Swather for kidney beans

A windrower and kidney bean technology, applied to harvesters, agricultural machinery and implements, applications, etc., can solve the problems of low efficiency, poor quality, and difficulty in harvesting low crops of kidney beans, etc., to achieve reduced storage space, strong rigidity, Reduced effect of driving force into soil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

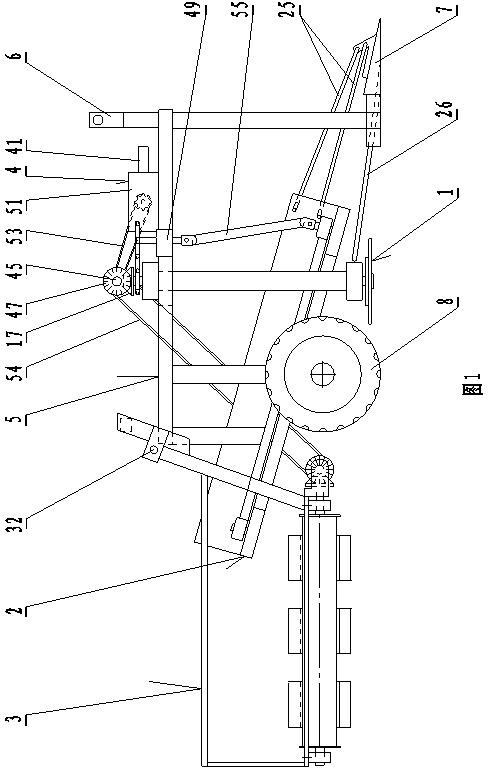

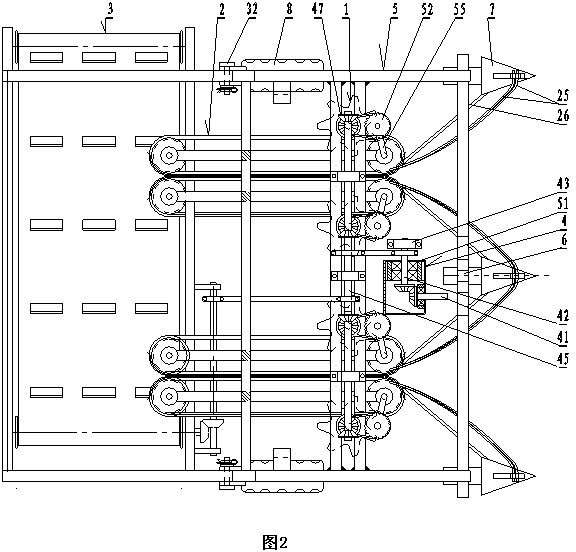

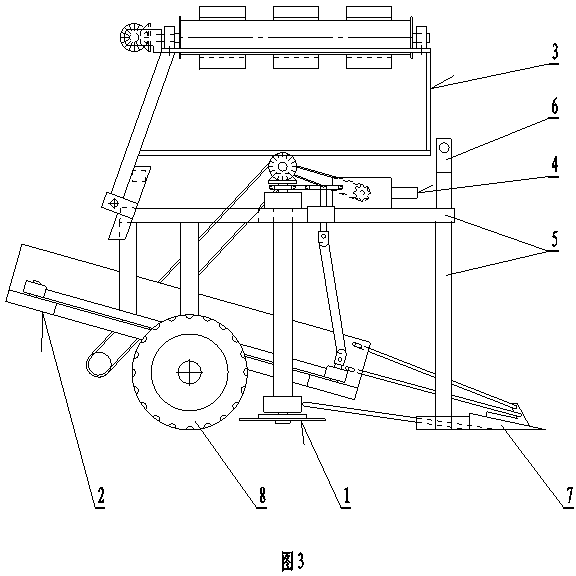

[0037] see Figure 1 to Figure 14, Kidney bean cutting and drying machine, which is composed of a ridge breaking device 1, a seedling lifting device 2, a reversible conveying device 3, a transmission device 4, a rack machine 5, a suspension frame 6, an angled iron share 7, and a ground wheel 8. . The frame machine 5 is welded together by square steel pipes. A suspension frame 6 is connected to the middle of the beam above the front end to hang with the tractor. Three vertical beams below the front end are connected to three vertical beams with angles. A ground wheel 8 is connected to the lower end of the vertical beam. Two sets of four ridge breaking devices 1 are respectively connected between two crossbeams of the frame frame 5 . Two sets of four groups of seedling lifting and delivery devices 2 are respectively connected on eight vertical beams of the frame frame 5, and are connected with the reversible conveying device 3 by the pin assembly 32 above the rear ends of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com