Swather

A technology for windrowers and headers, applied in the direction of harvesters, headers, cutters, etc., can solve the problems of complex adjustment structure, influence of rotating parts, and potential safety hazards, and achieve reasonable structure of the transmission system, avoiding sagging and swinging. , the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Below by embodiment and in conjunction with accompanying drawing, the present invention will be further described:

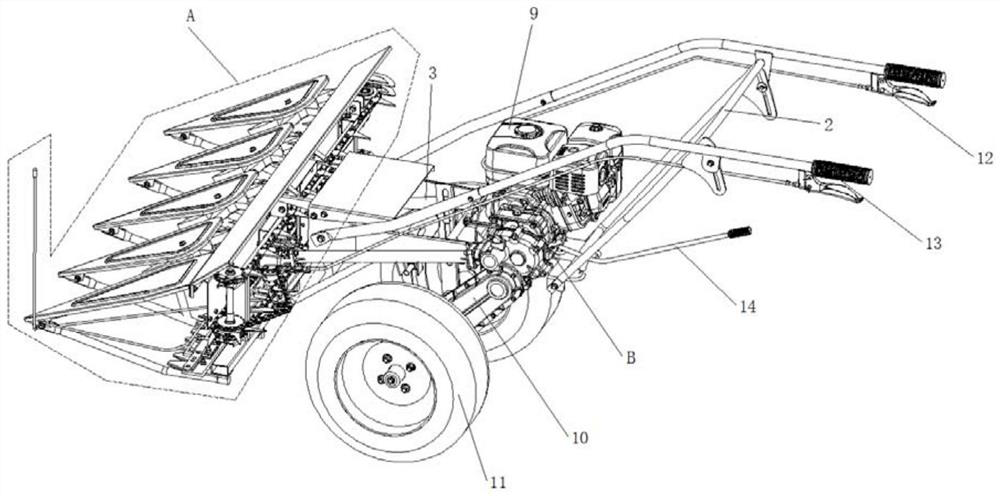

[0049] Such as figure 1 As shown, a windrower is mainly composed of engine 9, main transmission system B, main frame 3, walking box 10, armrest frame, support frame 2, header A, wheels 11, main clutch control handle 12, header clutch The control handle 13 and the shift lever 14 are composed. Header A is installed in the place ahead of main frame 3, and wheel 11 is positioned at the rear bottom of main frame 3, and two wheels 11 link to each other by wheel axle 15.

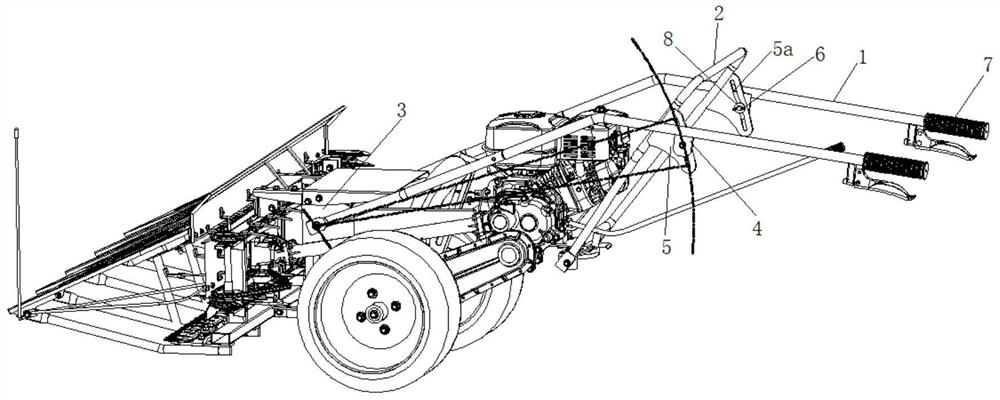

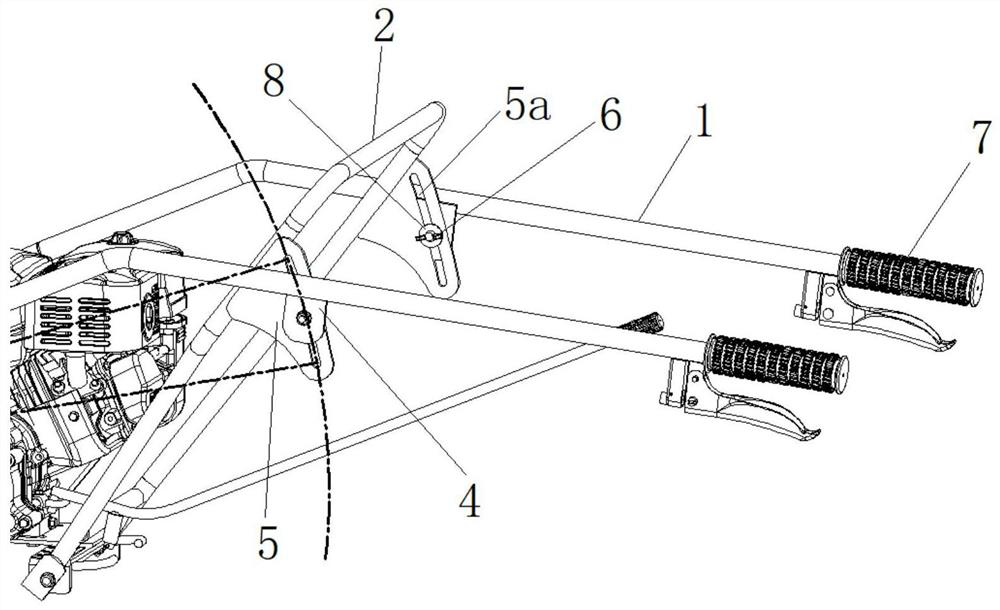

[0050] combine figure 2 , image 3 As shown, the armrest frame is divided into left and right two armrest bars 1, and the two armrest bars 1 are arranged separately, and are equipped with independent adjustment mechanisms to carry out respective lifting adjustments.

[0051] The support frame 2 is centrally arranged between two handrail bars 1, and the front end of each handrail bar 1 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com