Novel pillow packaging machine transverse heat sealing mechanism and processing technology thereof

A technology of pillow packaging machine and horizontal heat sealing, which is applied in the directions of packaging sealing/fastening, packaging, transportation packaging, etc., which can solve the problems of poor heat sealing effect of packaging bags, long heat sealing time, easy opening of bags, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

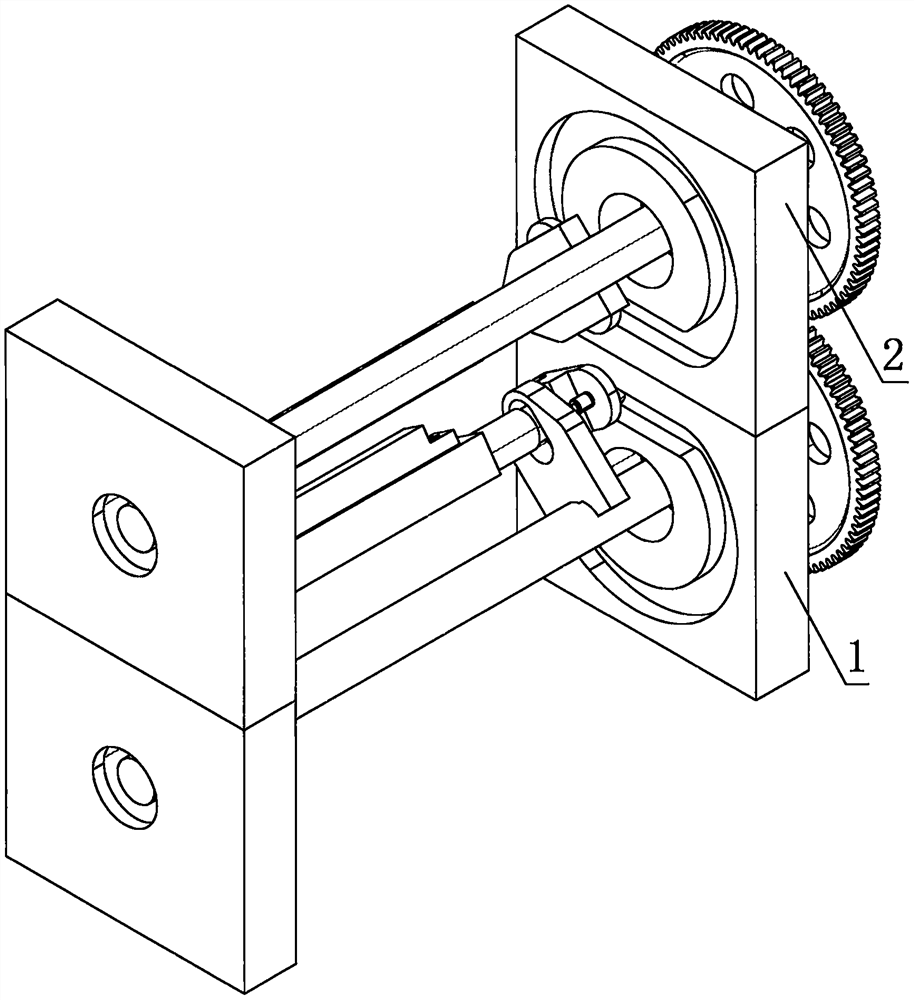

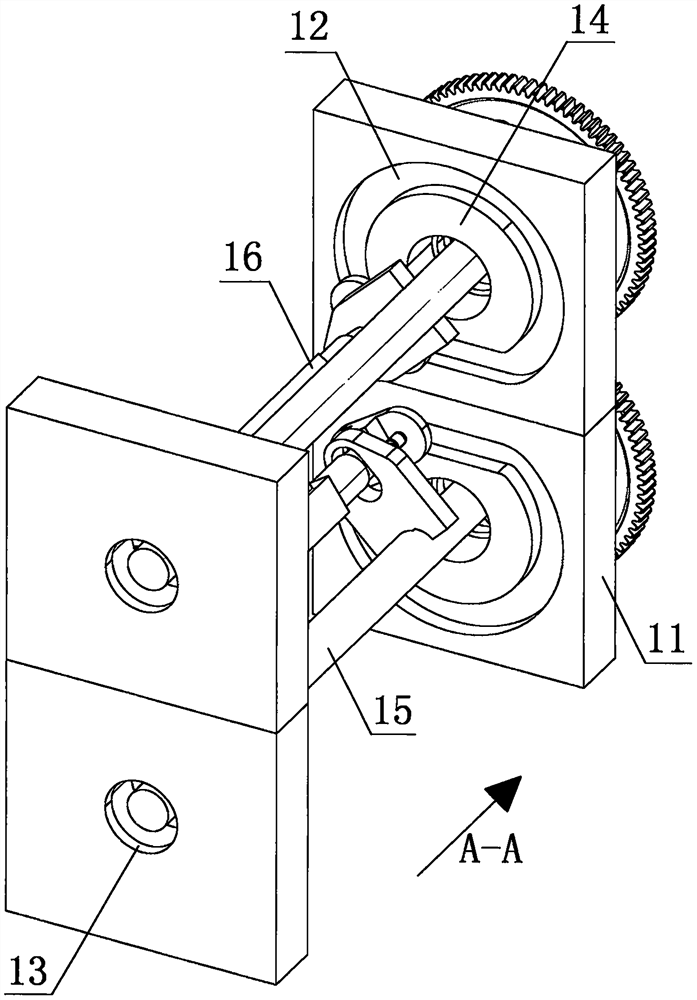

[0037] see figure 1 , figure 2 , image 3 , Figure 6 and Figure 7 , a new horizontal heat-sealing mechanism for pillow packaging machines, including a first heat-sealing mechanism 1 and a second heat-sealing mechanism 2, the second heat-sealing mechanism 2 is exactly the same as the first heat-sealing mechanism 1, and the second heat-sealing mechanism 2 are installed side by side on the upper end of the first heat-sealing mechanism 1.

[0038] The first heat-sealing mechanism 1 includes a side plate base 11, an installation groove 12, an installation hole 13, a bearing 14, a screw rod 15, a heat sealer 16 and a transmission gear 17, and two identical side plate bases 11 are respectively arranged side by side in parallel, And the middle part between the side walls of the side plate base 11 is respectively provided with corresponding mounting grooves 12, and the middle part of the mounting grooves 12 is provided with mounting holes 13, and the inner cavities of the mounti...

Embodiment 2

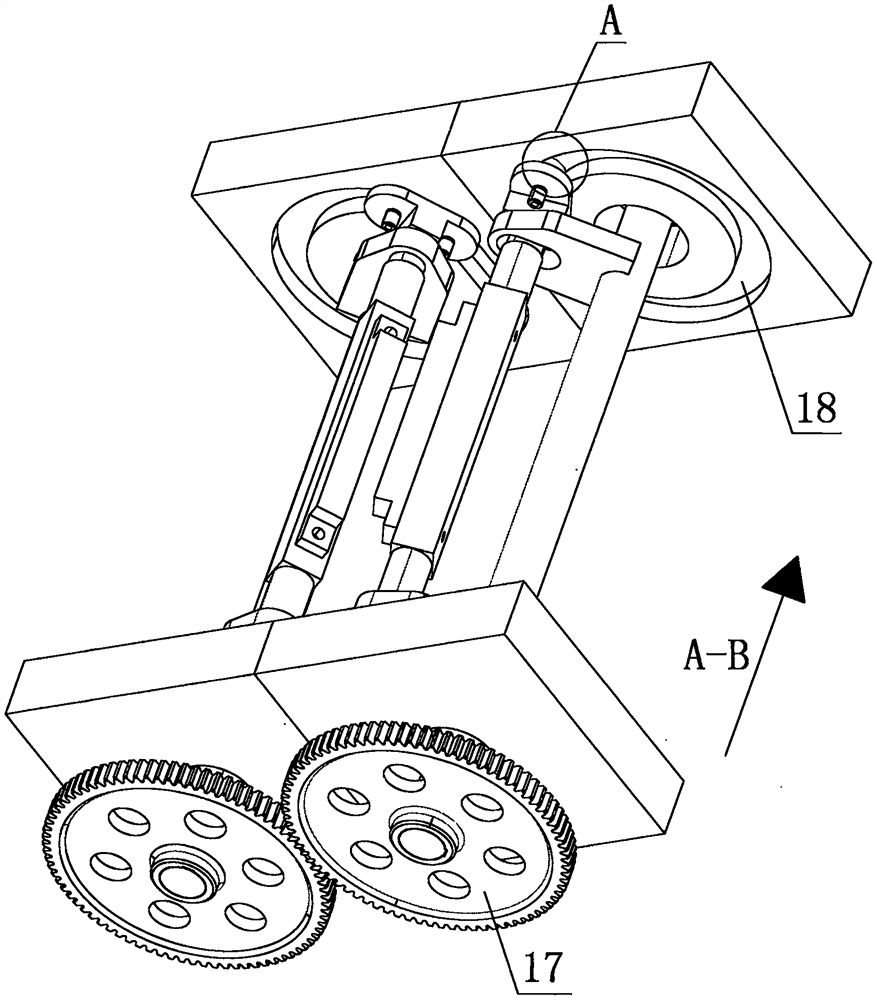

[0041] see figure 2 , Figure 4 , Figure 5 , a new horizontal heat-sealing mechanism for pillow packaging machines. The heat-sealer 16 includes a fixed plate 161, a limit hole 162, a cross bar 163, a heat-sealed strip 164 and an end connector 165. The fixed plate 161 is respectively arranged on two sides of the screw rod 15. On the outer wall of the end close to the bearing 14, the fixed plate 161 and the screw rod 15 form an integral structure, and the side walls of the fixed plate 161 are respectively provided with corresponding limit holes 162, and the inner cavities of the limit holes 162 are respectively sleeved with horizontal At both ends of the rod 163, a heat-seal strip 164 is arranged on one side of the outer wall of the cross bar 163, and the two ends of the cross bar 163 respectively extend to the outside of the fixing plate 161, and the end outer walls are respectively sleeved with end connectors 165, and the ends are The head connector 165 is attached to the ...

Embodiment 3

[0043] see image 3 and Figure 8 , a new horizontal heat-sealing mechanism for pillow packaging machines, the crossbar 163 includes a quadrangular prism part 1631 and a cylindrical part 1632, and the outer walls of the two ends of the quadrangular prism part 1631 are respectively provided with a cylindrical part 1632, a quadrangular prism part 1631 and a cylindrical part 1632 It is an integrated structure, and the quadrangular prism part 1631 is installed inside the limit hole 162 on the side wall of the fixed plate 161 through the cylindrical part 1632. A heat-sealing strip 164 is installed on one side of the outer wall of the prism part 1631 through fixing bolts, and the heat-sealing strips 164 of the first heat-sealing mechanism 1 and the second heat-sealing mechanism 2 are just opposite when they are close to each other.

[0044] In order to better demonstrate the processing technology of the horizontal heat-sealing mechanism of the new pillow-type packaging machine, thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com