Omnibearing profile device of swather

A profiling device and all-round technology, applied in harvesters, agricultural machinery and implements, applications, etc., can solve problems such as uneven cutting stubble, achieve the effect of smooth cutting stubble, easy operation, and meet the needs of harvesting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

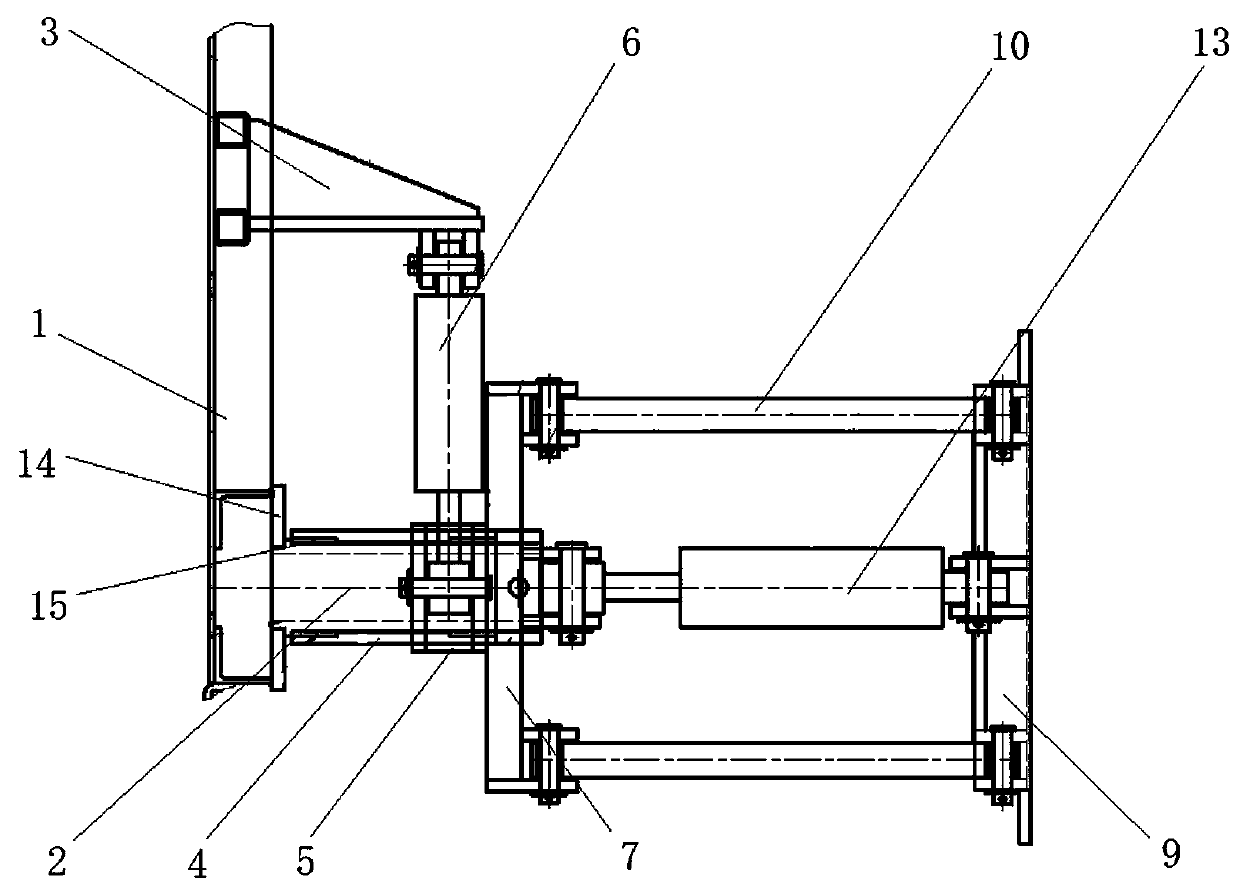

[0021] An all-round profiling device for a windrower, including a frame 1, a left and right profiling mechanism, an up and down lifting mechanism and a control mechanism:

[0022] The left and right profiling mechanism includes a hollow shaft 2 and a connecting frame 3 horizontally arranged on the rear side wall of the frame 1 and distributed left and right. A shaft sleeve 4 is arranged on the outside of the hollow shaft 2, and a strip steel plate 5 fixed thereon is arranged above the shaft sleeve 4. , the lower part of the strip steel plate 5 is provided with a left and right adjustment cylinder 6 with one end hinged to it and the other end hinged to the connecting frame 3;

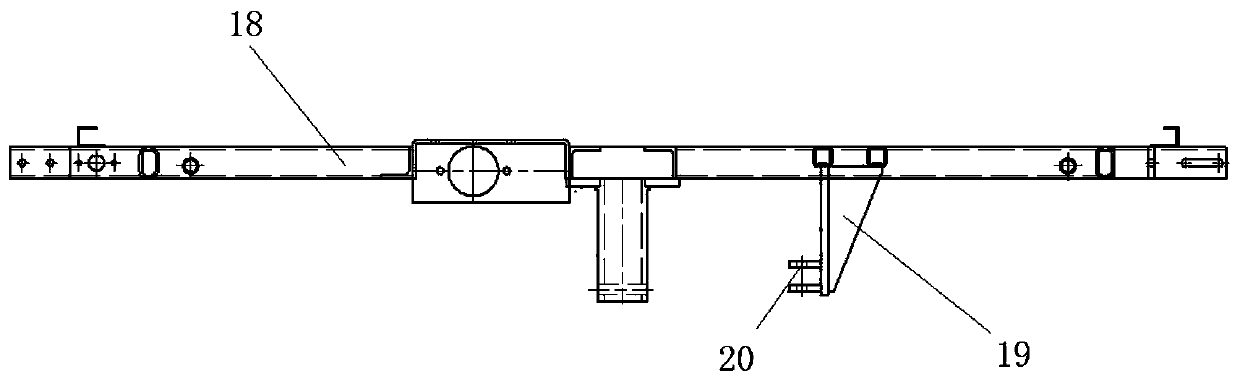

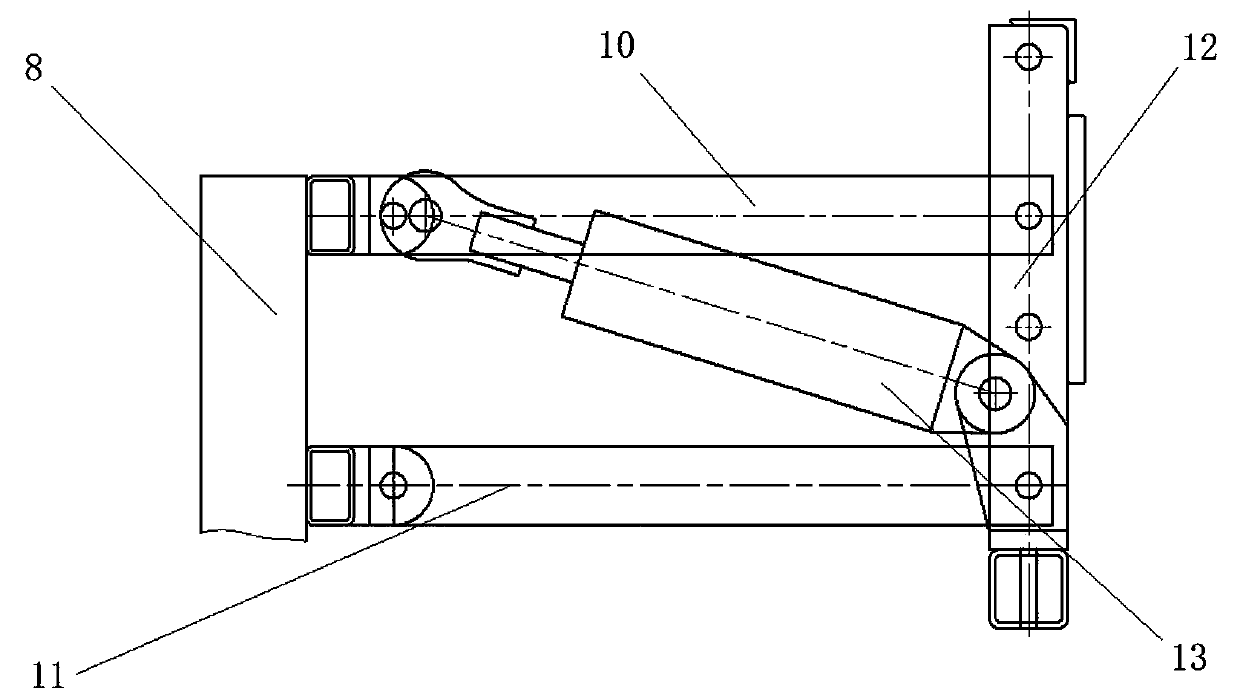

[0023] The up and down lifting mechanism comprises two horizontally arranged, distributed up and down and front lifting crossbeams 7 fixed with strip steel plates 5, between the two front lifting crossbeams 7 are fixed with front connecting rods 8 positioned at the left and right ends and placed verticall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com