Patents

Literature

108results about How to "Easy to heat seal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Biaxially oriented polylactic acid film with improved heat seal properties

ActiveUS20100323196A1Lower heat seal initiation temperatureHeat seal rangeSynthetic resin layered productsLaminationPolybutylene adipate co-terephthalatePolylactic acid

Multi-layer biaxially oriented polylactic acid (BOPLA) film with a novel formulation improves the heat seal initiation temperature and heat seal performance of BOPLA films while maintaining good optical clarity. The film may include a core layer including polylactic acid base polymer resin, and a heat sealable layer including amorphous polylactic acid base polymer and a modifier comprising polycaprolactone or poly(butylene-adipate-co-butylene terephthalate).

Owner:TORAY PLASTICS AMERICA

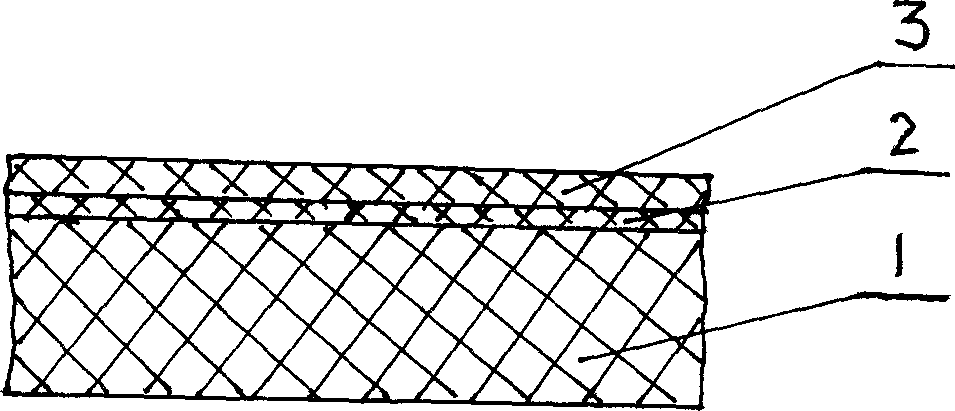

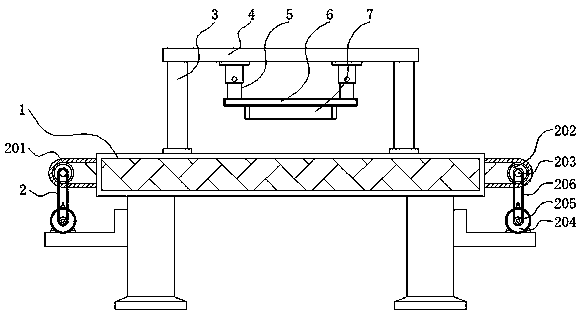

High-intensity low-gramweight embossing casting film and manufacture method thereof

An embossing and casting film with high intensity and low gram weight consists of a first flexible outer layer and a second flexible outer layer; wherein, a rigid bracing layer is arranged between the first flexible outer layer and the second flexible outer layer, and is respectively connected with the first flexible outer layer and the second flexible outer layer in an attaching way. The thickness of the rigid bracing layer is 1.3-1.8 times of that of the first flexible outer layer or the second flexible outer layer. The method for manufacturing the embossing and casting film with high intensity and low gram weight comprises the steps that a three-layer co-extrusion casting machine is used for extruding polyethylene material according to the structure of the first flexible outer layer-the rigid bracing layer-the second flexible outer layer. The invention promotes the intensity and the tenacity of the casting film with low gram weight by utilizing the flexible outer layers, provides good hand feeling, enhances the effects of heat seal and printing with other materials, and improves the stiffness and the rigidity of the casting film with low gram weight by utilizing the rigid bracing layer. Therefore, the technical problems of poor mechanical intensity and easiness producing of crease of the casting film with low gram weight in the prior art are solved.

Owner:SHANGHAI ZIHUA FILM TECH CO LTD

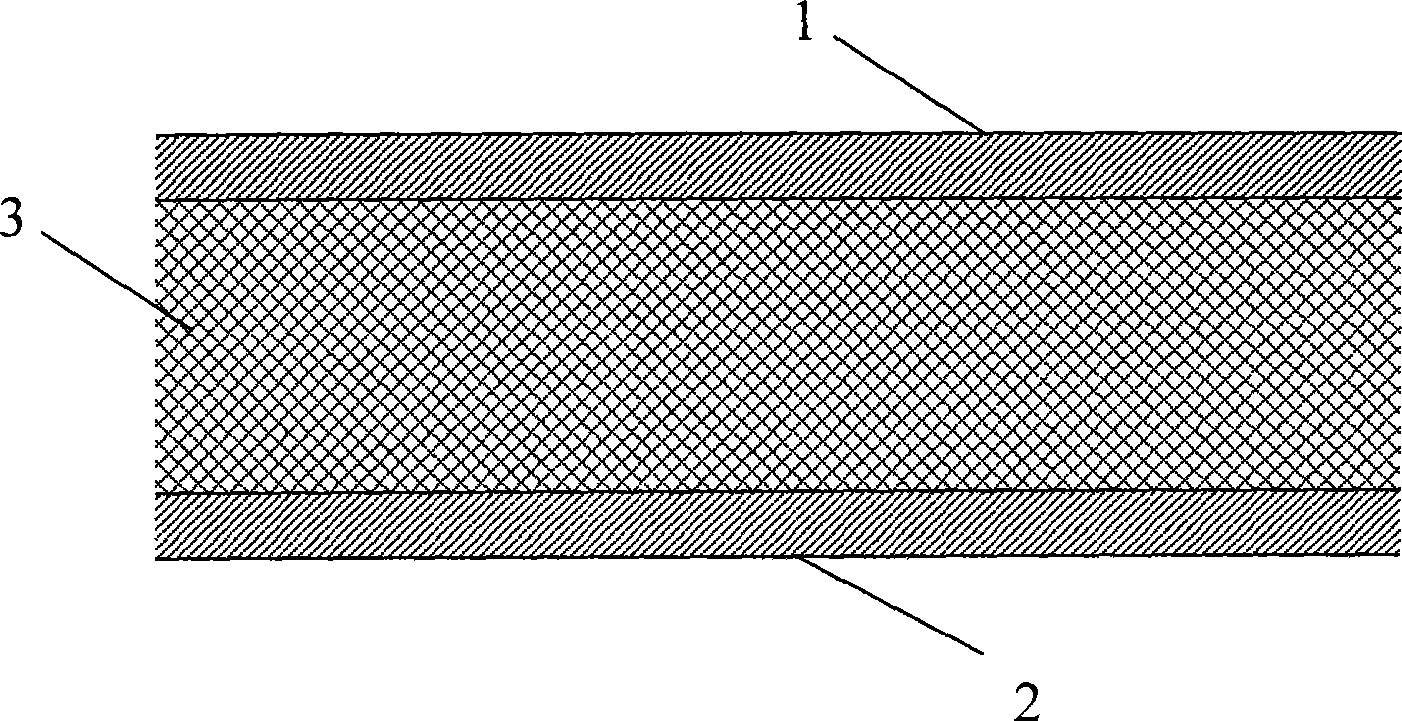

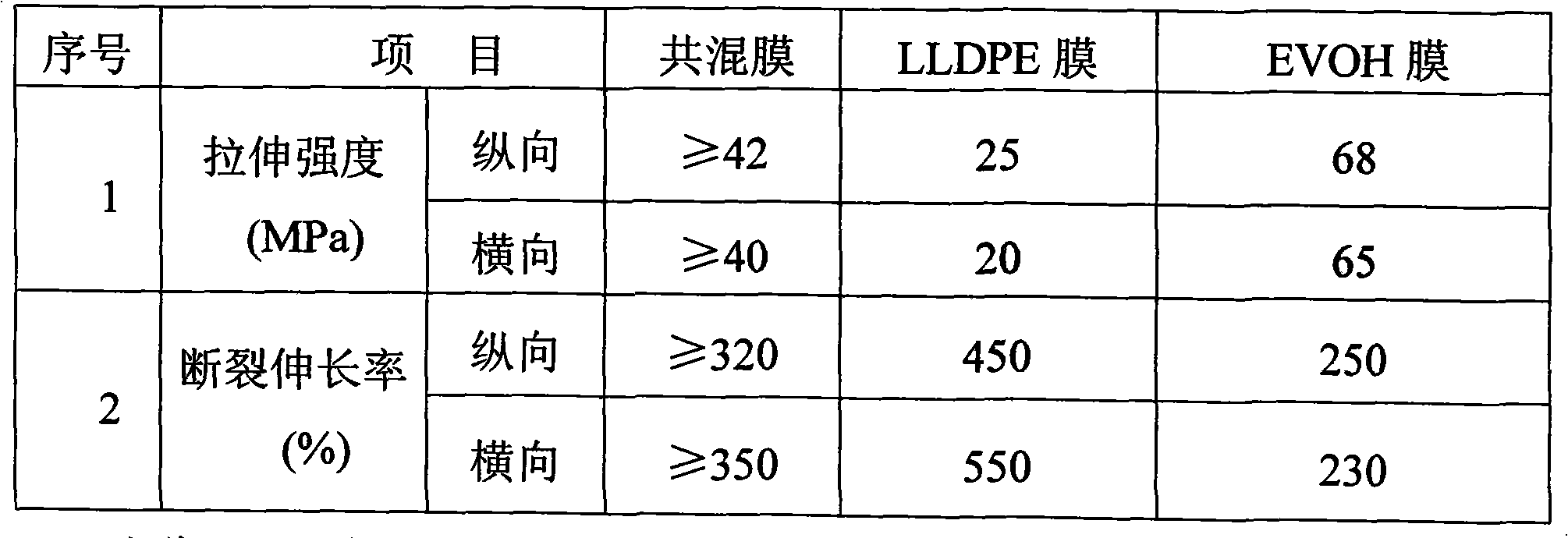

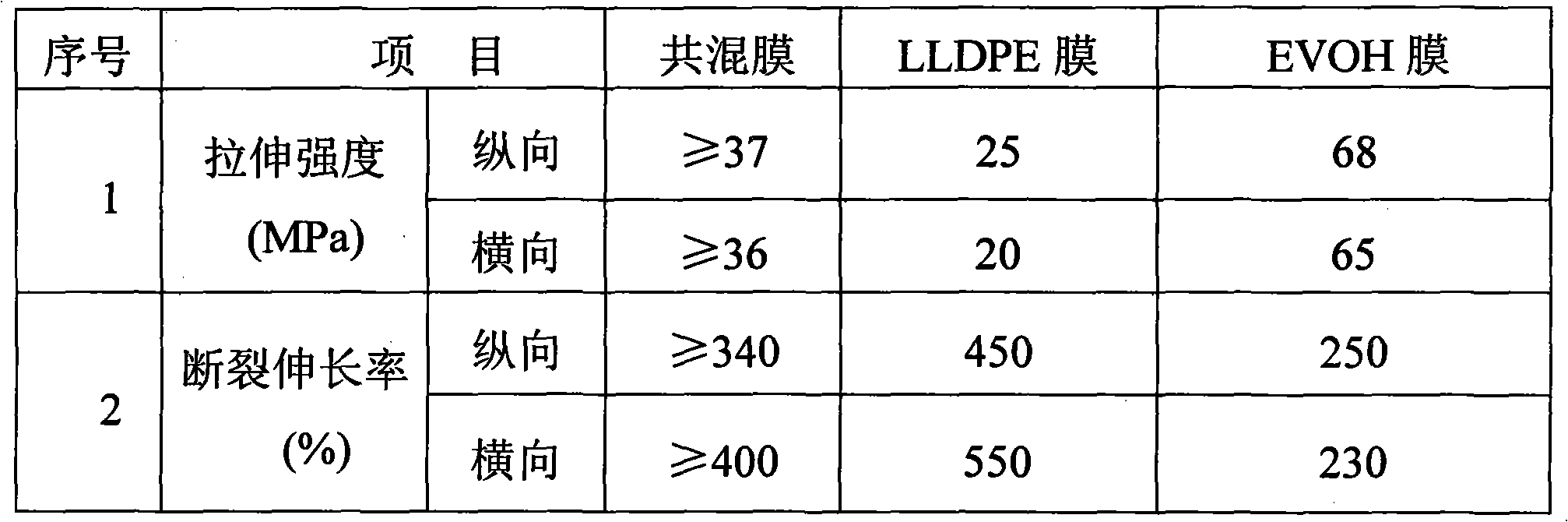

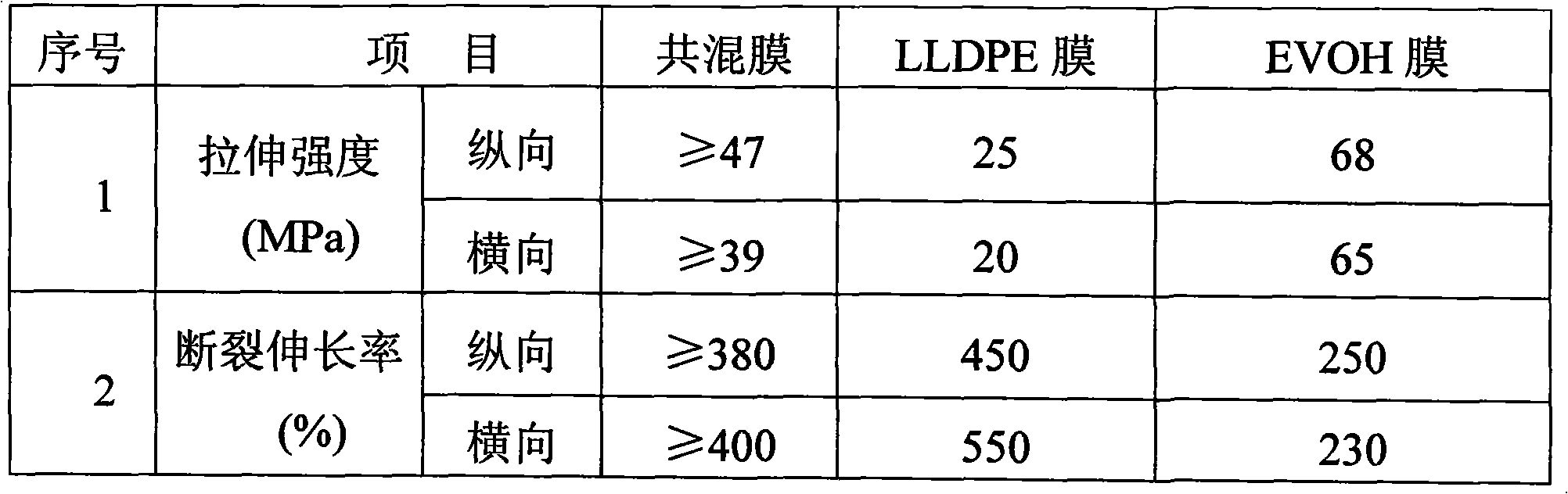

Linear low density blending film of polyethylene and ethylene-ethenol copolymer and method for making the same

InactiveCN101323685ARealize direct blending useImprove adhesionLinear low-density polyethyleneLow density

The invention discloses a blend film of linear low-density polyethylene and ethylene-vinyl alcohol copolymer and a manufacturing method thereof, which relates to a blend film and a making method thereof. The invention solves the problems that LLDPE and EVOH are incompatible and require a bonding layer in the middle when being used together. The blend film of the invention is made by linear low-density polyethylene, ethylene-vinyl alcohol copolymer, calcium carbonate master batches, dicumyl peroxide, dibenzoyl peroxide, dimethylformamide and a maleic anhydride monomer or acrylic acid. The manufacturing method of the invention includes that modified master batches are first prepared to be then used for manufacturing the blend film of the invention. The blend film of the invention can be directly obtained without adding a bonding layer between LLDPE and EVOH when in use of raw materials of LLDPE and EVOH.

Owner:哈尔滨隆华艺达包装制品有限公司

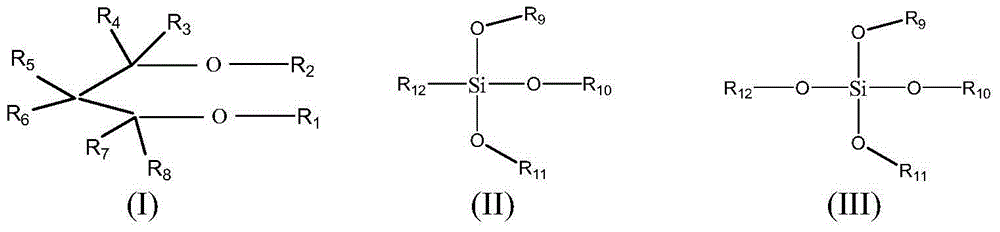

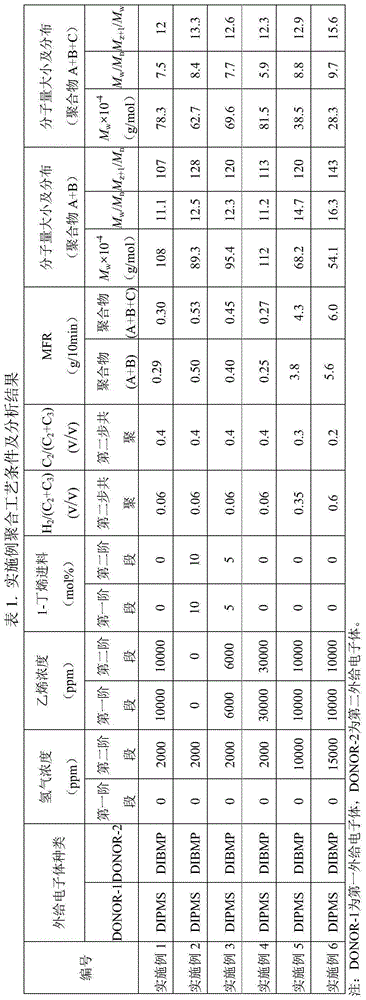

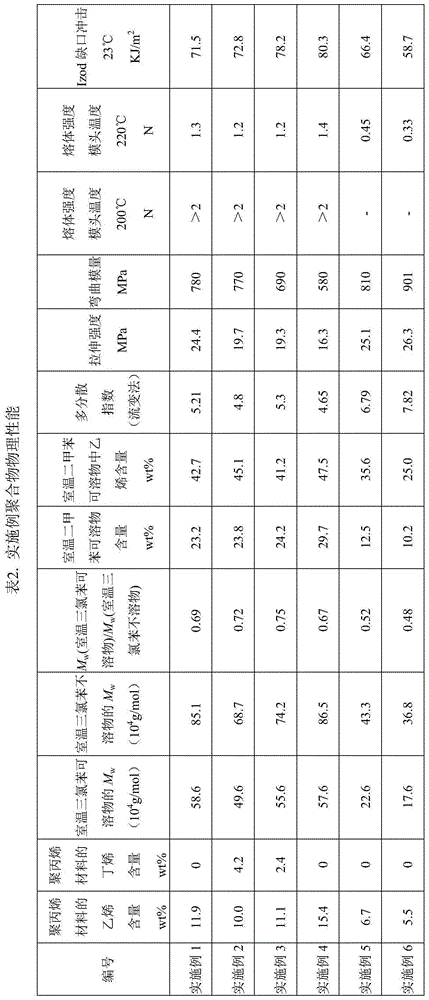

Method for preparing impact-resistant polypropylene material with high melt strength

The invention provides a method for preparing an impact-resistant polypropylene material with high melt strength. The method comprises the steps of carrying out a propenyl random copolymerization reaction in the presence of a first random copolymerization polypropylene so as to obtain a random-copolymerized polypropylene continuous phase containing the first random copolymerization polypropylene and a second random copolymerization polypropylene, and then, carrying out a propylene-ethylene copolymerization reaction in the presence of the random-copolymerized polypropylene continuous phase so as to obtain the polypropylene material containing a propylene-ethylene copolymer. According to the method, a random polypropylene continuous phase, which has a specific melt index, contains a large number of ultrahigh-molecular-weight ingredients and is extremely wide in molecular weight distribution, is prepared through using external electron donors of different types and use levels and a chain transfer agent, i.e., hydrogen gas of different use levels separately at different polymerization stages, then, propylene and ethylene copolymerization is further carried out so as to obtain a rubber phase dispersed in the continuous phase, and then, the impact-resistant polypropylene material with high melt strength, high rigidity and high toughness is obtained and is extensive in application.

Owner:CHINA PETROLEUM & CHEM CORP +1

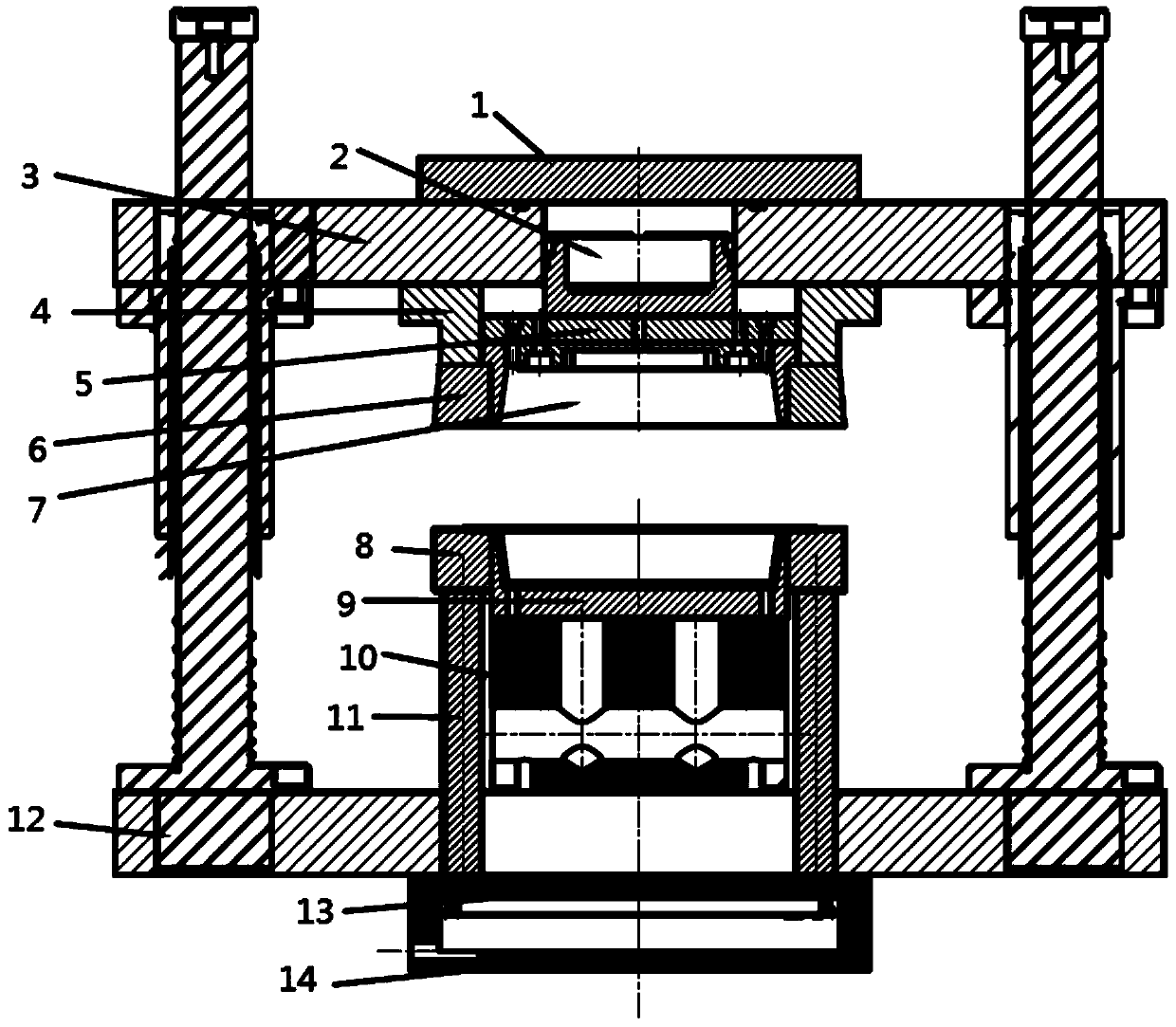

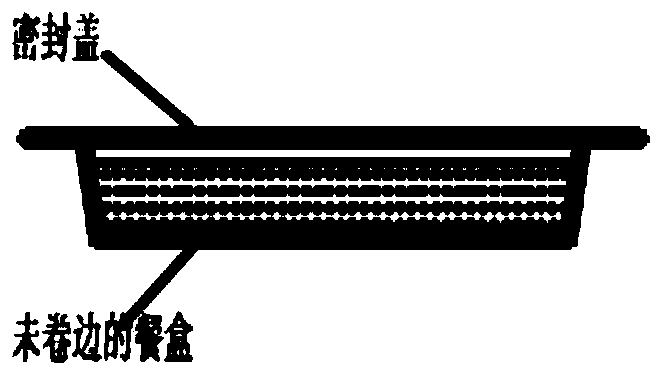

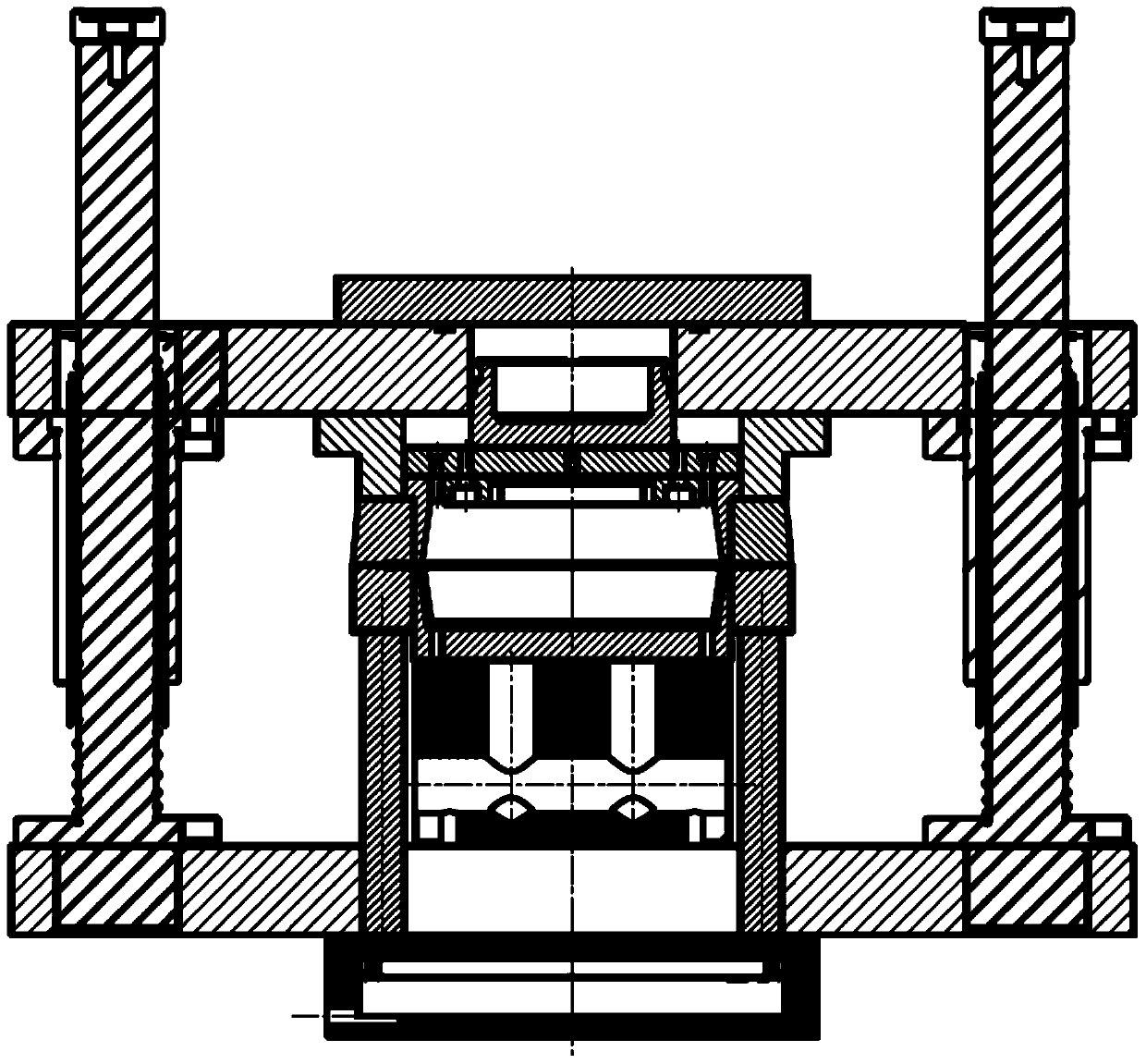

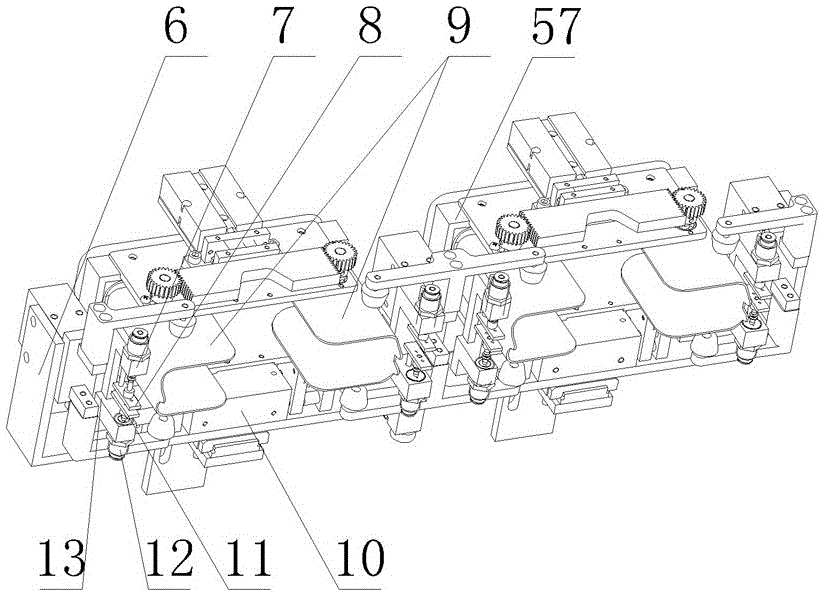

Pressing mold for two-layer edge curling opening sealing of sealed aluminum foil lunch box and opening sealing method

The invention relates to a pressing mold for two-layer edge curling opening sealing of a sealed aluminum foil lunch box. The pressing mold is characterized by comprising an upper mold part, a lower mold part and an upper and lower mold guide part, wherein the upper mold part comprises a mold mounting plate, an upper mold plate, an upper piston, an upper shearing opening seat, an upper shearing opening, an upper female mold and an upper female mold installing plate; the lower mold part comprises a lower edge pressing ring, a lower female mold, a lower female mold base, a lower air cylinder, a lower air cylinder ejector rod and a lower mold plate; the upper and lower mold guide part comprises guide rods and guide sleeves; the shape of the upper female mold is matched with that of an inner hole of the upper shearing opening for achieving guiding, the upper female mold installing plate is connected with the upper female mold, the upper piston acts on the upper female mold installing plate, the upper shearing opening seat is connected with the upper shearing opening, the upper mold plate is connected with the upper shearing opening seat, an external press is connected with the upper mold plate, and the whole upper mold part is driven to upwards and downwards move; and the shape of an inner hole of the lower edge pressing ring is matched with that of the lower female mold for achieving the guiding, an edge curling groove is formed in the lower edge pressing ring, the lower air cylinder pushes the lower edge pressing ring to do rebounding type movement through the lower air cylinder ejector rod, the lower female mold is fixedly arranged on the lower female mold base, and the lower female mold base is fixed on the lower mold plate.

Owner:佛山市施博能铝制品有限公司

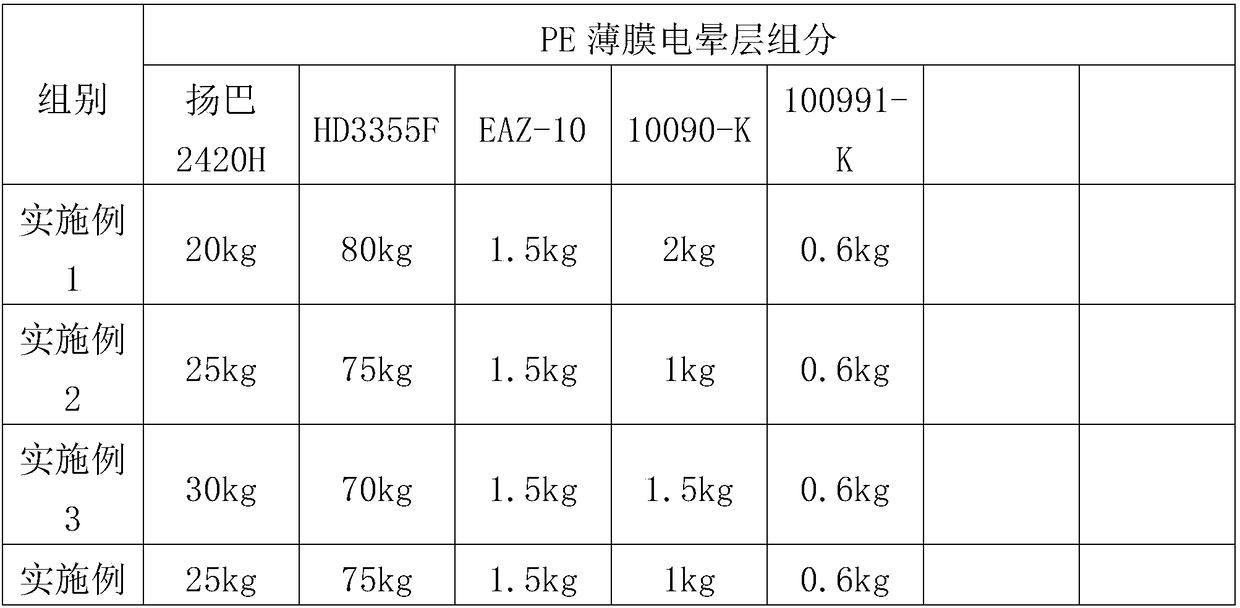

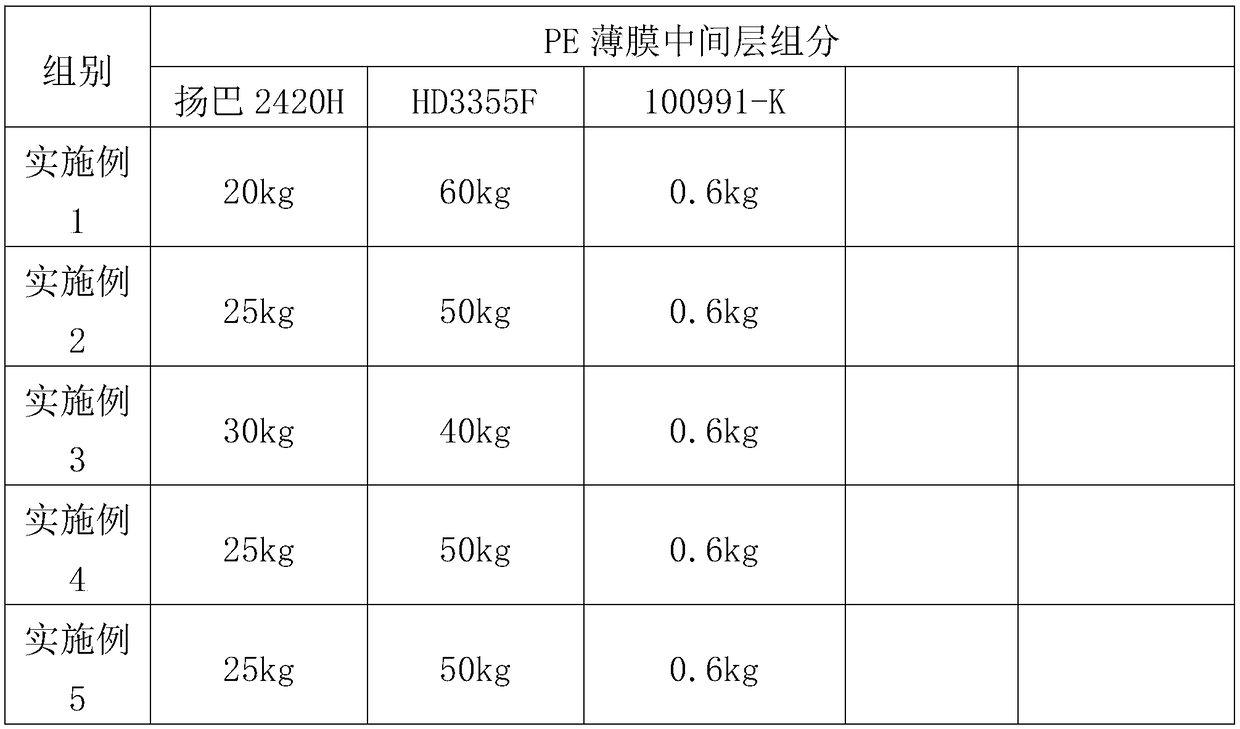

Heat-seal interface easily-torn PE thin film and preparation method thereof

InactiveCN108943949AImprove aging resistanceGood acid and alkali resistanceFlexible coversWrappersLow-density polyethylenePolyester

The invention discloses a heat-seal interface easily-torn PE thin film, which is formed by coextruding a corona layer, a middle layer and an inner layer, wherein the corona layer contains low-densitypolyethylene resin and high-density polyvinyl resin; the middle layer contains low-density polyethylene resin and high-density polyvinyl resin; the inner layer contains coated low-density polyethylene, high-density polyvinyl resin, polybutylene resin and polyester modified organosilicone. The coated low-density polyethylene is added into the inner layer, so that the thin film has good heat seal property, and the polyester modified organosilicone added into the inner layer has heat seal property, so that the heat-seal intensity value of the thin film is controlled within certain range and is easily torn off a heat-seal surface without complete damage or filament raising, and therefore, the PE thin film is suitable for being used as an easily-torn seal cup lid film, easily-torn mask productpackages and easily-torn medical dressing packages.

Owner:HUANGSHAN NOVEL

Preparation method of flexible packed super-capacitor

InactiveCN101763947AEasy to heat sealImprove cycle lifeCapacitor housing/encapsulationHybrid/EDL manufactureCapacitanceCelsius Degree

The invention discloses a preparation method of a flexible packed super-capacitor. The improvement of the invention includes that a liquid injection pipe with a copper bar is inserted into one side of an aluminum-plastic film bag after an electrical core is arranged in the bag, the open part and the joint part of the bag and the pipe are heat-sealed under the temperature of 200-300 degrees Celsius; the copper bar is pulled out and the bag is vacuumized to be under 0.05-0.09MPa, then is injected with electrolyte and laid aside for 8-12 hours under normal temperature, and then has formation process; the bag is vacuumized along with the formation, meanwhile, the inside pressure of the bag is kept within 0.01-0.05MPa, and the lost electrolyte is supplemented after the formation; finally, the protruding part of the liquid injection pipe is released from heat seal. The super-capacitor produced in the method has no gas expansion, avoids potential explosion danger, and guarantees good security and reliability; furthermore, the invention can ensure sufficient capacitance, improves the coherence of single body combination and cycle life of the module, and obtains excellent charge-discharge performance.

Owner:NANJING SHUANGDENG SCI TECH DEV RES INST

High-insulation low-static anti-wrinkle heat-seal type functional film

InactiveCN101987905ABright surfaceEasy to heat sealFlexible coversWrappersPolyvinyl chlorideMoisture absorption

The invention relates to a high-insulation low-static anti-wrinkle heat-seal type functional film which comprises the following components of PVC, stabilizing agent, H-16, AC316, MBS, oxidized polyethylene, silicon dioxide, ACR and epoxidized soybean oil, wherein PVC is polyvinyl chloride and poly aluminum hydrogen; the stabilizing agent is a common agent, in particular OM1; AC316 is tissuemat E; MBS is the terpolymer of methyl methacrylate (M), butadiene (B) and styrene (S); and ACR is acrylate copolymer. The components are fully mixed and then made into a film by using a blow molding machine. The high-insulation low-static anti-wrinkle heat-seal type functional film is prepared by the following steps of: fully mixing the components in proportion by weight and finally loading in the blow molding machine. The products produced by the technology has the advantages of no poison, high diaphaneity, bright surface, impact resistance, tear resistance, no combustion, no moisture absorption, and simple and firm heat seal, and is particularly suitable for meeting requirements of various high-speed automatic packaging machines.

Owner:JIESHOU CITY TIANHONG PACKAGING MATERIAL

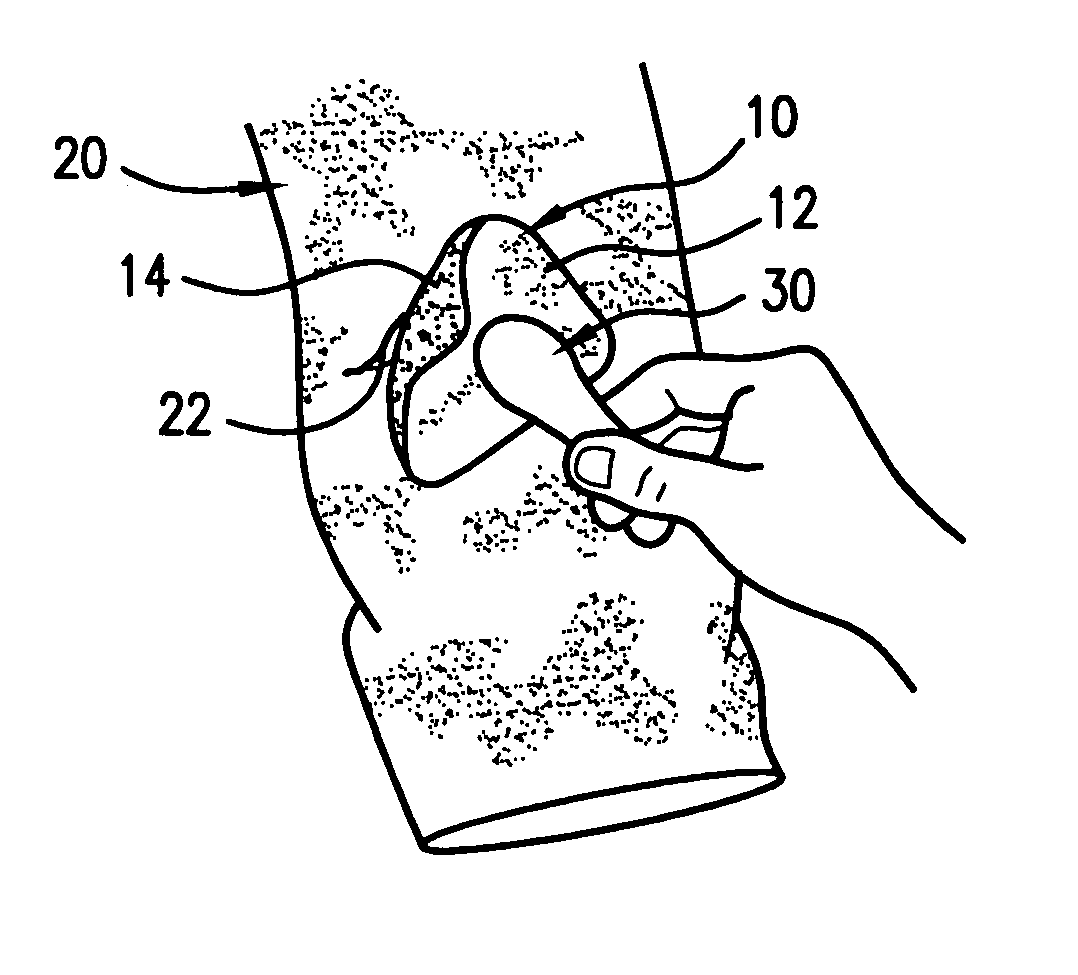

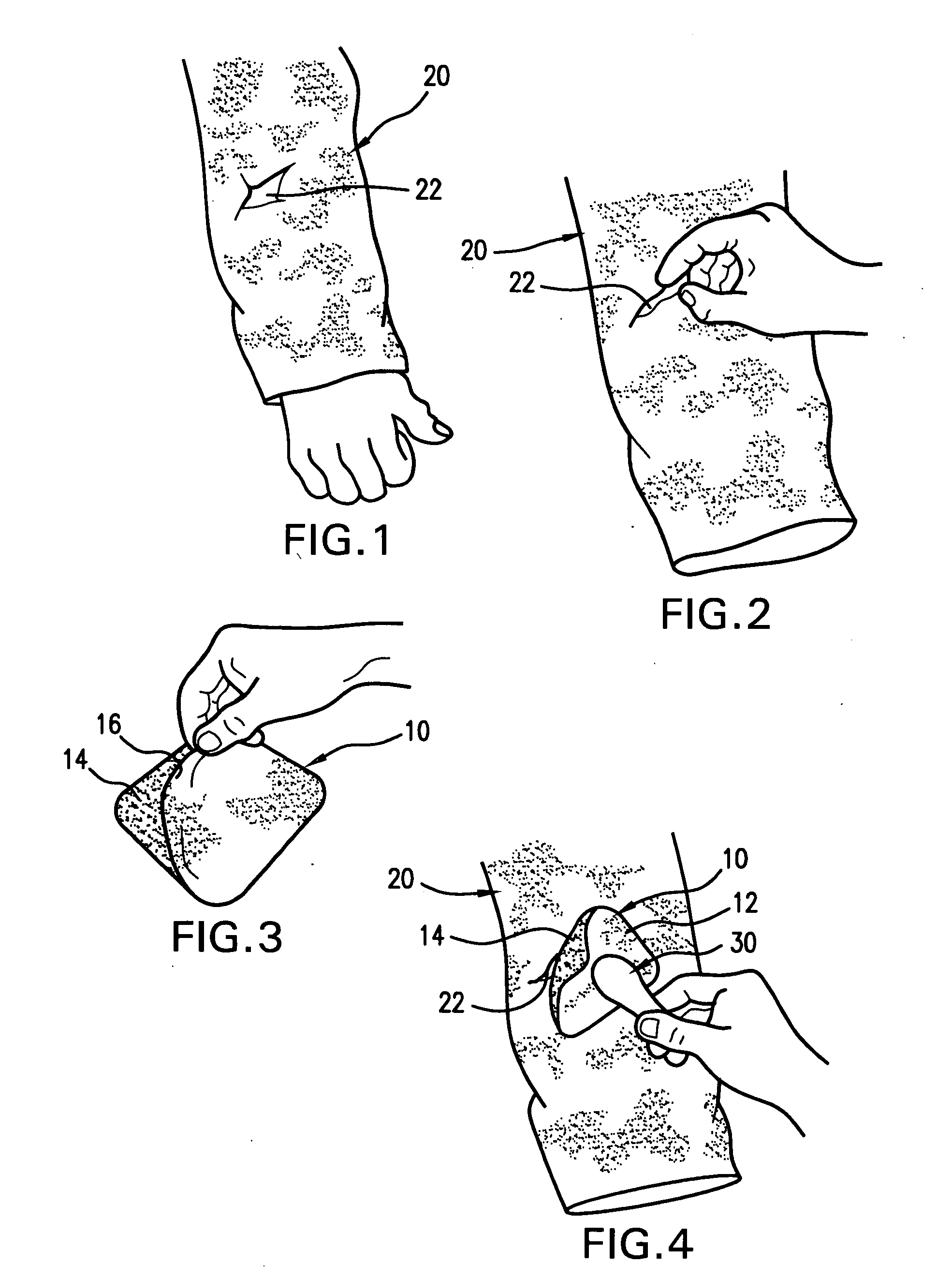

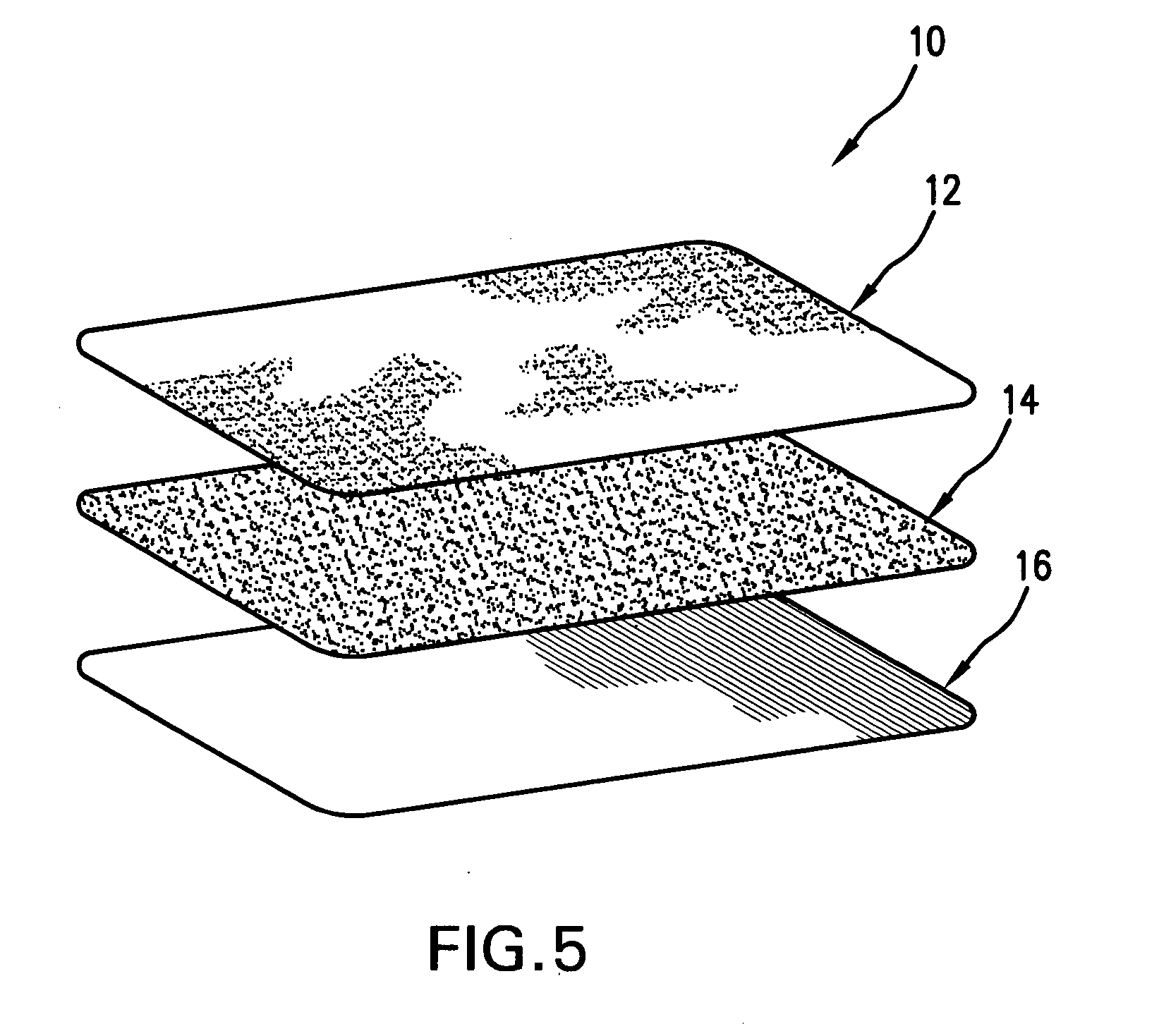

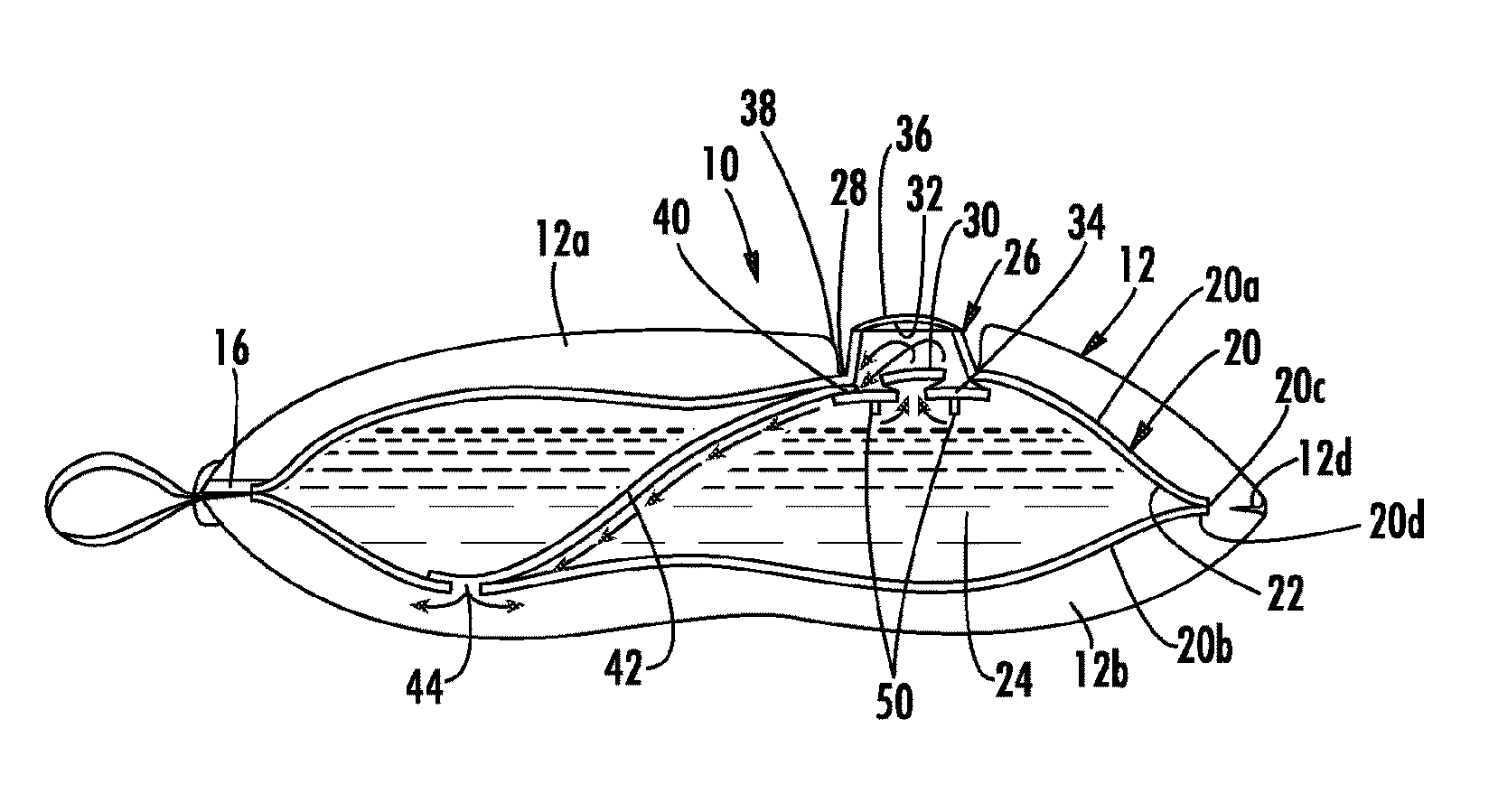

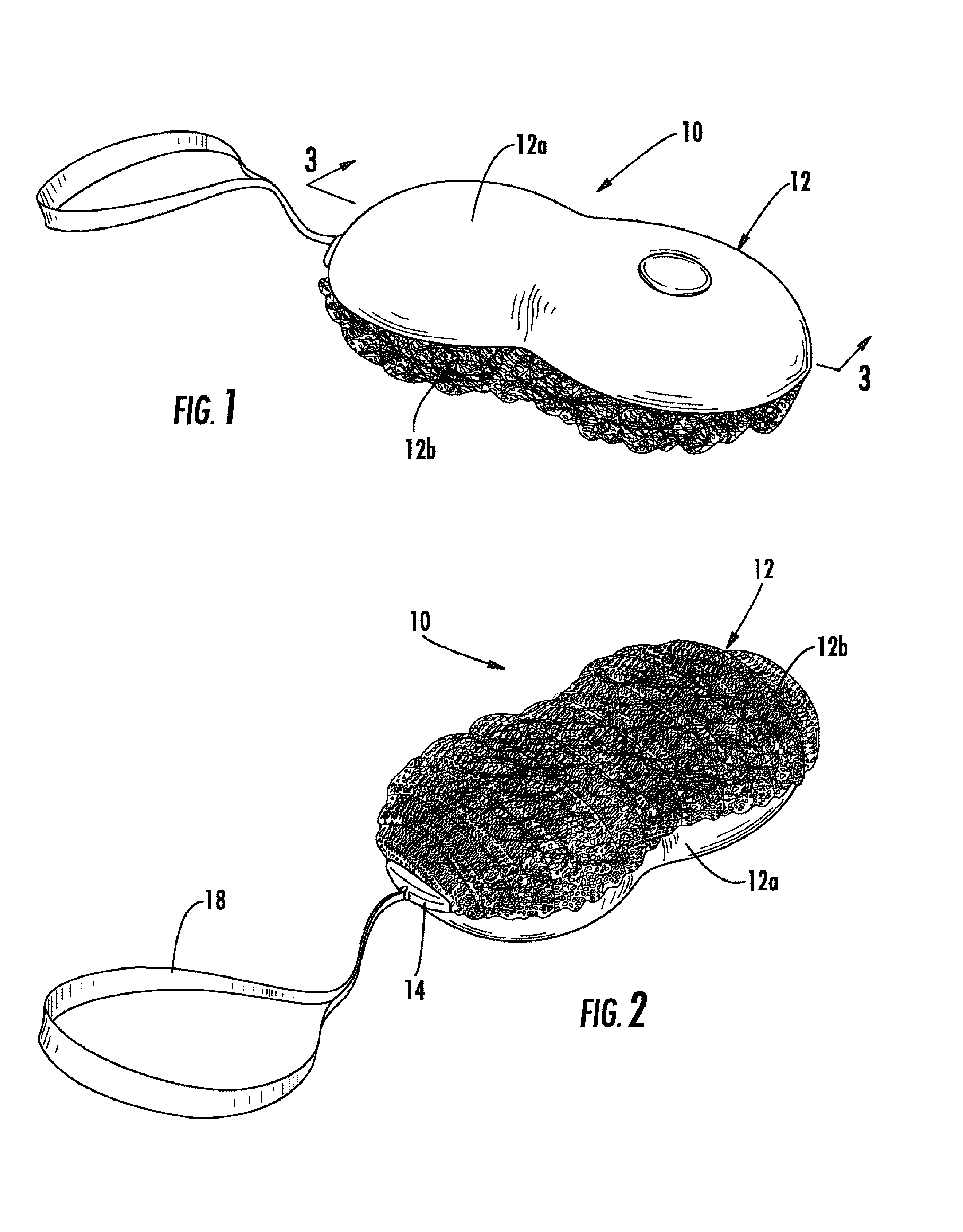

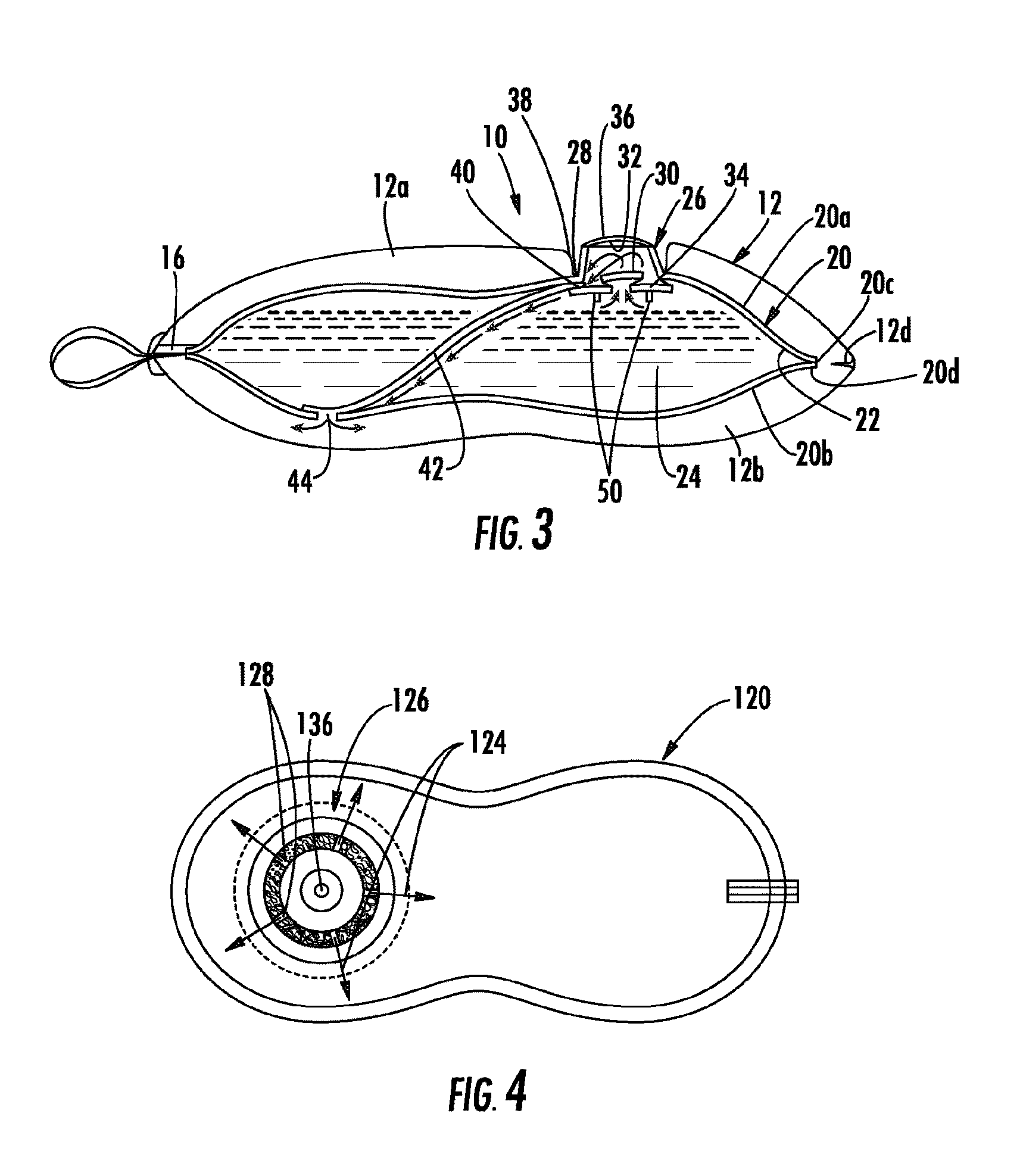

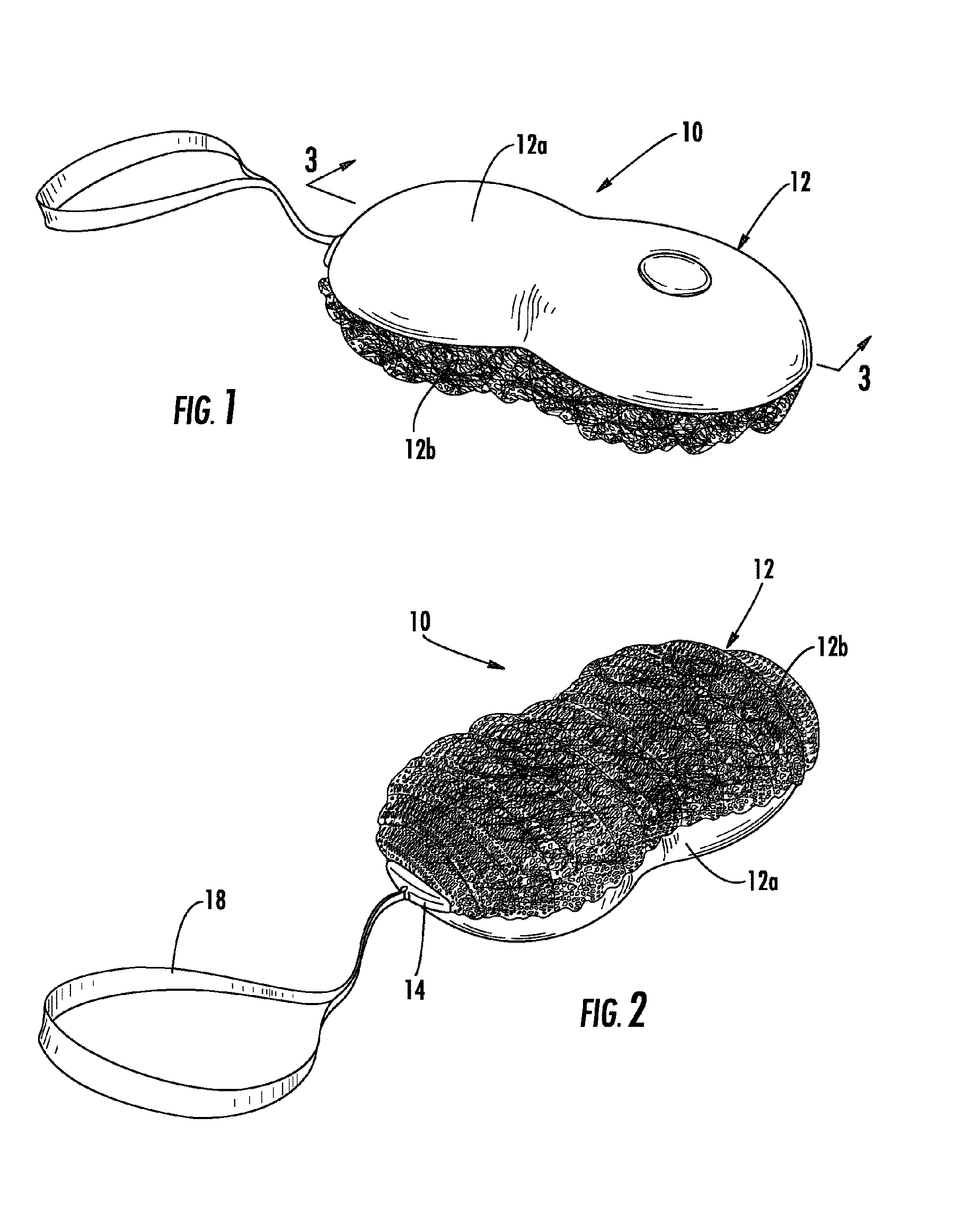

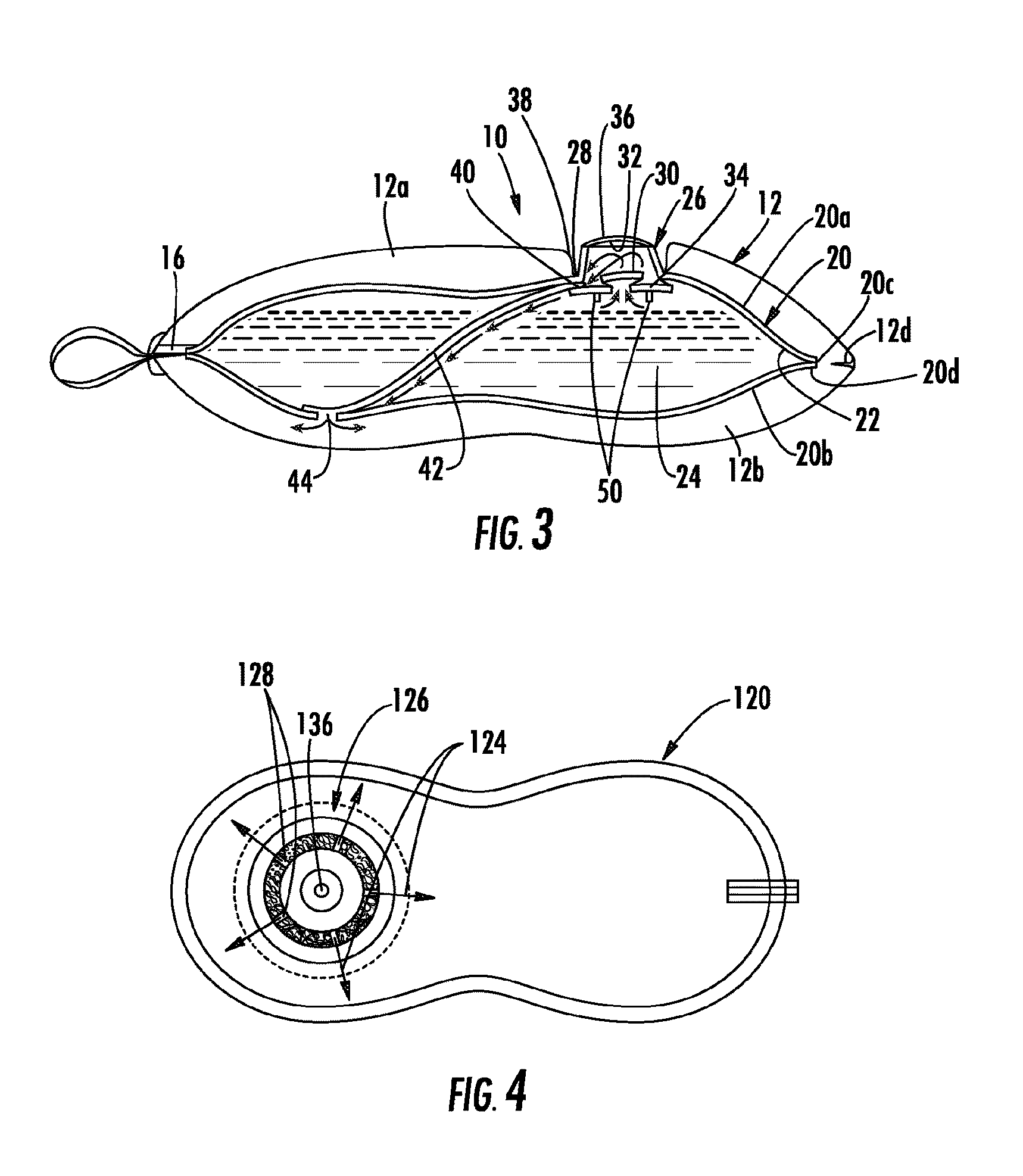

Self adhering fabric patch and moisture resistant flexible enclosure for containing the patch

InactiveUS20100021670A1Broaden applicationGood adhesionSynthetic resin layered productsLaminationFire-retardant fabricEngineering

A flame retardant patch for repairing a tear or hole in clothing or gear includes a flame resistant fabric and a pressure sensitive adhesive bonded to the fabric by hot melt lamination. The pressure sensitive adhesive contains halogenated flame retardant compounds. A release paper covers the pressure sensitive adhesive and is removed to allow application of the flame retardant patch to the clothing or other item being repaired. The patch is attached by applying pressure to the top fabric surface of the patch for approximately 45 seconds using the convex surface of a spoon-like object. The patch is contained in a flexible moisture resistant enclosure formed of a thermoplastic urethane composition.

Owner:LLANO MARK 51 +1

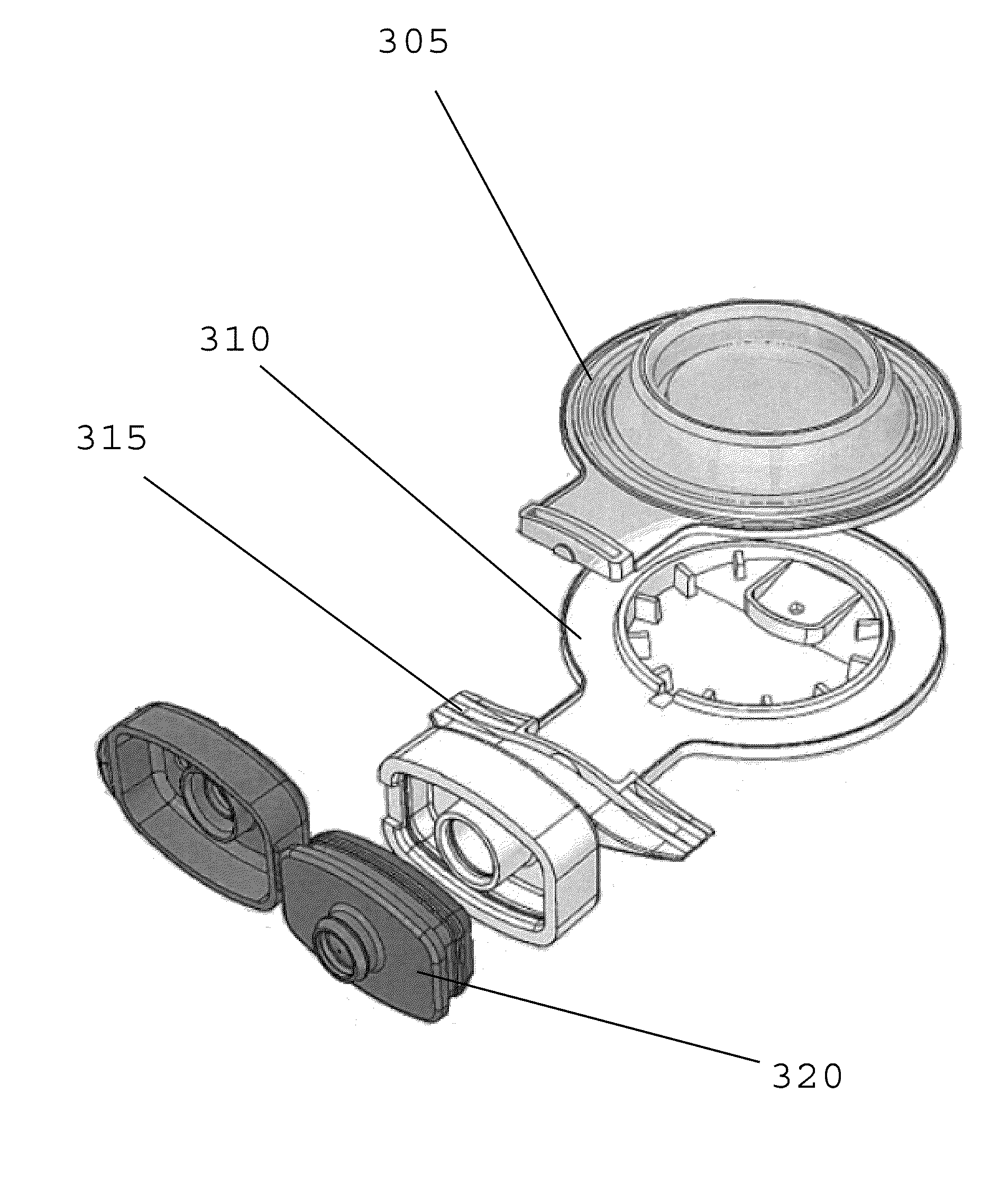

Metered Dispensing System With Stepped Flange Interface

Owner:1TOUCH HLDG INC

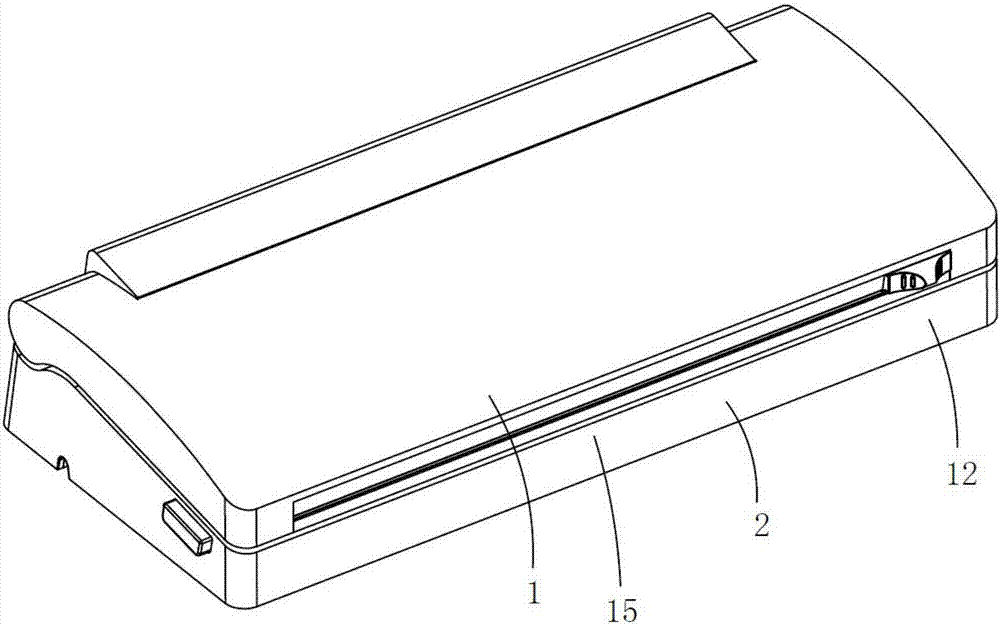

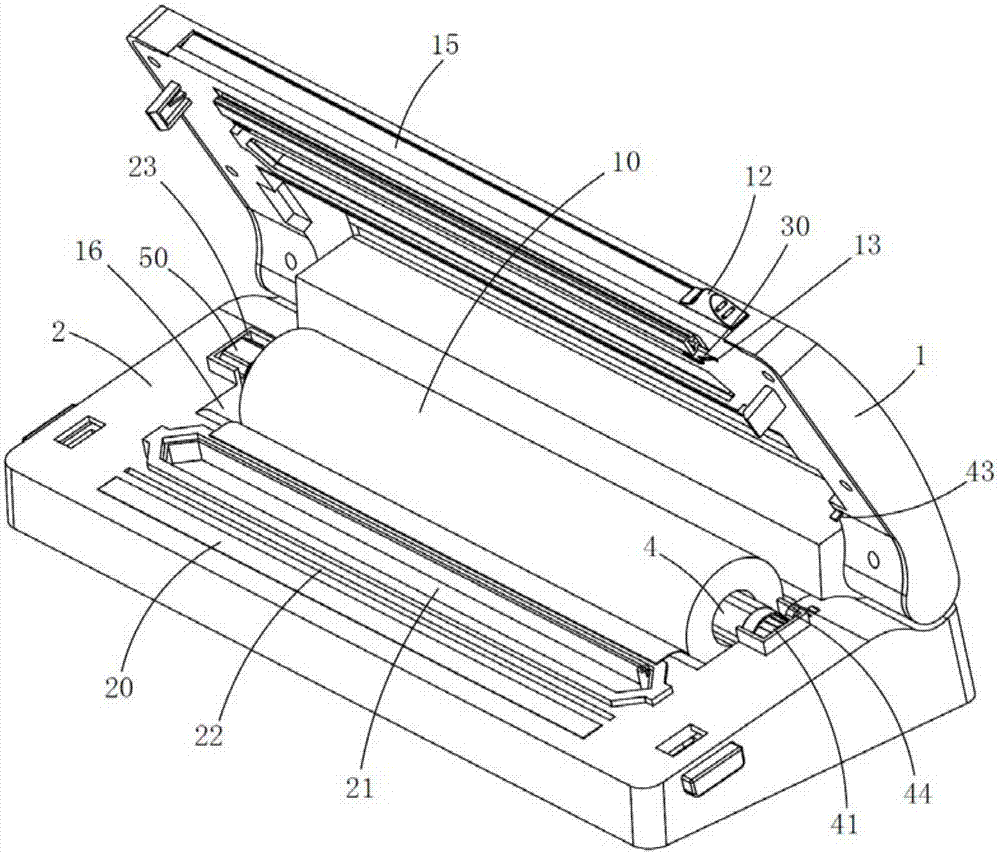

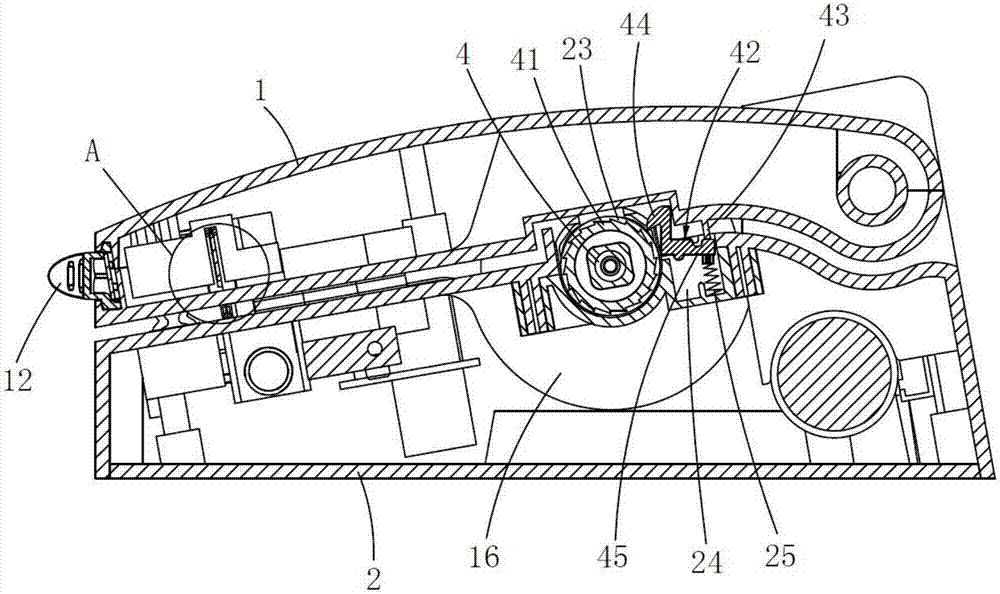

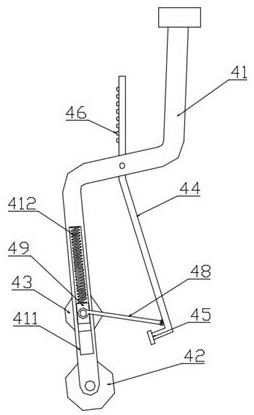

Vacuum sealer and bag-cutting type sealing method

ActiveCN107235193AReduce stepsEasy to operateWrapping material feeding apparatusPackaging by pressurising/gasifyingEngineeringPumping vacuum

The invention discloses a vacuum sealer and a bag-cutting type sealing method. In the vacuum sealer, at least one cutter device is slidably installed at an upper cover; a heat sealing strip and a vacuumizing groove are arranged at the front side of the upper part of the upper cover; the upper cover or a lower cover is provided with a bag body storage chamber; a dismountable automatic rewinding shaft is rotationally installed in the bag body storage chamber; an elastic rewinding mechanism used for driving the automatic rewinding shaft to rewind and an elastic one-way locking mechanism used for locking the automatic rewinding shaft are installed at the end part of the automatic rewinding shaft; the cutter device protrudes from the bottom surface of the lower cover; and after the upper cover is locked on the lower cover in a covering way, a cutter moves back and forth at one side of the heat sealing strip or one side of the vacuumizing groove and is used for cutting a bag body which is pressed tightly between the upper cover and the lower cover. The vacuum sealer disclosed by the invention is simple in structure; the bag is cut at the original heat sealing strip or vacuumizing groove of the lower cover, so more convenient bag cutting is realized; after being cut off, the bag body can be automatically rewound by a vacuum packaging bag roll after the cover is opened, so the operation steps of a user are reduced, and the vacuum sealer is simpler, more convenient and quicker to operate.

Owner:DONGGUAN BONSEN ELECTRONICS

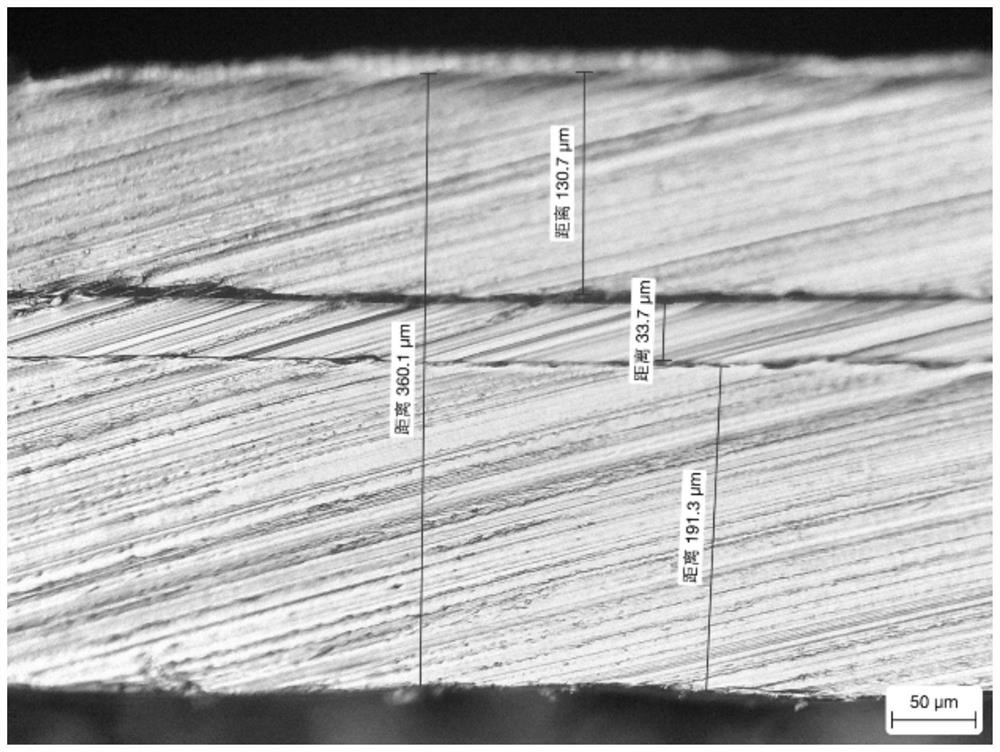

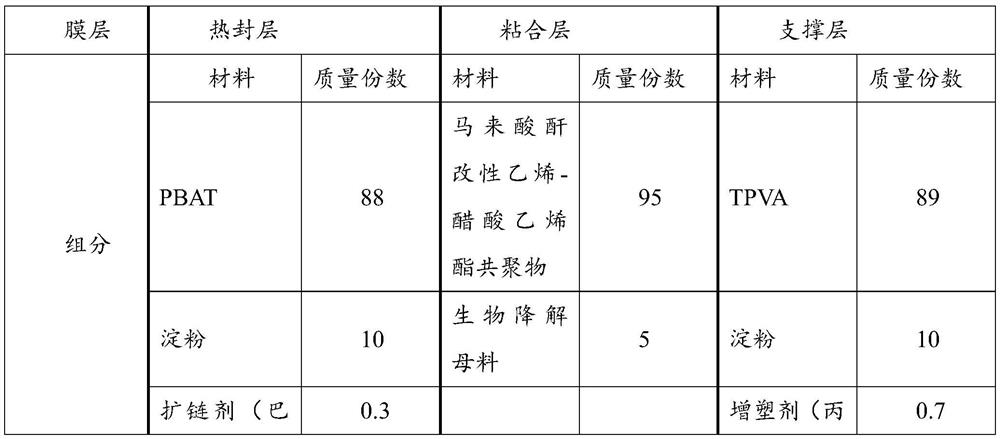

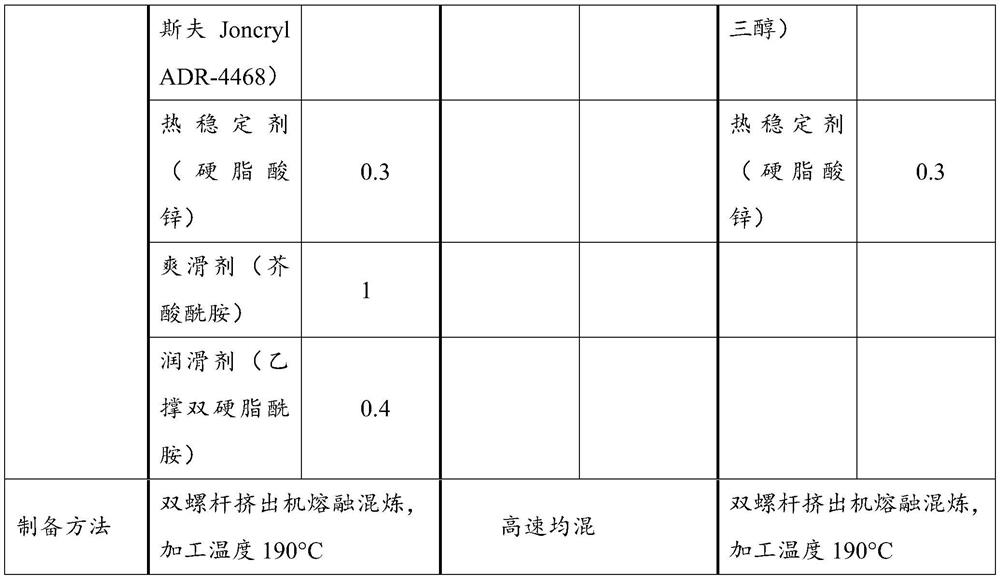

Composite film, preparation method thereof and plastic film product

PendingCN112677598AHigh strengthImprove toughnessSynthetic resin layered productsLaminationPolymer scienceComposite film

The invention discloses a composite film, a preparation method thereof and a plastic film product. The composite film comprises a heat sealing layer, a bonding layer and a supporting layer which are sequentially stacked, wherein based on the mass of the heat sealing layer, the heat sealing layer is prepared from a heat sealing layer raw material comprising 48-100 parts by mass of PBAT, 0-30 parts by mass of a filler, 0-20 parts by mass of a biodegradable material and 0-2 parts by mass of a processing aid, the bonding layer is prepared from a bonding layer raw material comprising bonding resin, the bonding resin is copolyester containing an active group, and the active group is a carboxyl or anhydride group; wherein the supporting layer is prepared from the following raw materials in parts by mass: 68-100 parts of thermoplastic modified polyvinyl alcohol, 0-20 parts of filler, 0-10 parts of biodegradable material and 0-2 parts of processing aid. The composite film provided by the invention has good mechanical properties, layers are not easy to separate, and the composite film has good application prospects.

Owner:佛山(华南)新材料研究院

Preparation method of color-printed high-temperature retort pouch

InactiveCN103057236AImprove air tightnessAppropriate amountLamination ancillary operationsLaminationColor printingRetort pouch

The invention discloses a preparation method of a color-printed high-temperature retort pouch, which is in a four-layer structure (PET / aluminium foil / nylon / CPP). The method selects polyurethane ink to perform color printing, and a hardening agent added in the ink accounts for 1.5wt%-2.0wt%. The prepared color-printed high-temperature retort pouch is free of decolorization, printed pattern fading, and folds after cooking at 123DEG C for 38min. The color-printed high-temperature retort pouch prepared by the invention has good air tightness, and its appearance, physical and mechanical properties, as well as hygienic performance are all in line with the requirements.

Owner:利辛县宏达铝塑包装有限公司

Roller-type fed material bagging machine

The invention discloses a roller-type fed material bagging machine which is provided with a rack and a roller. A bag feeding device and a heat sealing device are arranged on the outer side of the roller. Work grooves are evenly formed in the rollers. A bag propping mechanism is arranged at a feeding position of a material bagging machine and is provided with a bag propping frame. U-shaped bag propping rods are arranged on the two sides of the bag propping frame. Bag opening mechanisms are arranged at the work grooves. The roller-type fed material bagging machine is characterized in that packaging bag tensioning mechanisms are arranged on one sides of the U-shaped bag propping rods; a bag rubbing mechanism is arranged above the work grooves; and bag grabbing and pulling mechanisms are arranged at discharge outlets of the work grooves. By adoption of the bagging machine, tensioning of a bag opening during material feeding of a packaging bag is achieved, tilting-up or wrinkling of the two edges of the packaging bag is avoided, the two walls of the packaging bag can be rubbed open when the bag needs to be opened, and the bag opening effect is guaranteed; and before heat sealing, the bag opening of the packaging bag is pulled to be level, so that the bag opening after heat sealing is flat, and a good packaging effect is achieved.

Owner:WENZHOU RUIDA MACHINERY

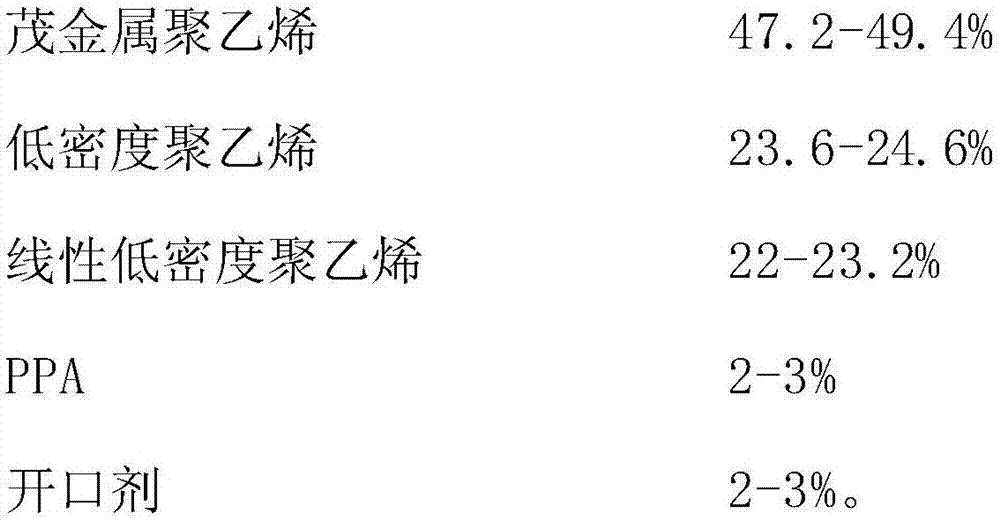

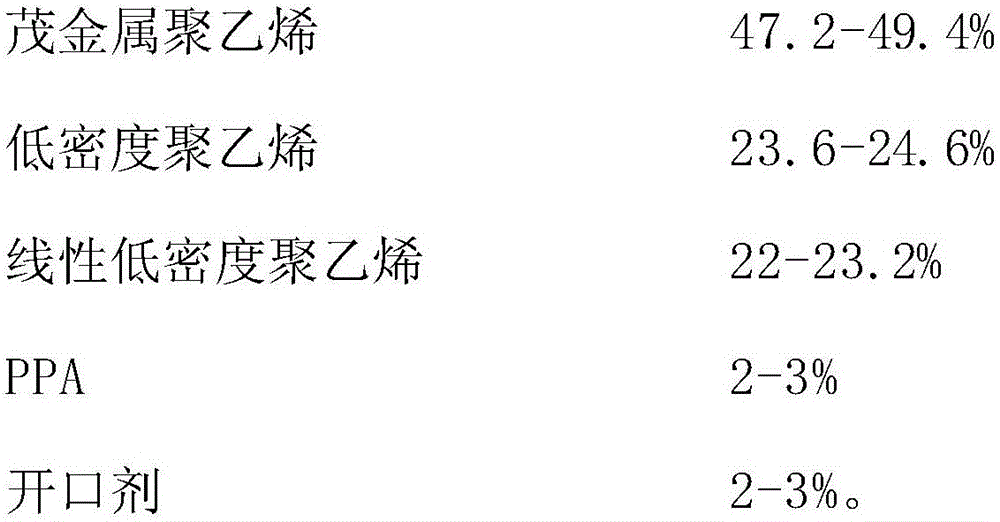

Low-temperature-resistant and high-toughness packaging film material and preparation method for same

InactiveCN107471789AGuaranteed attachment rateGuaranteed friction performanceSynthetic resin layered productsElastomerLinear low-density polyethylene

The invention relates to a low-temperature-resistant and high-toughness packaging film material, which is divided into inner, middle and outer layers, wherein the inner layer is prepared from the following raw materials in parts by weight: 30 to 40 parts of metallocene polyethylene, 10 to 20 parts of linear low density polyethylene, 3 to 5 parts of a plastic lubricant and 2 to 3 parts of a slipping agent; the middle layer is prepared from the following raw materials in parts by weight: 30 to 40 parts of metallocene polyethylene, 60 to 70 parts of linear low density polyethylene and 3 to 5 parts of a propylene-based elastomer; the outer layer is prepared from the following raw materials in parts by weight: 30 to 40 parts of metallocene polyethylene, 10 to 15 parts of linear low density polyethylene, 3 to 5 parts of an anti-slip agent and 2 to 3 parts of an ink binder. The packaging film material has the advantages of low-temperature resistance and high toughness, and a package can be prevented from being broken at a 3m height at -20 DEG C; the performance is ensured, and meanwhile, the lowest using cost and a better packaging effect are achieved.

Owner:安徽天大环保新材料股份有限公司

Preparation method of fusible multilayer composite asphalt filling bag

InactiveCN103231519AAvoid pollutionAvoid problems such as recycling difficultiesBlow moldingPolymer science

The invention discloses a preparation method of a fusible multilayer composite asphalt filling bag. The method is characterized in that the method comprises the following steps: utilizing polyolefin, a modified polyolefin material and a compounding agent to prepare a fusible multilayer composite asphalt filling bag film blowing material, carrying out blow molding of the film blowing material and processing master batches through adopting a film blowing set to form a fusible multilayer composite asphalt filling bag body having a thickness of 20-100mum, and carrying out slitting and heat sealing to prepare the fusible multilayer composite asphalt filling bag. The processing master batches are a fusion compound comprising a polyethylene resin and a processing assistant. The fusible multilayer composite asphalt filling bag has the characteristics of high temperature filling resistance, realization of complete mixed fusion with asphalt, no edge leakage, no seepage, high heat sealing strength, wide range of the use temperature, ultraviolet resistance, weather resistance, strong designability, and relative low price. The fusible multilayer composite asphalt filling bag is used for the high and low temperature filling of pavement asphalt and various modified asphalts, and can be widely used in the petroleum field and the building field.

Owner:宁波江东晟利工业产品设计有限公司 +2

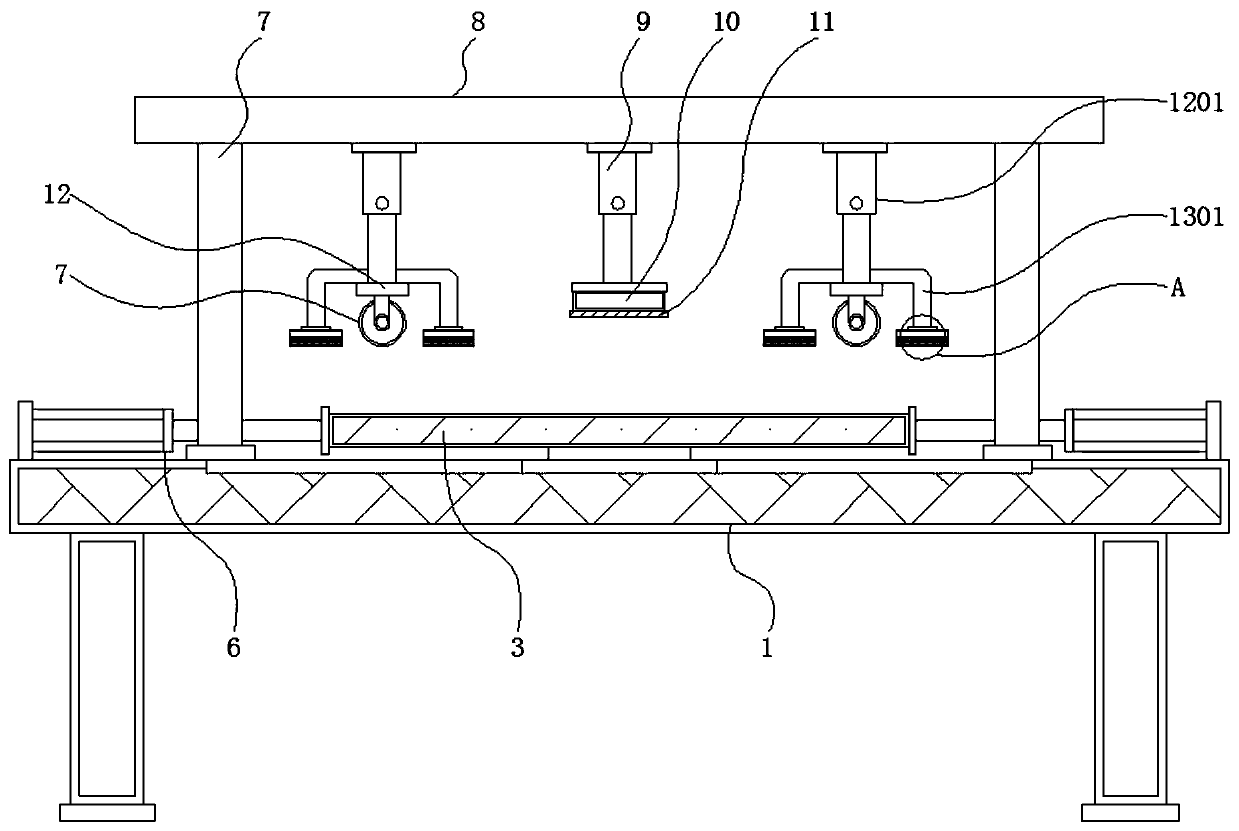

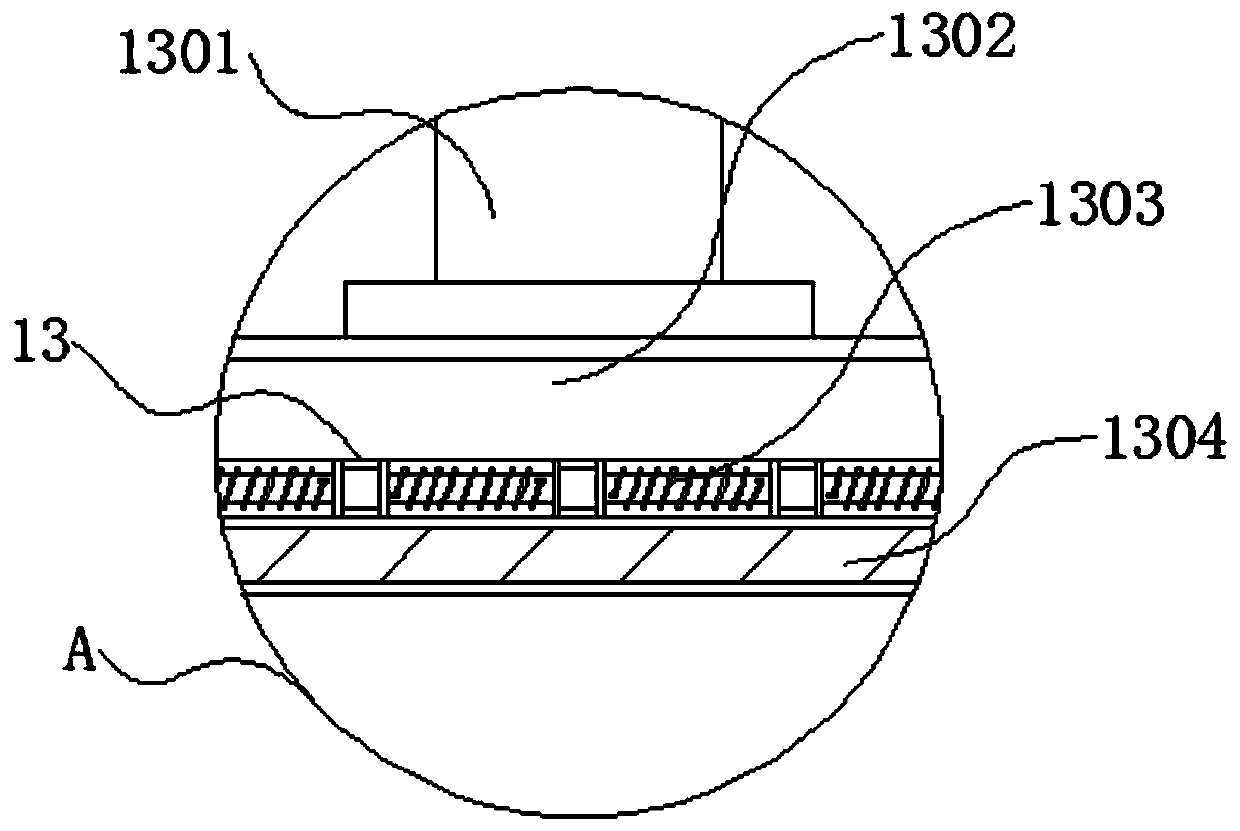

Sleeve plastic heat sealing device for raincoat production

InactiveCN110861308AEasy to moveImprove processing efficiencyDomestic articlesRotational axisEngineering

The invention discloses a sleeve plastic heat sealing device for raincoat production, and relates to the technical field of raincoat production. The sleeve plastic heat sealing device for raincoat production comprises a workbench, a leveling mechanism and heat sealing tanks, wherein support columns are installed below the workbench; a heat sealing base is arranged above the workbench; sliding blocks are fixed on the two sides of the bottom of the heat sealing base; sliding grooves are arranged on the outer sides of the lower sides of the sliding blocks; air cylinders are installed at the two ends of the heat sealing base; supporting rods are fixed on the two sides of the upper portion of the workbench; and a top plate is installed on the upper portions of the supporting rods. The sleeve plastic heat sealing device for raincoat production has the beneficial effects that the leveling mechanism is arranged to facilitate leveling of raincoat sleeves; second electric push rods can conveniently telescopically adjust the position height of mounting frames and leveling rollers; the leveling rollers form a rotatable structure with the mounting frames through rotating shafts so that the leveling rollers can rotate through the rotating shafts to perform rolling leveling on the heat sealing positions of the raincoat sleeves in the heat sealing tanks below to prevent the heat sealing positions from wrinkling.

Owner:章玉奎

Metered dispensing system with nested boat fitment

Owner:1TOUCH HLDG INC

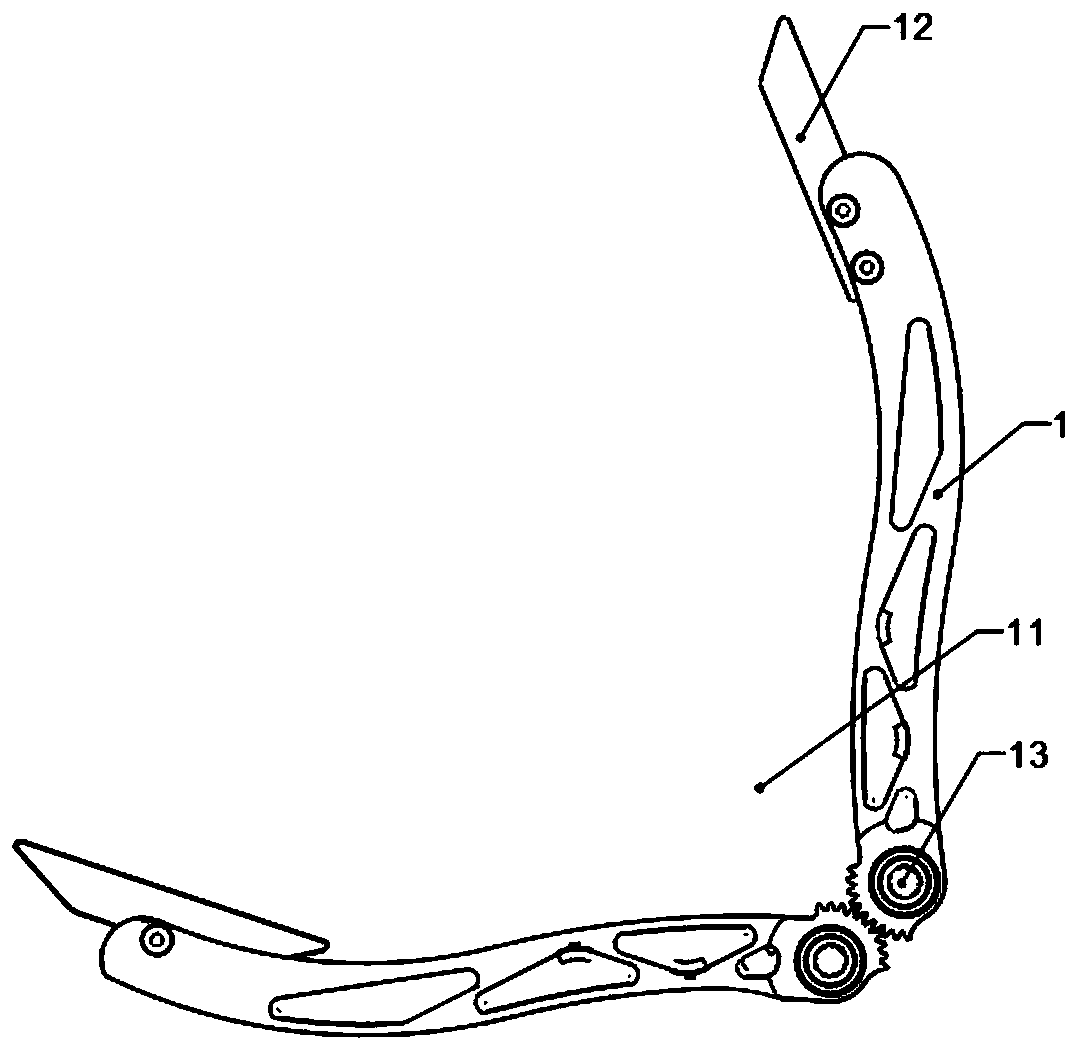

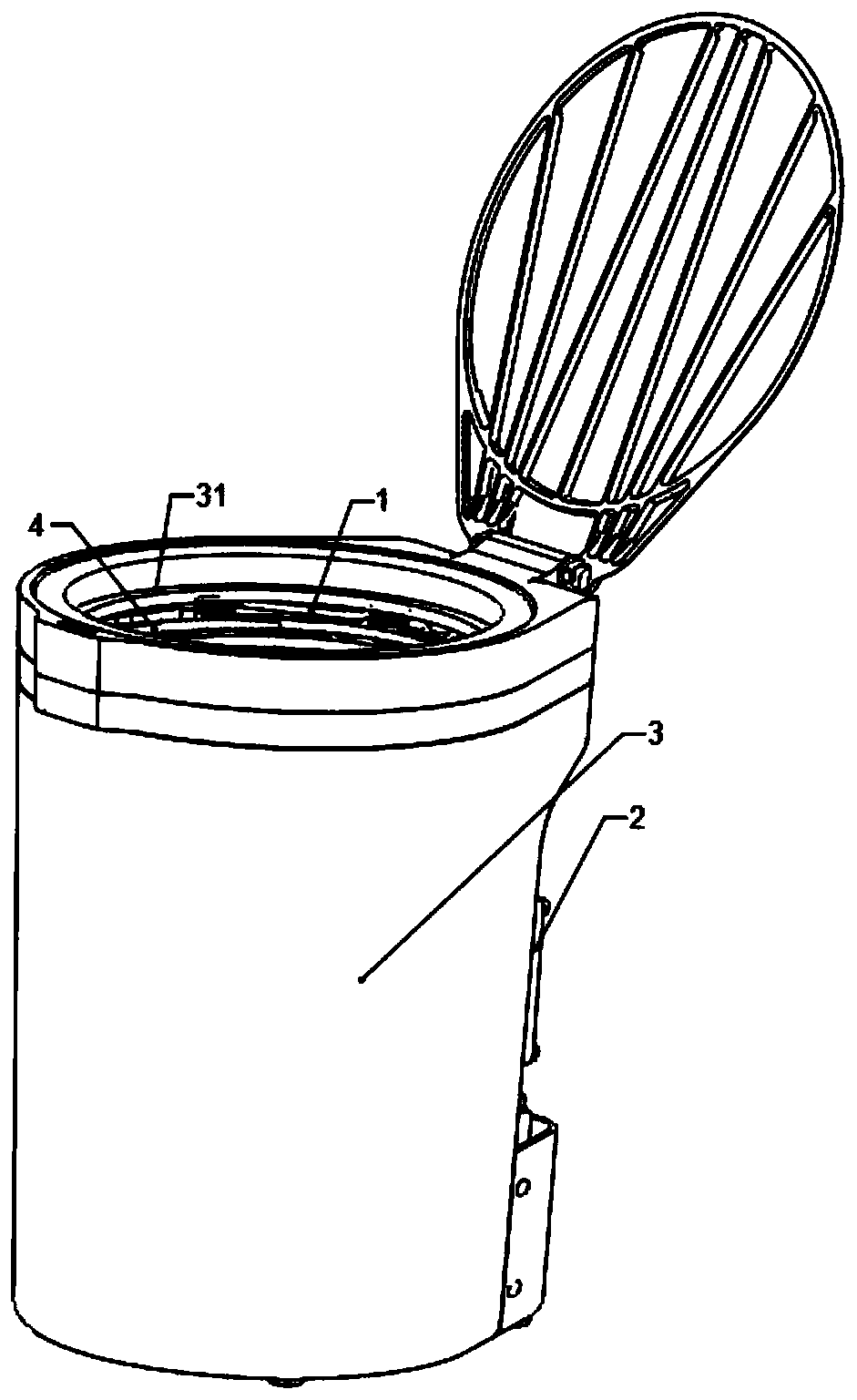

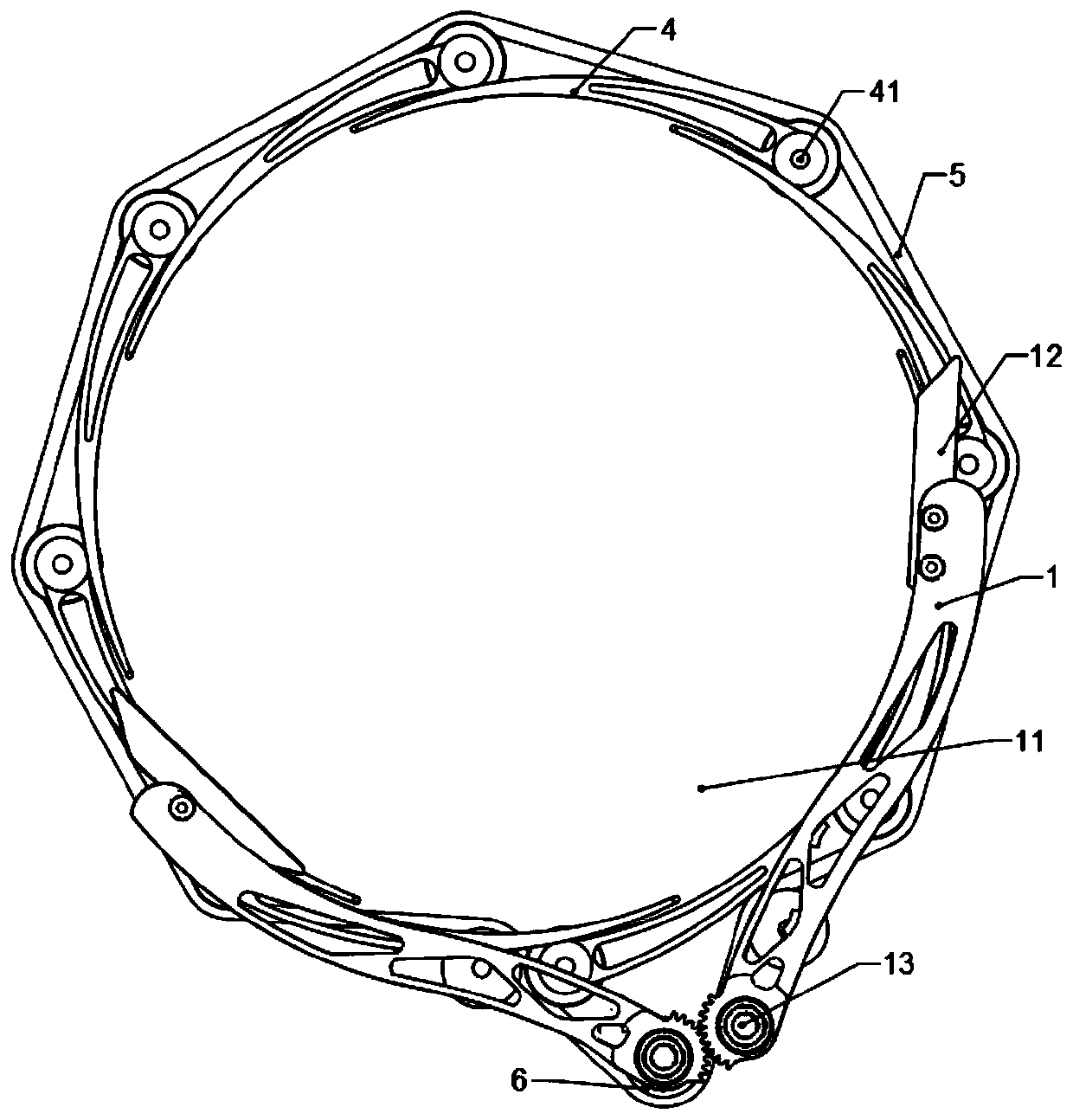

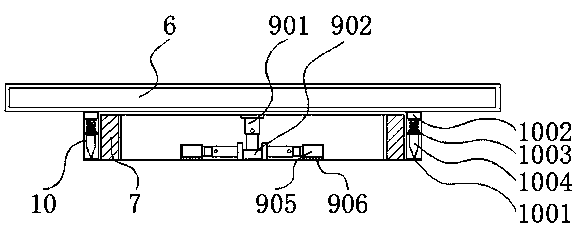

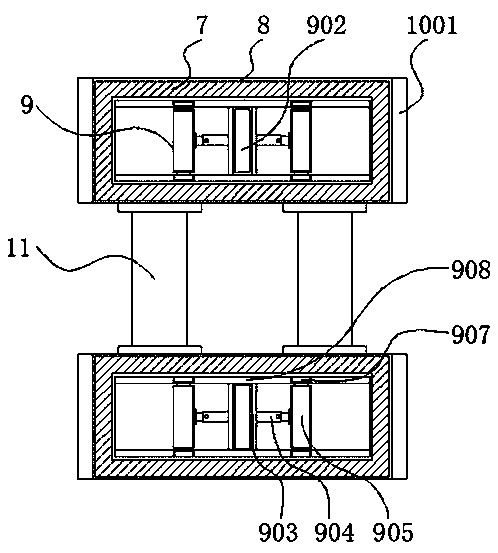

Garbage bag hot melting sealing device and garbage can

Owner:重庆彪鑫科技有限公司

Sheet for packaging food and medicine

InactiveCN1749117AImprove barrier propertiesBarrier property; good mechanical strengthFlexible coversWrappersChemical reactionPolyethylene terephthalate glycol

The present invention relates to sheet for packing food and medicine, and belongs to the field of shaped packing material. The sheet for packing food and medicine has basic material layer of non-crystalline polyethylene terephthalate, and has high obstruction performance on oxygen, water vapor, and smell of food and medicine, high mechanical strength, good thermal sealing performance, high thermal sealing strength, and high chemical stability without reaction with acid, alkali, salt, solvent and oil. The sheet for packing food and medicine coincides with the requirement of food sanitation, is harmful to human body, can be recovered for reuse. The present invention may be used widely in making food and medicine packing container.

Owner:ZHUOGAOTAI SUCKING PLASTIC

Full-biodegradable composite film and preparation method thereof

ActiveCN103937185AImprove antibacterial propertiesHigh transparencySynthetic resin layered productsPolymer scienceComposite film

The invention belongs to the technical field of polymer materials, and particularly relates to a full-biodegradable composite film and a preparation method thereof. The composite film is prepared from the following raw materials: polylactic acid, polyethylene glycol, citrate, ultrafine wool powder, a solubilizer, ultrafine zeolite powder, ultrafine aluminum powder, ultrafine vesuvianite powder, silicone oil and phosphite ester, is resistant in temperature, tearing and stretching, can be completely biodegraded, does not pollute environment, and has the characteristics of antibacterial property, good transparency, high glossiness and the like. The composite film can be used in the field of packaging bags, particularly in foods, daily necessities farmlands, shopping bags and the like. The preparation method adopts a three-layer co-extrusion casting film technology, can perform molding through a quenching roll, is high in accuracy, and can sufficiently exert performance of a processed material; and the size accuracy, optical performance, thickness uniformity and the like of the film can be guaranteed due to each process and parameter.

Owner:HUBEI GUANCHENG BIODEGRADABLE PLASTIC PRODS

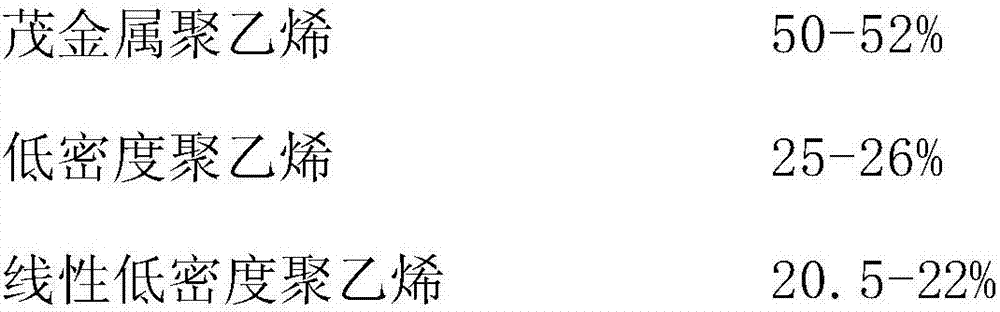

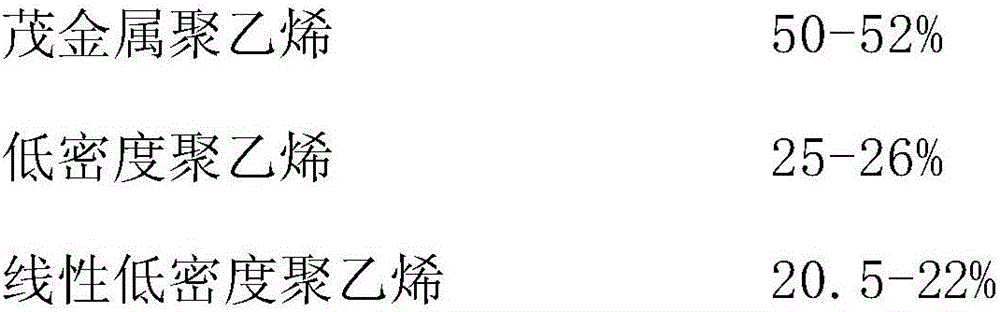

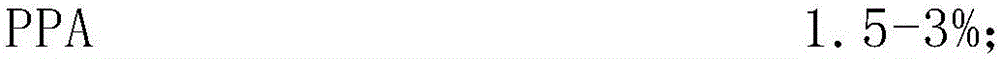

A heavy packaging film

ActiveCN106079768BHigh mechanical strengthGuaranteed StrengthSynthetic resin layered productsDomestic articlesLow-density polyethyleneLinear low-density polyethylene

The invention discloses a heavy packaging film. The heavy packaging film is formed by co-extruding a first layer, a second layer and a third layer, wherein the first layer is prepared from the following raw materials in percentage by weight: 45%-55% of metallocene polyethylene, 20%-30% of low density polyethylene and 17%-27% of linear low density polyethylene; the second layer is prepared from the following raw materials in percentage by weight: 60%-70% of linear low density polyethylene and 27%-37% of high density polyethylene; and the third layer is prepared from the following raw materials in percentage by weight: 45%-55% of metallocene polyethylene, 20%-30% of low density polyethylene and 17%-27% of linear low density polyethylene. The heavy packaging film provided by the invention has the advantages of high tensile strength and tearing strength, easiness of being hotly sealed, good anti-blocking property and excellent anti-falling performance and stacking performance.

Owner:SHANGHAI FANSHUN PACKAGING

Heat-sealing overlock device for mask processing

InactiveCN111251616AImprove processing efficiencyFacilitate heat sealing operationDomestic articlesPhysicsMechanical engineering

The invention discloses a heat-sealing overlock device for mask processing, and relates to the technical field of mask processing. The heat-sealing overlock device comprises a rack, heat-sealing frames and positioning and leveling mechanisms. A conveying mechanism is arranged at the inner upper part of the rack, a support pillar is fixedly arranged at the upper part of the rack, and a mounting topplate is fixedly arranged at the upper part of the support pillar. An electric push rod is arranged at the lower part of the mounting top plate, and a lifting plate is fixedly arranged at the lower part of the electric push rod. The heat-sealing frames are arranged at the lower part of the lifting plate, and thermal insulating layers are arranged on the inner side and the outer side of each heat-sealing frame. The positioning and leveling mechanisms are arranged in the heat-sealing frames, and connecting rods are fixedly arranged between the heat-sealing frames. Cutting mechanisms are arranged on the two sides of the heat-sealing frames. The heat-sealing overlock device has the beneficial effects that the device is convenient to position and level a mask through the positioning and leveling mechanisms, is convenient to lift up and down the height a positioning pressure block through a first hydraulic rod, so that the positioning pressure block can position the middle part of the maskunder the heat-sealing frames to avoid the mask moving during heat-sealing overlock.

Owner:DONGGUAN RONGGONG AUTOMATION TECH CO LTD

Bag sealing device

PendingCN111169734AEasy to heat sealImprove efficiencyWrapper twisting/gatheringConveyor partsProcess engineeringMechanical engineering

The invention provides a bag sealing device and belongs to the technical field of bag production. The bag sealing device comprises a bag taking mechanism and a bag sealing mechanism, wherein the bag taking mechanism is used for grabbing a packaging bag waiting for heat sealing and transferring the packaging bag to a bag sealing station; the bag sealing mechanism comprises a first linear driver anda second linear driver oppositely arranged on the two sides of the bag sealing station; a lining plate is fixedly arranged at the driving end of the first linear driver; a heating plate is fixedly arranged at the driving end of the second linear driver; the lining plate and the heating plate are in parallel and can realize mutual involution under the driving action of the first linear driver andthe second linear driver; and the lining plate and the heating plate realize mutual involution to carry out heat sealing on the opening of a to-be-heated packaging bag on the bag sealing station. Thebag sealing device can realize automatic continuous operation of bag feeding, opening sealing and bag discharging in sequence of a plurality of packaging bags to improve the production bag sealing efficiency and quality.

Owner:深圳市道元实业有限公司

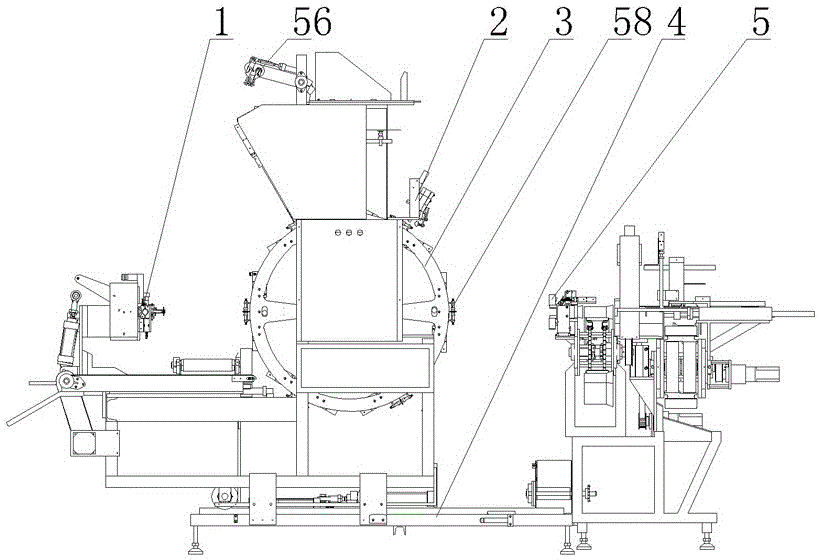

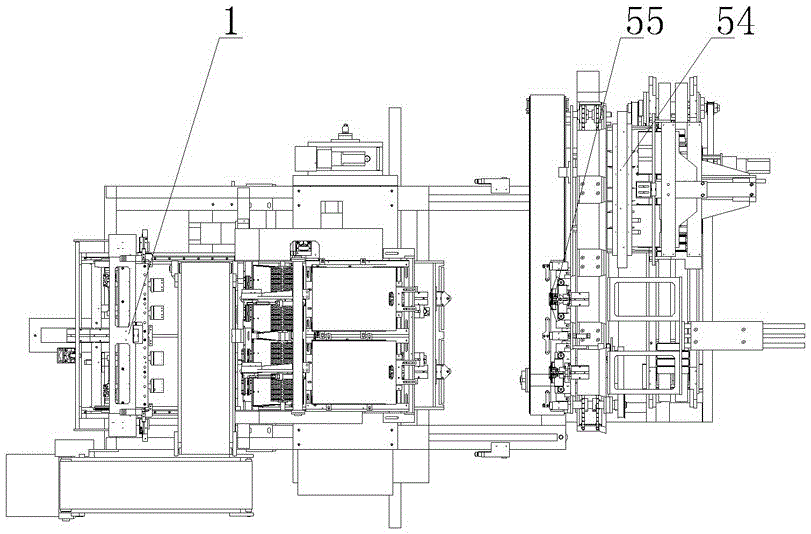

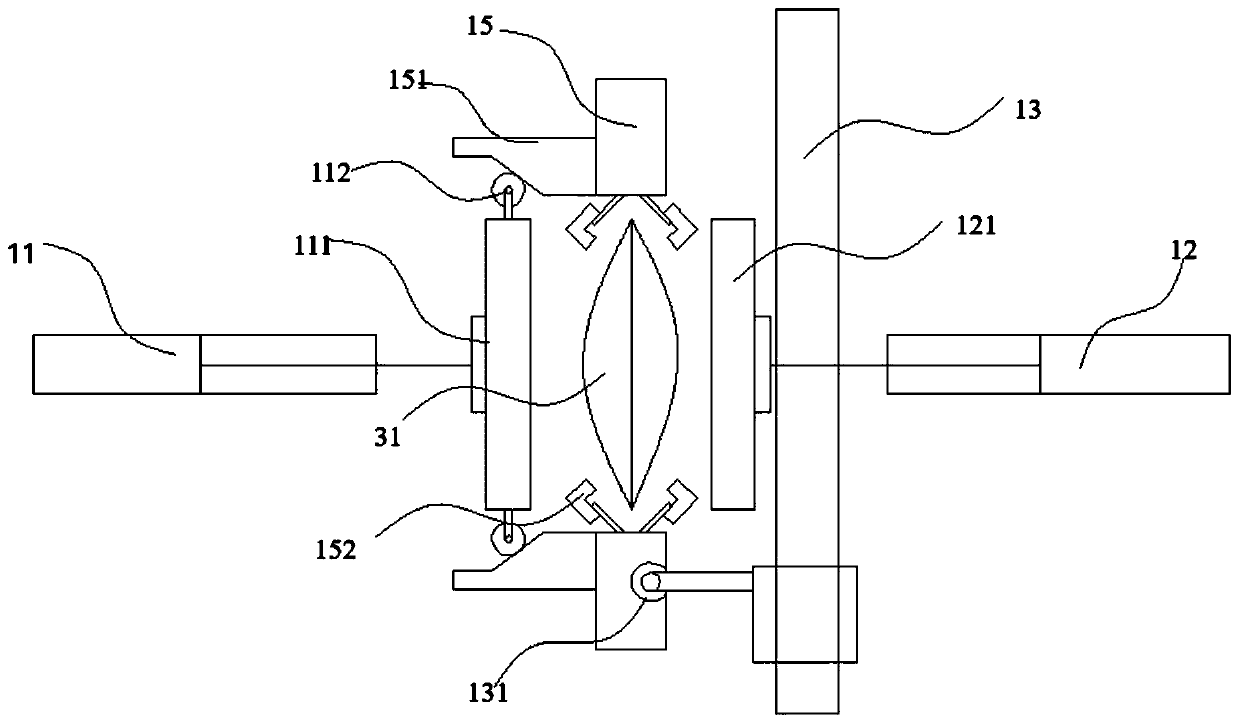

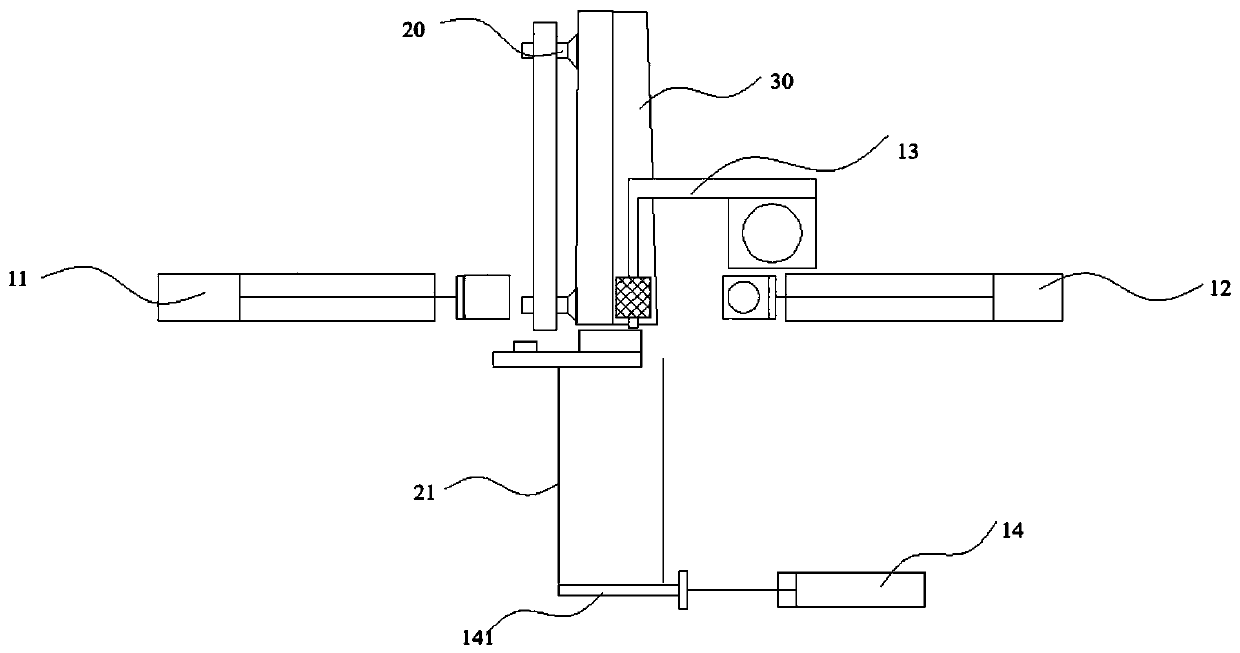

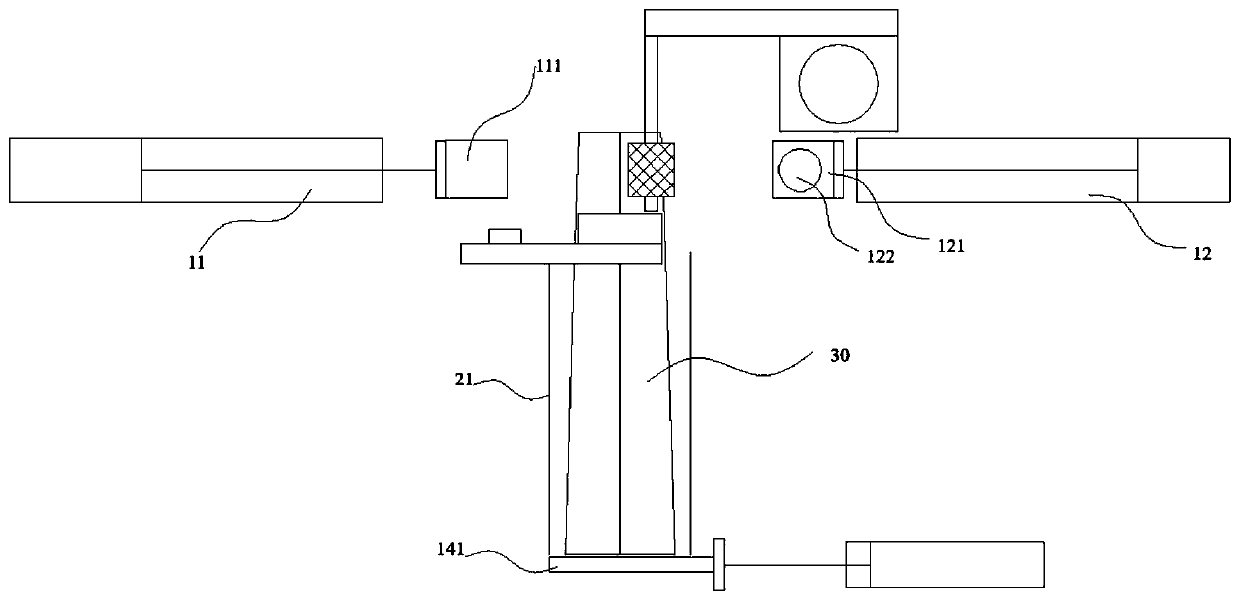

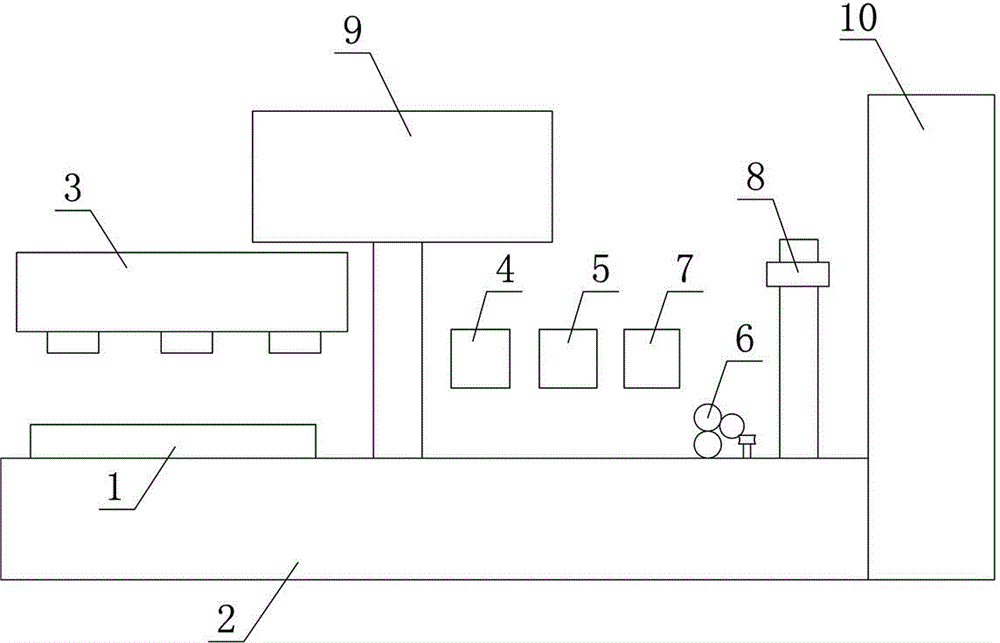

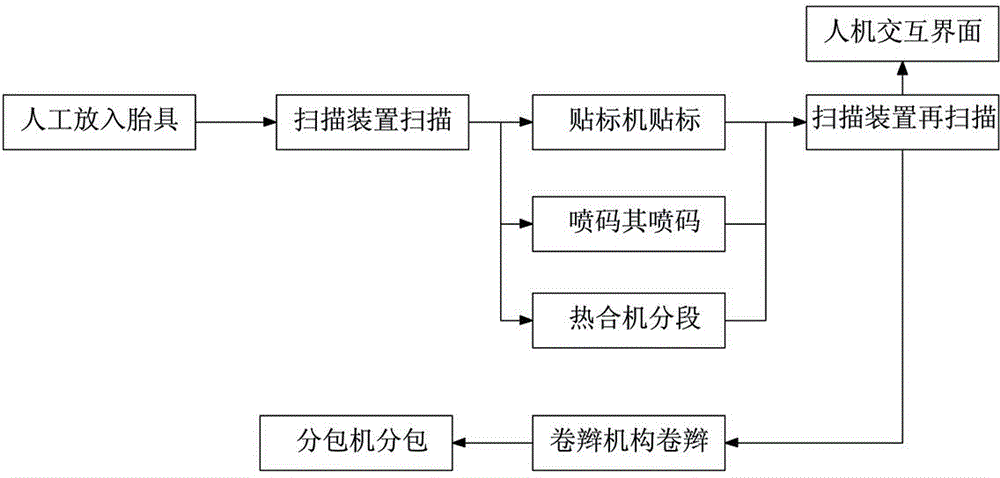

Erythrocyte bag labeling, checking and subpackaging machine and erythrocyte bag checking and subpackaging method

ActiveCN104787405AReduce artificial ginsengDegree of reductionWrapper twisting/gatheringPackaging automatic controlInteraction interfaceHuman–robot interaction

The invention provides an erythrocyte bag labeling, checking and subpackaging machine which comprises a mold, a conveying mechanism, a scanning device, a labeling machine, an ink-jet printing machine, a hot-sealing machine, a braid winding mechanism, a vertical subpackaging machine, a mechanical hand, a human-computer interaction interface and a master control device. The invention further provides an erythrocyte bag checking and subpackaging method. The method comprises the steps that 1, erythrocyte bags are manually placed into the mold, 2, scanning and photographing are carried out, and information on electronic signs are recognized; 3, the labeling machine carries out labeling work; 4, ink-jet printing and hot-sealing section partition are carried out; 5, secondary scanning is carried out, and a scanning result is sent to the human-computer interaction interface; 6, the braid winding mechanism carries out braid winding; 7, the mechanical hand grabs the erythrocyte bags into the vertical subpackaging machine to be packaged and stored. The erythrocyte bag labeling, checking and subpackaging machine has the advantages of being scientific in design, rapid, accurate and high in automation degree. The erythrocyte bag checking and subpackaging method has the advantages of being easy to operate, high in automation degree and high in accuracy rate.

Owner:ZHENGZHOU FEILONG MEDICAL EQUIP CO LTD

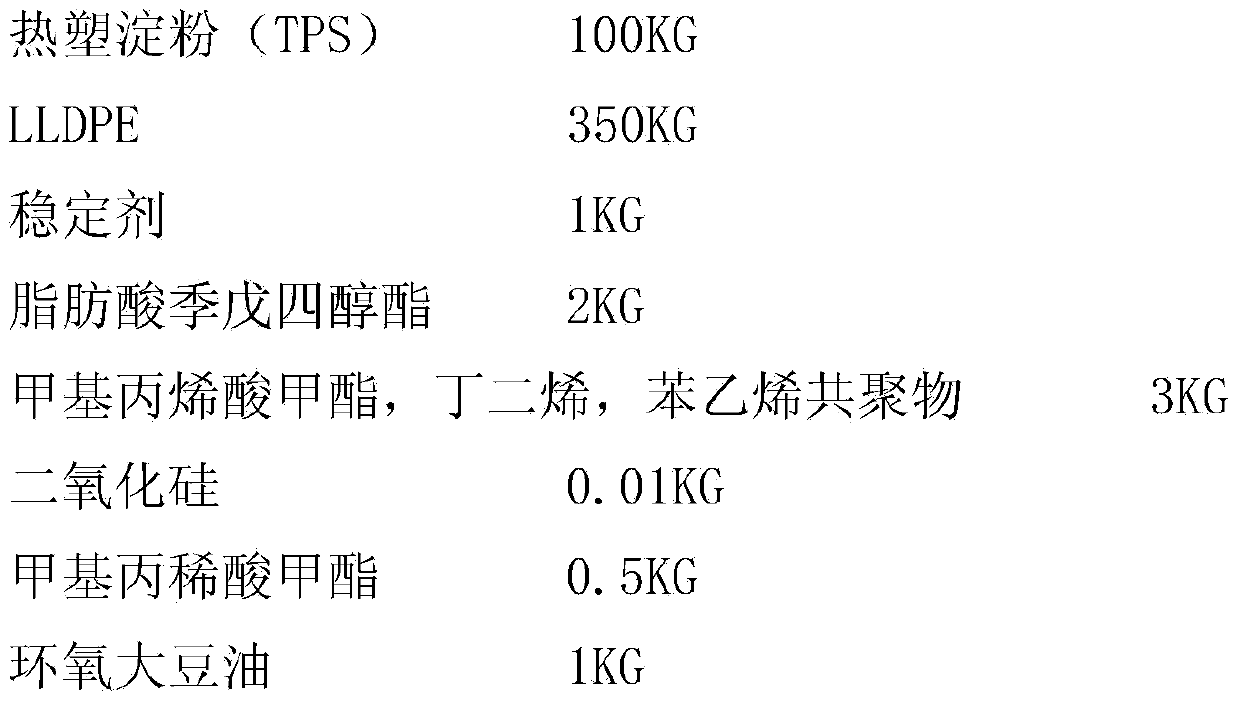

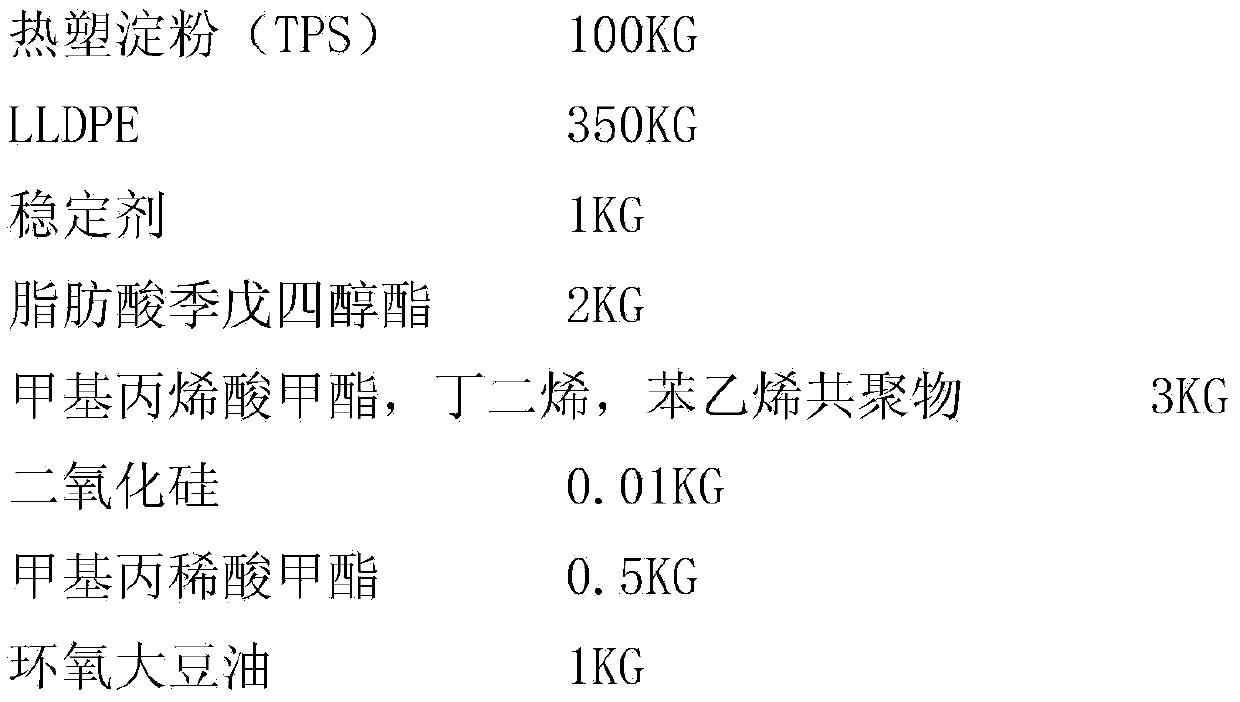

Environment-friendly anti-crease shrink package film

InactiveCN103739923ABright surfaceEasy to heat sealFlexible coversWrappersLinear low-density polyethylenePentaerythritol

The invention provides an environment-friendly anti-crease shrink package film, and relates to a package film. The environment-friendly anti-crease shrink package film is characterized by comprising the following components by weight: 100KG of thermoplastic starch (TPS), 350KG of LLDPE (Linear Low Density Polyethylene), 1.9KG of stabilizer, 2KG of pentaerythritol mixed aliphatic ester, 3KG of methyl methacrylate-butadiene-styrene copolymer, 0.01KG of silicon dioxide, 0.6KG of methyl methacrylate and 1KG of epoxidized soybean oil. The environment-friendly anti-crease shrink package film has the beneficial effects that the product produced by the process is toxic, highly transparent, bright in surface, impact-resistant, tear-resistant, non-combustible, nonhygroscopic, and easy and firm for hot sealing, and thus especially capable of meeting the requirements of various high-speed automatic packaging machines. As a result, the environment-friendly anti-crease shrink package film can be widely applied to the cigarette industry and the printing industry, and to the packages of medicine, audiovisual products and various boxed products, and is capable of achieving the effects of moisture protection and dust prevention.

Owner:戴骏超 +1

Heavy packaging film

ActiveCN106079768AHigh mechanical strengthGuaranteed StrengthSynthetic resin layered productsDomestic articlesLow-density polyethyleneLinear low-density polyethylene

The invention discloses a heavy packaging film. The heavy packaging film is formed by co-extruding a first layer, a second layer and a third layer, wherein the first layer is prepared from the following raw materials in percentage by weight: 45%-55% of metallocene polyethylene, 20%-30% of low density polyethylene and 17%-27% of linear low density polyethylene; the second layer is prepared from the following raw materials in percentage by weight: 60%-70% of linear low density polyethylene and 27%-37% of high density polyethylene; and the third layer is prepared from the following raw materials in percentage by weight: 45%-55% of metallocene polyethylene, 20%-30% of low density polyethylene and 17%-27% of linear low density polyethylene. The heavy packaging film provided by the invention has the advantages of high tensile strength and tearing strength, easiness of being hotly sealed, good anti-blocking property and excellent anti-falling performance and stacking performance.

Owner:SHANGHAI FANSHUN PACKAGING

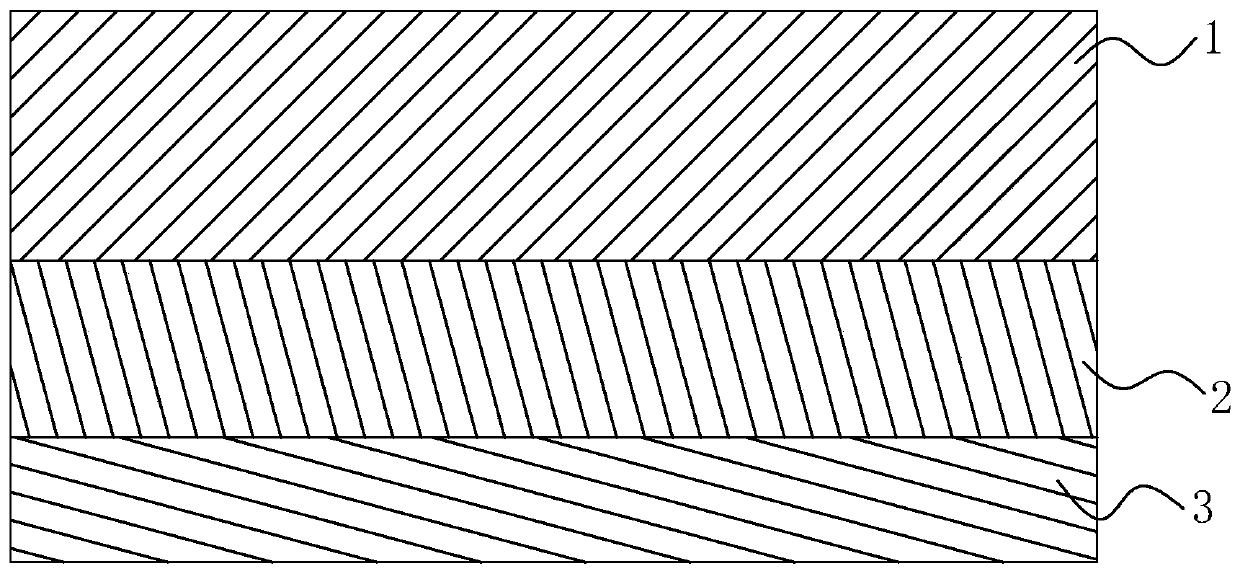

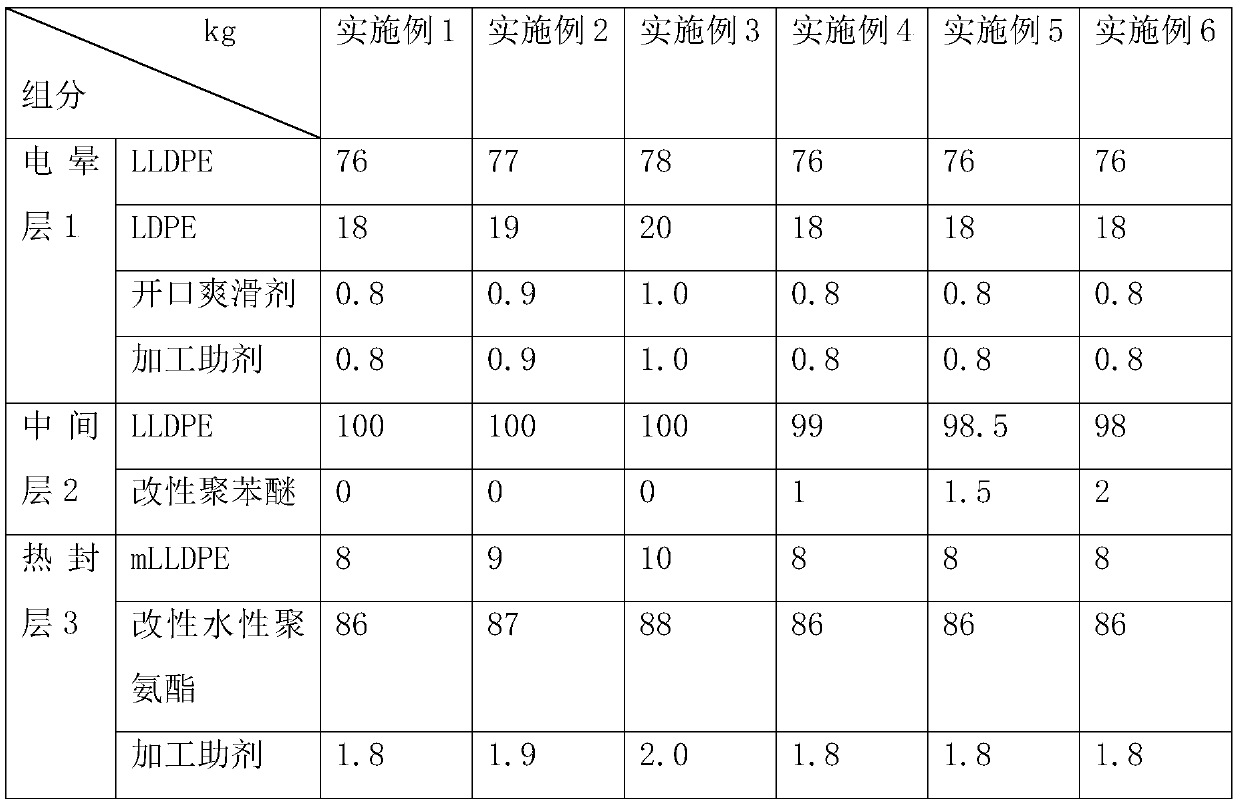

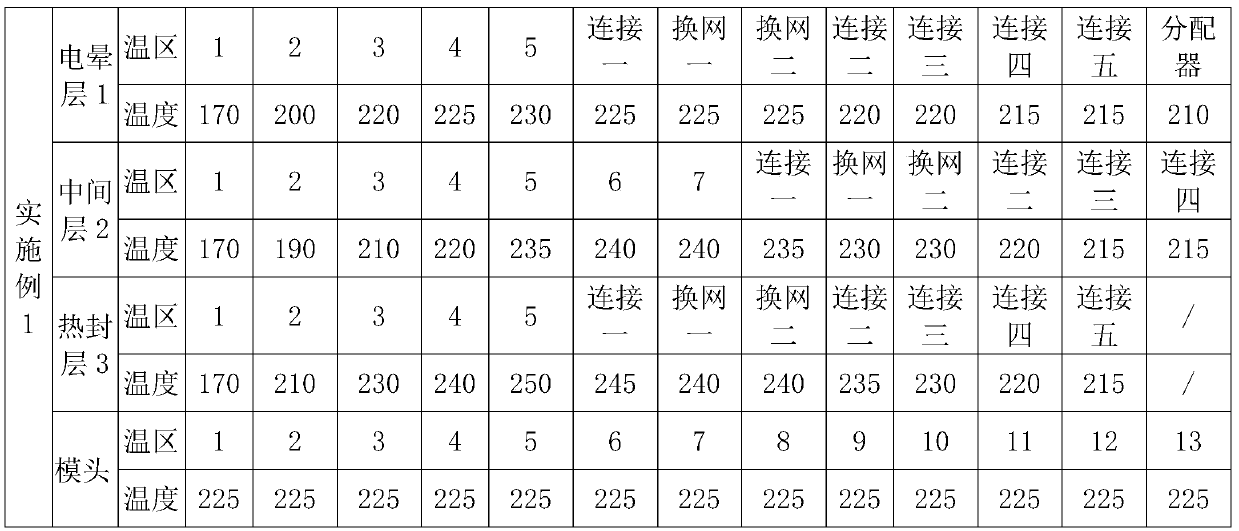

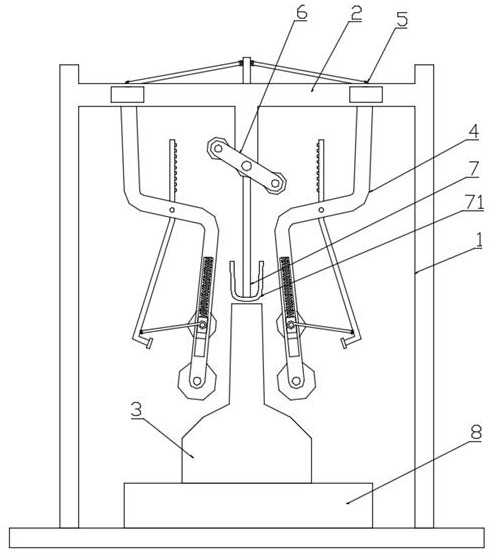

Cast chlorinated polyethylene (CPE) heat-sealing easy-tearing cover film and preparation method thereof

ActiveCN110539537AImprove easy peel and tear performanceEasy to heat sealSynthetic resin layered productsLow-density polyethyleneLinear low-density polyethylene

The invention discloses a cast chlorinated polyethylene (CPE) heat-sealing easy-tearing cover film and a preparation method thereof. The cast CPE heat-sealing easy-tearing cover film comprises a corona layer, an intermediate layer and a heat-sealing layer which are sequentially connected; the corona layer comprises the following raw materials in parts by weight: 76-80 parts of linear low density polyethylene (LLDPE), 18-22 parts of low-density polyethylene (LDPE), 0.8-1.2 parts of an opening slip agent and 0.8-1.2 parts of a processing aid; the intermediate layer comprises LLDPE; and the heat-sealing layer comprises the following raw materials in parts by weight: 8-12 parts of metallocene linear low density polyethylene (mLLDPE), 86-90 parts of modified waterborne polyurethane and 1.8-2.2parts of a processing aid. The cast CPE heat-sealing easy-tearing cover film has the advantages of being easily heat-sealed with cup bodies made of polyethylene terephthalate (PET) / polyvinyl chloride(PVC) / polystyrene(PS) / polyethylene(PE), and being easily torn and stripped.

Owner:福建立邦包装有限公司

Heat sealing device for food packaging bag

InactiveCN114655518AEasy to heat sealAvoid affecting the heat sealing effectWrapper twisting/gatheringHeat sealerEngineering

The invention discloses a heat sealing device of a food packaging bag, and relates to the technical field of packaging auxiliary equipment.The heat sealing device comprises a heat sealing rack and two heat sealing mechanisms, the top of the heat sealing rack is provided with a top frame, and each heat sealing mechanism comprises a side pressing support, a side pressing roller, a flattening piece and a heat sealing rotating supporting rod; the side pressing roller is arranged at the end, away from the top frame, of the side pressing support, the leveling piece is slidably arranged on the rod wall of the side pressing roller, the side pressing roller is provided with an elastic returning piece, the heat-sealing rotating supporting rod penetrates through the middle of the side pressing support and is rotationally connected with the side portion of the side pressing support, and a heat-sealing melting pressing plate is arranged at the bottom of the heat-sealing rotating supporting rod; a push-pull rod is arranged between the end part of the flattening piece and the heat-sealing rotating support rod; the device further comprises a driving piece and a flattening shifting piece. The flat shifting piece is arranged on the top frame and located between the two heat sealing mechanisms. The food packaging bag heat sealing device is simple in structure, the heat sealing flatness of food packaging bags can be improved through flatness and side pressure, then the heat sealing effect is improved, operation is convenient and fast, and practicability is high.

Owner:安徽德隆环保包装科技有限公司

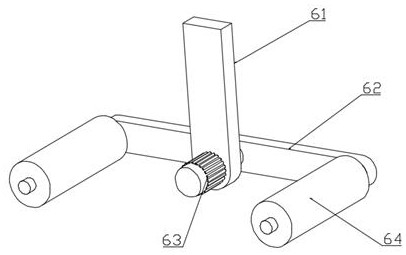

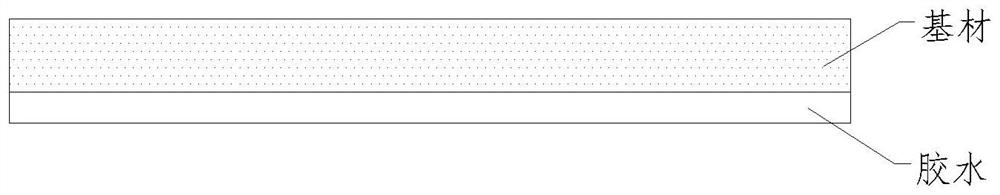

Expansion adhesive tape for lithium battery cell

PendingCN114181634AImprove adhesionStrong adhesionFilm/foil adhesivesPretreated surfacesElectrolytic agentPhysical chemistry

The invention relates to the technical field of adhesive tapes for lithium battery cells, in particular to an expansion adhesive tape for lithium battery cells, which comprises a base material and glue, the glue is arranged on the inner side surface of the base material, and the adhesive tape expands when encountering electrolyte, so that the cells can be fixed, and the existing termination adhesive tape is replaced. Compared with other surface treatment modes, the base material is formed by casting and coating non-acid-resistant and degradable films such as CPP, OPS, TPU, PLA and PO, off-line rewinding is not needed during coating, coating is carried out between longitudinal stretching and transverse stretching, a transverse stretching section is used as a drying oven to dry coating liquid, and the production efficiency is high; the coating is uniform, the coating is thinner than off-line coating, the coating effect is better, the coating cost can be obviously reduced, the surface tension of the film subjected to corona treatment is gradually attenuated along with time, the surface of the film subjected to coating treatment does not have the corona attenuation problem, and the acrylic acid glue is selected for coating, so that the adaptability is high, the drying speed is high, and the coating quality is high. The adhesive force to a base material is strong, and the leveling property and transparency are good.

Owner:SHENZHEN HORAE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com