Patents

Literature

38results about How to "Solve the installation accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

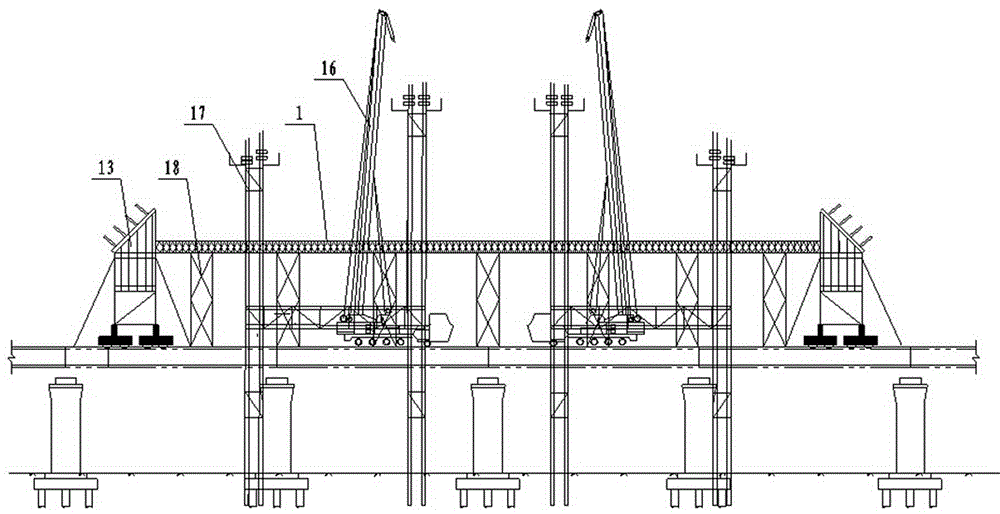

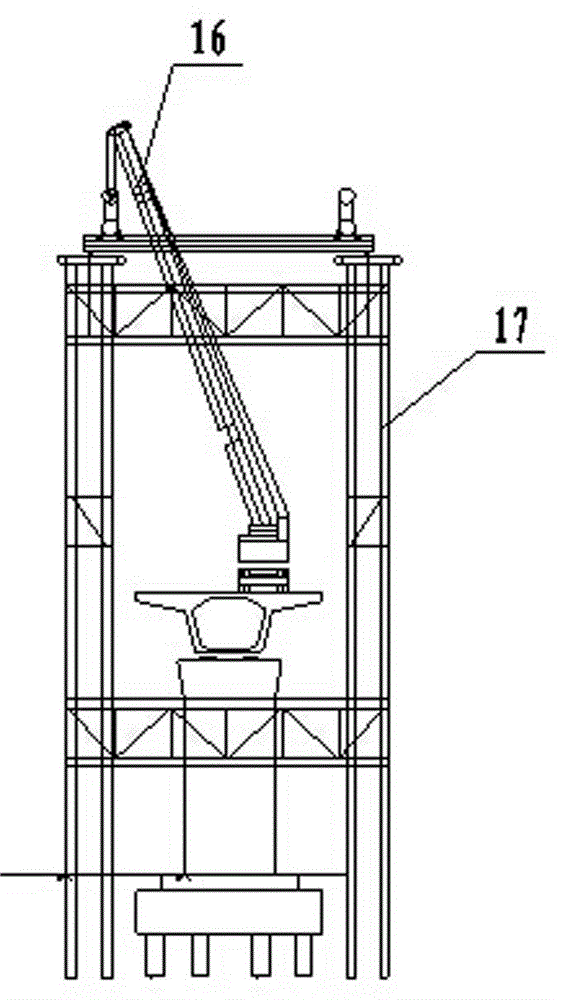

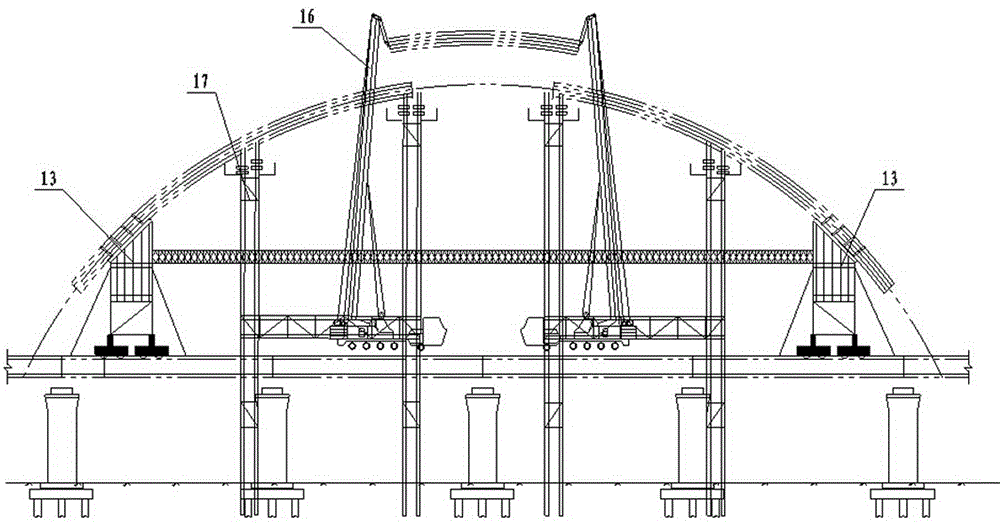

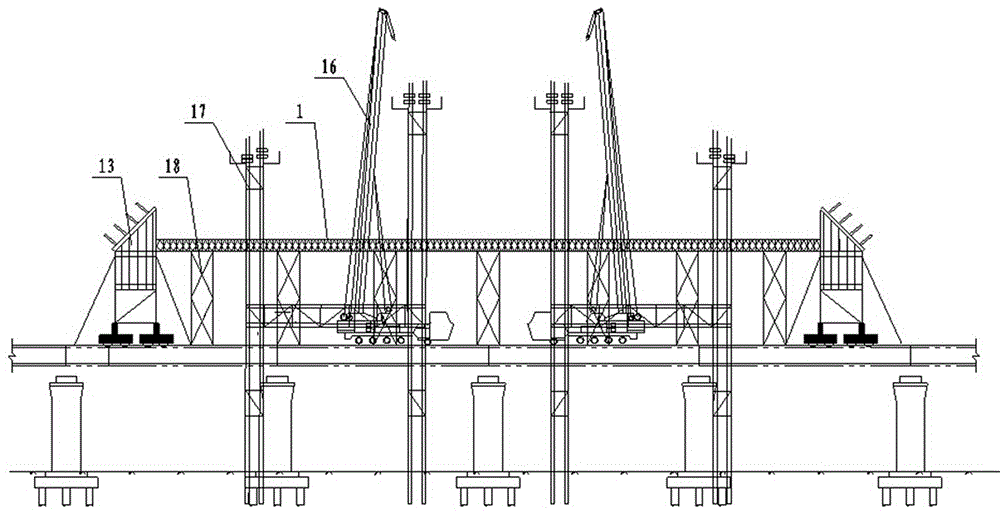

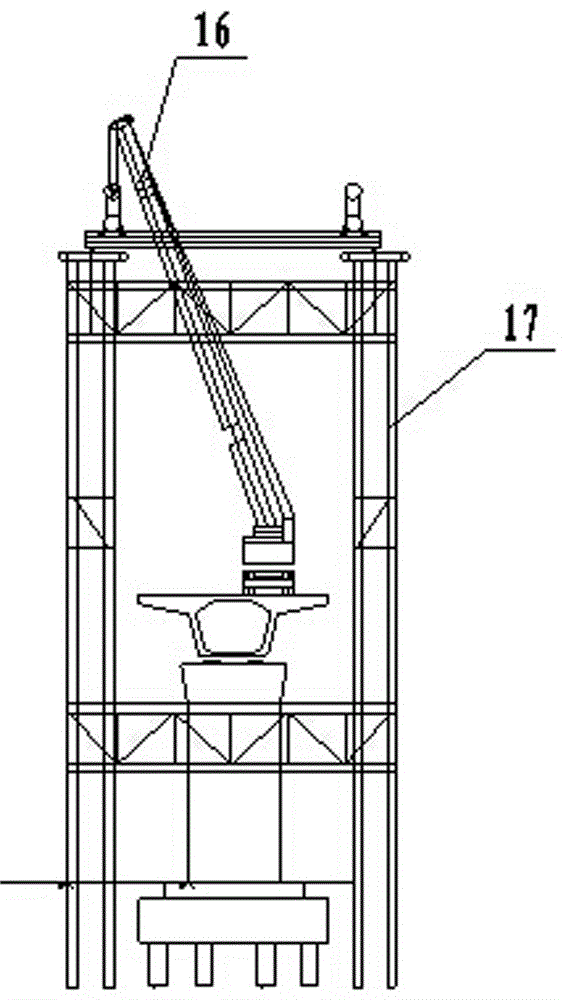

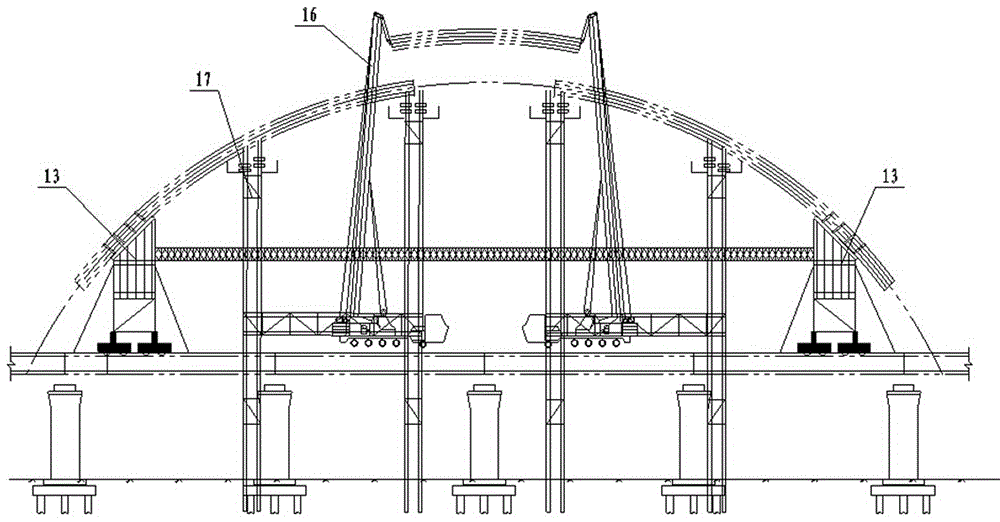

Construction method for continuous tie bar steel tube arch bridge

ActiveCN104562936AStress state is the sameSolving the Linear Control ChallengeBridge erection/assemblyArch-type bridgeEngineeringAbutment

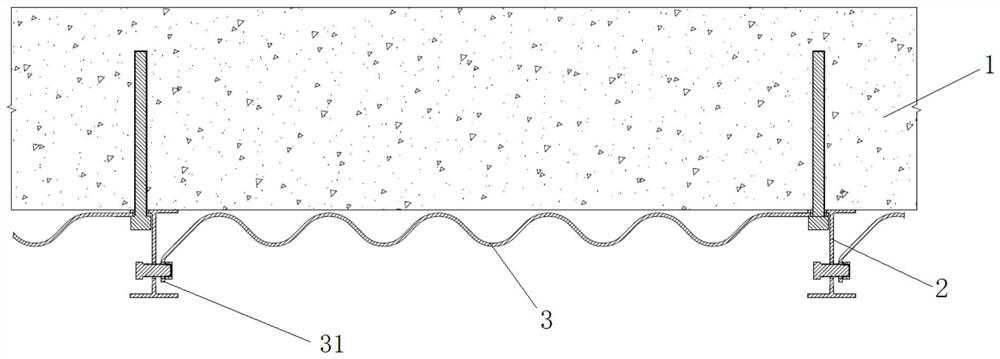

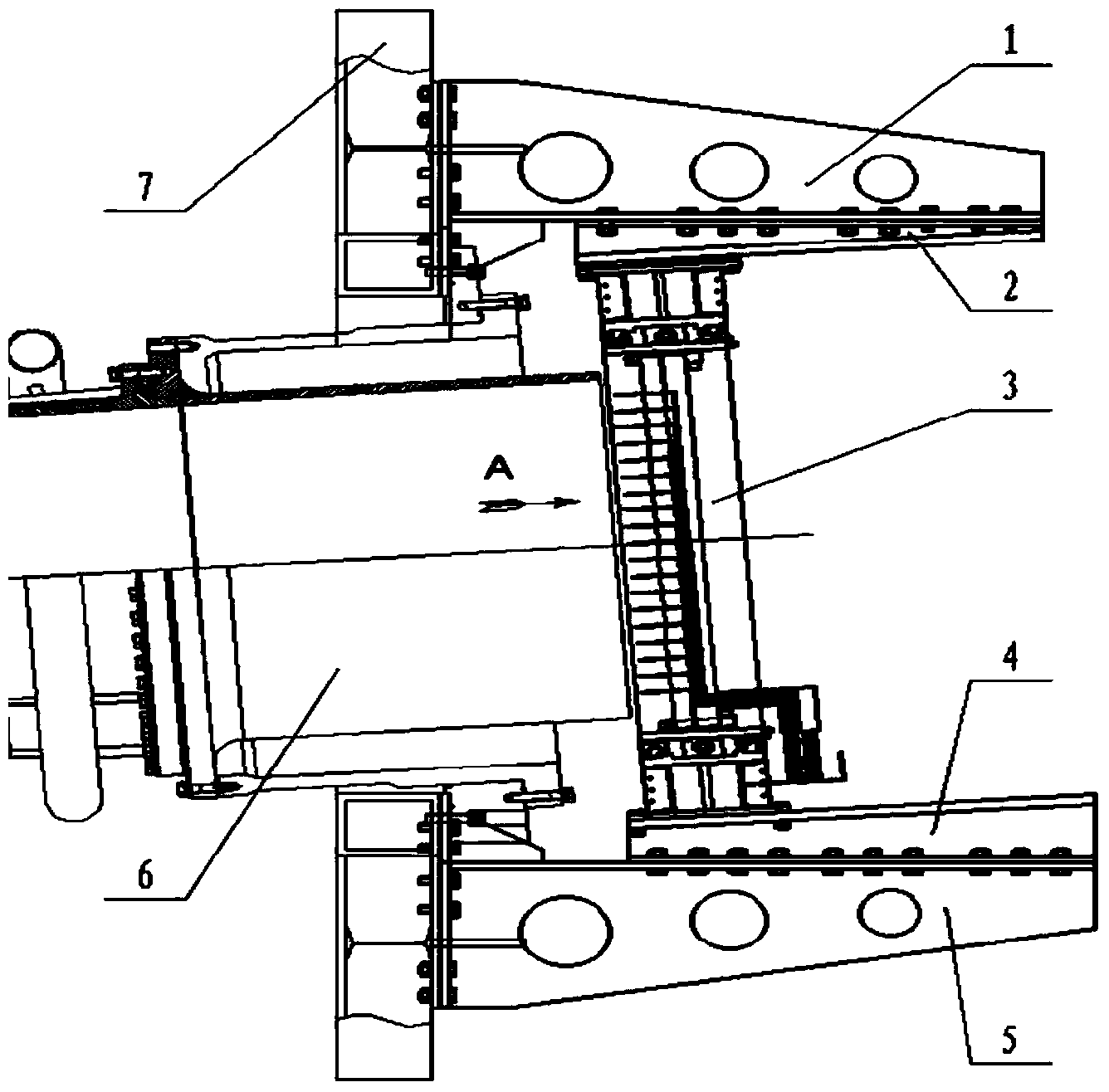

The invention relates to a bridge construction method, in particular to a construction method for a continuous tie bar steel tube arch bridge; the construction method aims at solving the problems that the construction cycle is long, the potential safety hazard is big, the construction difficulty is big, and the like by adopting the existing support method. The construction method comprises the following steps of performing construction on assembling supports for a steel tube arch; processing the steel tube arch by stages, and hoisting the steel tube arch onto the assembling supports; installing temporary abutment supports and opposite-pull steel stranded wires to enable the steel tube arch to form a bowstring whole bearing structure; supporting the steel tube arch by the temporary abutment supports instead of the assembling supports, and removing the whole assembling supports; installing a longitudinal movement pushing system for the steel tube arch to enable the steel tube arch to move forward; welding the steel tube arch after the steel tube arch are pushed in place. Firstly, The difficult problem that the safety risk is big due to the fact that the pushing distance is far and the steel tube arch needs to cross the existing railways and highways after the steel tube arch is assembled is solved; secondly, the problem that arch feet are low in installation accuracy is solved, so that the linearity and design linearity of the whole steel tube arch are enabled to be consistent, and the stress state and the design state of the steel tube arch are finally enabled to be consistent; thirdly, the stress state and the design state of a beam body are consistent, so the construction quality is finally guaranteed.

Owner:CHINA RAILWAY SIXTH GRP CO LTD

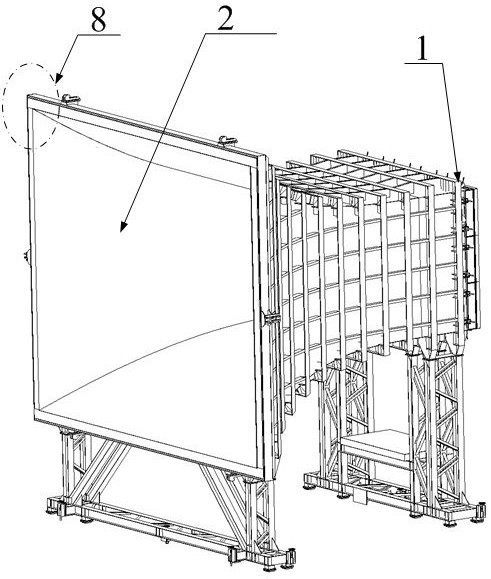

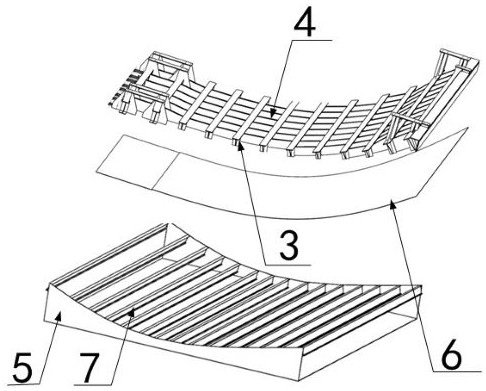

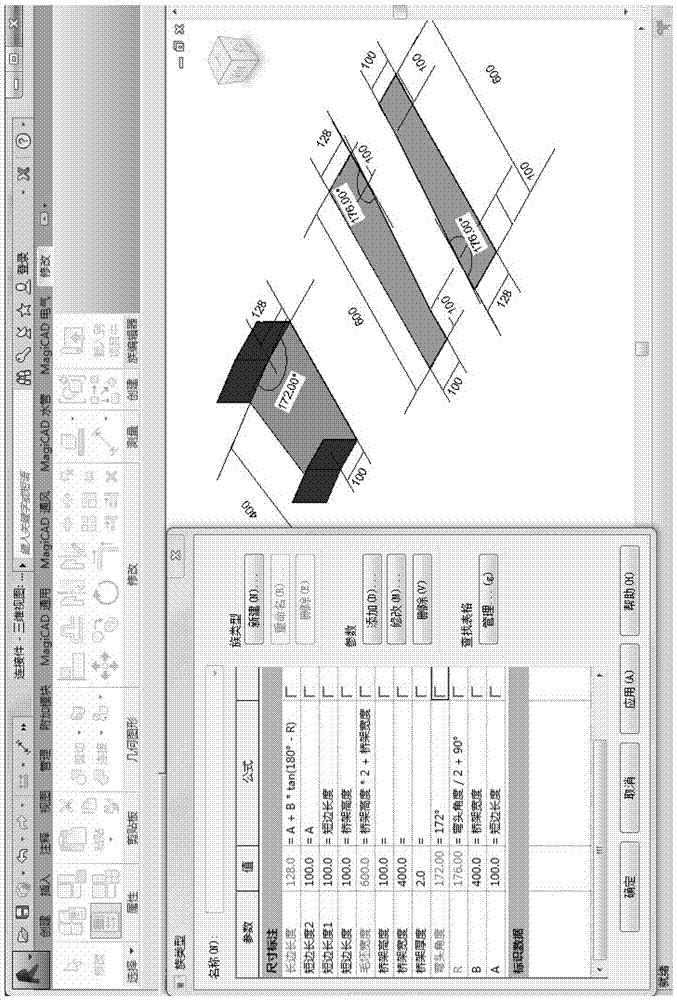

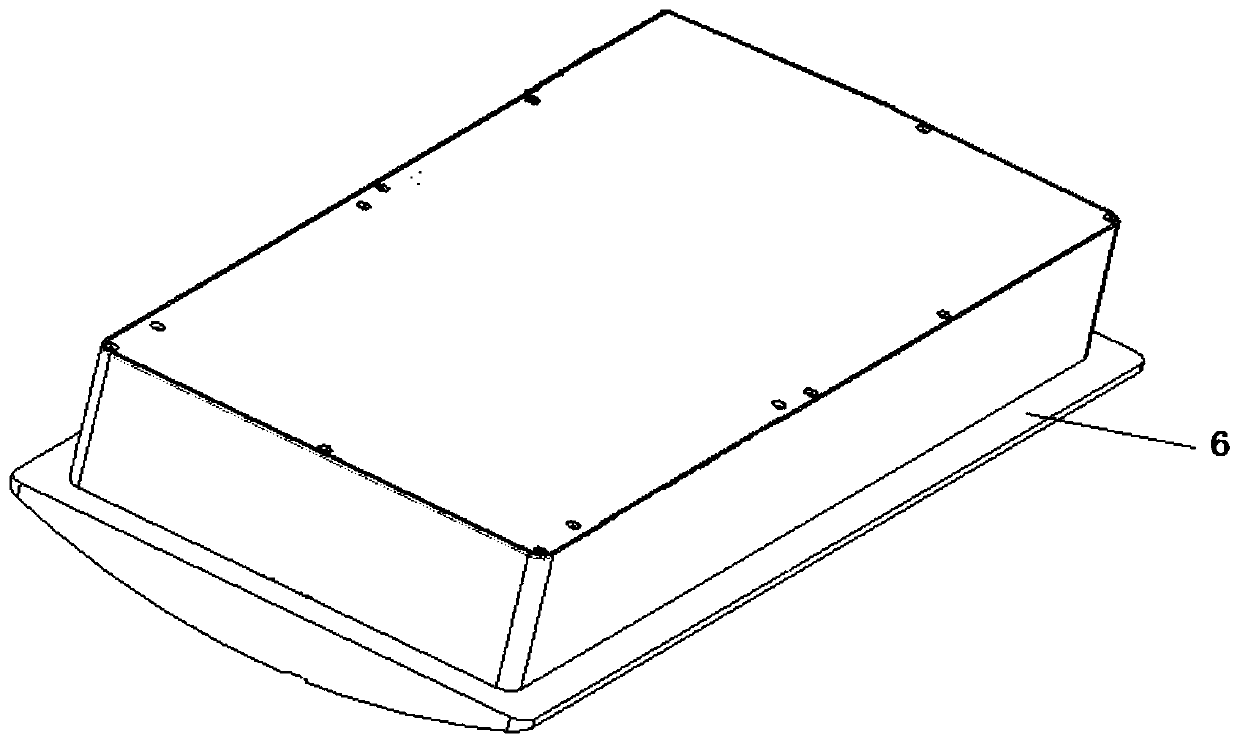

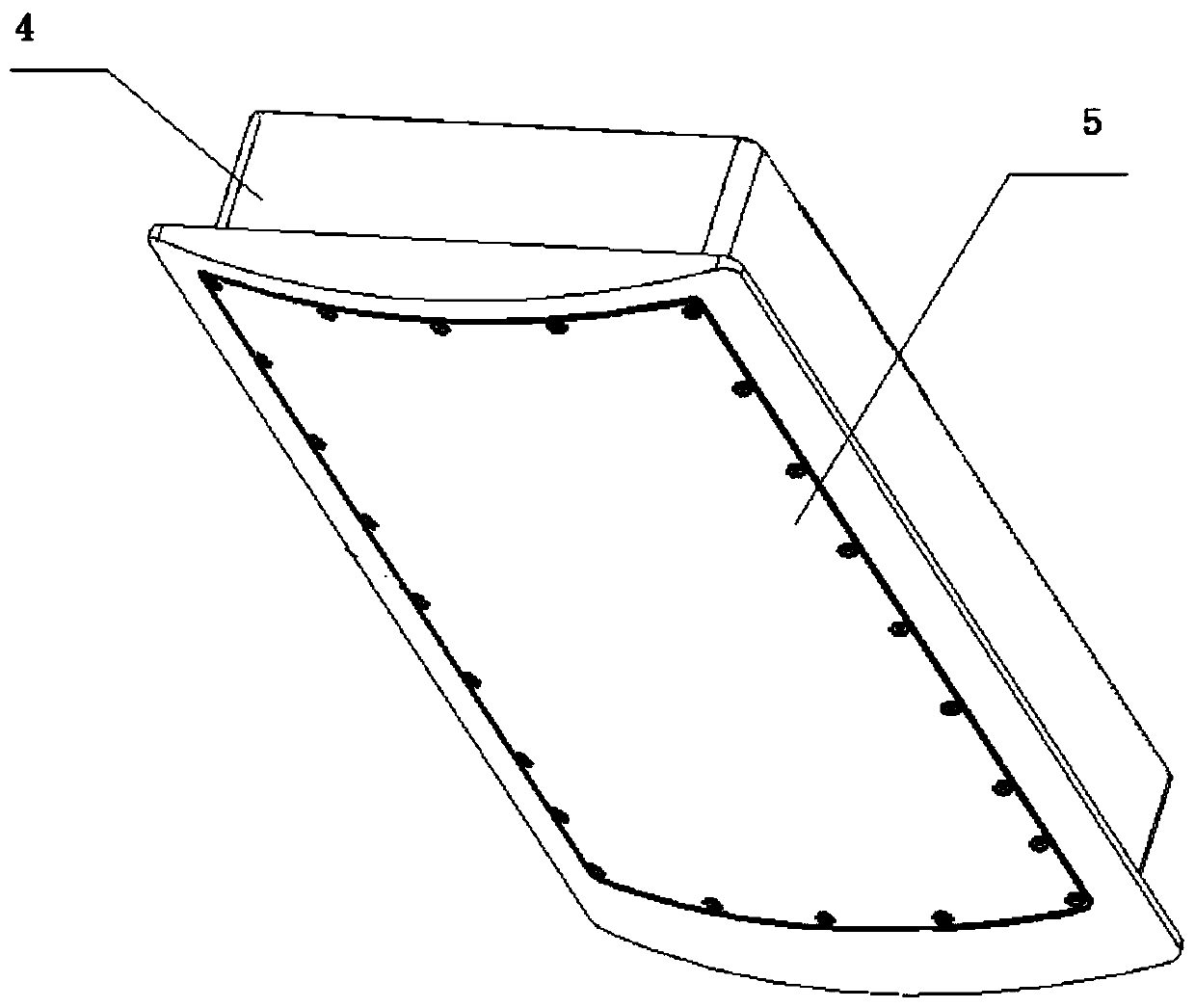

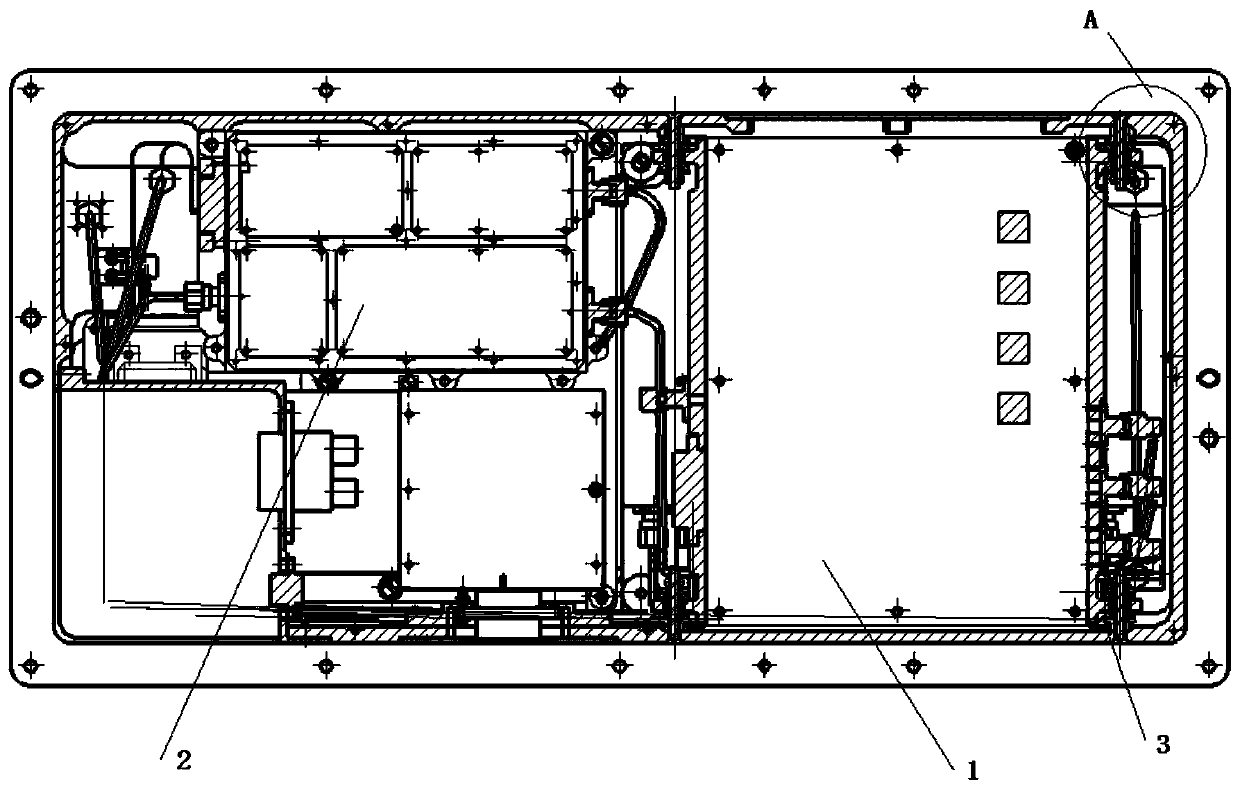

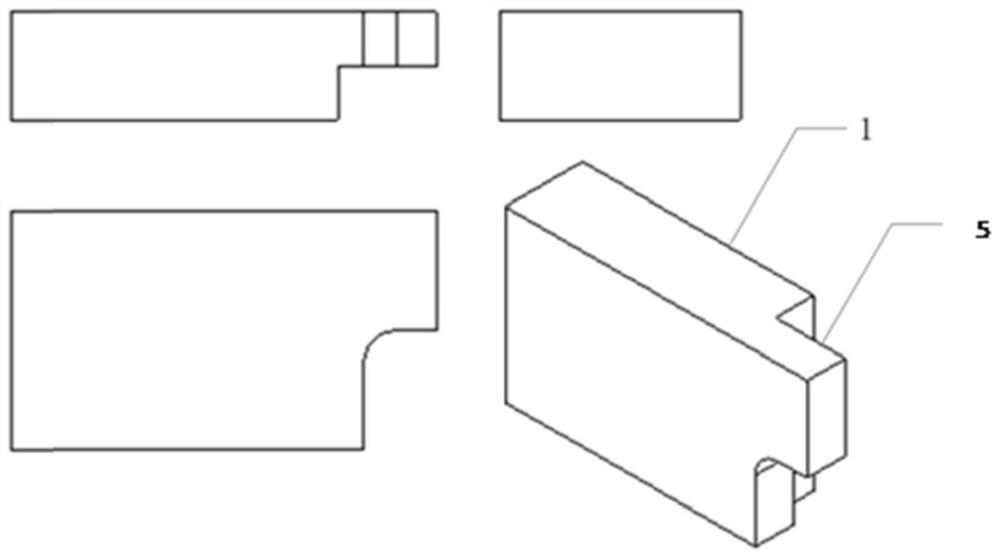

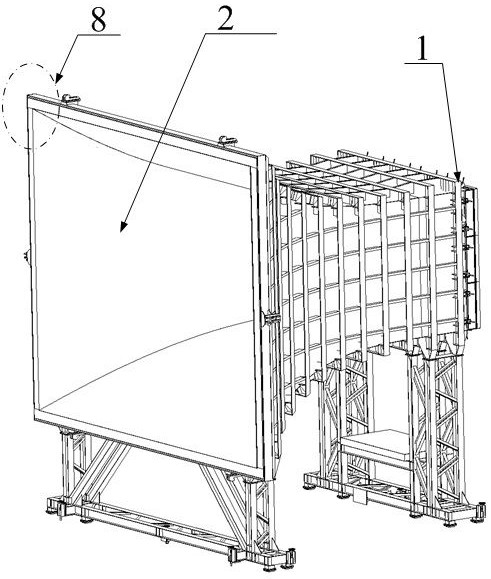

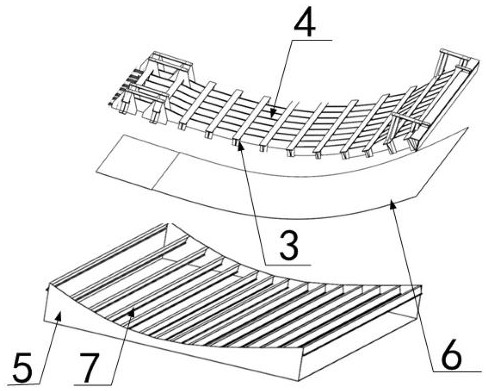

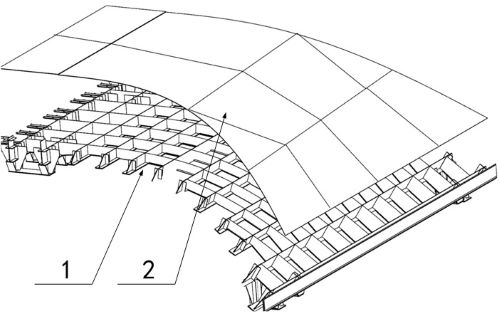

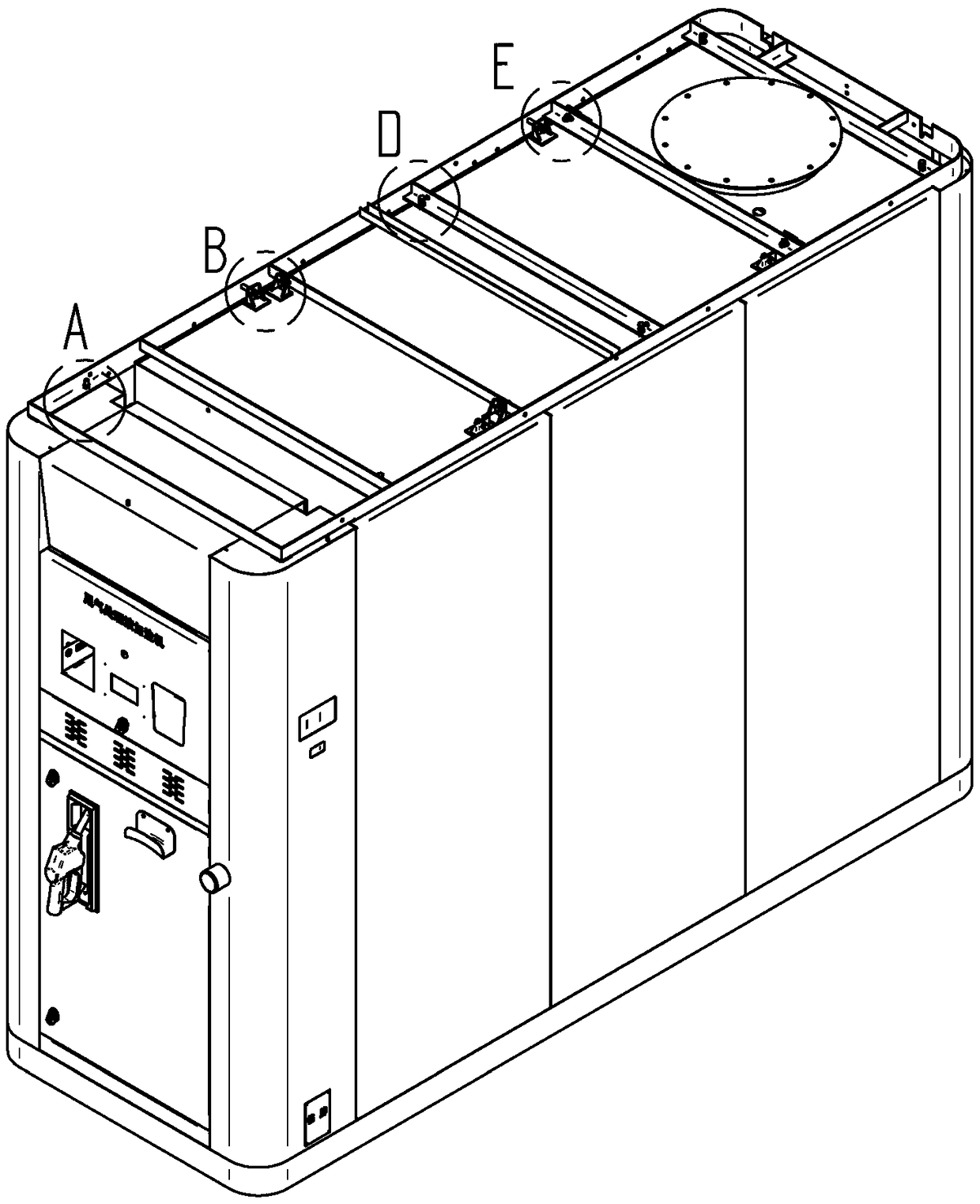

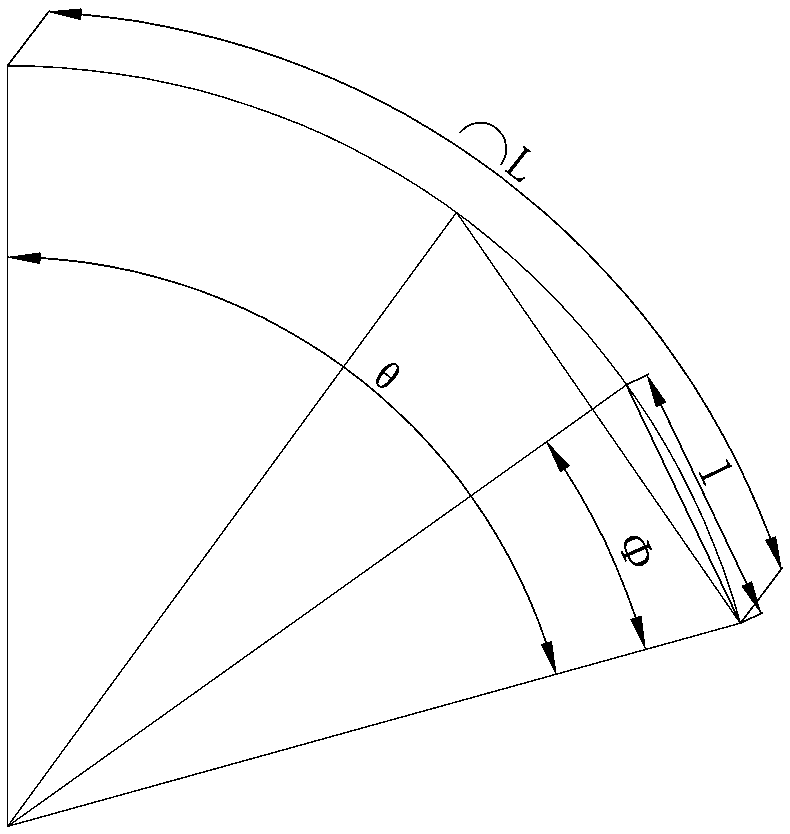

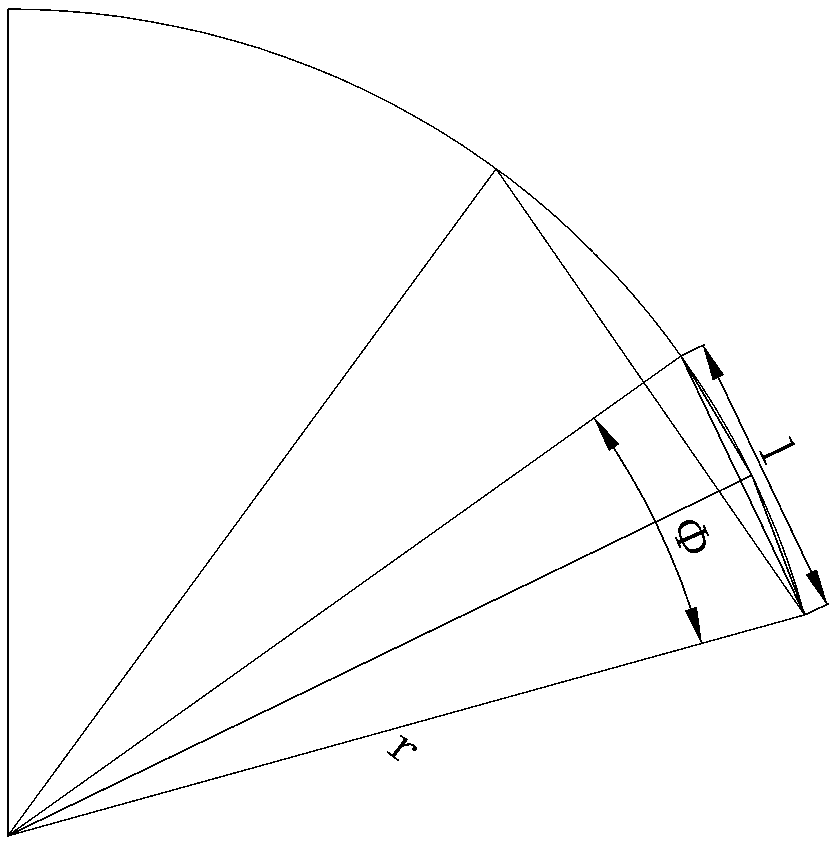

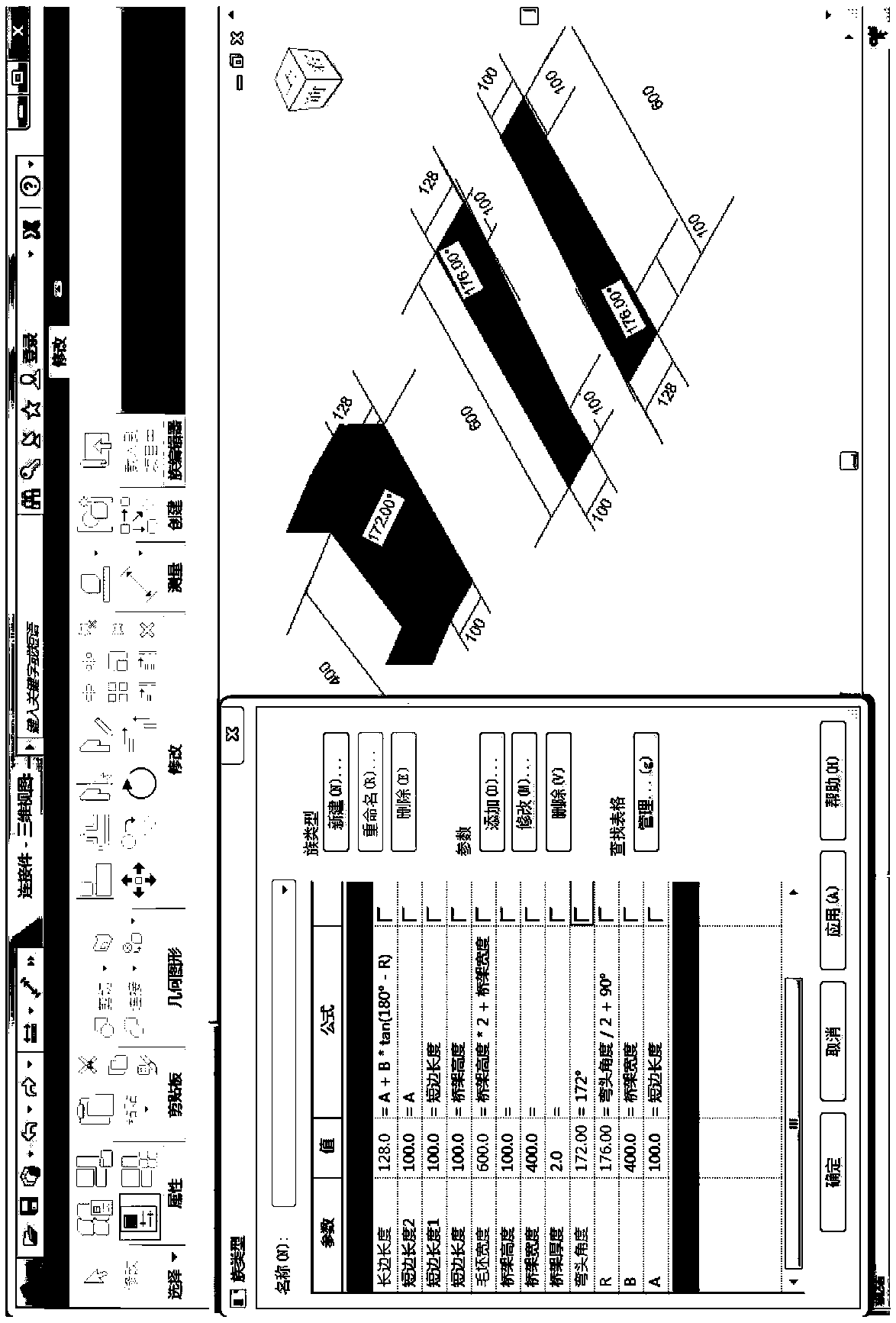

Large wind tunnel contraction section manufacturing method

ActiveCN113714748ASolve the deformationSolve the installation accuracySustainable transportationAerodynamic testingBody frameManufacturing engineering

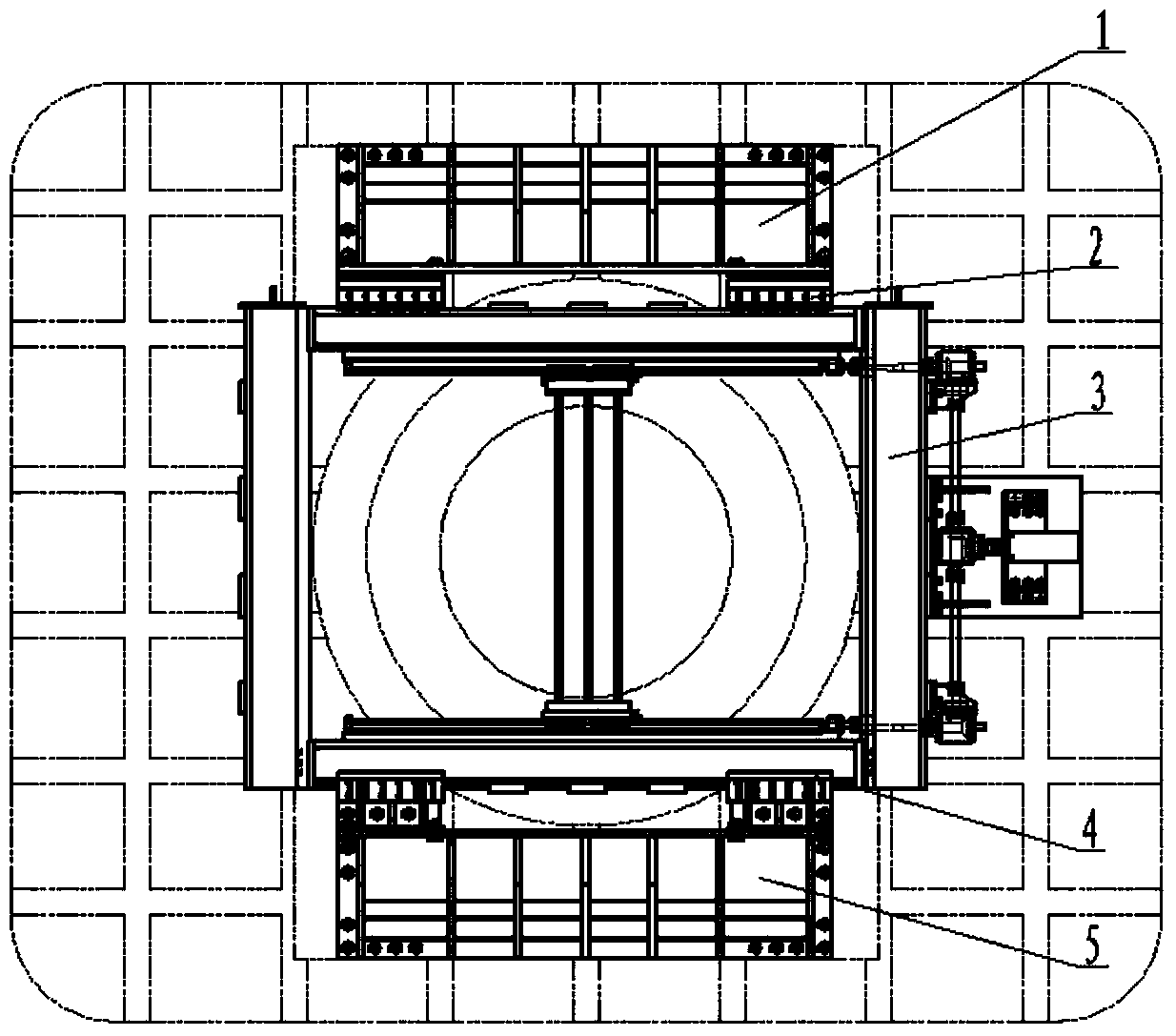

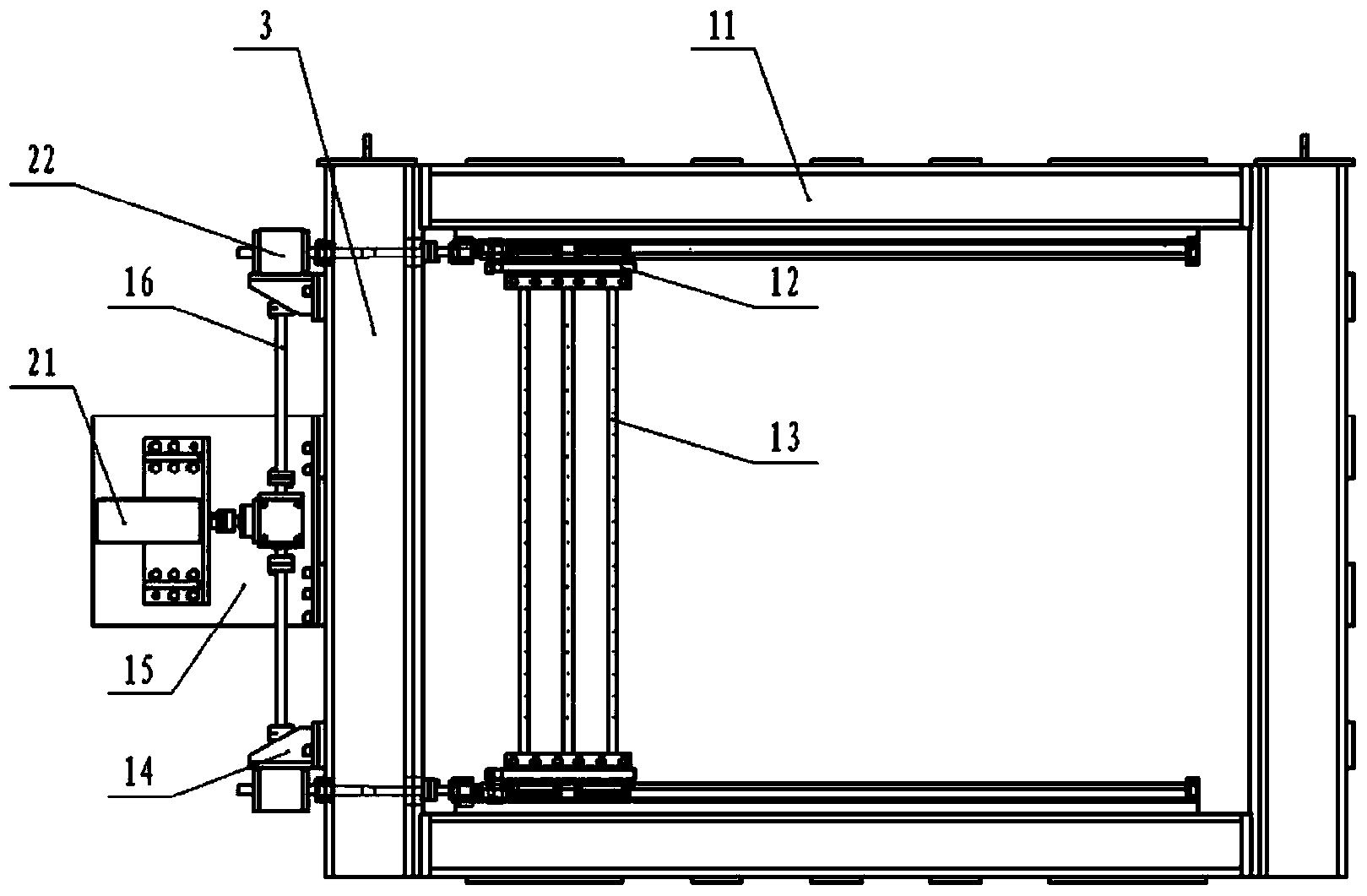

The invention discloses a large wind tunnel contraction section manufacturing method. The method comprises the steps that a reverse molded surface mould is designed and manufactured according to the size of a wind tunnel contraction section; scribing is carried out on the installation positions of contraction section shell body frames on the molded surface mould; rechecking is carried out on the assembly positions after scribing; then assembling and welding are carried out on the contraction section frames on the mould; after welding is completed, checking is carried out on the size of the frame; overturning is carried out after the size is checked to be qualified, so that the inner molded surface is upward, and skin assembly is carried out; and finally, integrally assembling is carried out, and the upper frame, the lower frame, the left frame and the right frame are welded together. The manufacturing method can effectively guarantee the molded surface size of the large wind tunnel contraction section, has the advantages of being easy and convenient to operate, capable of saving the construction period, wide in application range and the like, and has important reference and application value for manufacturing other large-size and poor-rigidity curved surface steel structure equipment.

Owner:LOW SPEED AERODYNAMIC INST OF CHINESE AERODYNAMIC RES & DEV CENT

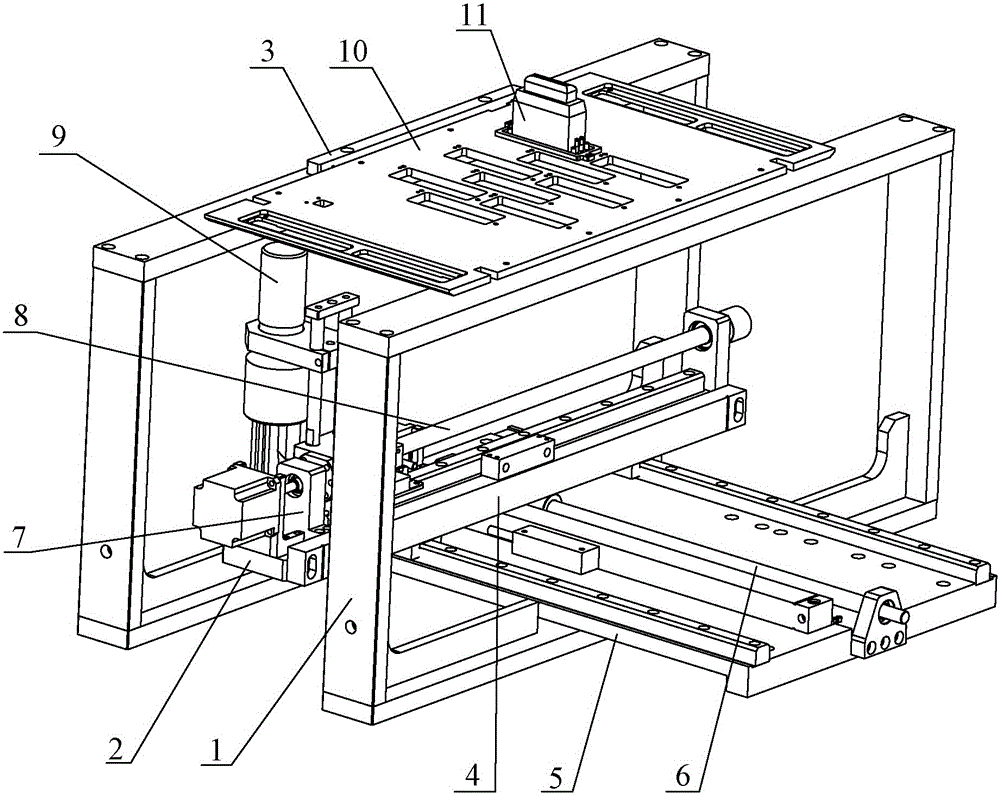

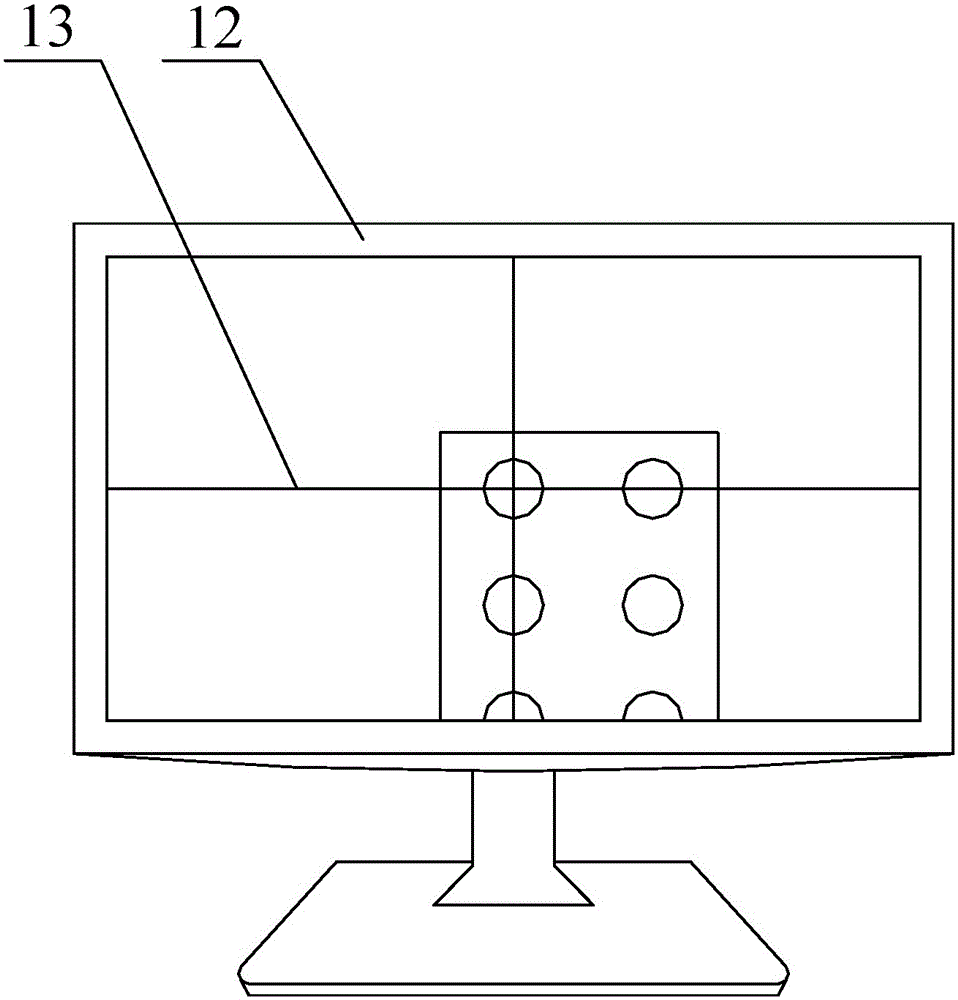

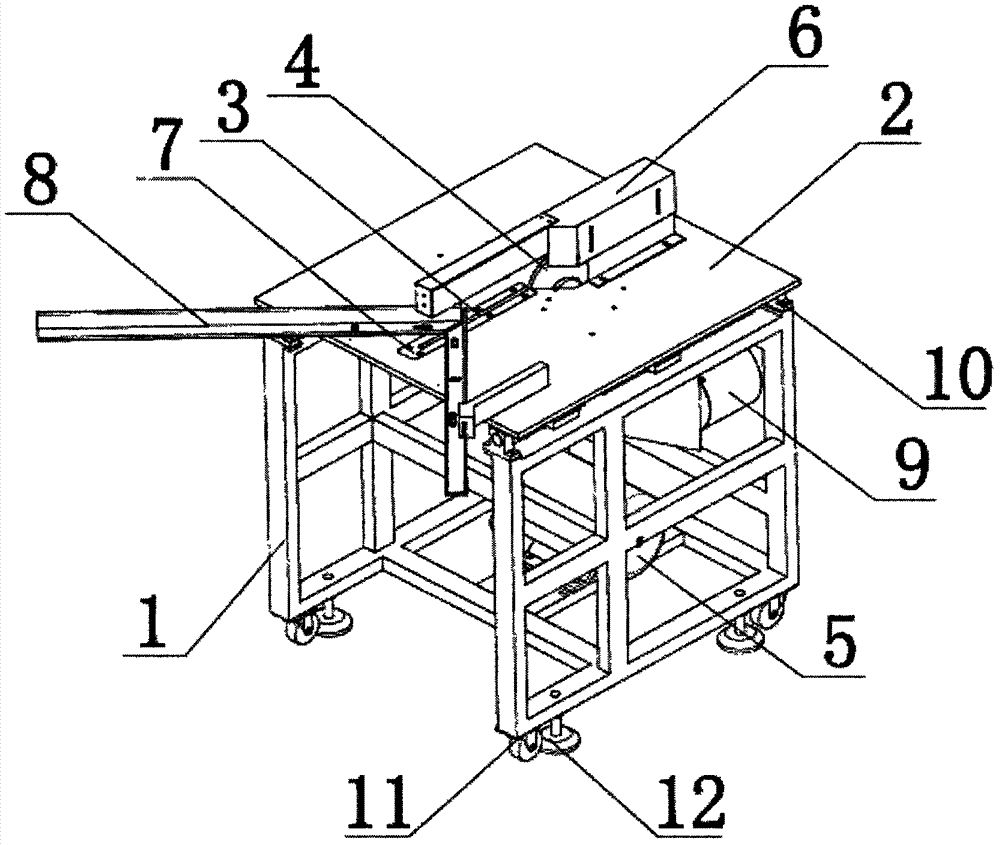

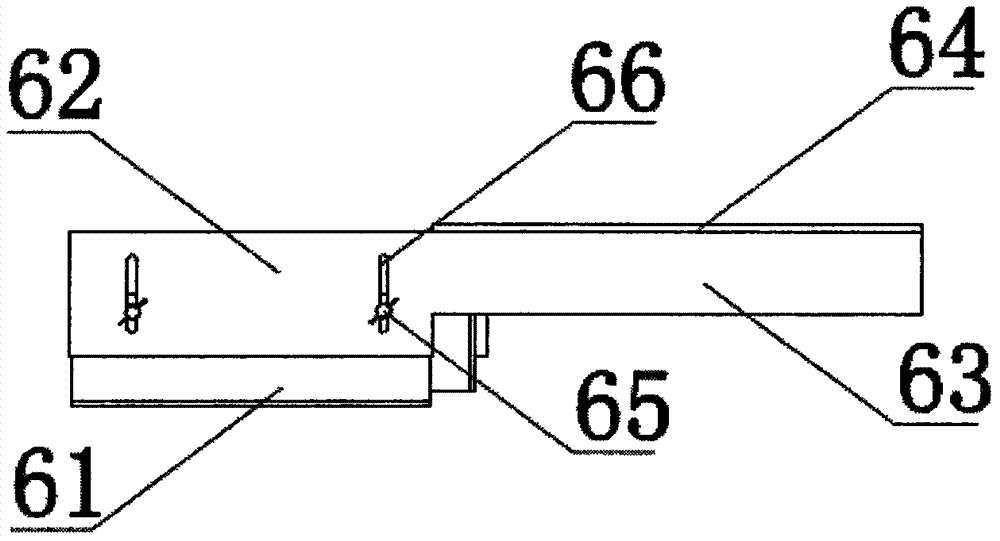

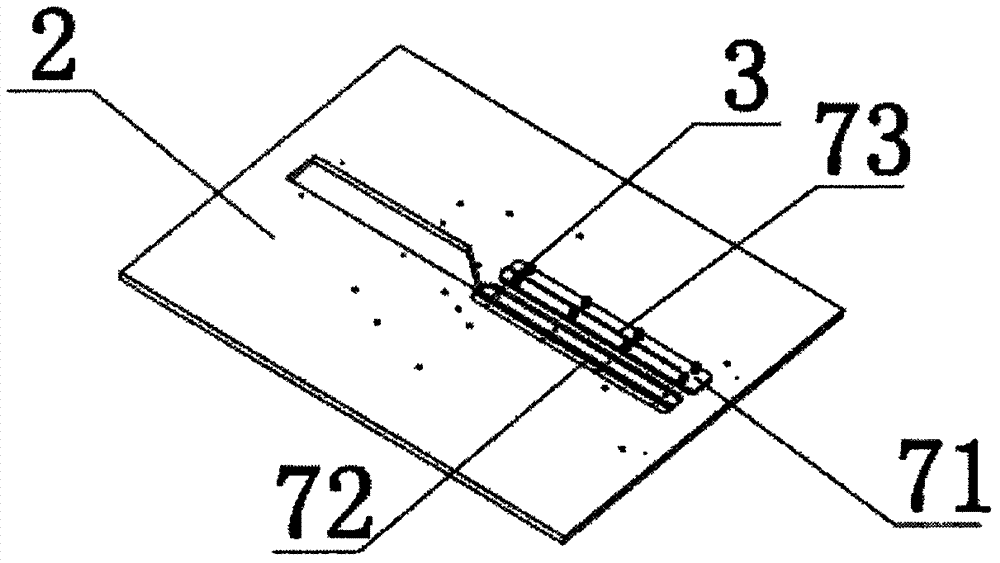

Calibration method, calibrating device, and calibration method of calico printing machine sprayer head

ActiveCN105150687AEasy to adjustSolve the installation accuracyPrintingPictoral communicationComputer graphics (images)Display device

The invention discloses a calibration method, a calibrating device, and a calibration method of a calico printing machine sprayer head. A to-be-calibrated target is shot by using a shooting device; an image shot by the shooting device is outputted to a display device provided with a reference mark; the shooting device is moved, so that a location, displayed on display device, of a first reference point of the target is aligned at the reference mark; and the location of the target is adjusted, so that a location, displayed on display device, of a second reference point of the target is aligned at the reference mark. According to the invention, a location of a target can be adjusted precisely; an adjusting result can be watched from the display device at any time during the adjusting process; and the adjusting process becomes simple and fast. Adjustment is completed completely based on objective reference marks without being dependent on experience of the installing and debugging staff, so that calibration becomes precise and reliable and a problem of poor sprayer head installation precision due to human factors can be solved.

Owner:HAIJIE DIGITAL TECH SUZHOU CO LTD

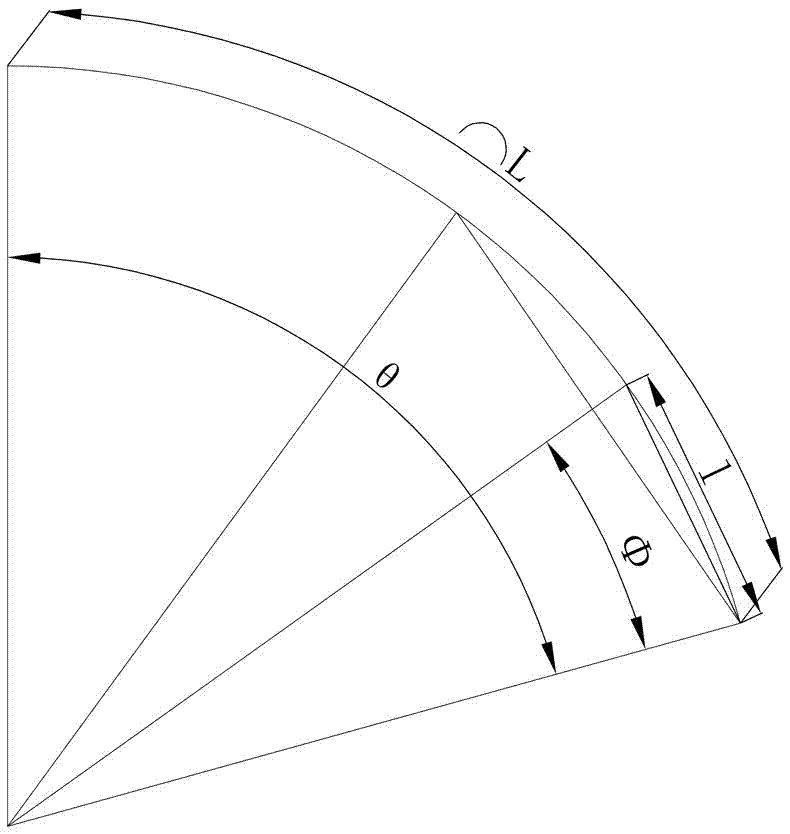

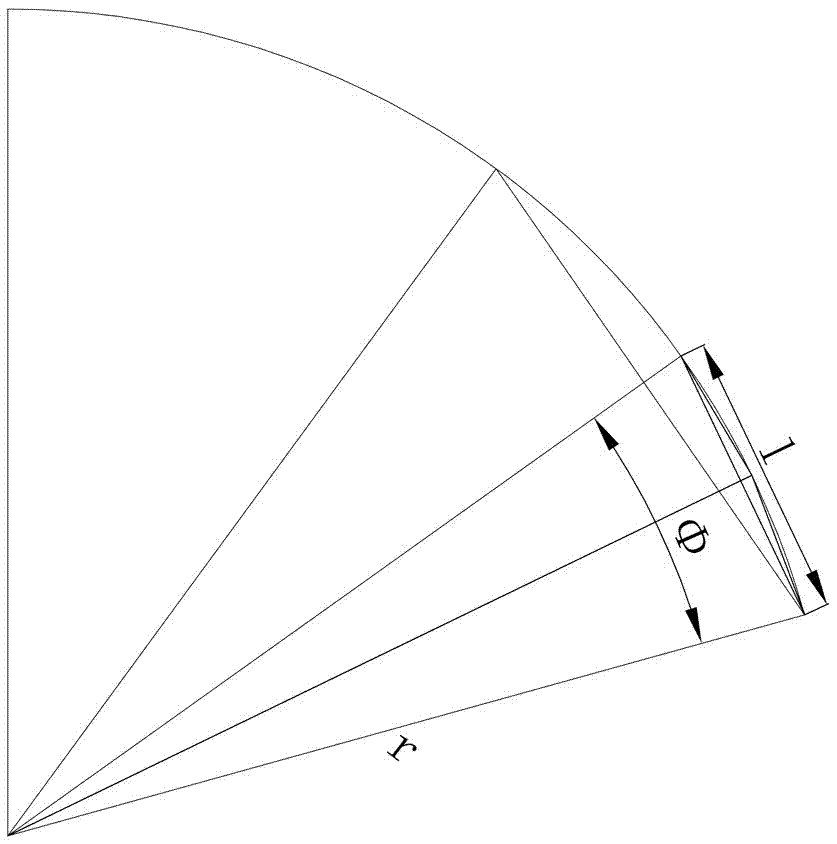

Construction method of arc cable wire slot structure

ActiveCN107230956AAchieve installationRealize the constructionCable installation apparatusButt jointEngineering

The invention discloses a construction method of an arc cable wire slot structure. The arc cable wire slot structure comprises a cable wire slot and a wire slot bearing part, wherein the cable wire slot comprises two segments of linear wire slots and an arc wire slot for connecting the two sections of linear wire slots; the arc segment wire slot is slot-shaped and comprises two connecting units with the same shape and size; two connecting units are in left-right mirroring butt joint, each connecting unit comprises a bottom plate, and a long ledge and a short ledge which are respectively vertical to the bottom plate. The construction method comprises the steps of computing the bend angle of the arc segment wire slot, counting the angle and the type of the arc segment wire slot, drawing a blank part detail drawing by using the 3D software, processing to produce the arc segment wire slot and numbering, paying off according to the mounting of a wire slot support by a design drawing, and mounting the wire slot. The construction method can satisfy the demand of the rigid cable wire slot mounting when the municipal integrated trench construction arc structure part is high in occupancy, the arc wire slot is multiple in specification and model, the cable laying quality requirement is high, and the mounting space arrangement difficulty is large.

Owner:BEIJING URBAN CONSTR FIFTH CONSTR GRP

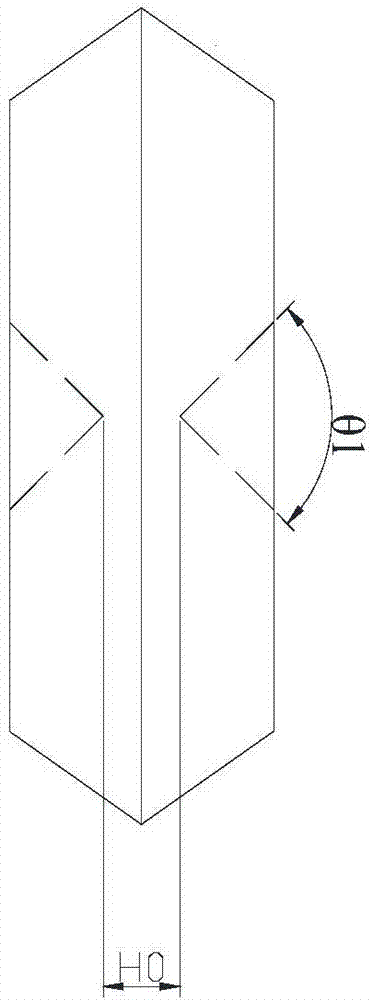

Angle cutter realizing smooth cutting and preventing burrs of end side and implementation method of angle cutter

ActiveCN106984867AAvoid fluffingSolve the installation accuracyPositioning apparatusMetal-working holdersEngineeringMechanical engineering

The invention discloses an angle cutter realizing smooth cutting and preventing burrs of an end side and an implementation method of the angle cutter. The angle cutter comprises a bedplate; the bedplate is provided with a cutting slot; the cutting slot is used for a cutting knife wheel to pass through and is arranged along a rectilinear direction; inside the cutting slot, one end provided with no cutting knife wheel is filled with a fragile insert; and an exposed end face of the fragile insert is smooth and is flush with the upper end face of the bedplate. The main concept of the angle cutters still starts with elimination of a clearance between the cutting knife wheel and the cutting slot to make sure that a sawed material is always supported and burrs caused by inertial rupture in a cutting process can be prevented, so the first problem to be solved is installation precision; however, the angle cutter disclosed by the invention steers clear of the installation precision problem, the cutting slot and the cutting knife wheel still have the clearance, but the cutting slot is filled with the fragile insert, and the final actual movement direction of the cutting knife wheel is generated by cutting when being started for the first time, so the cutting knife wheel has no clearance with the clearance at the fragile insert.

Owner:SHENZHEN JINRONGKE TECH CO LTD

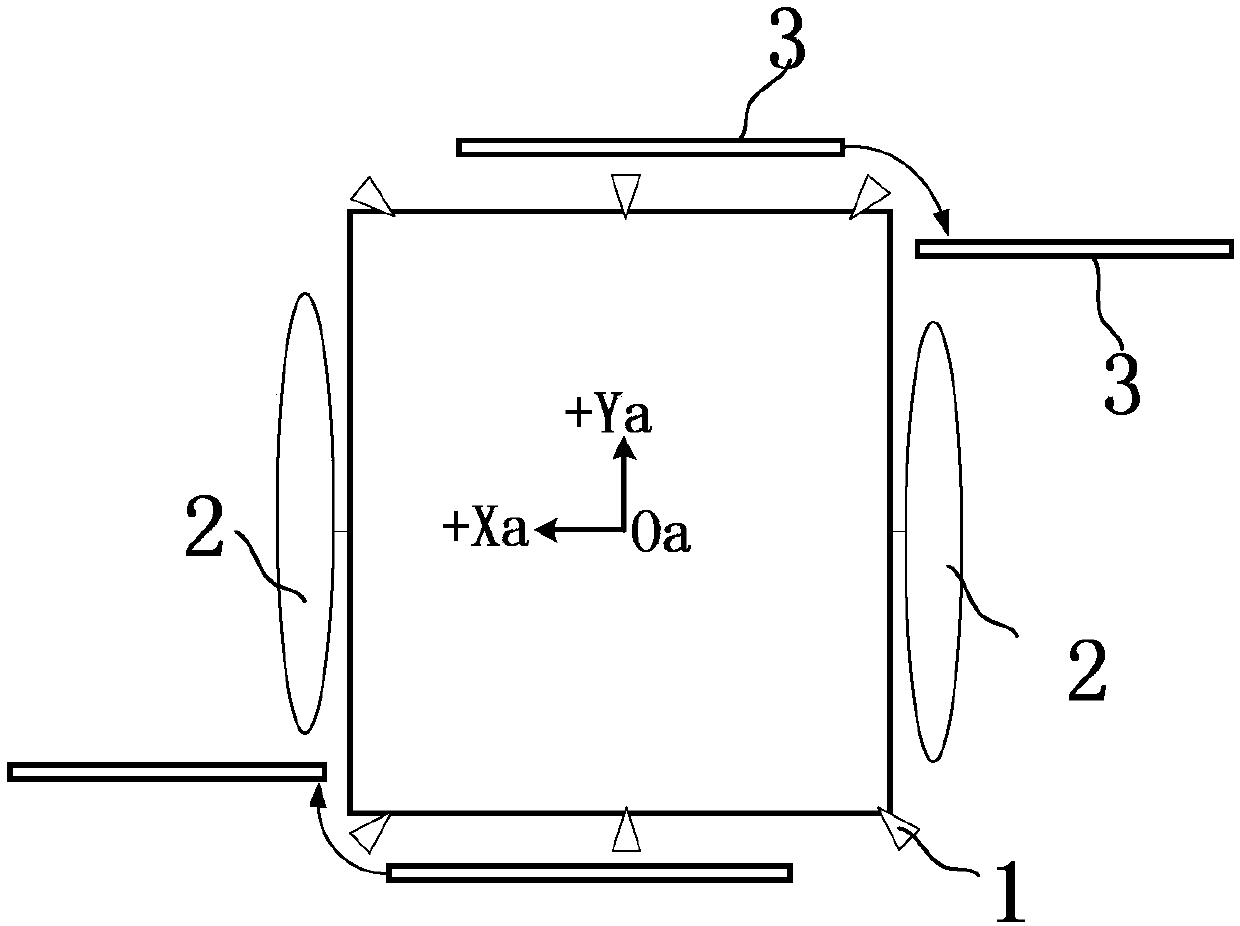

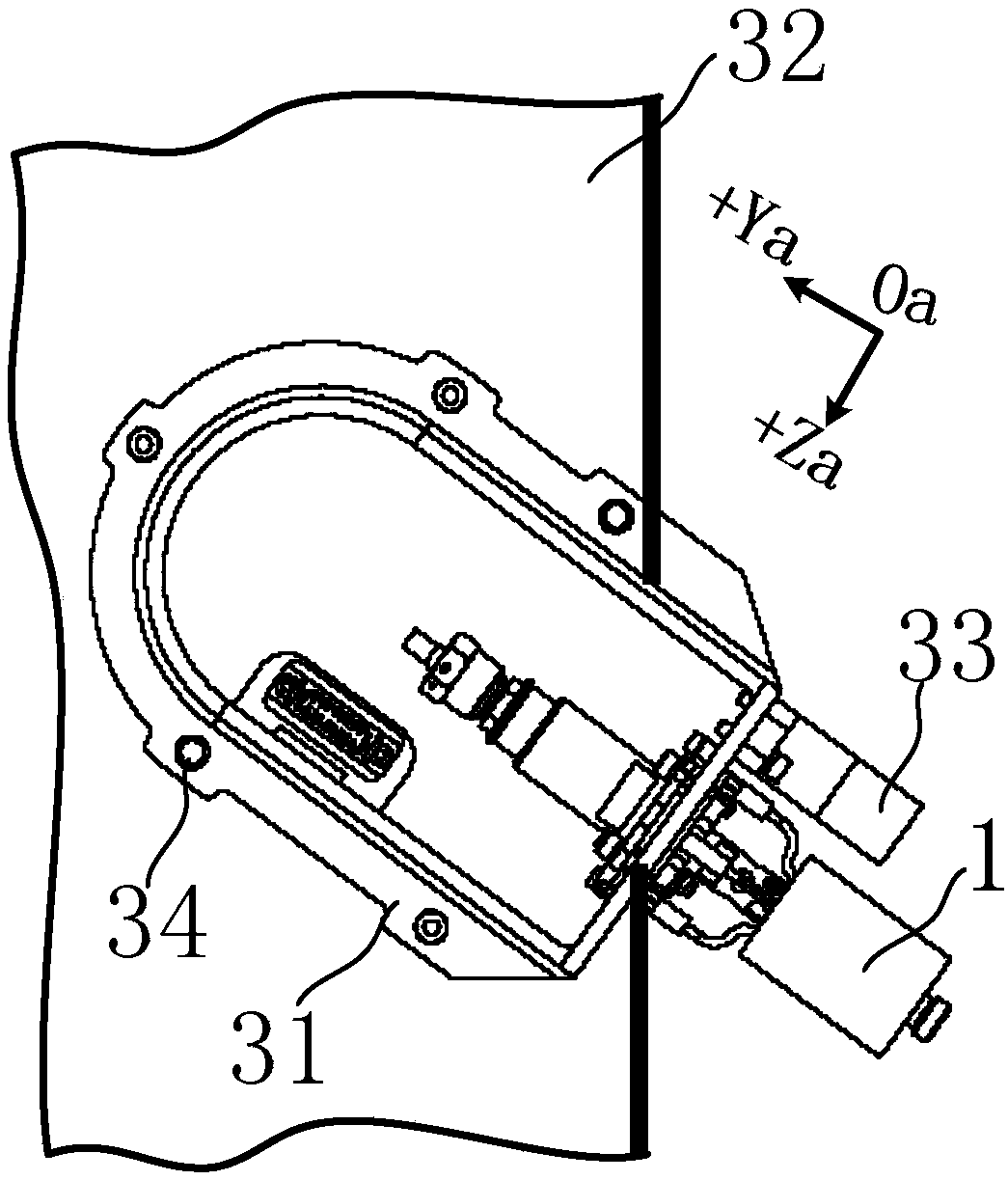

Formation layout and installation system for three-axis stabilization satellite

ActiveCN107839900AGuaranteed craftsmanshipSolve the installation accuracyArtificial satellitesSpacecraft guiding apparatusFlight directionSolar battery

The invention discloses a formation layout and installation system for a three-axis stabilization satellite. In order to meet the formation requirement for the satellite, formation thrusters need to be added to the satellite on the basis of a posture control thruster and a track control thruster; under a launching state, effective load and solar battery arrays of the satellite are drawn to the periphery of the satellite; when the satellite stays on the track, the effective load and the solar battery arrays are all spread in the Xa direction of the flight direction of the satellite to ensure that plumes of the formation thrusters do not intervene in the solar battery arrays and the effective load, and guarantee the maximization of the efficiency of the formation thrusters; according to theflight posture of the satellite, the formation thrusters are divided into two groups, the two groups are distributed at a +- Ya side of the satellite separately, the planes of the thrusters are perpendicular to the direction, pointing to the ground, of the satellite, and the formation thrusters cooperate with one another to pass through an average centroid of the satellite when the satellite staysat an on-track flight state. By adopting the formation layout and installation system, the satellite installation accuracy of the formation thrusters and the manufacturability of operation implementation are ensured; the demands of the formation thrusters for installation, accuracy measurement and formation control in the satellite can be effectively met.

Owner:SHANGHAI SATELLITE ENG INST

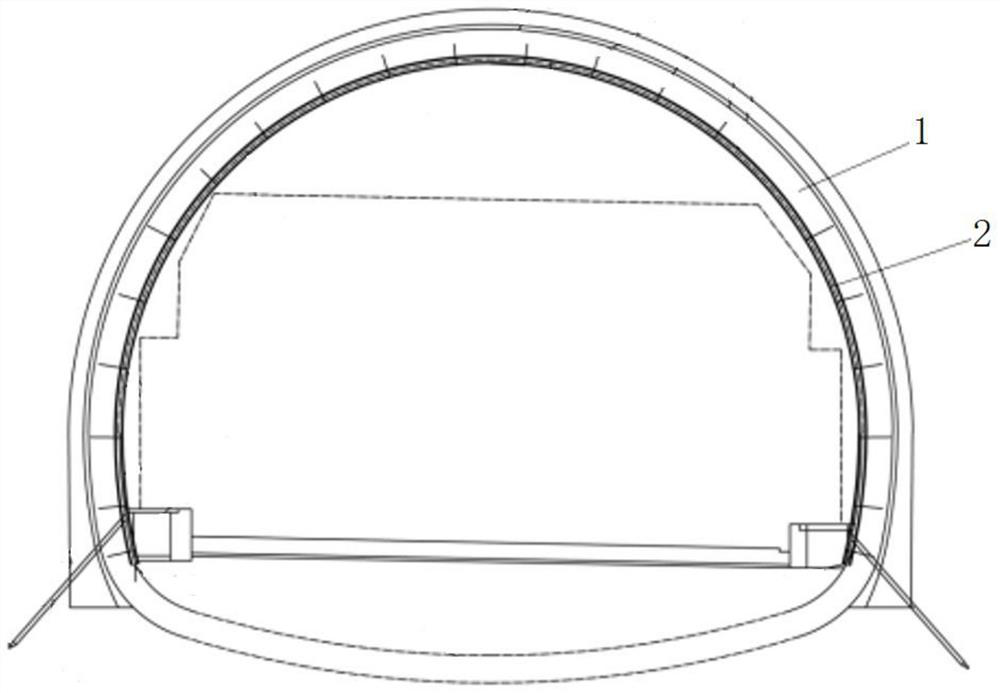

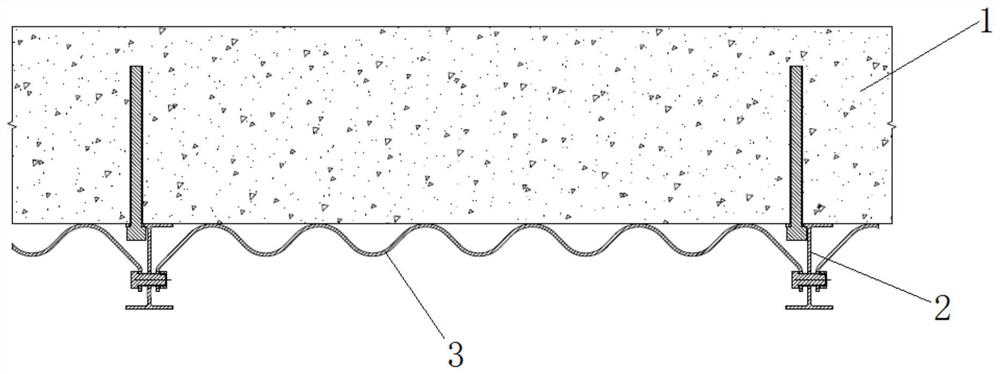

Tunnel corrugated steel plate reinforcing device and method

ActiveCN111963213AImprove mechanical performanceAvoid security issuesUnderground chambersTunnel liningArchitectural engineeringStructural engineering

The invention discloses a tunnel corrugated steel plate reinforcing device and method. The tunnel corrugated steel plate reinforcing device comprises protective fixing frames and a corrugated steel plate; a corrugated steel plate is installed in a channel formed between the two protective fixing frames, and two ends of the corrugated steel plate in a corrugated extending direction are fixed on theprotective fixing frames. According to the invention, the protection fixing frames are arranged, to be capable of protecting and reinforcing lining in advance, the possible safety problems of fallingand the like of the lining before the construction of the corrugated steel plate is completed are solved; secondly, after the protective fixing frames are installed, parallel construction can be conducted on multiple working faces, the problem that according to a traditional corrugated steel plate installation method, serial construction needs to be conducted is solved, the construction speed isincreased by multiple times, the construction period is shortened, and the risk of tunnel lining accidents in the construction process is reduced; and thirdly, the protective fixing frame further enhances the safety of the lining and improves the capability of resisting water pressure and unbalanced pressure.

Owner:北京鸿锐嘉科技发展有限公司

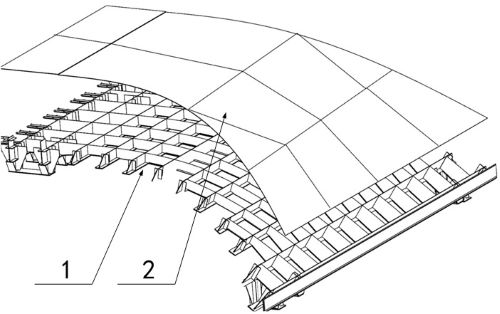

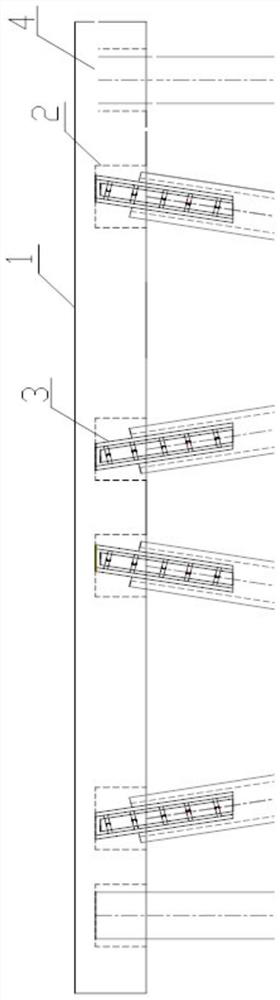

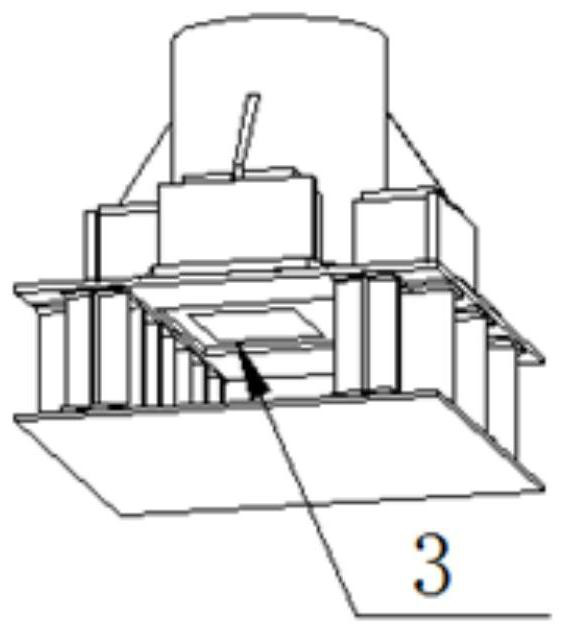

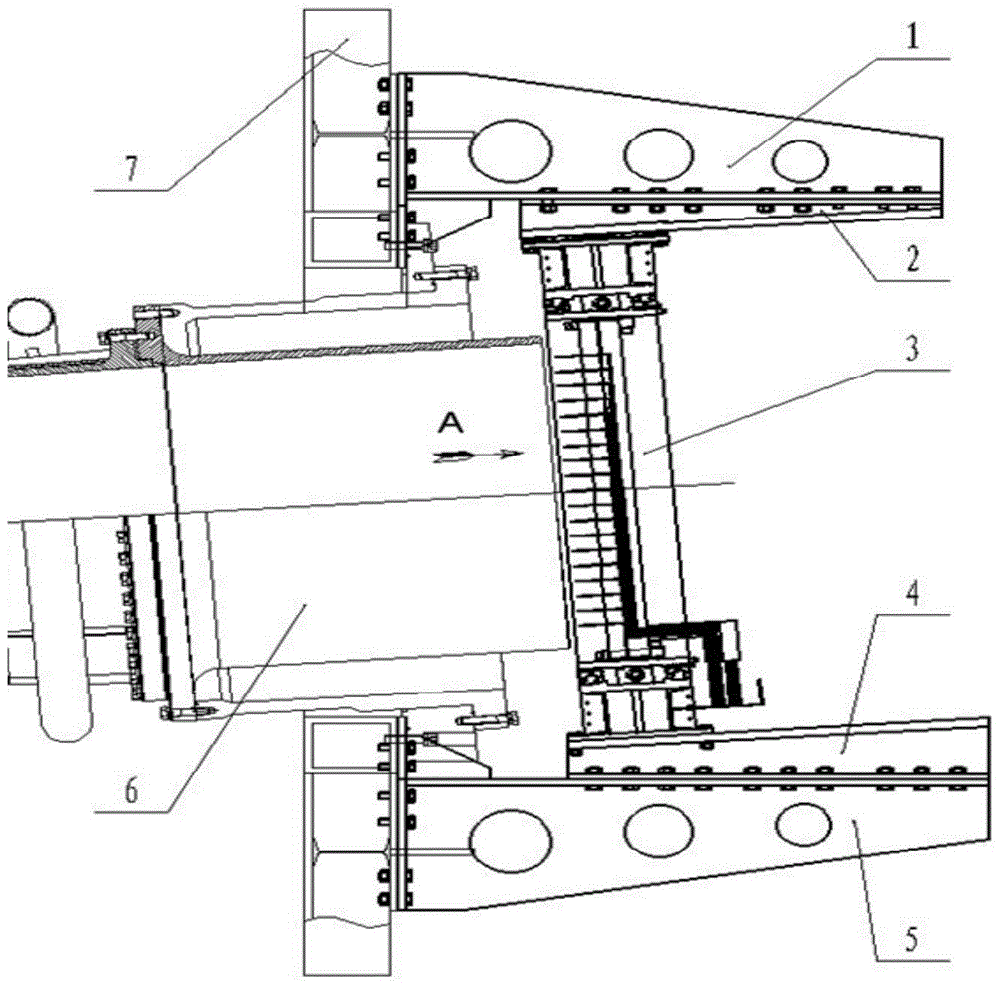

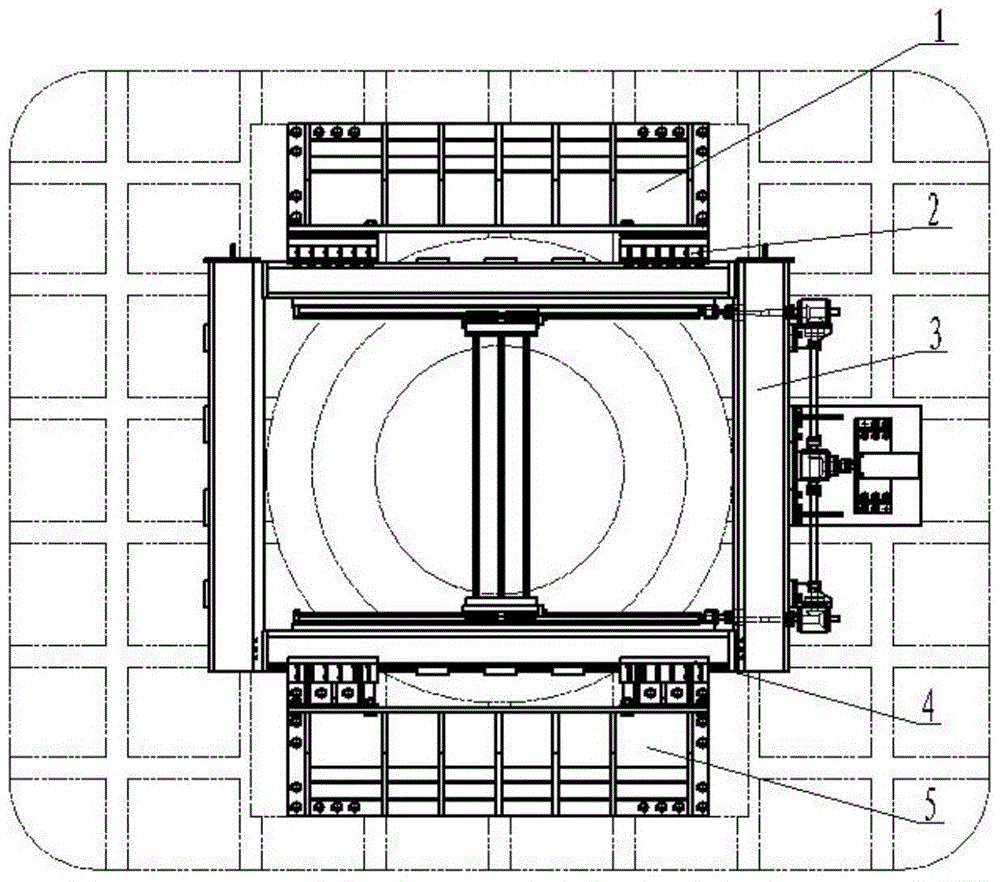

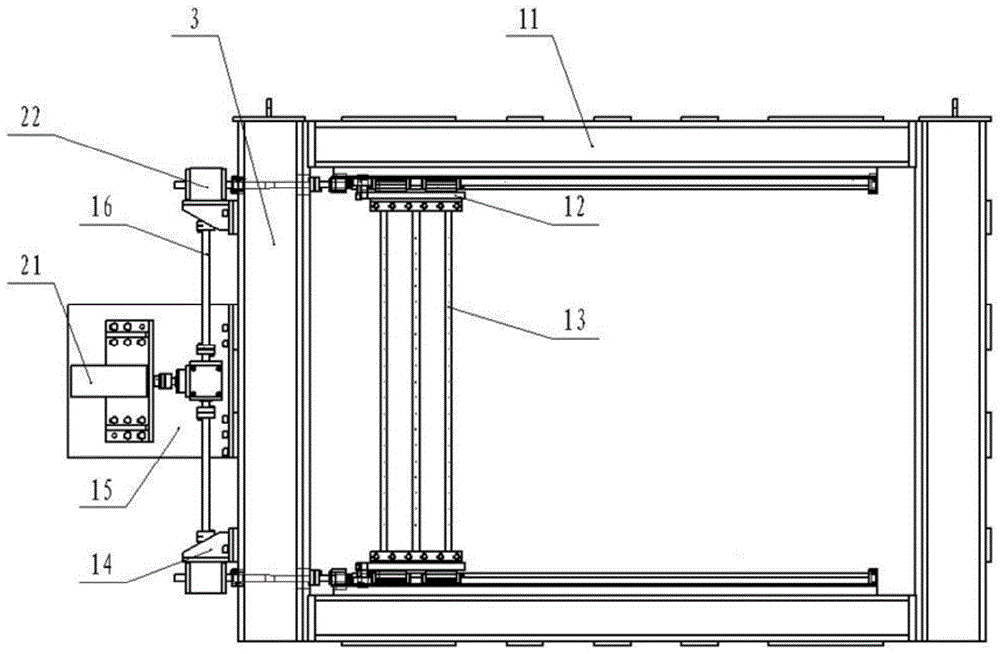

Flow field calibration apparatus

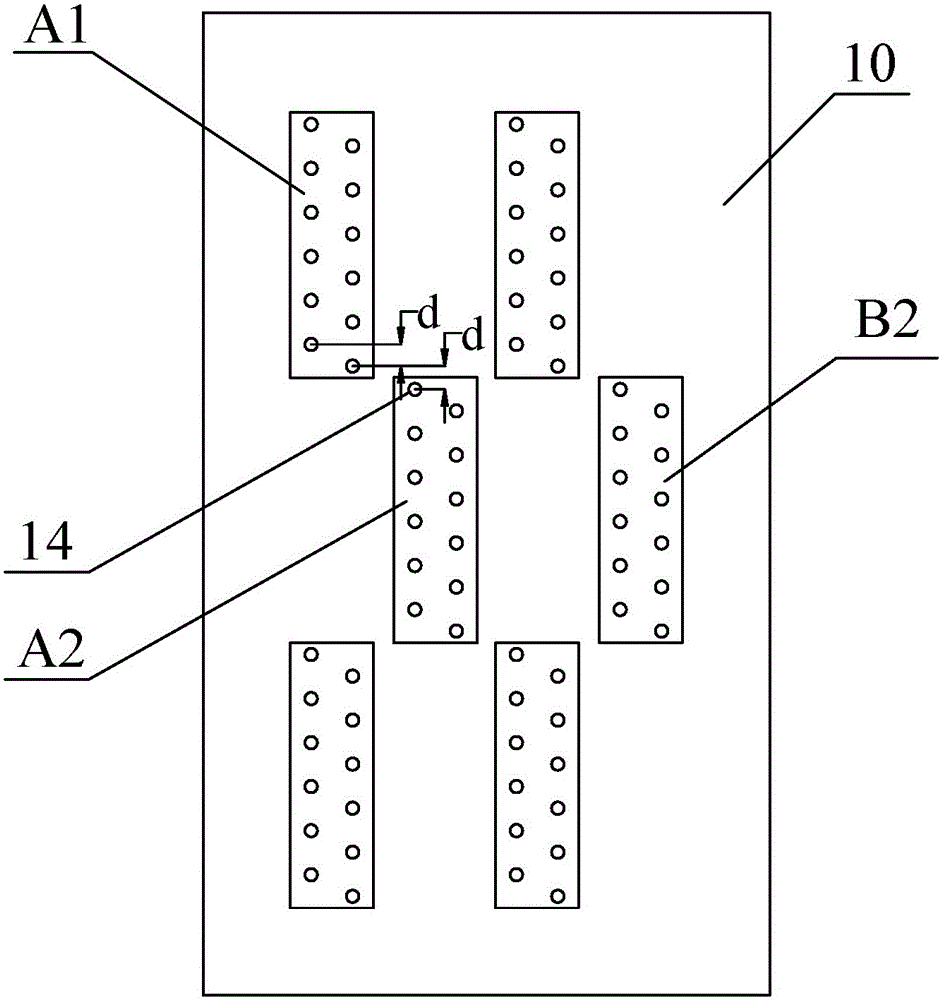

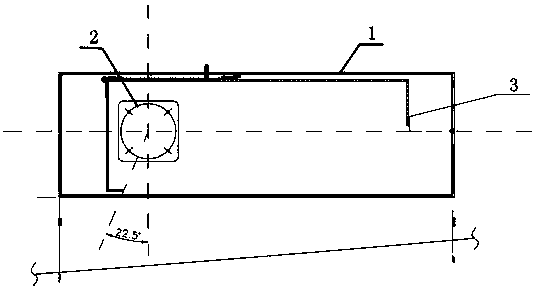

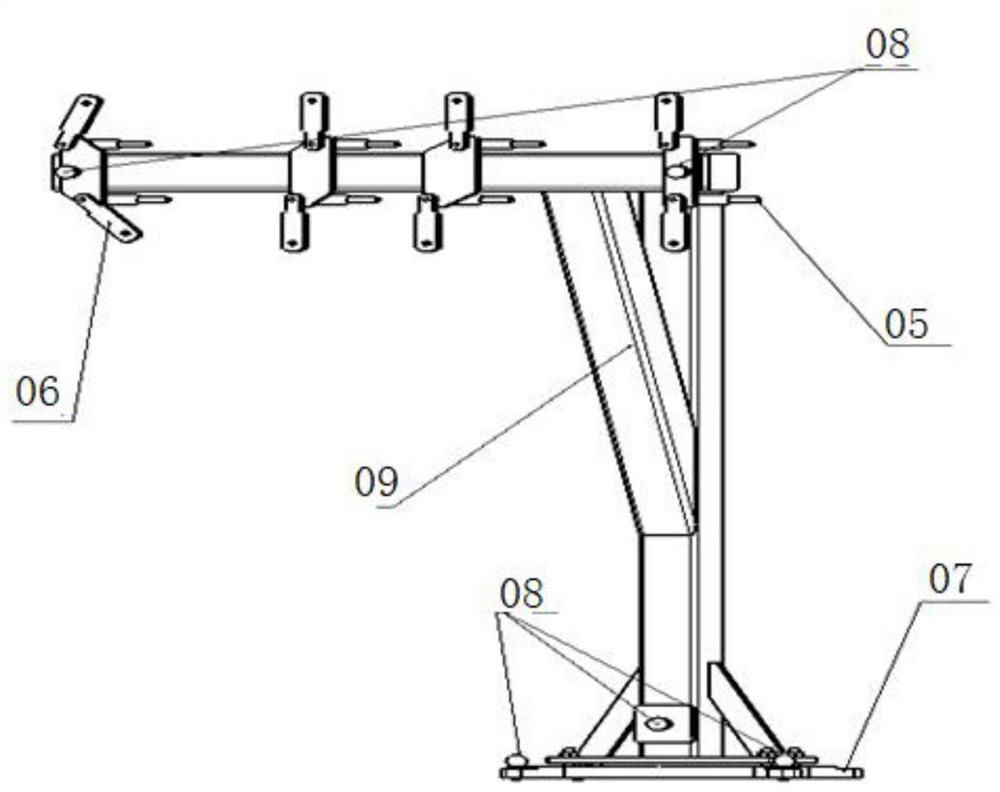

InactiveCN104390759AAvoid troubleEasy to disassemble and assemble repeatedlyAerodynamic testingLinear motionSprayer

Provided in the invention is a flow field calibration apparatus comprising a mounting frame, a support frame, a measuring mechanism and a driving mechanism. The mounting frame is fixed at an upper side wall and a lower side wall of a sprayer nozzle outlet of a test cabin by bolts. The support frame consists of an upper inclined support unit and a lower inclined support unit; the upper inclined support unit and the lower inclined support unit are respectively provided with mounting inclined surfaces for installing the measuring mechanism and are respectively fixed right above and below the sprayer nozzle by the mounting frame, wherein the mounting inclined surfaces of the upper inclined support unit and the lower inclined support unit are respectively parallel to the axis of the sprayer nozzle. Bolt holes that are arranged in rows are respectively formed in the upper inclined support unit and the lower inclined support unit; and bolt holes that are arranged in multiple rows and correspond to each other are formed in the walls of the upper inclined support unit and the lower inclined support unit along the axis direction of the sprayer nozzle. The measuring mechanism includes a measuring frame, a measuring rake group, and an adapter piece; the measuring frame is installed at the support frame; and the measuring rake group is installed at the measuring frame. The driving mechanism is installed at the measuring mechanism, so that the measuring rake group can be driven to make linear motion at the measuring frame.

Owner:BEIJING AEROSPACE YISEN WIND TUNNEL ENG TECH

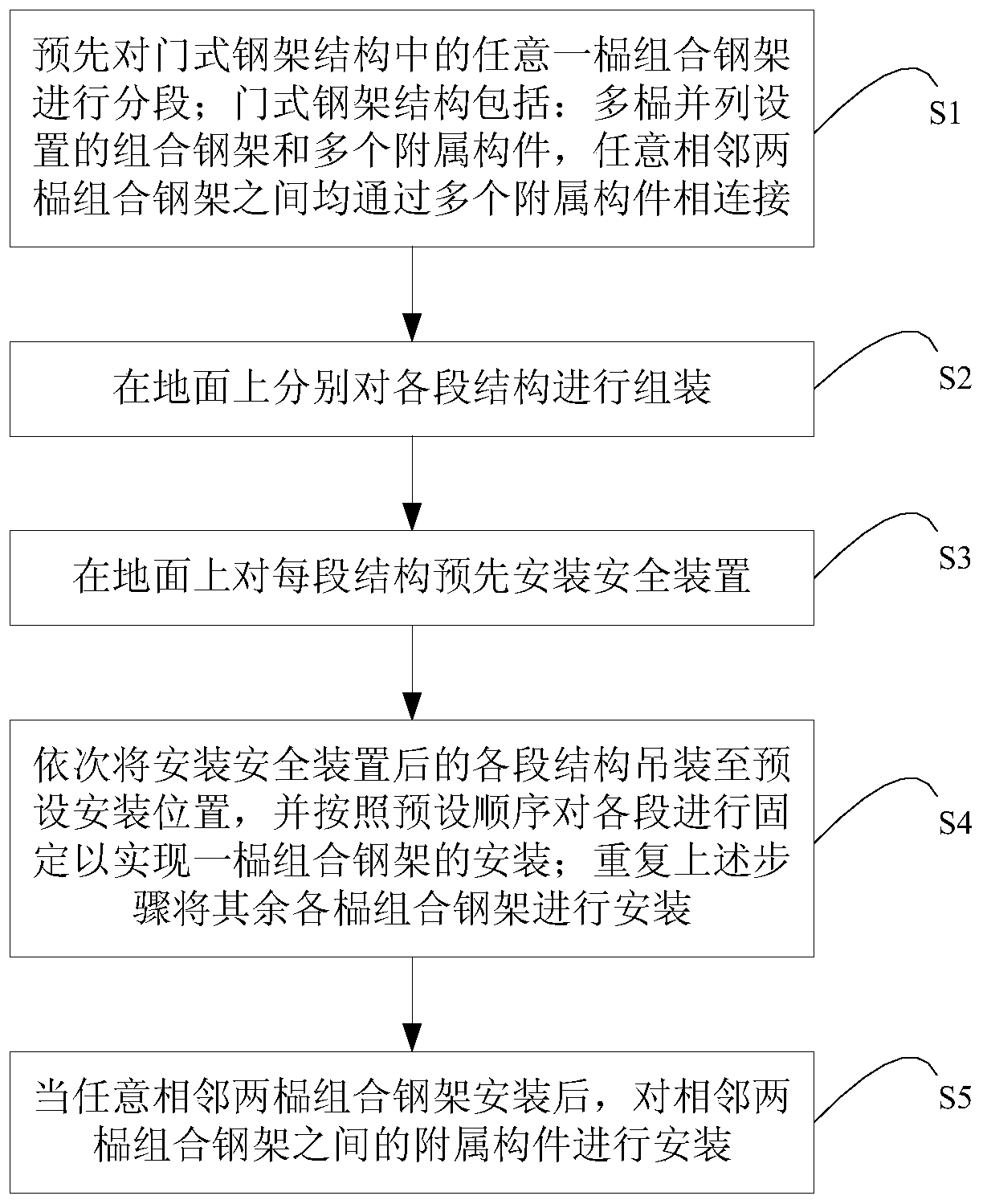

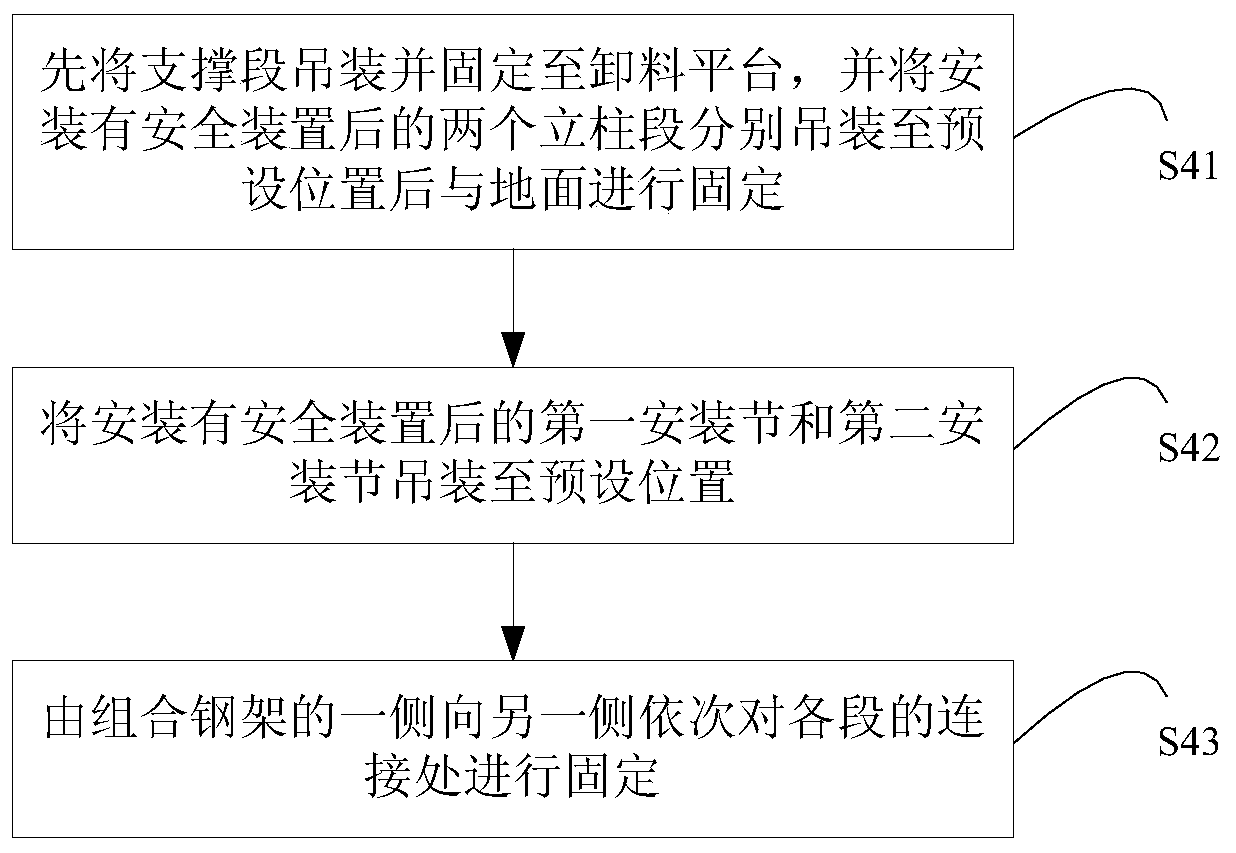

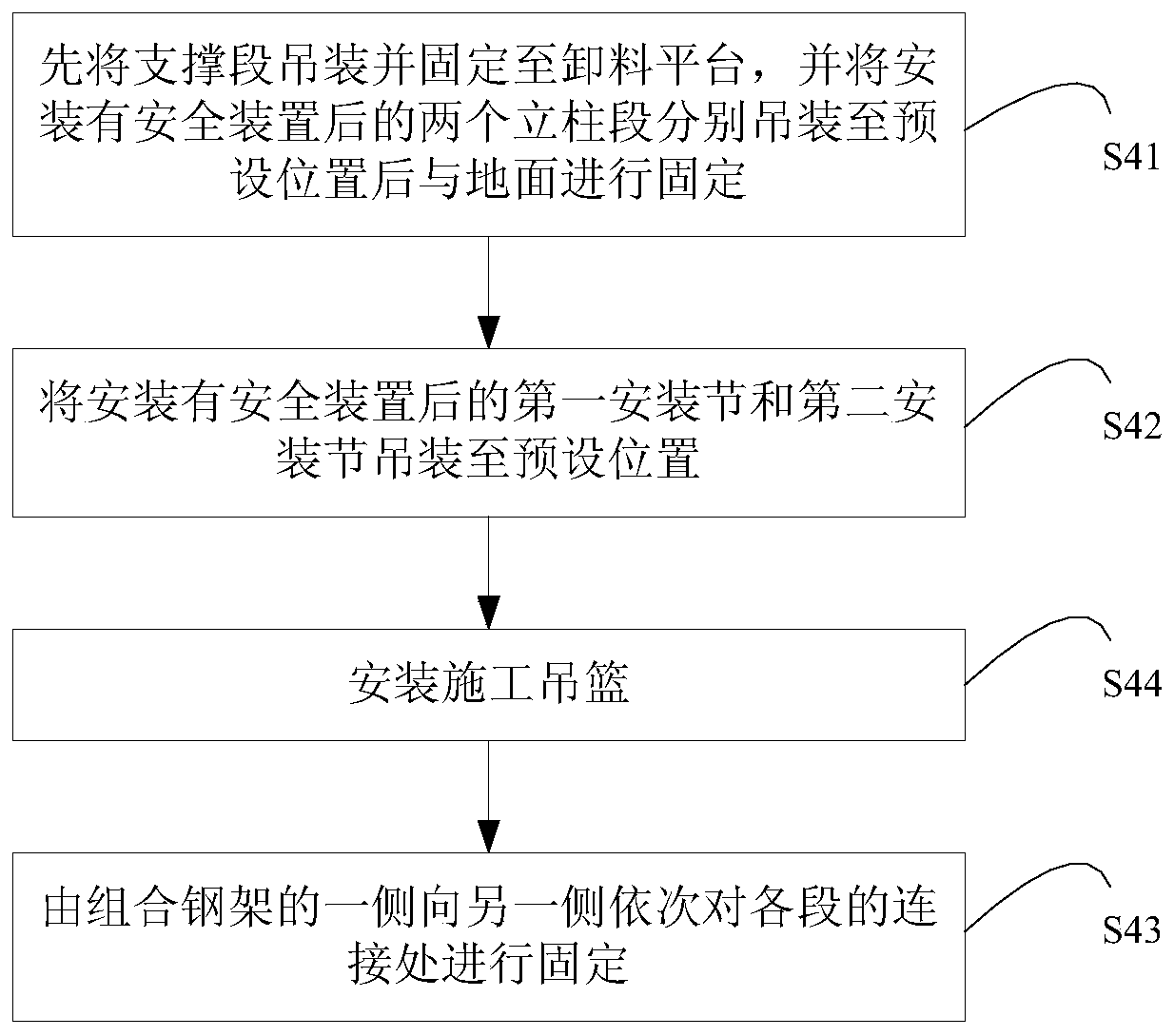

Mounting method for door-type steel frame structure of C-type closed material field

The invention provides a mounting method for a door-type steel frame structure of a C-type closed material field. The method comprises the following steps of sectioning, assembling, mounting, hoistingand fixing, and accessory member mounting, wherein in the step of sectioning, sectioning is conducted on any combined steel frame in the door-type steel frame structure in advance; in the step of assembling, assembling is conducted on each section structure on the ground; in the step of mounting, a safety device is mounted on each section structure on the ground in advance; in the step of hoisting and fixing, each section structure with the corresponding safety device mounted is sequentially hoisted to the pres-set mounting position, fixing is conducted on each section according to the presetsequence so as to achieve mounting of each assembled steel frame, and mounting is conducted on the rest of assembled steel frames by repeating the above steps; and in the step of accessory member mounting, after every two adjacent assembled steel frames are mounted, mounting is conducted on an accessory member between the two adjacent assembled steel frames. By means of the method, the transportation of various components and the assembly on the ground are facilitated, the controllability of each safety device during mounting is effectively guaranteed, the mounting time is shortened, the quality and accuracy after mounting are ensured, and the consumption of resources is further reduced.

Owner:CHINA MCC20 GRP CORP

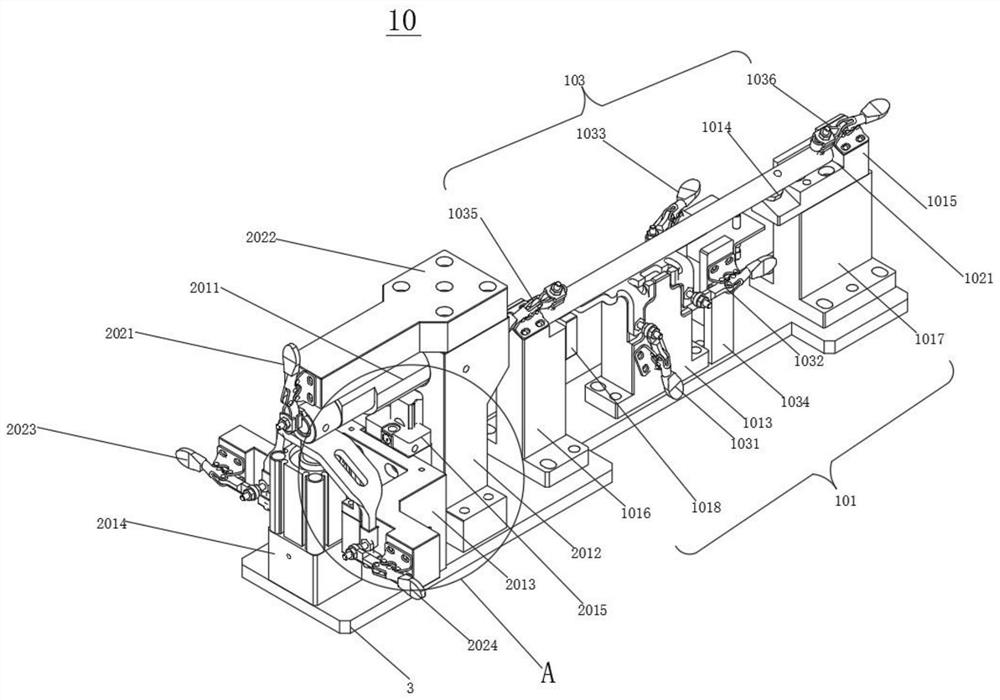

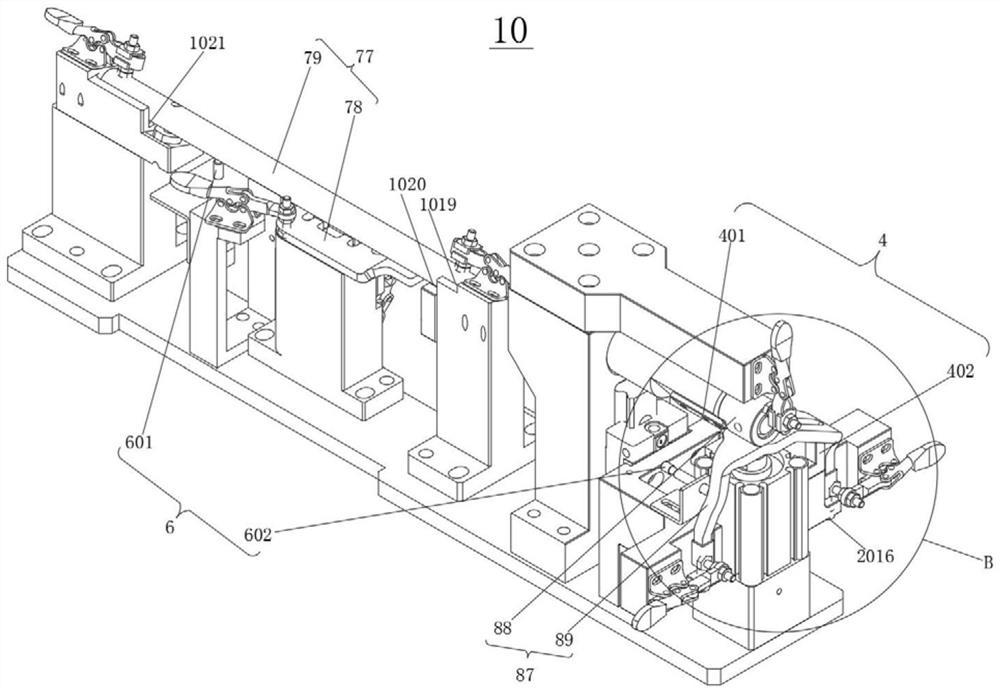

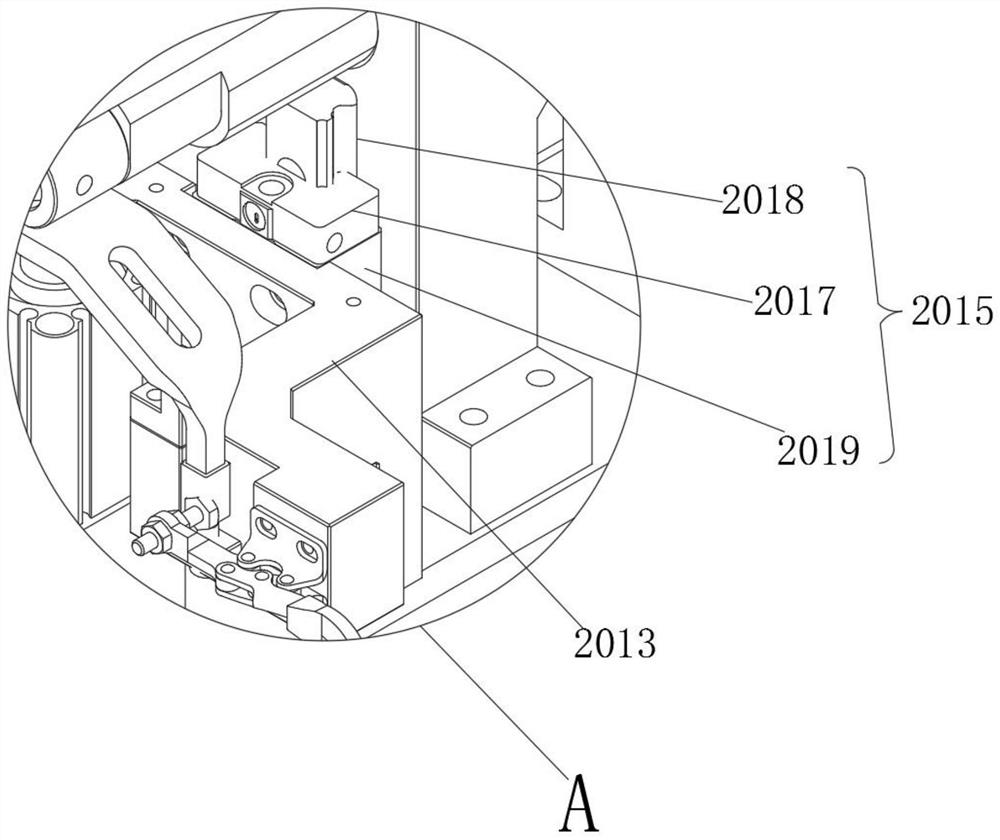

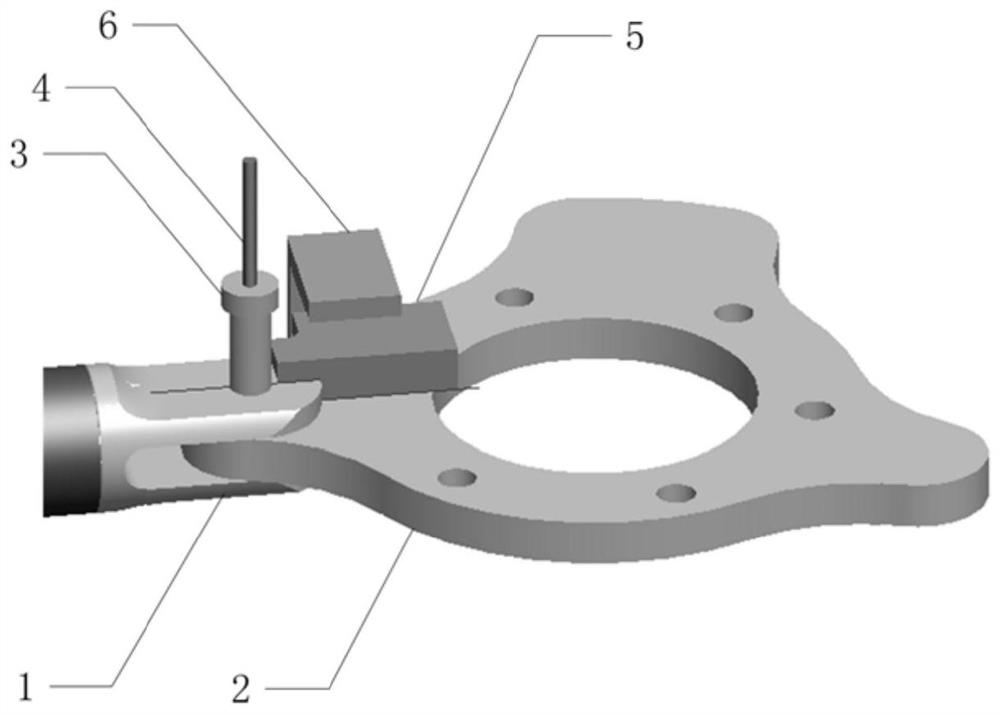

Shifting fork assembly combined welding clamp and shifting fork assembly combined welding system

ActiveCN112388153AGuaranteed location accuracyGuaranteed accuracyLaser beam welding apparatusControl engineeringControl theory

The invention discloses a shifting fork assembly combined welding clamp which comprises a forward gear shifting fork assembly clamp, a fifth-sixth gear shifting fork assembly clamp and a base, and theforward gear shifting fork assembly clamp and the fifth-sixth gear shifting fork assembly clamp are fixedly installed on the base. The forward gear shifting fork assembly clamp is used for fixing anautomobile forward gear shifting fork assembly and comprises a forward gear positioning mechanism and a forward gear locking mechanism. The forward gear positioning mechanism is arranged on the base,and the forward gear locking mechanism is arranged on the forward gear positioning mechanism. The fifth-sixth gear shifting fork assembly clamp is used for fixing an automobile fifth-sixth gear shifting fork assembly and comprises a fifth-sixth gear positioning mechanism and a fifth-sixth gear locking mechanism. The fifth-sixth gear positioning mechanism is arranged on the base and adjacent to theforward gear positioning mechanism, and the fifth-sixth gear locking mechanism is arranged on the fifth-sixth gear positioning mechanism. According to the shifting fork assembly combined welding clamp and the shifting fork assembly combined welding system, the welding efficiency, the welding precision and the automation degree of an automobile forward gear and fifth-sixth gear shifting fork assembly welding process are improved, and the labor cost is reduced.

Owner:HANS LASER TECH IND GRP CO LTD +1

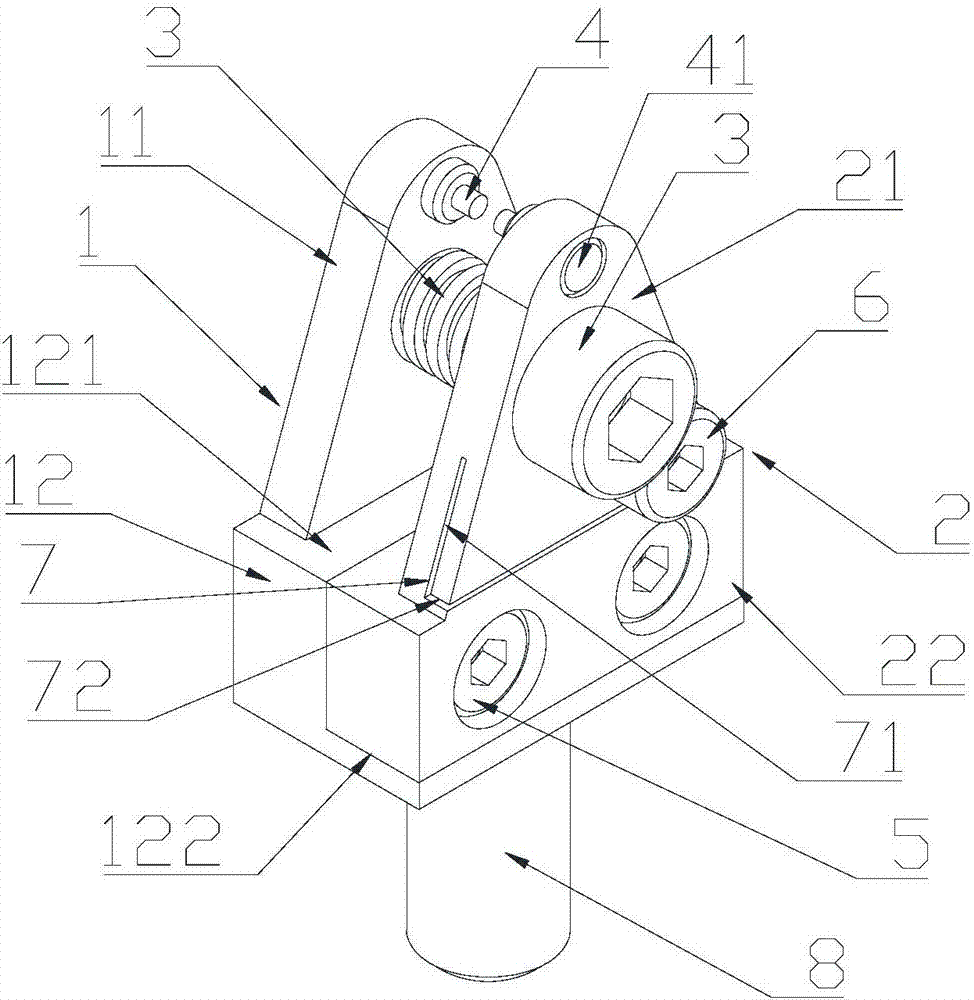

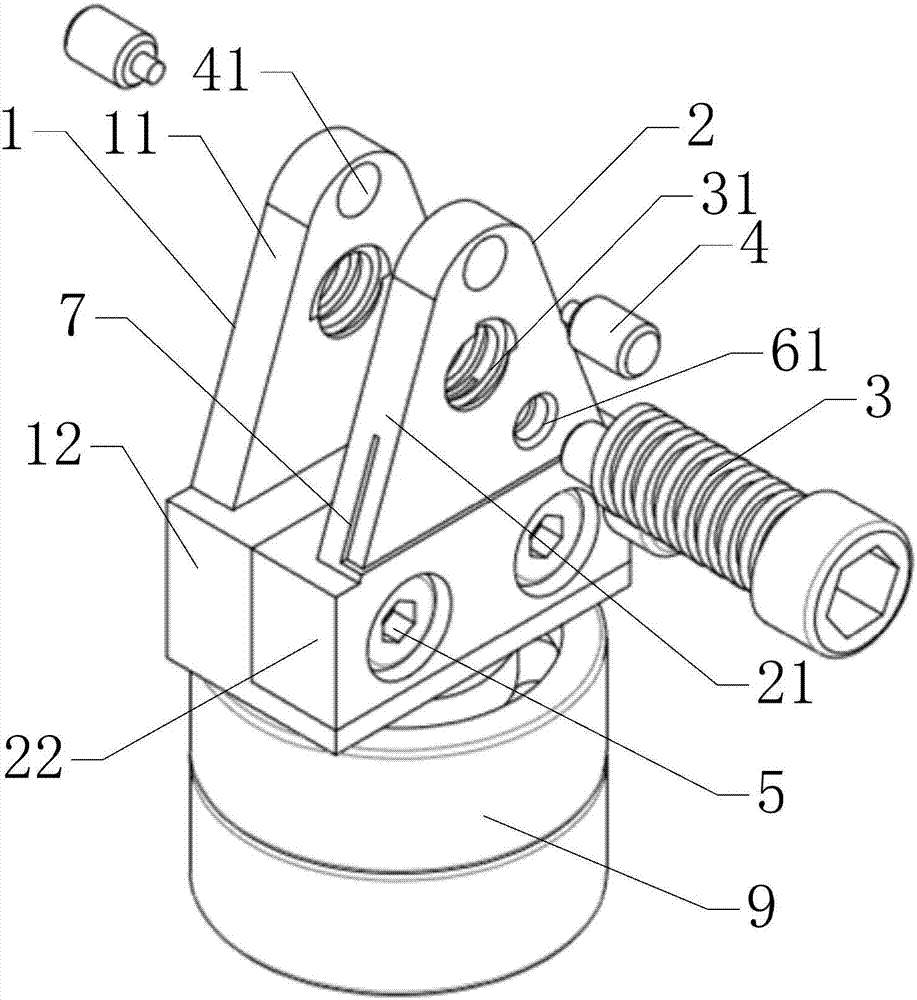

Detachable cutter wheel rack

The invention discloses a detachable cutter wheel rack. The cutter wheel rack is applied to imperforate cutter wheels. The cutter wheel rack comprises a first substrate and a second substrate, the second substrate is detachably installed on the first substrate, and the first substrate comprises a first supporting arm and a stepped first supporting base; the second substrate comprises a second supporting base and a second supporting arm which are oppositely arranged, inner walls of the first supporting arm and the second supporting arm are separately and coaxially provided with a locating shaft, a cross section of the locating shaft is in circular shape, and a locating slot of an imperforate cutter wheel is clamped on the locating shaft; the first supporting arm and the second supporting arm are respectively and coaxially opened with first through holes, the cutter wheel rack also comprises a fastener, and the fastener passes through the first through holes in order and is fastened to the first supporting arm and the second supporting arm. The cutter wheel rack has a simple structure, and can be matched with the imperforate cutter wheel for usage.

Owner:JIAXING WORLDIA DIAMOND TOOLS CO LTD

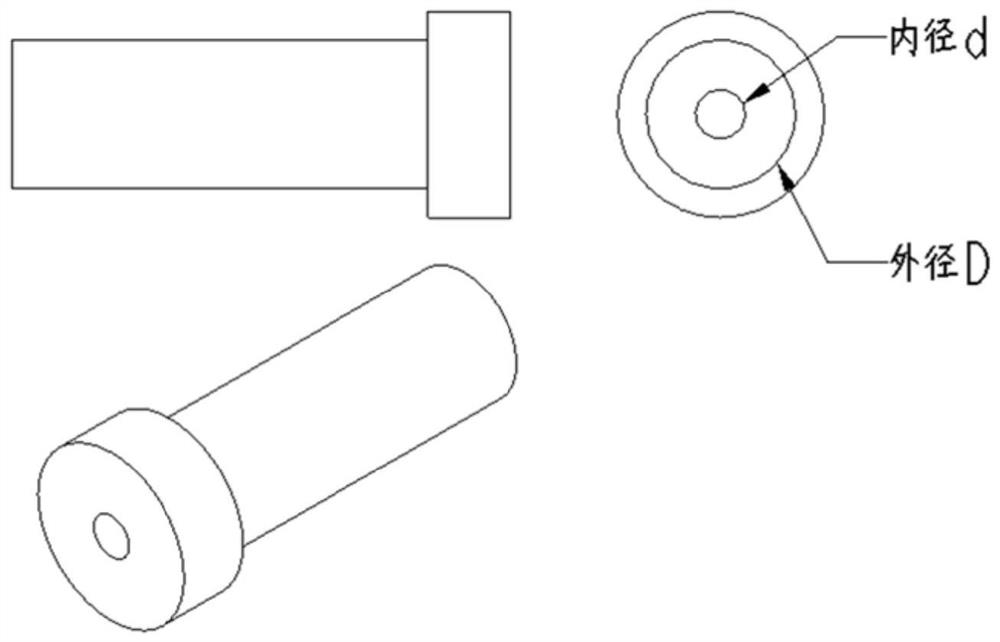

Installation method of slot type prefabricated part of assembly type long-pile wharf

PendingCN114508074AReduce usageReduce construction costsBreakwatersQuaysSupporting systemSupport system

According to the installation method of the assembled high-pile wharf slot type prefabricated component, the slot type component is a component with a built-in cavity, the built-in cavity is cylindrical, the circle center of the built-in cavity coincides with the center of a pile foundation, the diameter of the built-in cavity is 200-400 mm larger than that of the pile foundation, the pile foundation stretches into the component cavity, and the installation method comprises the steps that (1) a ship is in place; (2) erecting and installing an operation platform; (3) hoisting the components by the crane ship; (4) the component is rotated by 90 degrees in the longitudinal direction and the transverse direction; (5) the component is transversely hoisted to a mounting position; (6) falling and mounting the component; (7) adopting a pile top self-supporting method for the slot type component; and (8) after the slot type component is installed, concrete or grouting materials are poured in the built-in cavity of the component in time, so that stable post-poured joint connection is formed. The method is accurate in installation and positioning, use of a large number of waling supporting systems is avoided, and the construction cost is reduced; construction is efficient and convenient, and human input is avoided.

Owner:CCCC THIRD HARBOR ENG

Lifting device for wallboard installation

PendingCN112443143AMeet the installation accuracyImprove installation qualityBuilding constructionsScrew threadIndustrial engineering

Owner:ZHEJIANG YASHA DECORATION

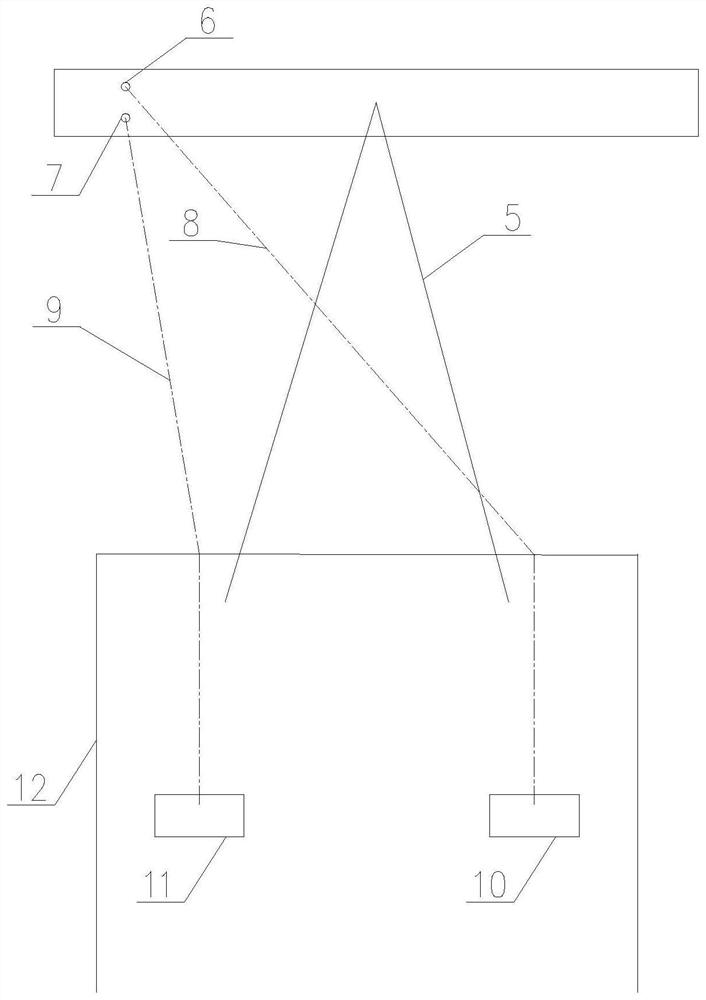

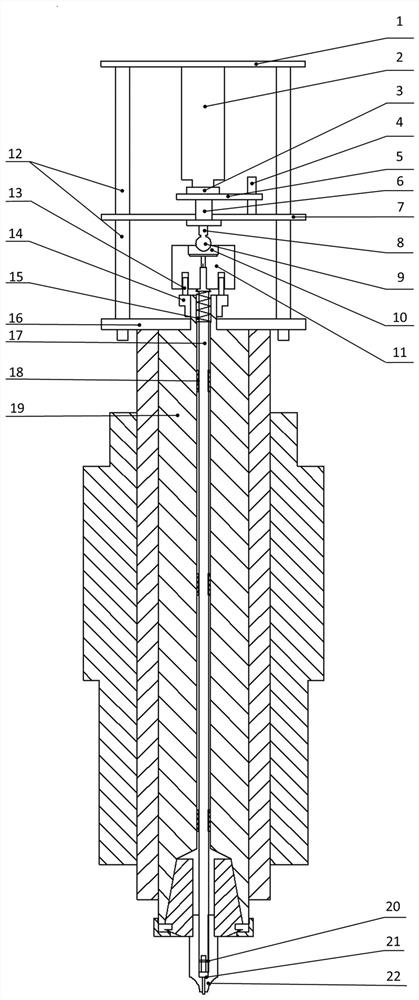

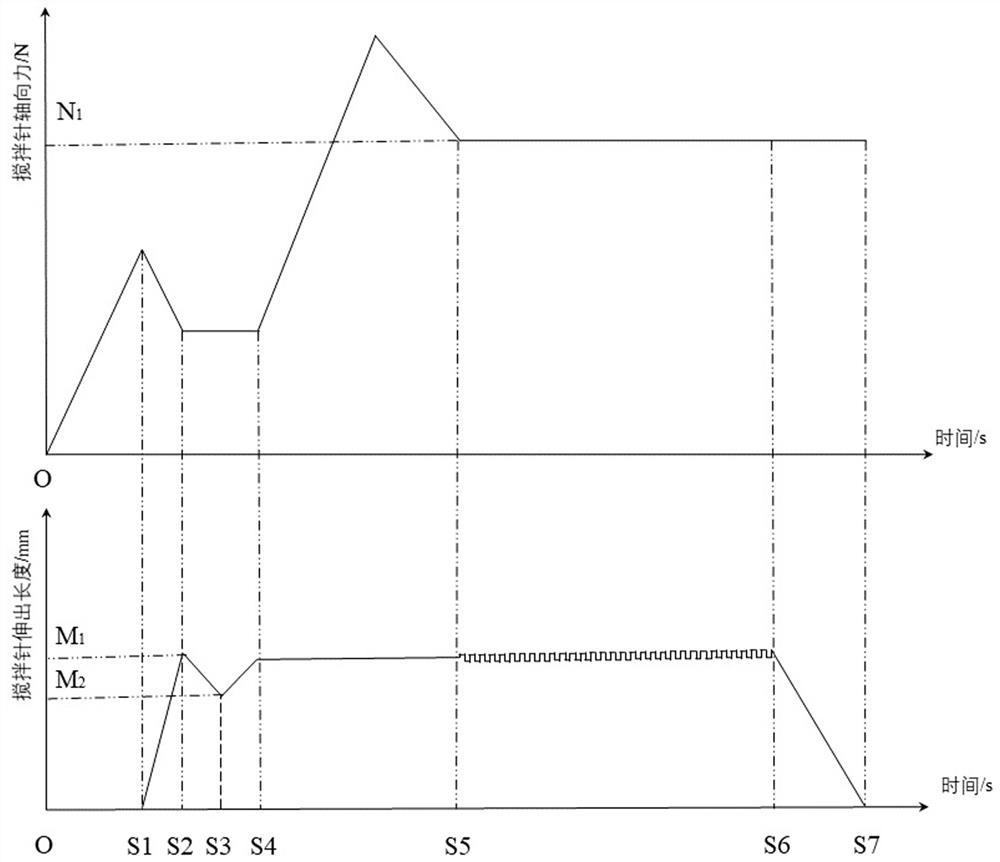

High-rotating-speed stirring friction adjusting method and welding tool with adjustable axial force of stirring needle

ActiveCN112548317AReal-time adjustment of axial forceSolve the installation accuracyNon-electric welding apparatusAxial displacementBall bearing

The invention discloses a high-rotating-speed stirring friction adjusting method and welding tool with adjustable axial force of a stirring needle, and belongs to the technical field of welding equipment. The high-rotating-speed stirring friction adjusting welding tool comprises a stepping motor, a connecting rod, a linear bearing, a connecting plate, a pressing ball, a ball bearing, a ball bearing connecting body, a T-shaped device, a fixing device, an electric main shaft, a bushing, a stirring needle connecting rod, a stirring needle and a shaft shoulder. Downward pressure is applied to thepressing ball through the stepping motor, upward elastic force is applied to the ball bearing connecting body through a spring, the devices are matched with each other, the pressing ball and the ballbearing are connected in a non-fastening mode, and axial displacement of the stirring needle is achieved. The real-time axial force of the stirring needle is obtained by subtracting the product of theelastic coefficient of the spring and the compression amount from the value measured by a pressure sensor mounted at the top end of a push rod of the stepping motor. The welding tool has the beneficial effects that the axial force of the stirring needle can be measured in real time, the compression type connection structure is simple, the tolerance is high, and a keyhole caused by high-rotating-speed friction stir welding can be eliminated.

Owner:JIANGSU UNIV OF SCI & TECH

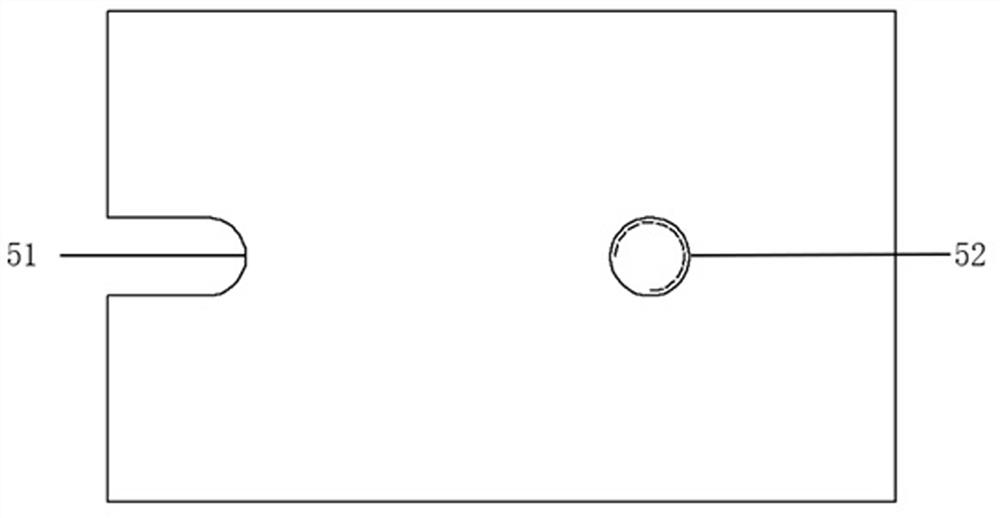

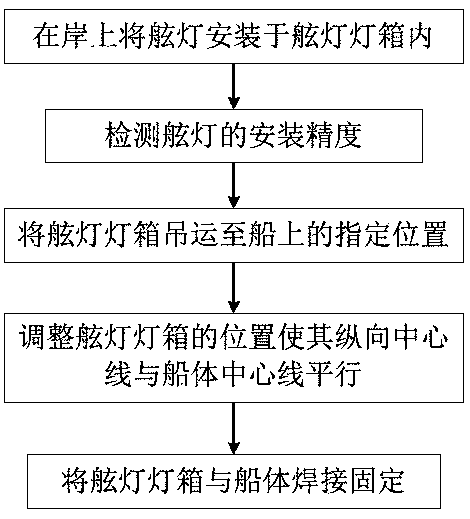

Method for testing side lamps of ships on shores

ActiveCN108195248ASolve the installation accuracyLow costMechanical measuring arrangementsTested timeShore

The invention discloses a method for testing side lamps of ships on shores. The method particularly includes steps of mounting the side lamps in side lamp boxes on the shores; detecting the mounting precision of the side lamps; transporting the side lamp boxes to specified locations on the ships by cranes; adjusting the locations of the side lamp boxes to allow the longitudinal center lines of theside lamp boxes to be parallel to the center lines of hulls; fixedly welding the side lamp boxes with the hulls. The method has the advantages that the method is simple and speedy and is high in reliability; the side lamps are mounted in the side lamp boxes on the shores, the mounting precision of the side lamps is detected, the side lamp boxes are transported onto the ships by the cranes after the precision of the side lamps is detected, accordingly, the problem of incapability of directly checking out the mounting precision of the side lamps on the ships can be effectively solved, the tugboat expense in later periods can be saved, the mooring test time can be saved, and the shipbuilding efficiency can be improved.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

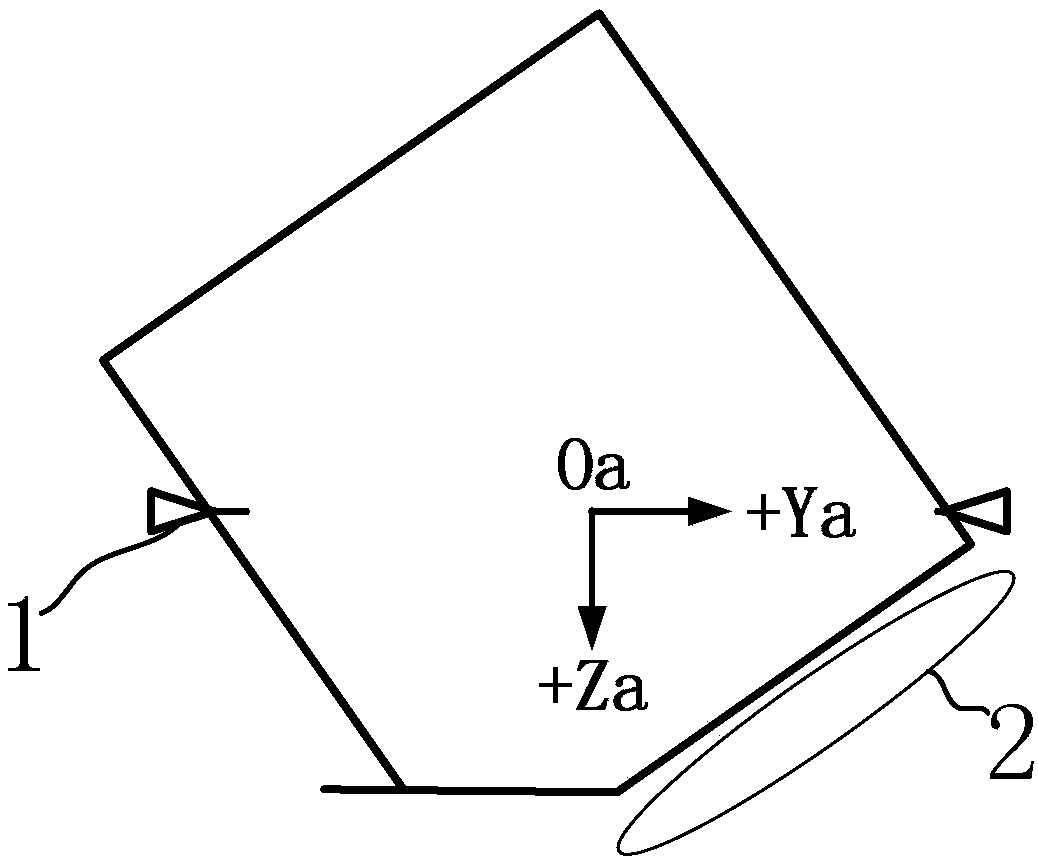

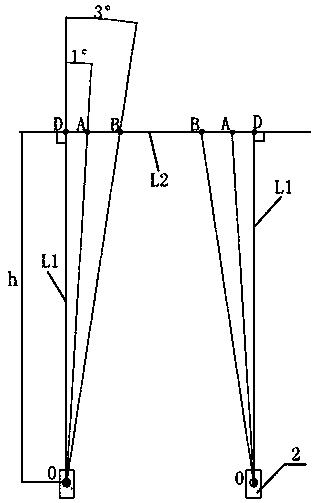

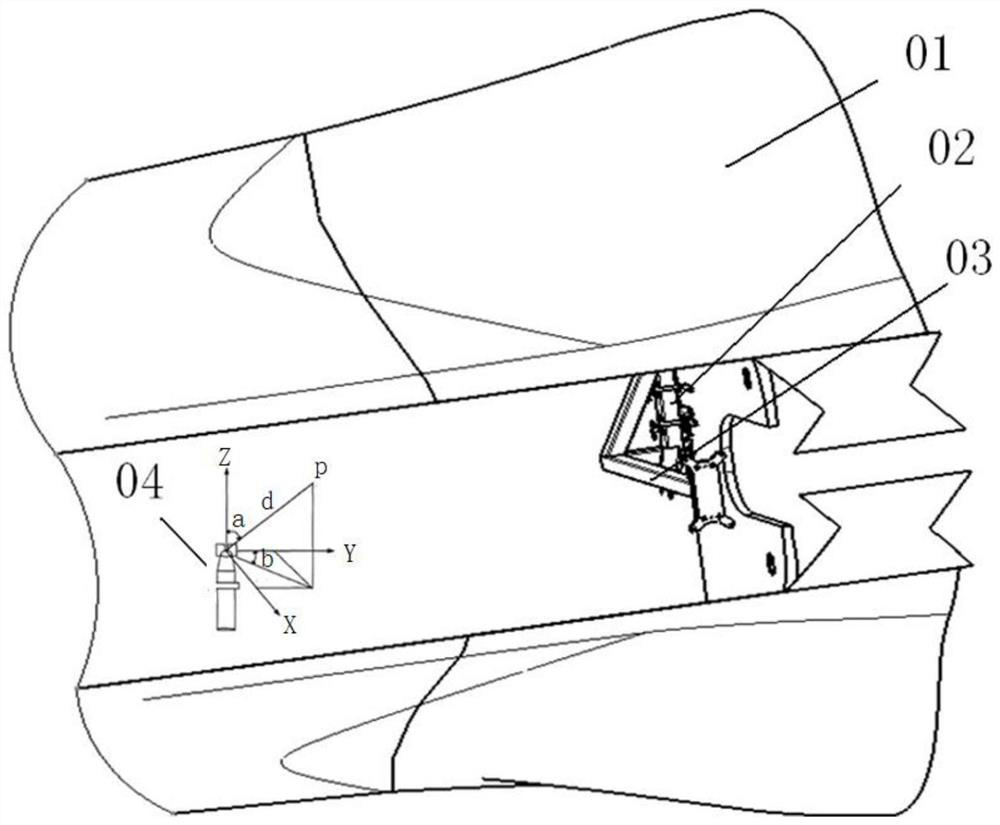

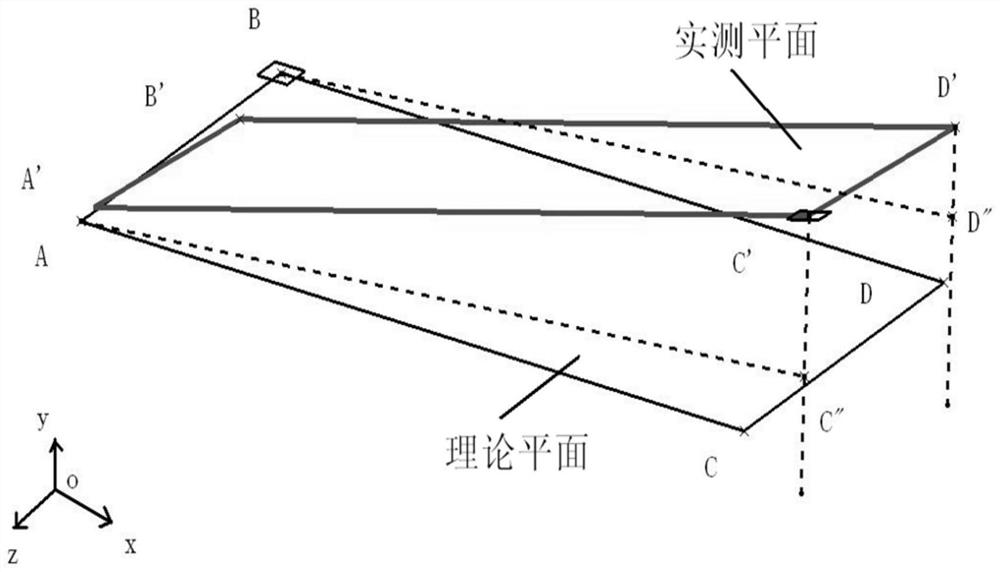

A digital installation method of acceleration sensor

ActiveCN108528755BSolve the installation accuracyImprove the level of assembly technologyAircraft assemblyAviationEngineering

A digital installation method of an acceleration sensor belongs to the field of aviation manufacturing engineering / aircraft assembly. The steps are as follows: firstly, after the aircraft is docked through digital integration, the aircraft coordinate system and the laser tracker space coordinate system are connected through the ground ERS or TB common reference point. The coordinate axes are aligned and fitted. Secondly, connect the transfer tooling, sensor support and the body structure, use a laser tracker to measure the measurement plate, import the measurement results into the theoretical three-dimensional digital model, and establish a spatial comparison between the theoretical plane and the measured plane. Finally, the deflection angle of the actual measured plane relative to the theoretical plane is obtained through digital and analog measurement and calculation, and the optimal compensation scheme for the body structure is obtained by overall translation along the X-axis. After the body structure is compensated, follow the above steps to connect and retest until the Design requirements. The invention can improve the assembly technology level, shorten the assembly production cycle, improve the installation efficiency, and have great significance for the assembly efficiency and quality of fuselage parts.

Owner:SHENYANG AIRCRAFT CORP

Speed measurement Doppler radar damping device

PendingCN111308425ARealize the installation precision requirements of structural technologyRealize structural anti-interference designRadio wave reradiation/reflectionAnti jammingRadar

The invention provides a speed measurement Doppler radar damping device, which mainly comprises a signal processing and receiving combination and an antenna shell, and is characterized by comprising amain shell and a damping system, wherein the upper end and the lower end of the main shell are open, the conformal radome is fixed on the projectile body through a flange frame on the main shell, andthe radian of the conformal radome is conformal with the projectile body; and a vibration reduction system is additionally arranged on the signal processing and receiving combination. The method improves the anti-interference capability, measurement precision and reliability of the Doppler radar, and meets the requirements of the Doppler radar on a high-speed aircraft.

Owner:BEIJING HUAHANG RADIO MEASUREMENT & RES INST

A multi-degree-of-freedom tie rod attitude adjustment and positioning method

ActiveCN112077368BSolve the installation accuracyFirmly connectedDrilling/boring measurement devicesDrill jigsControl engineeringControl theory

Owner:BEIJING SATELLITE MFG FACTORY

A method for manufacturing a shrinking section of a large wind tunnel

ActiveCN113714748BSolve the deformationSolve the installation accuracySustainable transportationAerodynamic testingEngineeringWelding

The invention discloses a method for manufacturing a contraction section of a large-scale wind tunnel. According to the size of the contraction section of the wind tunnel, a reverse profile mold is designed and manufactured; the installation position of the shell frame of the contraction section is marked on the mold mold; the line is marked Finally, re-inspect the assembly position; then perform pair welding on the shrinkage section frame on the mold; check the size of the frame after the welding is completed; turn over after the size inspection is qualified, so that the inner shape faces upward, and then assemble the skin; finally For overall assembly, weld the upper, lower, left and right frames together. This manufacturing method can effectively guarantee the profile size of the shrinking section of a large wind tunnel, and has the advantages of simple operation, saving construction period, and wide application range. Learn and apply value.

Owner:LOW SPEED AERODYNAMIC INST OF CHINESE AERODYNAMIC RES & DEV CENT

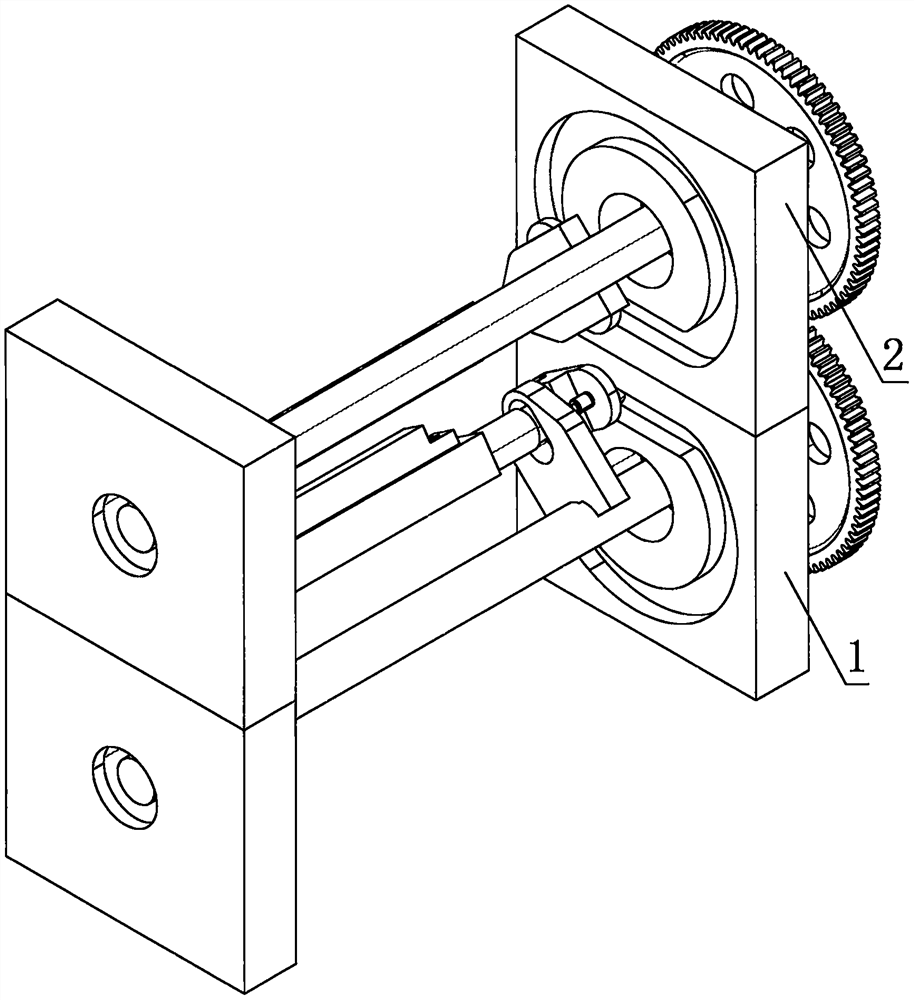

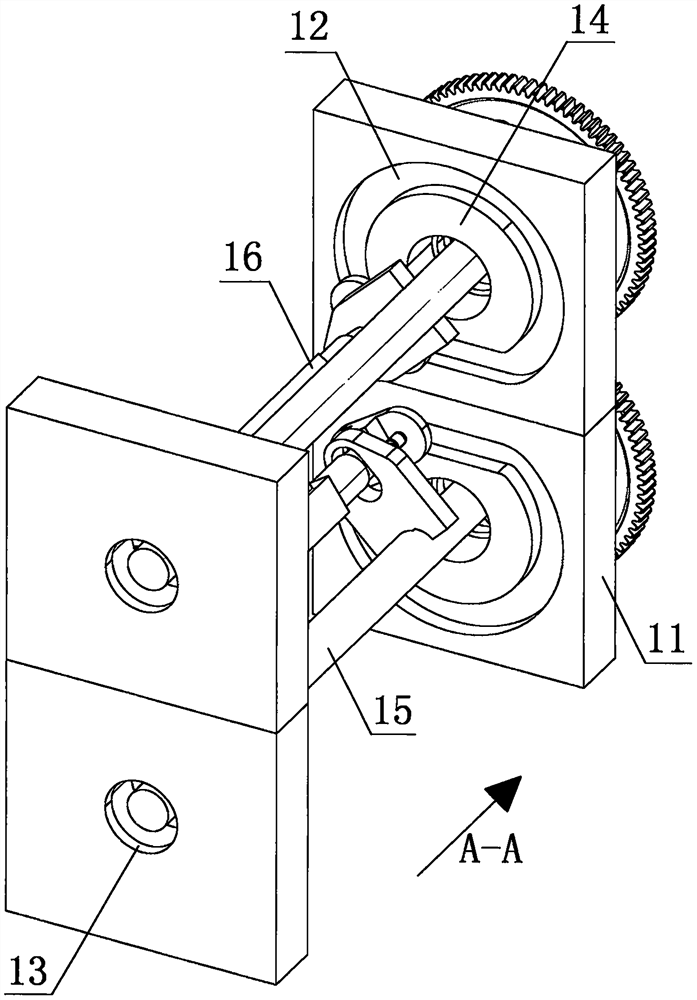

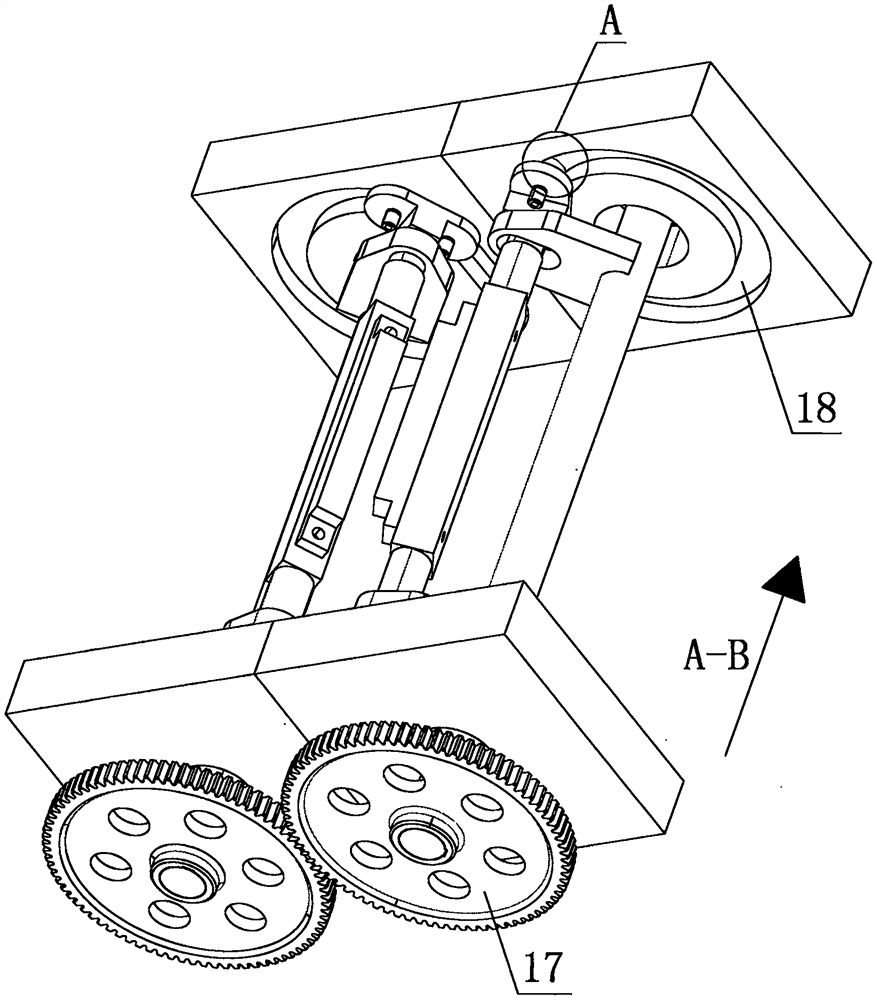

Novel pillow packaging machine transverse heat sealing mechanism and processing technology thereof

PendingCN111824519AImprove heat sealing efficiencyGood heat sealing performanceWrapper twisting/gatheringPackaging automatic controlHeat sealerElectric machinery

The invention discloses a novel pillow packaging machine transverse heat sealing mechanism and a processing technology thereof. Aiming at the problems that a heat sealing mechanism of existing pillowpackaging machines moves up and down to press and heat-seal a packaging bag, a bag opening of the packaging bag is liable to be damaged on one side, and the heat sealing effect is bad, by installing two sets of the same heat-sealing mechanism up and down side by side, a side plate base of the heat-sealing mechanism is provided with mounting grooves and mounting holes to cooperate with a bearing and a screw to be provided with a heat sealer, one end of the screw is provided with a meshing transmission gear and externally connected with a drive motor for rotation, heat sealing strips of the heatsealer simultaneously heat-seal both sides of a bag opening by synchronous and reverse rotation, the transmission gear rotates by a full turn, and the heat sealing strips can complete heat-sealing ofthe bag opening of the packaging bag. Through double-sided heat-sealing, the heat-sealing efficiency of the packaging bag is improved, the heat-sealing effect is also improved, the effect that the bag opening is heat-sealed firmly, does not separate easily and let packaged objects fall out, and the heat sealing mechanism is convenient and practical.

Owner:保定精诺自动化设备制造有限公司

Cantilever crane beam installation process

The invention discloses a cantilever type crane beam installing technology. The cantilever type crane beam installing technology comprises the steps that bracket column and crane beam connecting hole adjustment is conducted, chambering installation is adopted, and strengthening plates are additionally arranged on the face not influencing tracks and are drilled; elevation adjustment is conducted, after bracket column installation is finished, whole-course retest is conducted on the bracket column elevation firstly, the manufactured section height of each crane beam is checked, and after errors are found, and abrasive cushion plates are additionally arranged on the surfaces of bracket columns for adjustment; upper beam and lower beam track horizontal distance adjustment is conducted, if adjustment is conducted towards the inner sides of the bracket columns, abrasive cushion plates are additionally arranged at the upper beam and bracket column connecting positions, if adjustment is conducted towards the outer sides of the bracket columns, a notch is formed in an upper beam through repairing, meeting of the requirement for the adjusted distance is the standard, then, flange slabs the same in size are additionally made for equal-strength welding, and the adjusted distance for the outward movement is achieved for the upper beam. By the adoption of the cantilever type crane beam installing technology, construction precision control, construction scheme optimization and integral structure safety control can be more efficiently achieved

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD

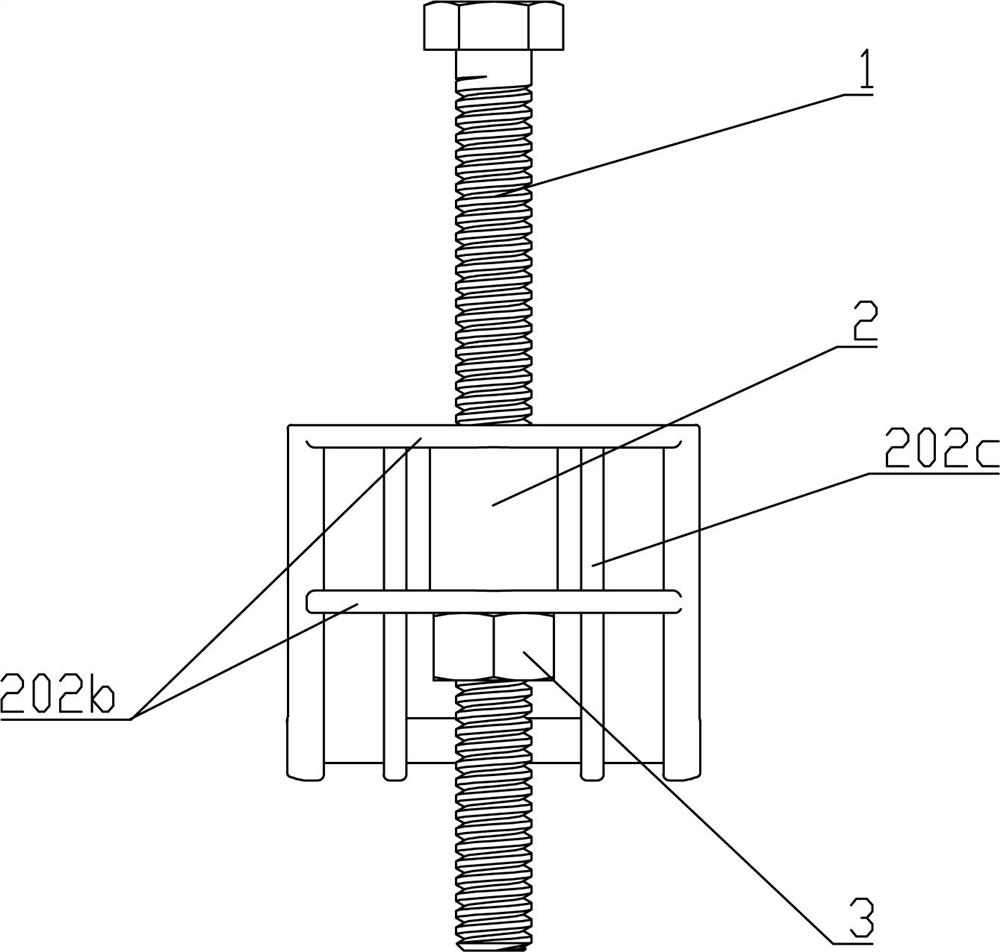

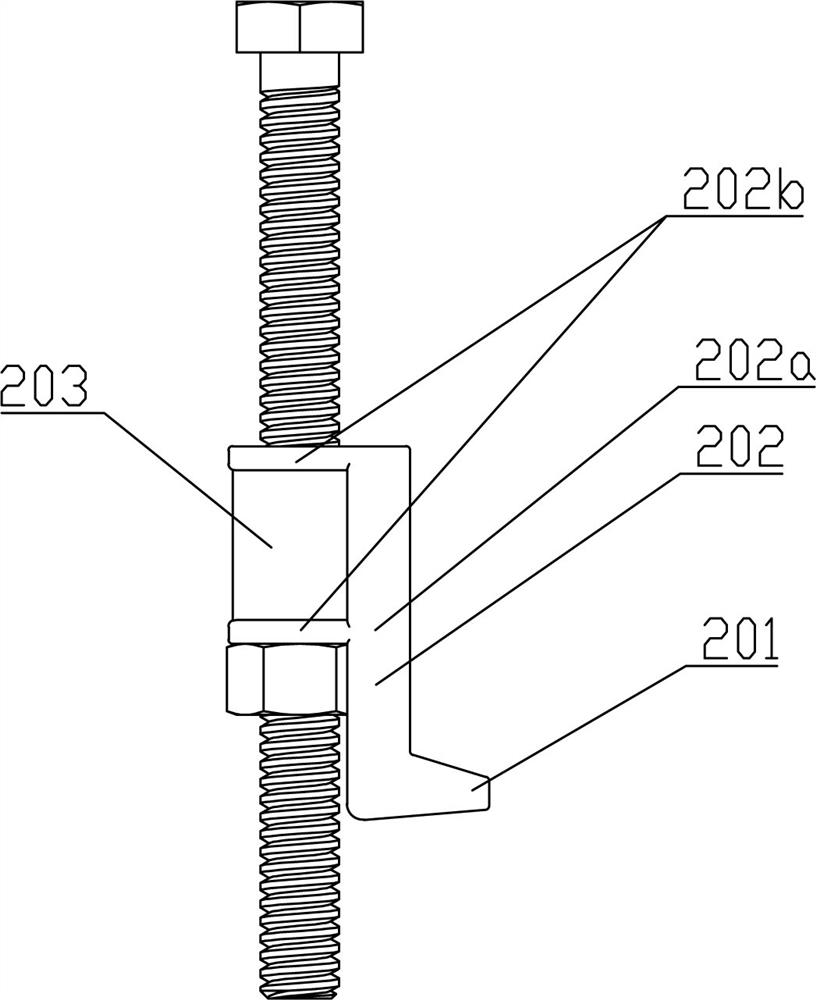

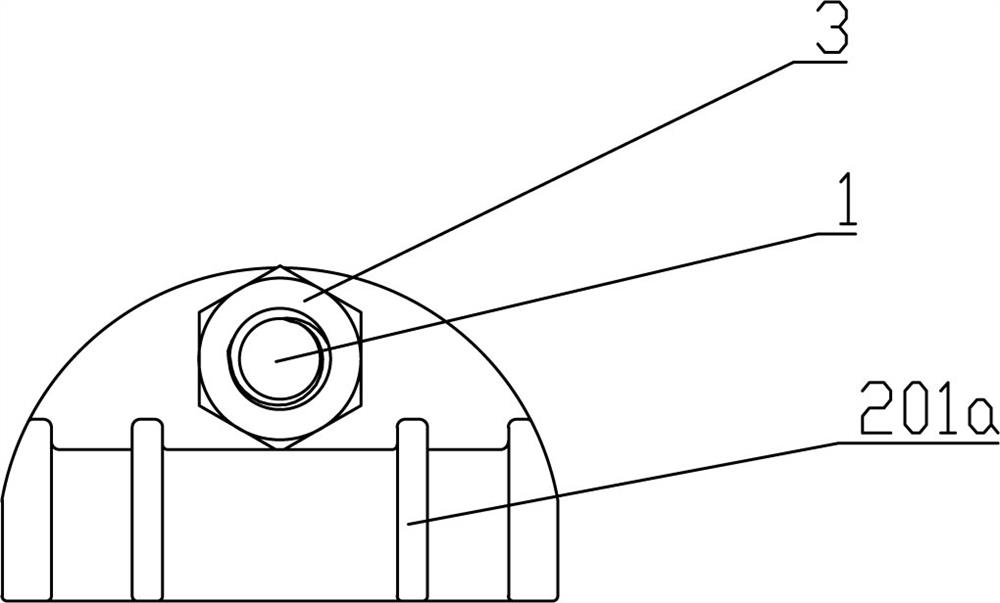

Pull screw reinforcing mechanism and reinforcing mechanism construction method

InactiveCN110295746ASolve the damageSolve the accuracy problemAuxillary members of forms/shuttering/falseworksEngineeringMechanical engineering

Owner:CHINA FIRST METALLURGICAL GROUP

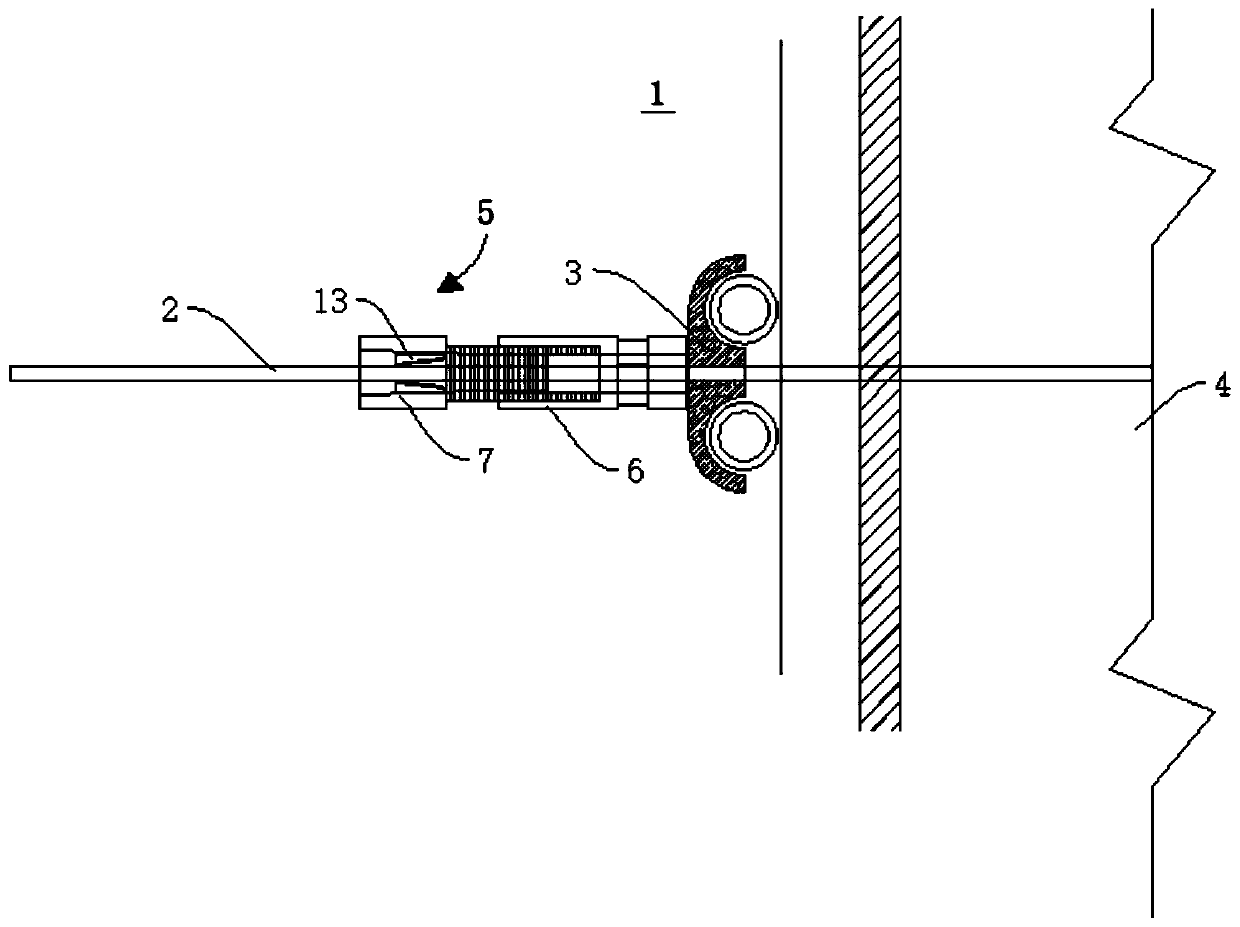

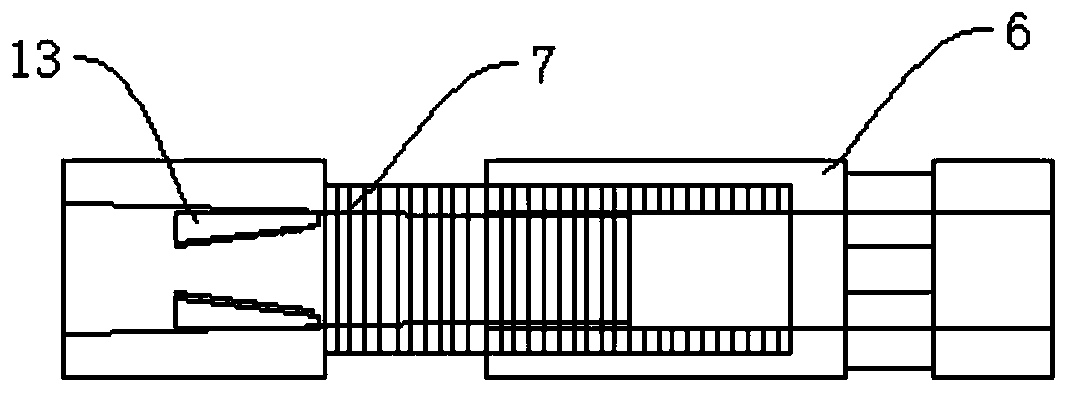

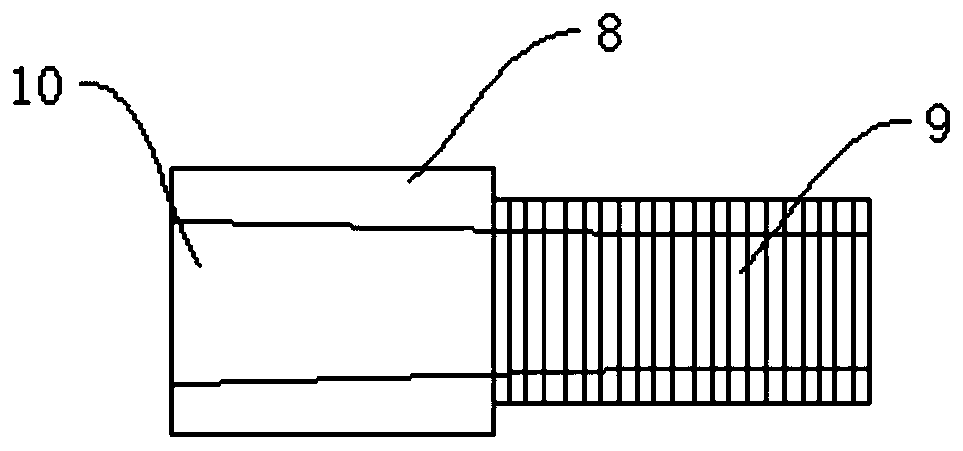

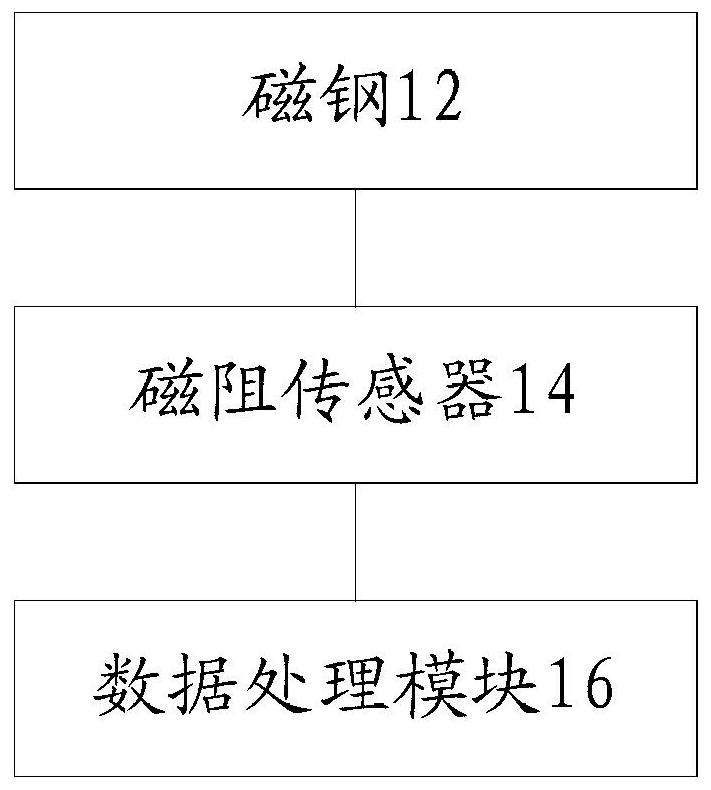

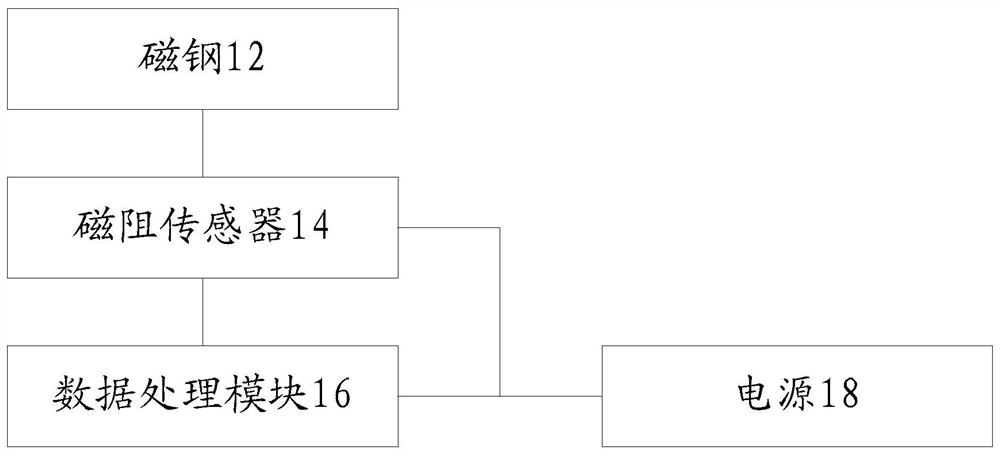

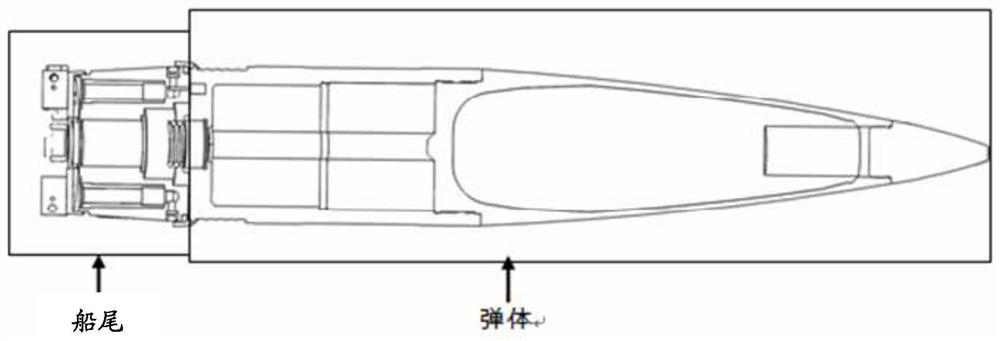

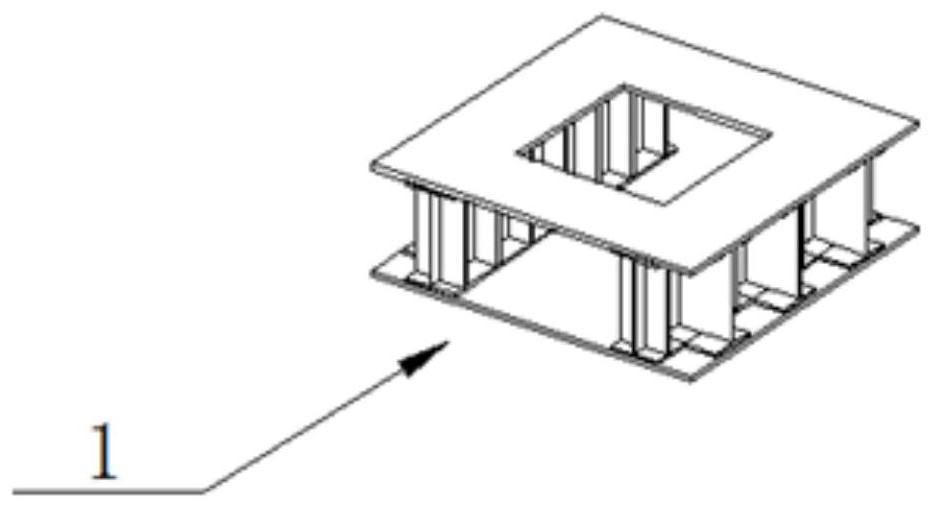

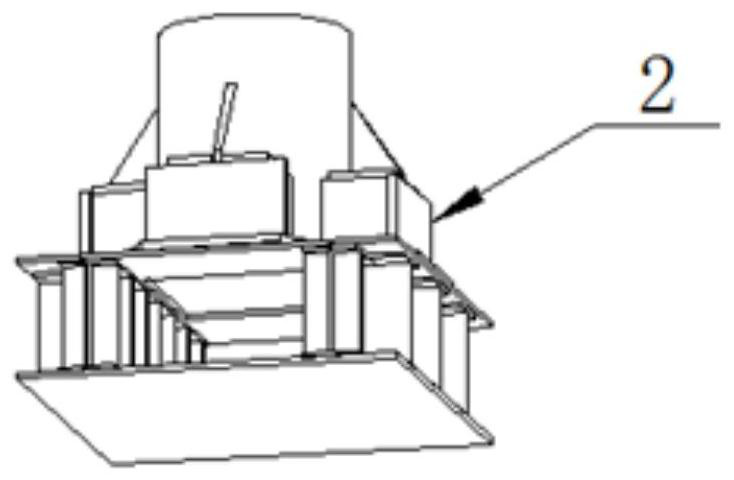

Relative rotation speed determination device

PendingCN113252932AAvoid volumeSolve the impact resistanceDevices using electric/magnetic meansFlight vehicleEngineering

The invention provides a relative rotation speed determination device. The elative rotation speed determination device comprises magnetic steel which is disposed on a housing of a projectile body of an aircraft, is used for generating a magnetic field, and carries out the first coaxial rotation with the projectile body according to a first speed; a magnetoresistive sensor which is connected with the magnetic steel and the data processing module, and is used for acquiring rotating speed data of a magnetic field generated by the magnetic steel, which is changed along with the first coaxial rotation, and sending the rotating speed data to the data processing module; and a data processing module which is used for determining the relative rotating speed between the stern of the aircraft and the projectile body according to the rotating speed data. By the adoption of the technical scheme, the problems that in the related technology, a device for determining the relative rotating speed between the two parts of equipment is large in installation occupied space and cannot adapt to large overload are solved.

Owner:BEIJING INFORMATION SCI & TECH UNIV +2

Installation process of the shock absorber for the topside module of the floating production storage and offloading unit

ActiveCN109625167BImprove shock absorptionHigh precisionVessel designingOil processingThermodynamics

An installation process of a shock absorber for an upper module of a floating production oil storage and unloading device adopts the following steps: 1: placing a hollow pad on the ground; 2: placing the upper module on the hollow pad, and reducing the Install the upper plate of the shock absorber on the upper module; 3: Mark the outer contour of the shock absorber and the column base of the upper module on the hull base; 4: Install the lower plate of the shock absorber on the hull base; 5: Install the shock absorber on the bottom plate of the shock absorber; 6: Install the guide plate for the upper module in place; 7: Lift the upper module to the hull base; 8: Connect the stainless steel plate to the base of the upper module column; 9: Remove the upper module positioning guide plate and install the stopper; ten: Install the elastic support. The invention not only solves the problem of the stability of the upper module equipment in the process of oil processing, but also improves the shock absorption performance of the upper module; moreover, it also solves the problems of the installation accuracy and operation efficiency of the upper module.

Owner:OFFSHORE OIL ENG QINGDAO +1

Flow field calibration device

InactiveCN104390759BAvoid troubleEasy to disassemble and assemble repeatedlyAerodynamic testingLinear motionSprayer

Provided in the invention is a flow field calibration apparatus comprising a mounting frame, a support frame, a measuring mechanism and a driving mechanism. The mounting frame is fixed at an upper side wall and a lower side wall of a sprayer nozzle outlet of a test cabin by bolts. The support frame consists of an upper inclined support unit and a lower inclined support unit; the upper inclined support unit and the lower inclined support unit are respectively provided with mounting inclined surfaces for installing the measuring mechanism and are respectively fixed right above and below the sprayer nozzle by the mounting frame, wherein the mounting inclined surfaces of the upper inclined support unit and the lower inclined support unit are respectively parallel to the axis of the sprayer nozzle. Bolt holes that are arranged in rows are respectively formed in the upper inclined support unit and the lower inclined support unit; and bolt holes that are arranged in multiple rows and correspond to each other are formed in the walls of the upper inclined support unit and the lower inclined support unit along the axis direction of the sprayer nozzle. The measuring mechanism includes a measuring frame, a measuring rake group, and an adapter piece; the measuring frame is installed at the support frame; and the measuring rake group is installed at the measuring frame. The driving mechanism is installed at the measuring mechanism, so that the measuring rake group can be driven to make linear motion at the measuring frame.

Owner:BEIJING AEROSPACE YISEN WIND TUNNEL ENG TECH

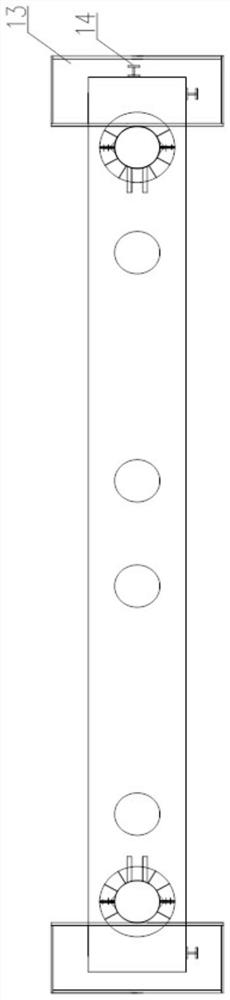

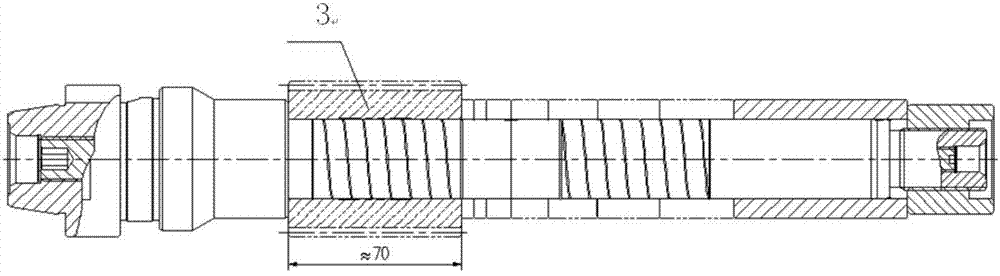

Hydraulic expansion type hob edge grinding cutter rod and use method thereof

PendingCN107571102AAvoid installation accuracy problemsGuaranteed Runout RequirementsMilling cuttersGrinding work supportsEngineeringHydraulic pressure

The invention discloses a hydraulic expansion type hob edge grinding cutter rod and a use method thereof. The hydraulic expansion type hob edge grinding cutter rod comprises a cutter rod body and a hob installed on the cutter rod body, wherein the tail end of the hob is clamped by a nut and a gasket; the cutter rod body is filled with liquid; a pressurizing screw is arranged at the front end of the cutter rod body; and the cutter rod body expands by extruding the liquid through the pressurizing screw so as to clamp the hob. The hydraulic expansion type hob edge grinding cutter rod is adopted,so that the tool table run-out requirement during edge grinding can be guaranteed only through one-time clamping, and the problem about installation accuracy caused by abrasion of the cutter rod bodyis avoided. The situation that the run-out value of the parts, at the two ends of the hob, of the tool table is within 0.01 mm can be guaranteed through one-time clamping. About 2800 hobs are subjected to edge grinding totally at present, and the situation that the edge grinding is unqualified does not appear.

Owner:XIAN FASHITE AUTOMOBILE TRANSMISSION CO LTD

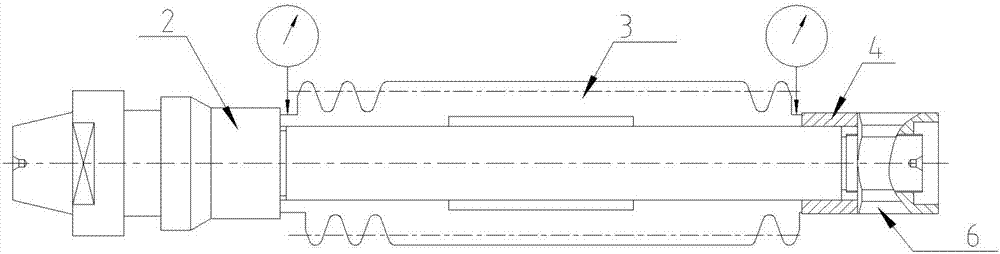

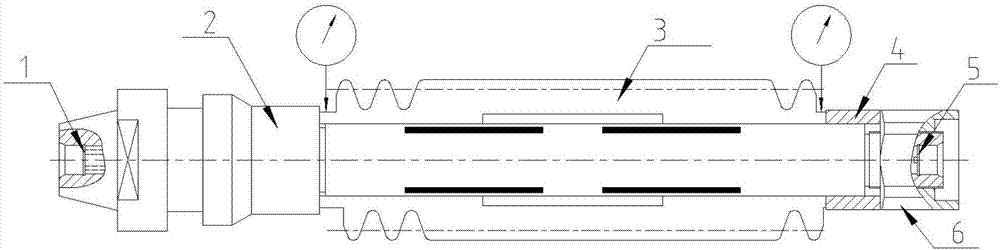

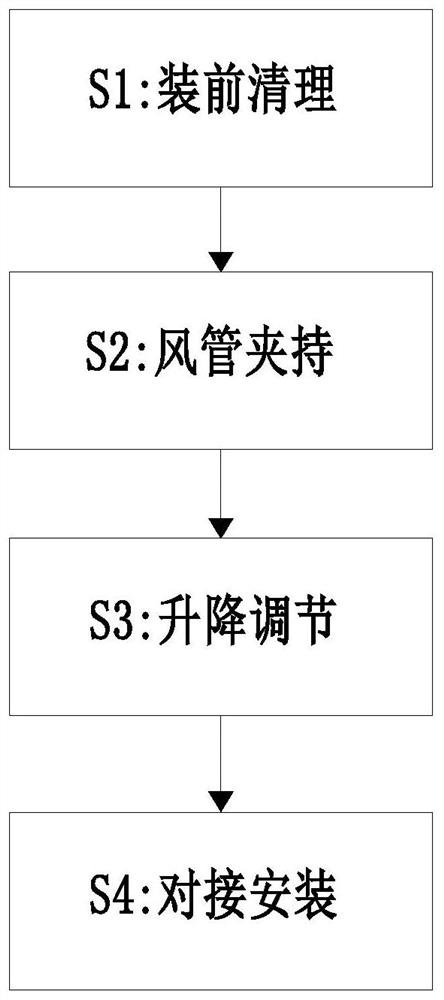

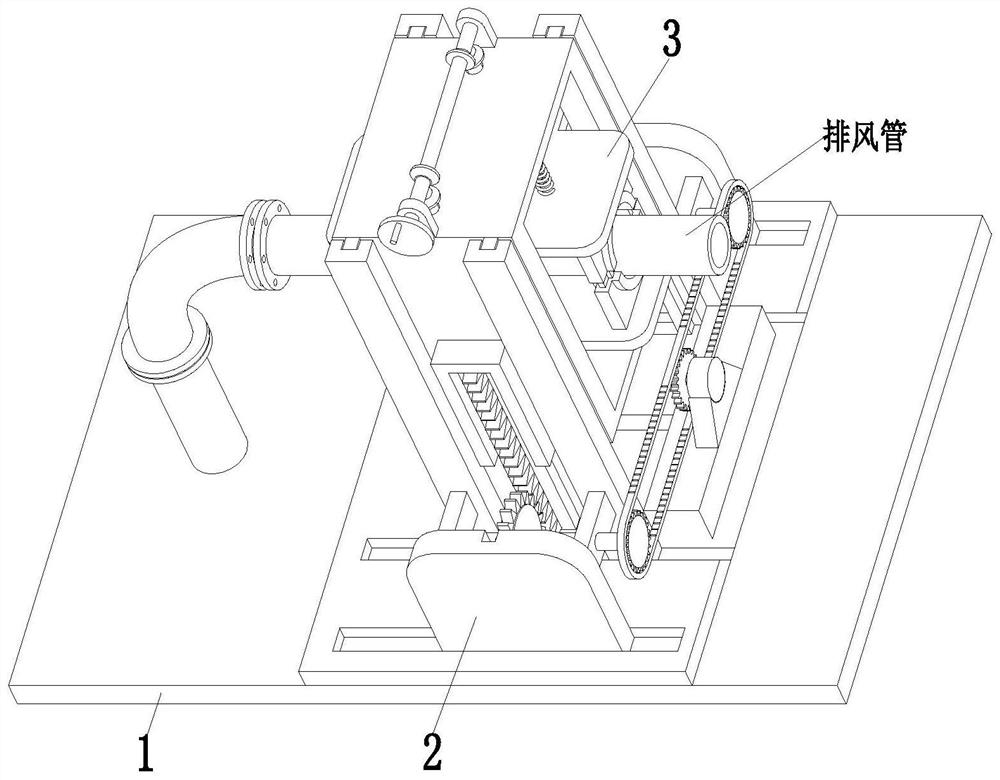

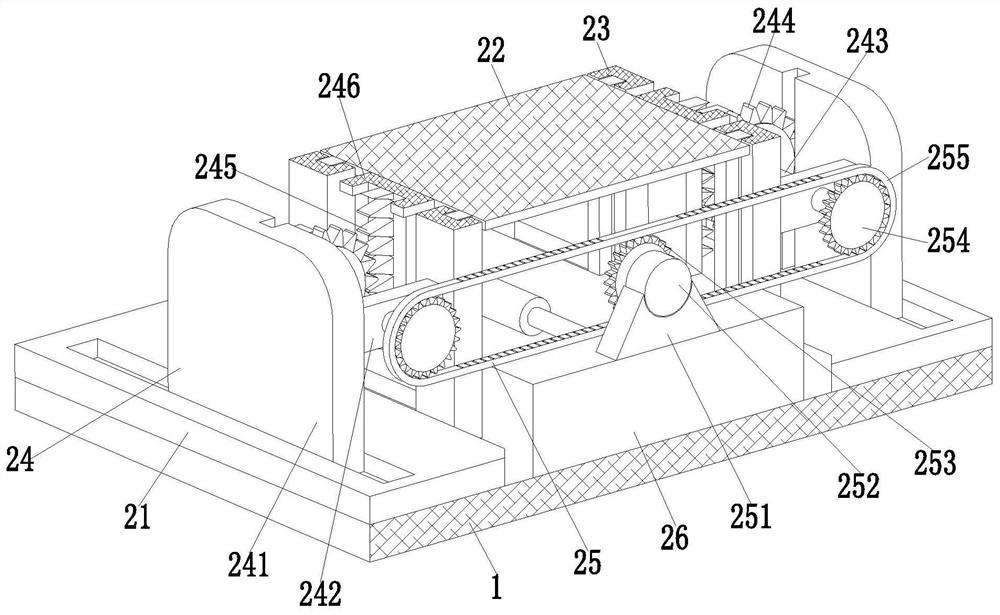

Exhaust tube mounting construction method for building industrial fresh air system

InactiveCN113310205ASolve the installation accuracySolve the problem of poor docking accuracy and easy air leakage at the interfaceDucting arrangementsLighting and heating apparatusButt jointArchitectural engineering

The invention relates to an exhaust tube mounting construction method for building an industrial fresh air system, an exhaust tube mounting construction device for building the industrial fresh air system is used. The exhaust tube mounting construction device for building the industrial fresh air system comprises a bottom plate, a lifting butt joint mechanism and a clamping mechanism, wherein the lifting butt joint mechanism is mounted on the bottom plate; and a clamping mechanism is mounted on the lifting butt joint mechanism in a sliding fit mode. The exhaust tube mounting construction device can solve the problems that an existing exhaust tube mounting construction device cannot stably clamp an exhaust tube before the exhaust tube is installed, so that the exhaust tube is unstable and prone to deviation during lifting mounting, and the mounting precision of the exhaust tube is affected, and further can solve the problems that an existing exhaust tube mounting construction device cannot stably lift the exhaust tube to be flush with the exhaust tube to be subjected to butt joint mounting, so that the exhaust tube is prone to inclination during butt joint mounting, the butt joint precision of the connector is poor, and air leakage is prone to occurring to the connector.

Owner:方教勇

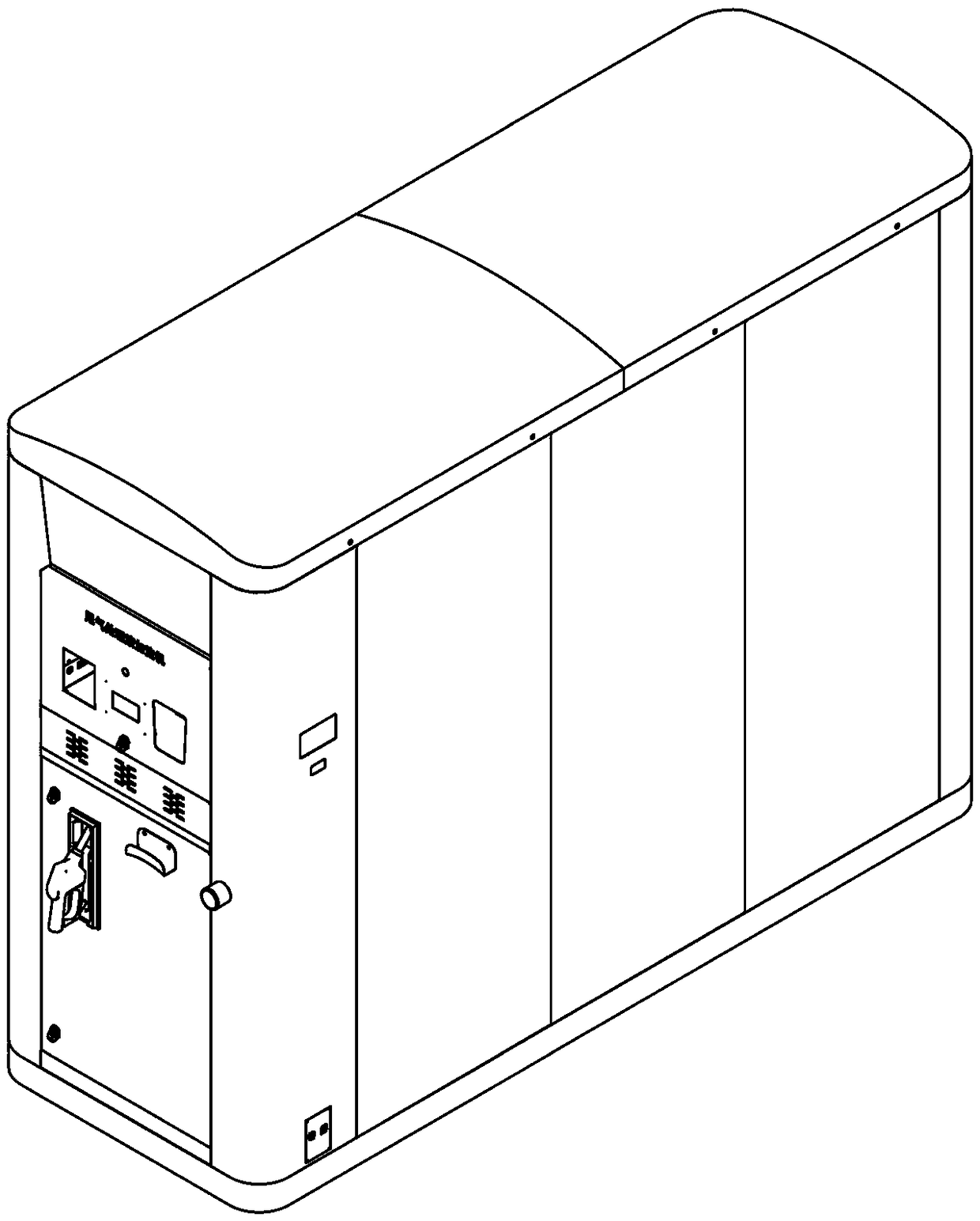

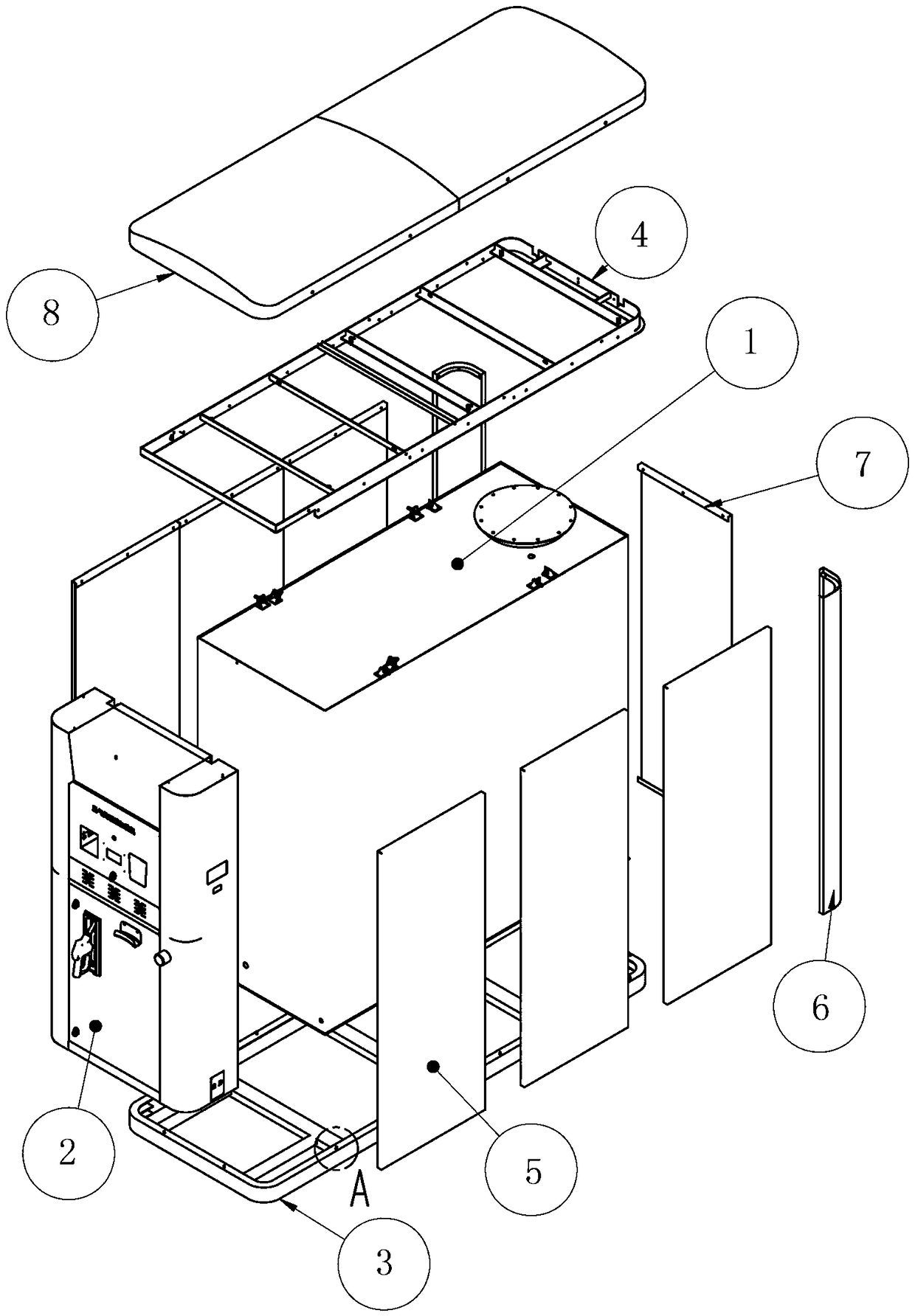

Integrated filling machine with outer encircling mechanism

PendingCN108557750ASolve the installation accuracyLiquid transferring devicesLiquid storage tankEngineering

The invention relates to an integrated filling machine with an outer encircling mechanism, which can be applied to the field of filling various liquids. The filling machine comprises a liquid storagetank and a filling machine matched in use. The filling machine is characterized by further comprising a base frame, a top fixed frame and a plurality of outer encircling plates, wherein the liquid storage tank and the filling machine are fixed to the base frame, and the top fixed frame is fixed to the tops of the liquid storage tank and the filling machine; the plurality of outer encircling platescoat the liquid storage tank and the filling machine, and each outer encircling plate is mounted through the base frame and / or the top fixed frame. The position of the top fixed frame is adjusted through a left-right adjusting device, a front-back adjusting device and an up-down adjusting device on the top of the liquid storage tank and the top fixed frame is fixed to the liquid storage tank, sothat influence on mounting precision and appearance of the encircling plates is avoided as the dimensional deviation of the liquid storage tank and the base is relatively great.

Owner:ハンツォウトップリフトマシーナリーカンパニーリミテッド

A construction method of continuous tie-rod steel pipe arch bridge

ActiveCN104562936BStress state is the sameSolving the Linear Control ChallengeBridge erection/assemblyArch-type bridgeAbutmentStressed state

The invention relates to a bridge construction method, in particular to a construction method for a continuous tie bar steel tube arch bridge; the construction method aims at solving the problems that the construction cycle is long, the potential safety hazard is big, the construction difficulty is big, and the like by adopting the existing support method. The construction method comprises the following steps of performing construction on assembling supports for a steel tube arch; processing the steel tube arch by stages, and hoisting the steel tube arch onto the assembling supports; installing temporary abutment supports and opposite-pull steel stranded wires to enable the steel tube arch to form a bowstring whole bearing structure; supporting the steel tube arch by the temporary abutment supports instead of the assembling supports, and removing the whole assembling supports; installing a longitudinal movement pushing system for the steel tube arch to enable the steel tube arch to move forward; welding the steel tube arch after the steel tube arch are pushed in place. Firstly, The difficult problem that the safety risk is big due to the fact that the pushing distance is far and the steel tube arch needs to cross the existing railways and highways after the steel tube arch is assembled is solved; secondly, the problem that arch feet are low in installation accuracy is solved, so that the linearity and design linearity of the whole steel tube arch are enabled to be consistent, and the stress state and the design state of the steel tube arch are finally enabled to be consistent; thirdly, the stress state and the design state of a beam body are consistent, so the construction quality is finally guaranteed.

Owner:CHINA RAILWAY SIXTH GRP CO LTD

Construction method of a curved cable trunking structure

ActiveCN107230956BAchieve installationRealize the constructionCable installation apparatusButt jointTrunking

The invention discloses a construction method of an arc cable wire slot structure. The arc cable wire slot structure comprises a cable wire slot and a wire slot bearing part, wherein the cable wire slot comprises two segments of linear wire slots and an arc wire slot for connecting the two sections of linear wire slots; the arc segment wire slot is slot-shaped and comprises two connecting units with the same shape and size; two connecting units are in left-right mirroring butt joint, each connecting unit comprises a bottom plate, and a long ledge and a short ledge which are respectively vertical to the bottom plate. The construction method comprises the steps of computing the bend angle of the arc segment wire slot, counting the angle and the type of the arc segment wire slot, drawing a blank part detail drawing by using the 3D software, processing to produce the arc segment wire slot and numbering, paying off according to the mounting of a wire slot support by a design drawing, and mounting the wire slot. The construction method can satisfy the demand of the rigid cable wire slot mounting when the municipal integrated trench construction arc structure part is high in occupancy, the arc wire slot is multiple in specification and model, the cable laying quality requirement is high, and the mounting space arrangement difficulty is large.

Owner:BEIJING URBAN CONSTR FIFTH CONSTR GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com