Slip ring structure for double-fed motor coiling type rotor

A doubly-fed motor and wire-wound technology, applied in the direction of structural connection, electrical components, electromechanical devices, etc., can solve the problems of increased encoder failure points, increased operation difficulty, and difficult control of assembly accuracy, so as to ensure reliability and operation The manufacturability, reduce the cost of the motor, reduce the effect of the axial size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

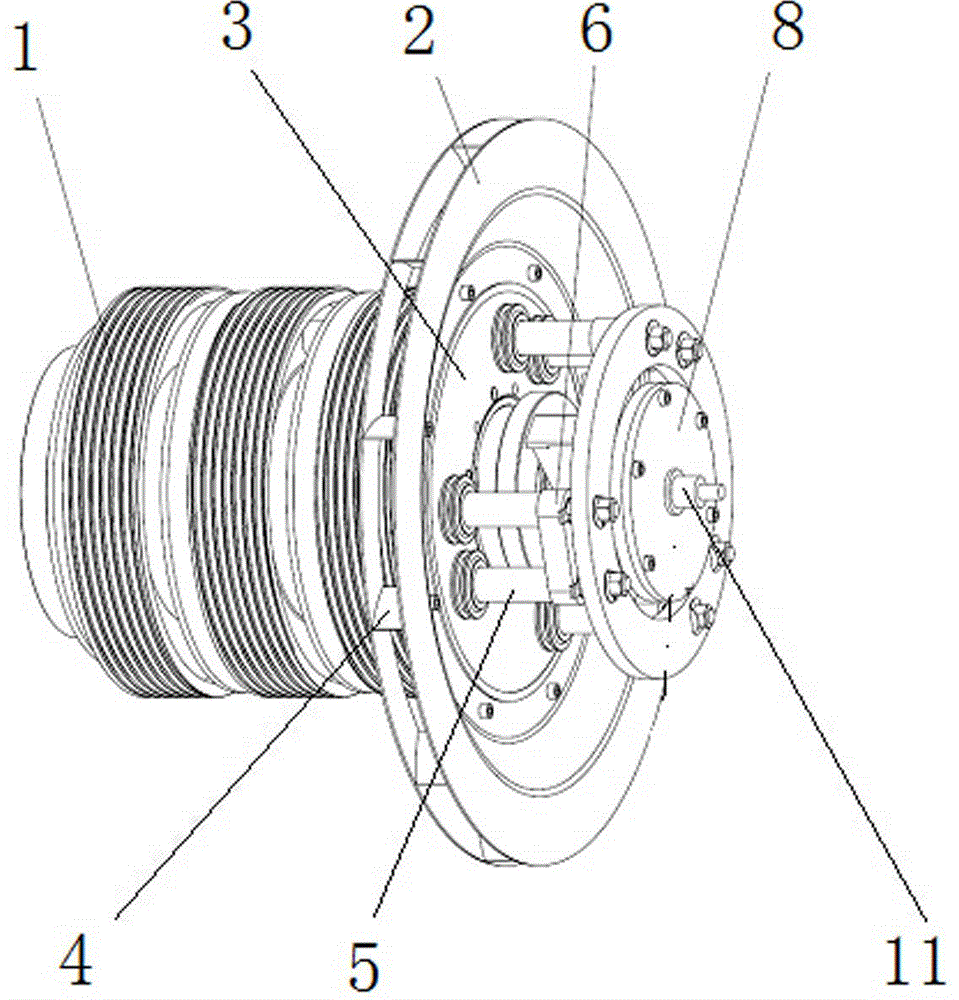

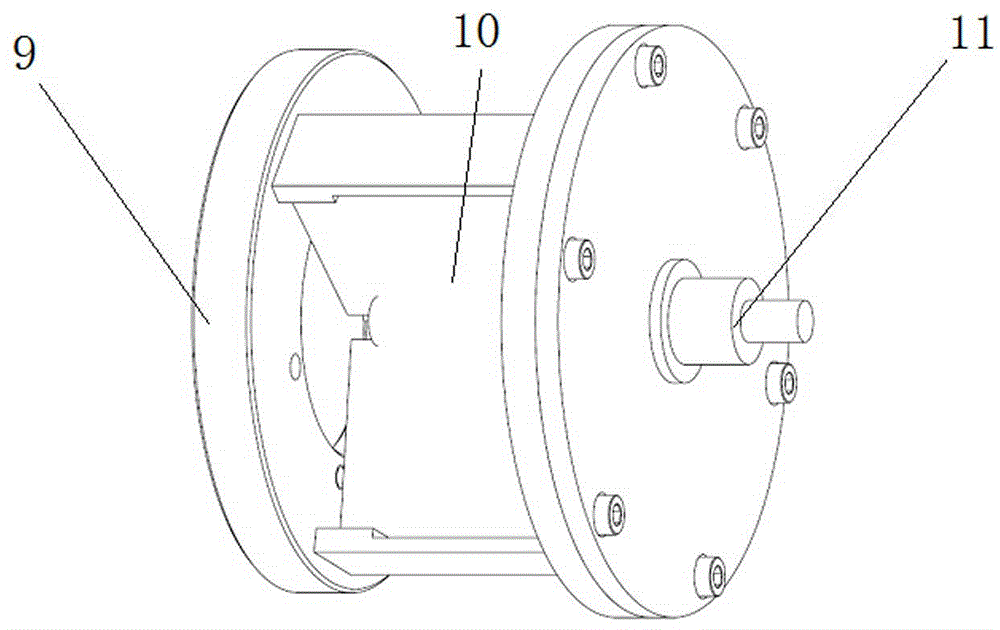

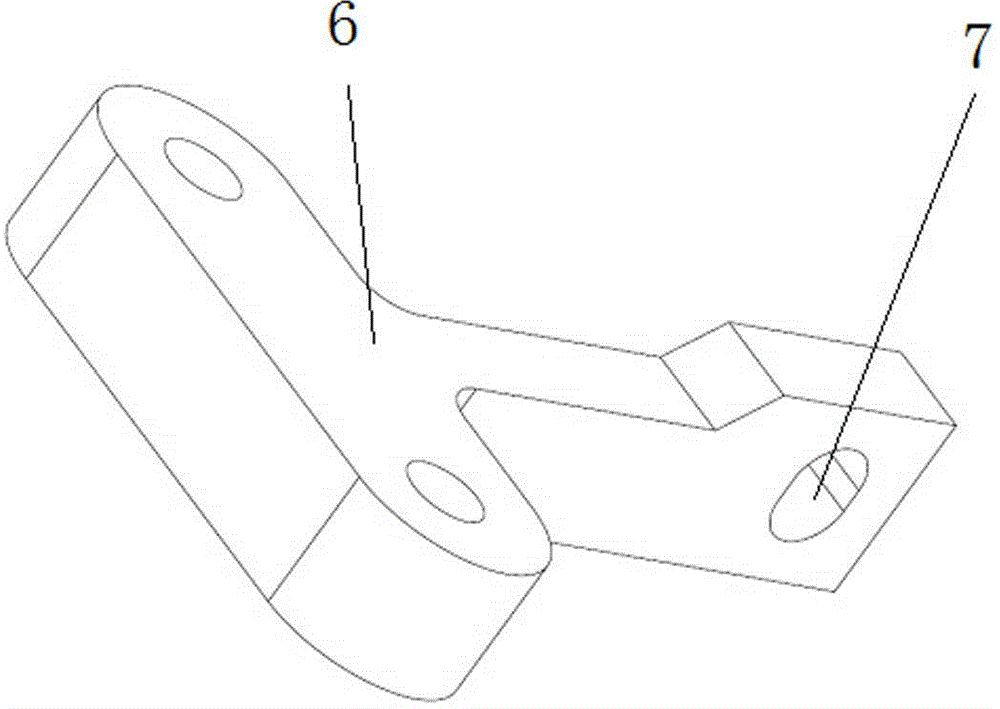

[0016] A slip ring structure for a wound rotor of a double-fed motor, including a slip ring main body 1, a cooling fan 2 is connected to the right end surface of the slip ring main body 1, and the cooling fan 2 is fixed on the outer side of the ring hub 3 by a ring hub 3 and Composed of blades 4, the annular hub 3 is provided with a number of pairs of conductive posts 5 fixed to the right end face of the slip ring main body 1 and evenly distributed with the axis center of the slip ring main body 1 as the center of the circle. Each pair of conductive posts 5 is covered with a T T-shaped conductive block 6, the inner side of T-shaped conductive block 6 is provided with wiring hole 7, the inner side of conductive column 5 is provided with encoder bracket 8 connected with the right end surface of slip ring main body 1, encoder bracket 8 includes two parallel disks 9 With the insulating spacer 10 located between the two disks 9 and separating the T-shaped conductive block 6 , an enc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com