Patents

Literature

130results about How to "Guaranteed craftsmanship" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

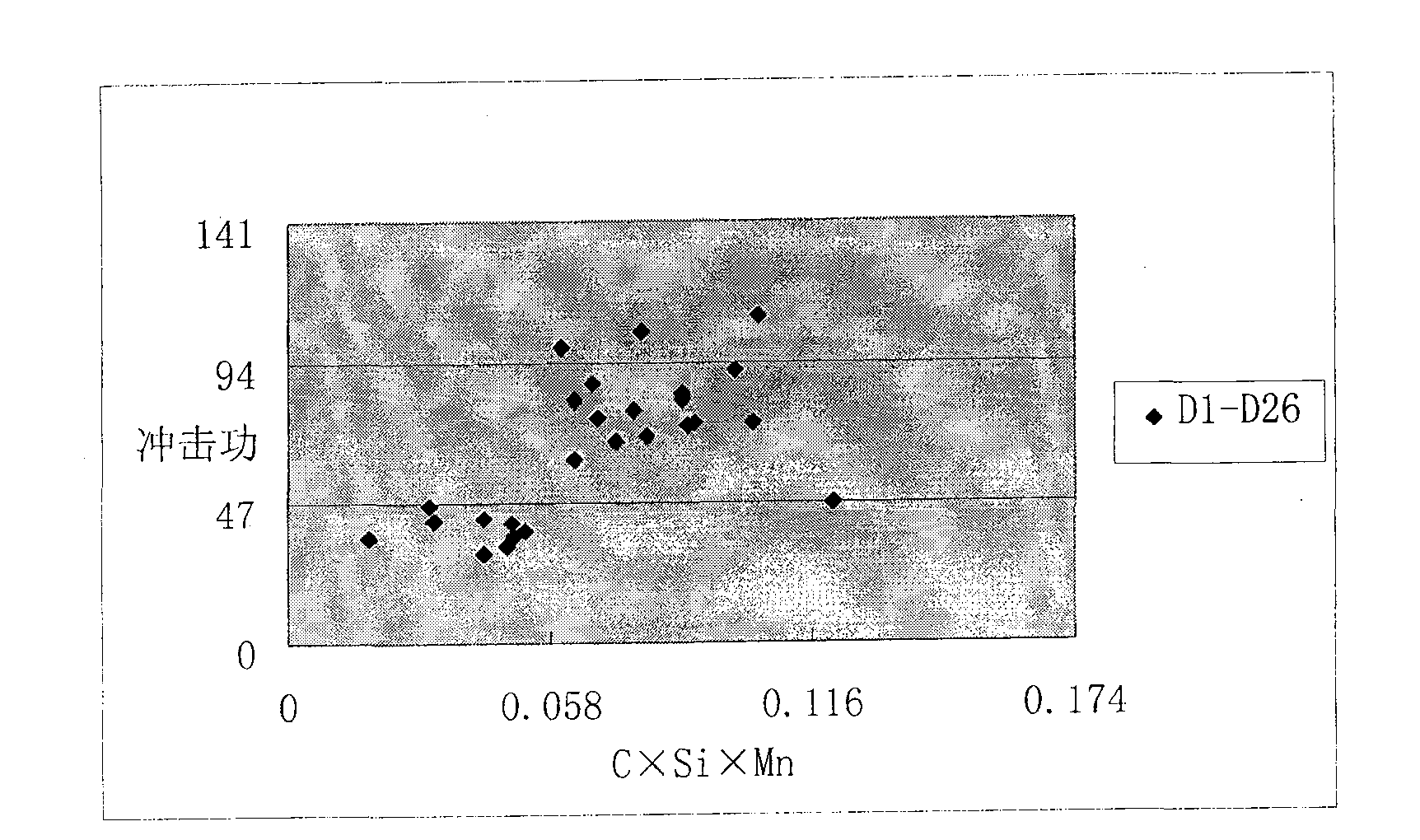

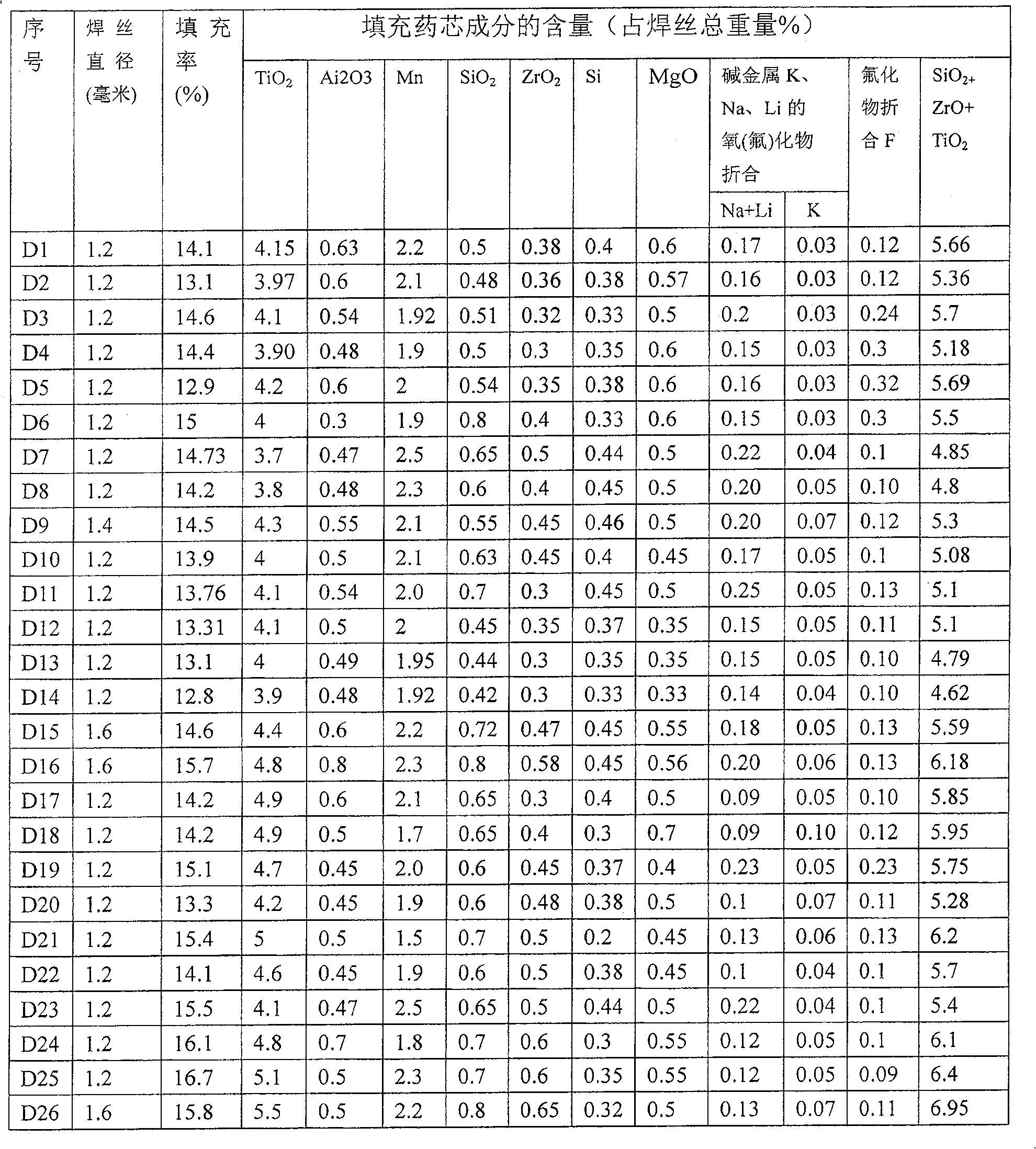

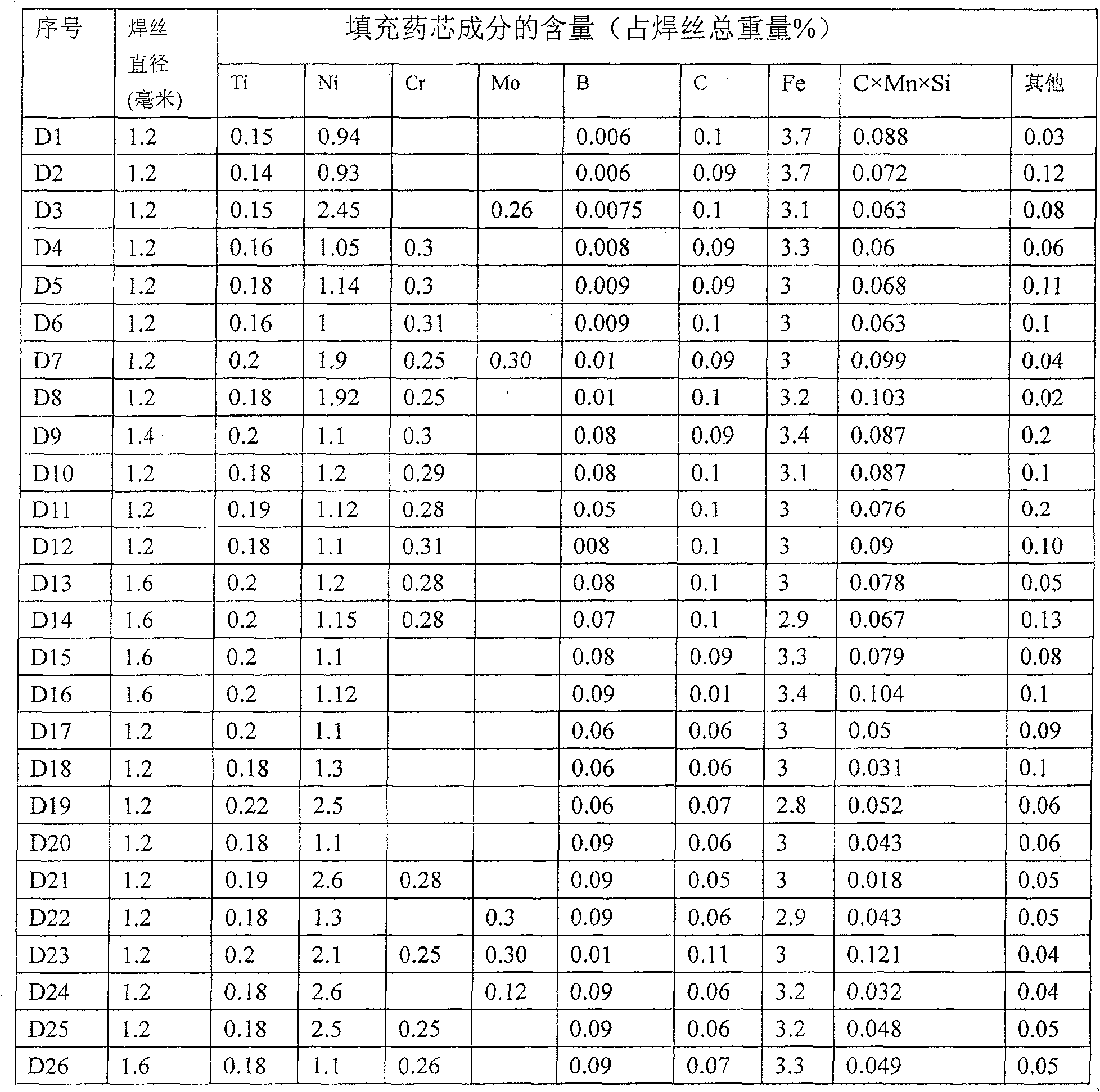

Low alloy steel flux-cored welding wire for carbon dioxide gas protection welding

InactiveCN101104232AImprove impact toughnessAccelerated corrosionArc welding apparatusWelding/cutting media/materialsArc stabilityCrack resistance

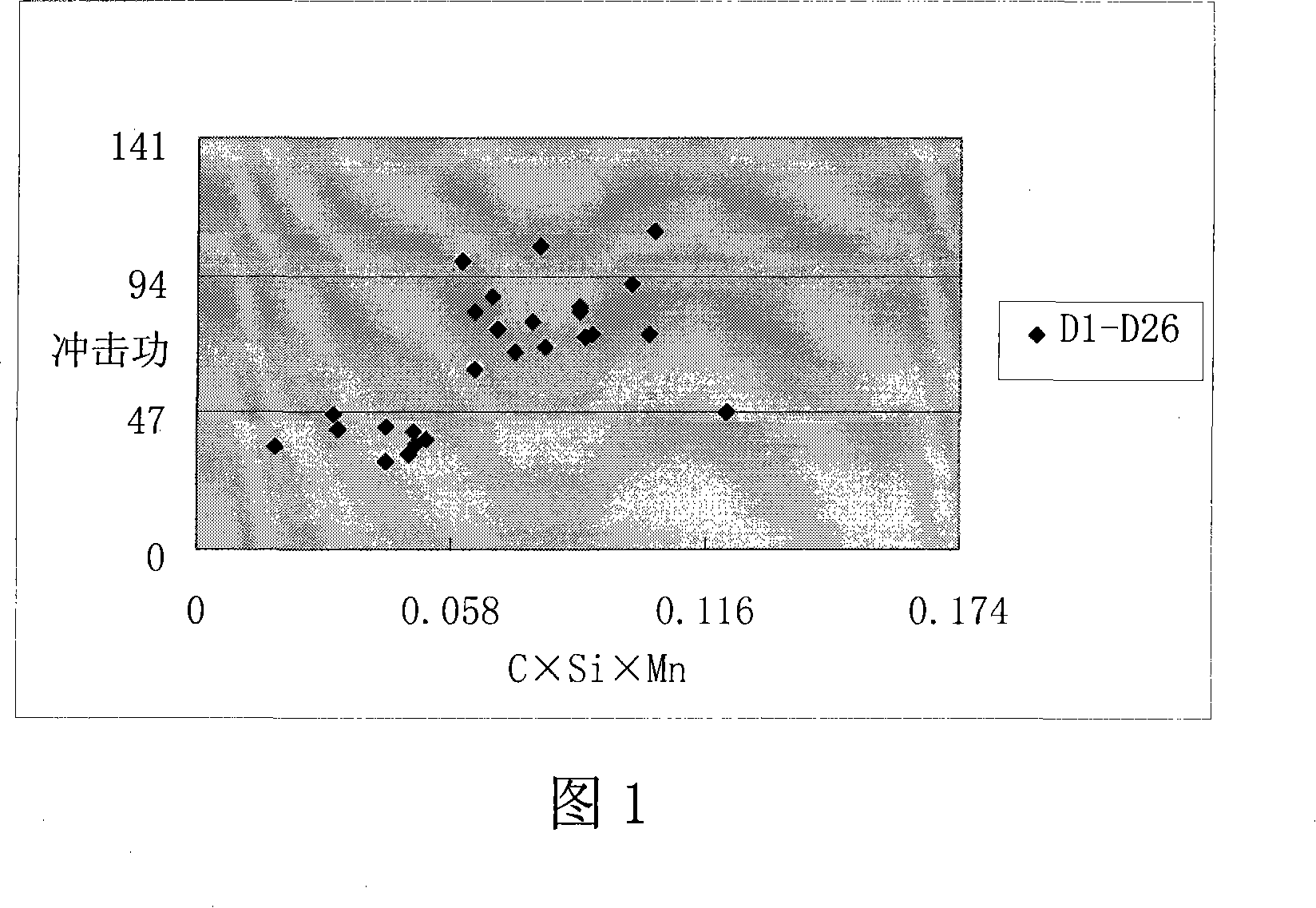

Disclosed is a low alloy steel drug core welding wire used in the carbon dioxide arc welding. The components of the drug core and the content occupying the total weight of the welding wire(percent ratio) are as following: Ti01 3-6, Si 0.3-0.5, Mn 1.5-3.2, Si02 0.1-0.8,Zr02 0.1-0.5, Fe 2-7, Al plus Mg 0.5-1.2, Ni 0.5 -5, B 0.002-0.015, Ti 0.1-0.3; oxide or fluoride of alkali metal K, Na and Li is converted into the content of K, Na and Li, that is, 0.1-0.35; the content of fluoride F is 0.05-0.2; fluoride or oxide of rare earth metal is converted into the content of the rare earth metal, that is, 0.005-0.2; the product of the contents of C, Si and Mn in the welding wire is 0.058-0.11. The invention has good process property for the whole position welding of high strength low alloy steel, and can keep good stability of electric arc and welding operating property in the conditions of large current and fast-speed welding with smooth welding seam, high connecting intensity, good impact toughness minus 40 DEG C low temperature and good crack resistance.

Owner:WUHAN TEMO WELDING CONSUMABLES CO LTD

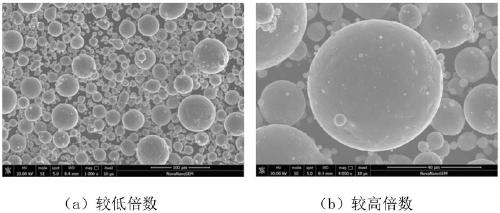

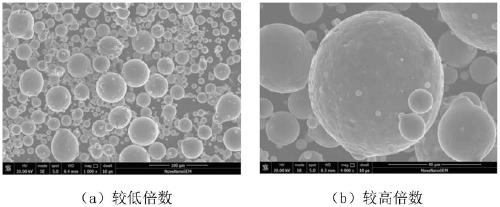

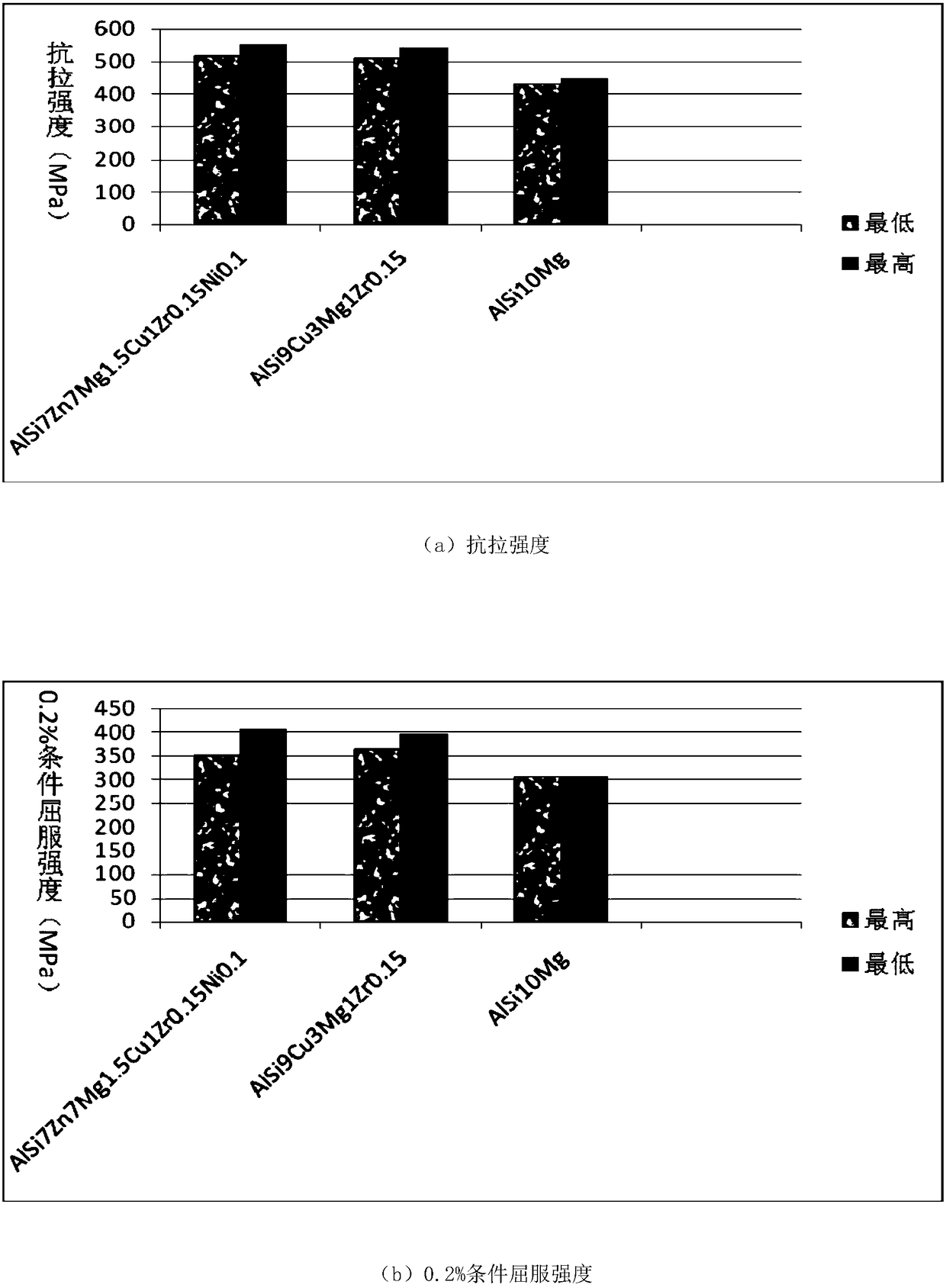

High-strength aluminum alloy for additive manufacturing and preparation method of high-strength aluminum alloy powder

ActiveCN109280820AGuaranteed yieldAvoid oxidation burnAdditive manufacturing apparatusTransportation and packagingTest sampleMedium frequency

The invention provides a high-strength aluminum alloy for additive manufacturing and a preparation method of high-strength aluminum alloy powder. The high-strength aluminum alloy powder is prepared byadopting a gas atomization process. The preparation method comprises the following steps of: firstly, melting an Al-Si-Zn-Cu-Mg-X alloy prefabricated ingot by adopting a medium frequency induction furnace, then powdering by adopting a supersonic speed gas atomization process, sieving and preparing powder of different specifications for additive manufacturing. A test sample obtained by adopting the high-strength aluminum alloy powder through additive manufacturing has compact texture without crack defects, the strength of extension exceeding 500MPa and the elongation exceeding 3%; the strengthperformance of the test sample is obviously superior to the strength performance of additive manufacturing test samples of AlSi10Mg, AlSi7Mg and AlSi12; and the performances of the test sample are also superior to the performances of additive manufacturing test samples of conventional 2000 series and 7000 series alloys. The alloy powder can be used for preparing aluminum alloy parts with compacttexture, complicated shapes and high strength in an additive manufacturing method to meet the requirements of use occasions on high specific strength and complicated shapes in the fields of aviation,spaceflight and automobiles.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

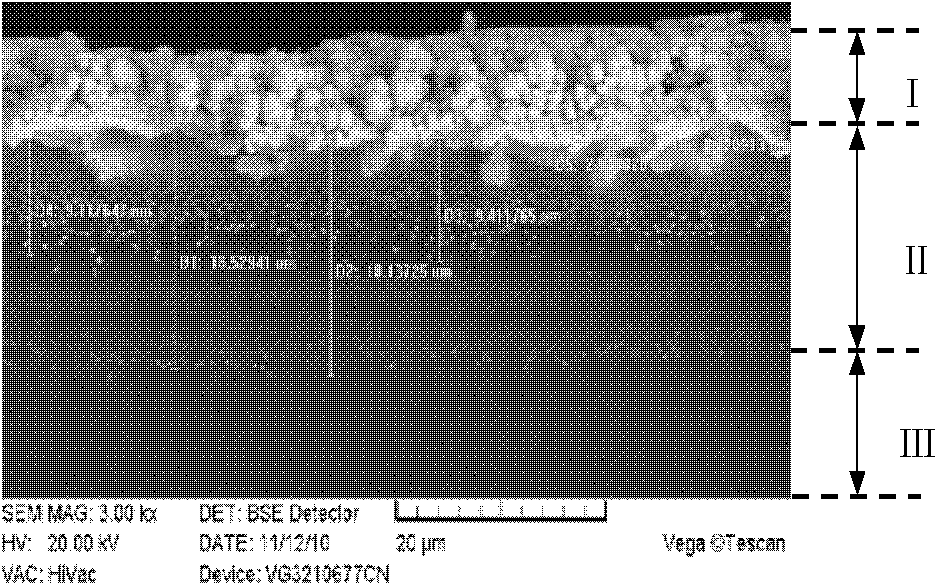

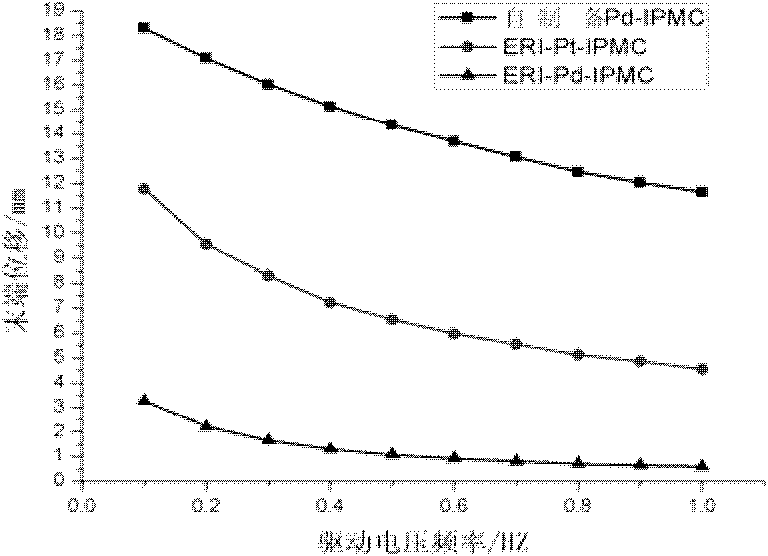

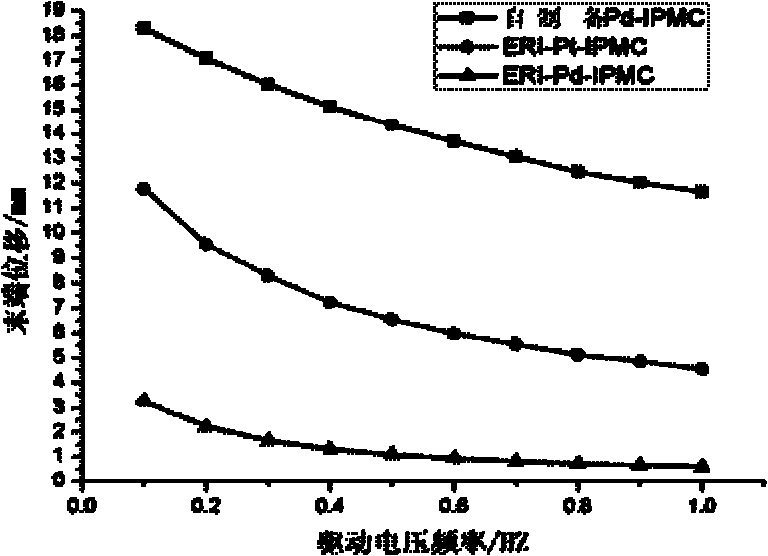

Preparation process of palladium electrode ion polymer and metal composite

InactiveCN102168260AIncrease profitImprove electrical actuation performanceLiquid/solution decomposition chemical coatingIonic polymer–metal compositesChemical plating

The invention discloses a preparation process of a palladium electrode ion polymer and metal composite, which is used for preparing a palladium metal electrode IPMC (Ion Polymer Metal Composite) by using immersion reduction plating and chemical plating methods in which an ion exchange membrane is used as a matrix material and [Pd (NH3)4] C12 is used as a main salt. The preparation process comprises the following four main steps of: (1) pretreatment of the matrix membrane: carrying out roughening, surface cleaning, foreign ion removal and full swelling on the matrix membrane; (2) immersion reduction plating including two processes, i.e., ion exchange and ion reduction: subjecting a pretreated Nafion membrane to repeated palladium ion immersion and exchange, and reducing the pretreated Nafion membrane with NaBH4 by adopting ultrasonic waves to form palladium metals on the surface and the internal surface of the ion exchange membrane; (3) chemical plating: wherein the thickening electrodes on the outer surface of a core material to compact internal surface electrodes by using an improved chemical plating method; and (4) postprocessing of the composite. The preparation process has a higher popularization value due to relatively improved efficiency, relatively lower cost and excellent actuation response.

Owner:XI AN JIAOTONG UNIV

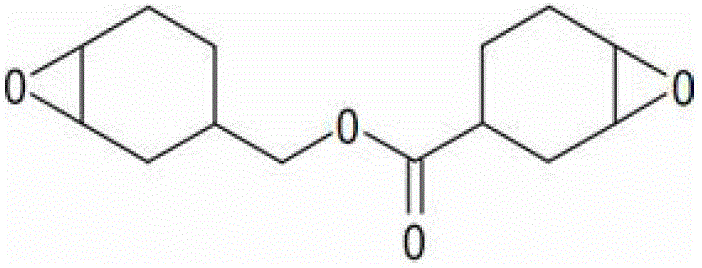

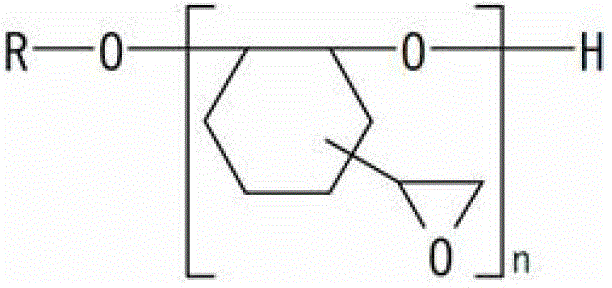

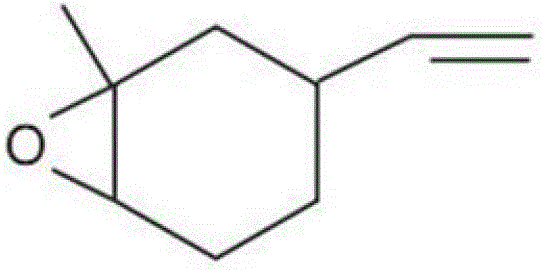

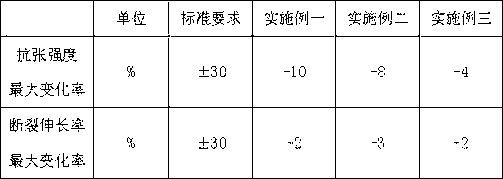

LED-packaging epoxy resin composition

InactiveCN102746487AGuaranteed crack resistanceGuaranteed craftsmanshipNon-macromolecular adhesive additivesEpoxy resin adhesivesPhosphonium saltPhosphate

The invention discloses a method for improving the performance of a large-power high-light-transmittance LED packaging epoxy resin composition. The composition is composed of a component A and a component B. The composition has excellent UV resistance and yellowing resistance. The composition is advantaged in good manufacturability, good light transmittance, and low light failure. The composition can be used in white-light and blue-light LED packaging. Compared with organosilicon, the composition is advantaged in low price. Innovatively, the component A of the composition is composed of liquid cycloaliphatic epoxy resin, solid cycloaliphatic epoxy resin, and hydrogenated bisphenol A epoxy resin. An anti-forming agent, a color complementary agent, and a dispensing agent are adopted in auxiliary. The system does not contain benzene ring, and yellowing is not easy to occur. The component B is prepared through the steps that: methyl hexahydrophthalic anhydride and hexahydrophthalic anhydride are subjected to a polymerization reaction with promoting agents or cationic initiators such as quaternary phosphonium salt, quaternary ammonium salts, DBU salt, and imidazole; with added phosphate antioxidant, a thermal yellowing capacity is improved. With the applications of an ultraviolet absorber and a light stabilizer, a UV yellowing resisting effect is further improved.

Owner:MIANYANG WELLS ELECTRONICS MATERIAIS +1

Method for preparing high-tenacity hot-melt prepreg by hot-melt resin matrix

ActiveCN102922855AEliminate prepreg layup loss and pressurization difficultiesImprove toughnessFibre treatmentSynthetic resin layered productsChemistryHot press

The invention provides a method for preparing a high-tenacity hot-melt prepreg by a hot-melt resin matrix. Aiming at conditions that preparation difficulty of a high-tenacity resin matrix is high and the difficulties of subsequent technical processes are easily increased, a non-high-tenacity or non-toughened resin matrix with excellent processing properties is adopted, a proper amount of small-grain-size toughening powder is added in a preparation process of the prepreg in a specific manner, the overlaying property of the prepreg can be maintained, parameters of a curing process of the prepreg are not basically changed, and the tenacity of a composite material can be greatly improved. According to the method for preparing the high-tenacity hot-melt prepreg by the hot-melt resin matrix, the tenacity of the composite material after being solidified is greatly improved when the processing property of the prepreg is maintained; and the method can be applied to hot press molding of aerospace composite material structures and can be applicable to high-tenacity composite material structures in national defense industry applications such as ships, warships and weapons as well as various composite material structures being subjected to hot press molding.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Micro-crystallizing glass-ceramic composite board and producing method thereof

InactiveCN101186129ALow raw material costGuaranteed craftsmanshipGlass shaping apparatusCeramic layered productsMetallurgySurface layer

The invention discloses a minicrystal glass-ceramic composite plate and a production method. The minicrystal glass-ceramic composite plate is compounded by a minicrystal glass surface layer and a ceramic core layer; the minicrystal glass comprises the compositions measured in weight: 50 to 68 portions of SiO2, 3 to 10 portions of Al2O3, 20 to 38 portions of CaO, 3 to 12 portions of R2O (Na2O+K2O+Li2O), 0 to 3 portions of B2O3, and 0 to 12 portions of MgO. On the precondition of ensuring the process performance and crystallization performance and appearance decorated effect of product, the invention has no BaO and ZnO compositions, thus obviously reducing the cost of the raw material of minicrystal glass-ceramic composite plate.

Owner:广东高微晶科技有限公司

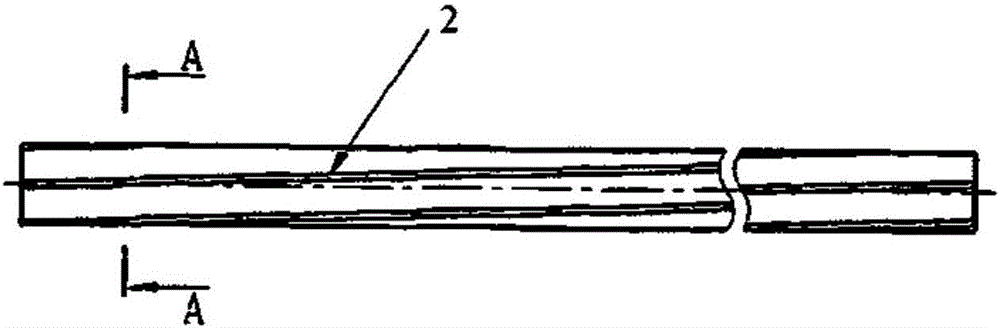

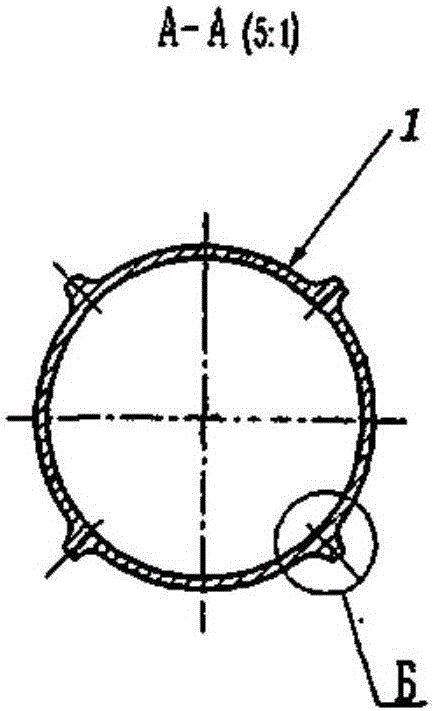

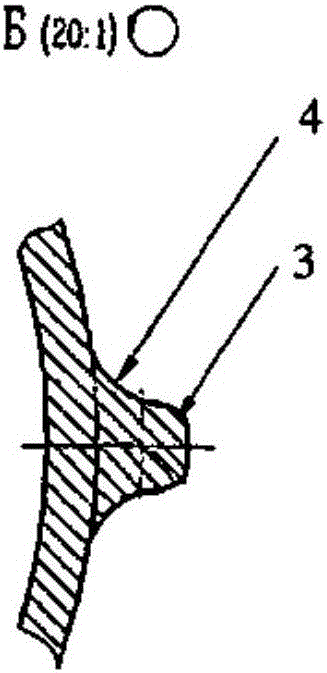

Fuel rod cladding, fuel rod and fuel assembly

ActiveCN105723465AImprove performanceAvoid corrosion damageFuel elementsNuclear energy generationNuclear engineeringLong term durability

The invention relates to the field of nuclear engineering and can be used in the manufacture of fuel rods and fuel assemblies for heavy liquid metal cooled reactors, and also in the manufacture of fuel rod simulators for use in irradiation devices designed to test the operability of real fuel assemblies. The present cladding of a fuel rod for a heavy liquid metal cooled reactor is in the form of a weldless tubular element with helically-coiled fins disposed on the outer surface of said element, which is made from a ferritic-martensitic chromium-silicon steel with a minimum ferrite grain size of 7 on the GOST 5639 scale, wherein each fin has an opening angle of from 22 to 40 DEG C (preferably from 30 to 40 DEG C) and the cross-section of the fin is in the shape of a trapezoid with rounded corners at the top of the trapezoid and smooth corners at the base of the trapezoid. Also disclosed are a fuel rod comprising the above cladding, and a fuel assembly. The technical result of the invention is an improvement in the performance characteristics of fuel rods and assemblies as a result of the long-term resistance of the cladding in the environment of a heavy liquid metal coolant such as lead or a eutectic of lead and bismuth.

Owner:JOINT CO AKME ENG

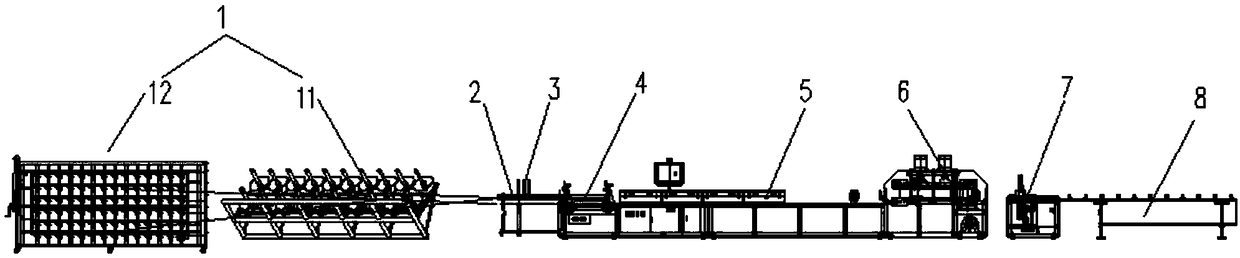

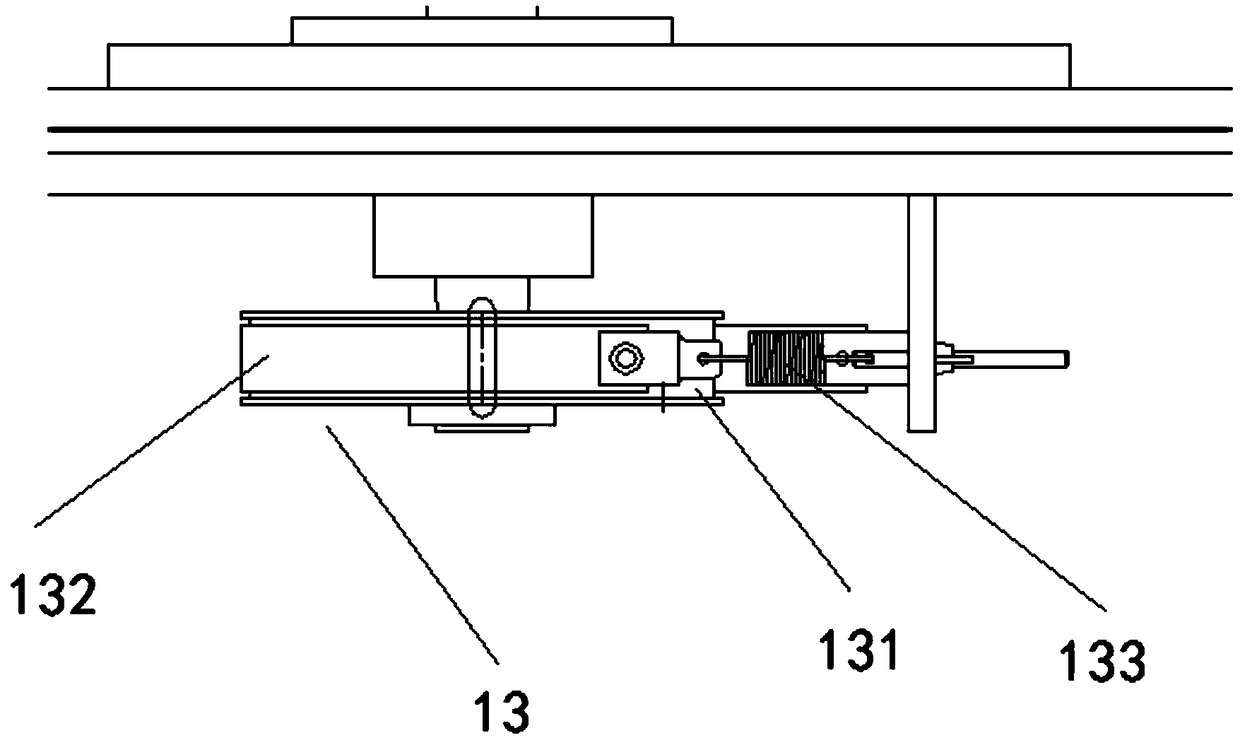

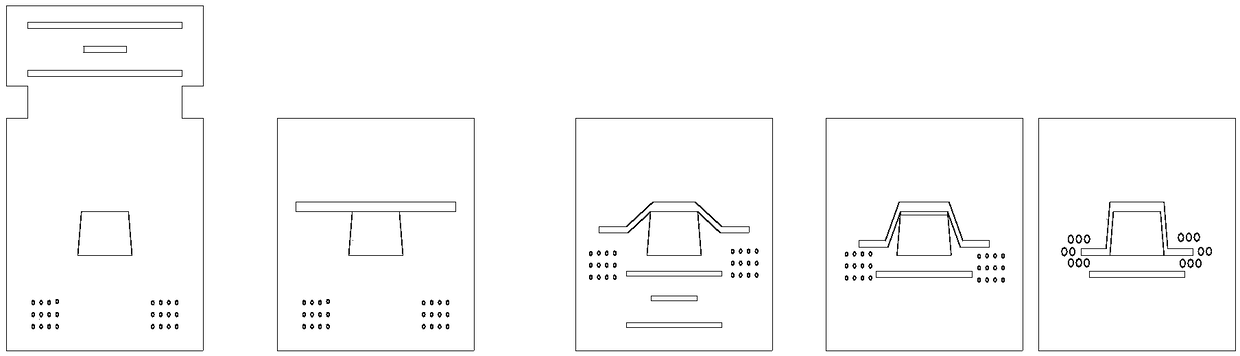

Equipment cabin pultrusion technology

The invention provides an equipment cabin pultrusion technology. The equipment cabin pultrusion technology comprises the steps that firstly, fiber yarn and fiber fabric are discharged at the same time, an equipment cabin body part is made of fiber fabric, and fiber yarn is adopted at the corner part or the thickened part; secondly, a pre-forming die is used for conducting pre-forming treatment onthe fiber yarn and the fiber fabric, the pre-forming die comprises a plurality of pre-forming plates, the pre-forming plates are provided with hollow grooves, the hollow grooves can gradually change,and finally the product shape is formed; thirdly, glue injection type pultrusion is conducted on the pre-formed fiber yarn and the pre-formed fiber fabric; fourthly, a curing die is used for conducting curing on the fiber yarn and the fiber fabric obtained after pultrusion; and fifthly, an automatic cutting machine is used for cutting the cured fiber yarn and the cured fiber fabric. Compared withthe prior art, the fiber fabric and fiber yarn mixed pultrusion manner is adopted, holes of the fiber fabric are filled, the fiber content reaches up to 80%, and the equipment cabin mass is further reduced.

Owner:NEWTRY COMPOSITE

Building microcrystalline glass and producing method thereof

The invention discloses a building glass-ceramic, which contains 50-68 portions of SiO2, 3-10 portions of Al2O3, 20-38 portions of CaO, 3-12 portions of R2O(Na2O+K2O+ Li2O), 0-3 portions of B2O3 and 0-12 portions of MgO. Besides, 0-1.5 portions of clarifier or 0-10 portions of colorant can be applied to the glass technique for clarifying and coloring. The glass batch limited by the components is melted, water quenched, sintered and crystallized, and then the surface is ground and polished, thereby obtaining the glass-ceramic with appearance similar to natural stone. On the premise of guaranteeing technique performance, crystallization performance and the decoration effect to the appearance of the product, the invention contains no BaO and ZnO, thus obviously reducing the cost of the raw materials of the building glass-ceramic.

Owner:霍镰泉

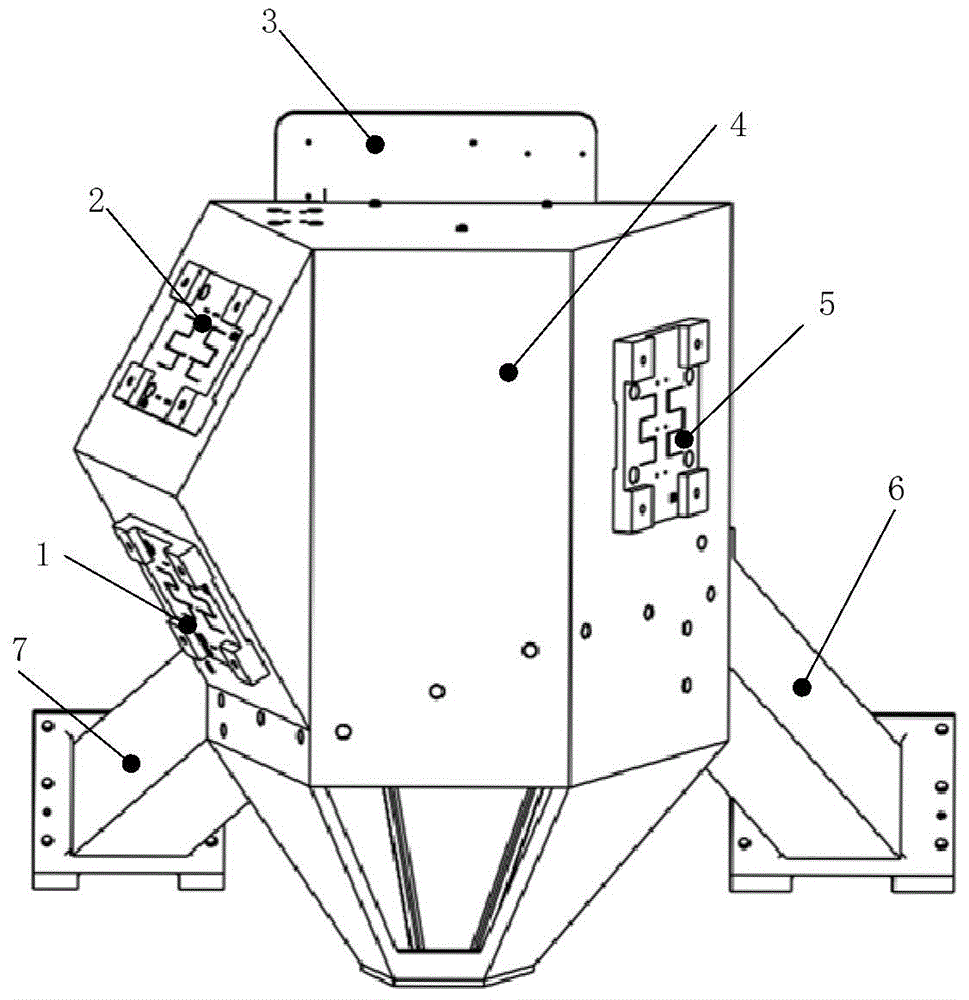

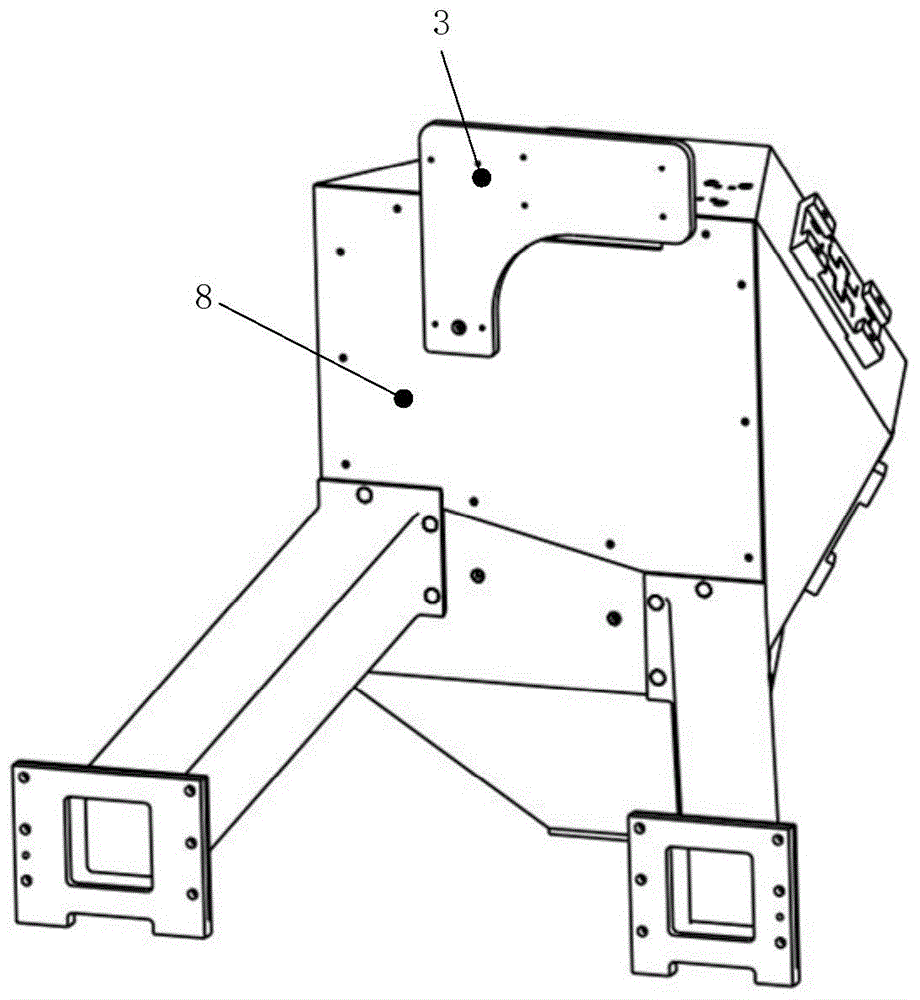

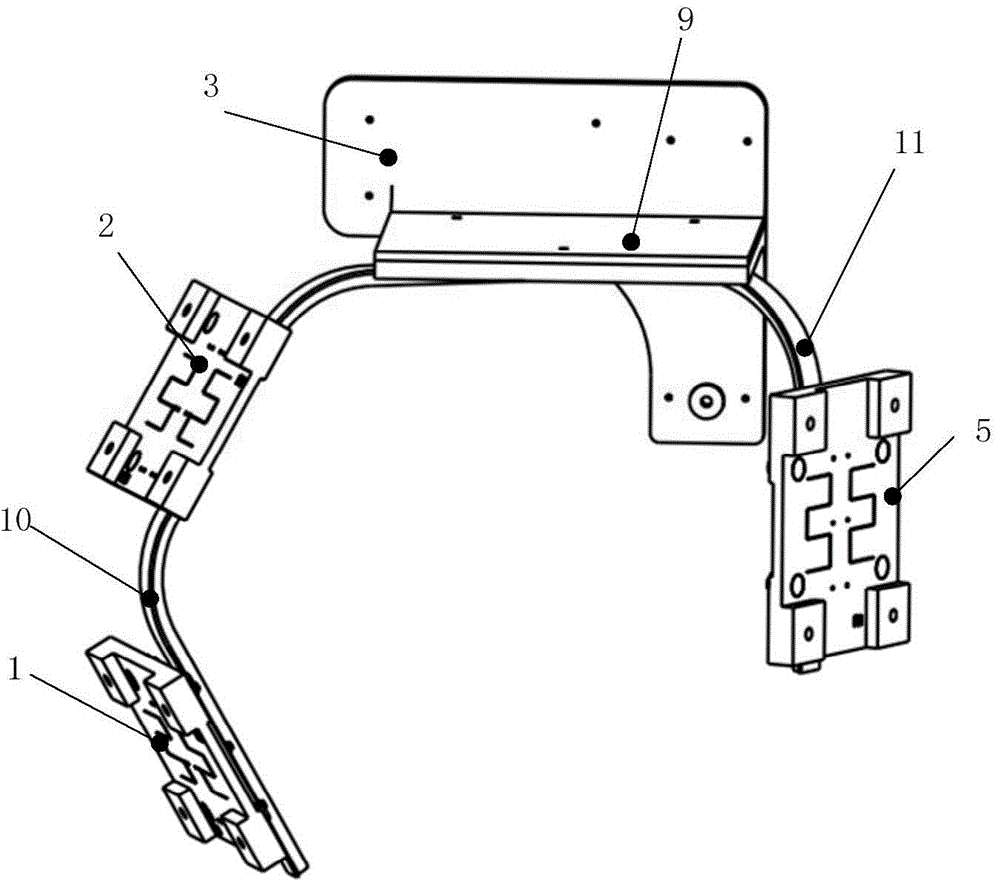

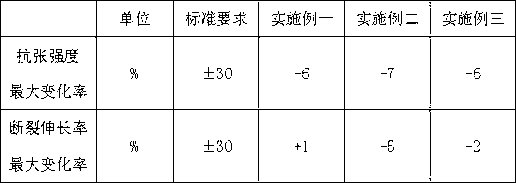

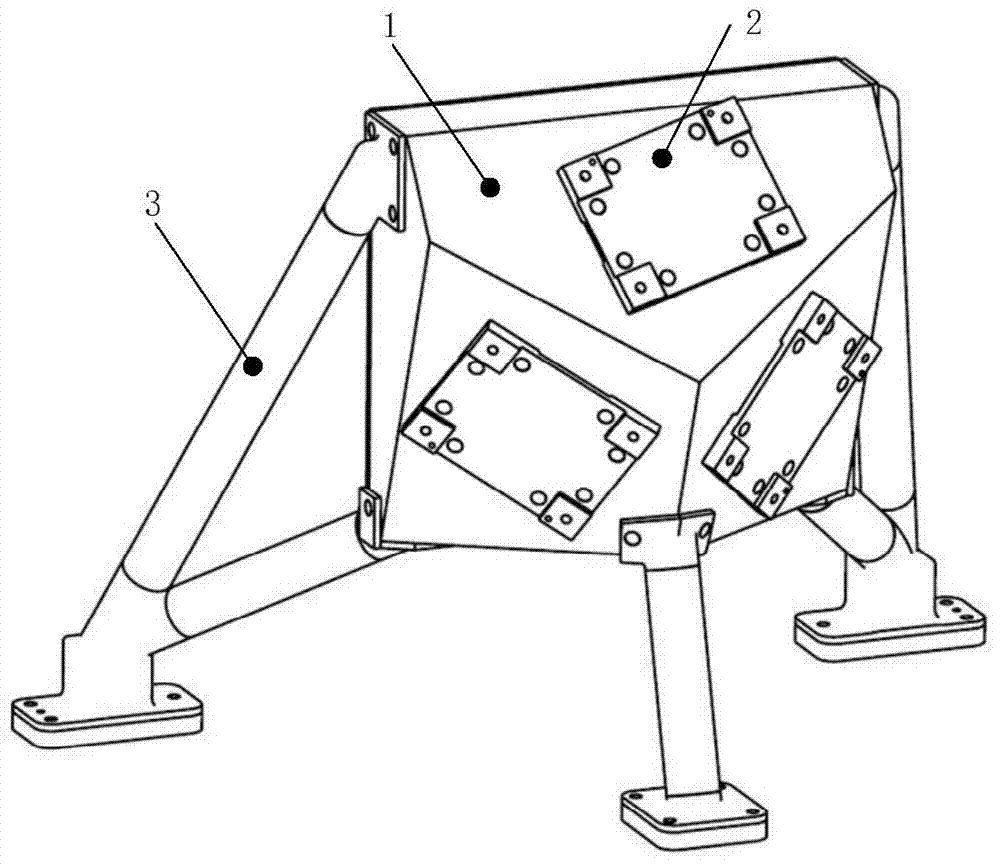

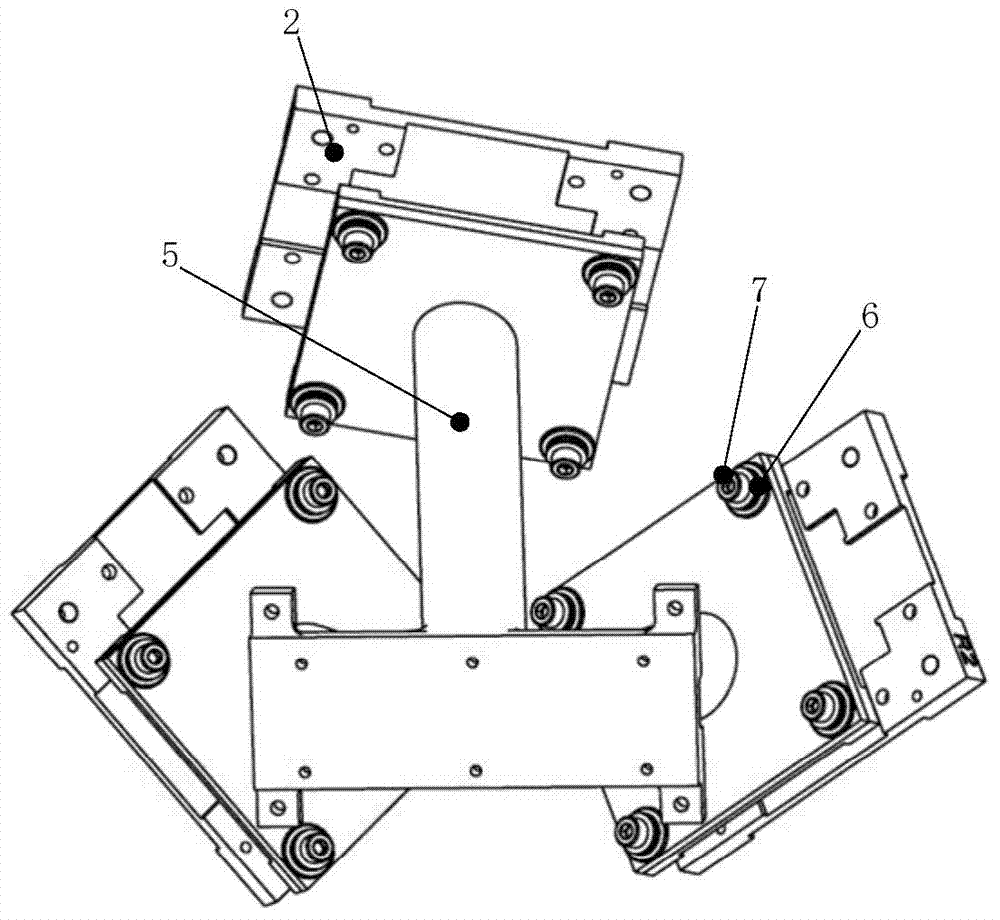

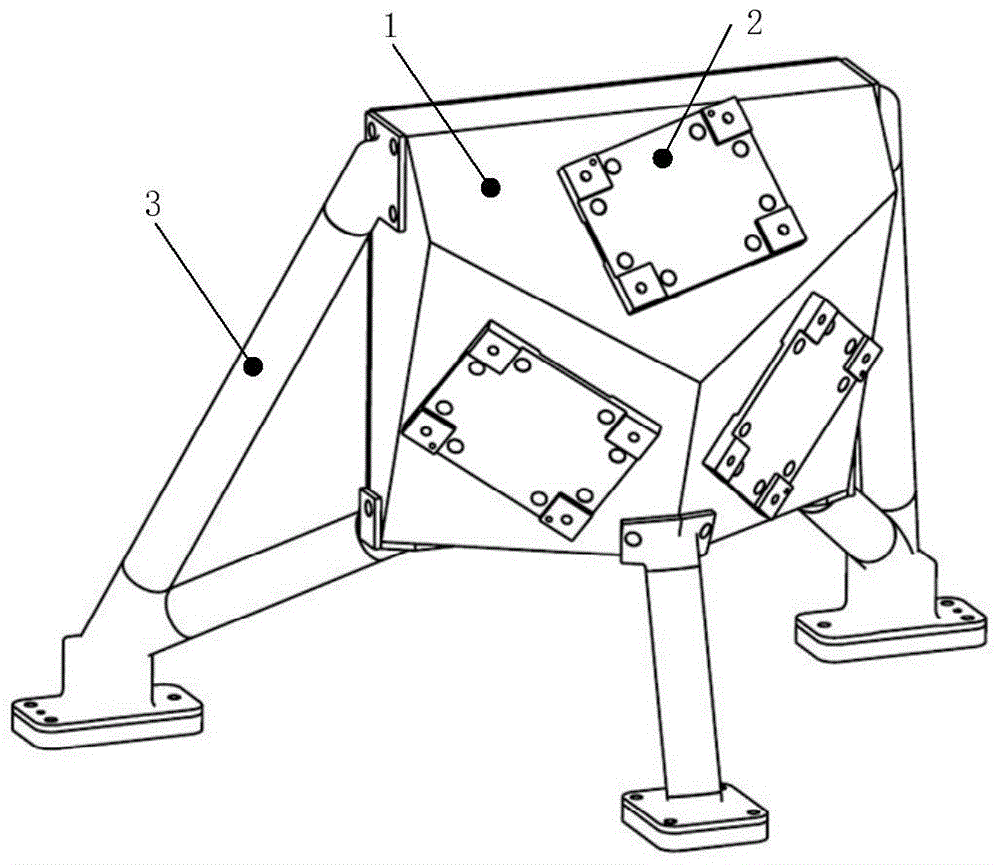

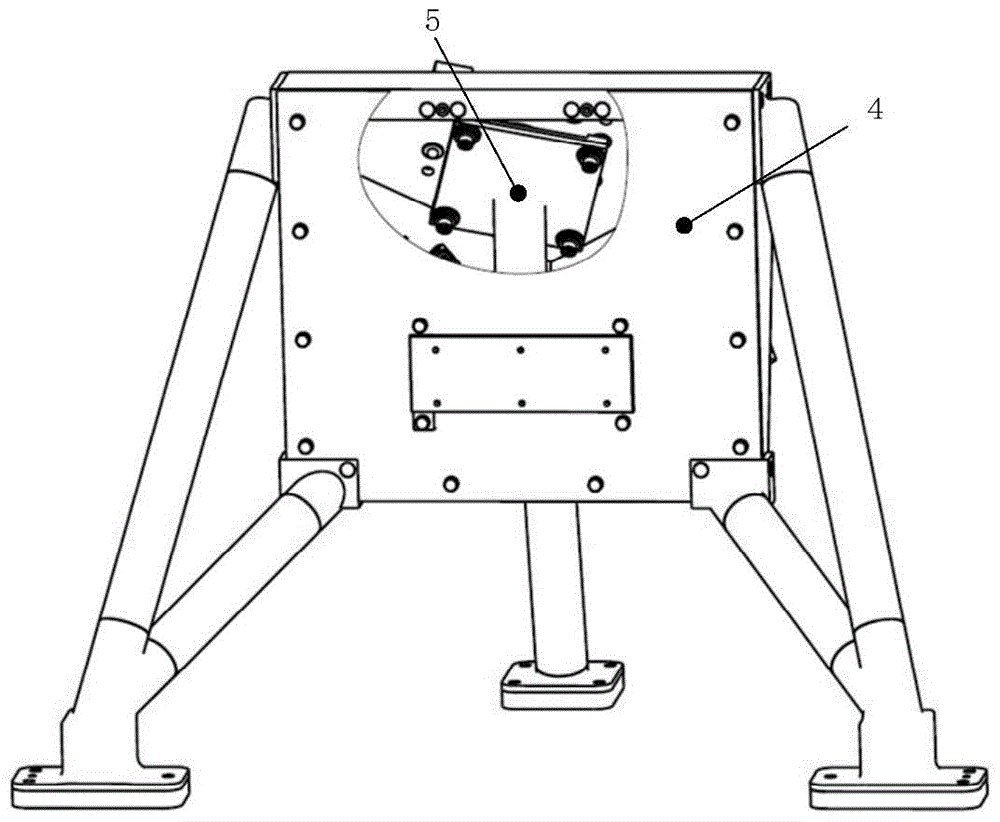

High-accuracy micro deformation star sensor mounting bracket

ActiveCN104691790AAccuracy meetsFulfil requirementsCosmonautic vehiclesCosmonautic partsThermal deformationEngineering

The invention discloses a high-accuracy micro deformation star sensor mounting bracket. A star sensor mounting plate is connected to the outer surface of a thin-wall shell structure; a heat pipe is positioned inside the thin-wall shell structure; one end of the heat pipe is connected to the star sensor mounting plate; the other end of the heat pipe is connected with a heat collecting plate; the heat collecting plate is connected to the inner side of the top of the thin-wall shell structure and partially extends out of the top of the thin-wall shell structure; a first insulation mat is mounted between the heat collecting plate and the thin-wall shell structure; a rear cover board is connected to the back of the thin-wall shell structure so as to form a mounting bracket head; one end of a strut assembly is connected with the mounting bracket head; the other end of the strut assembly is used for mounting a spacecraft optical imaging effective load structure body. The high-accuracy micro deformation star sensor mounting bracket solves the technical difficult problem of harsh thermal deformation of a high-orbit spacecraft star sensor mounting bracket so as to meet the requirements on high-accuracy attitude determination of a spacecraft and image navigation registration, and meanwhile, has the advantages of novel structural form, light weight and the like.

Owner:SHANGHAI SATELLITE ENG INST

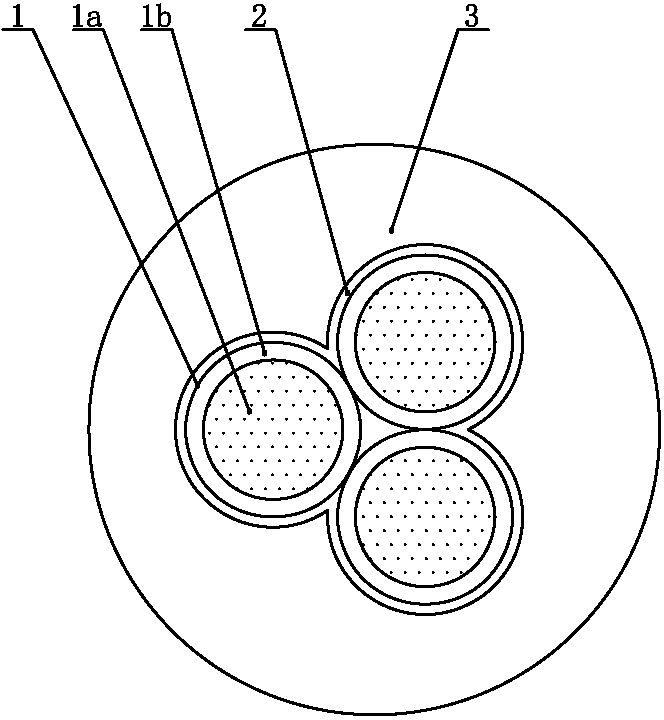

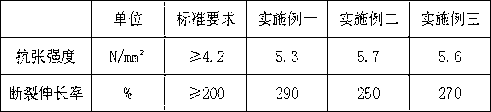

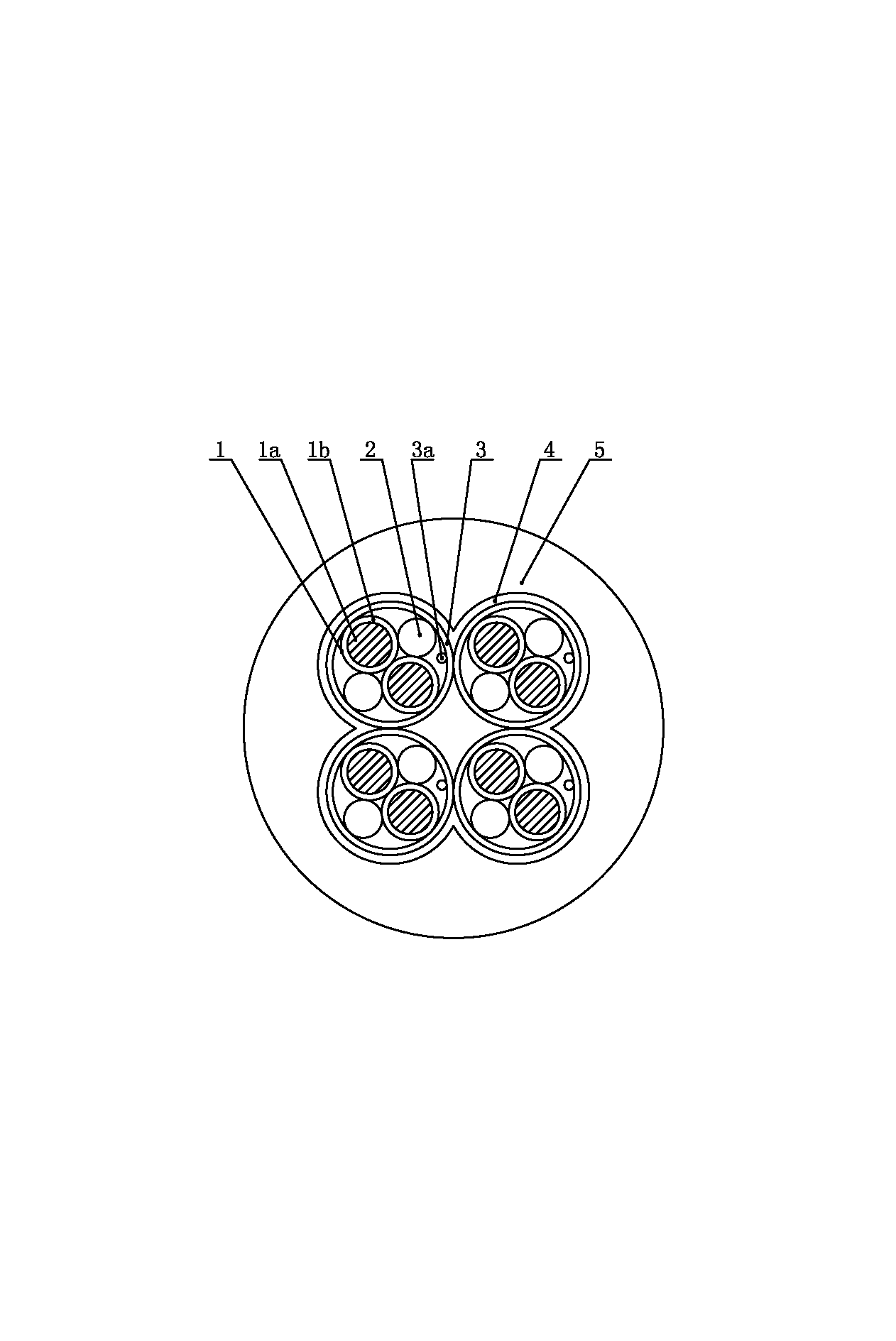

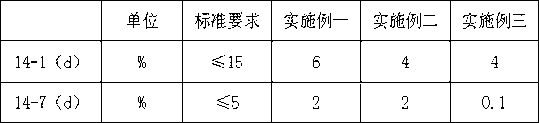

Salt corrosion resistant and twisting resistant power cable for ocean wind power and manufacturing method of power cable

ActiveCN103227008AReduce tensionEliminate voidsPower cablesInsulating conductors/cablesCopper conductorElectricity

The invention relates to a salt corrosion resistant and twisting resistant power cable for ocean wind power and a manufacturing method of the power cable. A stranded copper conductor is uniformly wrapped in a salt corrosion resistant and twisting resistant extruded rubber insulation layer to form a power cable insulated core; a plurality of power cable insulated cores are mutually stranded to form a power cable core; the power cable core is wrapped in a low-strength non-woven fabric longitudinal wrap on the periphery; and the low-strength non-woven fabric longitudinal wrap is wrapped in an extruded sheath. The power cable provided by the invention adopts the low-strength non-woven fabric longitudinal wrap which completely fits the power cable insulated cores in shape, so that gaps between the low-strength non-woven fabric longitudinal wrap and the power cable insulated cores are eliminated, convenience is provided for stopping flame from spreading inwards under a combustion condition and the resistance to moisture impregnation is enhanced; and meanwhile, the low-strength non-woven fabric longitudinal wrap can ensure that the sheath is not stuck to the insulated cores, and provides convenience for stripping the sheath in a construction process without damaging the insulated cores.

Owner:浙江华威设备制造有限公司

High-precision micro-deformation attitude control instrument installing structure for spaceflight

ActiveCN104743138AStrong enoughRigid enoughCosmonautic vehiclesCosmonautic partsHeat conductingAttitude control

The invention discloses a high-precision micro-deformation attitude control instrument installing structure for a spaceflight. An instrument installing plate comprises a first wing plate, a second wing plate and a web plate. The first wing plate is fixed to the outer surface of a thin-wall shell structure. The second wing plate is arranged in the thin-wall shell structure and connected with a plane butt-joint flange of a heat conducting body. The first wing plate and the second wing plate are connected through the web plate and carry out heat exchange through the web plate. The installing face of the heat conducting body is connected to a sealing cover plate which is connected with the thin-wall shell structure to form a head of the installing structure. One end of a supporting rod assembly is connected with the head of the installing structure. The other end of the supporting rod assembly is installed on a body of an optical imaging effective load structure of the spaceflight. The technical problem of rigorous thermal deformation of the attitude control instrument installing structure is solved, the installing structure has an excellent heat transfer property and a thermal deformation isolation property, the requirement for high-precision attitude determination and image navigation rectification of the spaceflight is met, and the installing structure has the advantages of being novel in structural form, light in mass and the like.

Owner:SHANGHAI SATELLITE ENG INST

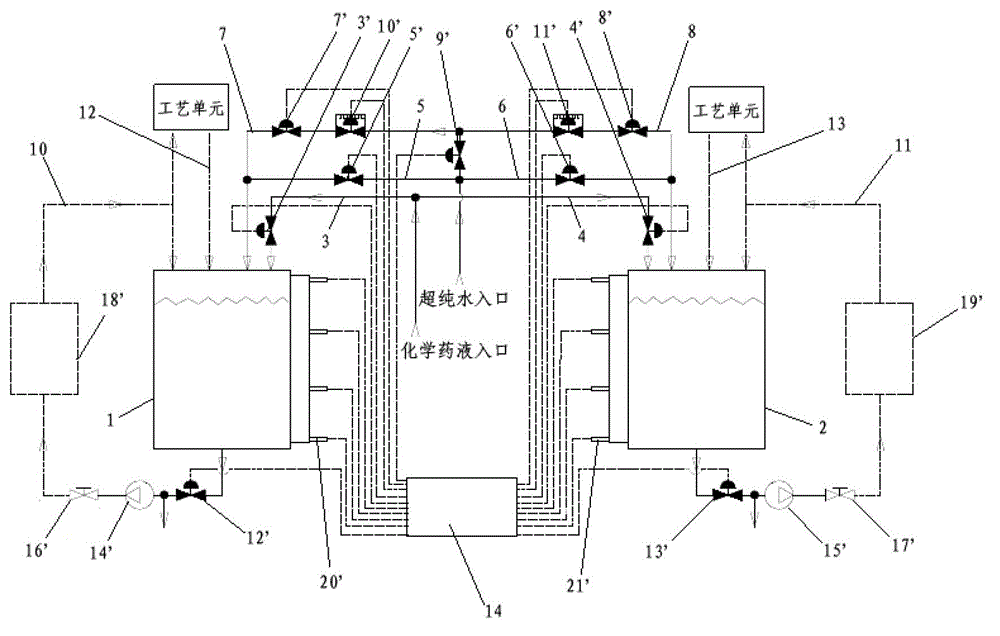

Liquid-replenishing device

ActiveCN102878429AGuaranteed concentrationGuaranteed craftsmanshipSemiconductor/solid-state device manufacturingPipeline systemsLiquid storage tankEngineering

Owner:BEIJING SEVENSTAR ELECTRONICS CO LTD

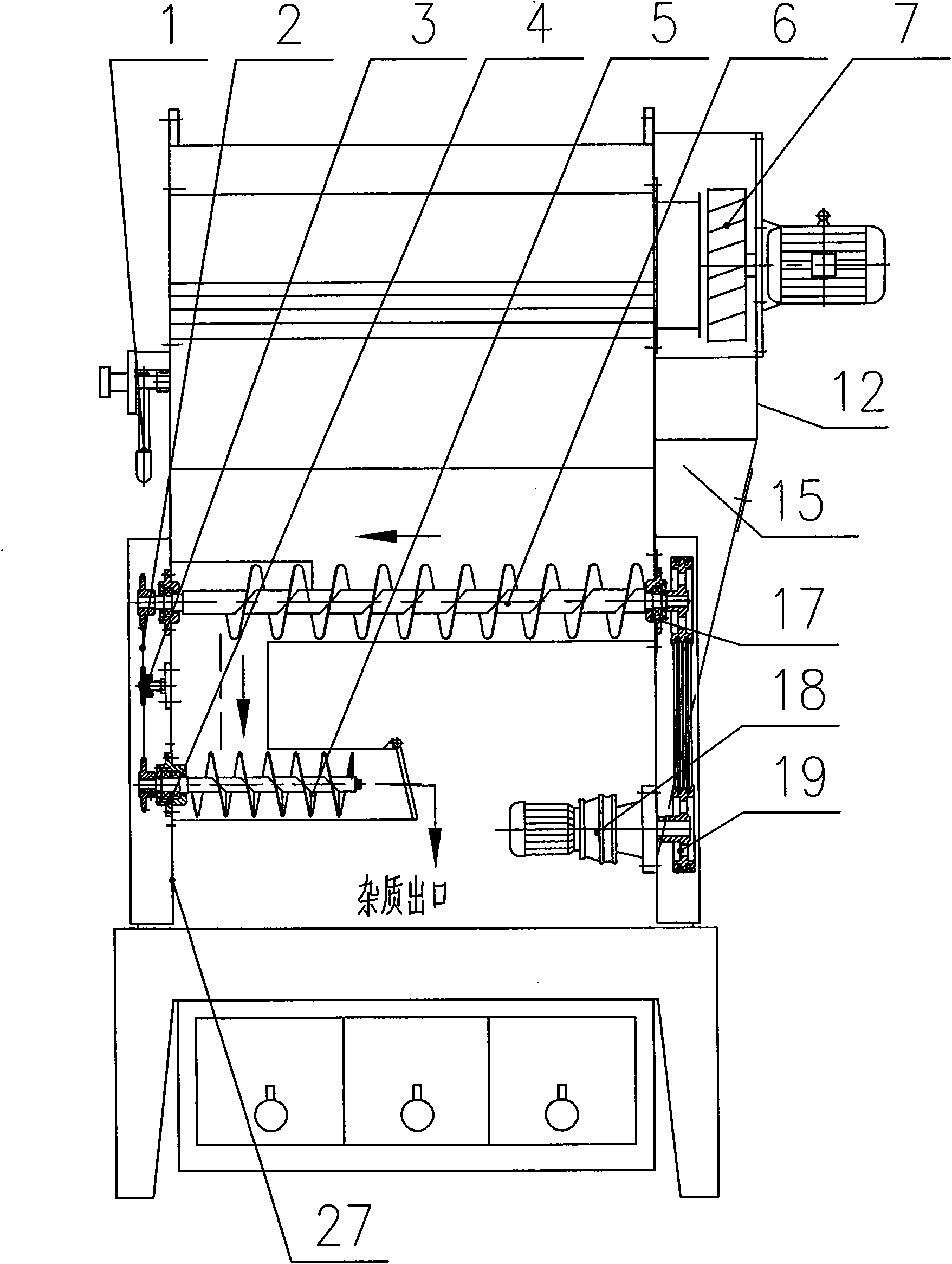

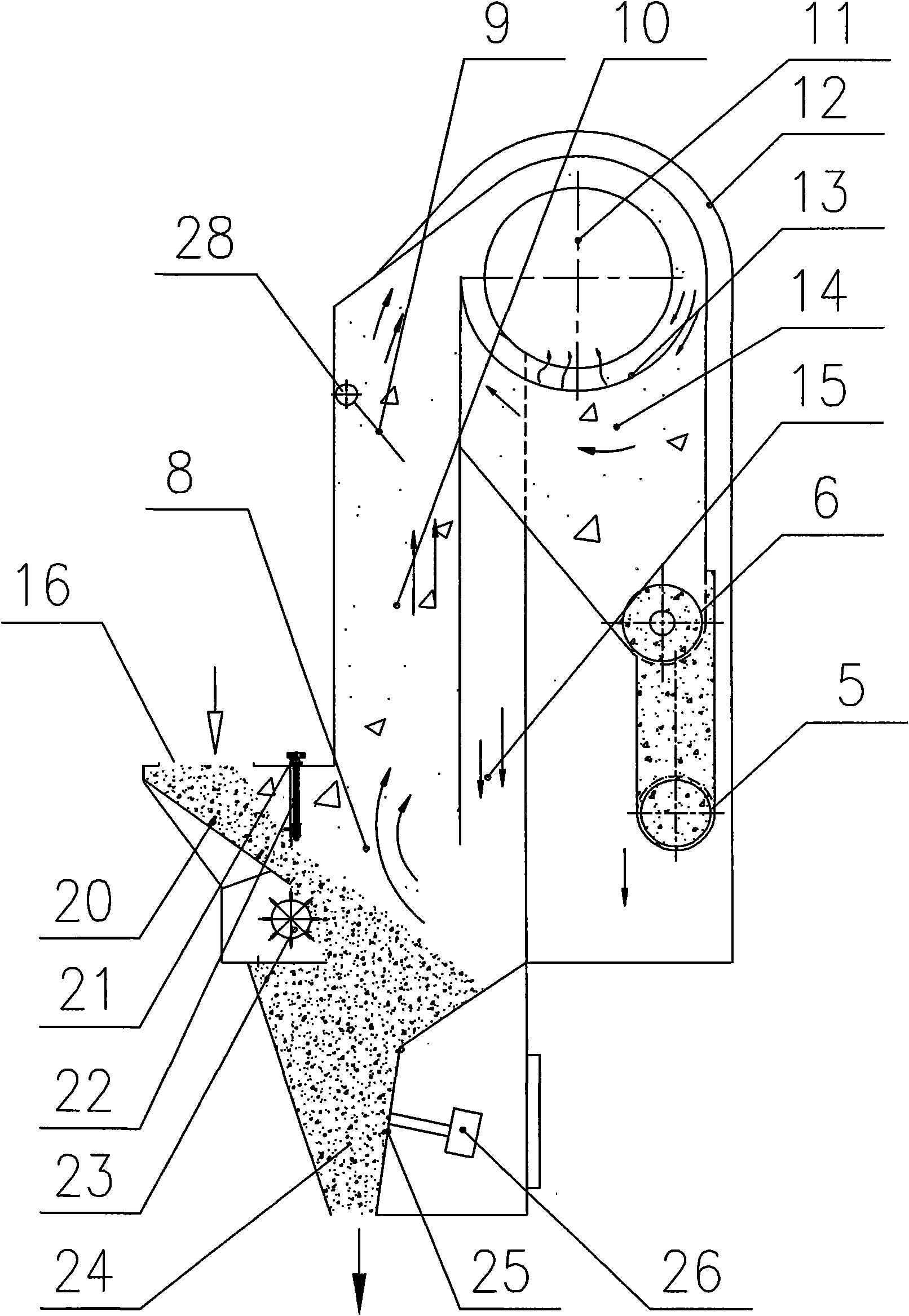

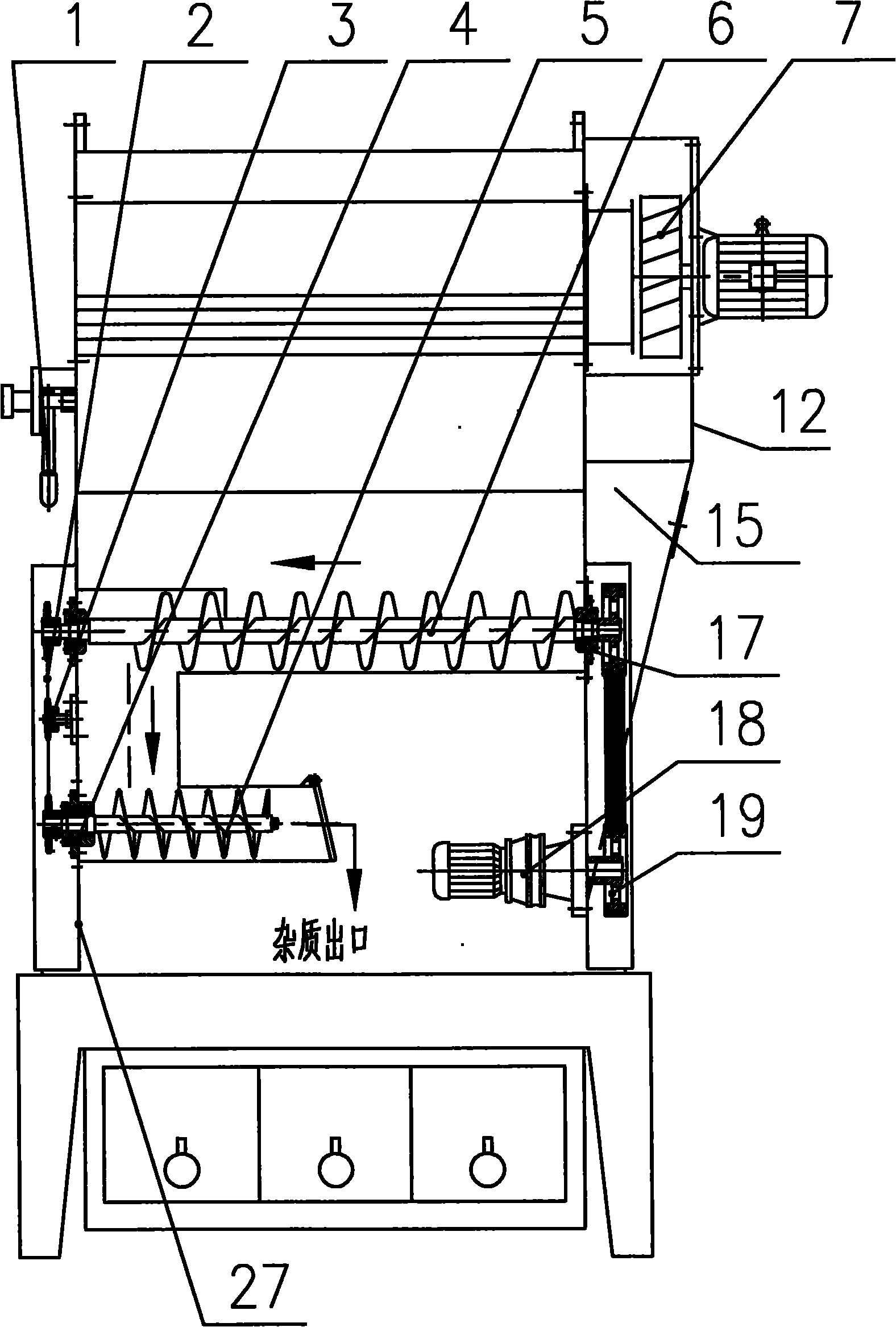

Circulating winnowing machine

InactiveCN101966520ASatisfied with the separation effectGuaranteed craftsmanshipGas current separationEngineeringAirlock

The invention relates to the field of the structure of grain machinery, in particular to a circulating winnowing machine which comprises a stand, wherein a feed port and a discharge port are arranged at the back end of the stand; an air intake channel and a separating zone are arranged in the stand; a separating cartridge is arranged above the separating zone; the separating cartridge is fixedly connected in the stand; a blower is arranged on at least one side of the separating cartridge; the blower is fixedly connected on the stand; a return channel is arranged below the blower outside the stand; the lower end of the return channel is communicated with the air intake channel; a dust chamber is arranged below the separating cartridge; an auger is arranged below the dust chamber; the left end and the right end of the auger are respectively supported on the stand; one end of the auger is connected with a driving device; the other end of the auger is connected with an auger airlock through a chain; the auger airlock is arranged below the auger; one end of the auger airlock is supported on the stand; a pressure valve is hinged in the stand and arranged at the discharge port; and a balancing weight is arranged on the pressure valve. The invention can reduce the impurity content of grain.

Owner:扬州市仙龙粮食机械有限公司

Low alloy steel flux-cored welding wire for carbon dioxide gas protection welding

InactiveCN100515655CImprove impact toughnessAccelerated corrosionArc welding apparatusWelding/cutting media/materialsCrack resistanceArc stability

A low-alloy steel flux-cored welding wire for carbon dioxide gas shielded welding, the composition and content of the flux core in % of the total weight of the welding wire are as follows: TiO2: 3-6, Si: 0.3-0.5, Mn: 1.5-3.2, SiO2: 0.1 -0.8, ZrO2: 0.1-0.5, Fe: 2-7, Al+Mg: 0.5-1.2, Ni: 0.5-5, B: 0.002-0.015, Ti: 0.1-0.3, oxidation of alkali metal K, Na, Li The content of fluoride or fluoride equivalent to K, Na, and Li is 0.1-0.35, the content of fluoride F is 0.05-0.2, the fluoride or oxide of rare earth metal is equivalent to 0.005-0.2 of rare earth metal, and the content of C, Si, and Mn in the welding wire The product of the contents is 0.058-0.11. For high-strength low-alloy steel all-position welding process performance is good, it can maintain good arc stability and welding operation performance under the condition of high current and fast welding, the weld seam is smooth, the connection strength is high and it has a good -40 ℃ low temperature Impact toughness and excellent crack resistance.

Owner:WUHAN TEMO WELDING CONSUMABLES CO LTD

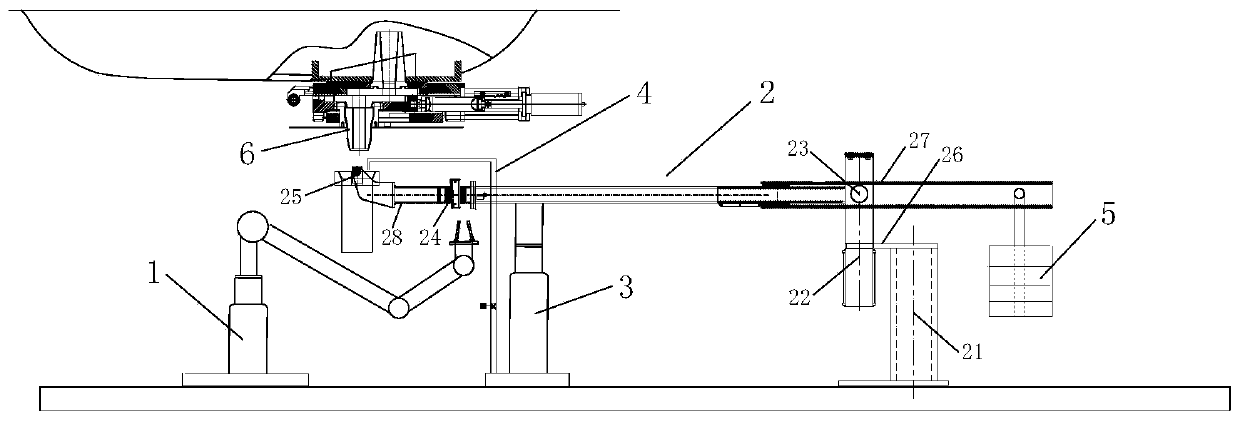

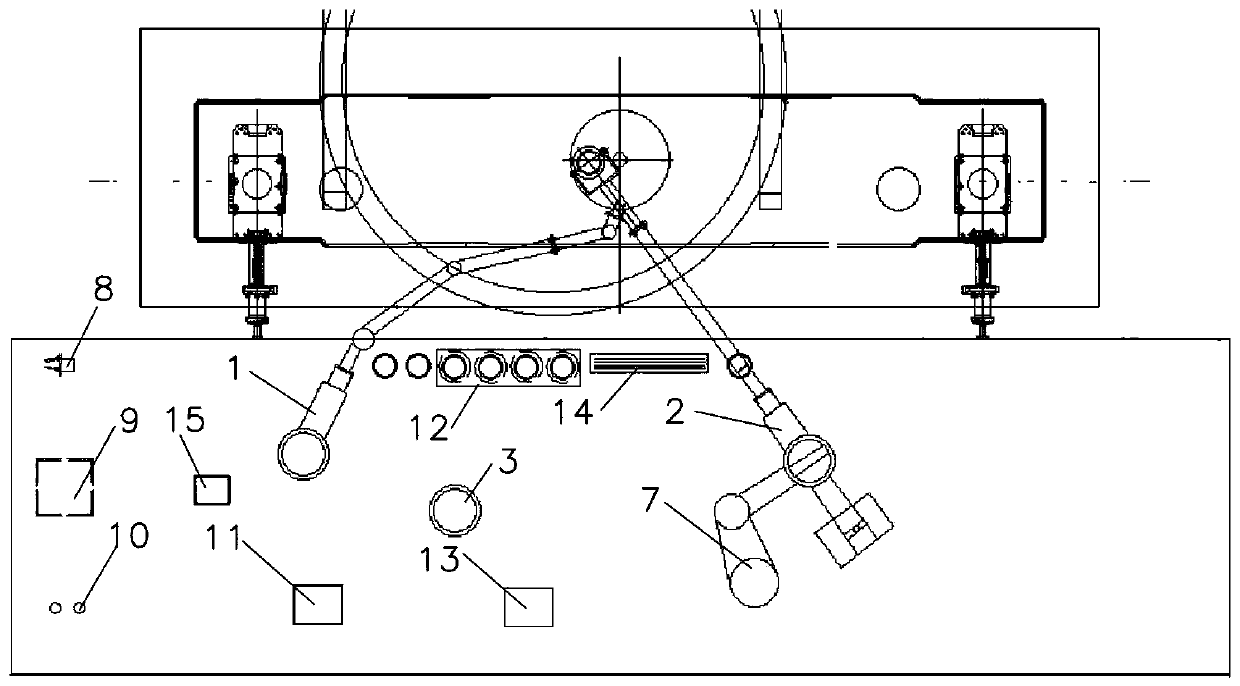

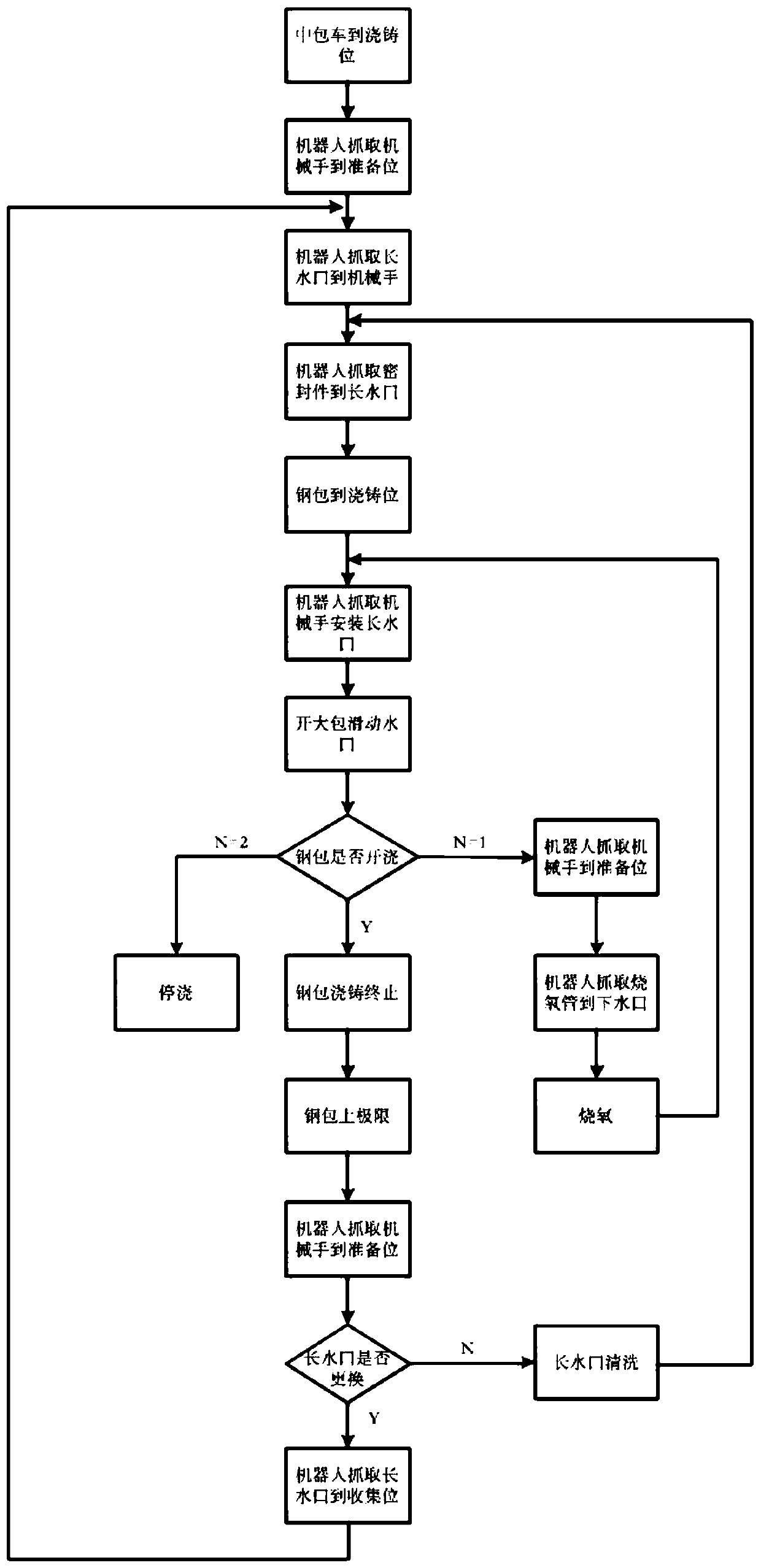

Unmanned system and operation method of steel ladle casting area

ActiveCN111168051AEnsure health and safetyReduce investmentMelt-holding vesselsCasting parameters measurement/indication devicesRobot handEngineering

The invention relates to an unmanned system and operation method of a steel ladle casting area. The method comprises the steps that a mechanical arm is prepared, wherein a robot grabs the mechanical arm from a mechanical arm standby station, the mechanical arm is placed into a fixed bayonet of a locating pile, and the mechanical arm is released; a long nozzle is prepared, wherein the robot takes out the long nozzle from a long nozzle storage device, the long nozzle approaches a mechanical arm long nozzle backing ring according to the set position, the position of the long nozzle is finely adjusted through a robot vision recognition system and a mechanical arm recognition mark, and then the long nozzle is placed into the long nozzle backing ring; a sealing part is mounted, wherein the sealing part is grabbed by the robot from a sealing part storage device and is placed into the long nozzle; and the long nozzle is mounted, wherein after a steel ladle rotates in place, the mechanical armis grabbed by the robot to drive the long nozzle and a lower nozzle to be aligned, the long nozzle is mounted in, the robot retreats, and the mechanical arm supports the long nozzle and presses the lower nozzle all the time. The unmanned system and operation method have the advantages that the mechanical arm and the robot cooperate to replace manual operation, and operations of long nozzle replacement, tundish molten steel temperature measuring and sampling, tundish covering agent adding and steel ladle oxygen pipe burning are completed.

Owner:ANGANG STEEL CO LTD

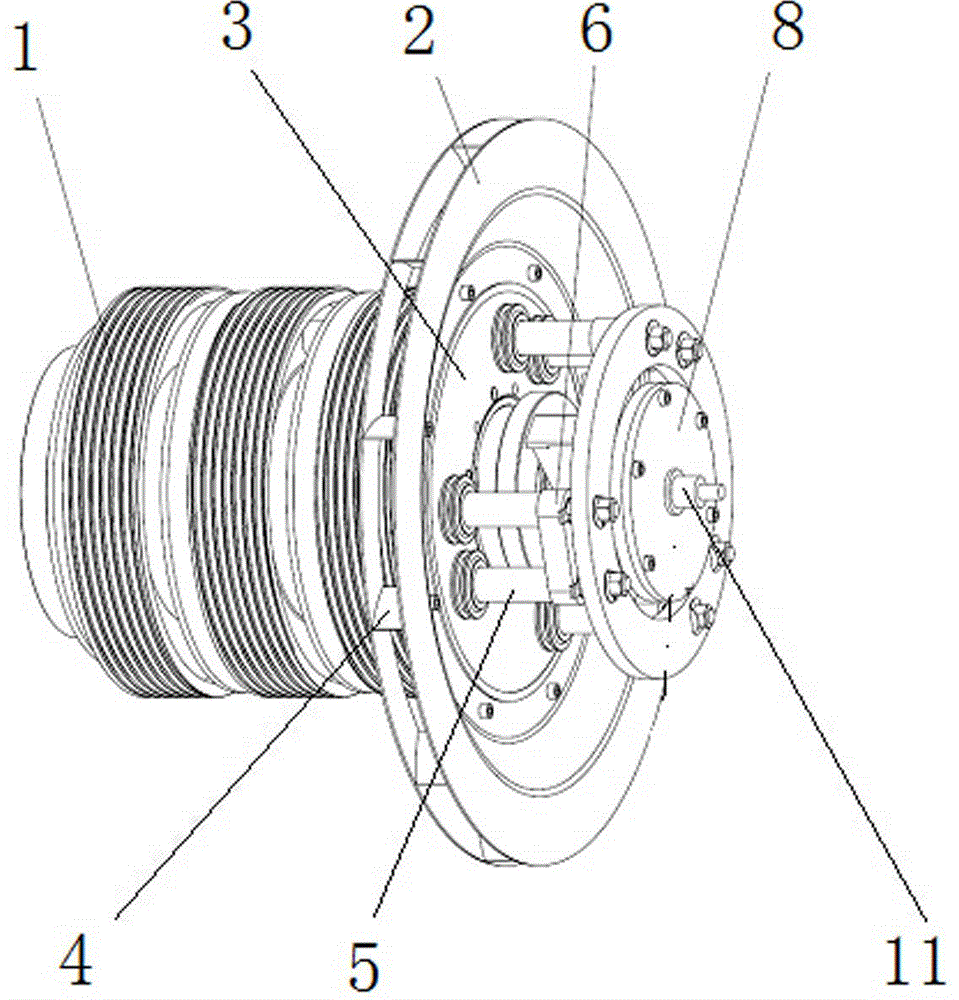

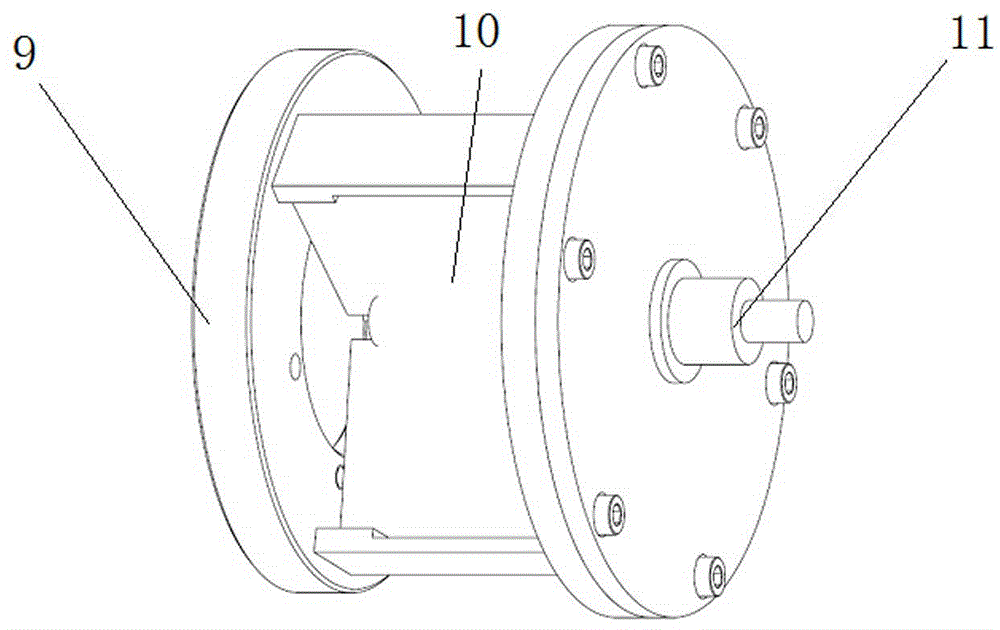

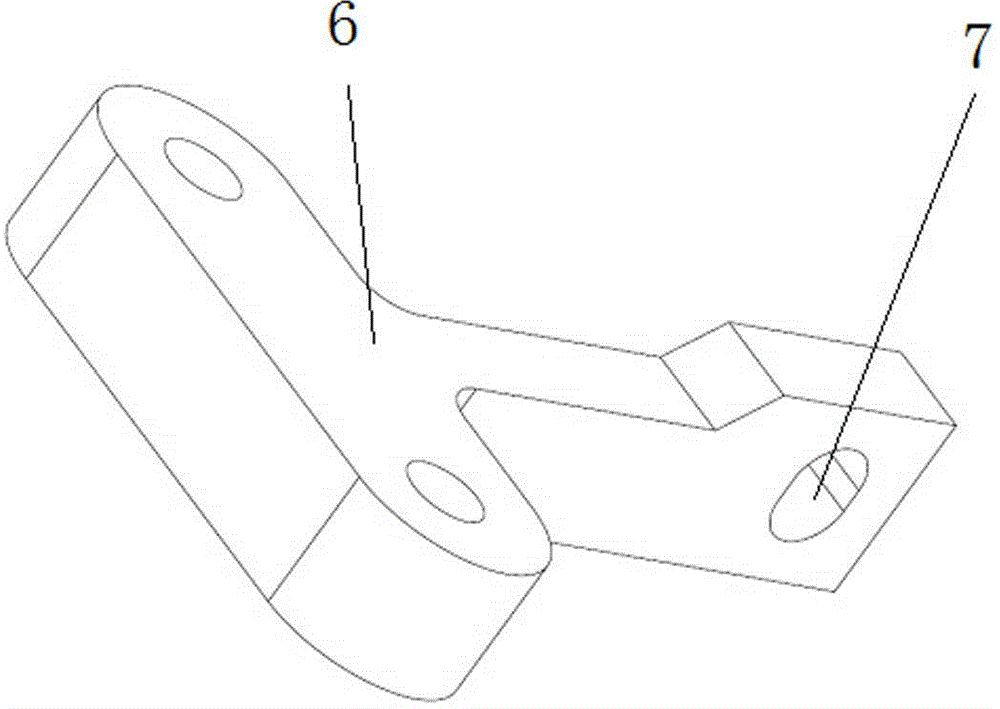

Slip ring structure for double-fed motor coiling type rotor

ActiveCN104158351ALow costReduce axial sizeStructural associationCooling/ventillation arrangementEngineeringSlip ring

The invention specifically discloses a slip ring structure for a double-fed motor coiling type rotor, for solving the problems of increased fault points, difficult control of assembling precision and enhanced operation difficulties by use of a conventional motor slip ring installation cooler and an encoder. The right end surface of a slip ring main body is connected with a cooling fan, an annular wheel hub is internally provided with a plurality of pairs of conductive poles which are fixed to the right end surface of the slip ring main body and are uniformly arranged by taking the axle center of the slip ring main body as a circle center, each pair of conductive poles are sleeved by a T-shaped conducting block, the inner sides of the T-shaped conducting blocks are provided with wiring holes, the inner sides of the conductive poles are provided with an encoder support connected with the right end surface of the slip ring main body, the encoder support comprises two discs arranged in parallel and an insulation spacer disposed between the two discs for separating the T-shaped conducting blocks, and the center of the disc at the right side of the encoder support is provided with an encoder connection shaft. By using the slip ring structure for the double-fed motor coiling type rotor, the heat dissipation problem of a slip ring is solved, the axial dimension is reduced, and the connection reliability and the operation manufacturability are guaranteed.

Owner:CRRC YONGJI ELECTRIC CO LTD

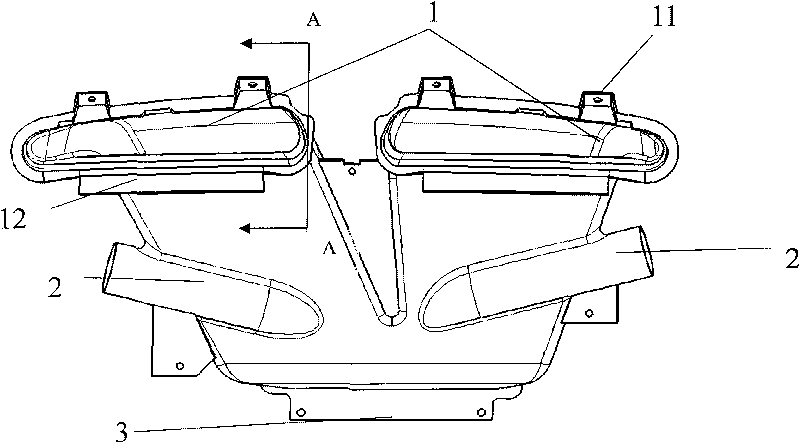

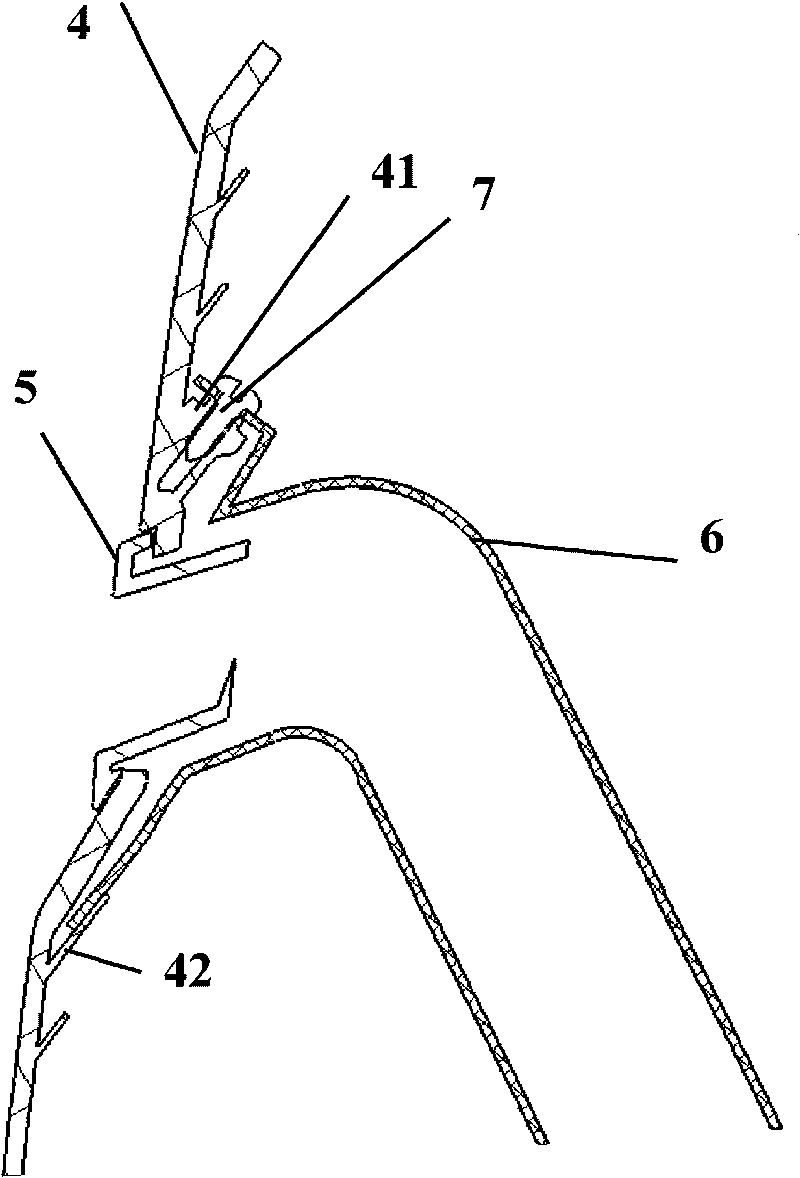

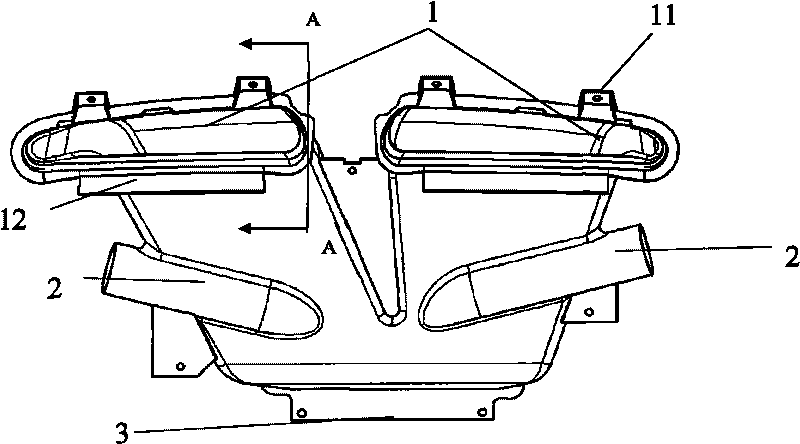

Automotive central defrosting air pipe and mounting structure for same and instrument board

InactiveCN101722817AGuaranteed tightnessReduce distortionAir-treating devicesVehicle heating/cooling devicesBlow moldingButt joint

The invention provides an automotive central defrosting air pipe. The air pipe body of the air pipe is an integral pipe by blow molding. The lower end of the air pipe body is provided with an air inlet which is in butt joint with an air outlet of an HVAC after the air inlet is connected with a surface-blowing air pipe. The upper end of the air pipe body is divided right and left to form two symmetrical air outlets with oblong sections. The upper end of the air pipe body is arranged to an inner side face of the instrument board and the lower end of the air pipe body is connected with the surface-blowing air pipe. In order to solve the problems of air outlet deformation, insufficient intensity and the like which are possibly caused by the blow molding technology, at least two connecting blocks with mounting holes are formed on the external sides of upper edges of the air outlets; the air pipe body is mounted on the inner side face of the instrument board through screws; and a malposition-preventing flanging is formed on a lower edge of each air outlet, wherein the malposition-preventing flanging extends outwards in a horn shape relative to the air outlet. The automotive central defrosting air pipe has the advantages of improving the airtightness, avoiding the deformation of the air outlets of the air pipe, guaranteeing the manufacturability in assembly with the defrosting grille, increasing the intensity, contributing to reducing the development cost of a finished automobile, and reducing the weight of the finished automobile.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

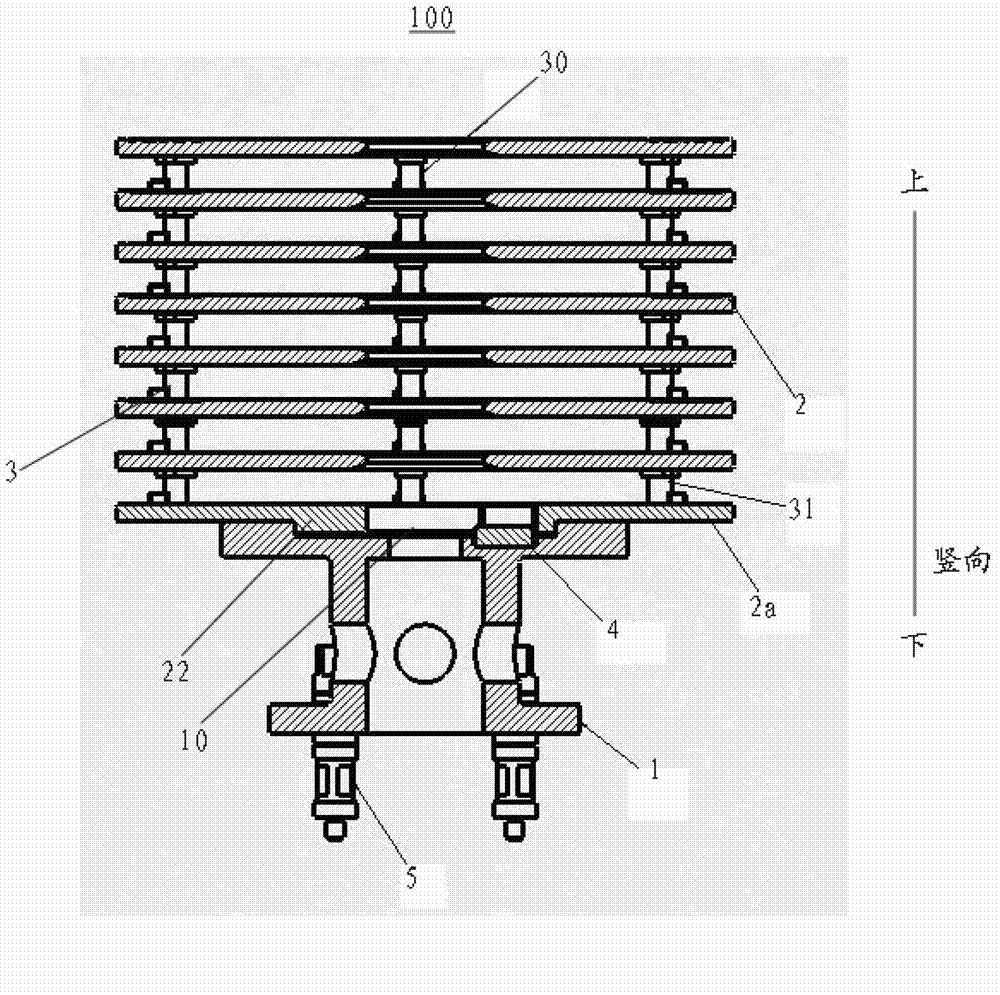

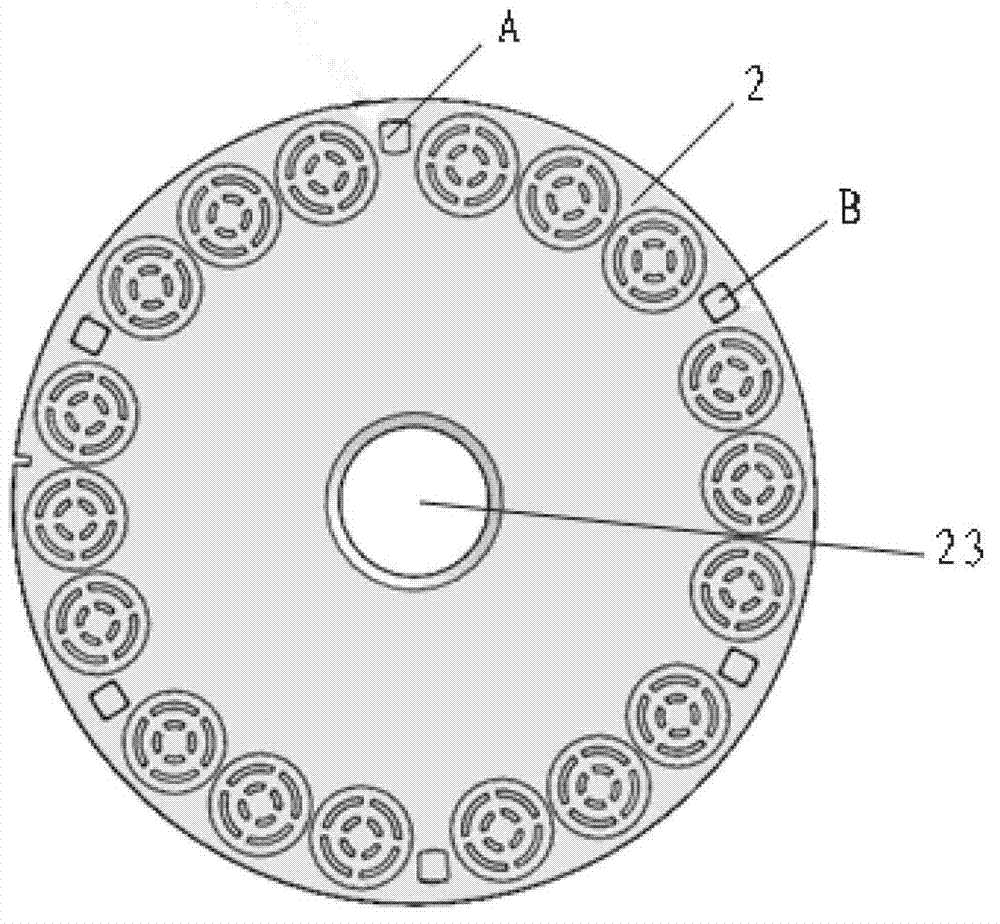

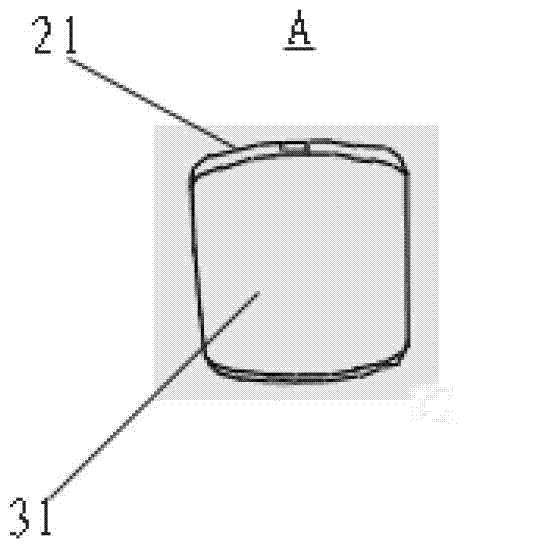

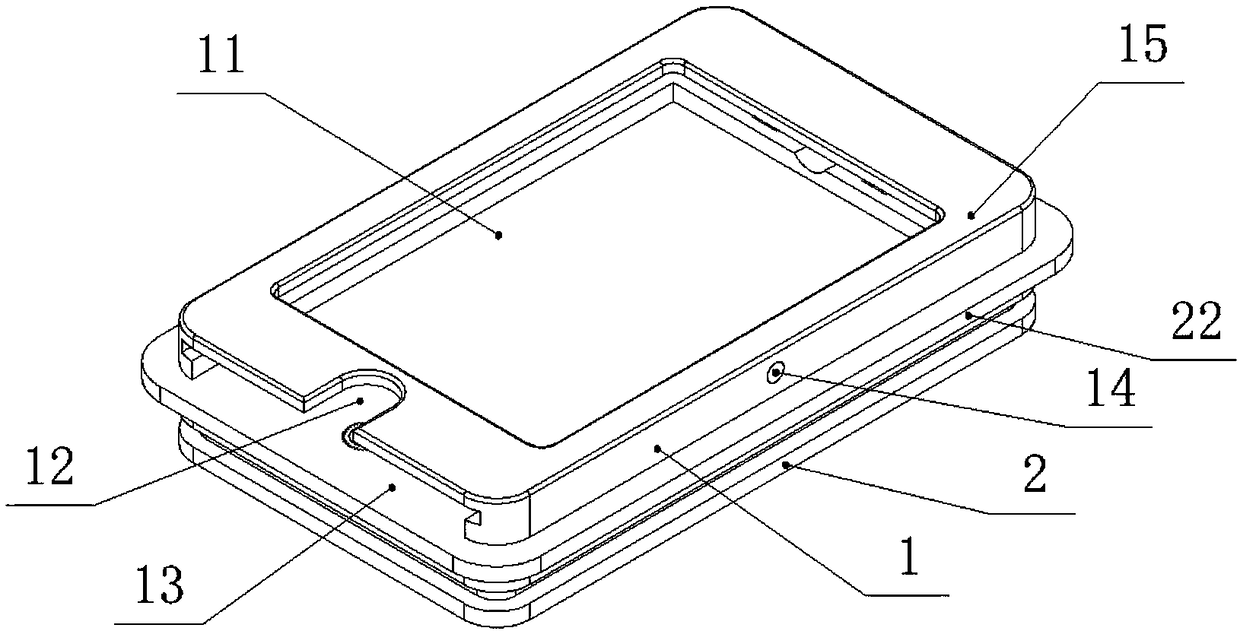

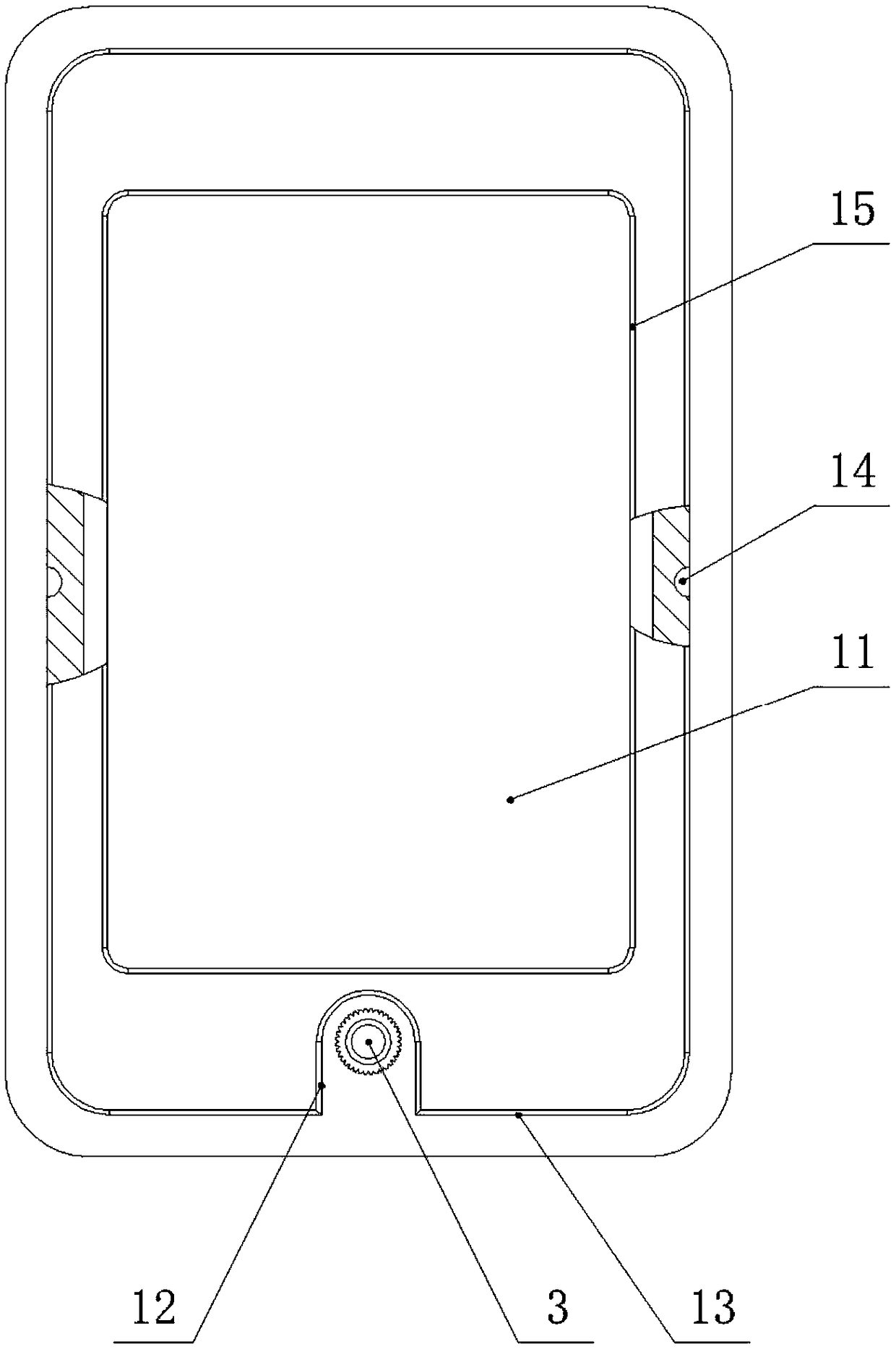

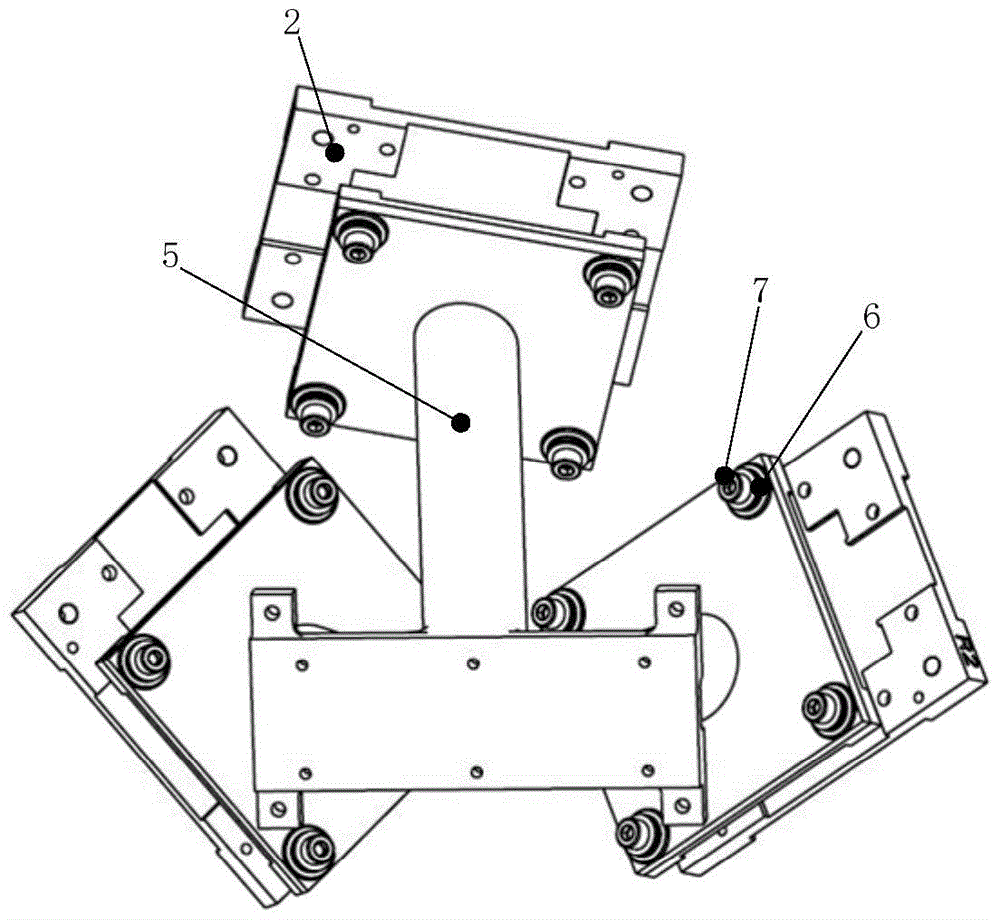

Tray assembly and MOCVD equipment with the same

ActiveCN103590020ARotation stabilizationImprove process effectChemical vapor deposition coatingOrganic chemicalsAirflow

The invention provides a tray assembly, which includes a rotary bracket and multiple layers of trays. The multiple layers of trays are vertically arranged at intervals; the lowest layer of tray is arranged on the bracket; an upper tray and a lower tray in two adjacent layers of trays are connected by a support assembly; and the support assembly is adjacent to the edge of the trays. According to the tray assembly in the embodiment of the invention, a bracket is employed to support multiple layers of trays, so that multiple layers of trays are more stably during rotation; and the two adjacent layers of trays in the multiple layers of trays are connected by the edge support assemblies, so as to not block or cut an central intake airflow, facilitate the formation of stable laminar flow of central intake airflow on the surfaces of the trays and improve process effect. The invention also provides MOCVD (Metal Organic Chemical Vapor Deposition) equipment with the above tray assembly.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

Salt corrosion and torsion resisting type shielding telecommunication cable used for ocean wind power and manufacturing method thereof

ActiveCN103187127AEliminate voidsExcellent impregnationRubber insulatorsInsulating conductors/cablesCopper conductorFiber

The invention relates to a salt corrosion and torsion resisting type shielding telecommunication cable used for ocean wind power and a manufacturing method thereof. A salt corrosion and torsion resisting type rubber insulating layer is uniformly extruded to wrap the peripheries of stranded copper conductors in order to form insulating wires, the insulating wires are stranded in pairs to form a stranded wire pair, the gap of the stranded wire pair is filled with a flame-retardant non-hygroscopic fiber filling core, the periphery of each group of stranded wire pair is wound with a copper foil polyester compounding belt shielding layer to form a stranded group, multiple stranded groups are mutually stranded to form a cable core, and the periphery of the cable core is wrapped with low strength non-woven fabrics, and is extruded with a protective sleeve. According to the salt corrosion and torsion resisting type shielding telecommunication cable, a longitudinal low strength non-woven fabric wrapping layer is adopted, and is completely matched with the insulating wire core in shape, so that the gap between the longitudinal low strength non-woven fabric wrapping layer and the insulating wire core is eliminated, a flame can be favorably prevented from being continuously transmitted to the inside under the combustion condition, and the humidity steeping resistance is improved. Meanwhile, the longitudinal low strength non-woven fabric wrapping layer can ensure that the protective sleeve does not adhere to the insulating wire core, and facilitates the stripping of the protective sleeve in the construction process without damages on the insulating wire core.

Owner:浙江华威设备制造有限公司

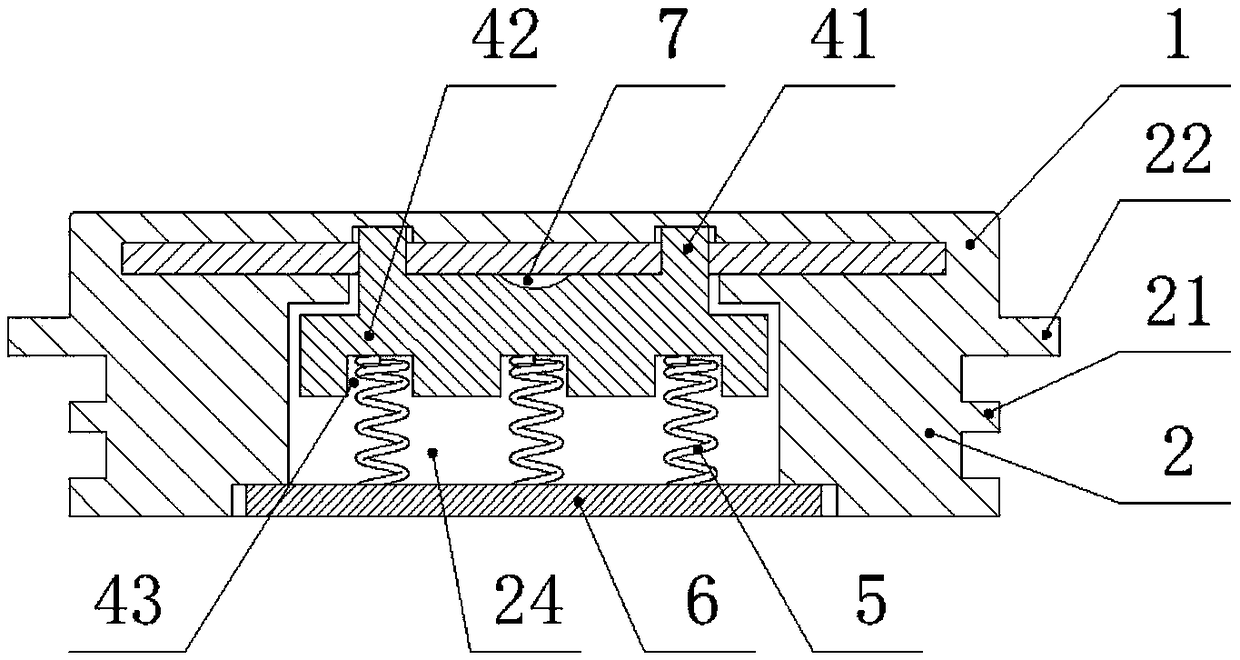

Medium voltage mutual inductor electronic label packaging device

PendingCN108090550AWon't leakGuarantee the appearance qualityRecord carriers used with machinesIdentity recognitionInductor

The invention discloses a medium voltage mutual inductor electronic label packaging device. An electronic label board includes an upper card insertion layer and a lower installation layer. The card insertion layer and the installation layer are integrally poured, and the card insertion layer is provided with a card insertion cavity for placing an electronic label. A card insertion port which is open is located at one side of the card insertion layer and in front of the card insertion cavity. An anti-plug umbrella skirt and a seal stop ring are arranged at the side of the installation layer. Anaccommodation cavity is arranged at the bottom of the installation layer. The accommodation cavity is communicated with the card insertion cavity. The accommodation cavity is provided with a lock assembly, a spring and a cover plate in sequence from top to bottom, the spring and the cover plate are against the lock assembly, the cover plate fixes the lock assembly and the spring in the accommodation cavity, the lock assembly comprises a lock at the top and a base at the bottom, and the top of the lock is shaped like an inclined plane. The electronic label is provided whit a locking port whichis matched with the top of the lock. The device avoids the replacement of electronic labels by lawless persons and ensures valid identity recognition of the mutual inductor during the whole life circle of the mutual inductor.

Owner:ZHEJIANG HORIZON INSTR TRANSFORMERS

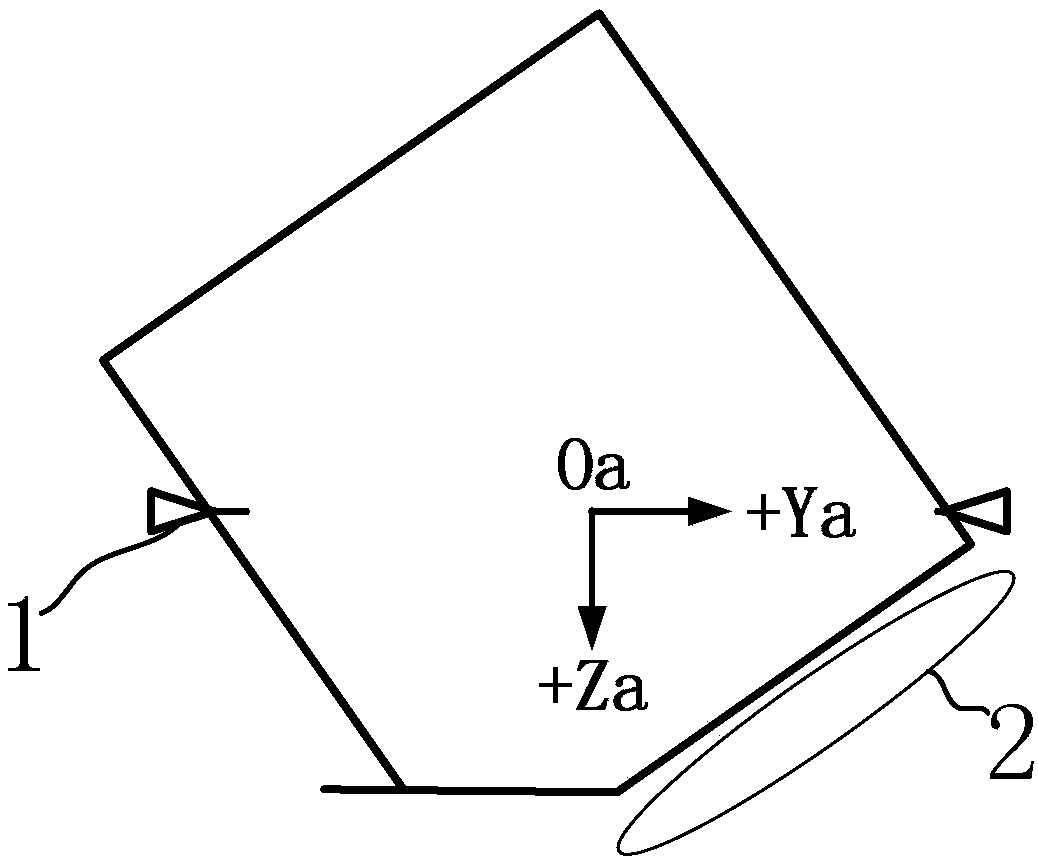

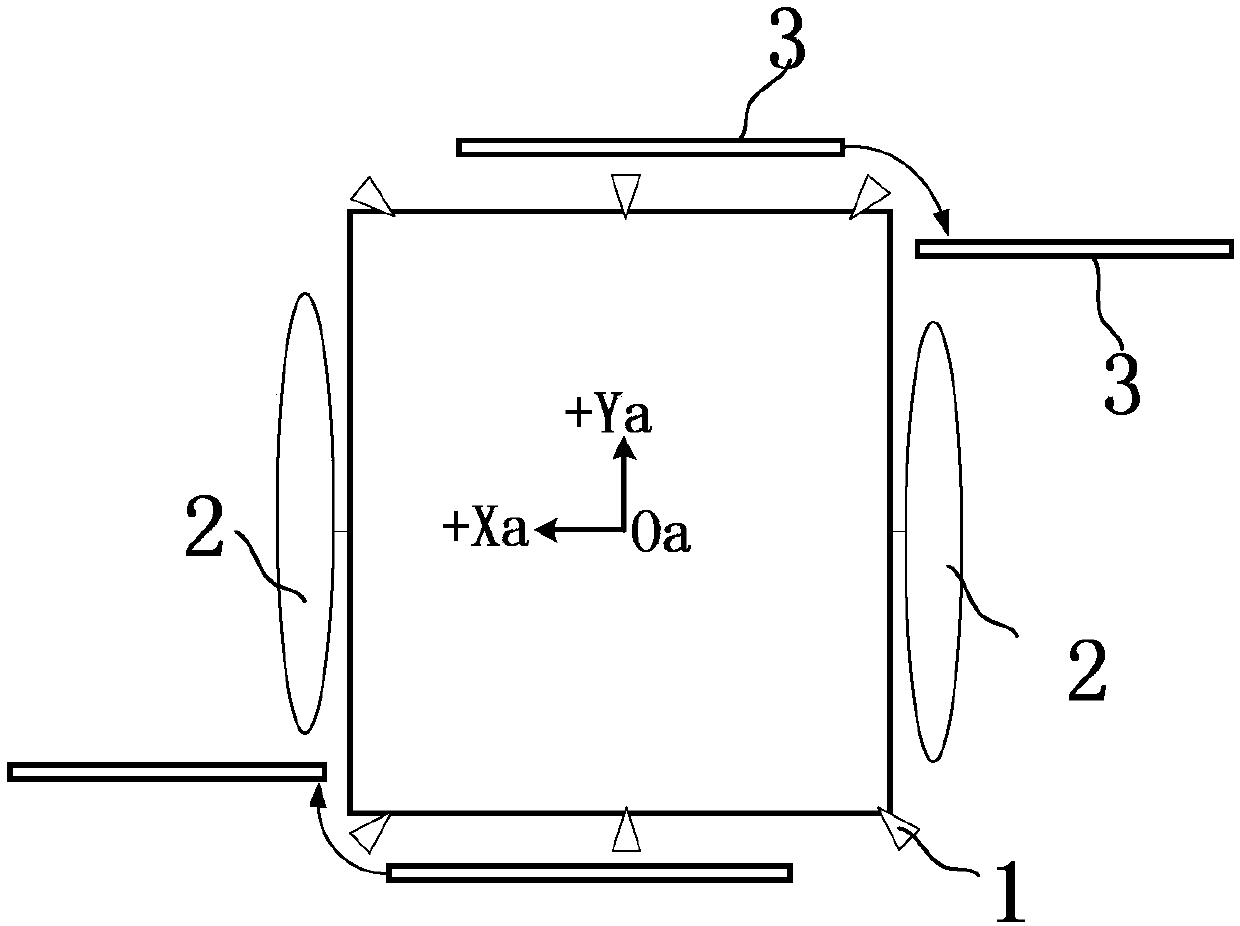

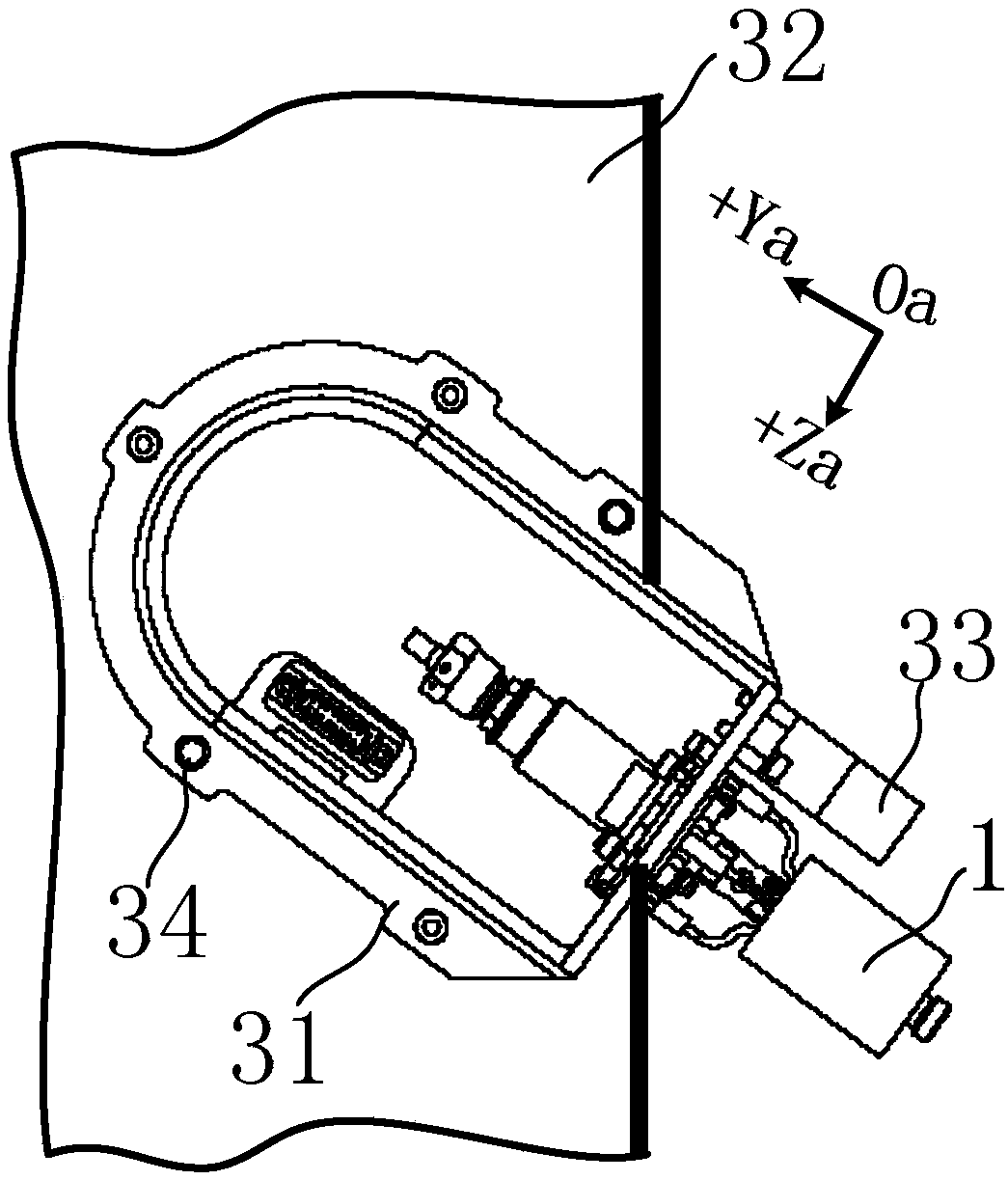

Formation layout and installation system for three-axis stabilization satellite

ActiveCN107839900AGuaranteed craftsmanshipSolve the installation accuracyArtificial satellitesSpacecraft guiding apparatusFlight directionSolar battery

The invention discloses a formation layout and installation system for a three-axis stabilization satellite. In order to meet the formation requirement for the satellite, formation thrusters need to be added to the satellite on the basis of a posture control thruster and a track control thruster; under a launching state, effective load and solar battery arrays of the satellite are drawn to the periphery of the satellite; when the satellite stays on the track, the effective load and the solar battery arrays are all spread in the Xa direction of the flight direction of the satellite to ensure that plumes of the formation thrusters do not intervene in the solar battery arrays and the effective load, and guarantee the maximization of the efficiency of the formation thrusters; according to theflight posture of the satellite, the formation thrusters are divided into two groups, the two groups are distributed at a +- Ya side of the satellite separately, the planes of the thrusters are perpendicular to the direction, pointing to the ground, of the satellite, and the formation thrusters cooperate with one another to pass through an average centroid of the satellite when the satellite staysat an on-track flight state. By adopting the formation layout and installation system, the satellite installation accuracy of the formation thrusters and the manufacturability of operation implementation are ensured; the demands of the formation thrusters for installation, accuracy measurement and formation control in the satellite can be effectively met.

Owner:SHANGHAI SATELLITE ENG INST

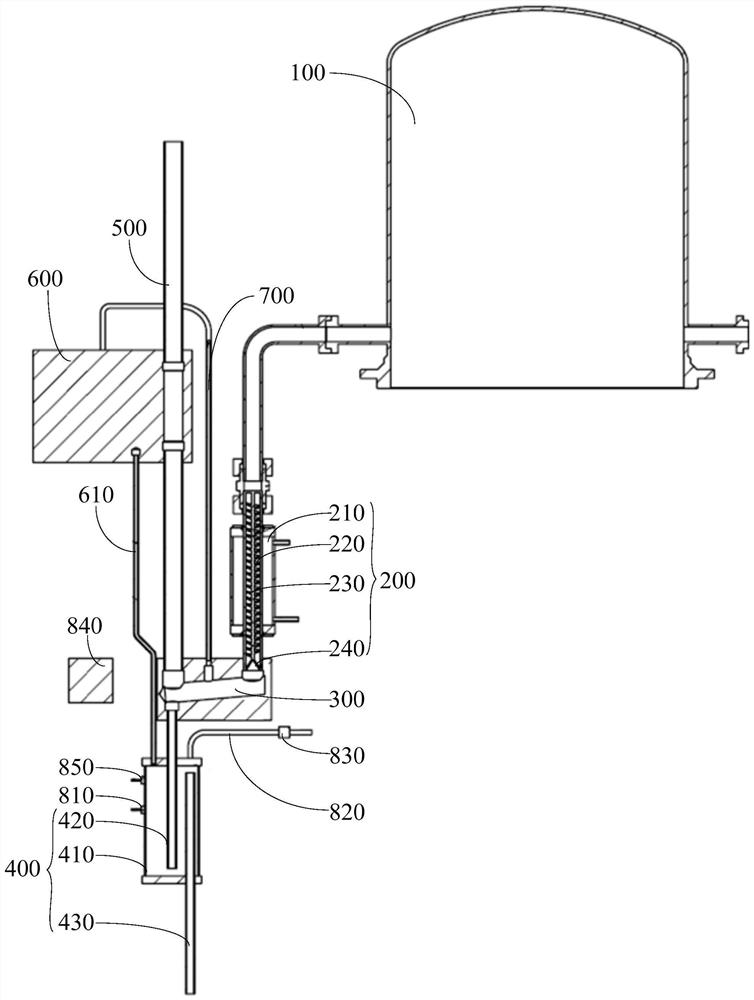

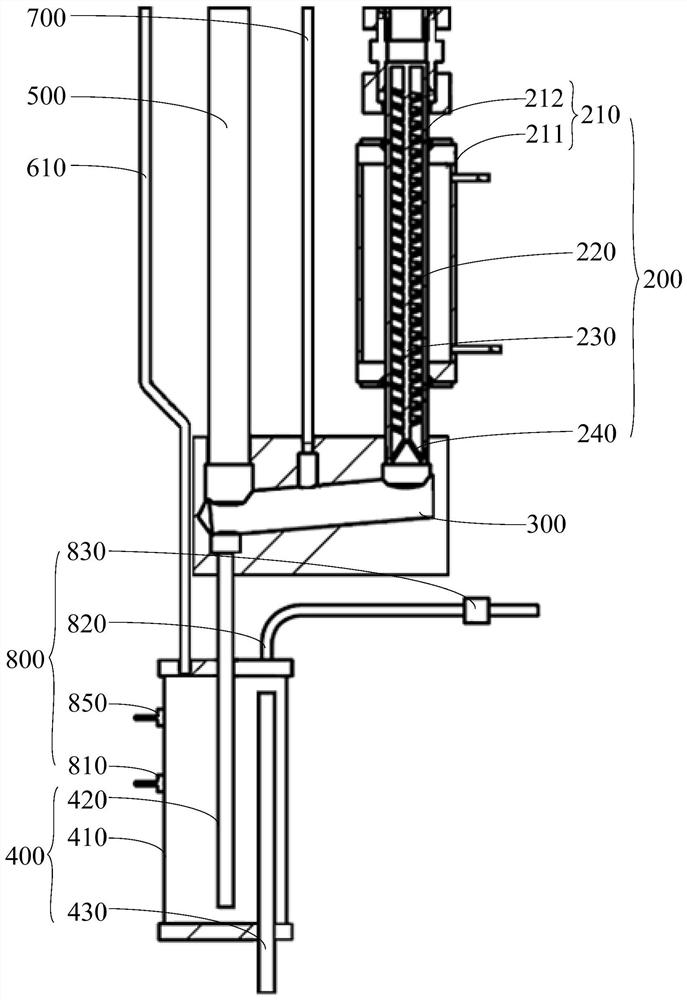

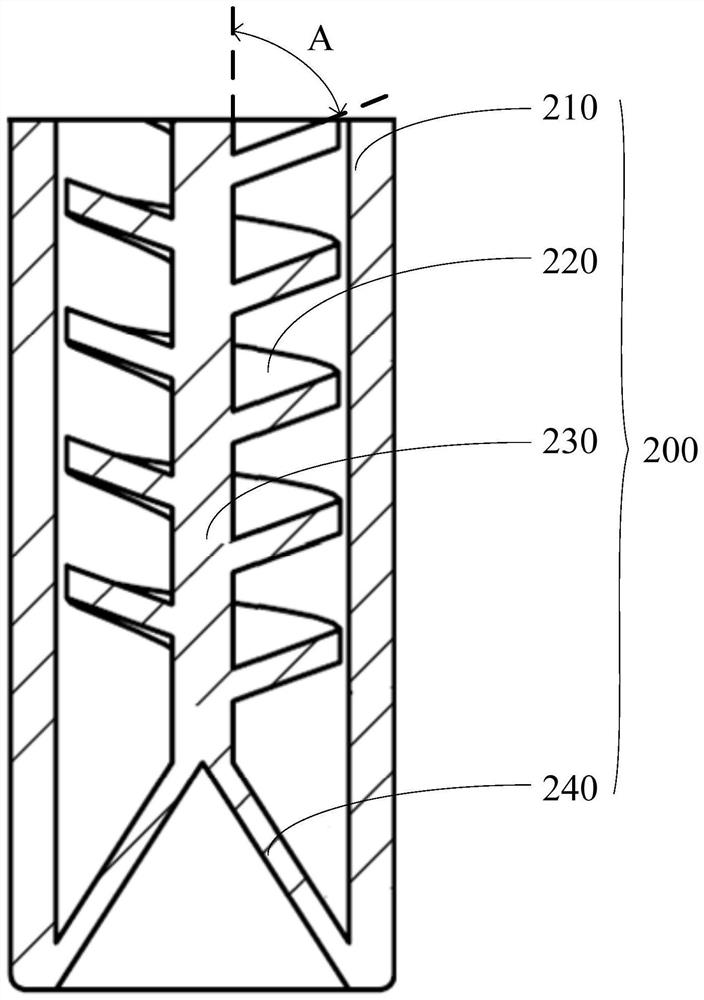

Semiconductor processing equipment

PendingCN112864054AReduce resistanceGuaranteed detection accuracySemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingProcess equipmentMechanical engineering

The invention discloses semiconductor processing equipment, which comprises a reaction chamber (100), a condenser (200), a switching part (300) and a water box (400), wherein the reaction chamber (100), the condenser (200), the switching part (300) and the water box (400) are communicated in sequence, the condenser (200) comprises a pipe body (210) and a spiral damping sheet (220) arranged in the pipe body (210), the spiral damping sheet (220) is provided with a spiral face facing the air inlet end opening of the pipe body (210), and the included angle (A) between the spiral face and the axis direction of the pipe body (210) is smaller than 90 degrees. According to the scheme, the problem that the process effect is not ideal due to the fact that semiconductor process equipment cannot quickly respond to pressure changes can be solved.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

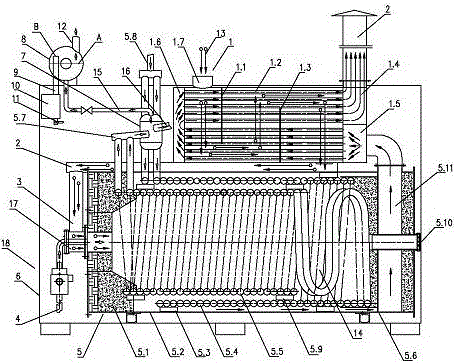

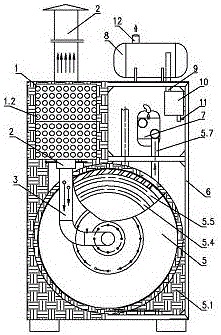

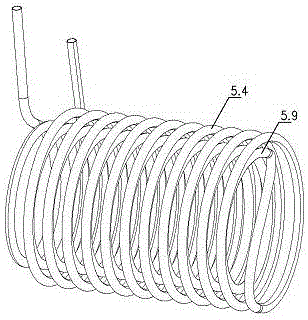

Fuel gas mold temperature controller

InactiveCN106382746ARealize automatic adjustmentEasy to controlFuel supply regulationStorage heatersOil temperatureEnergy conversion efficiency

The invention discloses a fuel gas mold temperature controller. The fuel gas mold temperature controller comprises a rack and a heat conduction oil furnace. A smoke heat recoverer is arranged on the rack which is above the heat conduction oil furnace. One end of the smoke heat recoverer is connected with a smoke chamber and a smoke guiding-in chamber in a sealed mode, and a smoke reversing chamber is arranged at the other end of the smoke heat recoverer in a sealed mode. A plurality of thread smoke tubes are arranged in the smoke heat recoverer in parallel. An oil-gas separation tank and an oil overflowing tank are arranged on the rack which is above the heat conduction oil furnace. The oil-gas separation tank is located below the oil overflowing tank. The oil-gas separation tank is communicated with a coiled tube through an oil outlet tube, the oil outlet tube is arranged on one side of the oil-gas separation tank, a separation tank oil outlet tube is arranged on the other side of the oil-gas separation tank, and the oil-gas separation tank is communicated with the oil overflowing tank. The rack is further provided with an oil temperature control device. The fuel gas mold temperature controller has the benefits that the smoke heat conversion efficiency is good, oil-gas separation is sufficient and thorough, and the oil temperature control is stable and high in precision.

Owner:DONGTAI SANCANG ENERGY SAVING BOILER

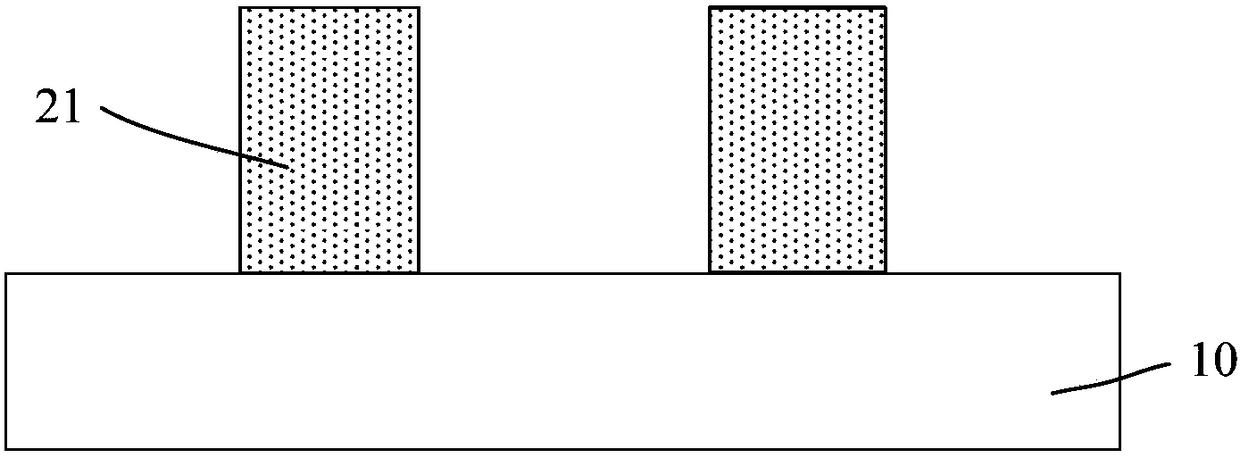

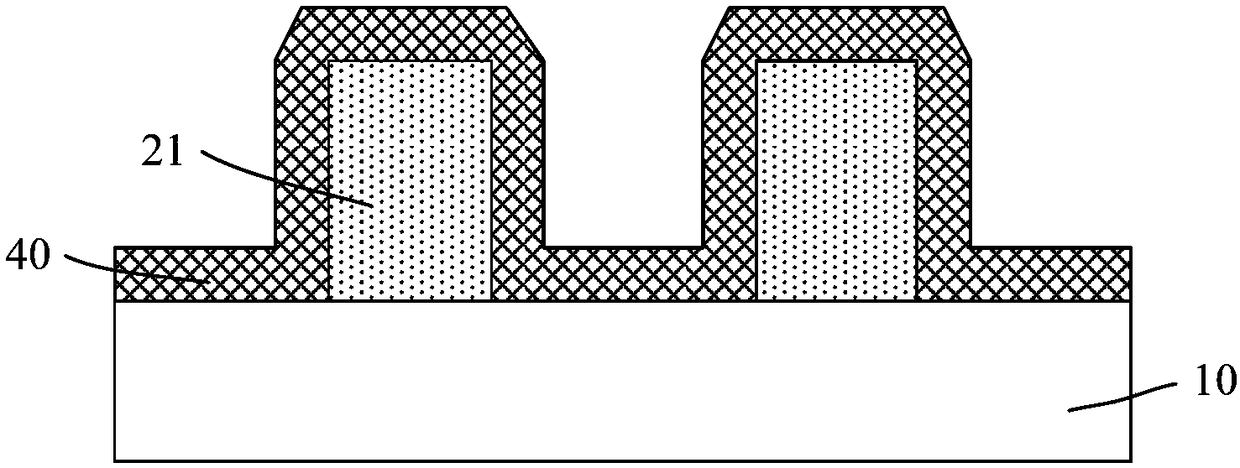

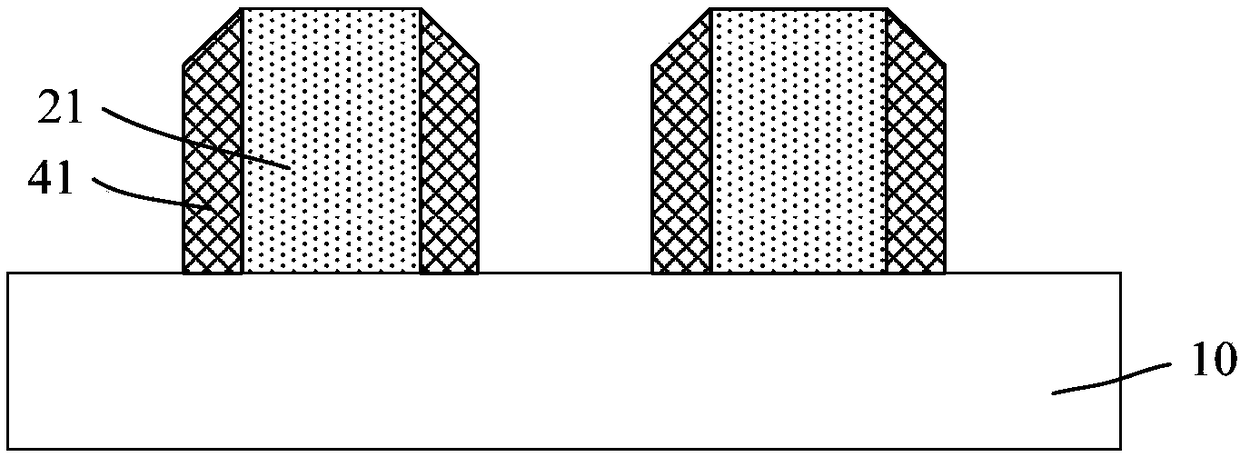

Semiconductor structure and formation method thereof

ActiveCN108574010AAvoid problems with sloping surfacesPlay a protective effectSemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductor structureEngineering

The invention relates to a semiconductor structure and a formation method thereof. The formation method comprises the steps of providing a material layer to be etched; forming patterned core layers onthe material layer to be etched; forming a side wall film on the top and side walls of the core layers and on the material layer to be etched; performing at least one time of top treatment on the side wall film to remove the side wall film higher than the top of the core layers, reserving the side wall film on the side walls of the core layers to serve as a first portion of a side wall layer, reserving the side wall film on the material layer to be etched to serve as a second portion of the side wall layer, wherein the top treatment comprises the steps of forming a sacrificial layer coveringthe surface of the side wall film on the side walls and the top of the core layers on the side wall film, removing the sacrificial layer higher than the top of the core layers and part or all thickness of the side wall film and removing the remaining sacrificial layer; removing the core layers; and removing the second portion of the side wall layer after the core layers are removed. The first portion of the side wall layer is symmetrical in shape, and a target pattern with the shape being good can be obtained by etching the material layer to be etched by taking the first portion of the side wall layer as a mask.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

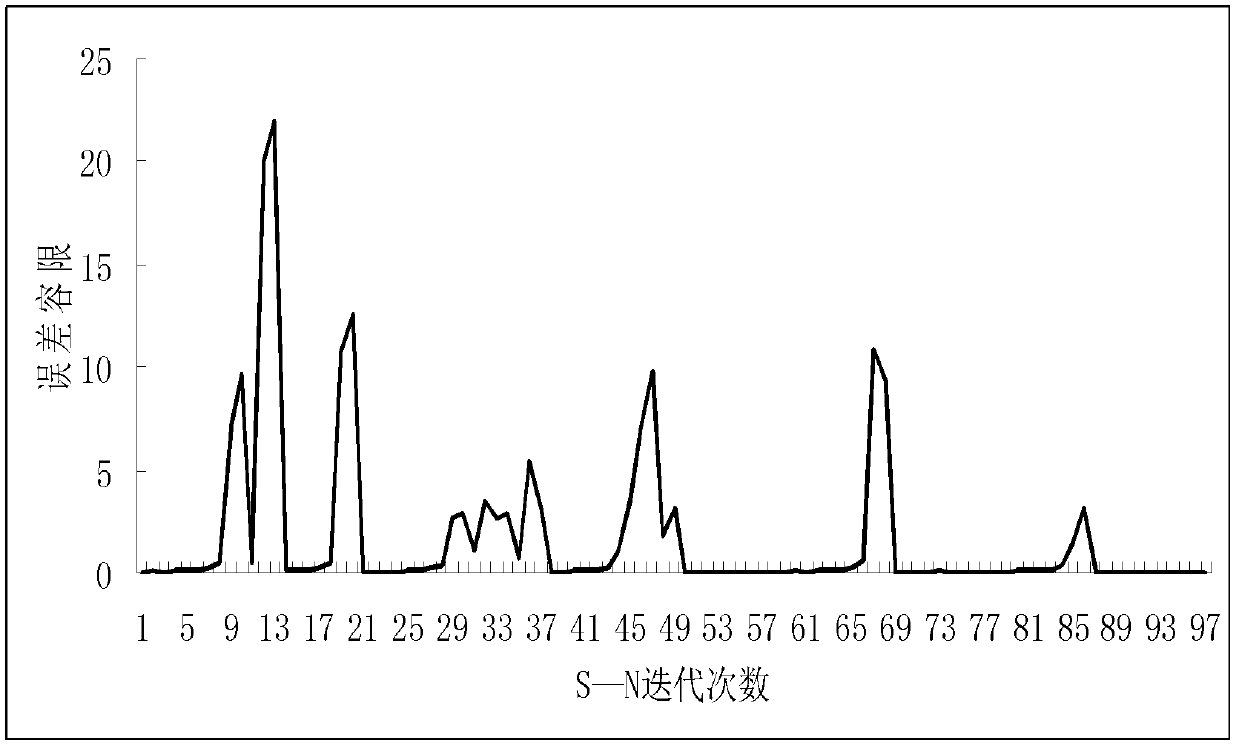

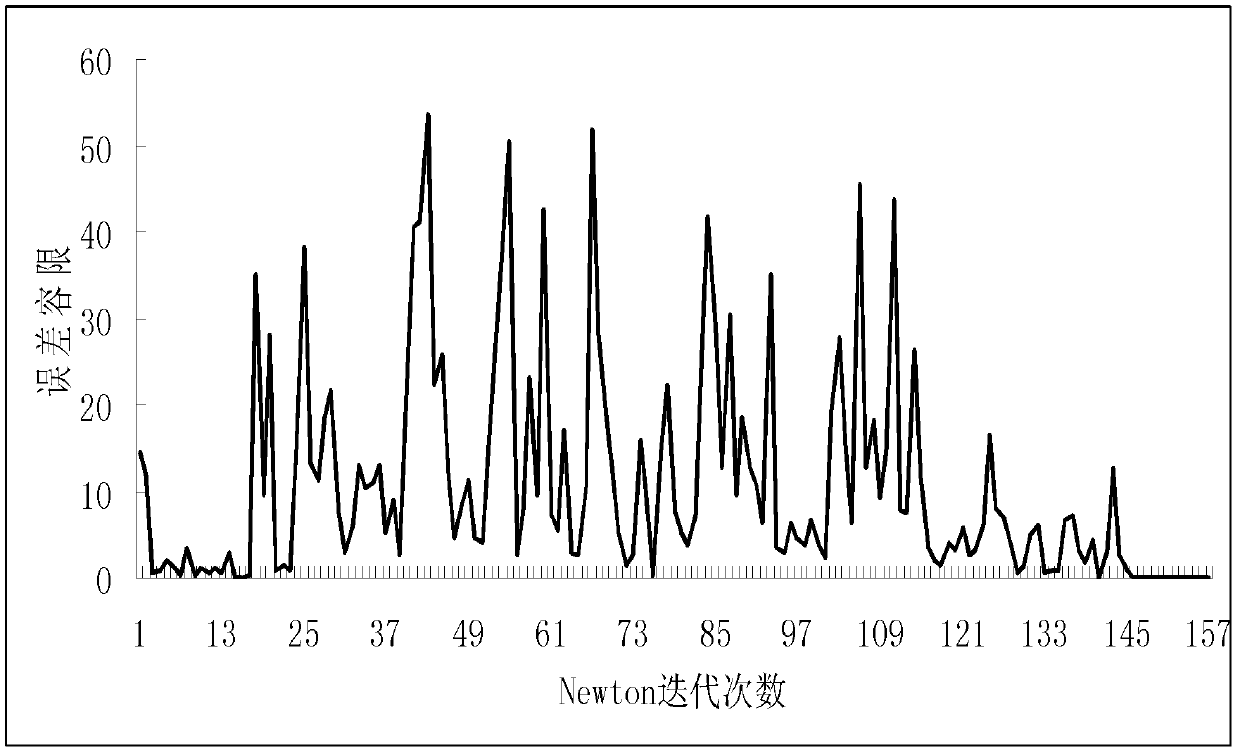

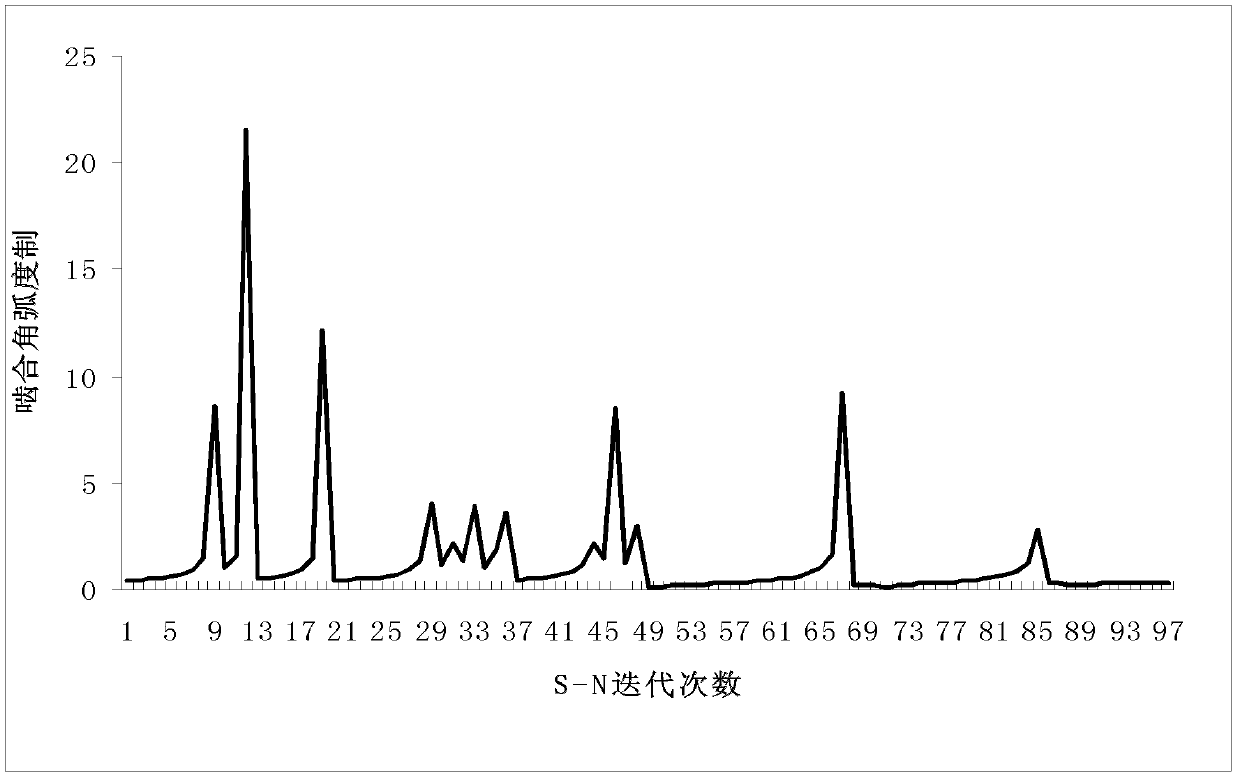

Gear shaving and modifying based engagement-angle calculating method

ActiveCN102699450ASolve the technical problems of calculation accuracySolve for stabilityGear teeth manufacturing toolsGear teethEngineeringCalculation methods

The invention discloses a Stephenson-Newton iteration method based on gear shaving and modifying and engagement-angle calculating, which is applied to the technical field of the modifying of the gear shaver for the first time. The optimal solution of the engagement angle can be obtained by adopting the existing general approximate calculating method of the end surface engagement angle, the calculation error of the length of the engagement line, which is caused by the calculation error of the engagement angle, can be avoided, the modifying position of the gear shaver can be calculated more accurately, and the process effect of removing the concave shape of the shaved gear can be guaranteed effectively.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

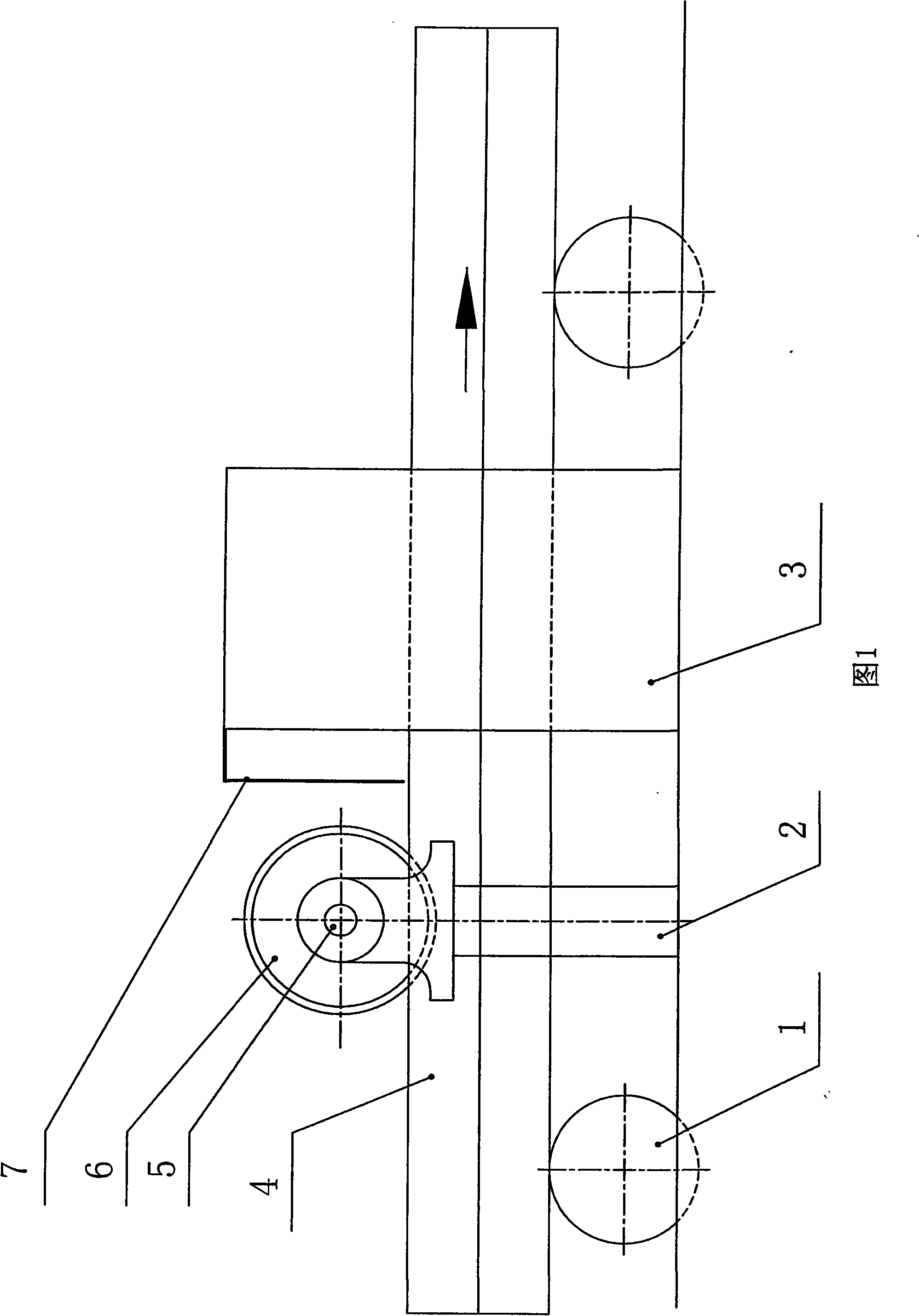

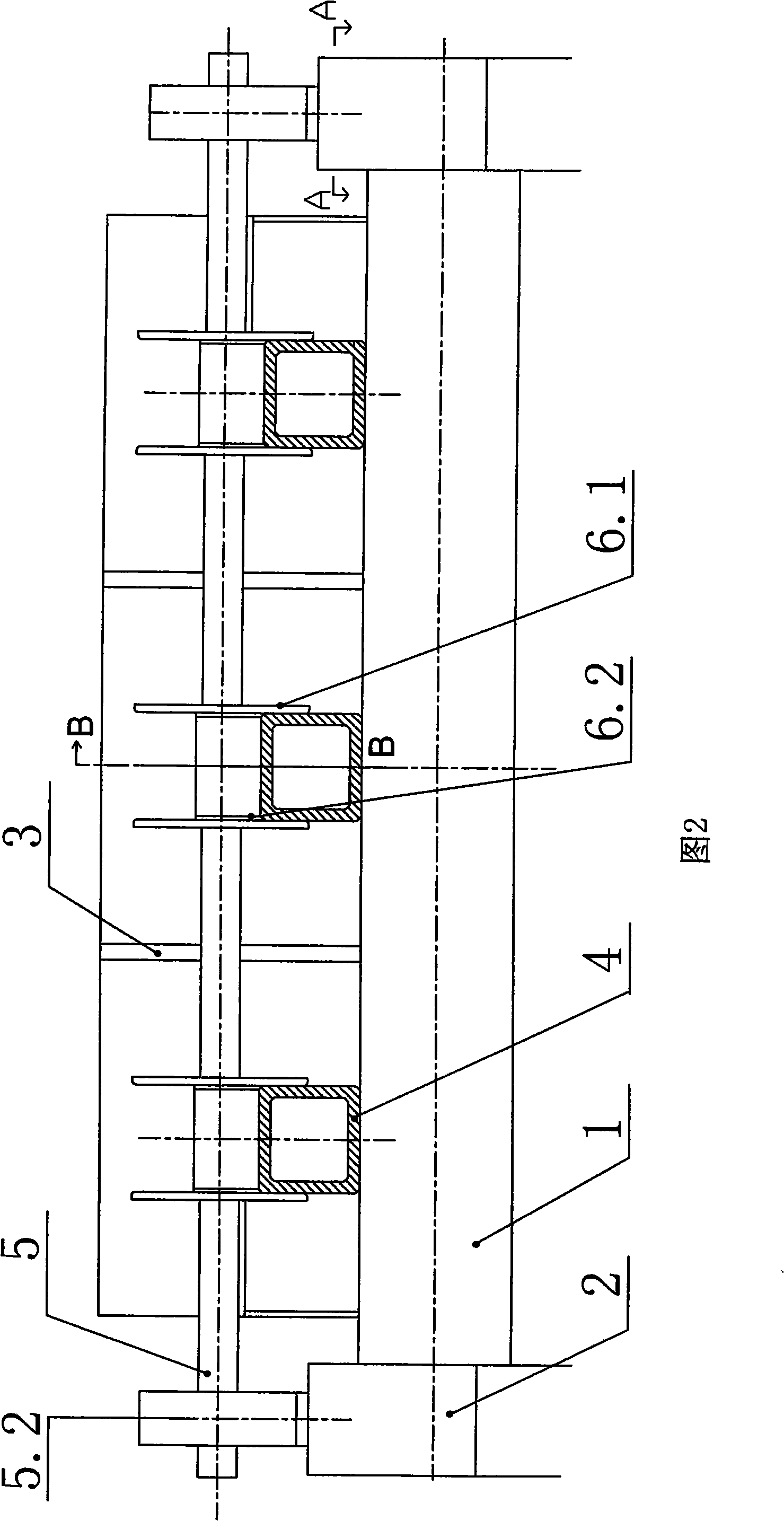

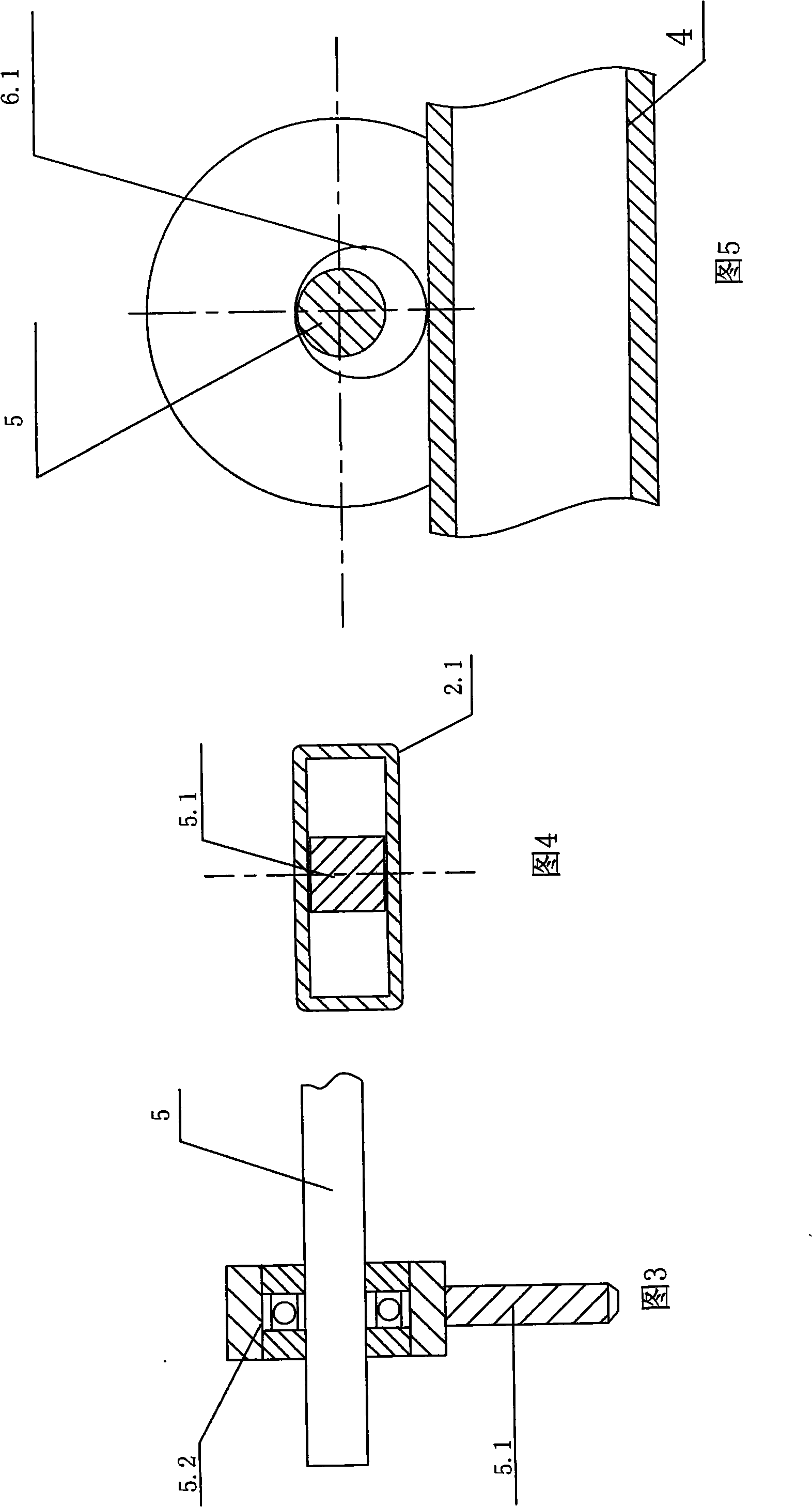

Novel continuous jet cooling quenching machine for steel tubes

InactiveCN101307381ASolve the problem of quenching and tempering heat treatment processExpand the scope of heat treatment processFurnace typesHeat treatment furnacesQuenchingSteel tube

The invention relates to a novel continuous steel tube jet cooling quenching machine, which is matched with a continuous steel tube annealing furnace and is mainly used for quenching heat treatment process of special steel tubes. The machine comprises a traveling roller table (1), supporting bases (2), a guide roll (5), guide water-retaining modules (6) and a quenching nozzle (3), wherein, the supporting bases (2) are arranged on both sides of the traveling roller table (1), the guide roll (5) is erected between the two supporting bases (2), both ends of the guide roll (5) are provided with bearings (5.2), the lower part of a shell of each bearing (5.2) is provided with a square steel plunger (5.1), the center of each supporting base (2) is provided with a square slot (2.1), the guide water-retaining modules (6) are alternatively sleeved on the guide roll (5), the quenching nozzle (3) is arranged on the periphery of the traveling roller table (1) on the back of the guide roll (5), and a plurality of manger boards (7) are arranged on the front of the quenching nozzle (3). After the continuous steel tube annealing furnace widely used by cold-drawing tube mills is provided with the machine, the problem of quenching conditioning heat treatment process of the special steel tubes can be solved, and the heat treatment process range of the continuous steel tube annealing furnace is widened.

Owner:江苏界达特异新材料股份有限公司

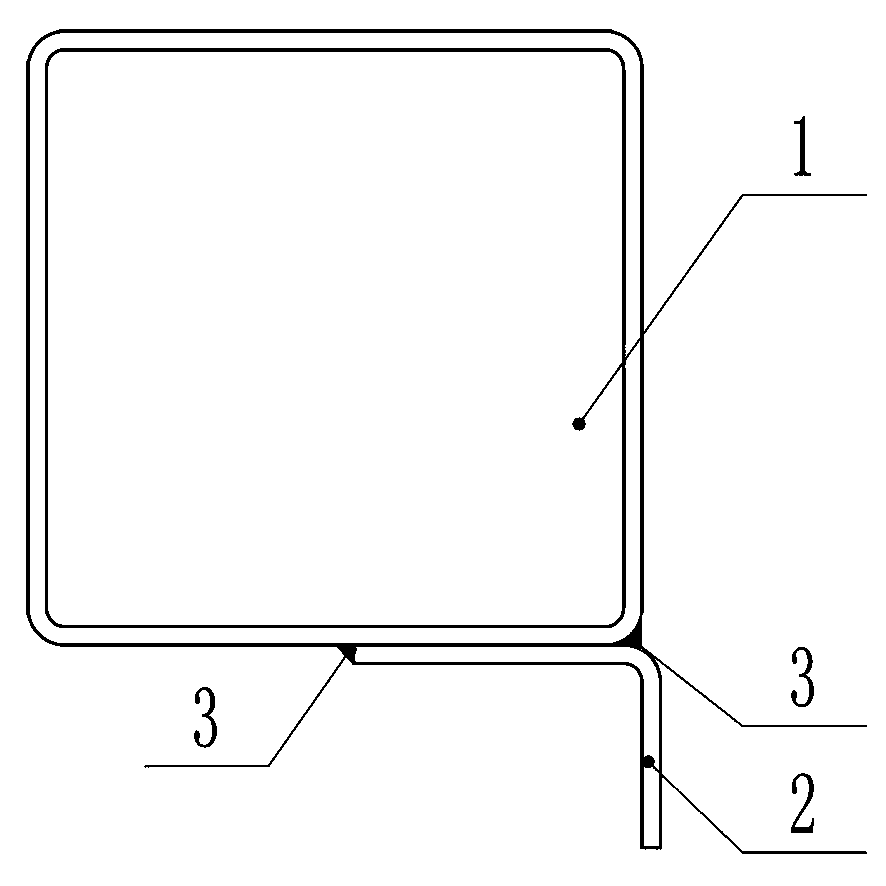

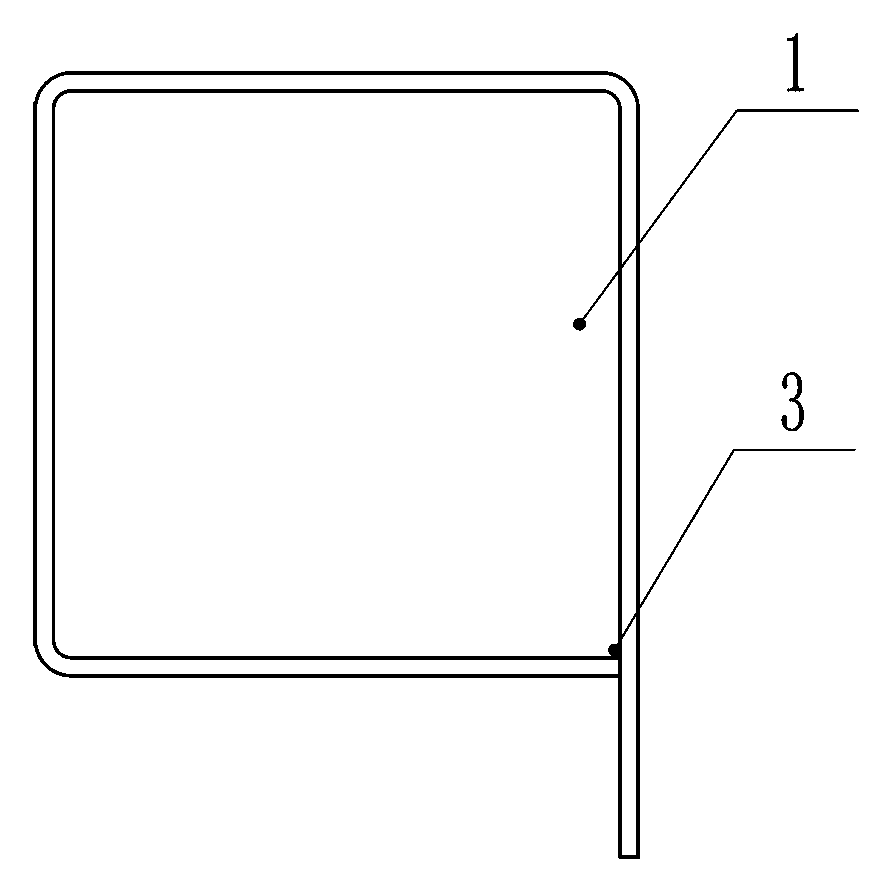

Special-shaped steel pipe

InactiveCN103791223AReduce welding processSave materialElongated constructional elementsPunchingEngineering

The invention provides a special-shaped steel pipe which is of an integral structure. The cross section of the special-shaped steel pipe is P-shaped, the shape similar to a P is formed by outwards and vertically extending and flanging one side of a hollow rectangular pipe as a main body, the special-shaped steel pipe is formed at one step through rolling or punching, and a seal of the rectangular pipe is a high-welding seal. The P-shaped pipe is formed by outwards and vertically extending and flanging one side of the rectangular pipe, and the special-shaped steel pipe serves as a section to be widely applied to various parts higher in requirements on sealability and matching gap. Especially, when the special-shaped steel pipe of the structure is adopted in the process of manufacturing an automobile door frame, welding process can be reduced, materials can be saved, and production cost can be lowered; manufacturability is guaranteed, and production efficiency and product quality are improved.

Owner:HUBEI DAYUN AUTOMOBILE

Installation structure of high-precision micro-deformation attitude control instrument for spacecraft

ActiveCN104743138BStrong enoughRigid enoughCosmonautic vehiclesCosmonautic partsAttitude controlHeat conducting

The invention discloses a high-precision micro-deformation attitude control instrument installing structure for a spaceflight. An instrument installing plate comprises a first wing plate, a second wing plate and a web plate. The first wing plate is fixed to the outer surface of a thin-wall shell structure. The second wing plate is arranged in the thin-wall shell structure and connected with a plane butt-joint flange of a heat conducting body. The first wing plate and the second wing plate are connected through the web plate and carry out heat exchange through the web plate. The installing face of the heat conducting body is connected to a sealing cover plate which is connected with the thin-wall shell structure to form a head of the installing structure. One end of a supporting rod assembly is connected with the head of the installing structure. The other end of the supporting rod assembly is installed on a body of an optical imaging effective load structure of the spaceflight. The technical problem of rigorous thermal deformation of the attitude control instrument installing structure is solved, the installing structure has an excellent heat transfer property and a thermal deformation isolation property, the requirement for high-precision attitude determination and image navigation rectification of the spaceflight is met, and the installing structure has the advantages of being novel in structural form, light in mass and the like.

Owner:SHANGHAI SATELLITE ENG INST

Waste acid double-effect concentration and recycling method for titanium dioxide production enterprises

ActiveCN110697660AReduce foulingReduce wearSulfur compoundsAcid concentrationEnvironmental engineering

The invention belongs to the technical field of green chemical engineering, and particularly relates to a waste acid double-effect concentration recycling method for titanium dioxide production enterprises. The method is capable of solving the problem that in recycling process of waste acid generated in titanium dioxide production enterprises in the prior art, effective utilization is difficult torealize because of too low waste acid concentration. The technical scheme comprises the following steps: (1) feeding the waste acid from titanium dioxide production process into a storage tank, and then pumping the waste acid into a primary evaporator for negative-pressure low-temperature evaporation and concentration; [2] pumping primary concentrated acid obtained after evaporation and concentration in the primary evaporator into a preheater for preheating through a pump, and then pumping the acid into a secondary evaporator to be subjected to negative-pressure medium-temperature evaporationand concentration; and (3) enabling secondary concentrated acid obtained after concentration in secondary evaporator to automatically flow into a curing tank, and then pumping the acid to a next process. The method is used for recycling the waste acid obtained in the titanium dioxide production process.

Owner:XIANGYANG LOMON TITANIUM IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com