Human-computer interface control system and control method for self-propelled swather

A man-machine interface control, windrower technology, applied in the direction of comprehensive factory control, harvester, electrical program control, etc., can solve the problems of low protection level, high labor intensity, vibration prone to malfunction, etc. High work efficiency and time saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

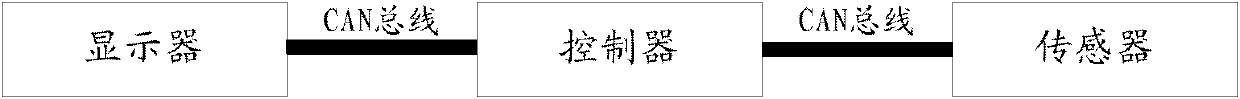

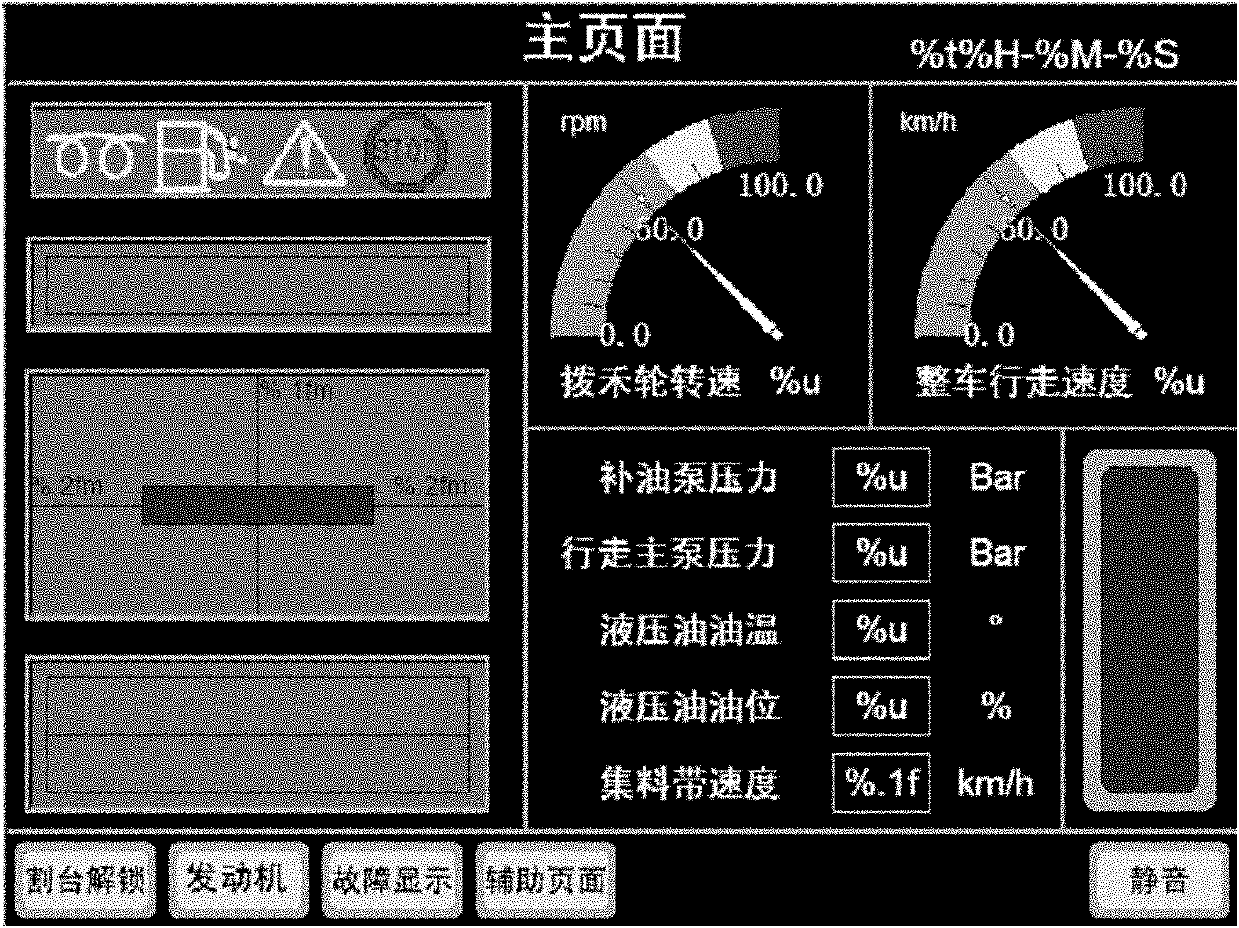

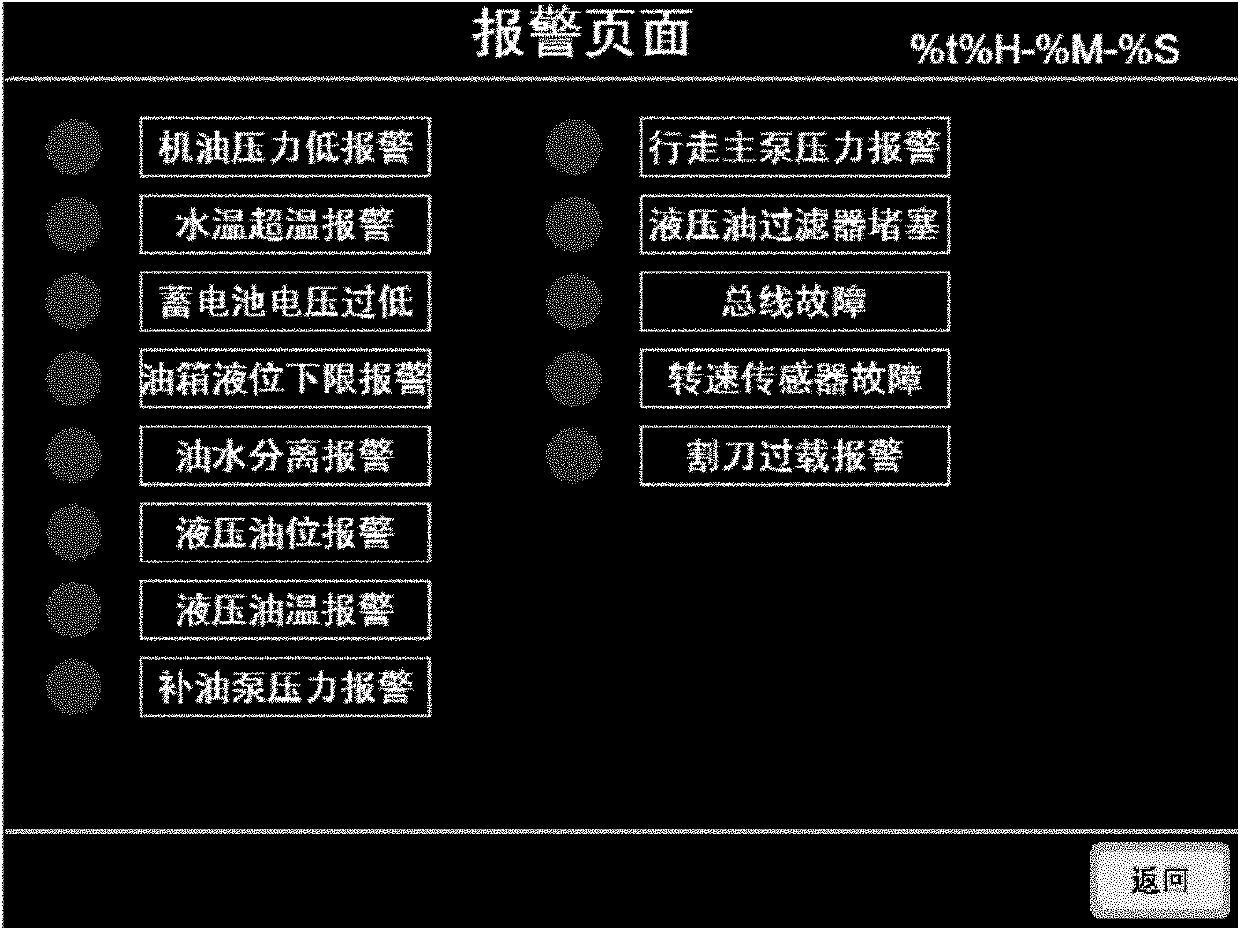

[0043] This embodiment provides a control system and man-machine interface of a self-propelled windrower, such as Figures 1 to 5 As shown, the control system includes a sensor, a controller connected with the sensor, a display connected with the controller and an alarm system.

[0044] 【sensor】

[0045] The sensor is used to sense the real-time working status of each component of the windrower; the sensor includes an engine status sensor, a hydraulic system status sensor, a travel gear sensor, a header status sensor, a reel status sensor, and a collecting belt status sensor ; The engine state sensor includes an engine water temperature sensor, an engine speed sensor, an oil pressure sensor and an engine oil temperature sensor; the header state sensor includes a header height sensor, a header angle sensor, and a cutter speed sensor; The wheel state sensor includes a reel speed sensor; the collecting belt state sensor includes a collecting belt speed sensor.

[0046] 【Control...

Embodiment 2

[0066] This embodiment provides a control method for the man-machine interface of the self-propelled windrower described in Embodiment 1, such as Image 6 As shown, the method includes the following steps:

[0067] Step 1, the sensor senses the working status of each component of the windrower; this step includes some or all of the following sensing steps:

[0068] A1) Engine water temperature sensor senses the water temperature in the engine to obtain engine water temperature parameters; The oil temperature sensor senses the oil temperature in the engine to obtain the engine oil temperature parameters;

[0069] A2) The state sensor of the hydraulic system senses and monitors the working pressure of the hydraulic system, the working pressure of the main pump, and the pressure of the charge pump; the state sensor of the hydraulic system is a pressure sensor;

[0070] A3) The gear selected by the walking gear sensor sensing the gear lever;

[0071] A4) The header height senso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com