Crop straw swather

A technology for crop straw and windrower, which is applied in the field of agricultural machinery, can solve the problems of poor straw transportation, increased harvest cost, inability to work, etc., and achieves the effects of improving the neat laying rate, simple structure and reducing the incidence of failures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0013] Specific implementation manners: the present invention is not limited by the following examples, and specific implementation manners can be determined according to the technical solutions of the present invention and actual conditions.

Embodiment

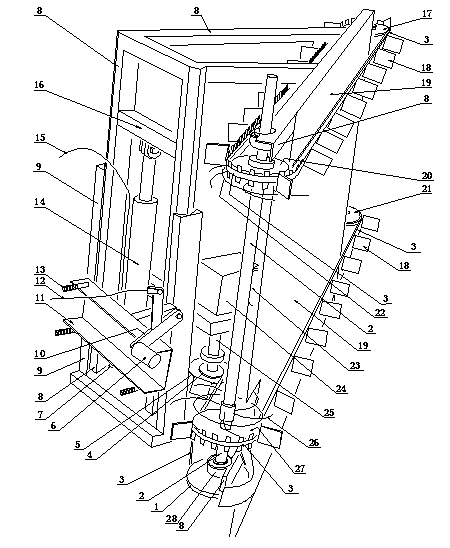

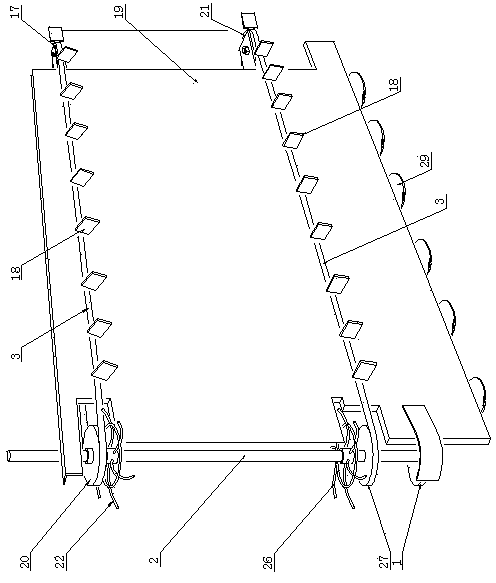

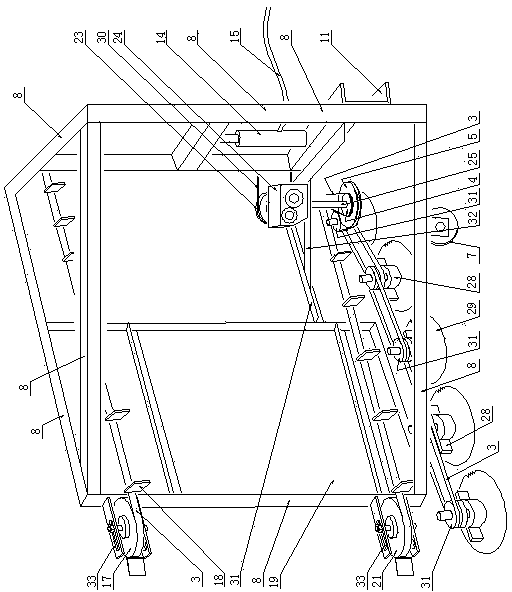

[0014] Example: such as figure 1 As shown in -4, the crop stalk windrowing machine is composed of a frame 8, a hydraulic lifting device, a power transmission, a variable speed and a stalk cutting device, and a stalk conveying device.

[0015] Straw transporting device: a panel 19 is installed between the upper and lower frames of the first facade of the triangular body cavity frame 8, and the right end of the second frame is respectively equipped with the upper right and lower right sprockets 20, 27, and the left end is respectively installed Bearing block 28 is arranged, and vertical shaft 2 is worn between the seats, and lower sprocket wheel 1 is equipped with in the axle lower end. On the vertical shaft 2 between the two bearing blocks 28, the left upper sprocket 17, the circular upper stalk disc 22, the lower stalk disc 26, and the left lower sprocket 21 are respectively installed from top to bottom. Between left and right upper sprocket wheel 17,20, left and right lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com