages the lift arms and provides a hitch for towing the header. Either the forward end of the beam is directly attached to the hitch for small headers or for larger headers a steerable front wheel assembly is connected to the hitch and includes a spring coupling which transfers load to the lift arms.

Owner:MACDON INDS

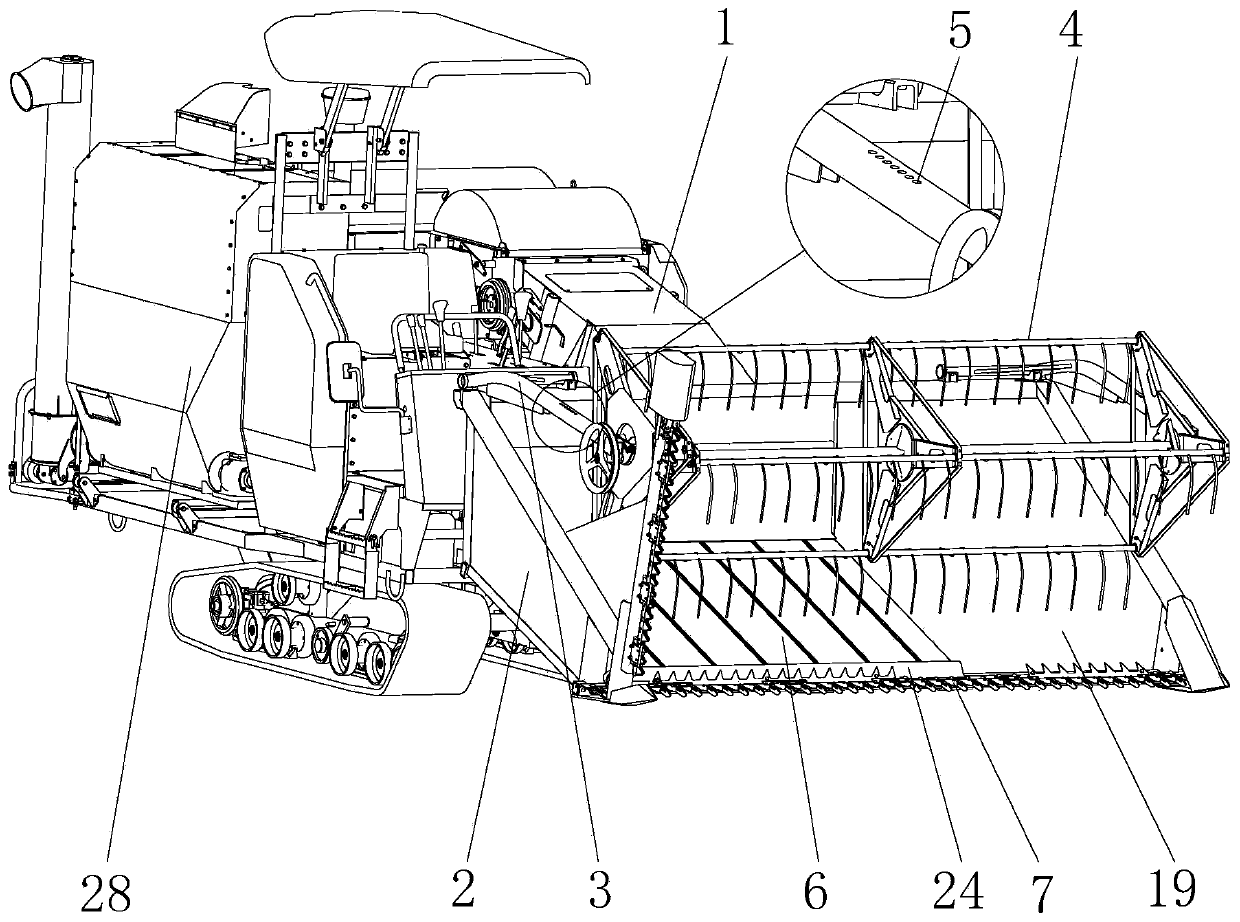

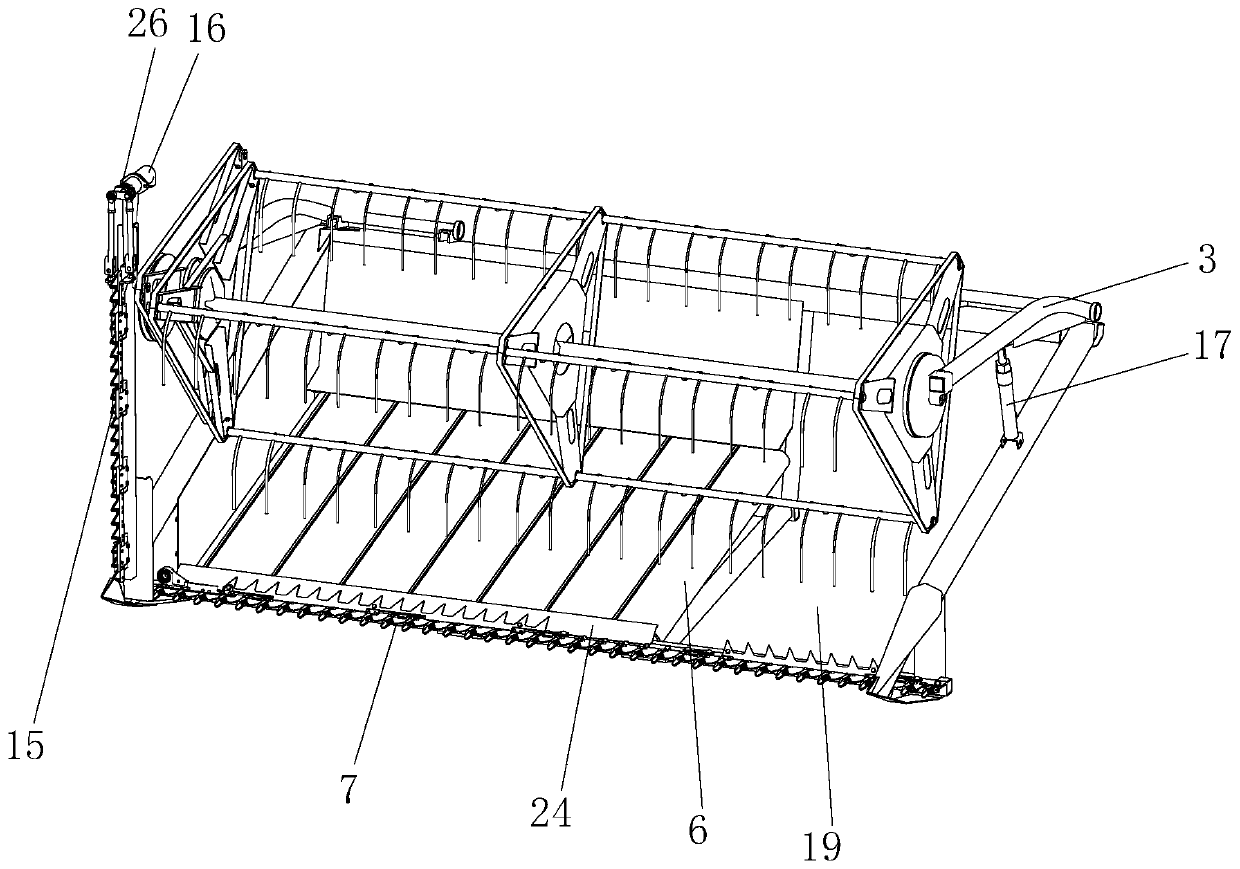

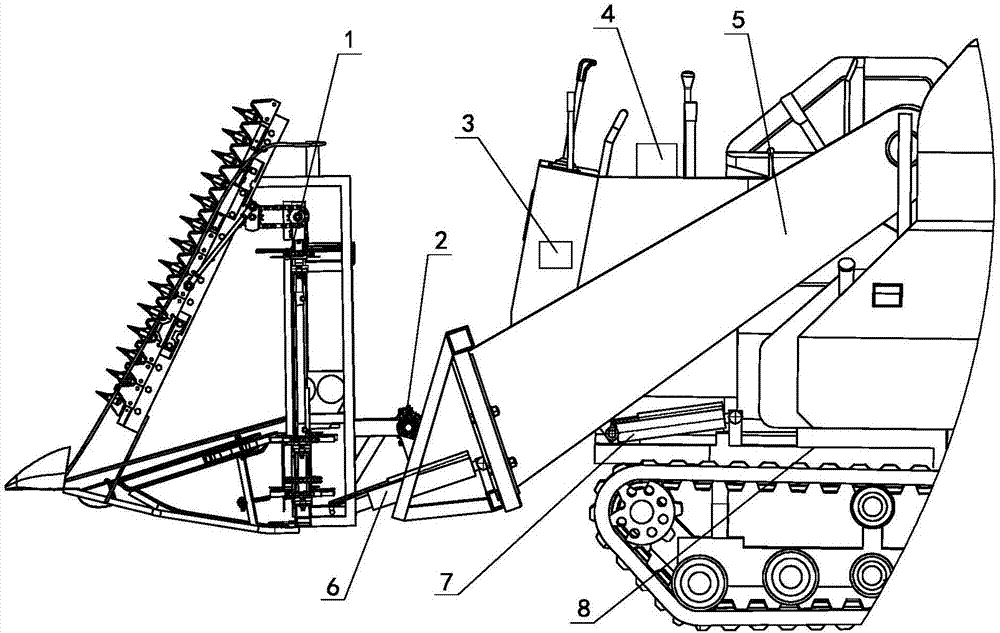

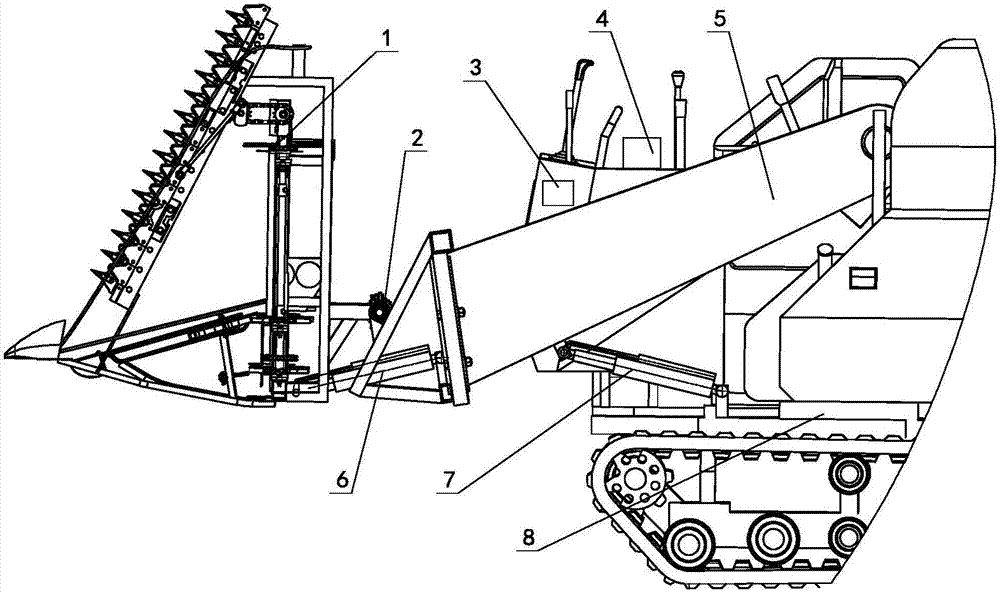

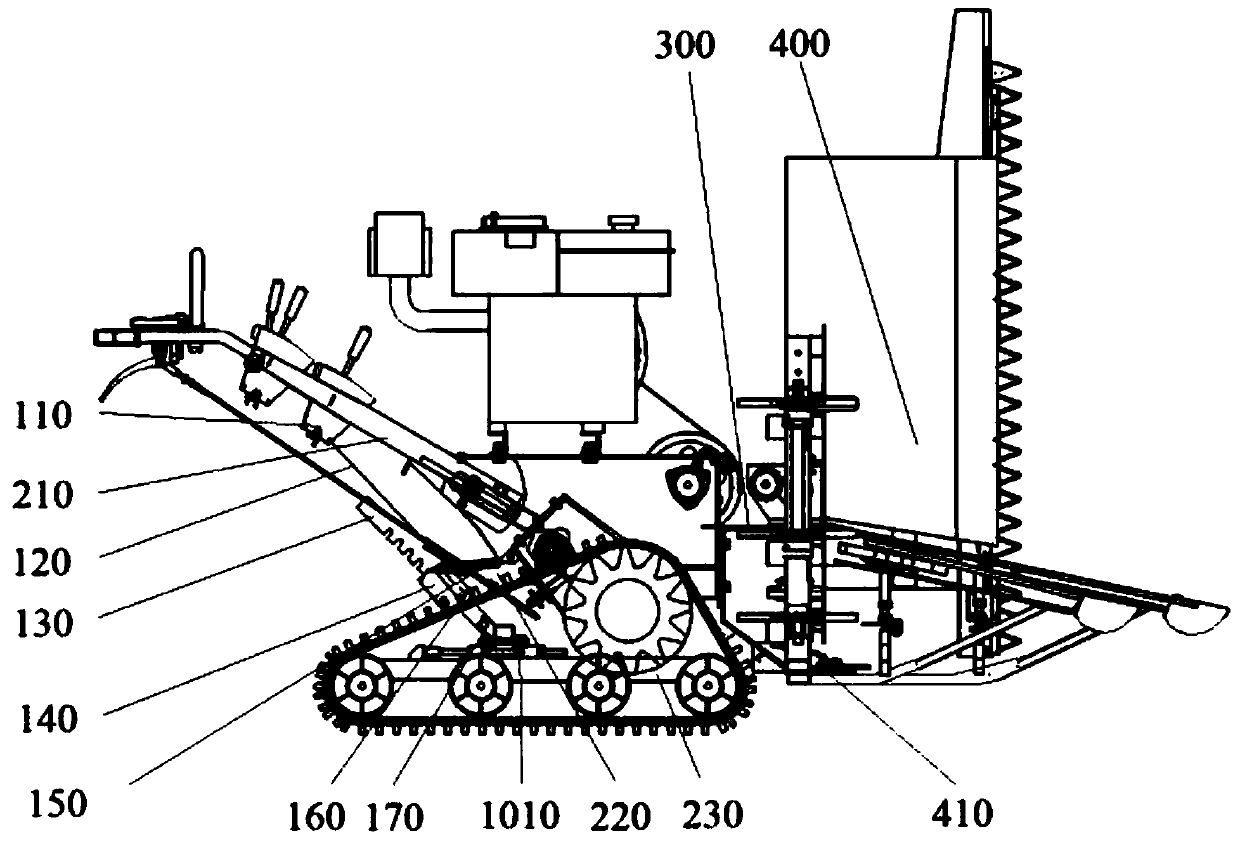

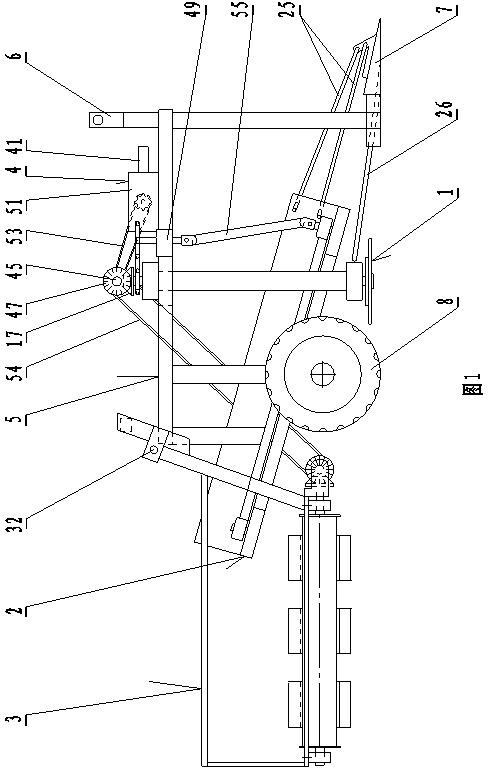

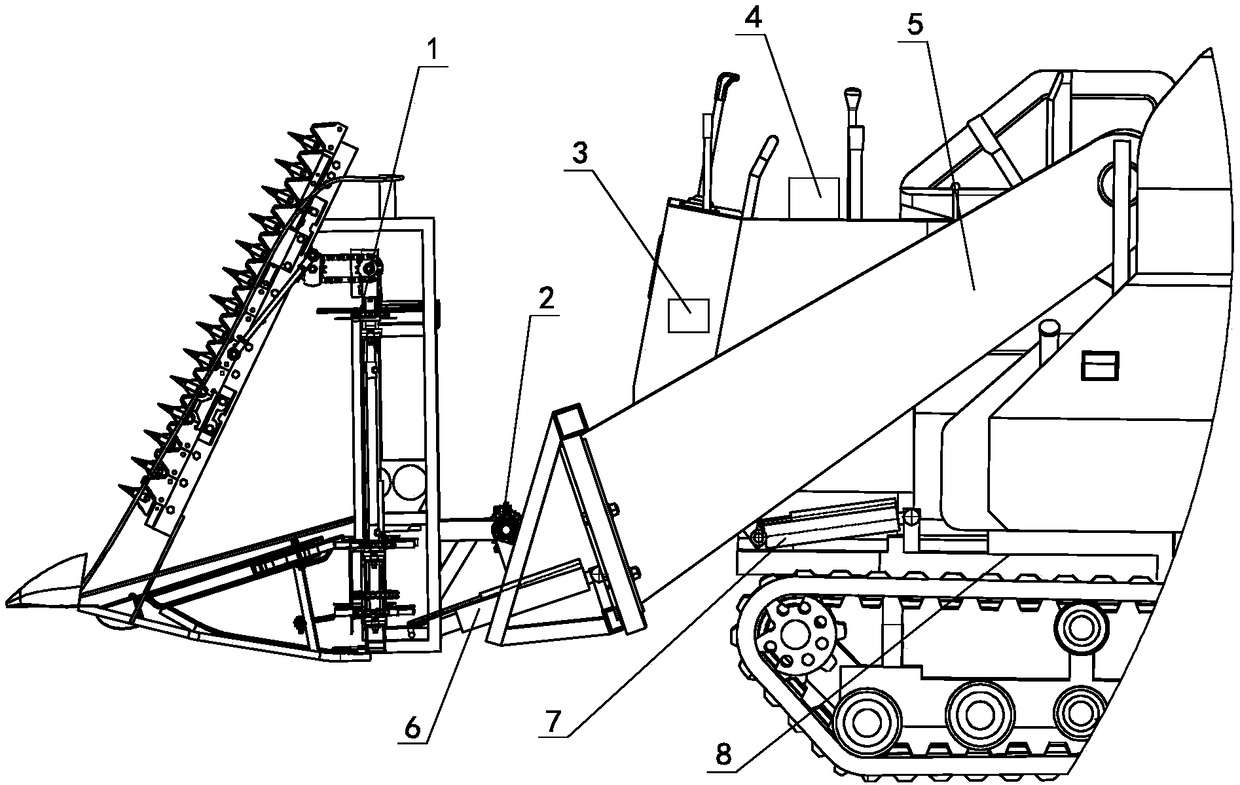

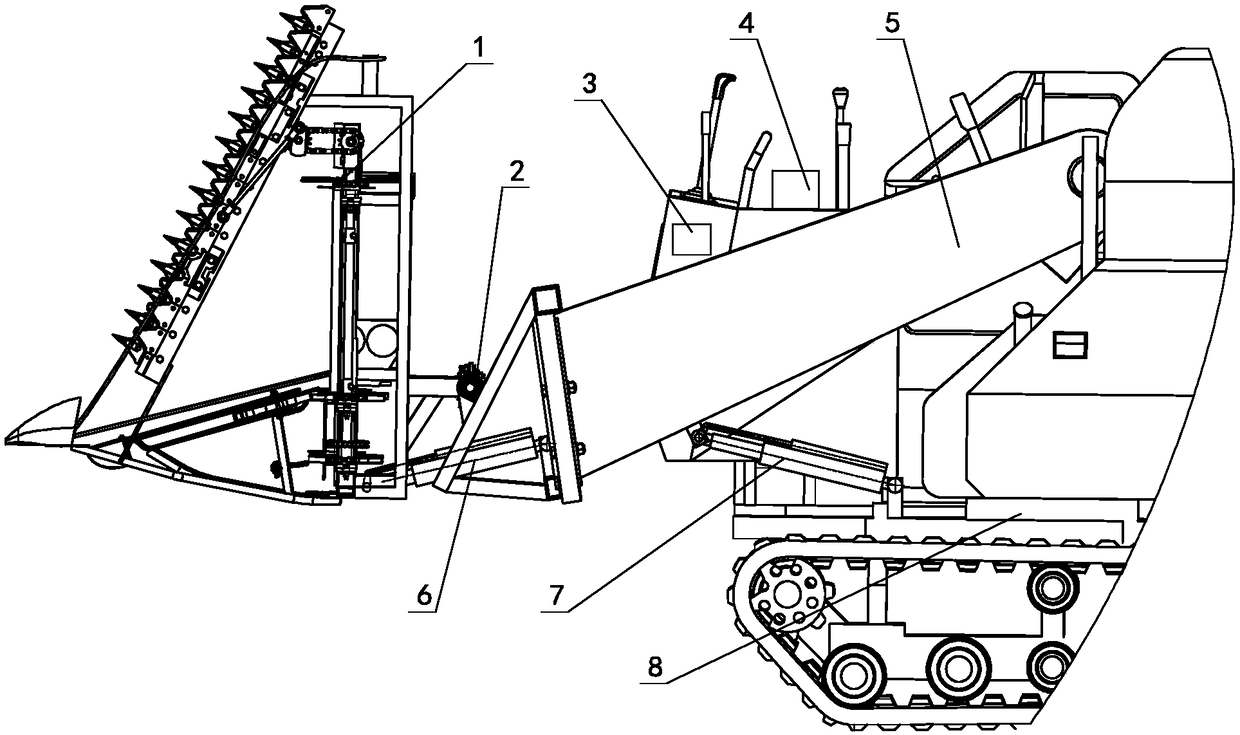

Crawler self-walking backpack type rape swather

PendingCN110547089AVertically compactSmall turning radiusMowersAgricultural undercarriagesAgricultural engineeringSwather

The invention discloses a crawler self-walking backpack type rape swather which comprises a pair of walking crawlers, a main machine frame, a cutting device, an auxiliary feeding and grain pulling device and a spreading device. The spreading device is obliquely arranged on the upper side of the front half portion of the walking crawlers towards to-be-harvested rape. The upper end of the spreadingdevice is installed on the main machine frame. The lower end of the spreading device is fixed to the cutting device. By using a frame and the spreading device in cooperation, emptying the middle of the machine to form a rape swathing and spreading channel and cutting off rape through a cutting and conveying device and then gathering the rape to the middle to be backwards spread, the conveying distance of the cut-off rape is reduced, and the conveying efficiency is improved; before operation, there is no need to form a way manually, rape stubbles in the middle spreading area are not rolled, itis ensured that plants are spread on the stubbles to be aired overhead without making contact with damp soil, light permeability and breathability are realized, after-ripening is facilitated, and subsequent mechanical picking and harvesting are facilitated.

Owner:HUAZHONG AGRI UNIV

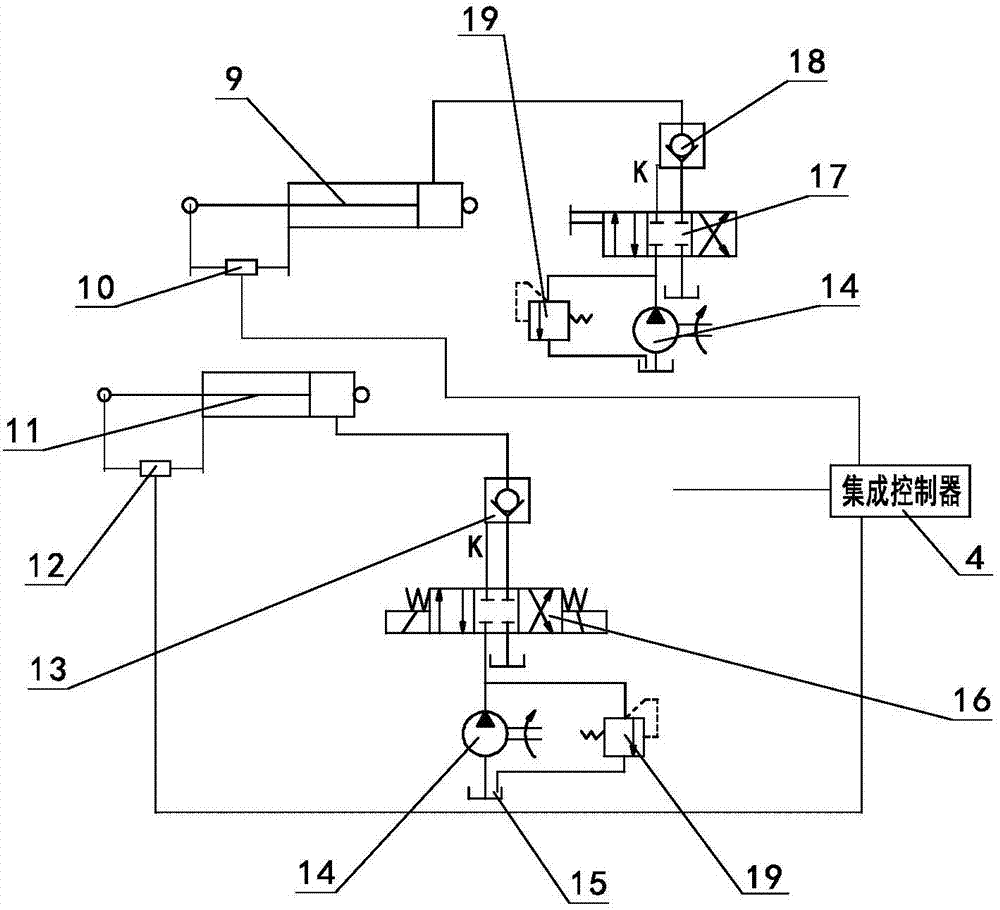

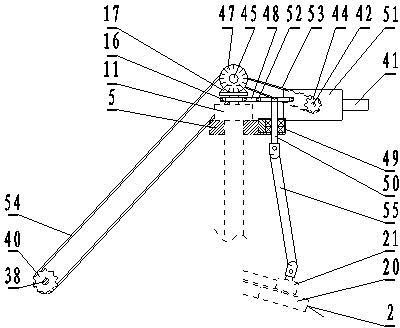

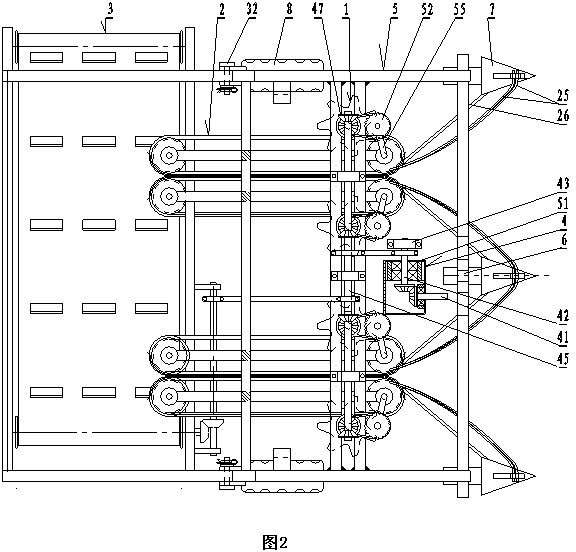

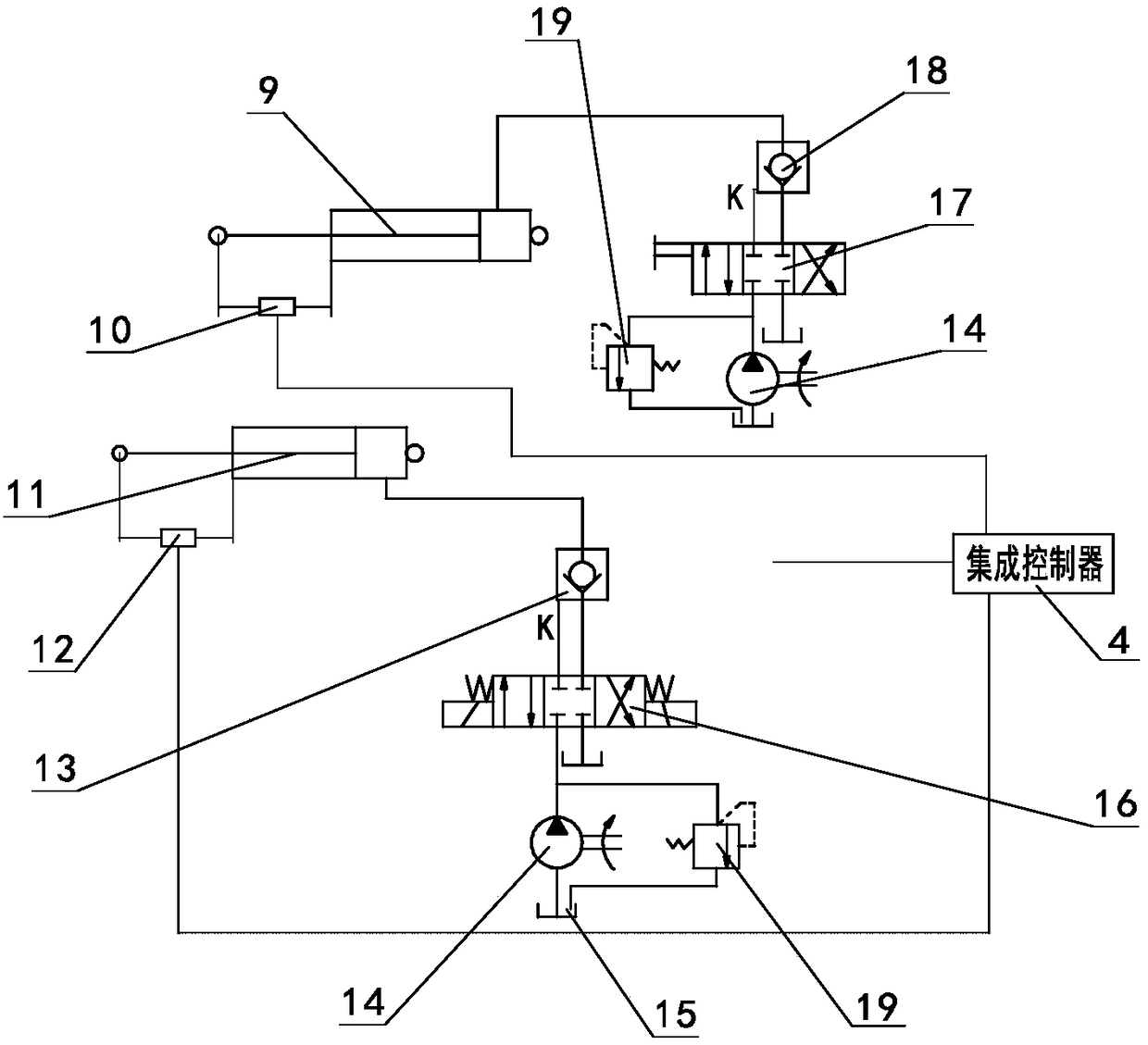

Swathing method of swather connected with combine harvester in hung mode

Disclosed is a swathing method of a swather connected with a combine harvester in a hung mode.The swather connected with the combine harvester in the hung mode is adopted for swathing operation and comprises a vertical swather cutting table, an intermediate connecting mechanism, an integrated hydraulic system, an integrated controller, a combine harvester conveying mechanism, a first oil cylinder execution feedback device, a second oil cylinder execution feedback device, a first hydraulic control one-way valve, a controllable hydraulic pump, a solenoid reversing valve, a manual control reversing valve, a second hydraulic control valve, a first bracket of the cutting table, a second bracket of the cutting table, a rack, a power transmission mechanism, a tensioning mechanism and an auxiliary mechanism, wherein the power transmission mechanism, the tensioning mechanism and the auxiliary mechanism are installed on the rack; through mechanical-electric-hydraulic automation, the angle of the vertical swather is automatically adjusted along with the height of the cutting table, so that the cutting table keeps perpendicular or approximately perpendicular to the ground, the response is rapid, the operation is simple, and therefore the operation effect is ensured.

Owner:HUNAN AGRICULTURAL UNIV

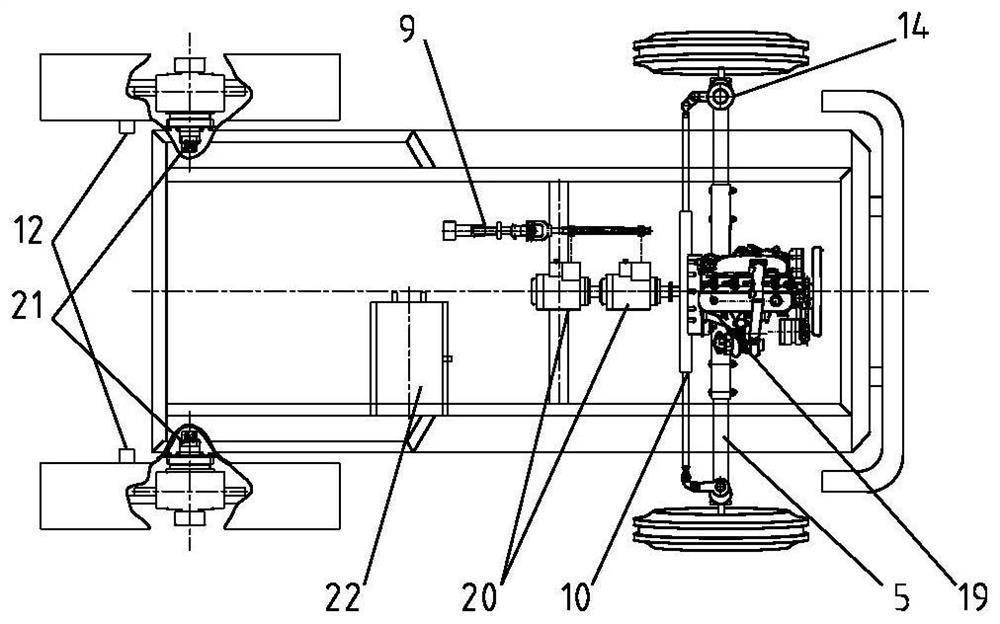

High-ground-clearance swather and linear walking and turning control method thereof

ActiveCN113086004AImprove securityRealize closed-loop controlGuiding agricultural machinesFluid steeringDrive wheelControl engineering

The present invention provides a high-ground-clearance swather which is reasonable in design, a walking driving system for front wheel driving, a rear wheel steering system for active steering of rear wheels and a front wheel auxiliary steering system are matched, the front wheel auxiliary steering system is in active differential matching with the rotating angles of the left rear wheel and the right rear wheel, two-pump and two-motor hydraulic transmission is adopted for front wheel driving, two front wheels are independently controlled. According to the high-ground-clearance swather, the slipping phenomenon caused by free differential speed of the left front wheel and the right front wheel is avoided, the problem that passive differential speed cannot be achieved easily due to the fact that the resistance of the driving wheels is large during turning is solved, and the high-ground-clearance cutter-rower has good walking and steering performance in a field with a poor working environment, and a control method for controlling the high-ground-clearance cutter-rower is further provided. The problems of efficient walking and steering of the high-ground-clearance windrower under the sticky and wet soil condition are solved, and the high-ground-clearance windrower is very practical and wide in application prospect.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

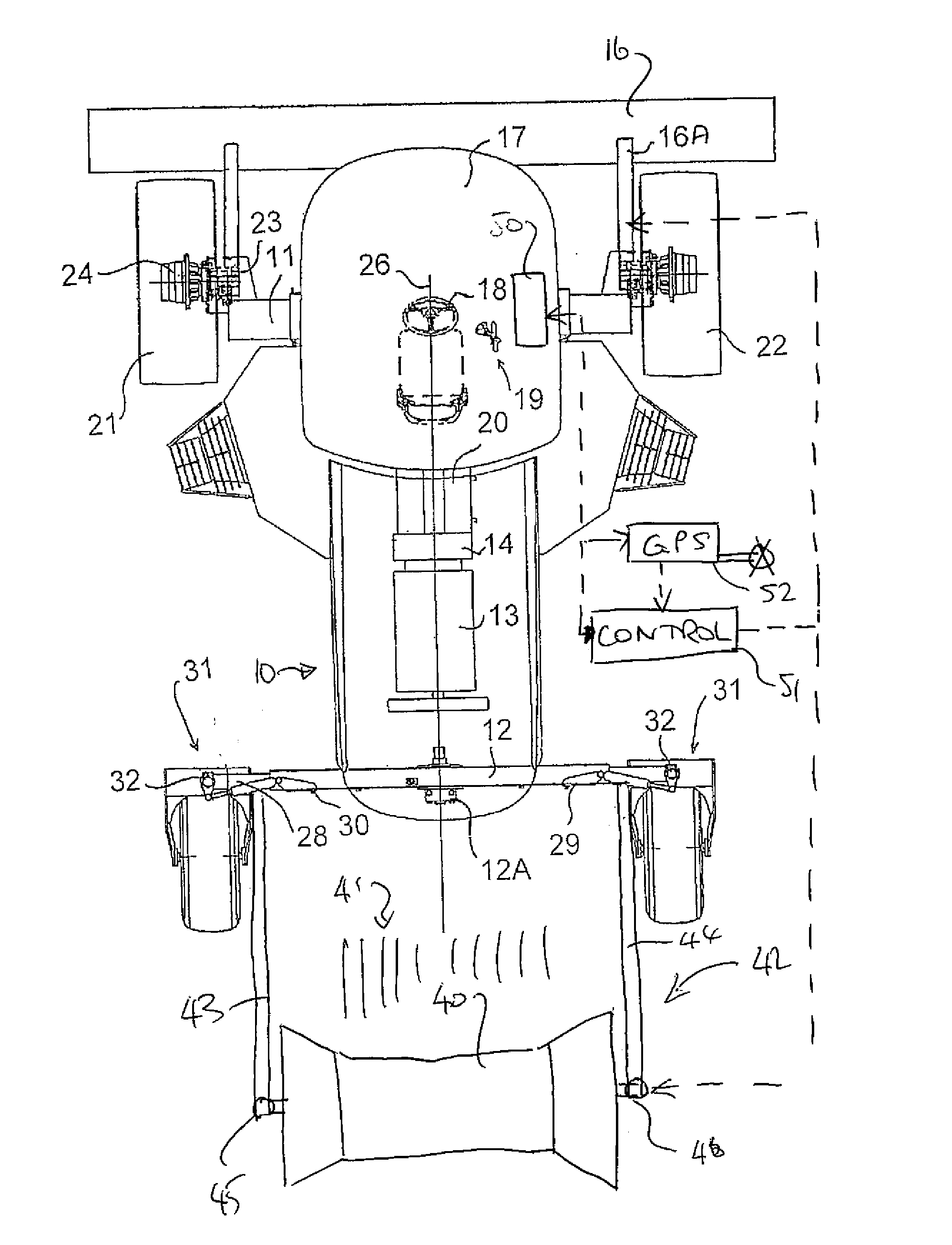

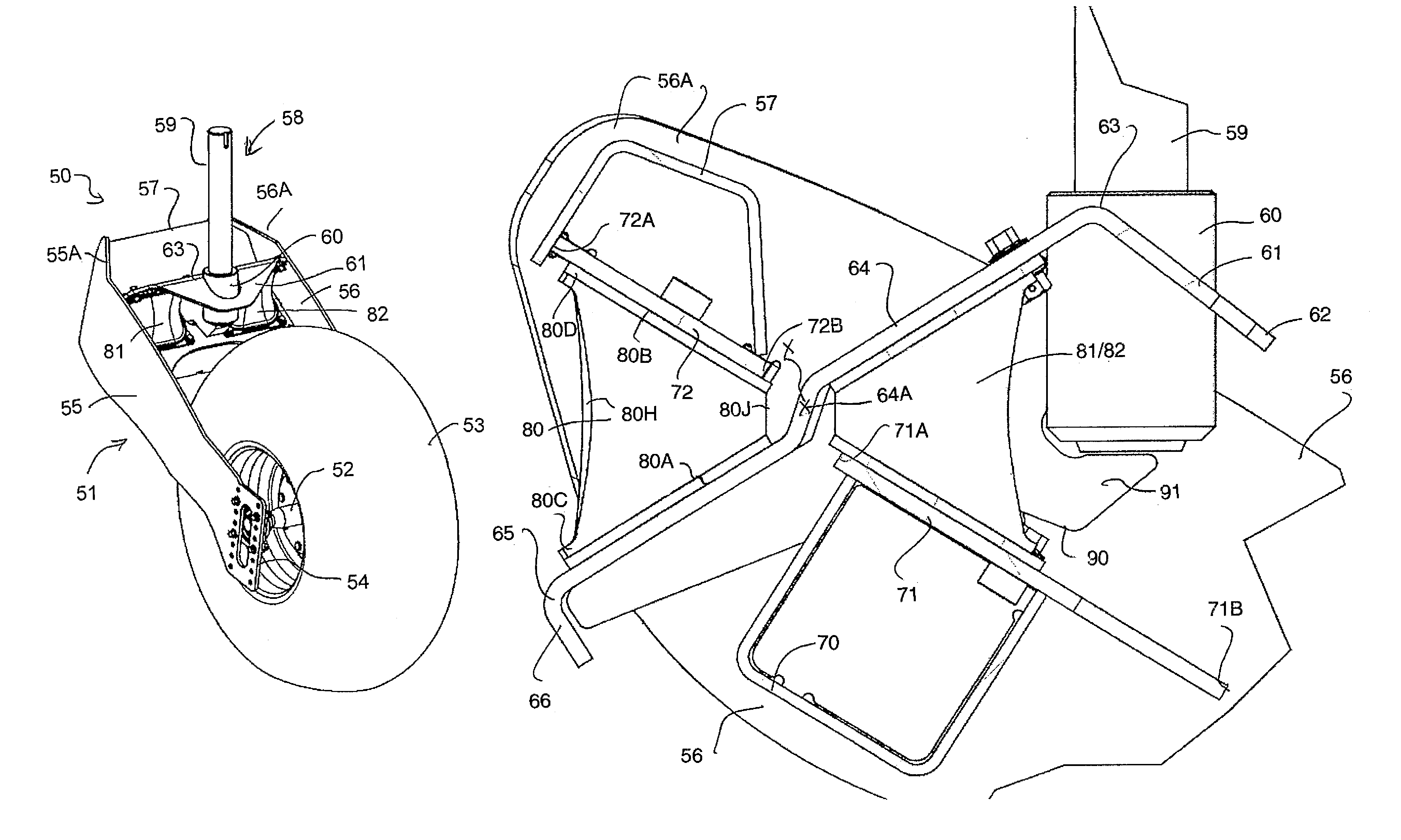

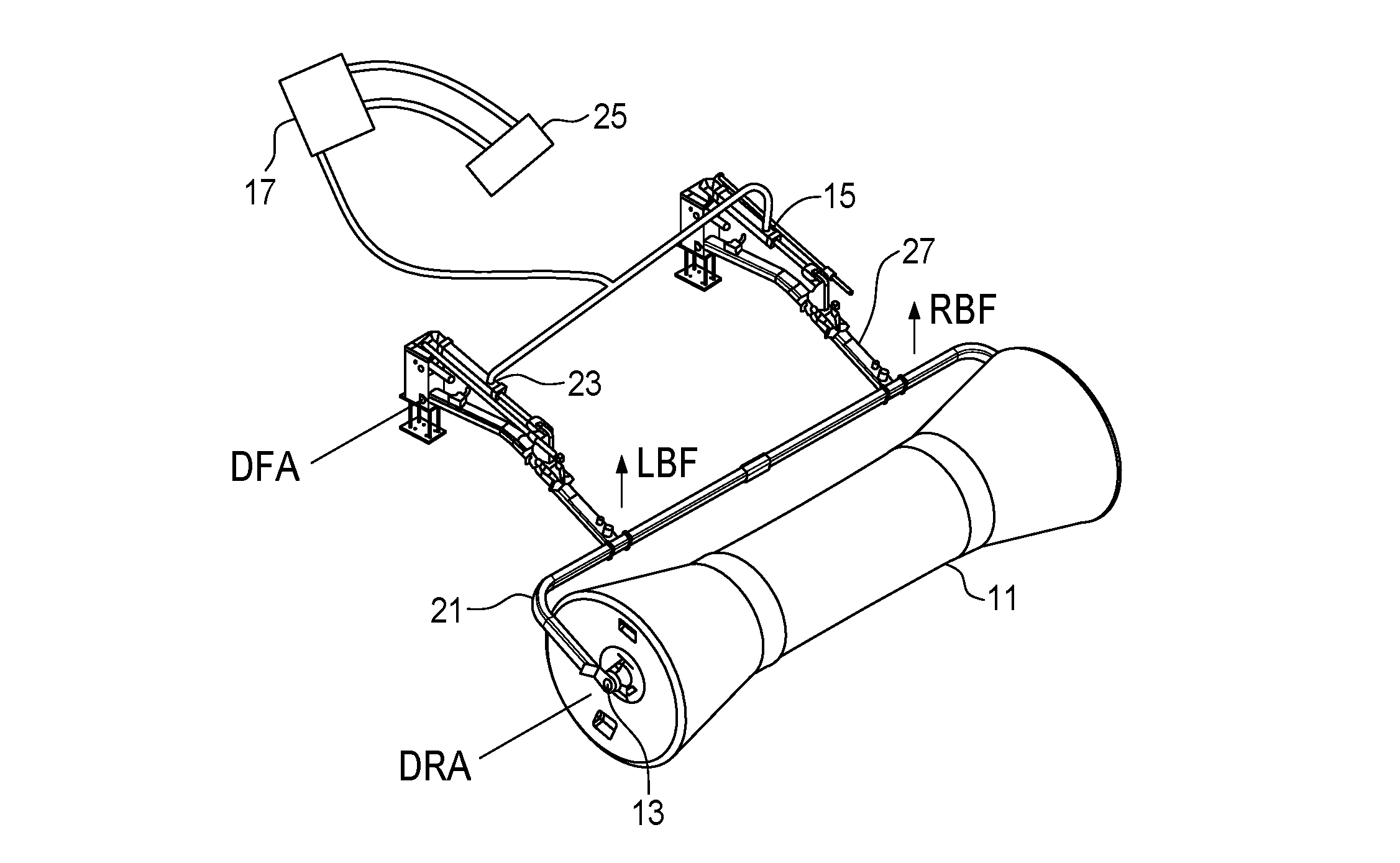

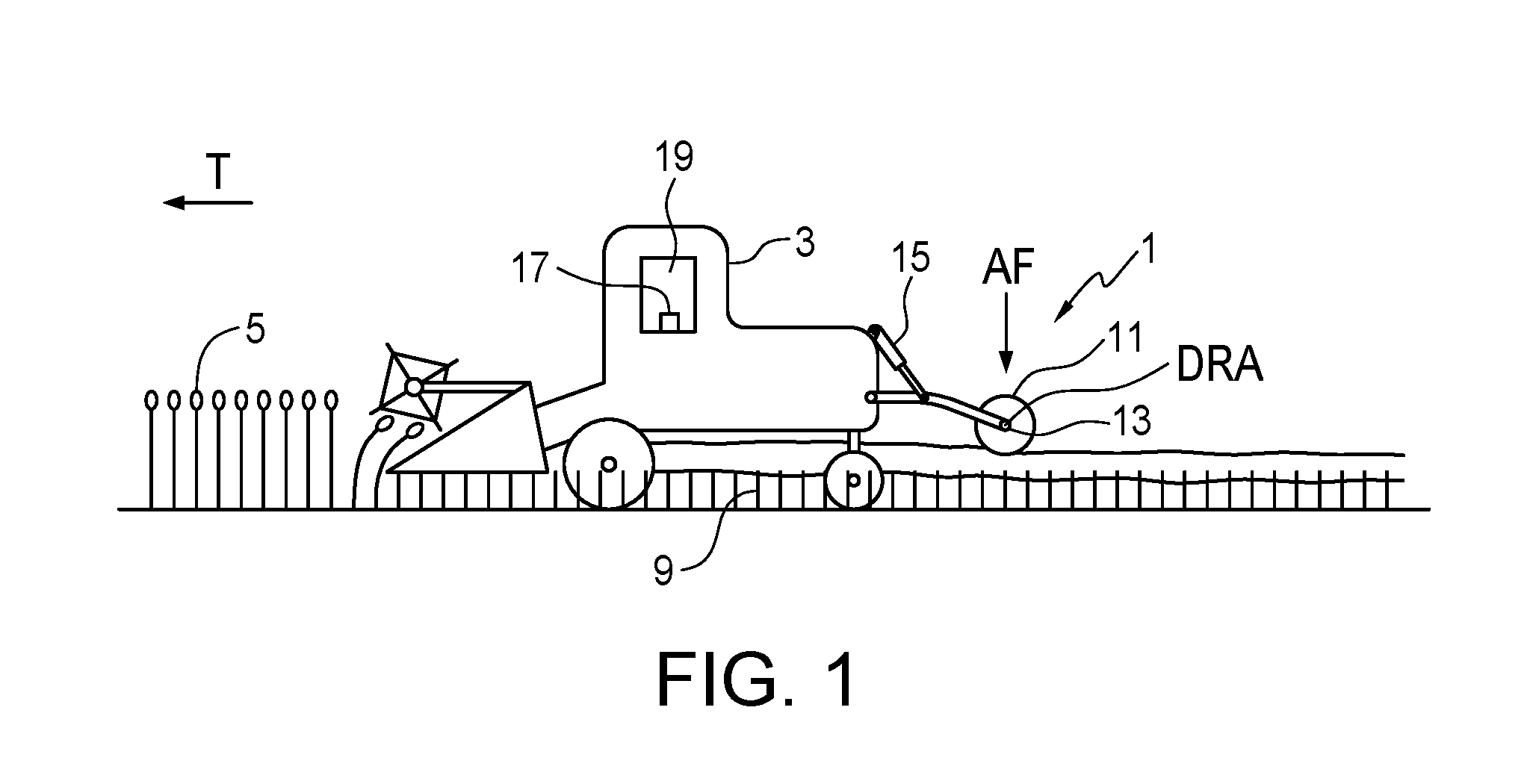

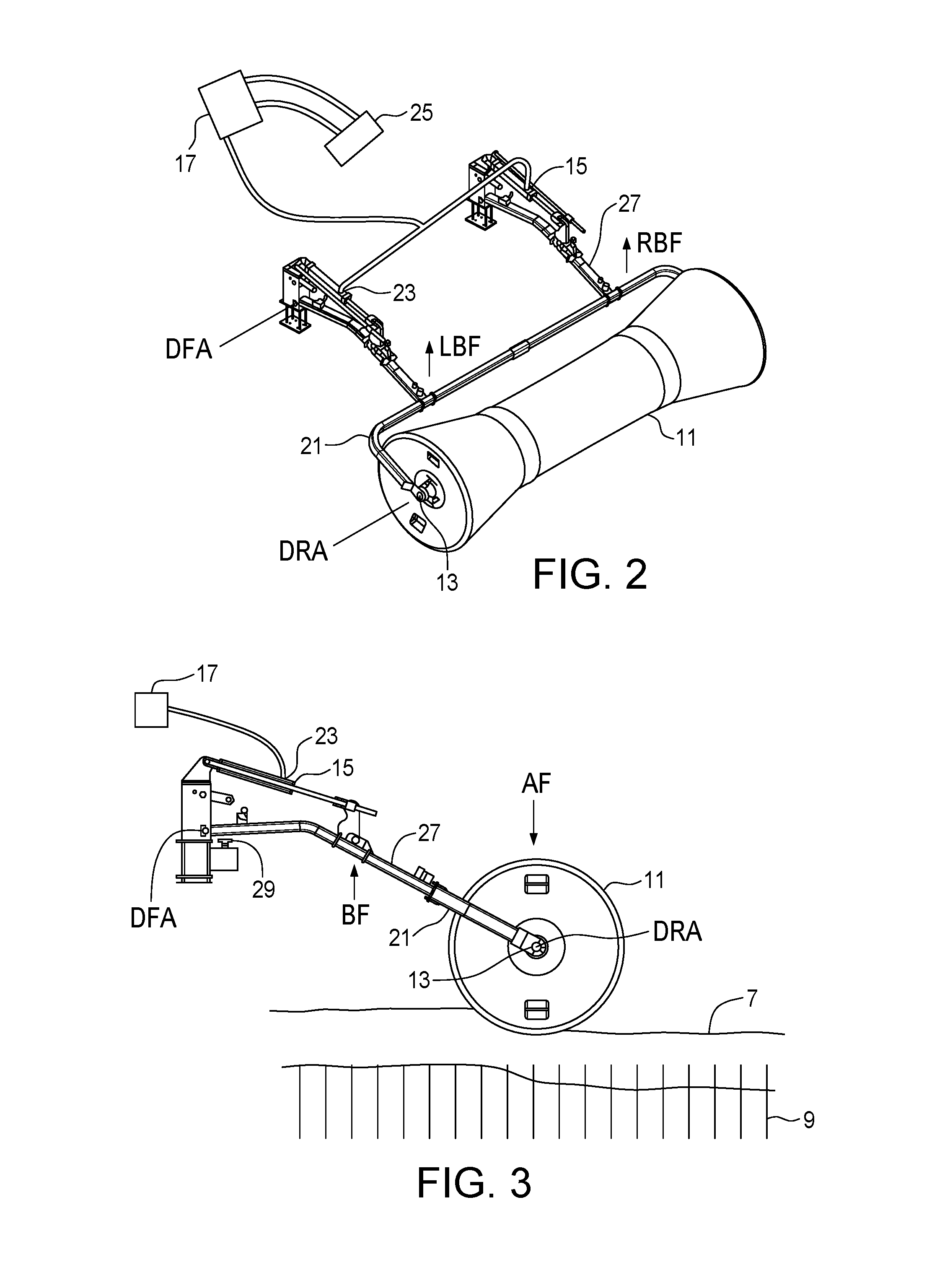

Swath Roller Attachment for a Swather Tractor

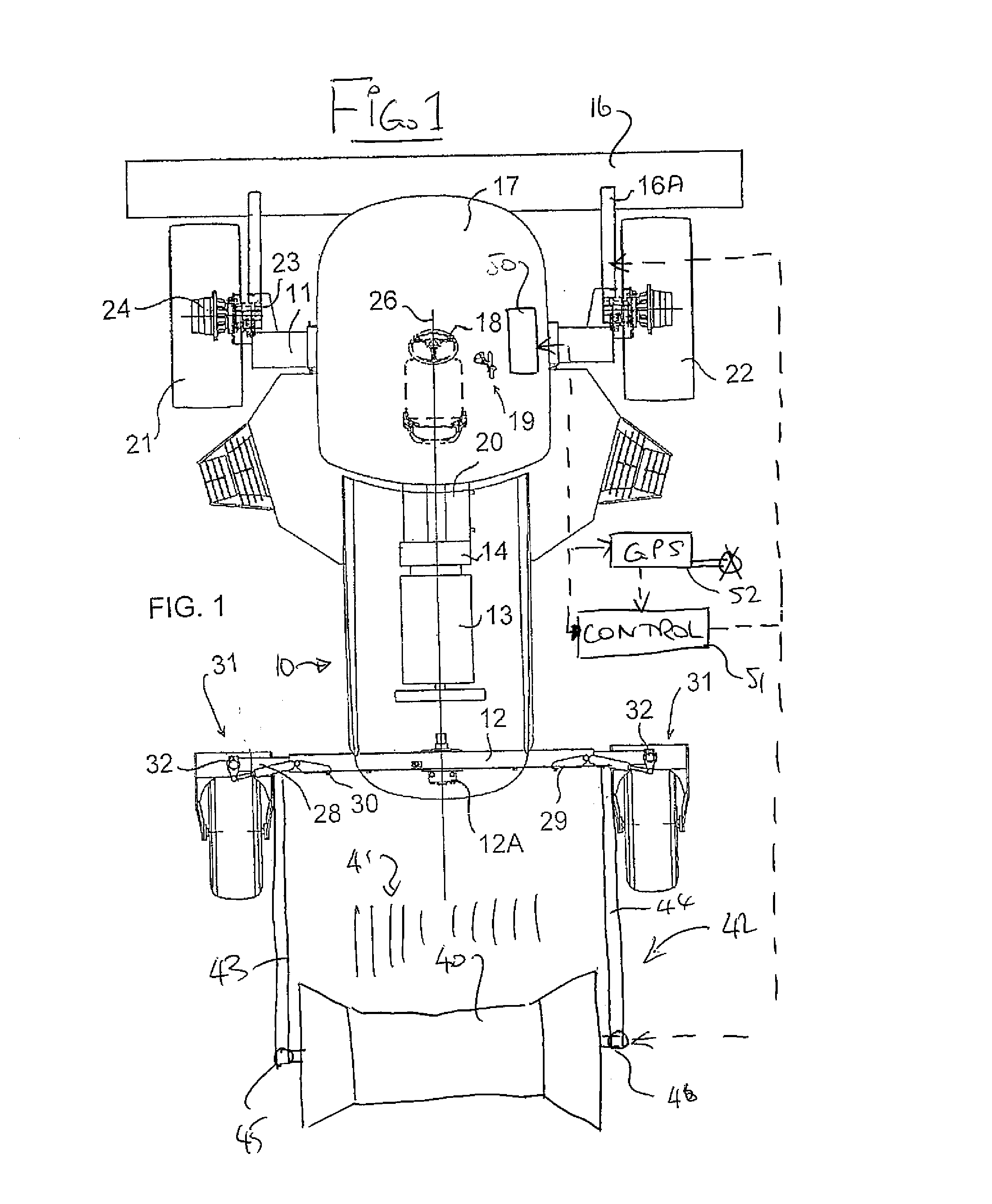

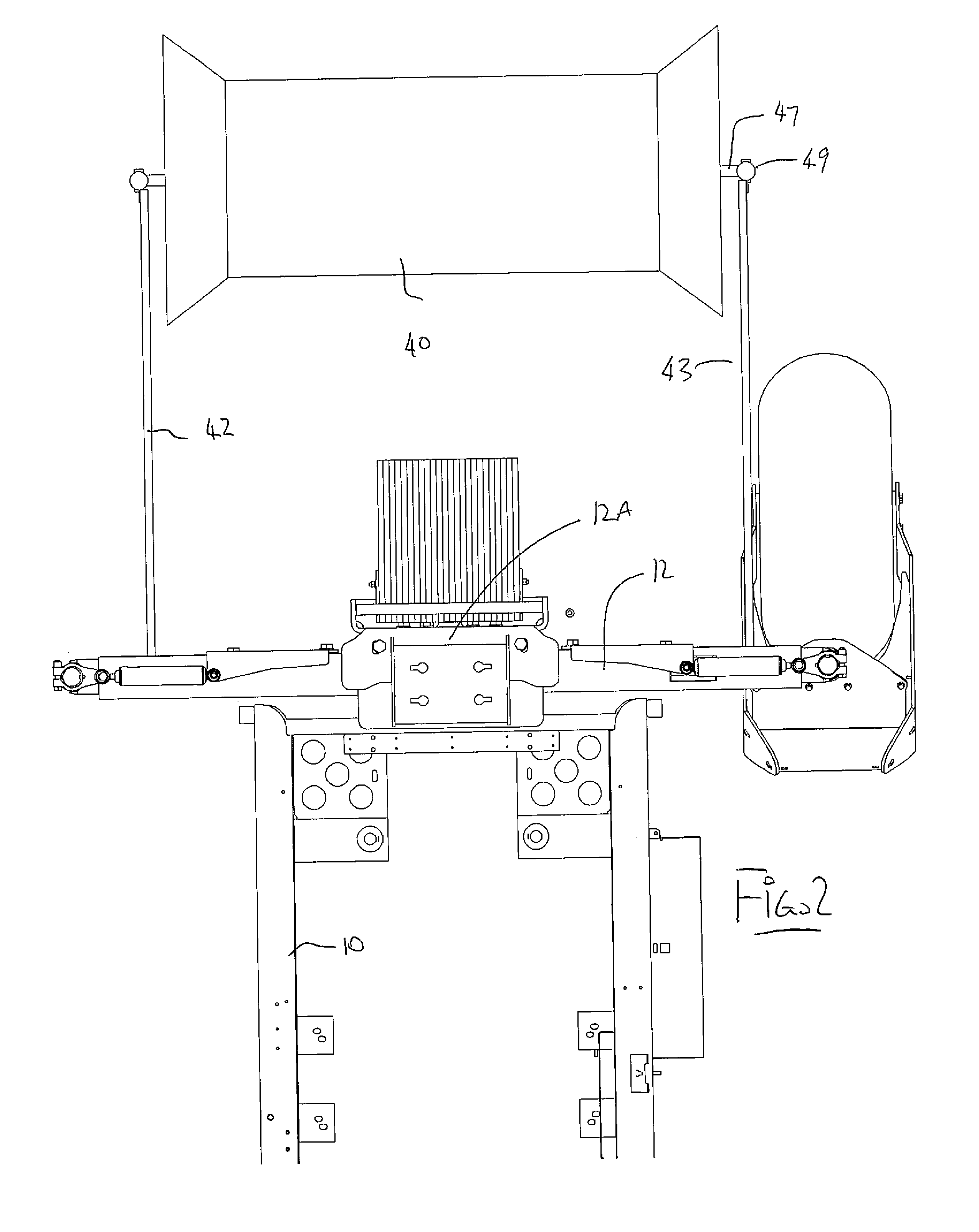

A swather with a crop cutting header includes a swath roller for rolling on the swath carried on a mounting assembly attached to the tractor frame and a lifting assembly for lifting the roller free from the swath where a control unit is arranged to lift the swath roller to the raised position thereof when the header is raised to the raised position thereof. The control unit also includes a GPS position sensing system so that the roller is lifted at positions determined by the GPS position sensing system. The mounting assembly comprises a mounting frame rigidly attached to the rear walking beam of the tractor so that the mounting frame is held at a set position relative to the tractor determined by a position of the beam so that the swath roller is not pivotally mounted relative to the tractor.

Owner:MACDON INDS

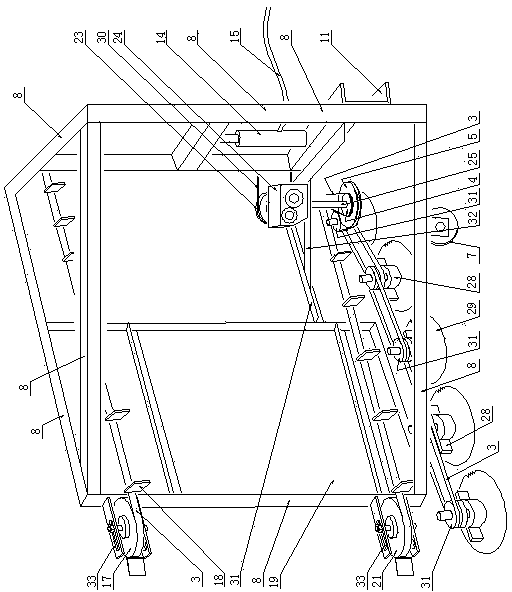

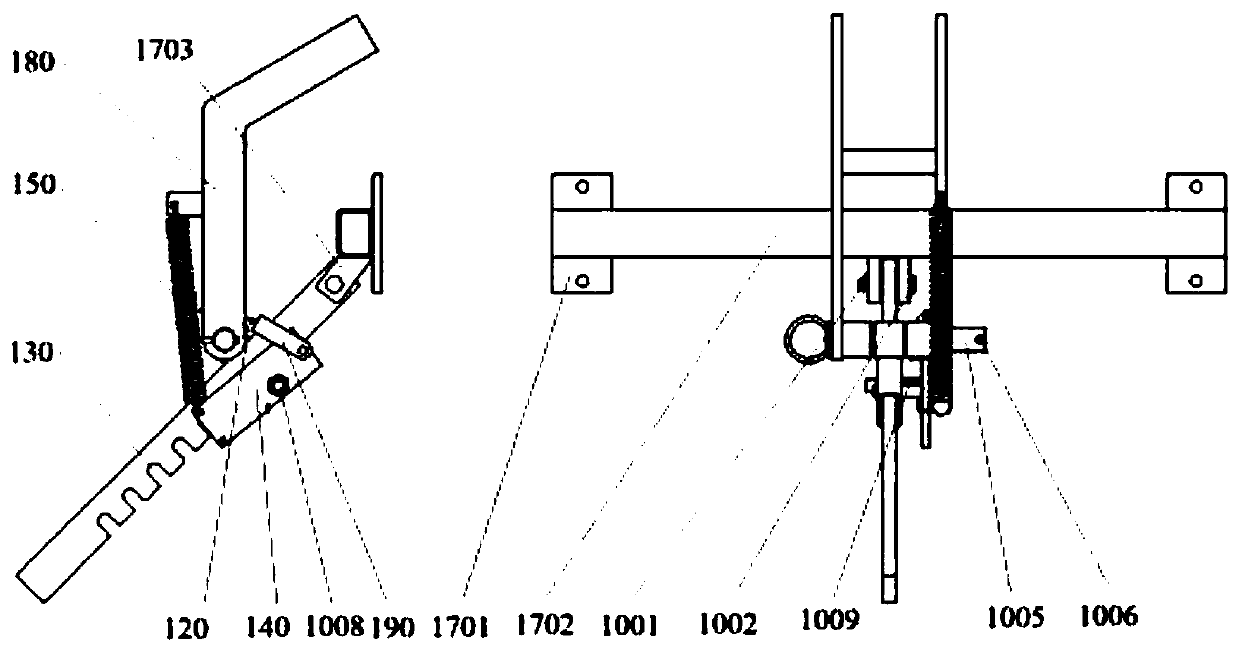

Omnibearing profile device of swather

PendingCN110972691AFulfill profiling requirementsReasonable and reliable structural designHarvestersAgricultural engineeringStructural engineering

The invention particularly discloses an omnibearing profile device of a swather and solves the problem of stubble cutting flatness of an existing swather during harvesting. A left-right profile mechanism comprises a hollow shaft and a connecting frame, wherein a shaft sleeve is arranged on the outer side of the hollow shaft, a strip-like steel plate is arranged above the shaft sleeve, and a left-right adjusting oil cylinder is arranged at the lower part of the strip-like steel plate; an up-down lifting mechanism comprises front lifting cross beams and back lifting cross beams, a front connecting rod is fixed between the two front lifting cross beams, upper lifting cross beams, lower lifting cross beams and front-back adjusting oil cylinders are arranged between the front lifting cross beams and between the back lifting cross beams, and a back connecting rod is arranged between the back lifting cross beams; and output ends of range sensors and range sensors I are connected with the input end of a controller, and the output end of the controller is connected with input ends of the front-back and left-right adjusting oil cylinders. The omnibearing profile device meets the profile requirement when harvesting crops on land which is uneven left and right and wavy front and back and can realize stubble cutting flatness so as to meet harvest requirements.

Owner:SHANXI AGRI UNIV +1

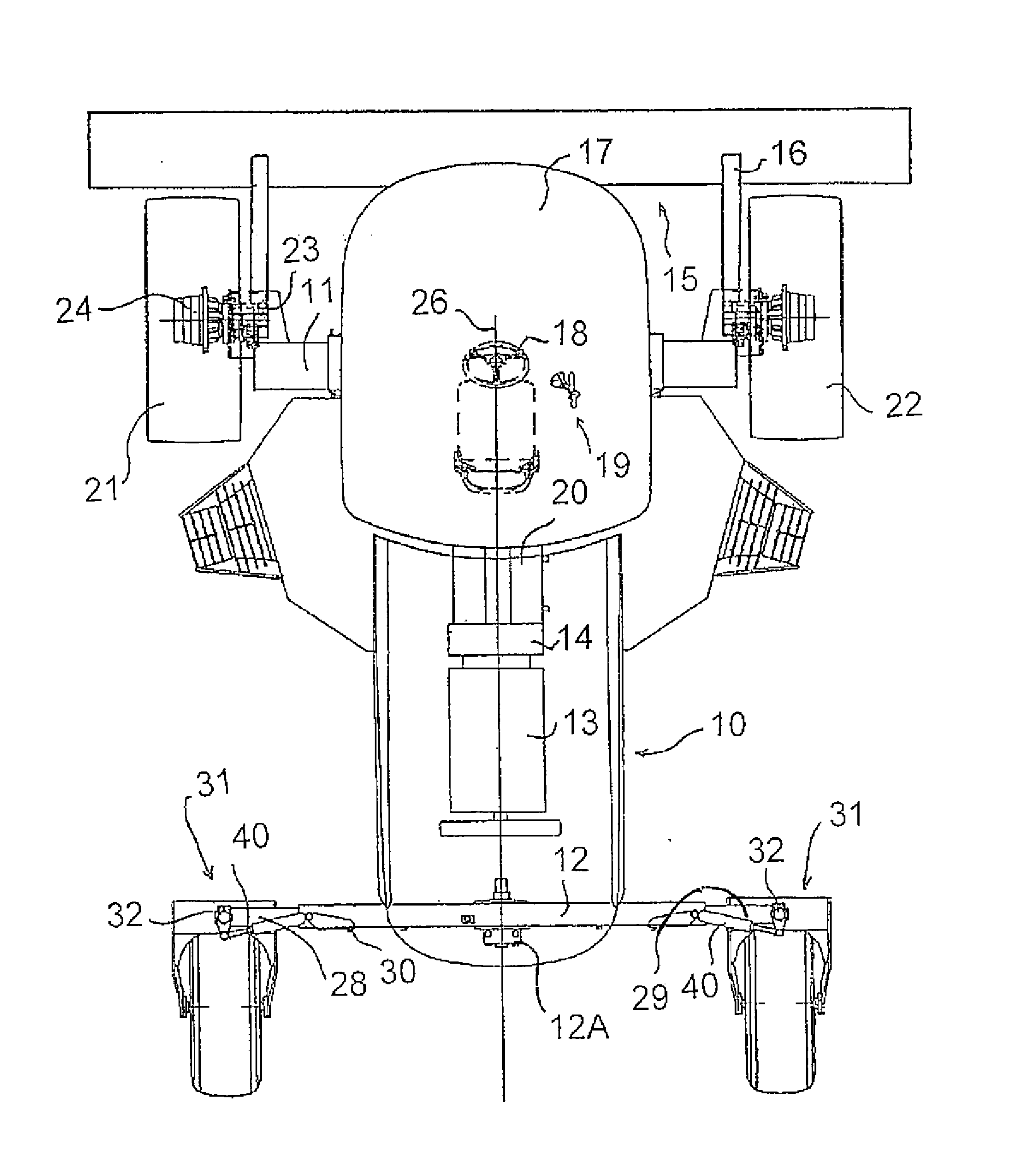

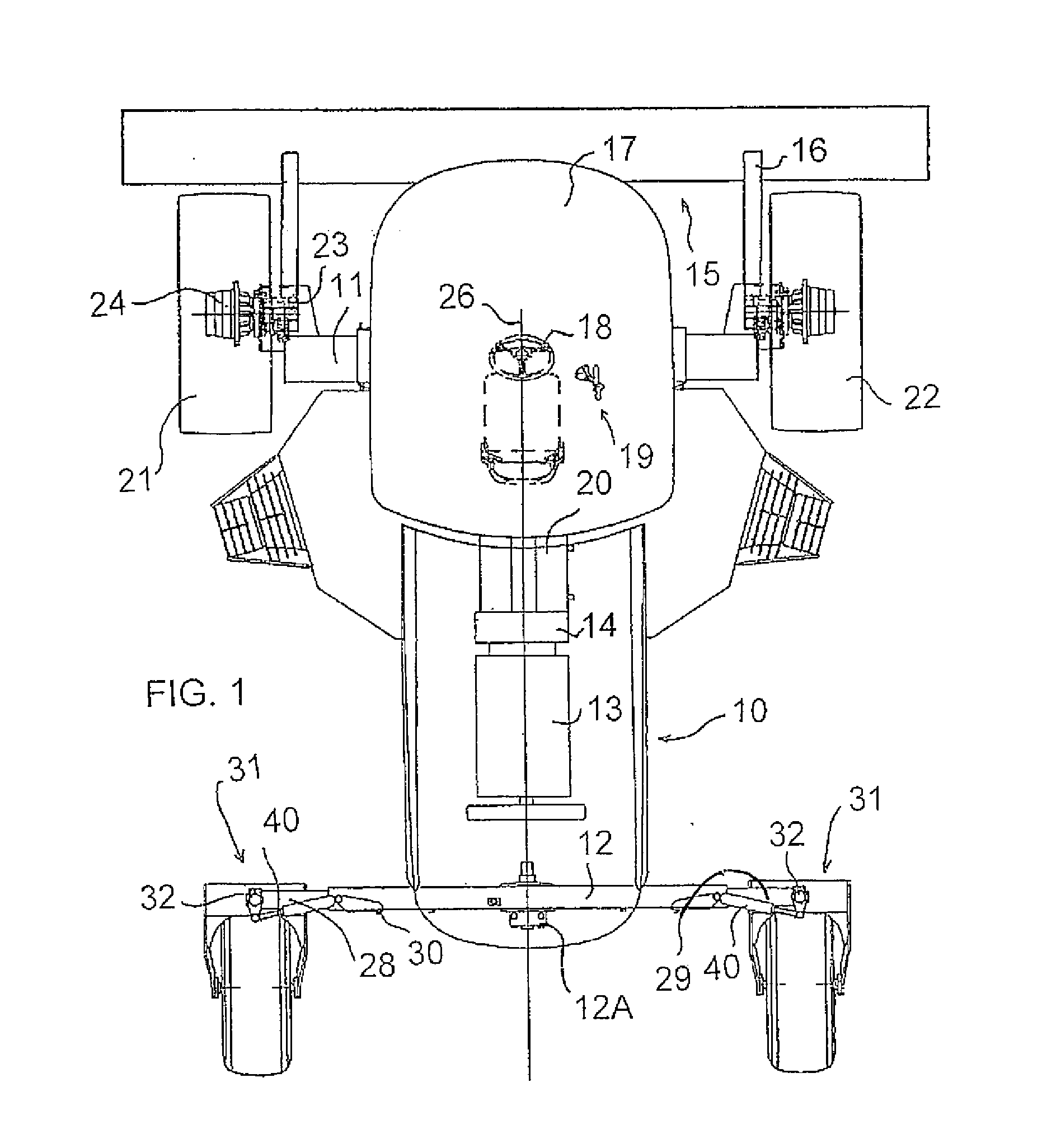

Trailer for a self-propelled swather

A trailer is provided for having a self-propelled swather mounted thereon. The trailer includes first and second caster wheel supports and first and second drive wheel supports. The caster wheel supports are selectively movable being stowed and support positions. The drive wheel supports are selectively movable between horizontally disposed and vertically disposed positions. Each of the caster wheel supports includes a caster wheel turning assembly to partially pivot the associated caster wheel as the swather is backed onto the trailer. The trailer also includes extenders for attachment to first and second ramps. The extenders may be stowed on the bumper.

Owner:DUOELEVATOR MFG

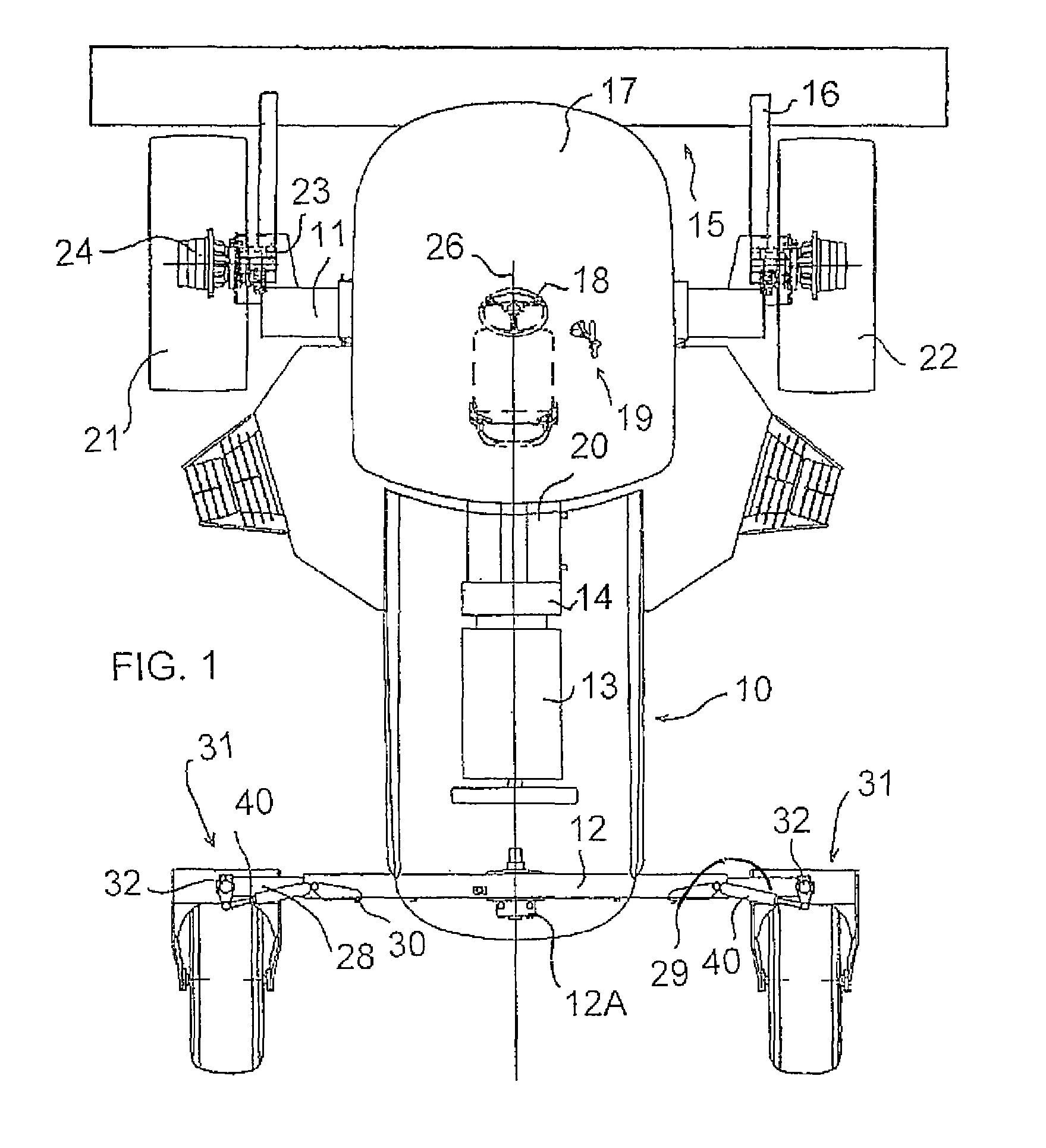

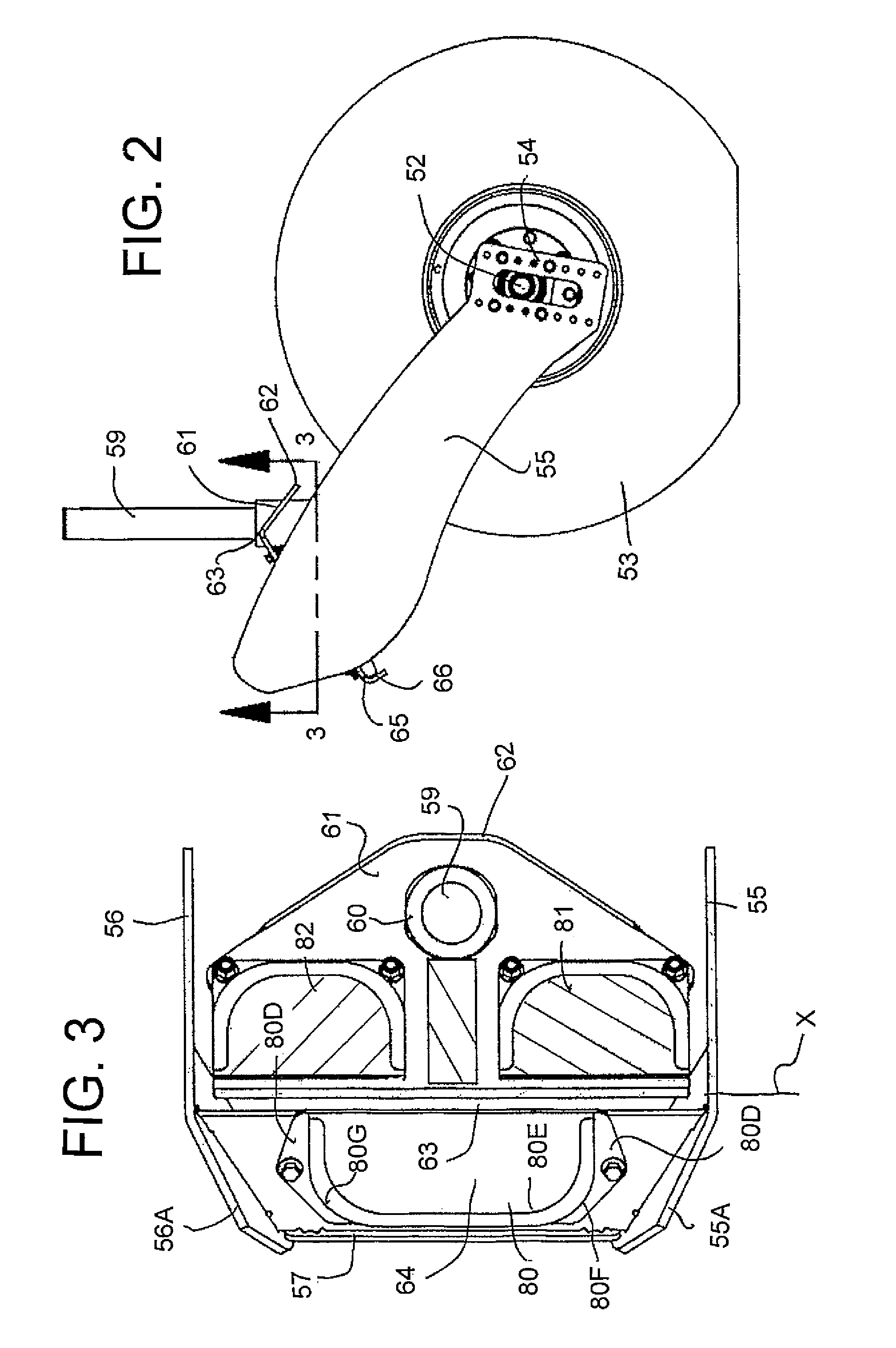

Rear suspension for swather tractor

ActiveUS9415651B2Optimize layout and packagingProviding lateral stiffnessInterconnection systemsResilient suspensionsCasterTractor

A rear castor wheel for a tractor includes a beam carried on a fork which connects to a castor mounting assembly attached to a rear pivotal beam of the tractor. A suspension system connects the fork to the mounting assembly to provide suspension movement and includes a first transverse plate assembly attached to the mounting assembly intersected by a second plate assembly attached across the two sides of the fork. The plates are connected by a single elastomeric block located on a first side of the axis remote from the beam and two elastomeric blocks located between the first and second plate assemblies on a side of the axis closer to the beam so that upward movement of the beam causes compression of the first and second elastomeric blocks which are shaped such that the internal strain of the block as the beam moves upwardly is substantially uniform through the block.

Owner:MACDON INDS

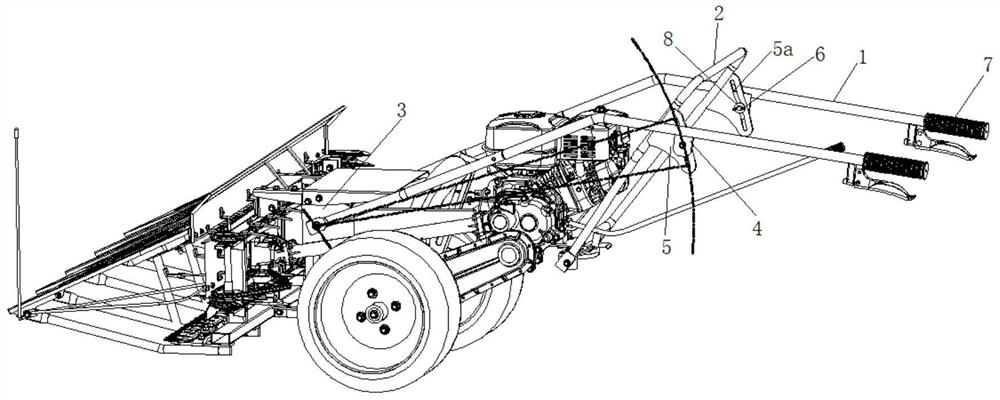

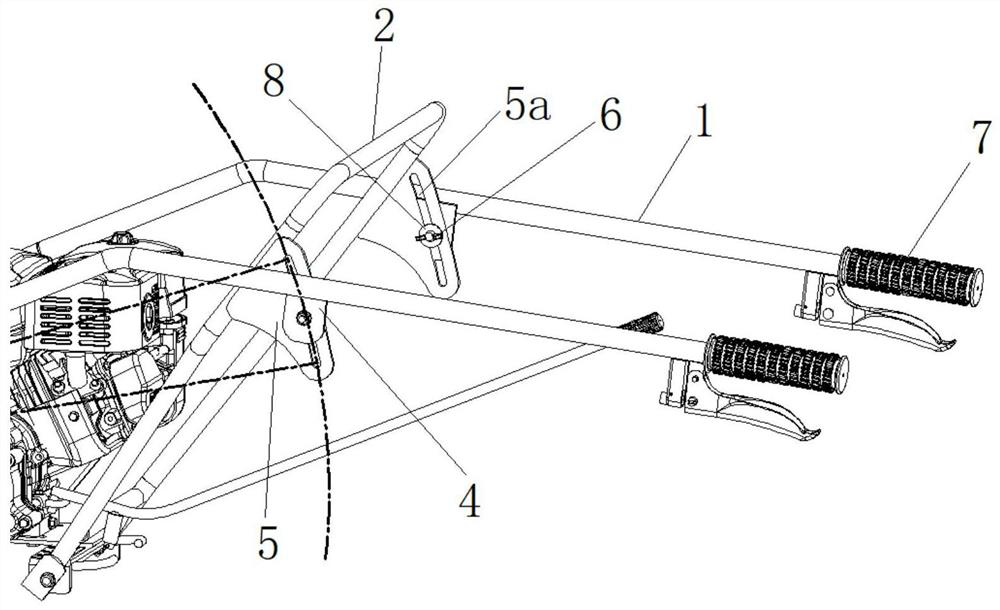

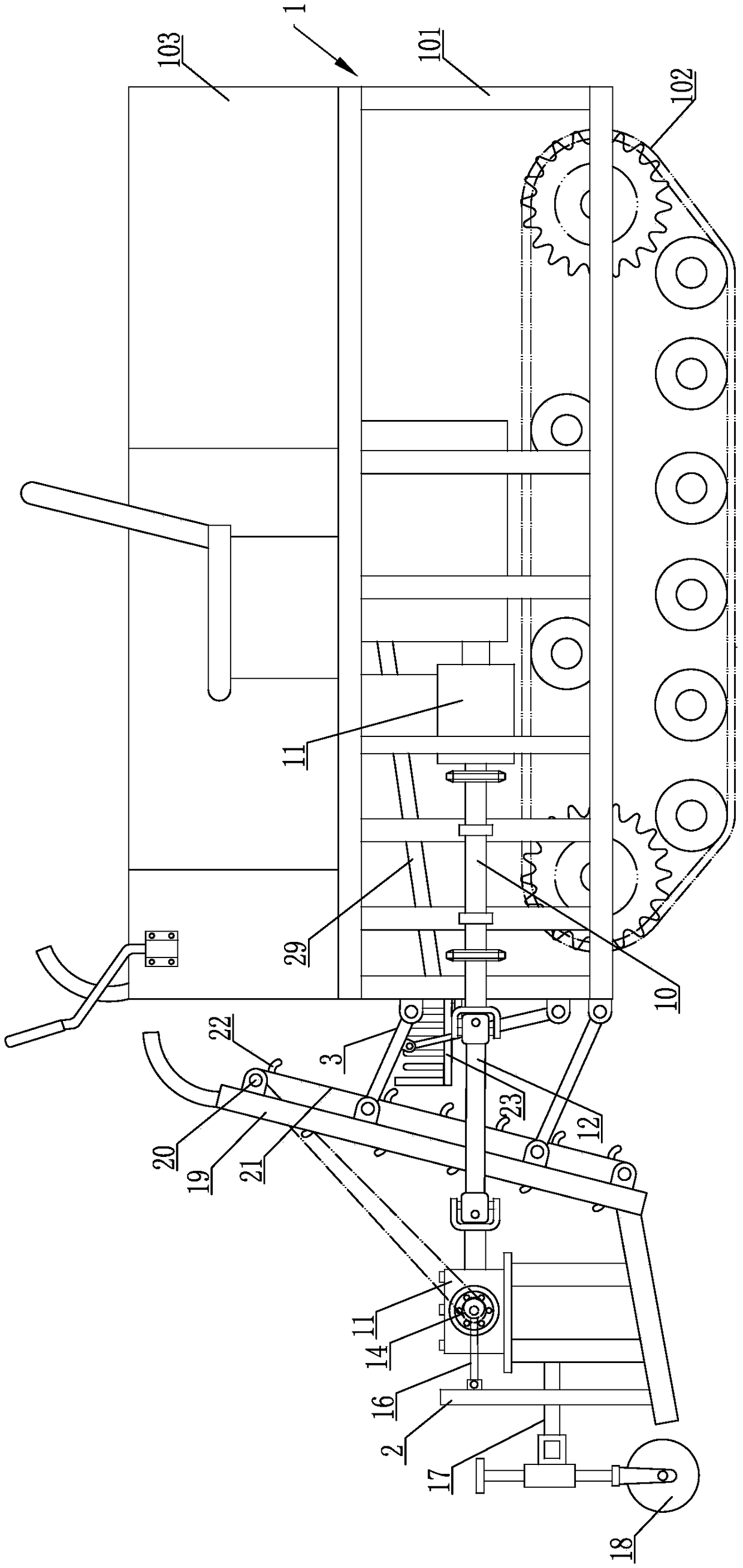

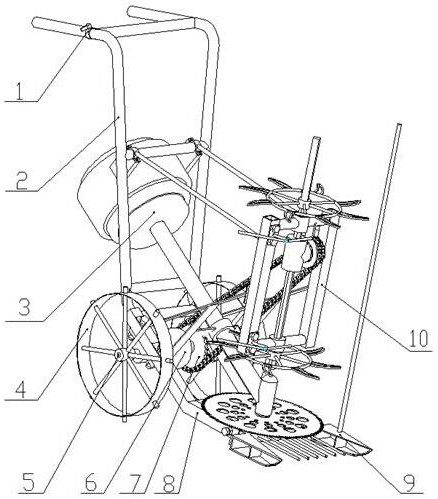

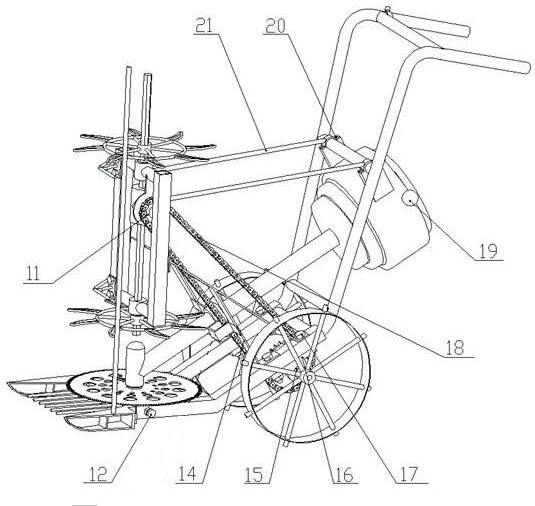

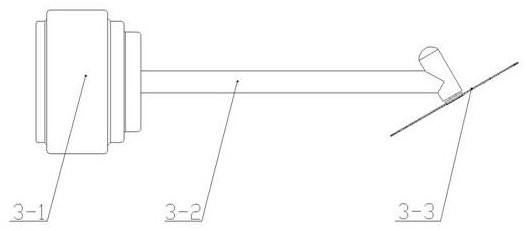

Swather

The invention discloses a swather which comprises an engine, a main transmission system, a main rack, a walking box, an armrest frame, a supporting frame, a header, wheels, a main clutch control handle, a header clutch control handle and a gear shifting rod. The main transmission system is connected with a header driving mechanism through a transmission shaft, the header driving mechanism comprises a header clutch assembly, an eccentric arm assembly and a driving disc, and the clutch assembly comprises a driving shaft, a header clutch arm, a clutch bevel gear, a header transmission shaft, a transmission bevel gear and a first clutch claw. Independent lifting adjustment of a left armrest and a right armrest can be realized, so that individual requirements of different operators can be met;the structure of header lifting adjustment is simplified, so that the header lifting adjustment is more convenient and faster; header driving has a clutch function, and the wheels can independently walk; the transmission structure of a main transmission mechanism is changed to improve the transmission efficiency; and the problems of drooping and swinging of a large-span chain wheel and chain conveying mechanism of the header are avoided.

Owner:CHONGQING DINKING POWER MACHINERY +1

Swather for kidney beans

The invention discloses a swather for kidney beans. The swather comprises ridging devices, seedling gathering and carrying devices, turnable conveying devices, a driving device, a frame, a suspension bracket, shares with angle irons and land wheels, wherein the suspension bracket is connected to the middle of a cross beam above the front end of the frame and is connected with a tractor in a suspension manner; three shares with the angle irons are connected onto three vertical beams below the front end of the frame; and the land wheels are connected with the lower end of an L-shaped vertical beam between two sides of the frame; two sets of ridging devices are respectively connected between the frame and two cross beams; two sets of seedling gathering and carrying devices are respectively connected to eight vertical beams of the frame; the upper parts at the rear ends of two side frames of the frame are connected with the turnable conveying devices through pin roll assemblies; and a transmission case is fixedly arranged at the middle above the front end of the frame and is respectively in driving connection with the ridging devices, the seedling gathering and carrying devices and the turnable conveying devices through transverse transmission shafts. Due to the adoption of the firm ridging devices, the seedling gathering and carrying devices formed by reliable compound elevating conveyor belts and the turnable conveying devices, the swathing quality and efficiency are greatly increased.

Owner:夏元海 +1

Self-propelled garlic harvester

PendingCN108811671AImprove harvesting efficiencySimple processLiftersTopping machinesSwatherAgricultural engineering

The invention discloses a self-propelled garlic harvester comprising a vehicle body and a power device; the front end of the vehicle body is hinged and provided with a garlic bulb soil screening device; the vehicle body is provided with a garlic bulb conveying device located at the rear end of the garlic bulb soil screening device; the vehicle body is provided with a secondary soil screening device located at the rear end of the garlic bulb conveying device; the vehicle body is provided with a garlic bulb outward-conveying device located at the garlic outlet end of the secondary soil screeningdevice; the garlic bulb soil screening device, the garlic bulb conveying device, the secondary soil screening device and the garlic bulb outward-conveying device are respectively driven by and connected to the power device. A cutting table of a swather is hung at the front end of the vehicle body and is used to be matched with the garlic bulb soil screening device to realize the unearthing, seedling cutting and primary soil screening of garlic, then, the garlic is conveyed to the secondary soil screening device for secondary soil screening by the garlic bulb conveying device and is outwards conveyed by the garlic bulb outward-conveying device, garlic bulbs can be directly placed into baskets at the end of the garlic bulb outward-conveying device, and the whole process can be finished by only additionally matching one person on a basket filling position, so that the garlic harvesting efficiency is high, and the process is simple and labor-saving.

Owner:陈义良

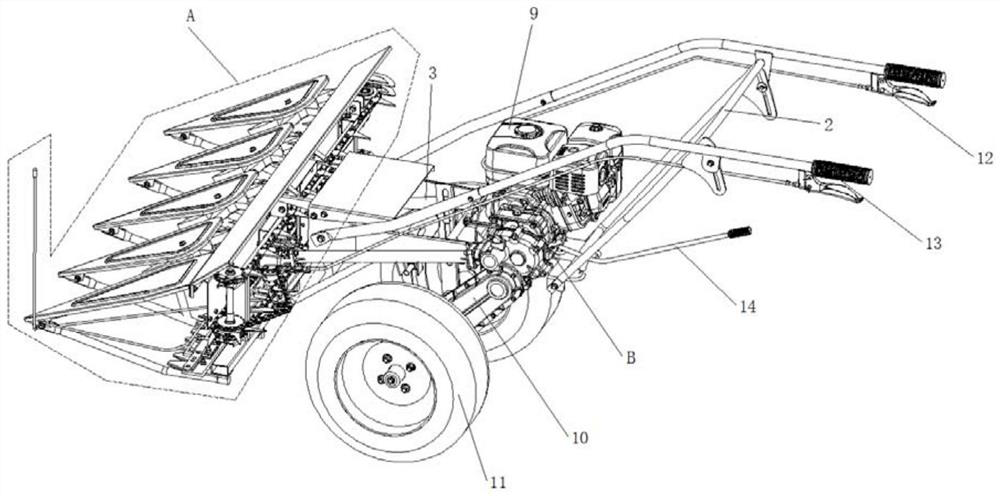

A miniature wheat windrower

ActiveCN108012661BLight in massReduce volumeHarvestersAgricultural engineeringStructural engineering

The invention provides a micro wheat swather. The wheat swather comprises a hand supporting rack and a machine rack which is installed at the lower end of the hand supporting rack, a land wheel axle is arranged on the lower portion of the machine rack, land wheels are arranged at the two ends of the land wheel axle respectively, a front frame is arranged at the front end of the machine rack, and an independent cutter is arranged on the upper portion of the front frame and matched with the front frame. A reeling device is arranged above the independent cutter and comprises a reeling frame, thereeling frame is connected with the machine rack, a reeling shaft is vertically sleeved with the reeling frame, an upper reeling disc and a lower reeling disc are arranged at the two ends of the reeling shaft respectively, the upper reeling disc and the lower reeling disc are located above the independent cutter and on the two sides of the reeling frame respectively, and the reeling shaft is sleeved with a bevel gear box which is linked with the land wheel axle. The micro wheat swather fills the gap in the field of micro wheat swathers, the problems that operation is conducted in hilly land, small land blocks and complex land blocks are solved, and the micro wheat swather has the advantages of being low in weight, small in size, small in swath, convenient in operation and the like.

Owner:GANSU AGRI UNIV

Trailer for a self-propelled swather

Owner:DUOELEVATOR MFG

Rear Suspension for Swather Tractor

ActiveUS20150336437A1Great articulationReduce intensityInterconnection systemsResilient suspensionsEngineeringTractor

A rear castor wheel for a tractor includes a beam carried on a fork which connects to a castor mounting assembly attached to a rear pivotal beam of the tractor. A suspension system connects the fork to the mounting assembly to provide suspension movement and includes a first transverse plate assembly attached to the mounting assembly intersected by a second plate assembly attached across the two sides of the fork. The plates are connected by a single elastomeric block located on a first side of the axis remote from the beam and two elastomeric blocks located between the first and second plate assemblies on a side of the axis closer to the beam so that upward movement of the beam causes compression of the first and second elastomeric blocks which are shaped such that the internal strain of the block as the beam moves upwardly is substantially uniform through the block.

Owner:MACDON INDS

Swath roller with controlled anchoring force

A swath roller apparatus is adapted to be attached to a swather, where the swather is operative to cut standing crop plants and lay cut plants in a swath as the swather moves along the ground in an operating travel direction. A drum is rotatably attached to an axle that is adapted to be movably attached to a rear portion of the swather such that the axle is oriented substantially horizontally and perpendicular to the operating travel direction, and such that the drum moves up and down and rolls along a top of the swath exerting a downward anchoring force on the swath. A bias element is operative to exert a bias force on the axle, and a bias force control is operative to vary the bias force to vary the anchoring force.

Owner:BOURGAULT INDS

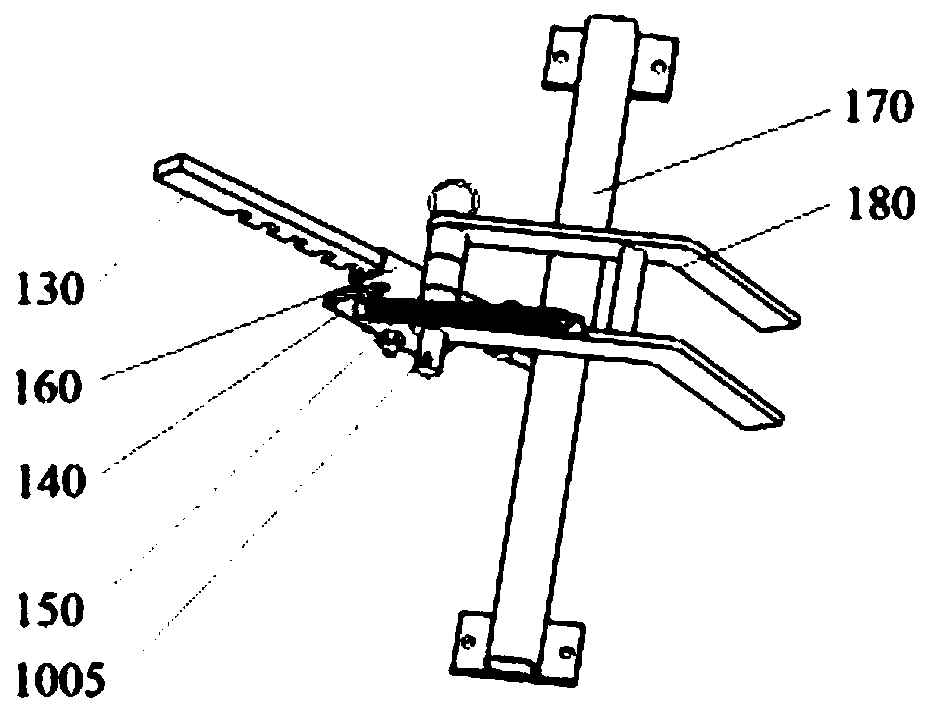

Stubble height adjusting mechanism for walking type oilseed rape swather

InactiveCN110731167AImprove adaptabilityReduce work intensityHarvestersAgricultural undercarriagesAnimal scienceEngineering

The invention belongs to the technical field of agricultural machinery and provides a stubble height adjusting mechanism for a walking type oilseed rape swather. The stubble height adjusting mechanismfor the walking type oilseed rape swather comprises a mounting frame, a U-shaped frame, a toothed slide rail, a ferrule welding part, an adjusting plate welding part, a U-shaped clamp and a reset spring. The mounting frame is fixedly arranged on a chassis of the walking type oilseed rape swather; the tail end of the U-shaped frame is fixedly arranged on the chassis of the walking type oilseed rape swather, positioned above the mounting frame and perpendicular to the mounting frame; one end of the toothed slide rail is provided with a plurality of U-shaped holes while the other end is fixedlyconnected with the mounting frame; the ferrule welding part sleeves the toothed slide rail and is fixedly arranged in the middle of the U-shaped frame; the adjusting plate welding part is arranged onone side of the ferrule welding part; the U-shaped clamp is provided with a pull wire. The stubble height of the swather can be adjusted according to different operating conditions, adaptability of the oilseed rape swather to oilseed rape with different characteristics is improved, operating efficiency is improved, and operating intensity of an operator is relieved.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

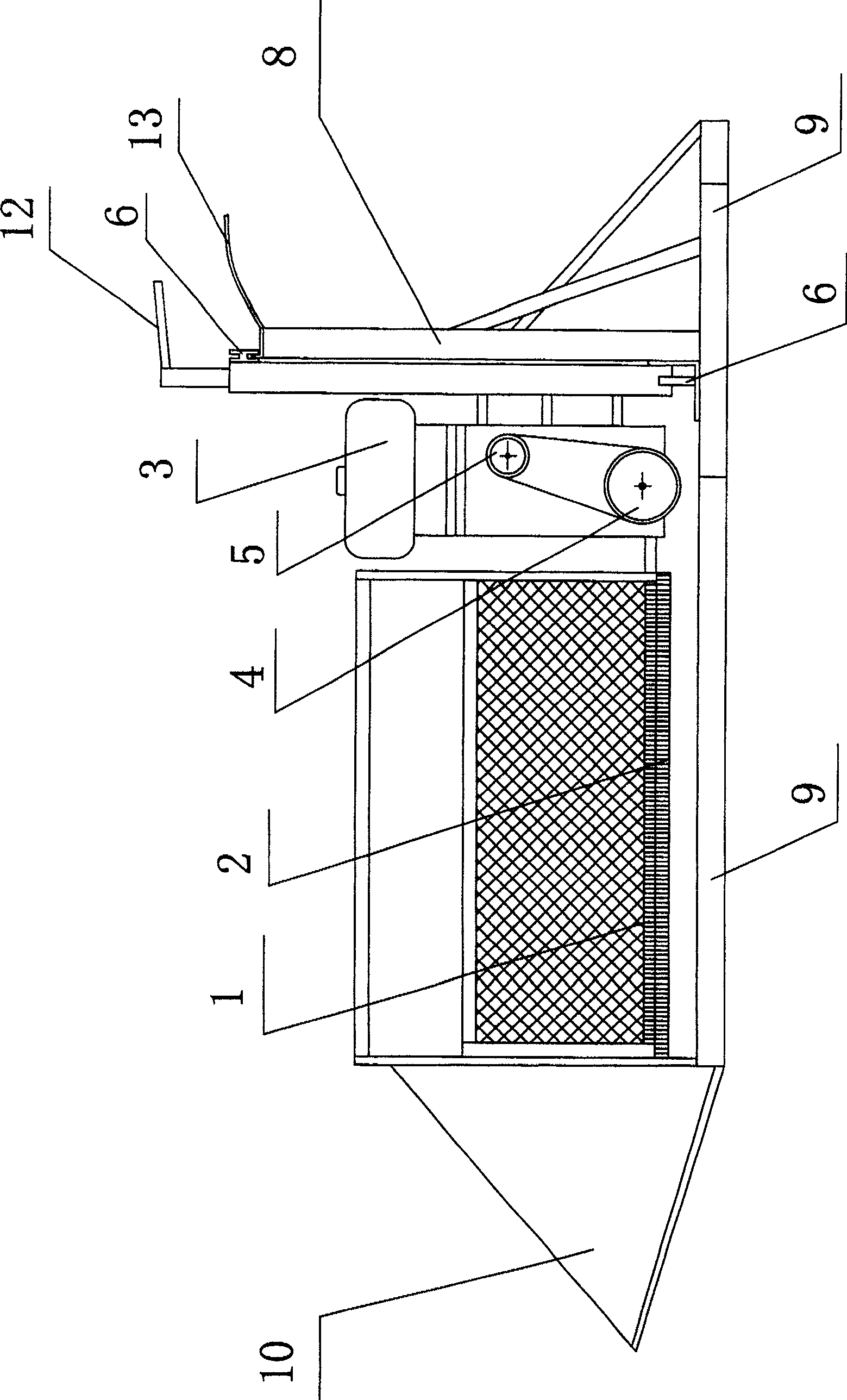

Miniature cutting and sunning machine

InactiveCN100508730CImprove efficiencyEasy to threshMowersOutside dividersReciprocating motionSemi automatic

The miniature windrower of the present invention is mainly used for cutting rice and wheat in the field. The cutting tool includes sawtooth-shaped upper and lower blades driven by a power machine and reciprocating along a straight line. , the short tooth edge of the small serration is parallel to the moving direction of the blade or the short tooth edge of the small serration is biased towards the tooth root of the large serration. The power machine is supported by the rollers on the bracket on the guide rail of the miniature windrower frame. The movement of the power machine brings the cutting tool to cut horizontally along the guide rail; there is also a snow sheath slide plate at the bottom of the frame to facilitate the miniature windrower on the field surface. promotion. The use of multiple new technologies described in the miniature windrowing machine of the present invention makes the windrowing semi-automatic, high in efficiency, easy to operate, and not limited by the site; the present invention has a wide range of uses, and is especially suitable for individual farmers because of its light weight and low price use. The cutter and power machine can be used separately from the frame, and are also ideal for mowing grass and trimming flowers.

Owner:莫小斌

Swather for kidney beans

The invention discloses a swather for kidney beans. The swather comprises ridging devices, seedling gathering and carrying devices, turnable conveying devices, a driving device, a frame, a suspension bracket, shares with angle irons and land wheels, wherein the suspension bracket is connected to the middle of a cross beam above the front end of the frame and is connected with a tractor in a suspension manner; three shares with the angle irons are connected onto three vertical beams below the front end of the frame; and the land wheels are connected with the lower end of an L-shaped vertical beam between two sides of the frame; two sets of ridging devices are respectively connected between the frame and two cross beams; two sets of seedling gathering and carrying devices are respectively connected to eight vertical beams of the frame; the upper parts at the rear ends of two side frames of the frame are connected with the turnable conveying devices through pin roll assemblies; and a transmission case is fixedly arranged at the middle above the front end of the frame and is respectively in driving connection with the ridging devices, the seedling gathering and carrying devices and the turnable conveying devices through transverse transmission shafts. Due to the adoption of the firm ridging devices, the seedling gathering and carrying devices formed by reliable compound elevating conveyor belts and the turnable conveying devices, the swathing quality and efficiency are greatly increased.

Owner:夏元海 +1

A windrower windrowing method connected with a combine harvester

Disclosed is a swathing method of a swather connected with a combine harvester in a hung mode.The swather connected with the combine harvester in the hung mode is adopted for swathing operation and comprises a vertical swather cutting table, an intermediate connecting mechanism, an integrated hydraulic system, an integrated controller, a combine harvester conveying mechanism, a first oil cylinder execution feedback device, a second oil cylinder execution feedback device, a first hydraulic control one-way valve, a controllable hydraulic pump, a solenoid reversing valve, a manual control reversing valve, a second hydraulic control valve, a first bracket of the cutting table, a second bracket of the cutting table, a rack, a power transmission mechanism, a tensioning mechanism and an auxiliary mechanism, wherein the power transmission mechanism, the tensioning mechanism and the auxiliary mechanism are installed on the rack; through mechanical-electric-hydraulic automation, the angle of the vertical swather is automatically adjusted along with the height of the cutting table, so that the cutting table keeps perpendicular or approximately perpendicular to the ground, the response is rapid, the operation is simple, and therefore the operation effect is ensured.

Owner:HUNAN AGRICULTURAL UNIV

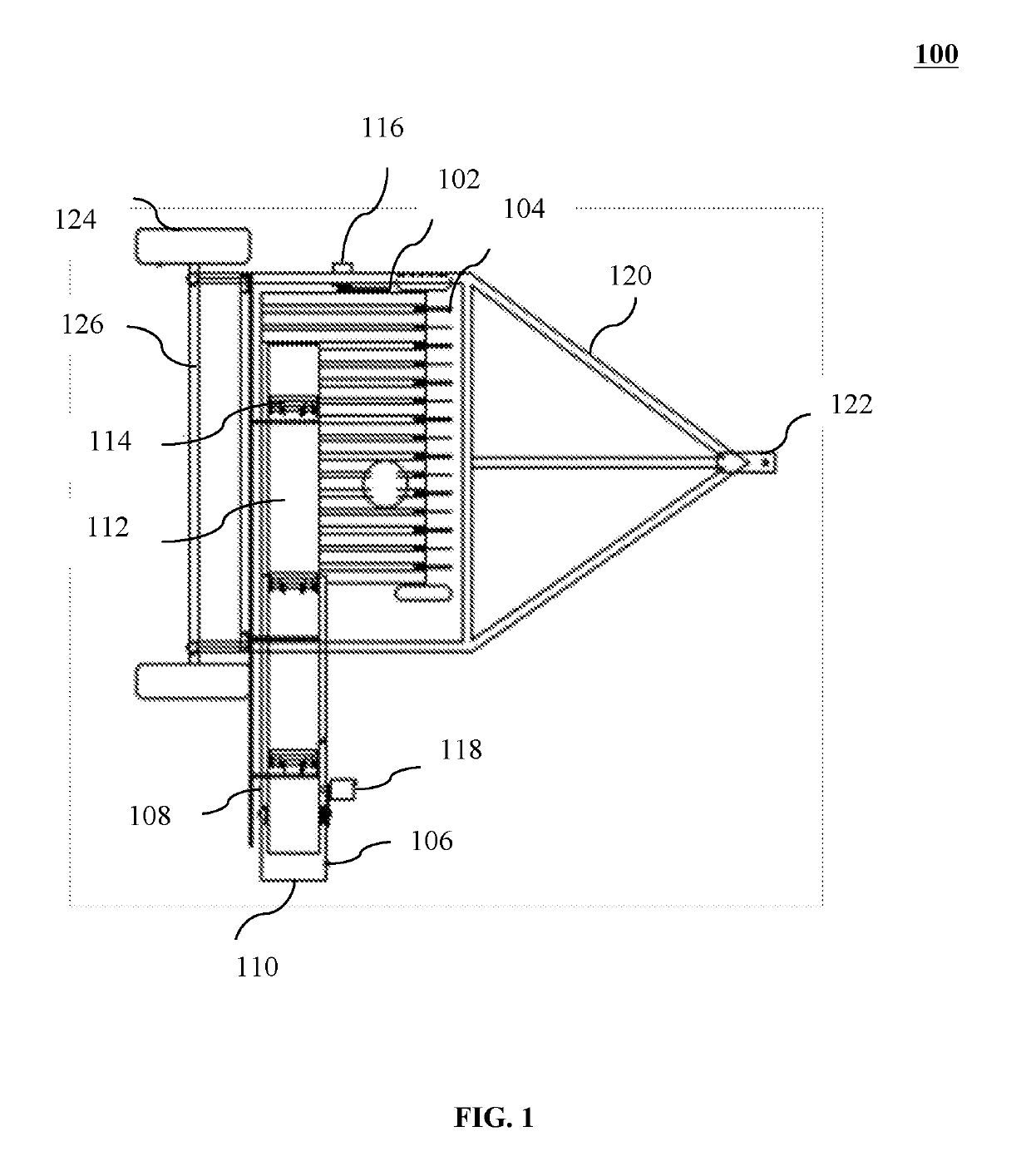

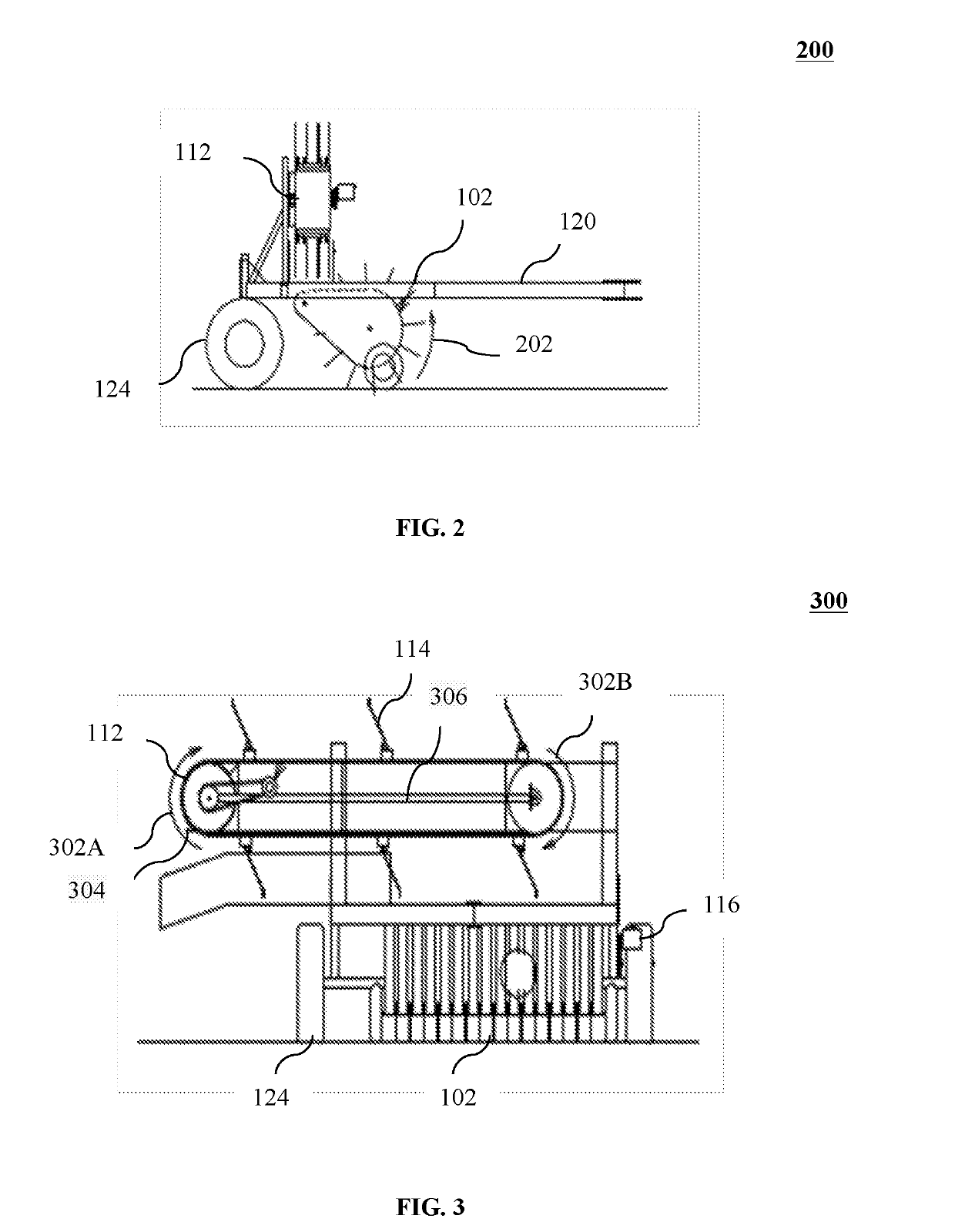

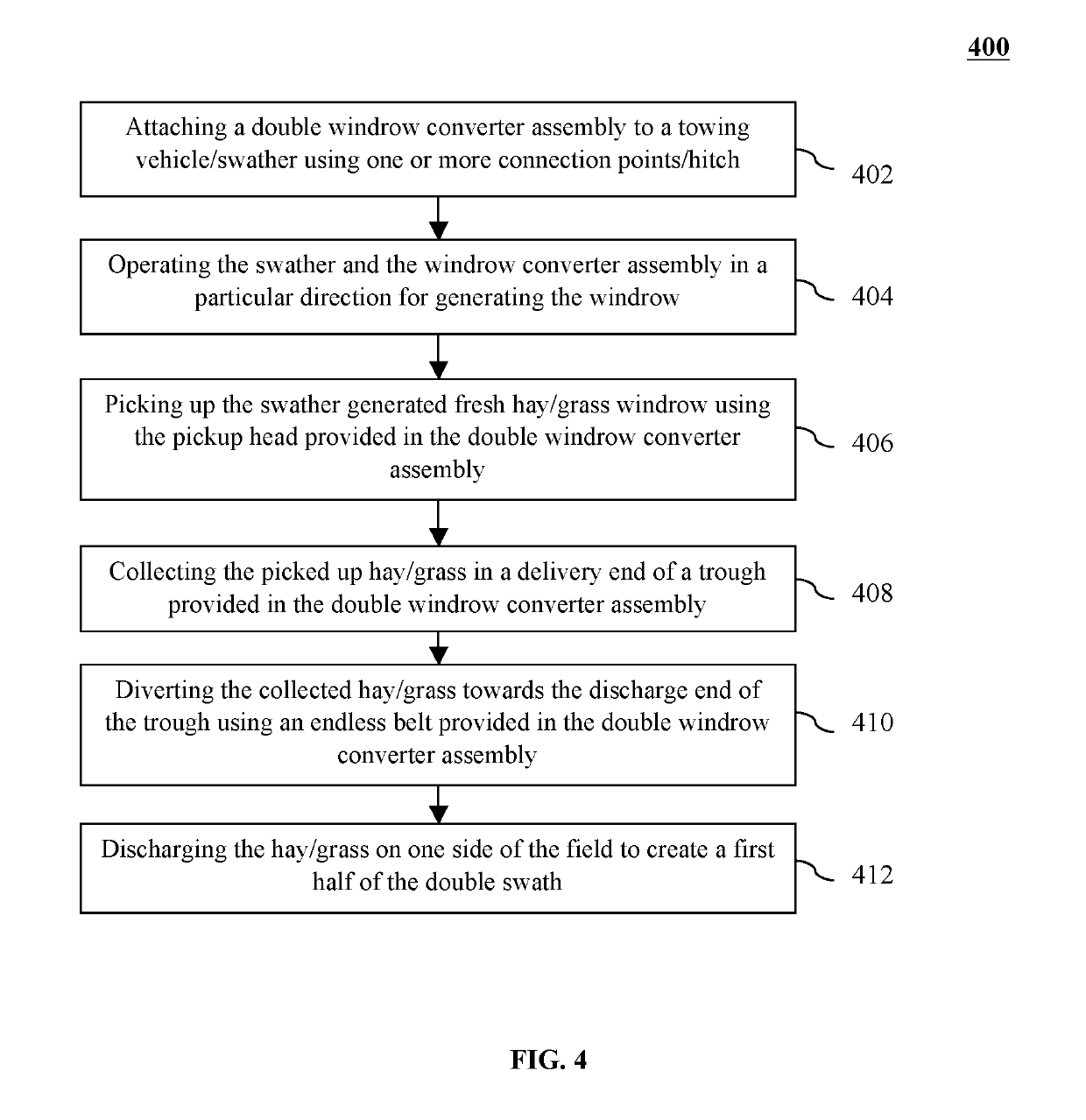

Double windrow converter

The embodiments herein provide a double windrow converter assembly. The double windrow converter assembly is removably attachable behind a towing vehicle or a swather. The converter enables creation of a double windrow of freshly cut hay (with high moisture content). The converter picks up the freshly cut hay windrow using a pickup head which is then diverted to a trough. The hay collected in the trough is discharged on one side of the field to create a first half of the double swath. The swather and the double windrow converter assembly are then operated in opposite direction to generate second half of double swath. Thus, use of the double windrow converter assembly along with swather helps in accomplishing two tasks / operations in a single pass. The assembly also eliminates need for using a rake to pick up dried hay from the field on waiting for a few days after swathing.

Owner:FERCH JAMES E

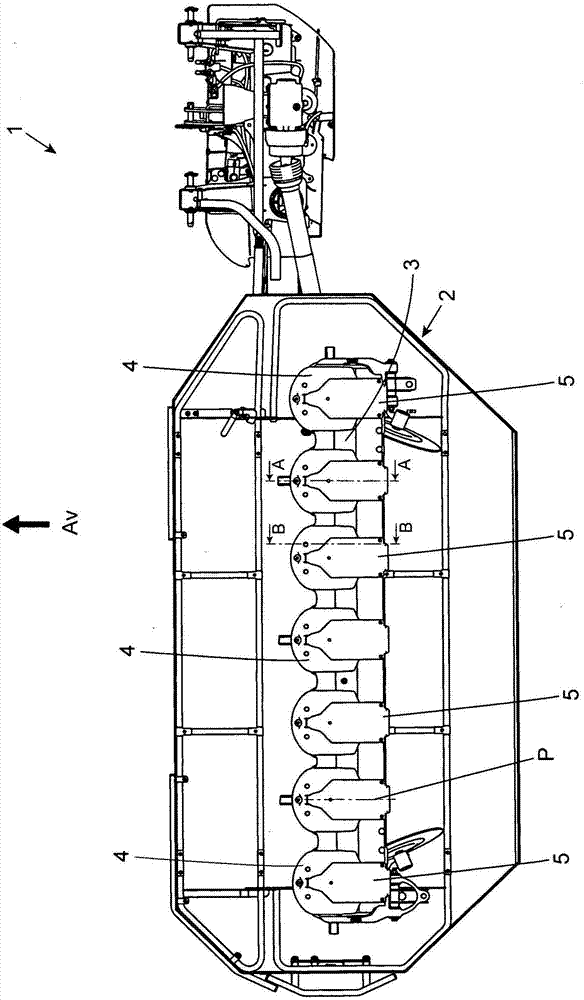

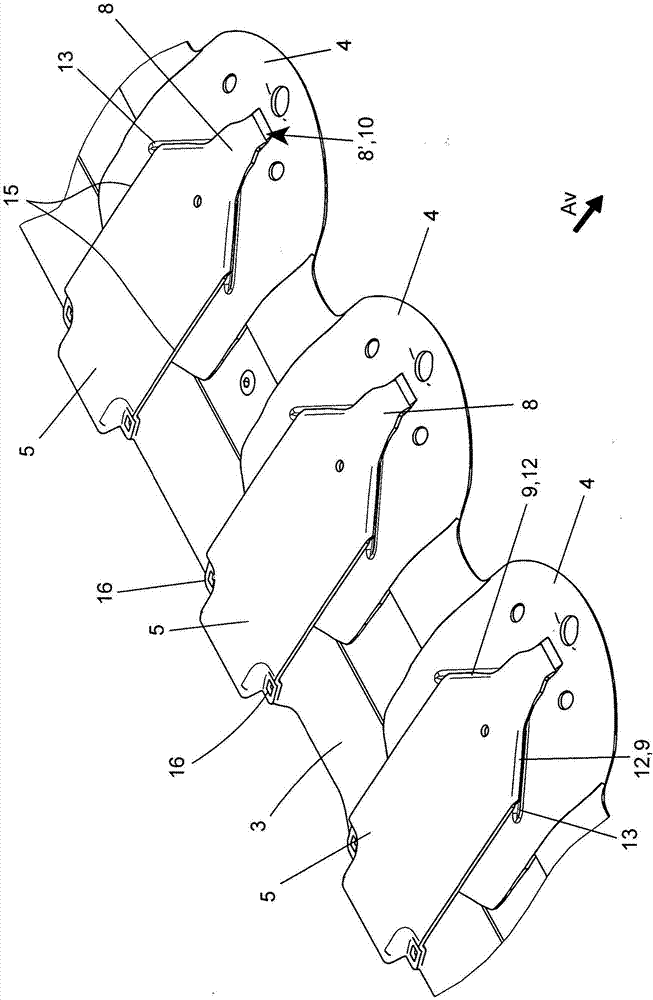

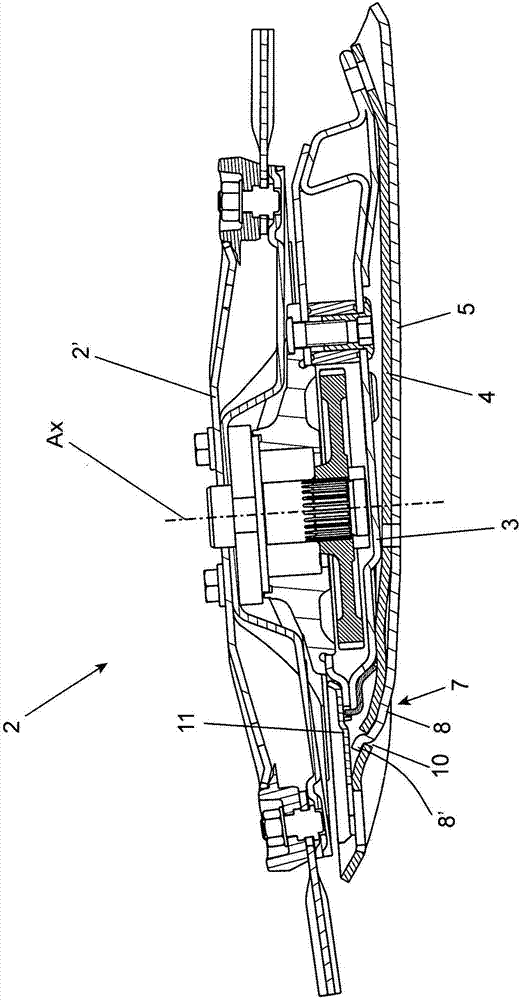

Agricultural machine with skates equipped with interchangeable linings

The invention relates to an agricultural machine with skids equipped with interchangeable liners. The agricultural machine is a disk mower, a swather or similar machine, resting at least partly in braced manner on the soil during its use and provided with a working element (2) and with skids (4) designed to slide on the soil. These skids (4) are formed in a lower wall (3) of the working element (2) or are integral with this lower wall (3), and each skid (4) is provided with a liner (5) having at least one frontal end and a frontal rim on each side of this frontal end (8). At least one of the frontal rims of the liner (5) of each skid (4) has a relief (12), at least one part of which penetrates into an indentation (13) formed in the corresponding skid (4).

Owner:KUHN SA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com