Miniature cutting and sunning machine

A windrower and miniature technology, which is applied in the field of agricultural machinery and tools, can solve the problems of increasing the conveying mechanism of the grass, the uneven placement of the seedlings, and the increase of the cost of the machine, and achieves the effect of cheap price, light weight and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

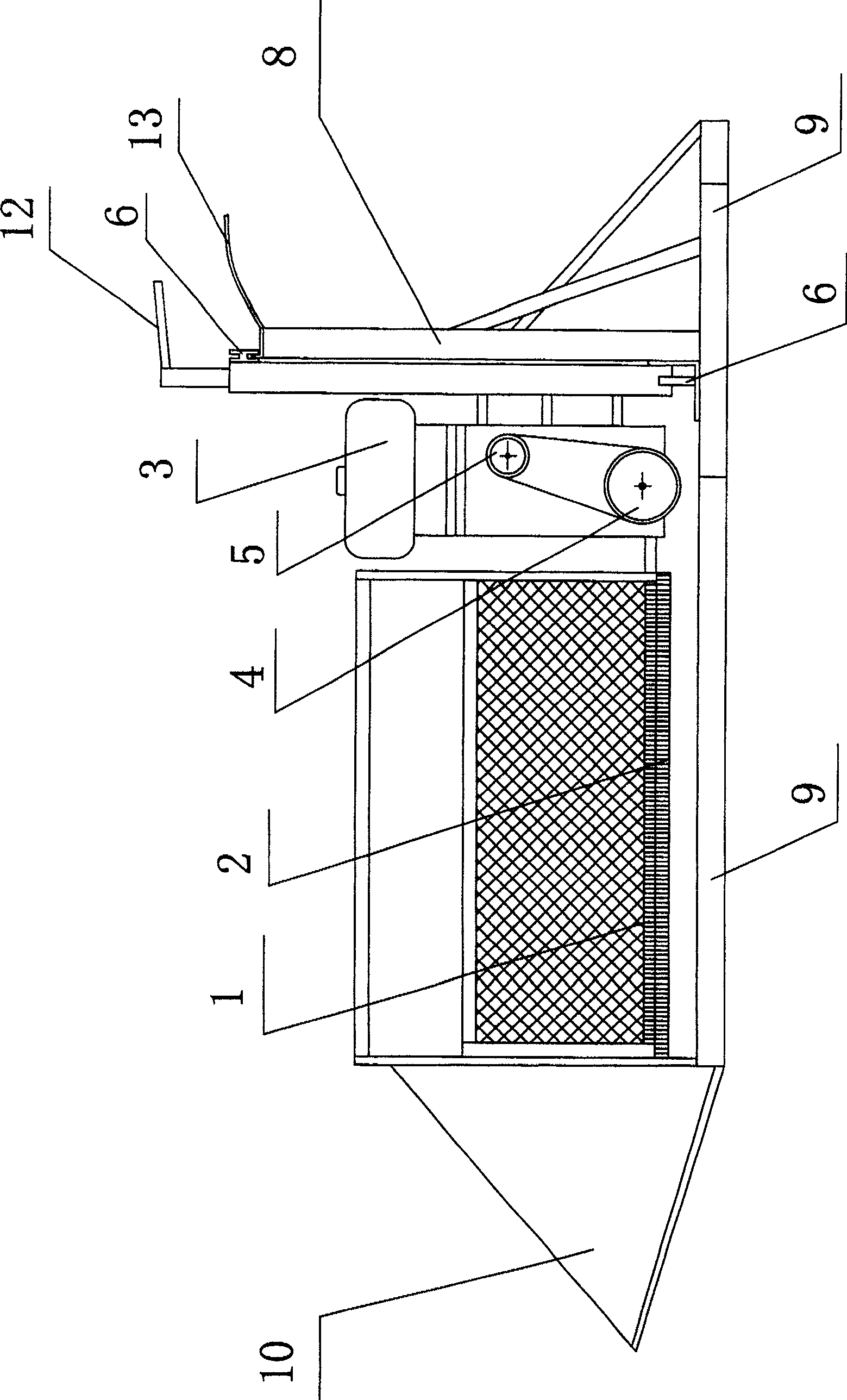

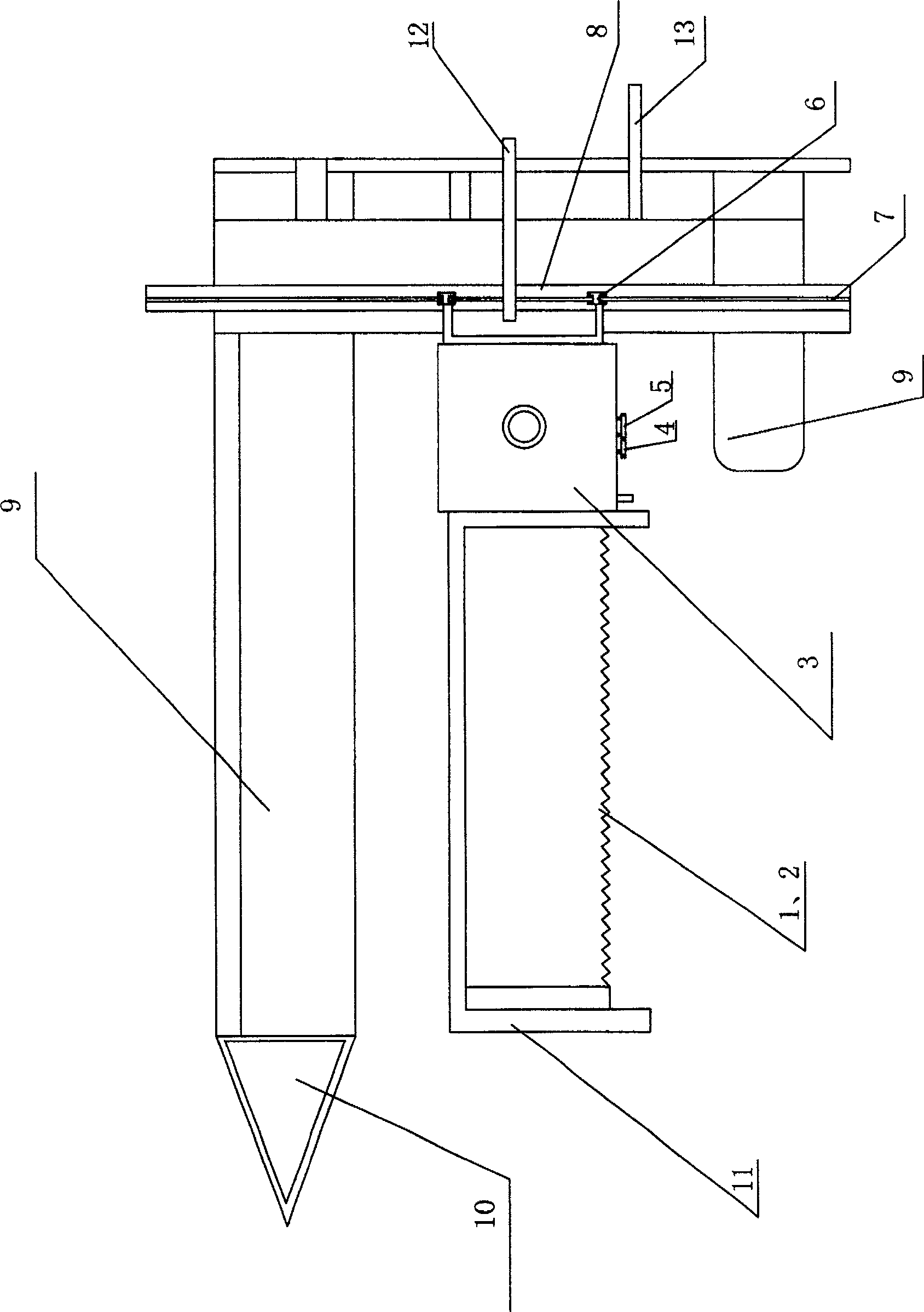

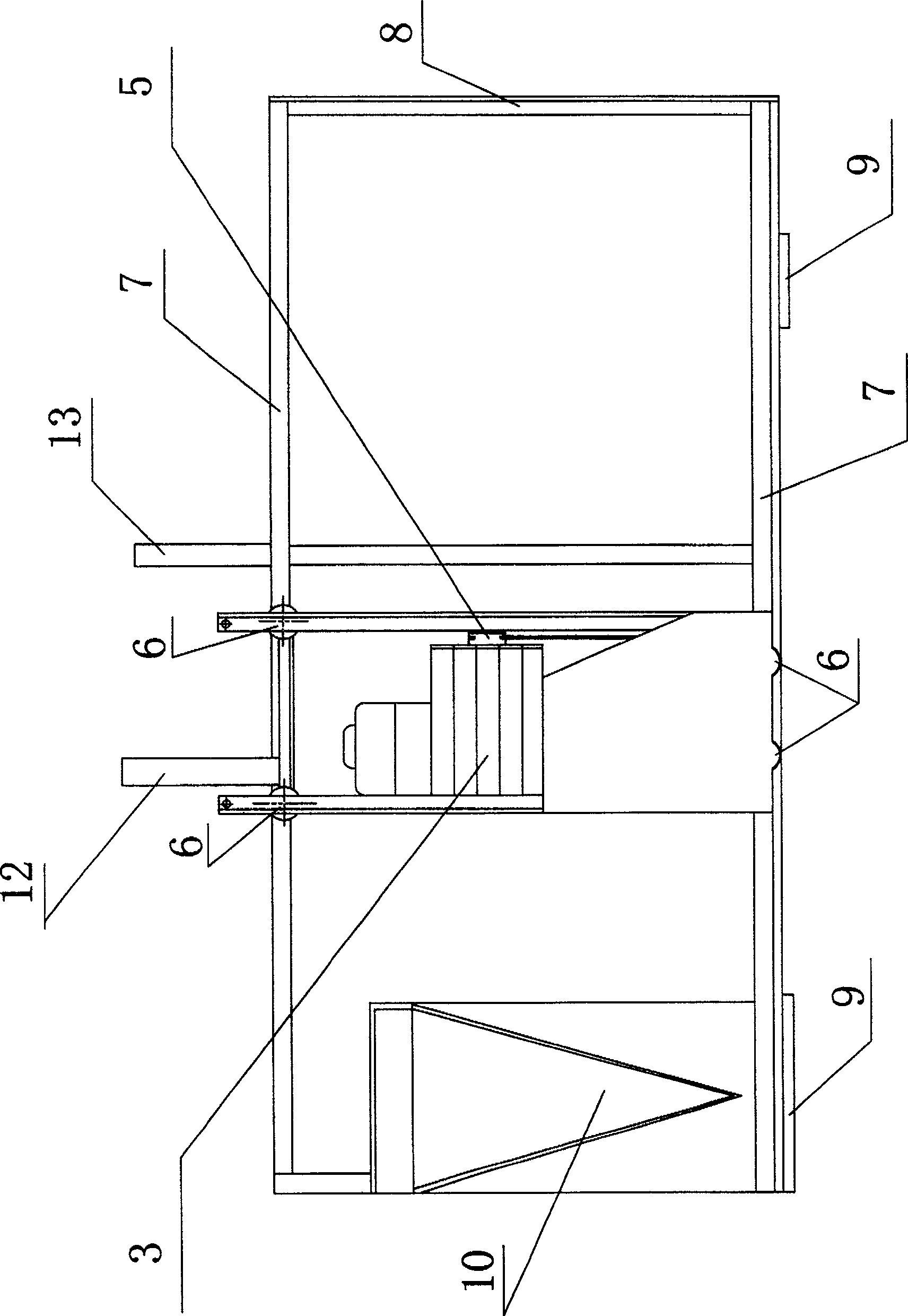

[0021] in such as figure 1 In one embodiment of the miniature windrower of the present invention shown, the miniature windrower has a vertical square frame 8, the upper and lower beams of the frame 8 double as guide rails 7, and the bottom of the frame 8 at both ends of the guide rail 7 is fixedly installed. It is the snow sheath slide 9 parallel to each other, and the snow sheath slide 9 is also perpendicular to the guide rail 7 while maintaining the level. Such as figure 2 As shown, the length of a snow sheath slide 9 is long, and the length of another snow sheath slide 9 is short, and one end of the long snow sheath slide 9 is defined as the cutting starting end of the mini windrower, and one end of the short snow sheath slide 9 is defined as For the cutting end of the micro windrower. The front end of the long snow sheath slide 9 is provided with a forward-stretching pointed slope, which is the crop divider 10, and the long snow sheath slide 9 and the frame 8 are also c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com