Secondary lining split mounting type blocking head device for metro underground excavation tunnel

A secondary lining and assembled technology, which is applied in the direction of tunnel lining, tunnel, shaft lining, etc., can solve the problems of easy disconnection of steel bars at construction joints, unreasonable structure, and inadequate installation of waterproof materials, etc., to achieve simple operation and saving Cost, good waterproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

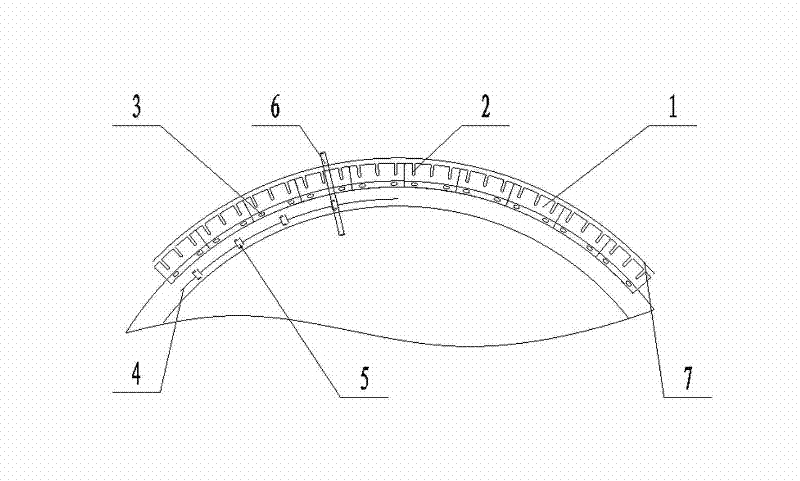

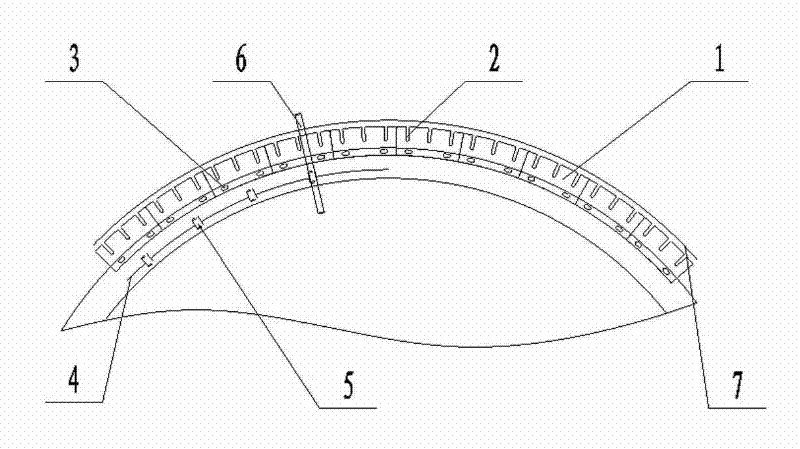

[0009] The assembled head stop device for the secondary lining of underground excavation tunnels in subways includes arc-shaped head stop steel plates. The inner arc side of the base body 1 has a keyway-shaped bolt hole 3, and the bolt hole 3 is screwed with a bolt connected to the outer arc section of the second lining trolley, and the inner side of the head plate is provided with an arc-shaped steel bar 4 fixed to the section of the second lining trolley , the reinforcement sleeve 5 arranged radially is evenly distributed on the steel bar 4, and the reinforcement sleeve 5 is provided with a reinforcement steel pipe 6 on one side of the rear surface of the head-stop steel plate. Wooden wedge, galvanized water-stop steel plate 7 is spot-welded with the outer circular arc end face of the head-stop steel plate. In the specific implementation process, the distance between the ends of the second lining trolley is 50cm, and the Φ50 reinforcement sleeve 5 is preset and reinforced wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com