A miniature wheat windrower

A windrower and wheat technology, applied to harvesters, agricultural machinery and implements, agriculture, etc., can solve the problems of inability to meet the actual needs of production, inconvenient maintenance, and inability to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

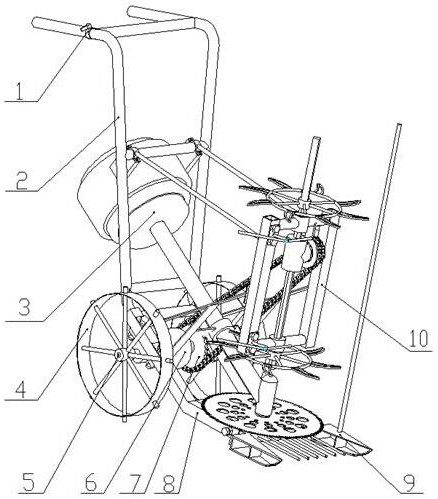

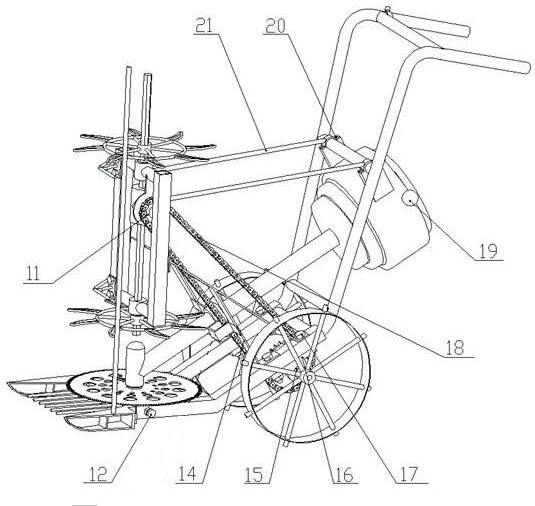

[0020] Below in conjunction with accompanying drawing, the present invention is described in further detail:

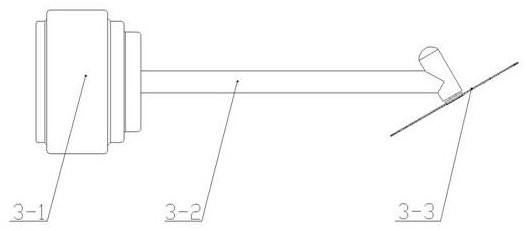

[0021] As shown in the figure, a miniature wheat windrowing machine includes a hand-held frame 2 and a frame 8. The lower end of the hand-held frame 2 is installed with a bolt 17 to install the frame 8, and the frame 8 is installed with a ground wheel shaft 5 through a bearing seat 16 and a bearing 15. , ground wheel axle 5 two ends are installed ground wheel 4 with key, and differential gear 6 and big chain wheel 7 are installed on ground wheel axle 5. The front end of the frame 8 is equipped with a front frame 9, an independent cutter 3 is arranged above the front frame 9, the independent cutter 3 is adapted to the front frame 9, and a reeling device 10 is installed above the independent cutter 3, and the reeling device 10 includes a reeling frame 10 -10, the reel frame 10-10 is connected with the frame 8, the reel frame 10-10 is vertically fitted with the reel shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com