Patents

Literature

31results about How to "Guaranteed friction performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Car brake block mixed with piemarker fiber and preparing method of car brake block

InactiveCN103836098AHigh melting pointModerate hardnessOther chemical processesFriction liningRare earthRenewable resource

The invention discloses a car brake block with a piemarker fiber and a preparing method of the car brake block. The car brake block comprises the natural piemarker fiber, aramid fiber pulp, rare-earth modified phenolic resin, a friction performance modifier, padding and the like, and comprises, by weight, 30-35 parts of reinforced fiber, 13-16 parts of binding agent, 9-12 parts of friction performance modifier and 40-45 parts of padding. The piemarker fiber on which the alkali treatment and ultrasonic treatment are carried out is low in price, light, high in specific strength, specific modulus and tensile strength and good in abrasion resistance and has other superior properties, and belongs to renewable resources. The car brake block prepared under the optimal technological condition and mixed with the piemarker fiber has a stable friction coefficient, a good brake effect and brake smoothness, is low in noise, good in comfort and friendly to the environment and is an ideal environment-friendly friction material.

Owner:QINGDAO UNIV

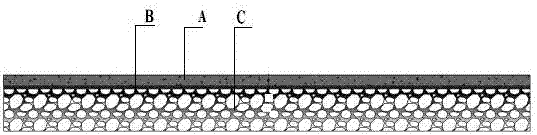

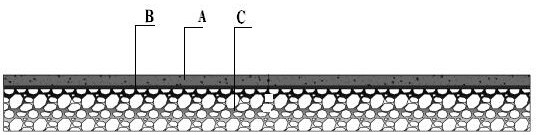

Maintenance construction method of asphalt road surface solid permeability wearing layer

ActiveCN108003639AFast constructionRepair early diseaseIn situ pavingsBuilding insulationsDistilled oilRoad surface

The invention discloses a maintenance construction method of an asphalt road surface solid permeability wearing layer. The construction method includes the following steps that the spreading amount ofa solid permeability agent is surveyed; a road surface is cleaned; the road surface is pre-processed; the solid permeability agent is sprayed; a wearing layer is spread; manual trimming is carried out; preliminary maintenance is carried out. According to the maintenance construction method, the solid permeability agent is demulsified immediately after being atomized or smeared on the original road surface, heavy cycloparaffin distilled oil rapidly infiltrates to restore old asphalt performance, early diseases of the original asphalt road surface are repaired, and meanwhile a matrix asphalt and tackifier mixture is left on the road surface to form a binding layer. A solid permeability layer is formed by the repaired original asphalt road surface and the binding layer. The maintenance construction method is high in construction speed and efficiency.

Owner:江苏瑞文戴尔交通科技有限公司

Low-temperature-resistant and high-toughness packaging film material and preparation method for same

InactiveCN107471789AGuaranteed attachment rateGuaranteed friction performanceSynthetic resin layered productsElastomerLinear low-density polyethylene

The invention relates to a low-temperature-resistant and high-toughness packaging film material, which is divided into inner, middle and outer layers, wherein the inner layer is prepared from the following raw materials in parts by weight: 30 to 40 parts of metallocene polyethylene, 10 to 20 parts of linear low density polyethylene, 3 to 5 parts of a plastic lubricant and 2 to 3 parts of a slipping agent; the middle layer is prepared from the following raw materials in parts by weight: 30 to 40 parts of metallocene polyethylene, 60 to 70 parts of linear low density polyethylene and 3 to 5 parts of a propylene-based elastomer; the outer layer is prepared from the following raw materials in parts by weight: 30 to 40 parts of metallocene polyethylene, 10 to 15 parts of linear low density polyethylene, 3 to 5 parts of an anti-slip agent and 2 to 3 parts of an ink binder. The packaging film material has the advantages of low-temperature resistance and high toughness, and a package can be prevented from being broken at a 3m height at -20 DEG C; the performance is ensured, and meanwhile, the lowest using cost and a better packaging effect are achieved.

Owner:安徽天大环保新材料股份有限公司

Heavy truck brake pad with man-made skeleton as framework and manufacturing method thereof

InactiveCN103836095ASmooth brakingNo damageOther chemical processesBraking membersFiberCarbon fibers

The invention relates to the field of manufacturing of heavy trunk brake pads, in particular to a heavy truck brake pad with a man-made skeleton as a framework and a manufacturing method of the heavy truck brake pad. The porous man-made skeleton framework is made of carbon fiber toughened ceramic, a porous framework material is filled with resin, friction performance modifier, filler and the like to make a high-performance special brake pad friction material, and thus the heavy truck brake pad can adapt to a special working environment and has the advantages of being low in density, high in strength, good in heat resistance, high in friction coefficient, stable and long in service life. The heavy truck brake pad can adapt to extreme working conditions with high temperature and high loads, is suitable for high-speed heavy trucks, lifting devices for mines and the like and has huge promotional application values.

Owner:QINGDAO UNIV

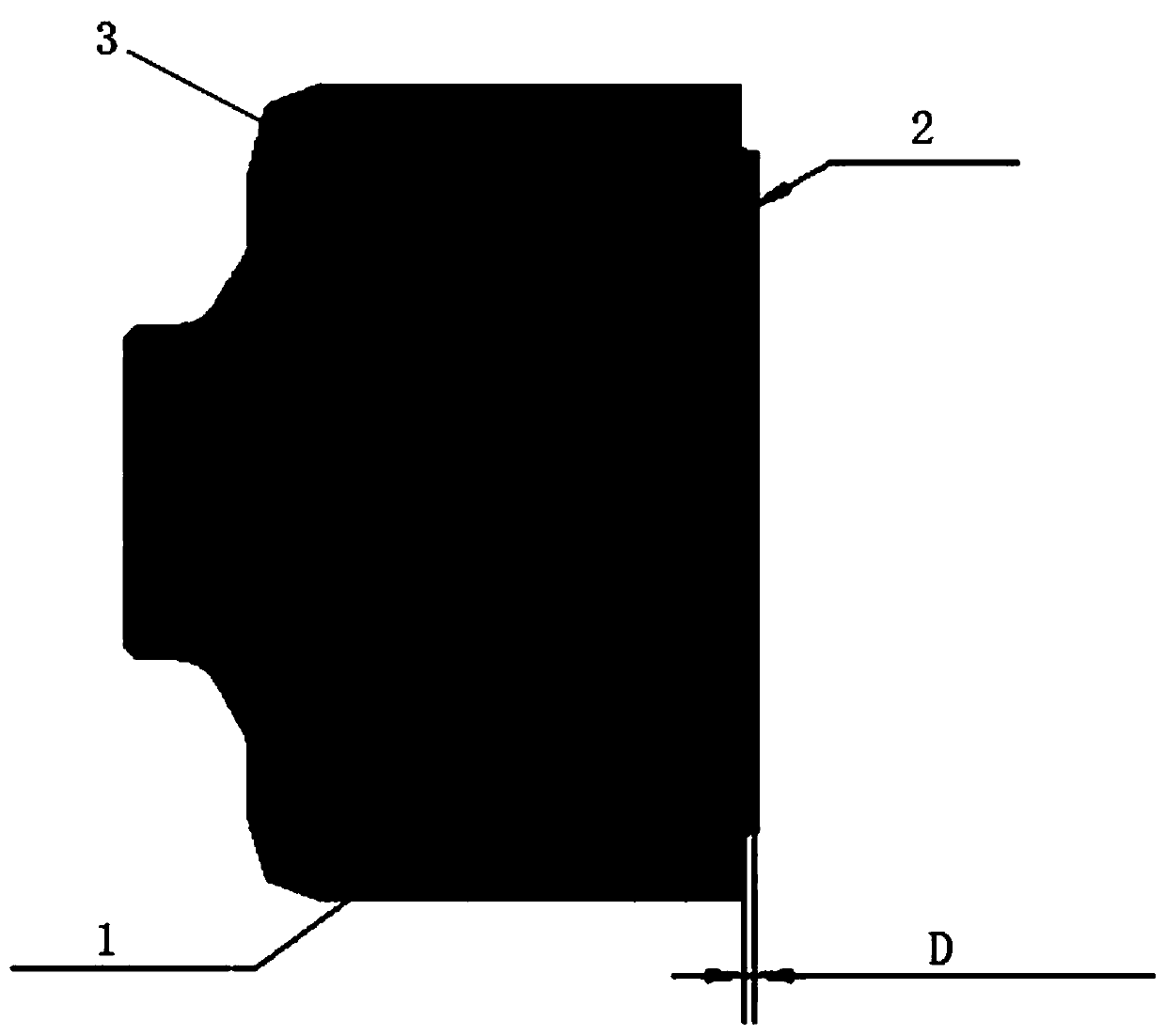

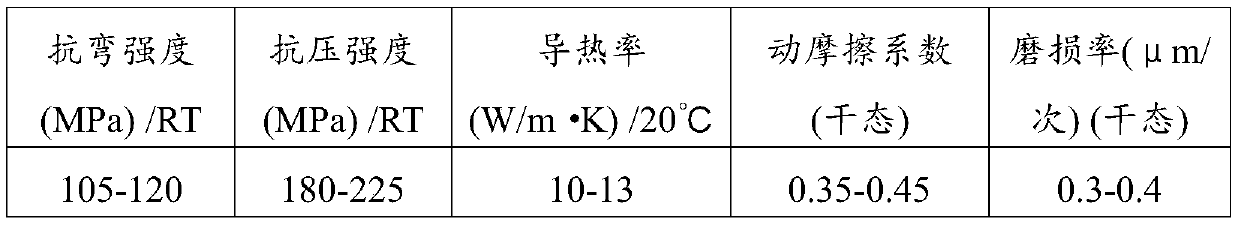

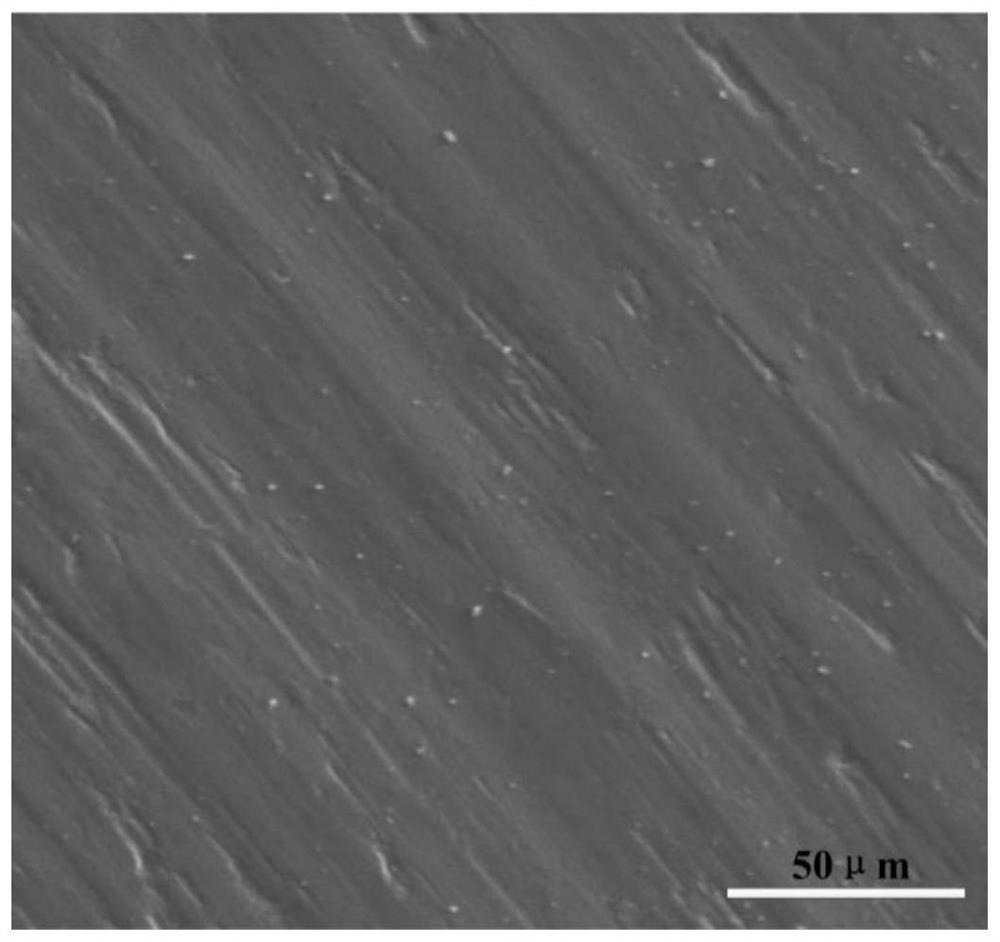

Bimetal cylinder block, friction pair and machining method for axial variable piston pump

InactiveCN111102185AGuaranteed friction performanceReduce coefficient of frictionPositive displacement pump componentsLiquid fuel engine componentsPlunger pumpFusion welding

The invention relates to a bimetal cylinder block, a friction pair and a machining method for an axial variable piston pump. A matrix of the cylinder block is made of a ductile cast iron material, thevalve surface of the cylinder block is made of a copper alloy material, a copper alloy is fused to the valve surface of the cylinder block through fusion welding, nitrocarburation is adopted in the heat treatment of the matrix, and an effective wear-resistant layer is formed in the surface of a cylinder block piston plug hole. According to the technical scheme of the bimetal cylinder block, the friction pair and the machining method, the wear problem of the original plane friction pair is solved. After long-term use, the copper alloy plane of the cylinder block and the friction surface of a valve plate have no obvious damage or abnormal wear, the plane valve effect is significantly improved, the service life is significantly prolonged, and the service life of the pump is significantly prolonged.

Owner:中船重工重庆液压机电有限公司

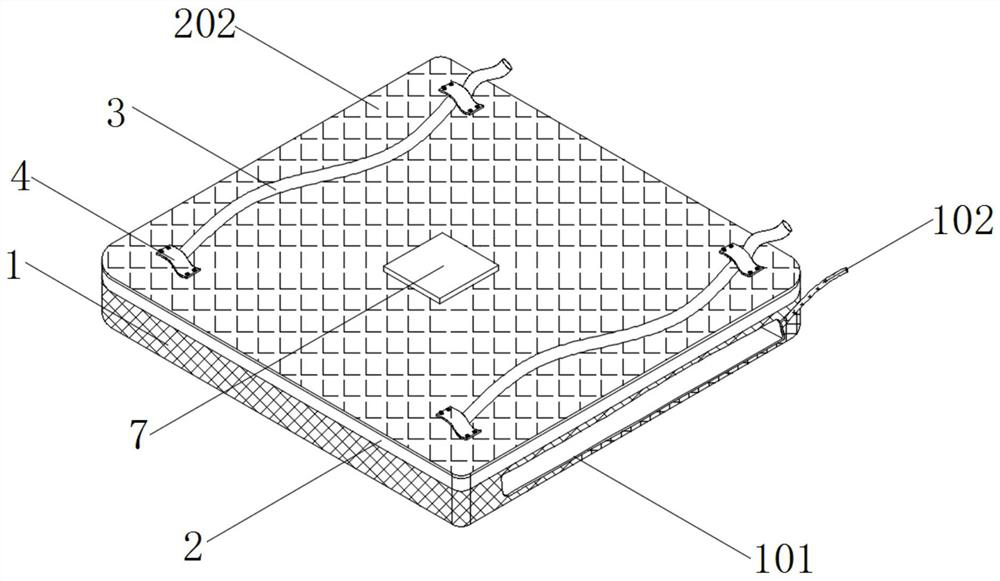

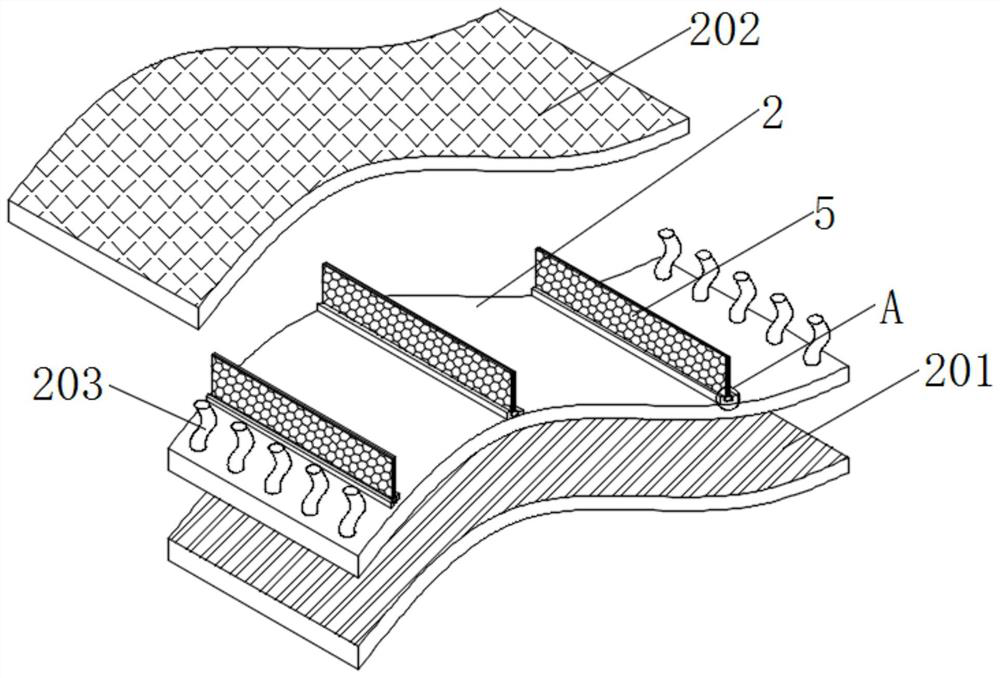

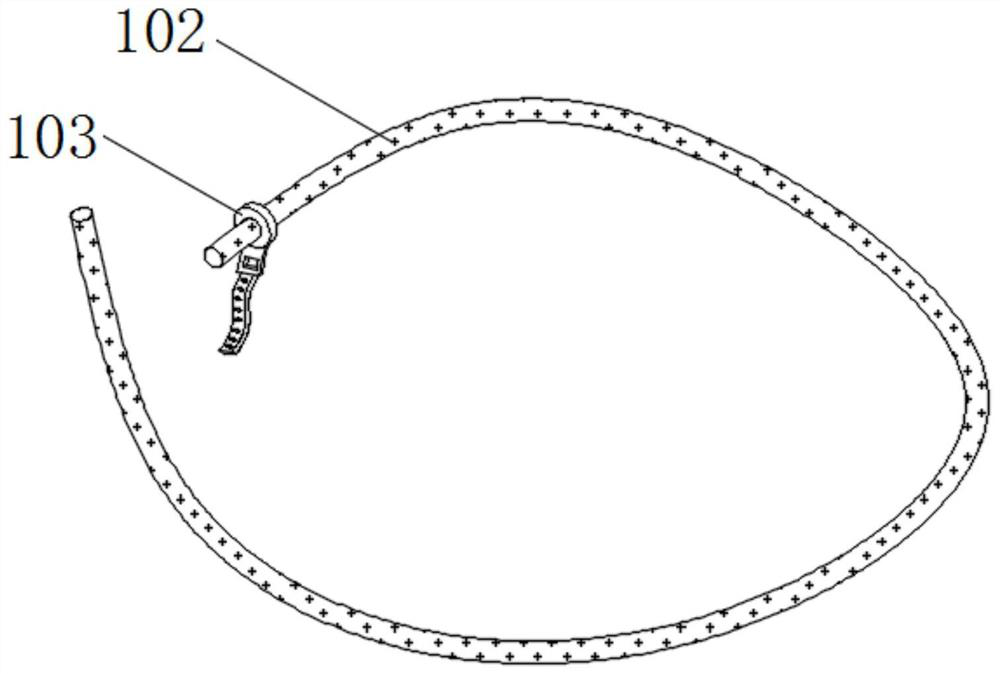

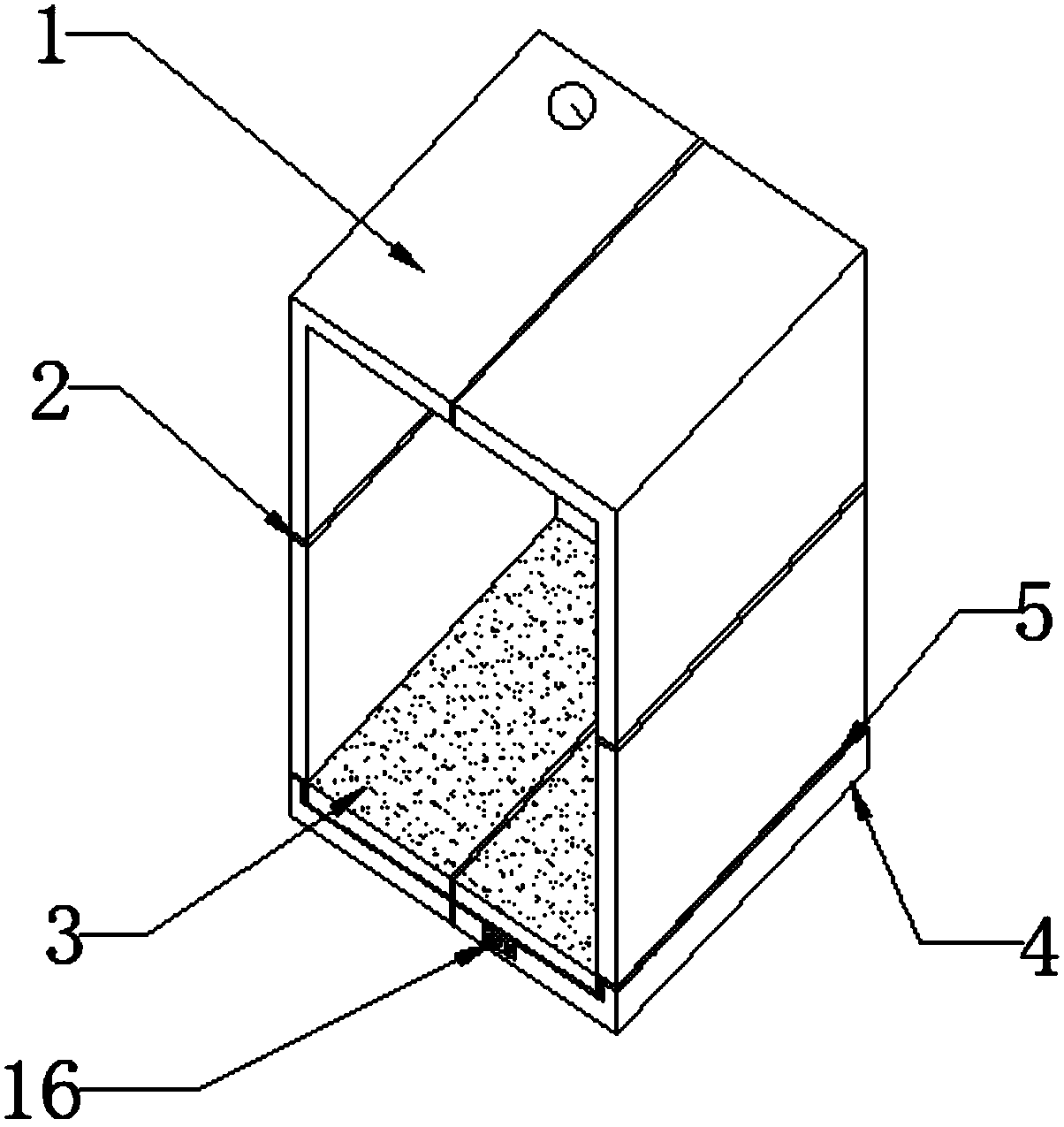

Leakproof flood control bag capable of rapidly absorbing water and expanding

ActiveCN113668459AStrengthening the effect of flood control and flood fightingGuaranteed drynessDamsDykesSuper absorbentFlood control

The invention discloses a leakproof flood control bag capable of rapidly absorbing water and expanding. The leakproof flood control bag comprises a sand bag, wherein a water-resisting layer is connected to the top of the sand bag, and an expansion bag is connected to the top of the water-resisting layer; rubber pull ropes are evenly arranged on the top surface of the expansion bag, and a filter screen is connected to the top ends of the rubber pull ropes; and extrusion structures which are arranged at equal intervals are installed on the top of the expansion bag, the extrusion structures are located in the middle of the rubber pull ropes, a marking frame is installed in the center of the top surface of the filter screen, a reinforcing bottom layer is installed at the bottom of the sand bag, binding blocks are respectively installed at the four corners of the top surface of the filter screen, and a detection bag is installed on the back surface of the sand bag. According to the leakproof flood control bag, the expansion bag and rubber strips are arranged, and rapid water absorption and expansion are achieved through internal super absorbent resin, so that the carrying and using of gravel are reduced, the expansion bag can be prevented from cracking through elastic limitation of the rubber strips, and the leakproof protection effect is achieved.

Owner:YELLOW RIVER INST OF HYDRAULIC RES YELLOW RIVER CONSERVANCY COMMISSION

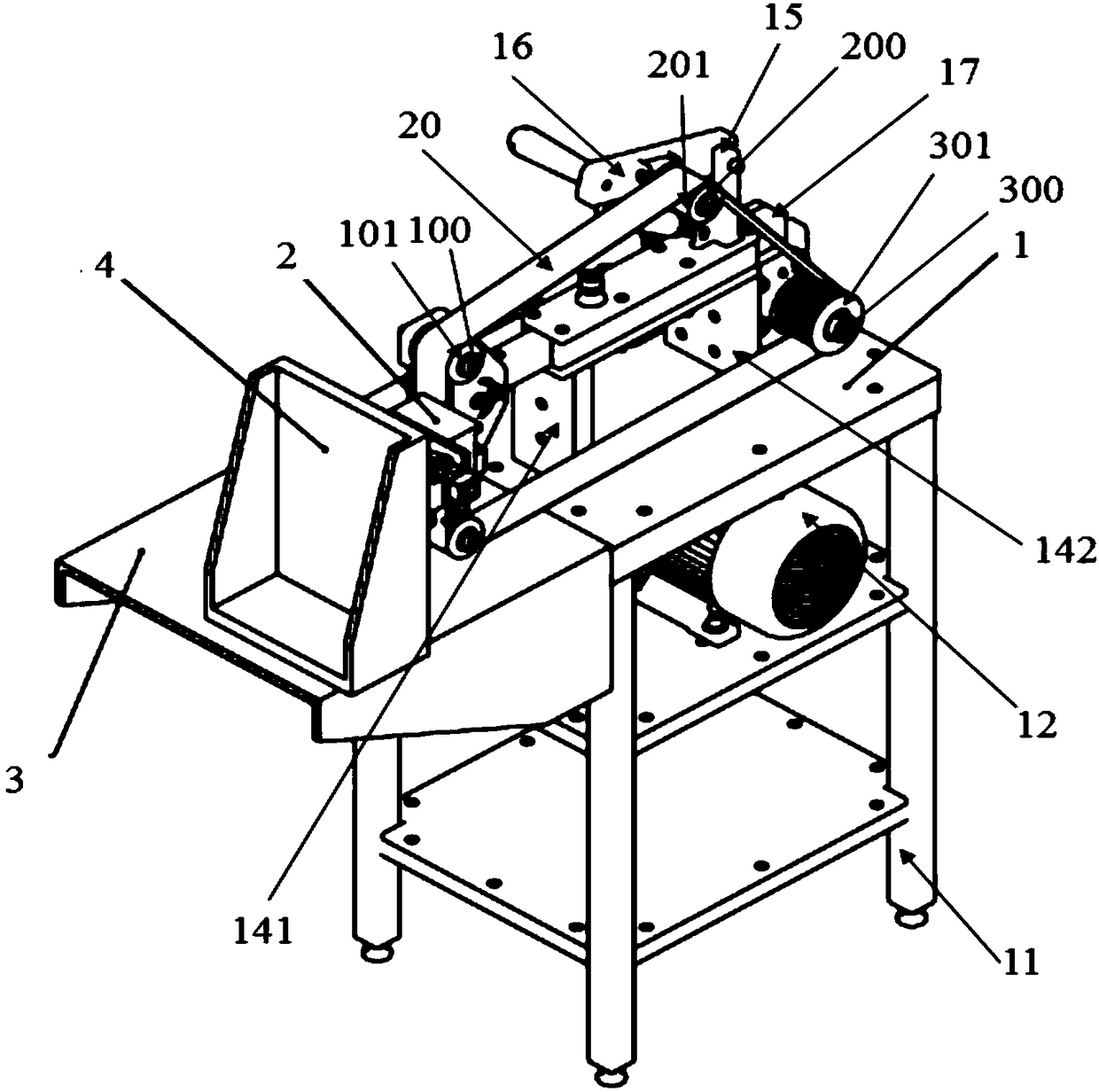

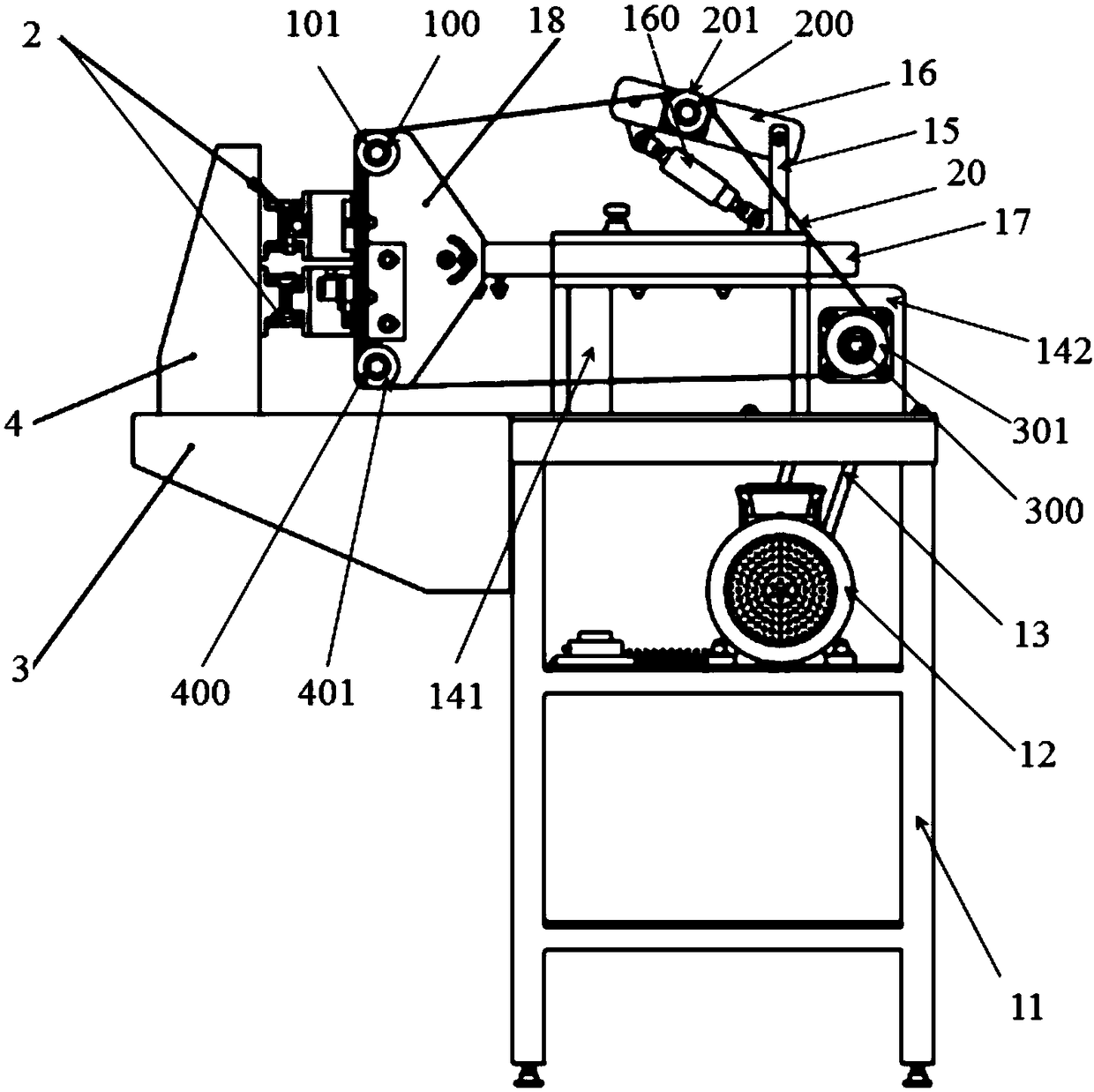

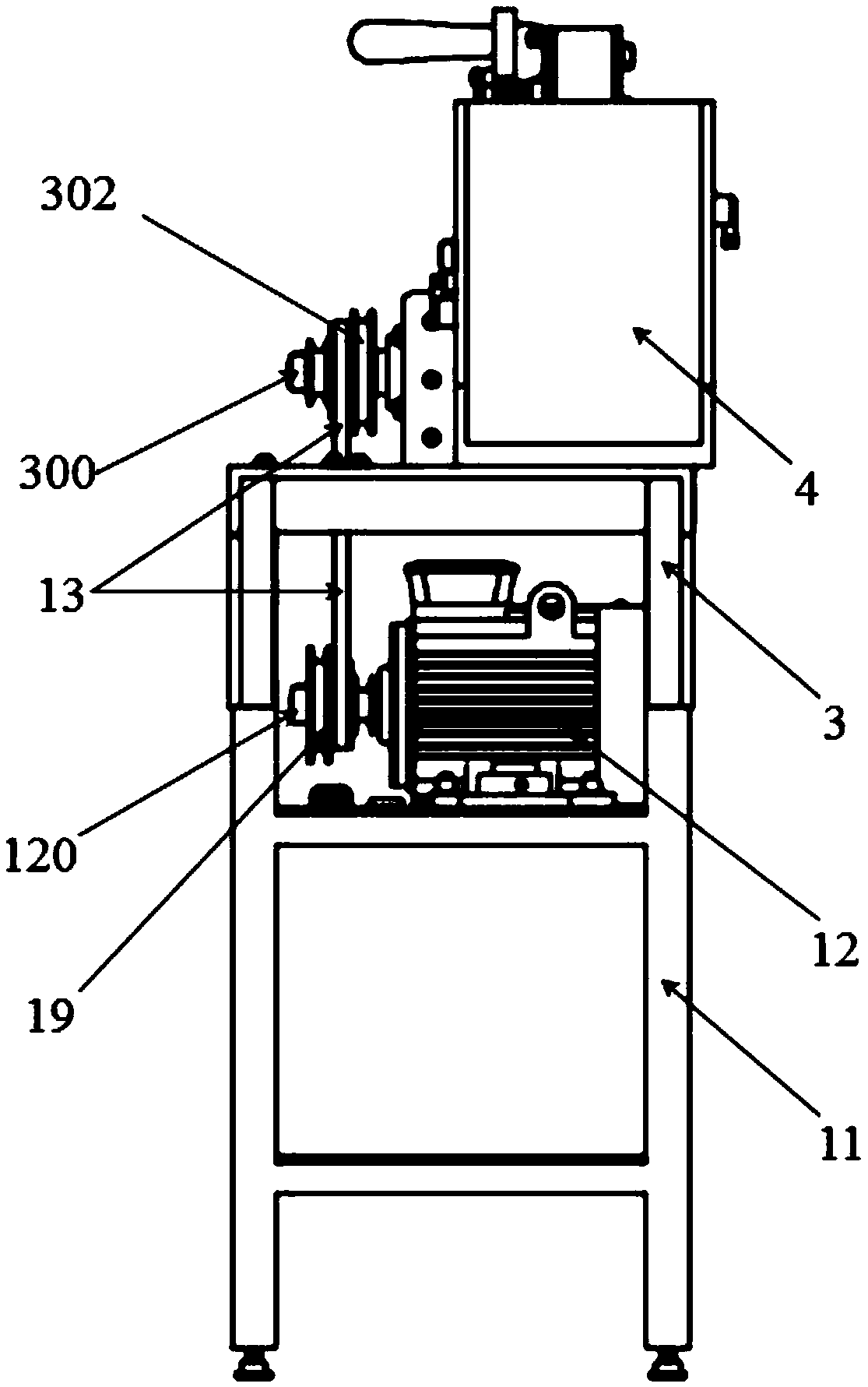

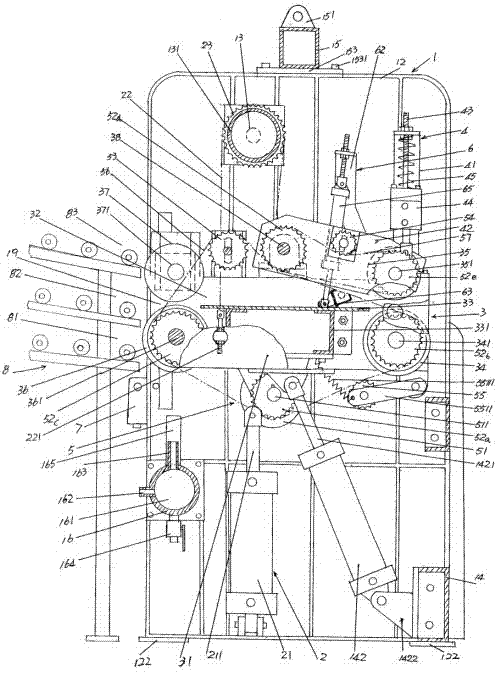

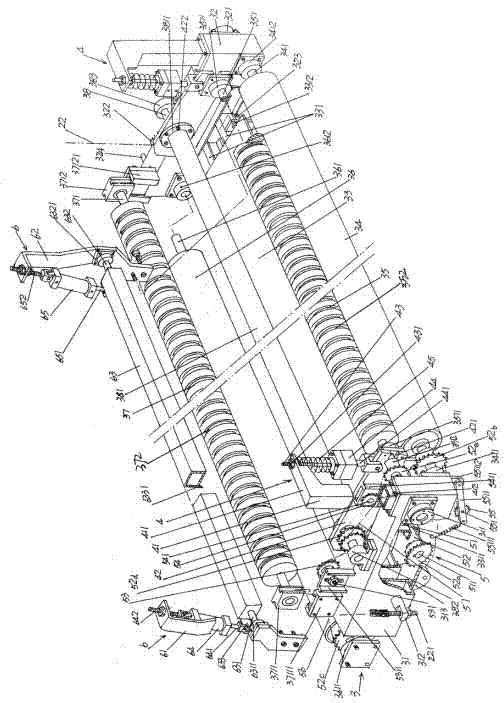

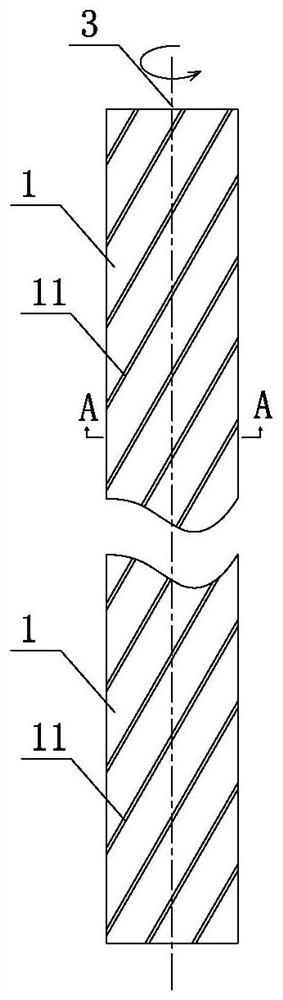

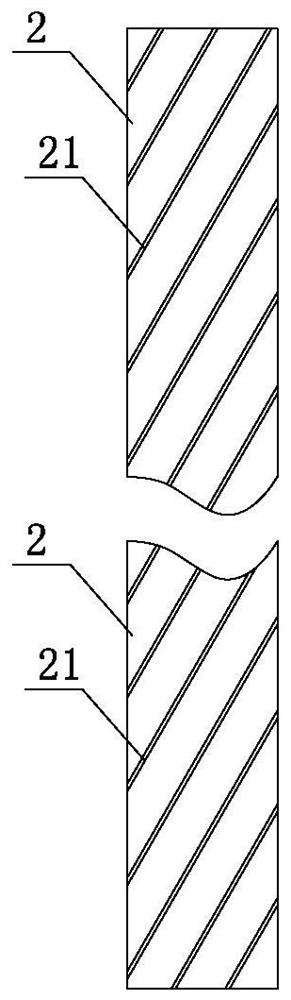

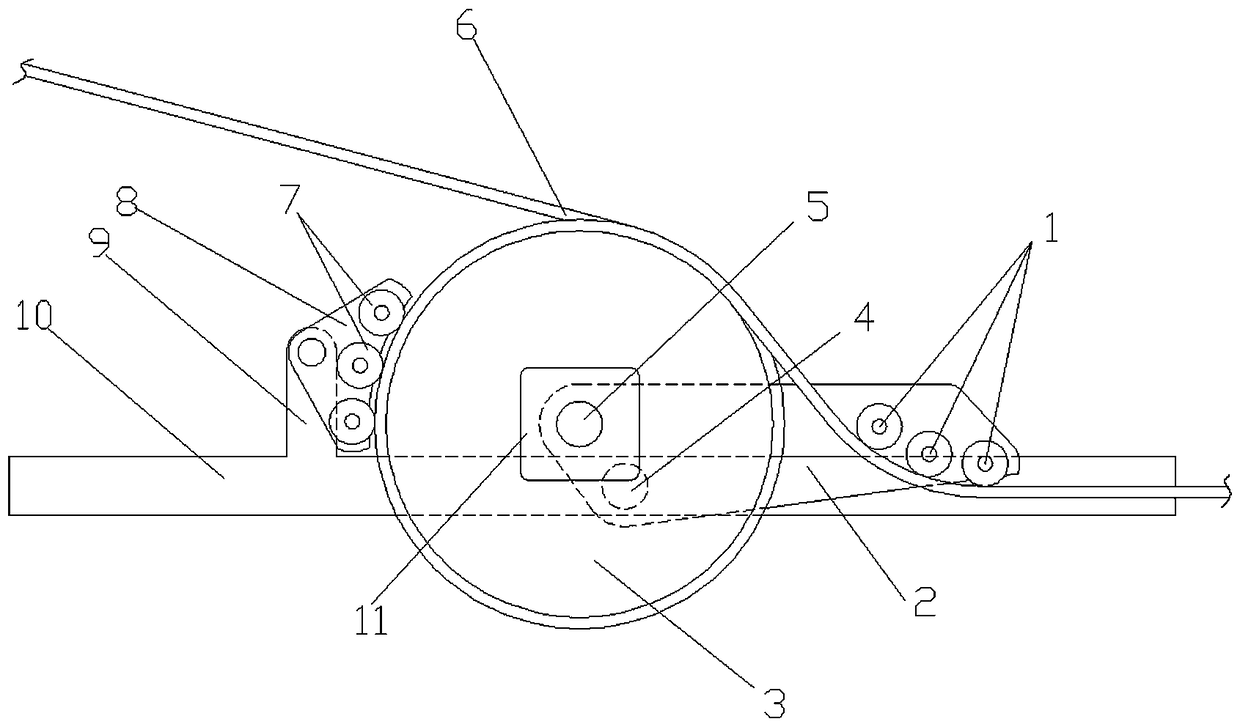

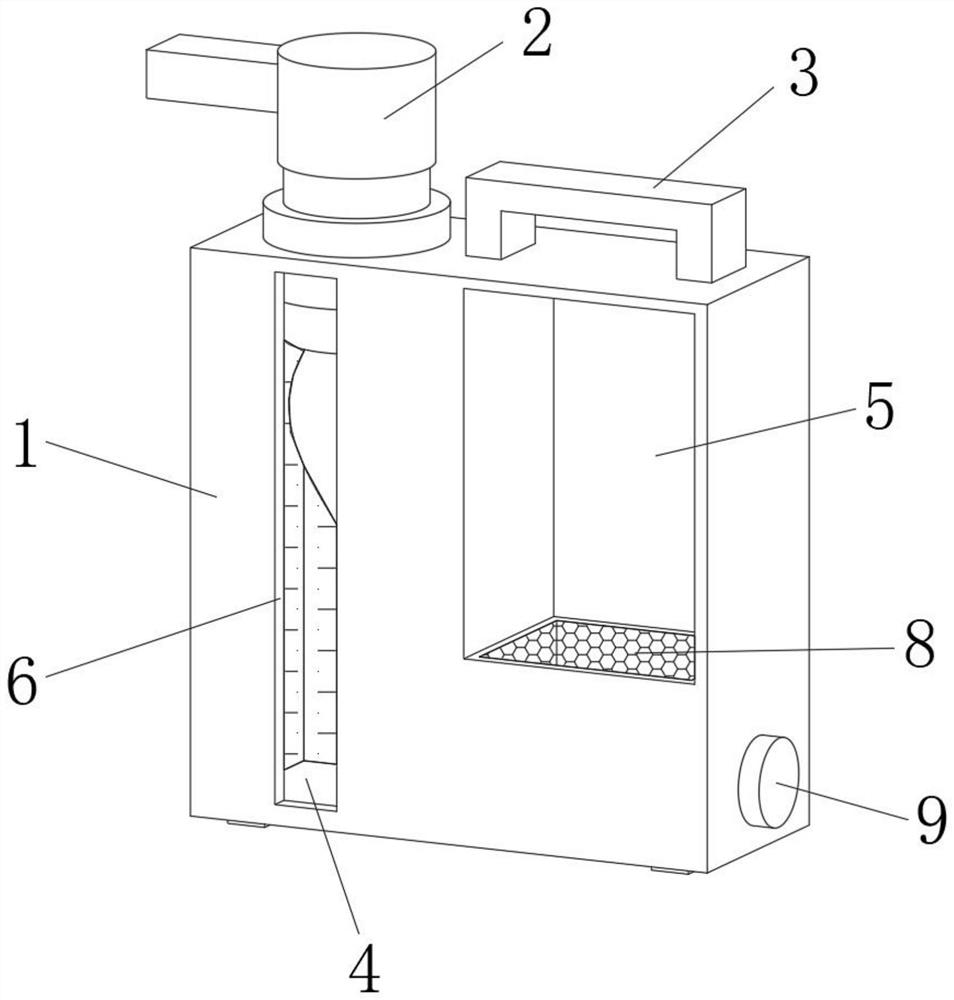

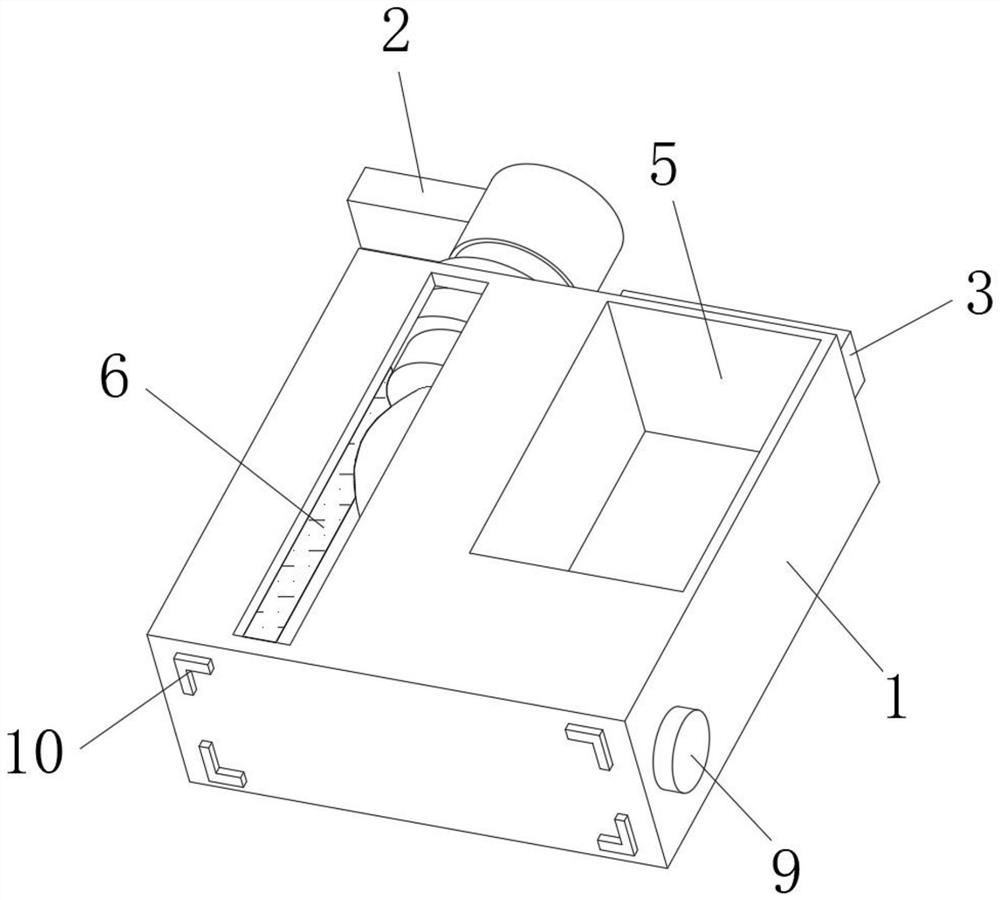

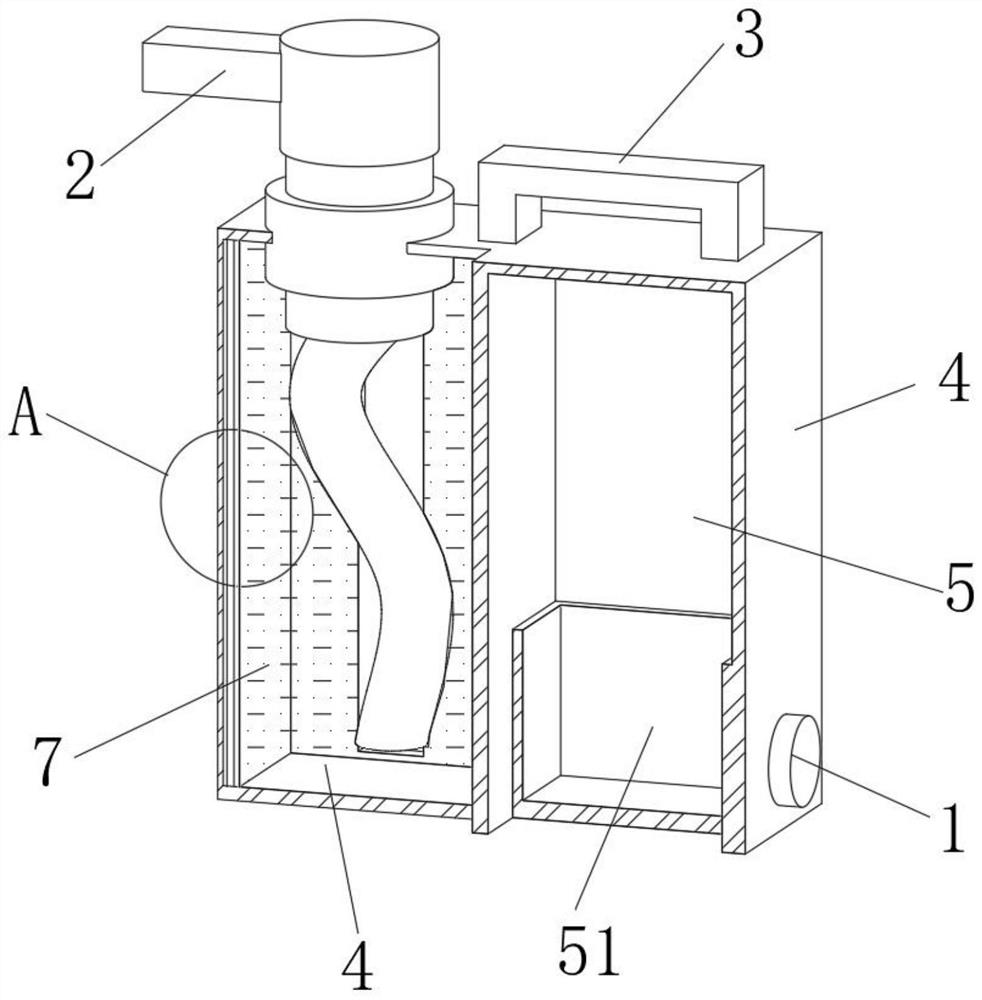

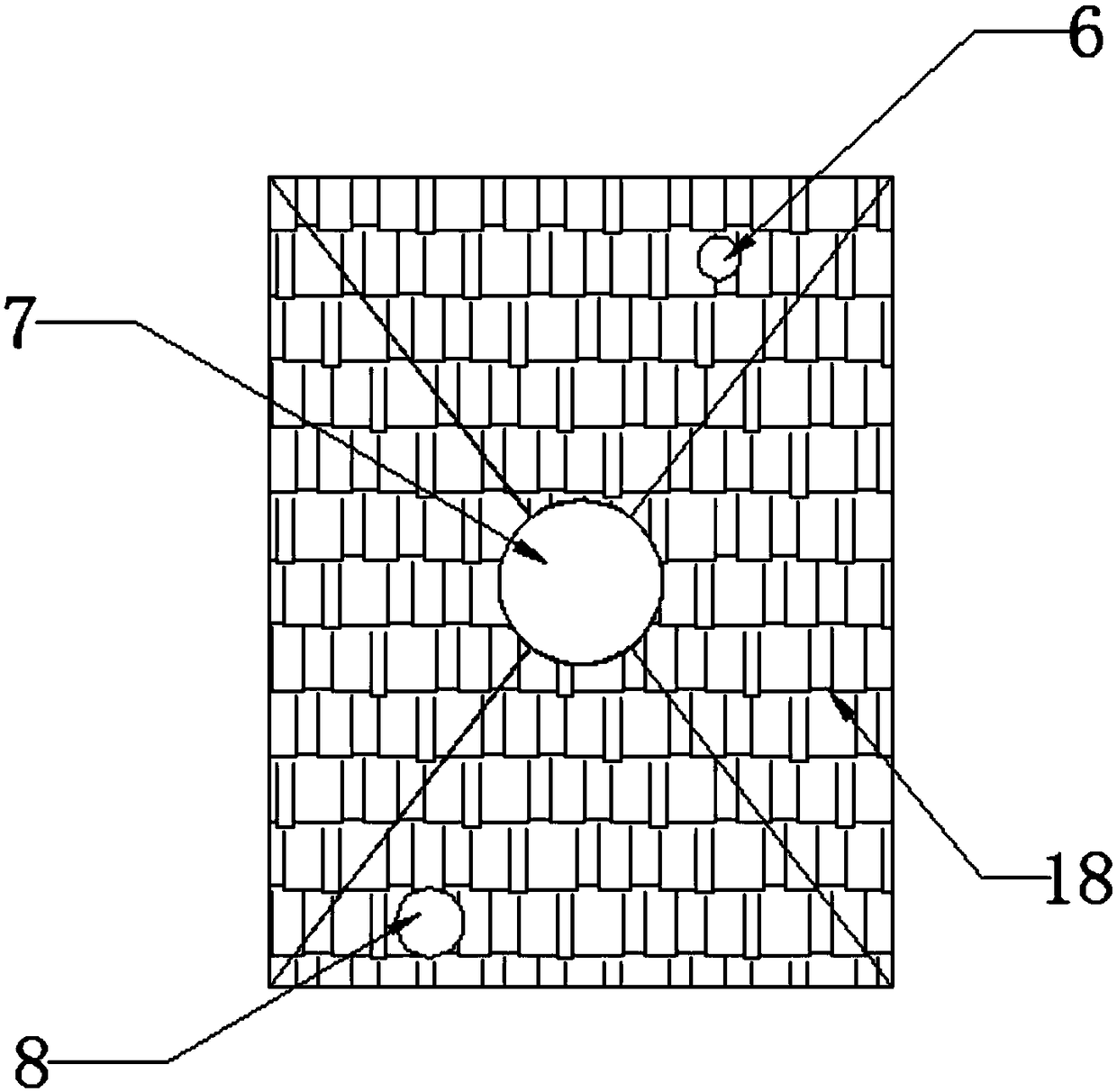

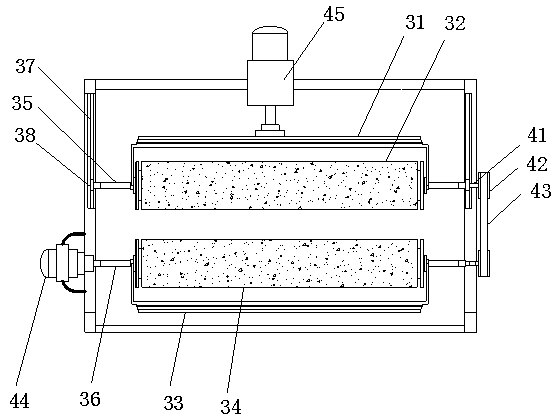

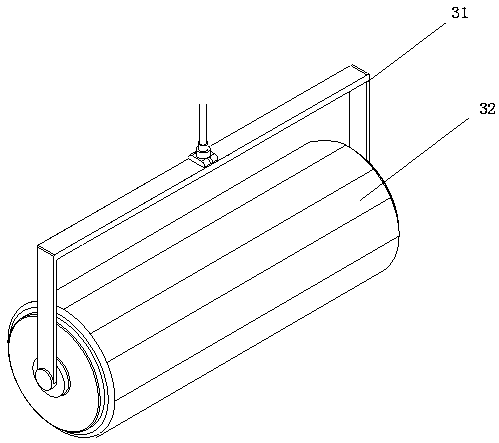

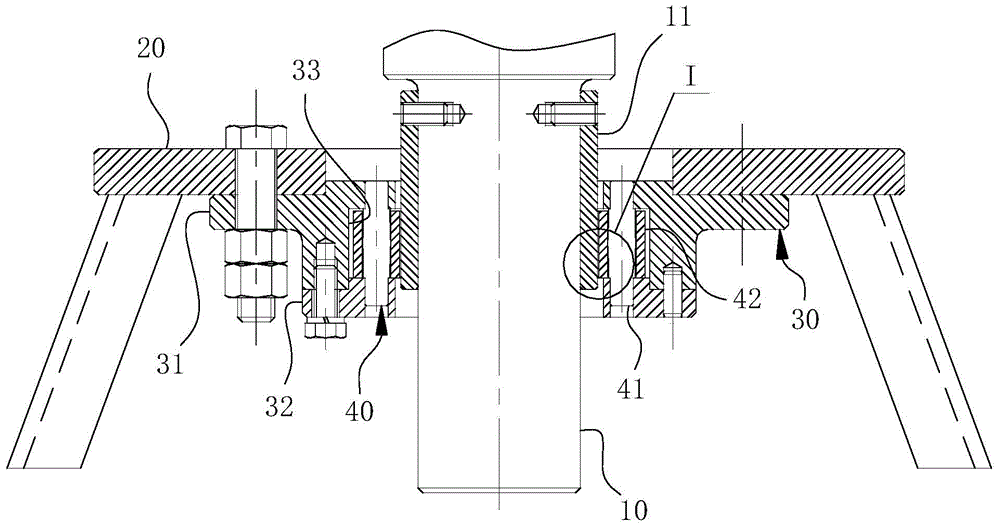

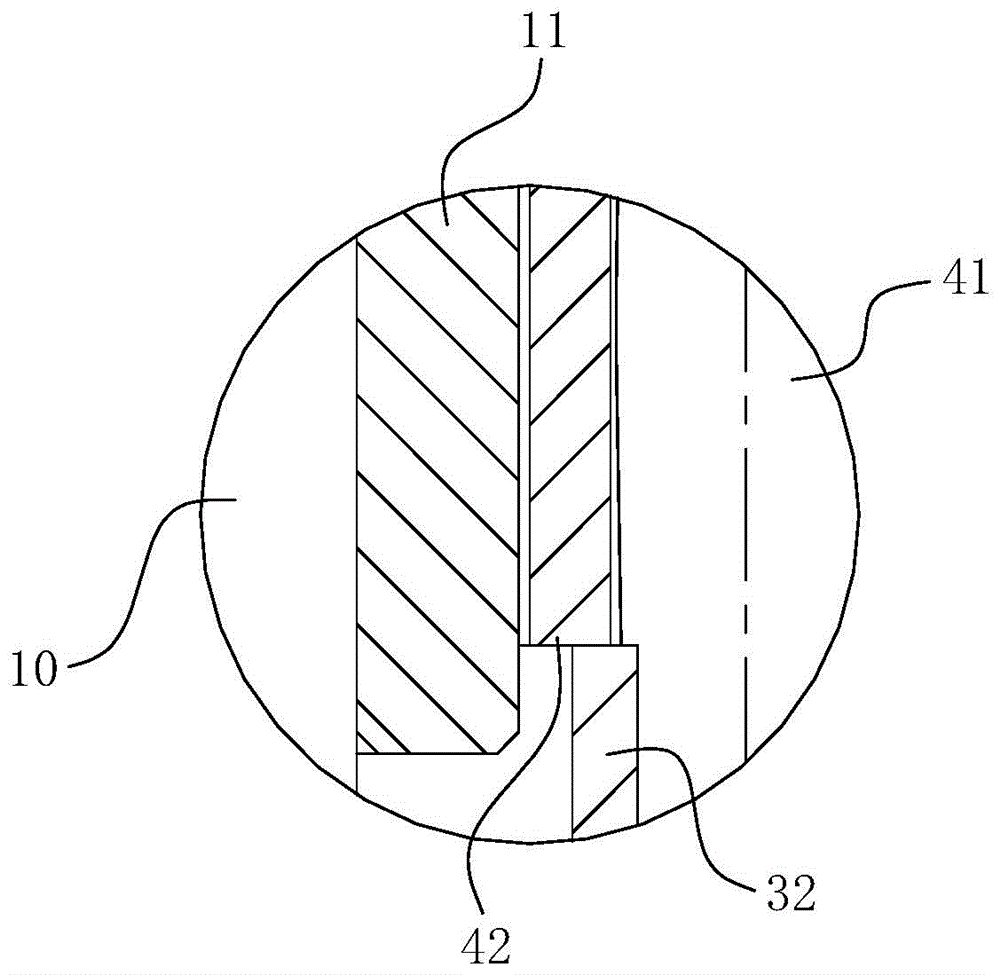

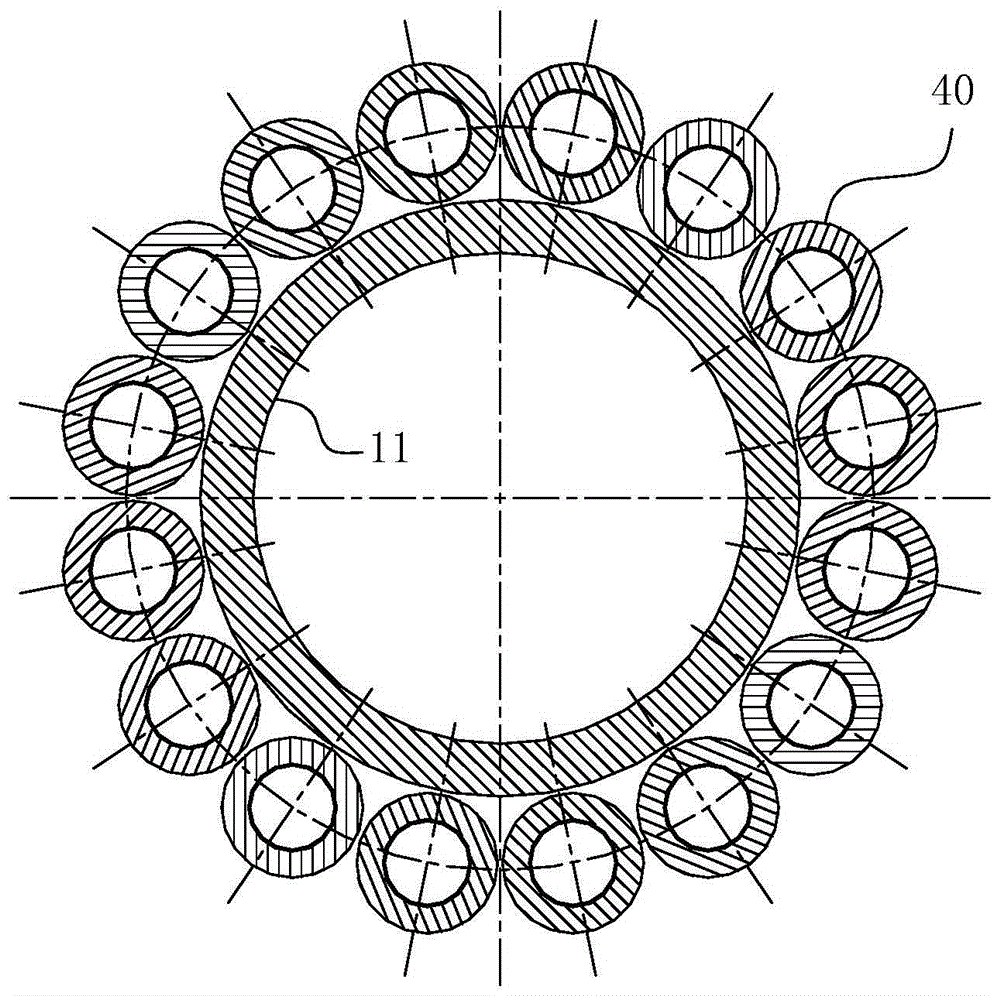

Novel friction wear testing machine for thin film

PendingCN108169048AGuaranteed friction performanceMeet the testing requirements of friction performanceInvestigating abrasion/wear resistanceWear testingEngineering

The invention discloses a novel friction wear testing machine for thin film. The machine comprises an abrasive belt grinding machine (1), and an abrasive belt (20) which can achieve circulation conveying is arranged in the belt grinding machine (1); two same testing sample clamping mechanisms (2) are arranged right at the left edge of the abrasive belt grinding machine (1), a testing sample (33) is placed on each testing sample clamping mechanism (2), and each testing sample clamping mechanism (2) is used for independently adjusting the distance between the corresponding testing sample (33) and the abrasive belt (20); the two testing sample clamping mechanisms (2) are vertically arranged and front and back symmetrically arranged in a staggered mode. According to the novel friction wear testing machine for the thin film, it can be guaranteed that under the same condition, the friction performance of two different kinds of thin film materials is subjected to comparison testing at the same time, the thin film material which most meets the user requirement is selected accordingly, and the machine is particularly suitable for precise testing of different thin film materials which have tiny difference on the friction performance and has wide market prospects.

Owner:TIANJIN UNIV OF COMMERCE

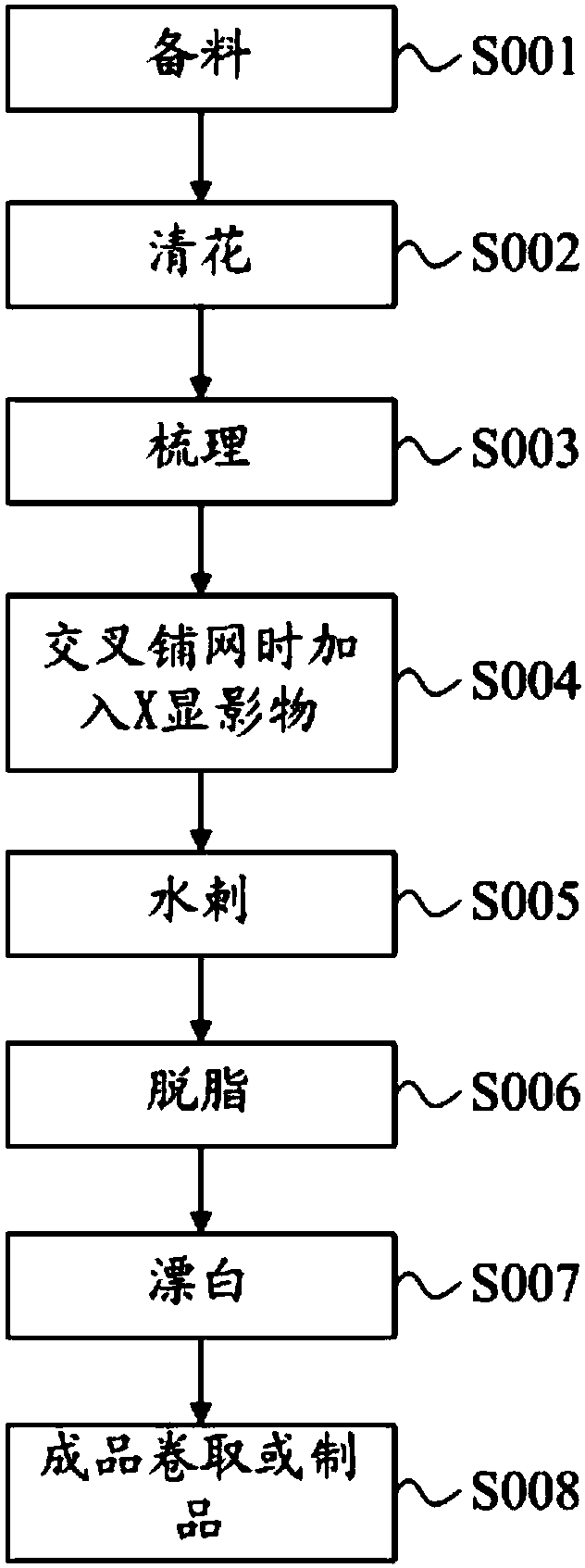

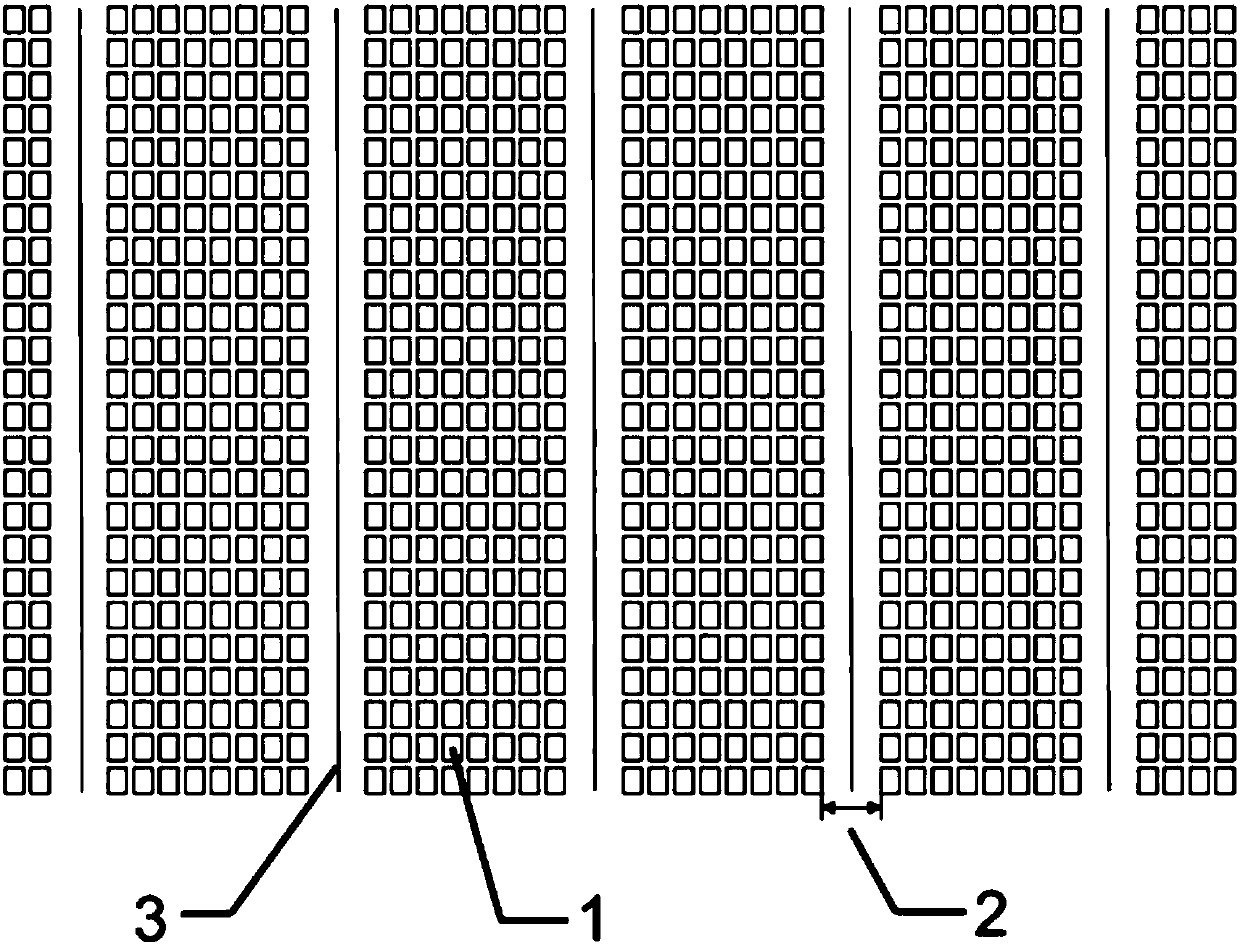

Gauze product containing X-ray developer and production method thereof

InactiveCN107587262ANot easy to break awayGuaranteed friction performanceNon-woven fabricsPlain weaveWoven fabric

The invention discloses a gauze product containing an X-ray developer and a production method thereof. The production method includes the steps of material preparation, blowing, carding, cross lapping, spunlacing, degreasing, bleaching, and finished product reeling or obtaining, wherein in the cross lapping process, the X-ray developer is added in a fiber web; the fiber web is spunlaced into a non-woven fabric with mesh parts and plain weave parts through a spunlacing process, dense meshes are distributed in the mesh parts, the plain weave parts are in a ribbon shape and separate the mesh parts, and the X-ray developer is combined on the plain weave parts in a spunlaced mode. As the X-ray developer is implanted in the gauze product, the gauze dressing can be irritated by an X-ray machine once left in the body of a patient during an operation, the position and size of the left matter can be accurately known at once, and then the left matter can be removed to avoid medical negligence; asthe X-ray developer is combined on the plain weave parts of the non-woven fabric in a spunlaced and tangled mode, the X-ray developer is not likely to be separated from the non-woven fabric, and themesh parts guarantee the high water absorbency and certain friction performance of the spunlaced gauze product.

Owner:WINNER MEDICAL CO LTD

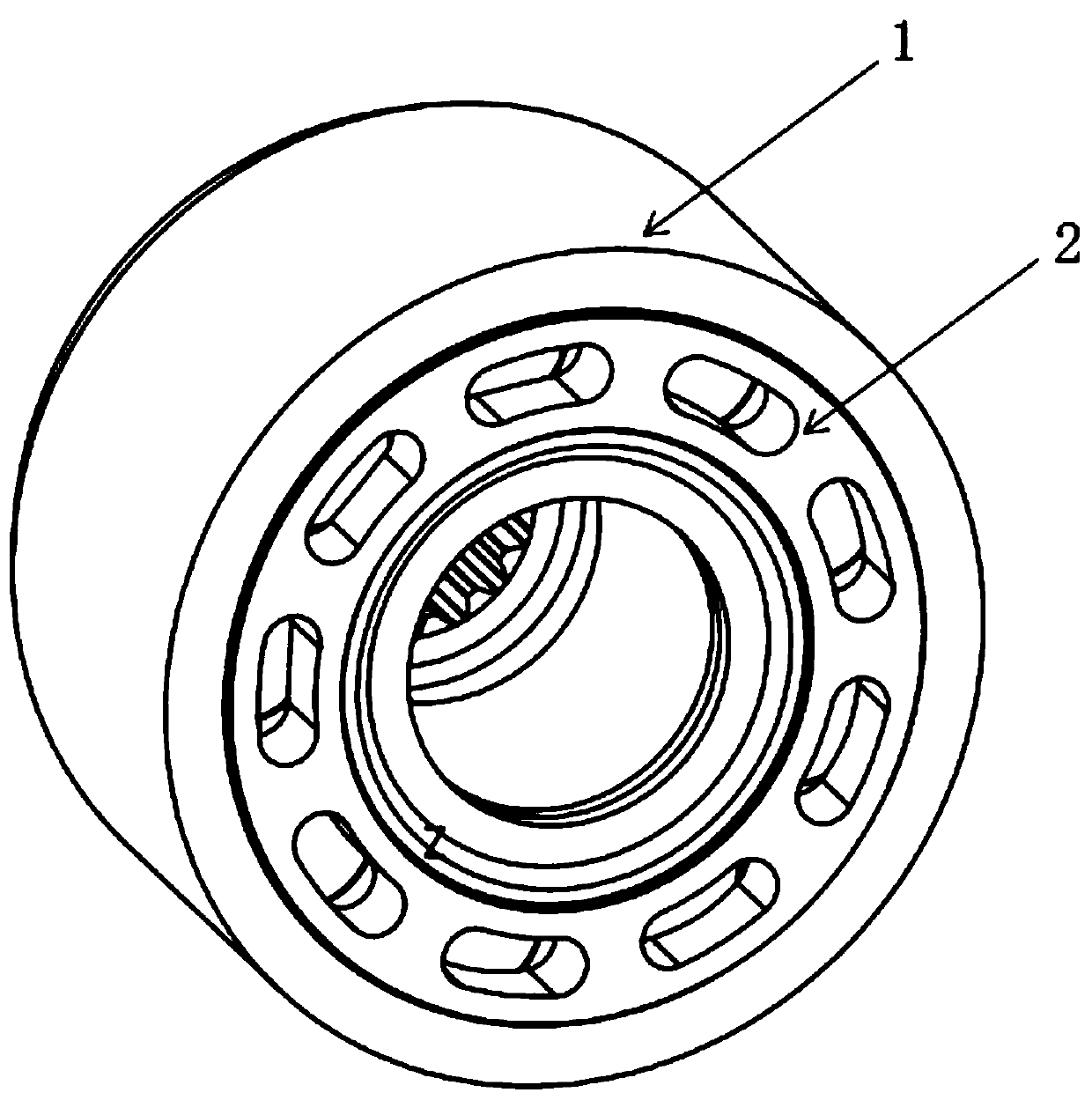

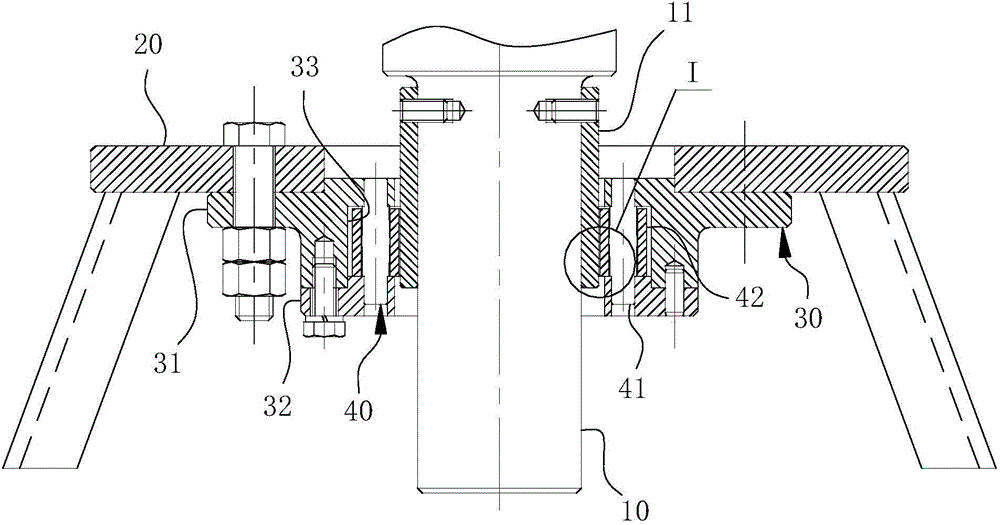

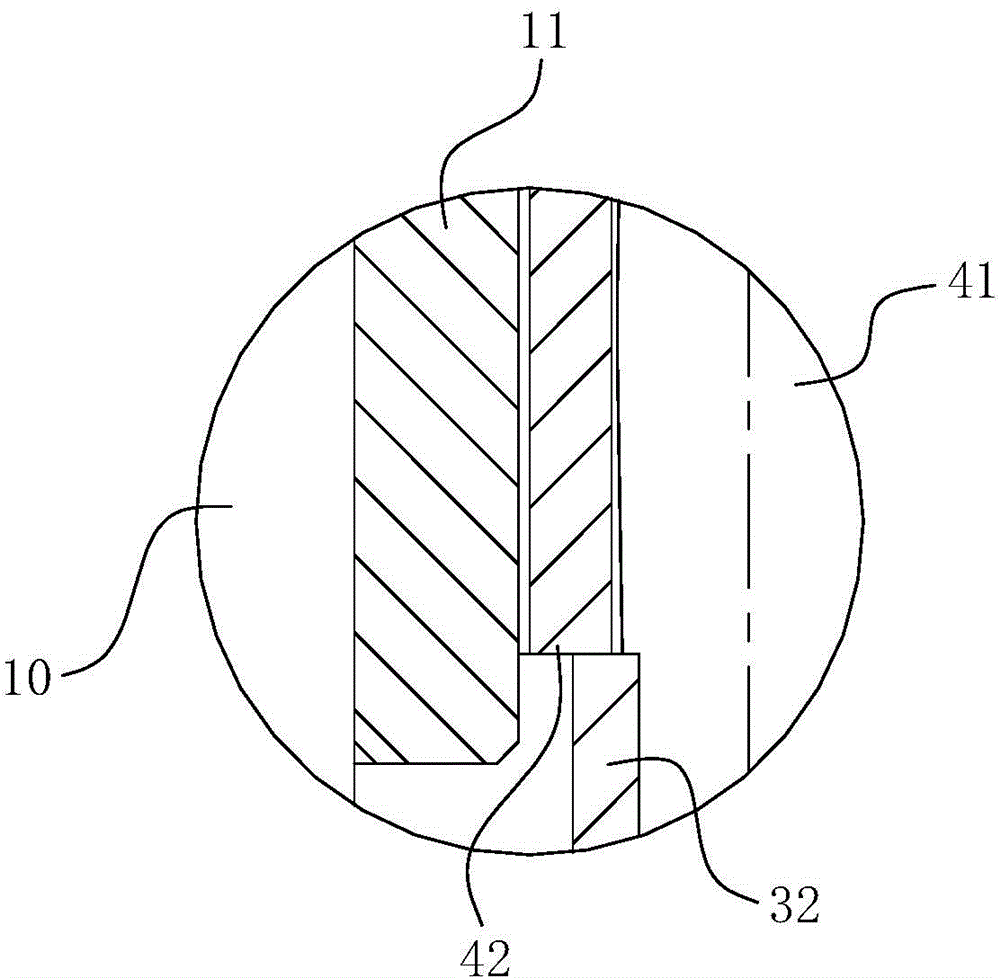

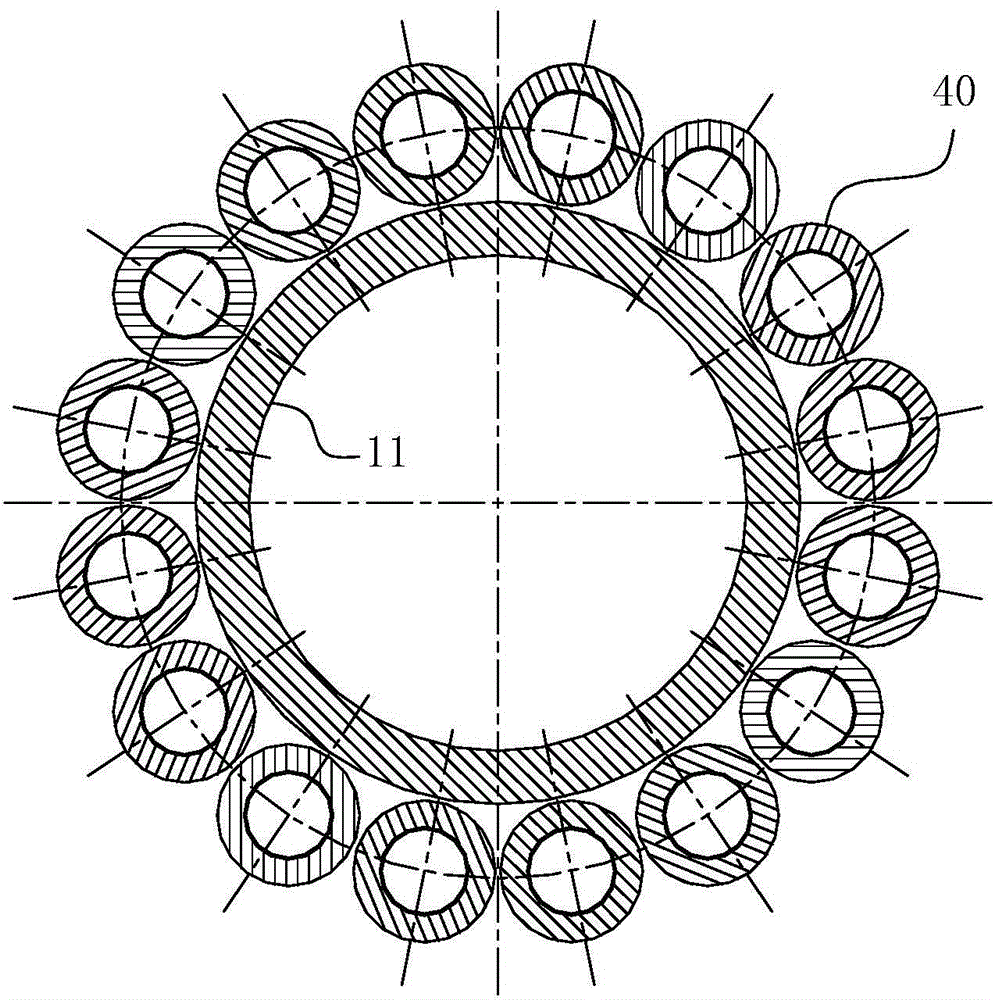

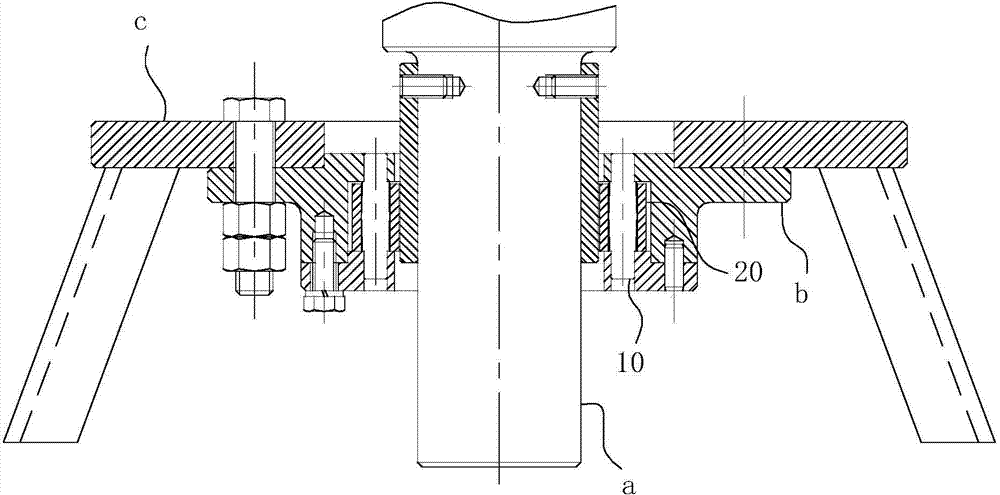

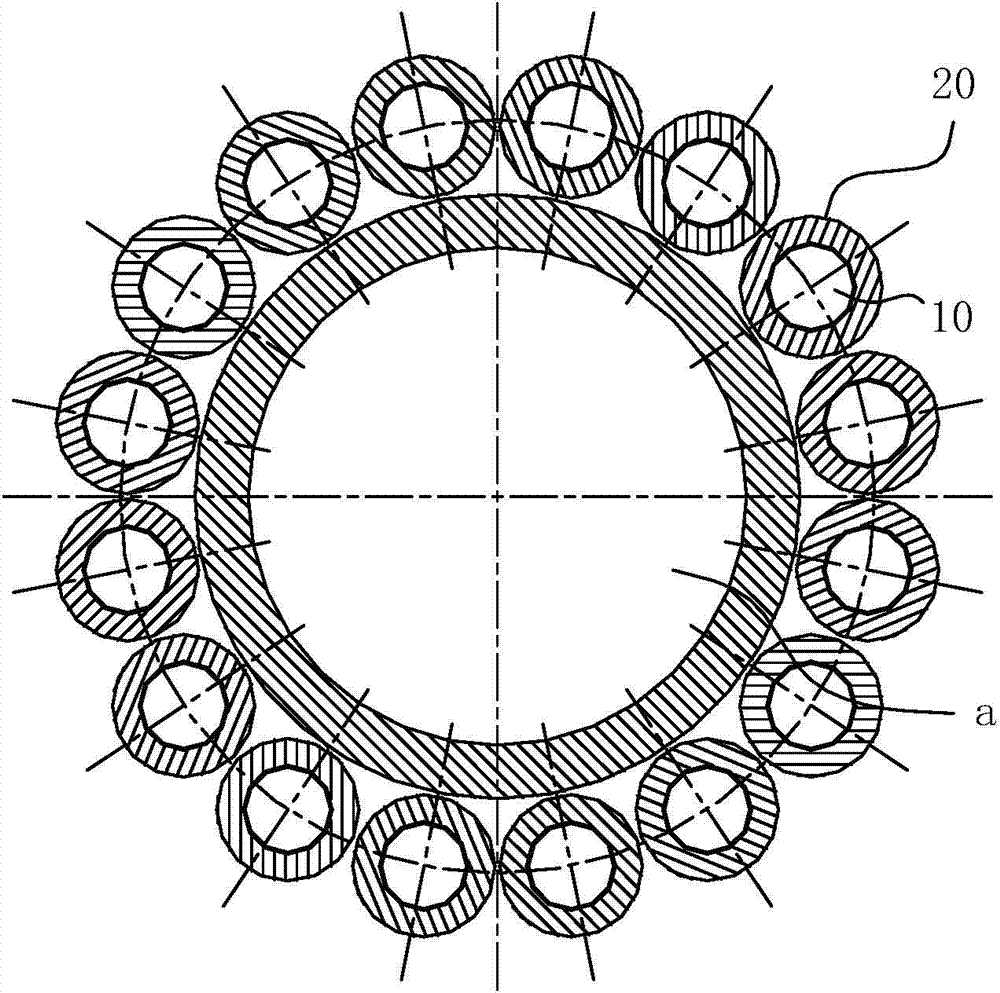

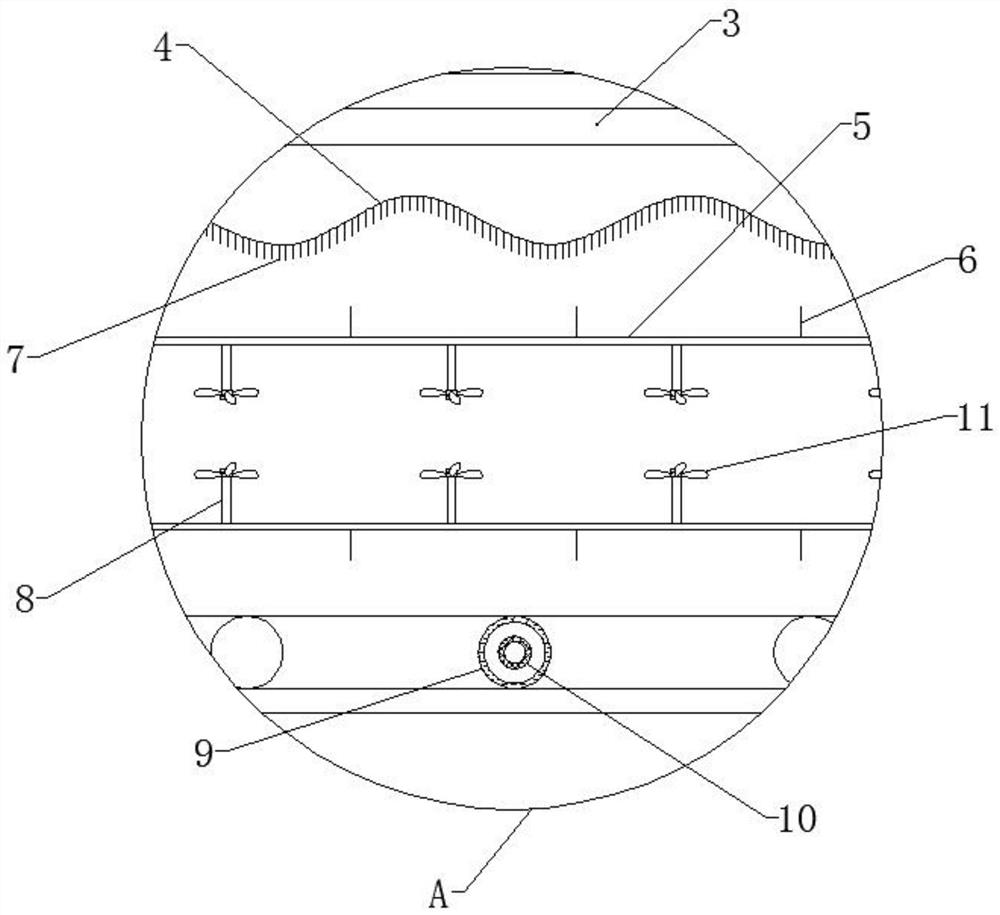

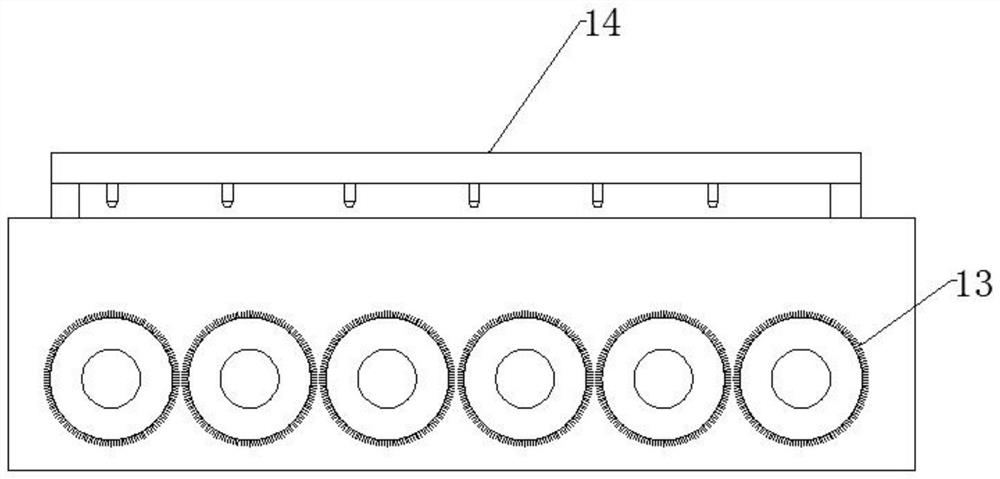

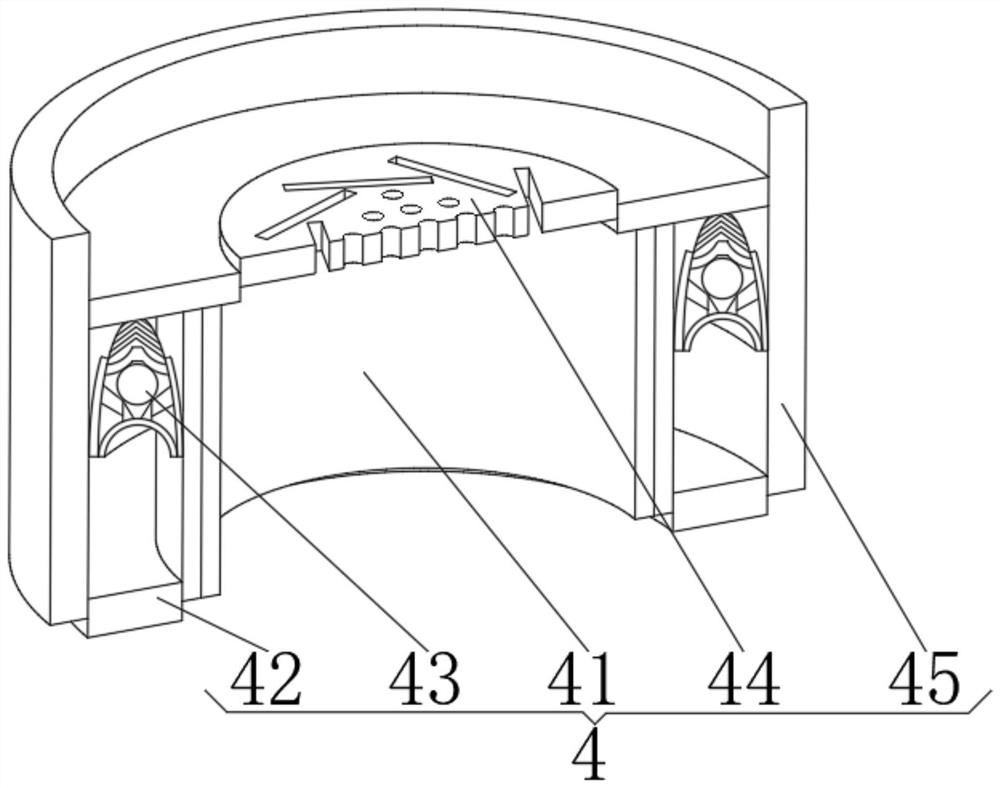

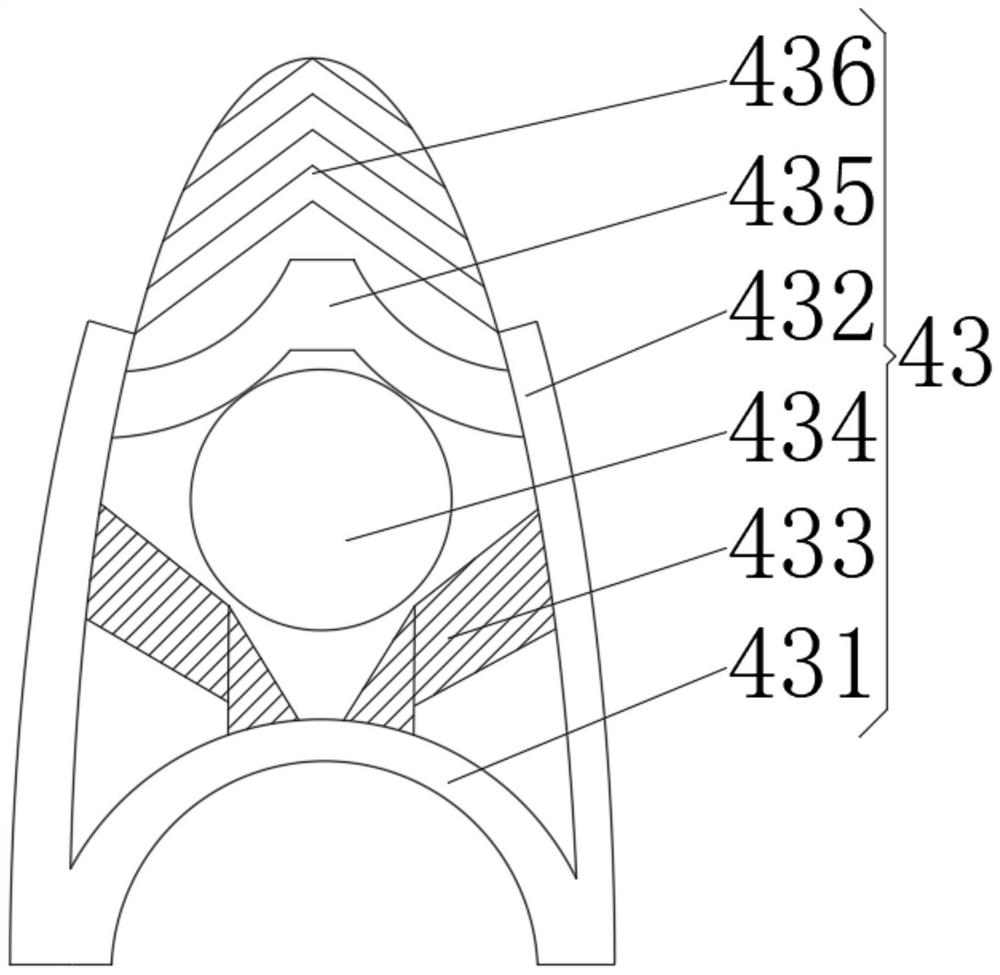

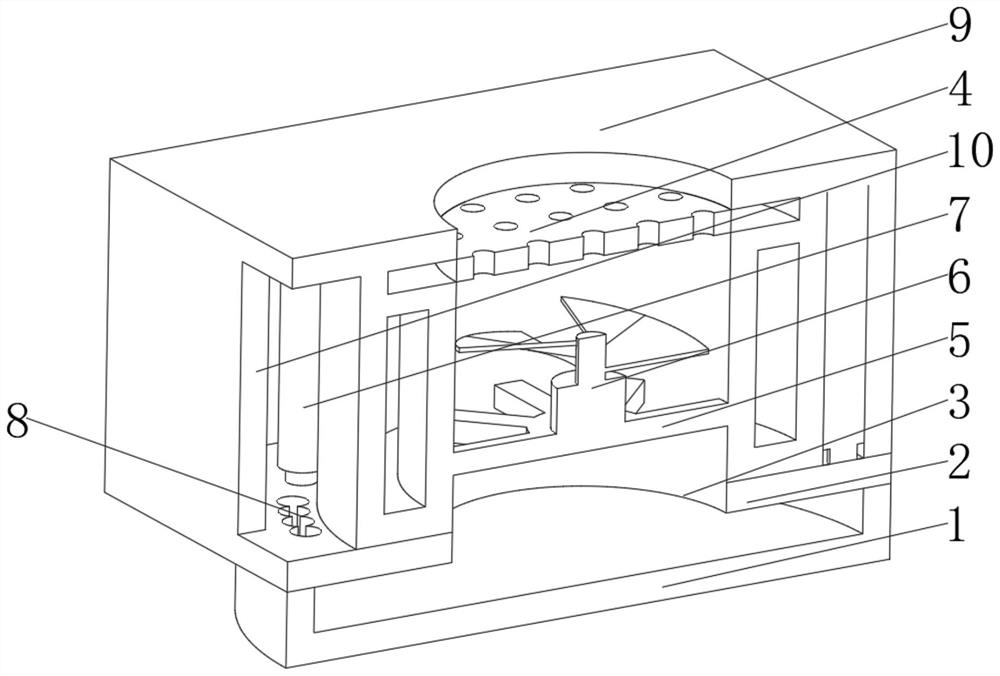

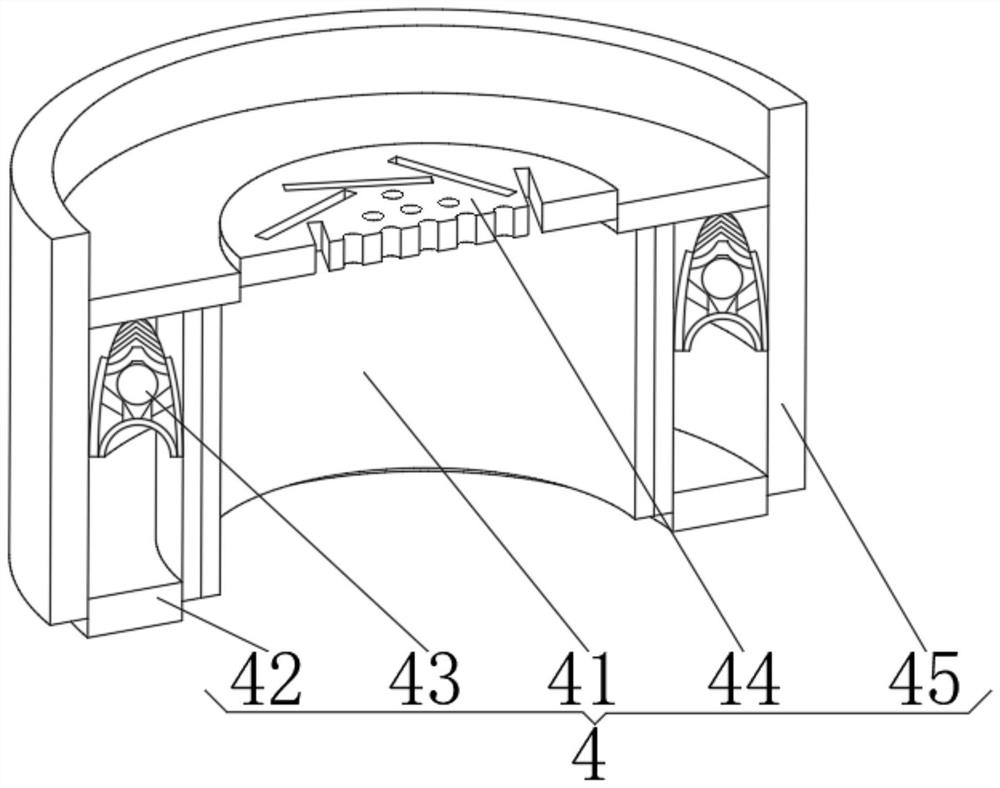

Composite bearing deflection limiting device for stirring shaft

The invention belongs to the field of structural design of stirring equipment, and in particular relates to a composite bearing deflection limiting device for a stirring shaft. The composite bearing deflection limiting device comprises a bearing block and a support frame, wherein the bearing block comprises an outer ring sleeve directly sleeving a shaft body of the stirring shaft, and a hole wall of the outer ring sleeve is spaced from the shaft body of the stirring shaft; a plurality of roll shaft parts are annularly arranged on the hole wall of the outer ring sleeve along the axial line of the hole wall, each roll shaft part comprises a stator shaft and a rotating sleeve, and the axial line of the outer ring sleeve, the axial line of a stator shaft and an ideal axial line of the stirring shaft are coaxially and vertically arranged; a section, matched with the rotating sleeve, of the stator shaft has a spindle-shaped structure, and the rotating sleeve correspondingly has a sleeve structure with a concave spherical inner cavity; on the axial cross section passing through the axial line of the stator shaft, the diameters of generatrixes of the stator shaft and the rotating sleeve at sections matched with each other are consistent and the circle centers are positioned on the same horizontal plane, and the diameter of the generatrix at a hole cavity of the rotating shaft is greater than that of the generatrix of the stator shaft. By adopting the composite bearing deflection limiting device provided by the invention, the effect of fixing the shaft body of the stirring shaft within an allowed deflection quantity range can be realized.

Owner:合肥华升泵阀股份有限公司

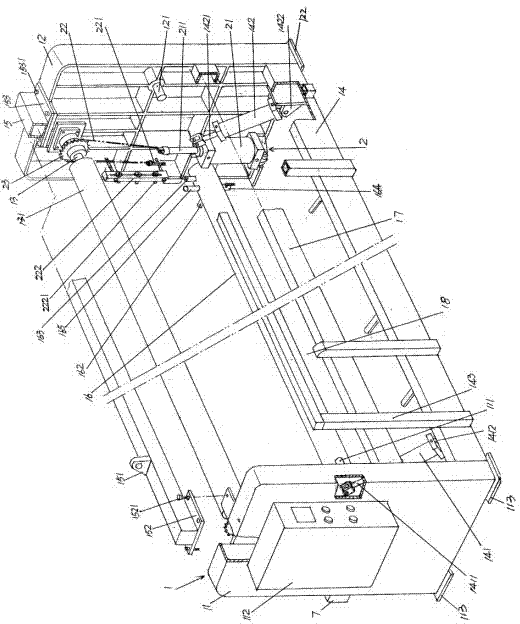

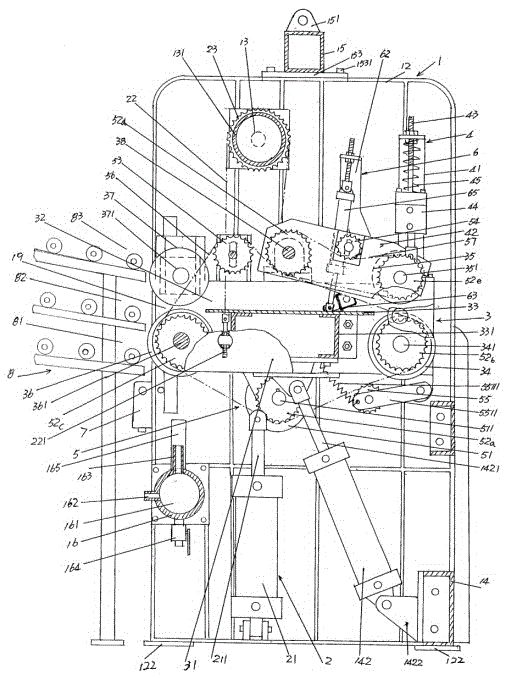

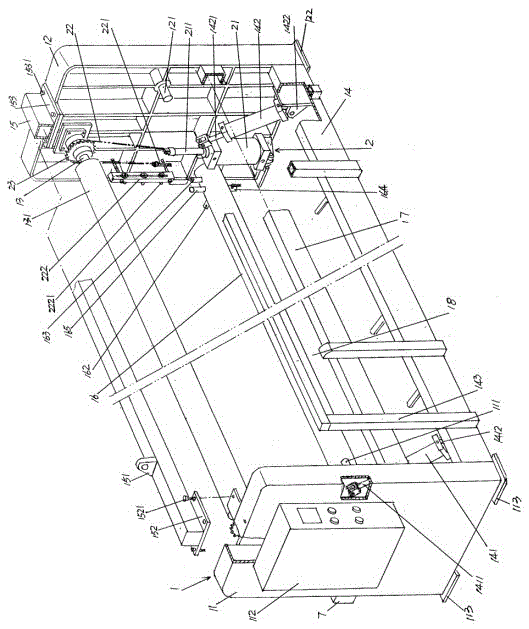

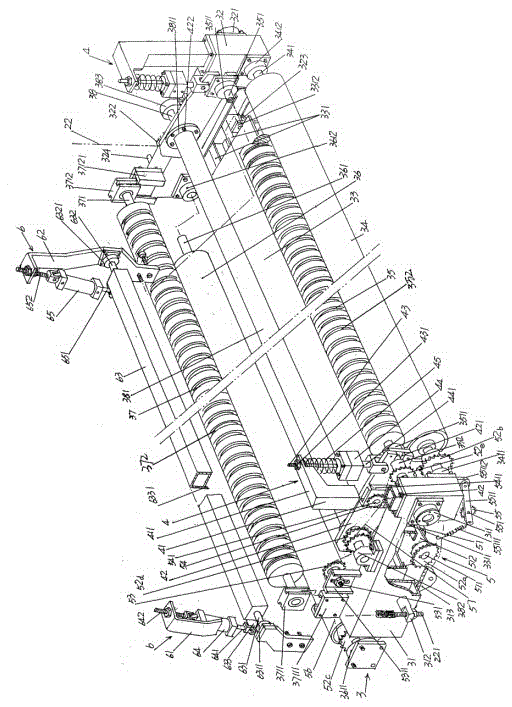

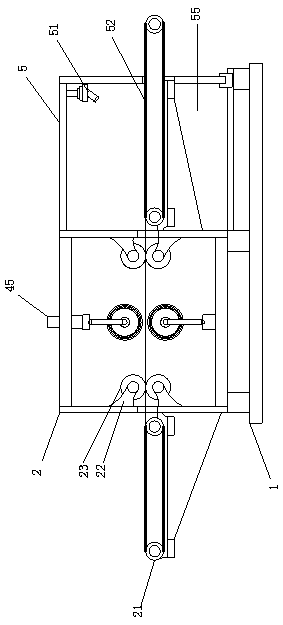

Automatic board continuous layer conveyor

ActiveCN104261160AReduce travel resistanceReduce work intensityArticle feedersFriction effectEngineering

The invention discloses an automatic board continuous layer conveyor and belongs to the technical field of sheet board conveying machinery. The board continuous layer conveyor comprises a machine frame, a pair of revolving platform elevating mechanisms which are mutually corresponding, a revolving type layered board sending mechanism, a first revolving frame driving action cylinder and a second revolving frame driving action cylinder; the machine frame comprises a first wallboard, a second wallboard, a revolving platform elevating mechanism connecting shaft and a bottom beam; the revolving type layered board sending mechanism is supported between central shafts of a first revolving frame and a second revolving frame; the pair of revolving platform elevating mechanisms comprise revolving platform lifting action cylinder chains and chain wheels; the revolving type layered board sending mechanism comprises a first revolving frame, a second revolving frame, a sheet wood conveying platform panel, an input roller, an input pressing roller, an output roller and an output pressing roller; front ends of the first revolving frame and the second revolving frame are provided with sheet wood input pressing roller lifting and pressing mechanisms; a power transmission mechanism is arranged on the first revolving frame; a sheet wood deflection proof mechanism is arranged between a first bearing beam fixing base and a second bearing beam fixing base; sheet wood input and output pressing rollers are rubber rollers. The board continuous layer conveyor reduces the operation intensity, saves manpower, guarantees a friction effect between sheet wood and reduces movement resistance to the sheet wood.

Owner:常熟市力恒木业机械厂

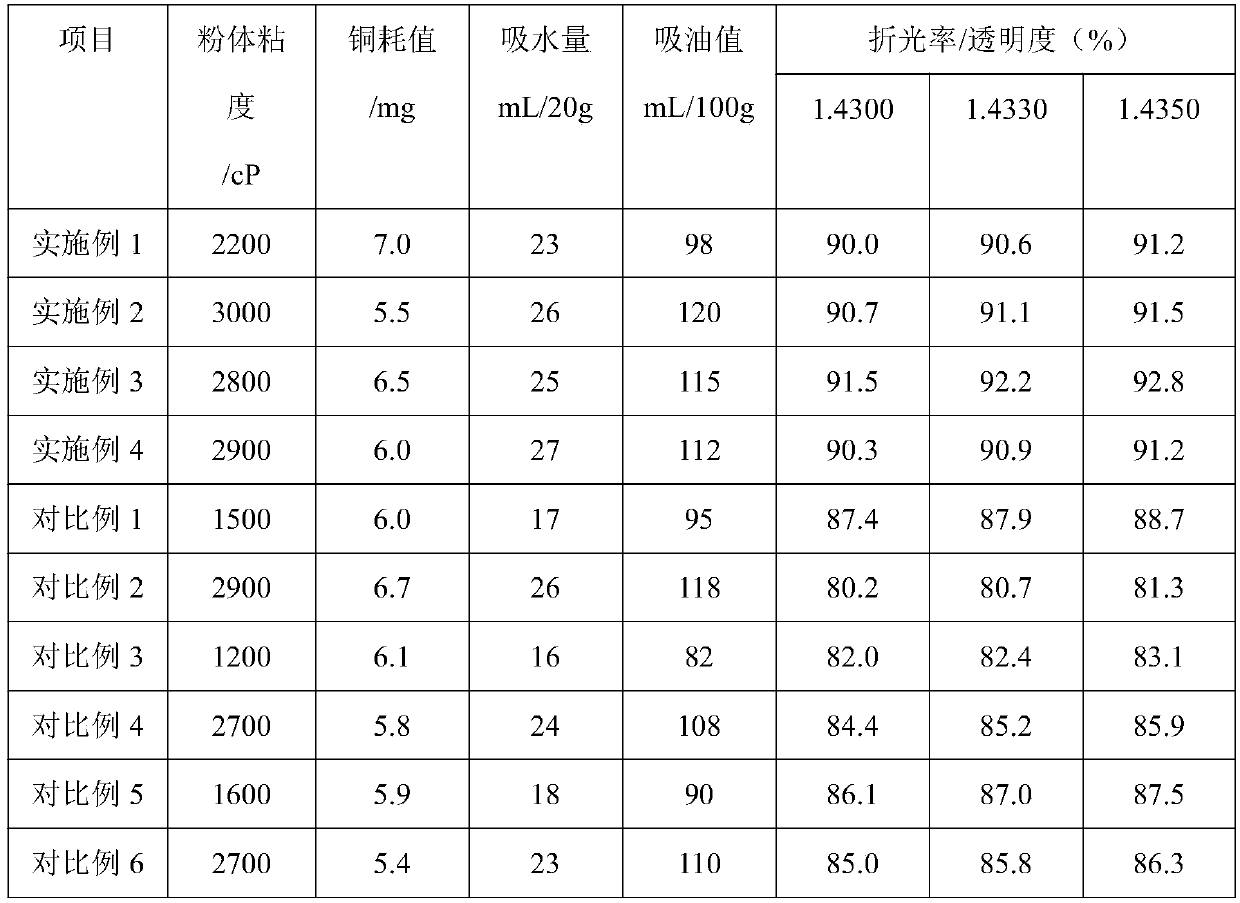

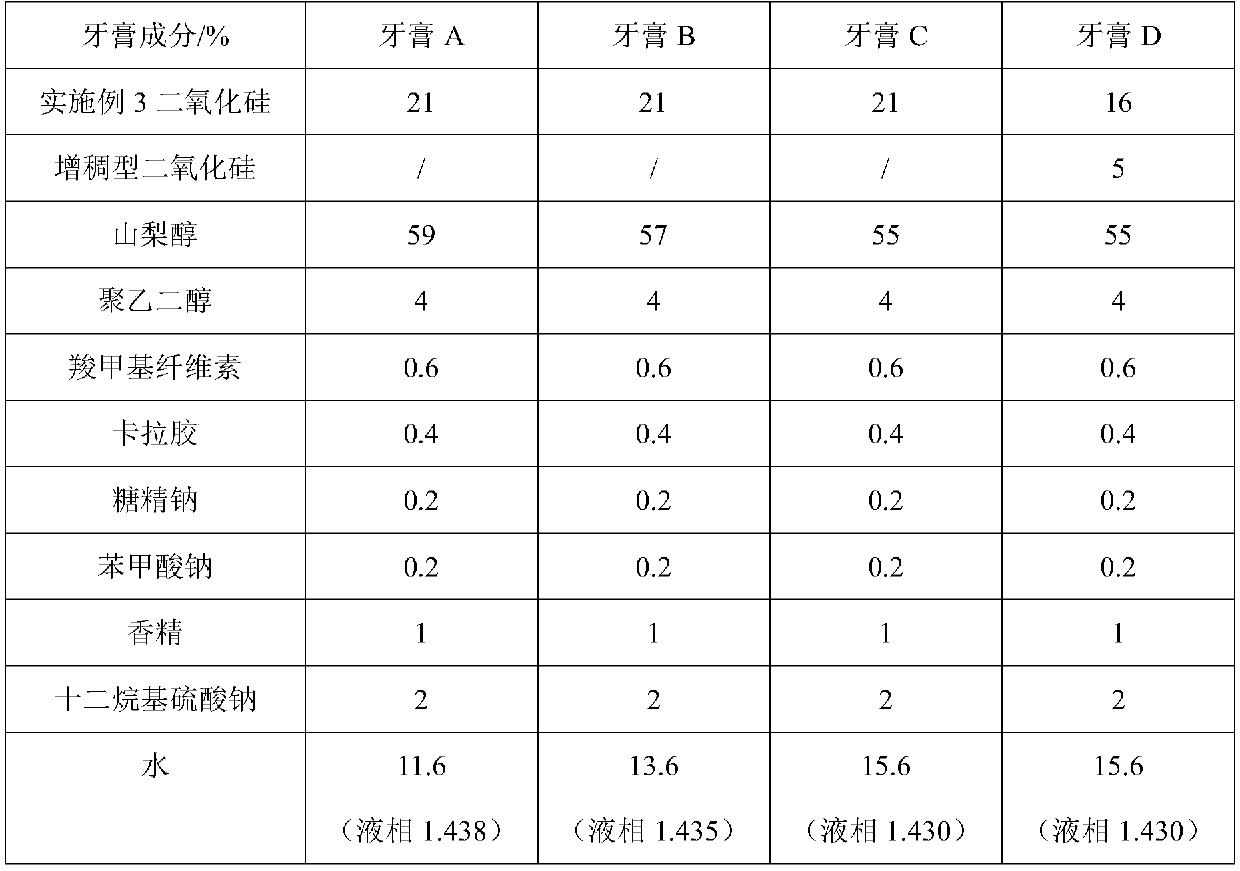

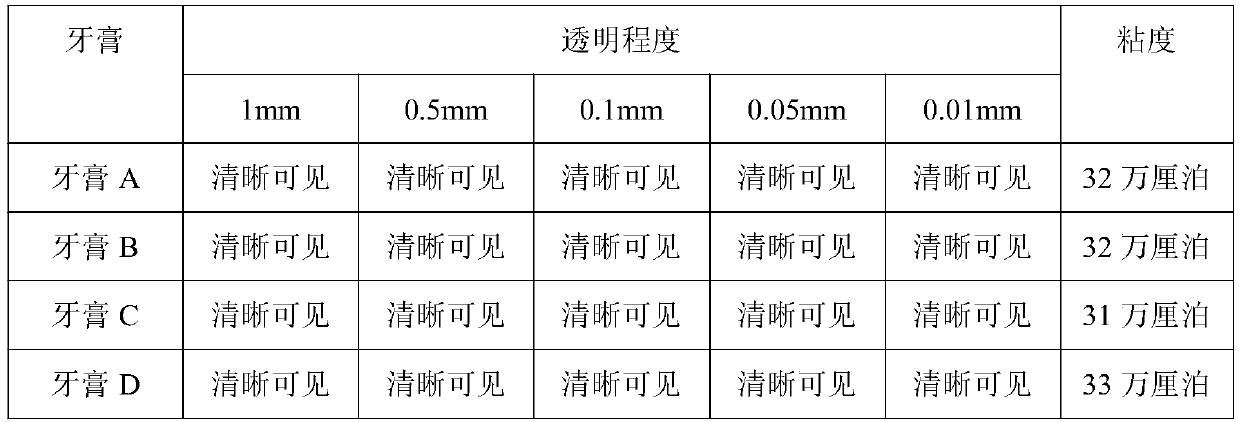

A kind of low-refractive high-viscosity friction silicon dioxide and its preparation method

ActiveCN108675307BReduce manufacturing costHigh transparencyCosmetic preparationsSilicaCarboxymethyl celluloseToothpaste

Provided are a method for preparing a low-refraction and high-viscosity friction type silicon dioxide and the silicon dioxide obtained thereby. The method comprises the following steps: S1, injecting water glass A with a modulus of 2.0-2.3 into a reaction tank, heating, stirring, dropwise adding sulfuric acid A, stopping adding the acid when the pH value is 10-11, so as to obtain a thickened silica sol; S2, injecting a sodium sulfate solution, and meanwhile, adding carboxymethyl cellulose, and heating; S3, dropwise adding water glass B with a modulus of 2.0-2.3 and sulfuric acid B at the same time, controlling the pH value to be 10.5-11.5, and after completion of dropwise adding water glass B, continously dropwise adding the acid until the pH value is 4.0-5.0, stopping adding the acid, stirring and aging; S4, press-filtering, washing, drying, crushing silicon dioxide to produce a product. The method is simple, easy to operate and stable, the prepared silicon dioxide has multiple characteristics such as low refractive index, high transparency, clean friction and thickening, and can be applied to transparent toothpaste without needing to compound the thickening silicon dioxide, thereby simplifying the toothpaste production process and reducing the production cost.

Owner:GUANGZHOU FEIXUE MATERIAL TECH

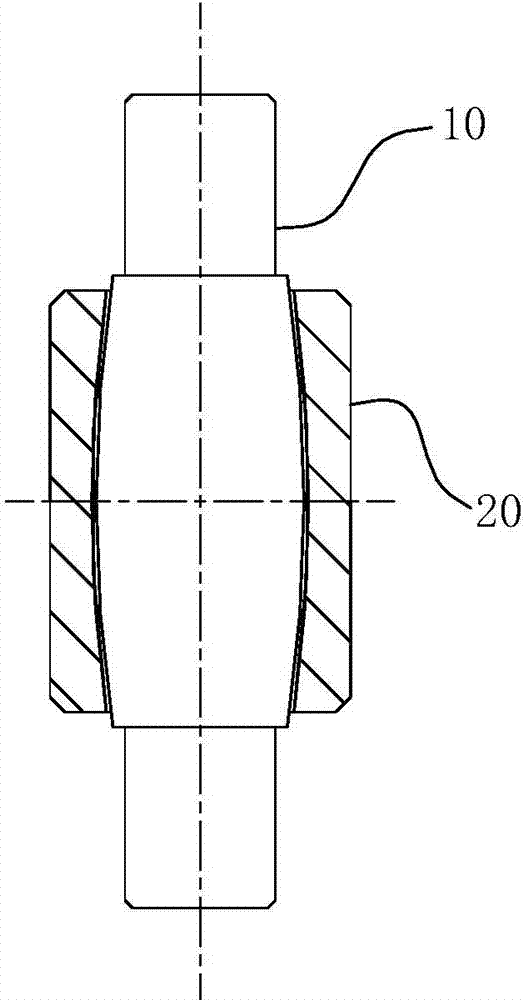

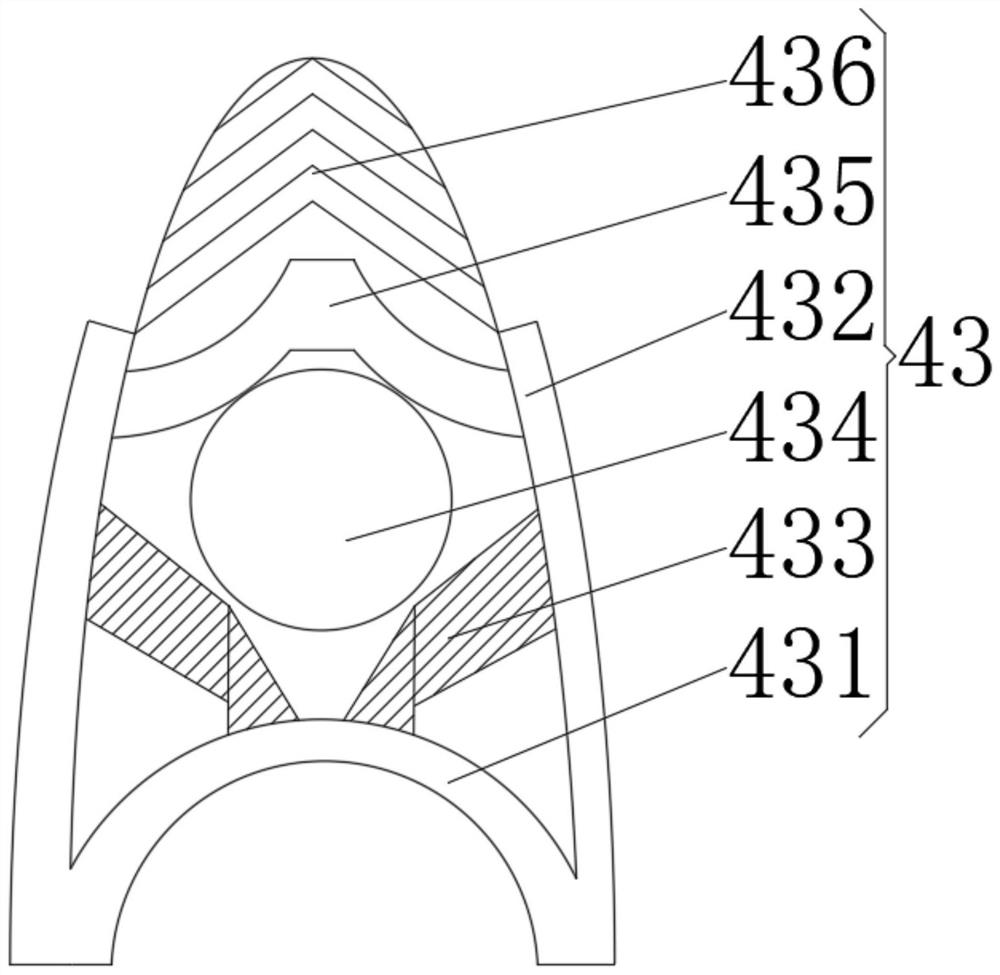

Self-aligning roll shaft unit

ActiveCN104514812AAvoid bitesRealize the hard limit effectRolling contact bearingsBearing unit rigid supportEngineeringMechanical engineering

The invention belongs to the field of structural design of stirring equipment and particularly relates to a self-aligning roll shaft unit. The unit comprises stator shafts and rotating sleeves capable of rotating relatively, wherein the stator shafts are sleeved with the rotating sleeves; matched sections, matched with the rotating sleeves, of the stator shafts are in cambiform structures which are thin at the two ends and thick in the middles; the rotating sleeves are in sleeve structures with concave spherical inner cavities; on axial sections through axes of the stator shafts, the diameters of generatrices of the stator shafts at the matched sections are the same; circle centers of the generatrices are located on the same horizontal plane; circle centers of generatrices of the rotating sleeves at the hole cavities are arranged on the same plane as the circle centers of the generatrices of the stator shafts; diameters of the generatrices of the rotating sleeves at the hole cavities are greater than those of the generatrices of the stator shafts; and when the circle centers of the generatrices of the stator shafts and the rotating sleeves are on the same plane, minimum clearances exist between matching surfaces of shaft bodies of the stator shafts and the hole cavities of the rotating sleeves in radial directions. The unit can be provided with the conventional bearing frame to achieve a shaft body fixing effect of a stirring shaft with an allowable deflection scope, is long in service life and operates stably and reliably.

Owner:合肥华升泵阀股份有限公司

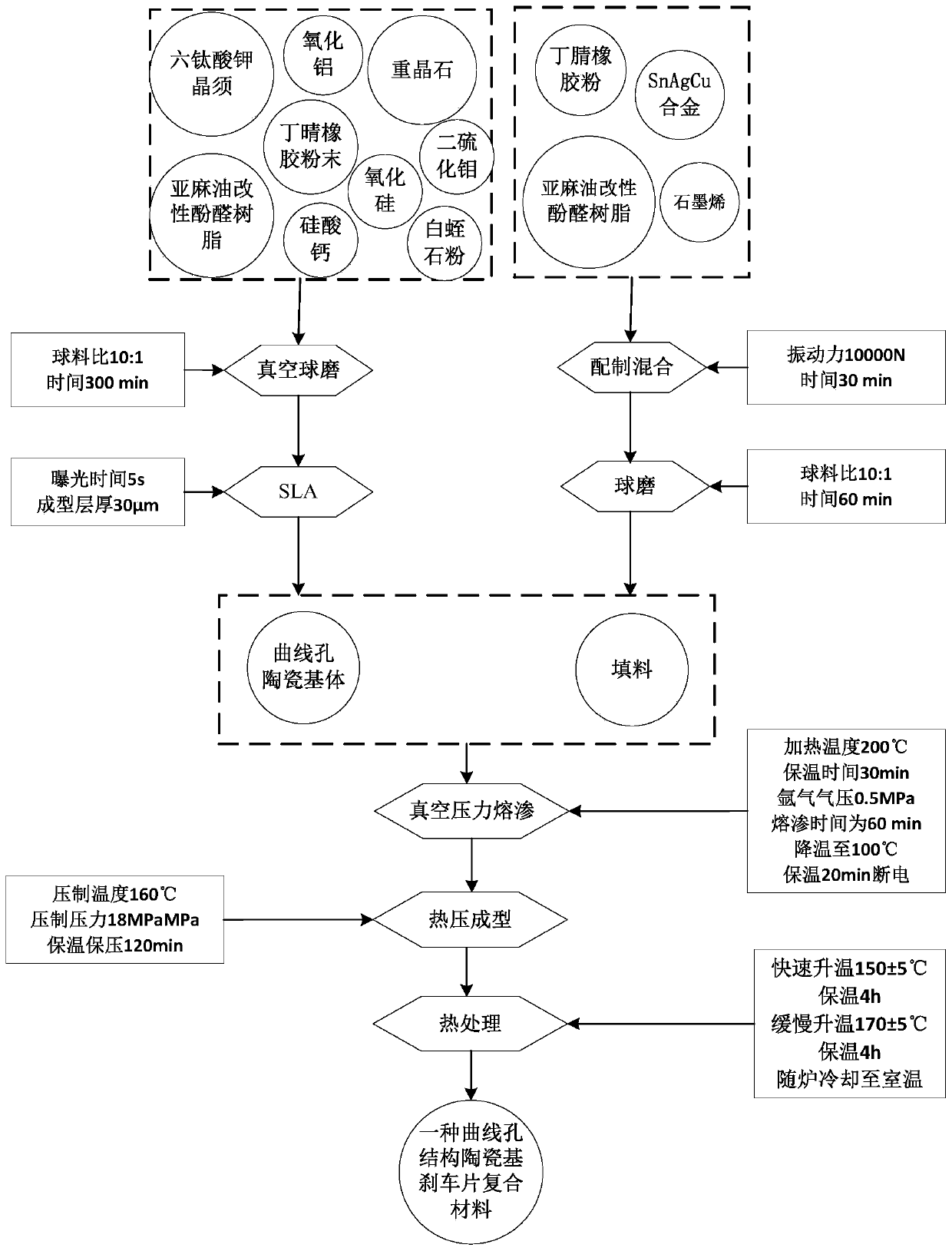

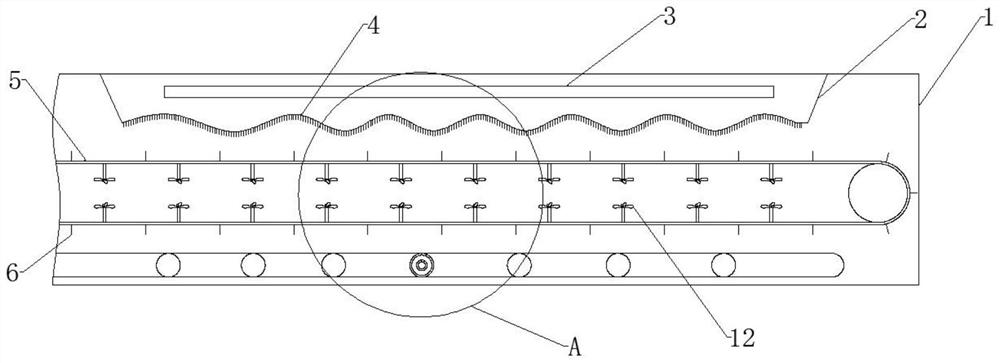

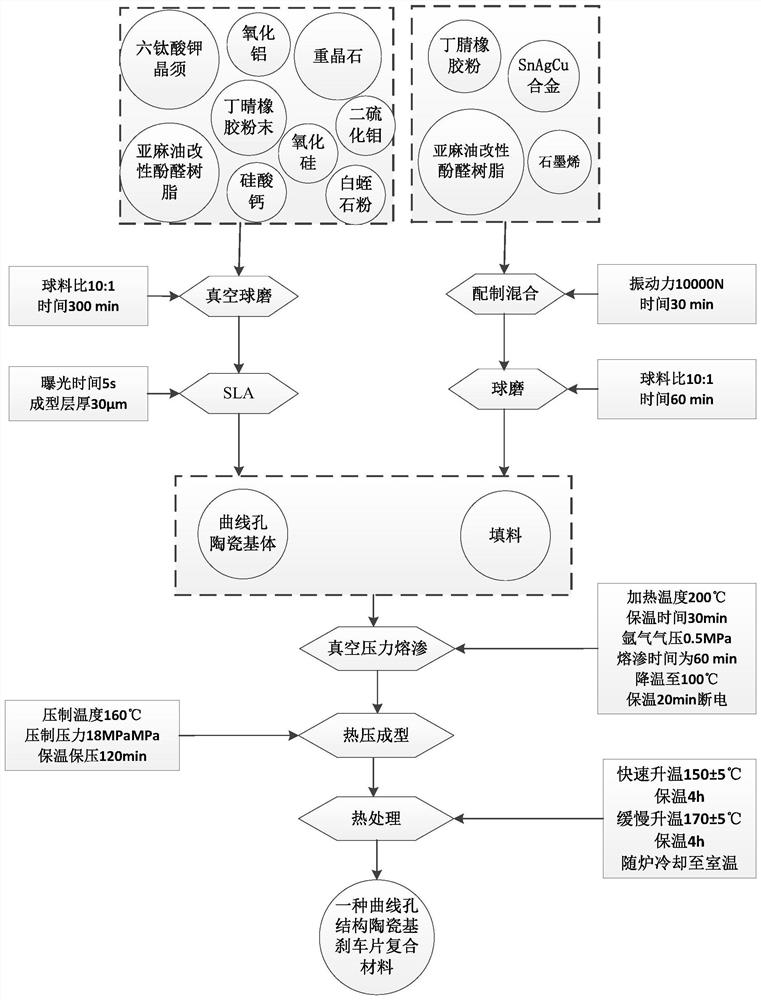

Curved-hole flow channel ceramic base brake pad composite material and preparation method thereof

ActiveCN110723925AExcellent frictional thermal stabilityReduce wear rateFriction liningActuatorsVacuum pressureGraphite

The invention discloses a curved-hole flow channel ceramic base brake pad composite material and a preparation method thereof. The curved-hole flow channel ceramic base is manufactured by using Stereolithography Apparatus (SLA), and graphene and Sn-Ag-Cu composite filler is prepared and filled into the curved hole flow channel by vacuum pressure infiltration technology, and then the curved-hole flow channel ceramic base brake pad composite material is prepared by hot pressing molding process. Compared with the traditional brake pad material, the unique structural design and the optimized filler formula of the invention are combined with the advanced preparation process, so that the average friction coefficient of the brake material of the invention is greater than 0.402 in the operation process, the friction coefficient changes stably, and the material wear rate is lower than 1.15*10<-7>cm<3>.N<-1>.m<-1>. All performance parameters are superior to national standards and traditional brake pad products.

Owner:WUHAN UNIV OF TECH

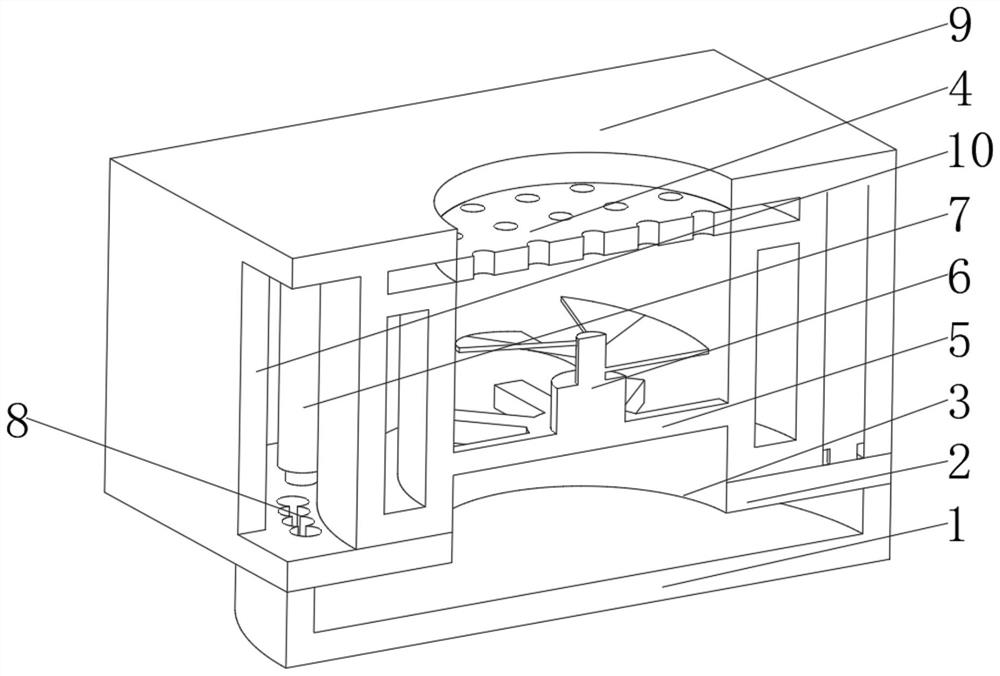

Fruit pre-treatment system for fruit wine

InactiveCN112641116AGood load carrying capacityPrecise positioningFood treatmentFruit wineEngineering

The invention discloses a fruit pre-treatment system for fruit wine in the field of fruit wine production. The fruit pre-treatment system comprises a bubble cleaning machine, wherein the bubble cleaning machine comprises a cleaning tank, a conveying mesh belt is arranged in the cleaning tank, a water spraying pipe and a bubble pipe are arranged below the conveying mesh belt, a plurality of turbulence paddles are rotatably connected to the inner side wall of the conveying mesh belt, and outlets of the water spraying pipe and the bubble pipe are obliquely arranged upwards. The problems that in the prior art, fruits for fruit wine production are not thoroughly pretreated and cleaned, and the fruit wine quality is affected can be solved.

Owner:重庆优久酒业有限公司

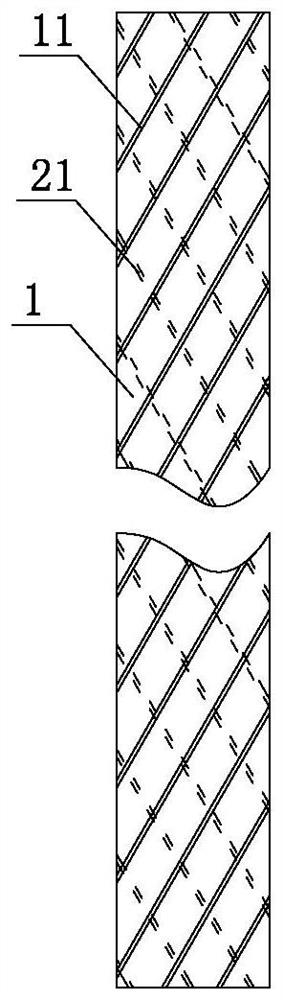

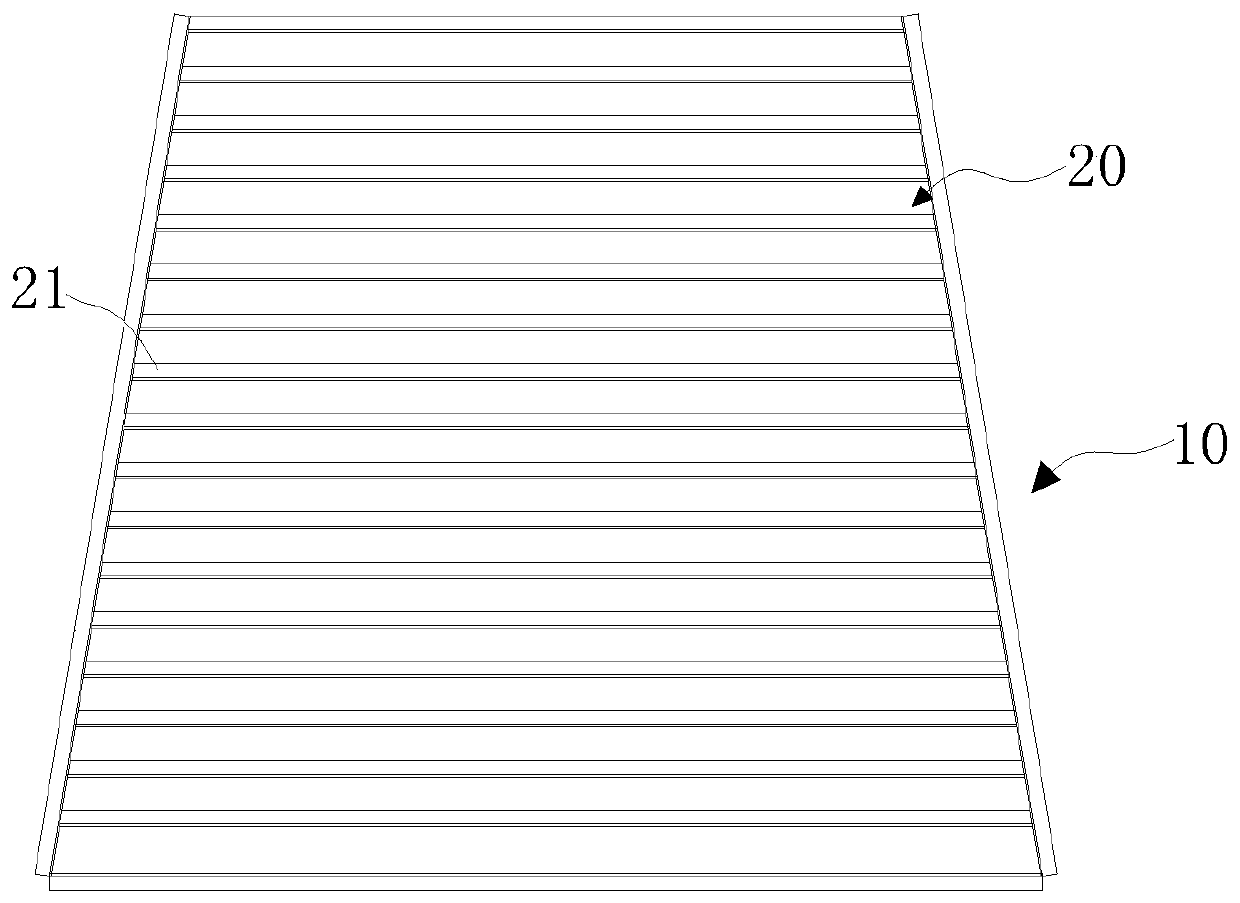

Flat packing belt

PendingCN114735355AGuaranteed tensile strengthReduced impact strengthFlexible elementsClassical mechanicsStructural engineering

The invention aims to provide a flat packing belt which is provided with a front surface and a back surface, the front surface and the back surface are provided with the same inclined raised grains, so that the inclined direction and the inclined angle of the inclined raised grains observed from the front surface orthographic projection and the inclined raised grains observed from the back surface orthographic projection of the flat packing belt are the same as the distance between the adjacent inclined raised grains. According to the invention, through the reverse and same design of the inclined grains of the front friction grains and the reverse friction grains of the packing belt, not only is the friction effect ensured, but also the belt conveying effect and the production quality are ensured during manufacturing, the rolling operation has small influence on the strength of the belt and the tensile strength of the belt is ensured, or under the condition of ensuring the same tensile strength, the gram weight can be reduced, and the production cost is reduced. Materials are saved and environmental protection is facilitated.

Owner:ZHEJIANG YONGCHUANG MACHINERY

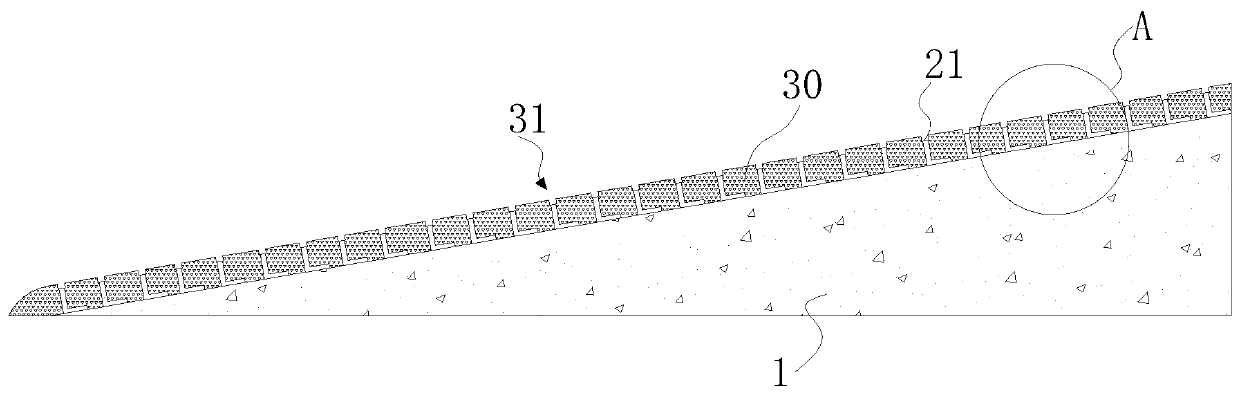

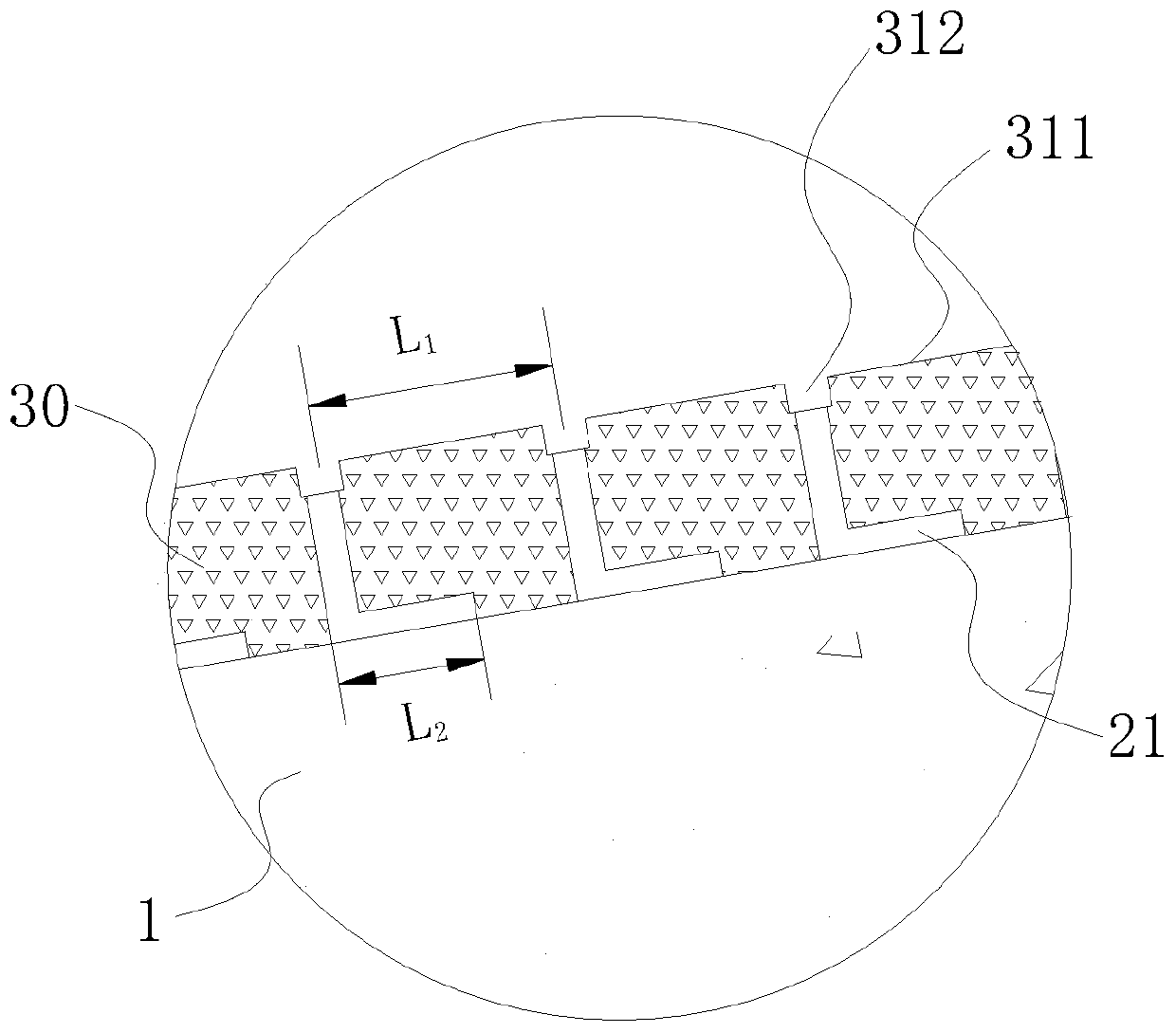

Ramp construction device and construction method thereof

PendingCN111042462AImprove discomfortAffect the anti-slip friction effectForms/shuttering/falseworksBuilding material handlingFriction effectArchitectural engineering

The invention belongs to the technical field of building construction, and particularly relates to a ramp construction device and a construction method thereof. The ramp construction device further comprises a supporting part which is arranged in a base body shaping part and used in cooperation with the base body shaping part, wherein a protective body formed after concrete is dried and solidifiedis arranged in the space between the base body shaping part and the supporting part; a concave-convex friction grain face is formed by the upper surface of the supporting part and the upper surface of the protective body; the supporting part is composed of a plurality of separation parts; and after concrete is poured into the space between the separation parts and dried and solidified, a foundation face is formed on the upper surface of each separation part. By means of the ramp construction device and the construction method thereof, discomfort of people when people pass through a bumpy rampcan be greatly reduced, meanwhile, the loss speed of the friction face of the ramp is reduced, and the friction effect is guaranteed.

Owner:ANHUI ELECTRIC POWER TRANSMISSION & TRANSFORMATION ENG +1

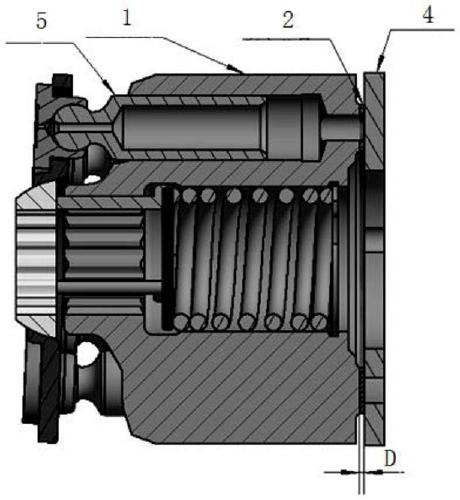

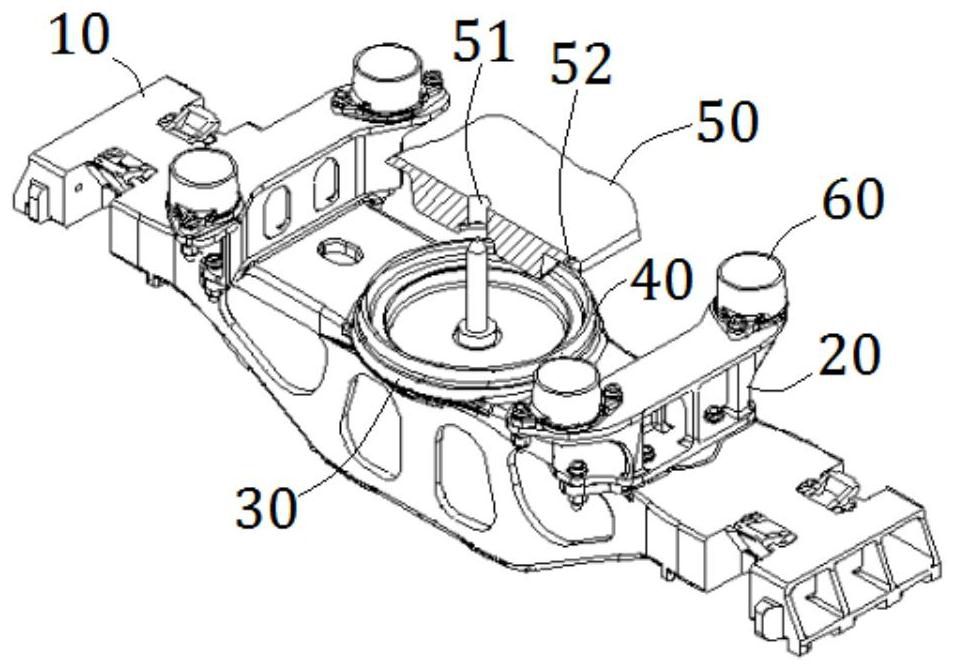

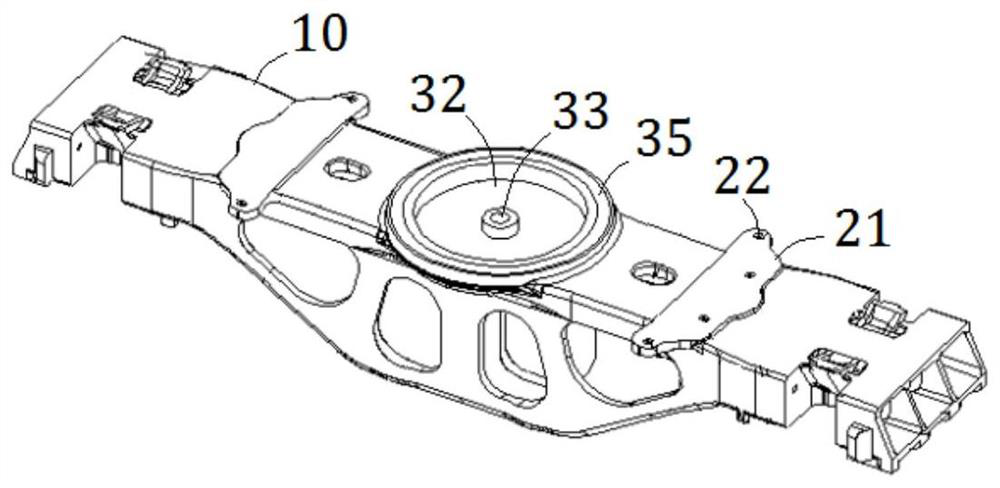

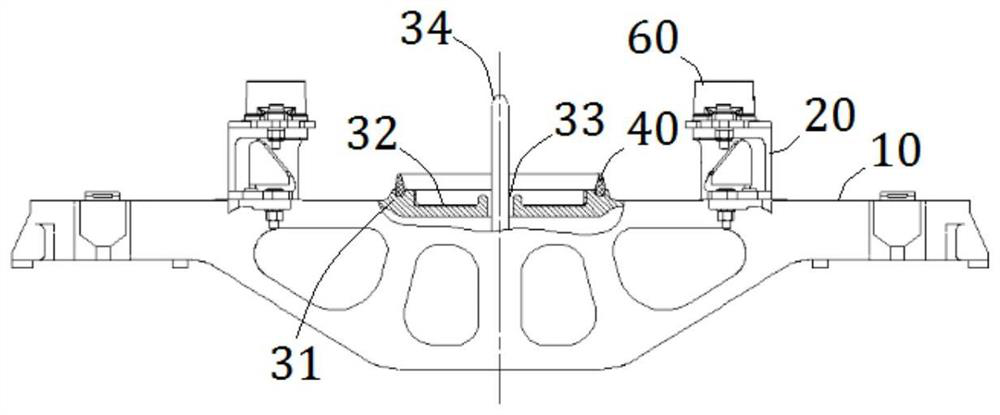

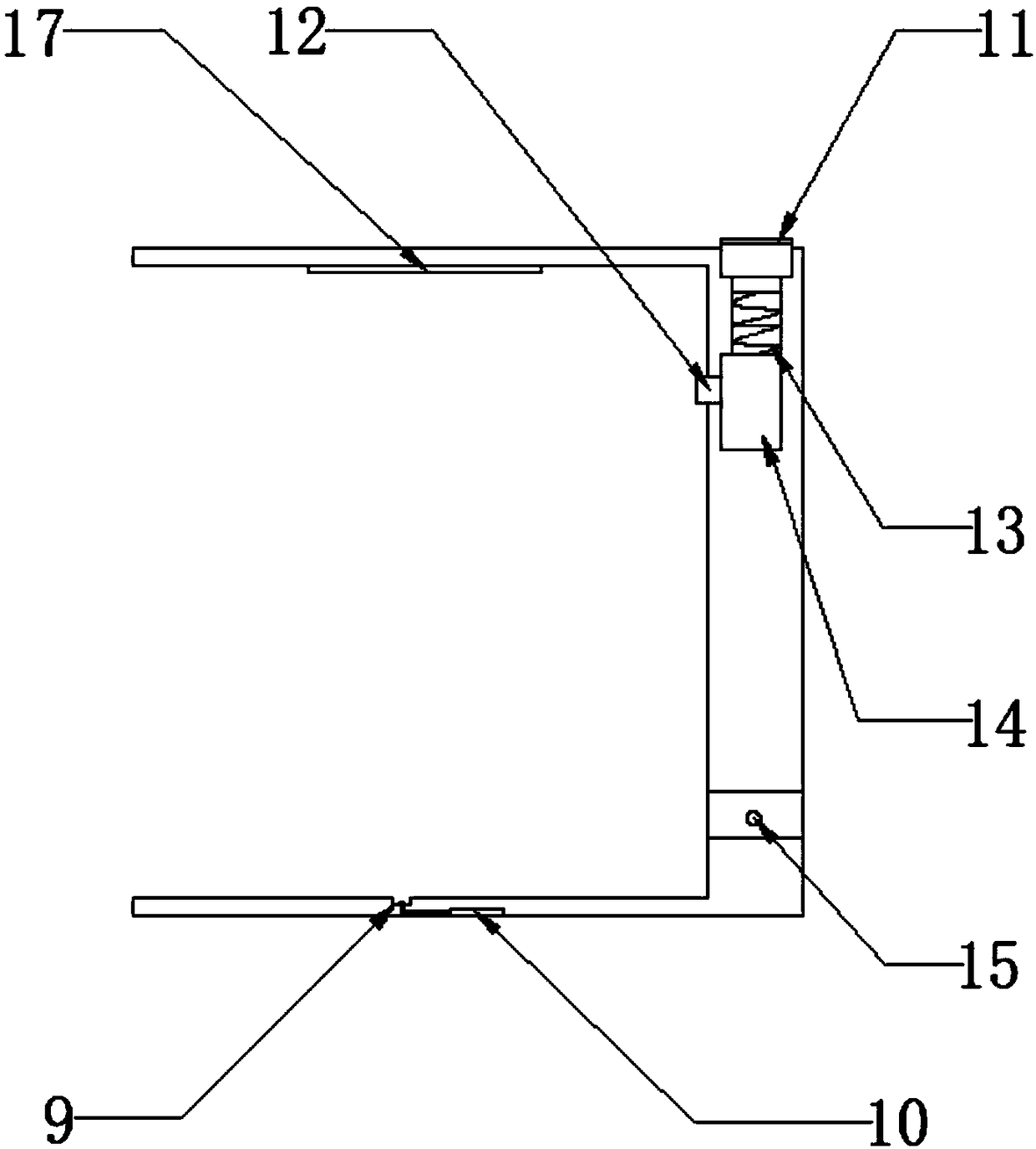

Traction mechanism

PendingCN109412083AIncrease frictionGuaranteed friction performanceApparatus for overhead lines/cablesRocker arm

The invention relates to a traction mechanism. The traction mechanism comprises a machine frame, wherein a rocker arm is rotationally assembled on the machine frame; a wire winding pressing wheel usedfor allowing one end of a corresponding traction part to be wound in and the other end to be wound out is rotationally assembled on the rocker arm; the rotating axis of the wire winding pressing wheel is parallel to that of the rocker arm; a pressing wheel driving mechanism for driving the wire winding pressing wheel to rotate is installed on the rocker arm; and a wire pressing rolling body matched with the wire winding pressing wheel to apply pressure to the traction part is arranged, beside the wire winding pressing wheel, on the machine frame. According to the traction mechanism, the problem that the structure is complex due to the fact that a plurality of friction winding wheels need to be arranged in a traction mechanism in the prior art is solved.

Owner:尚廷东

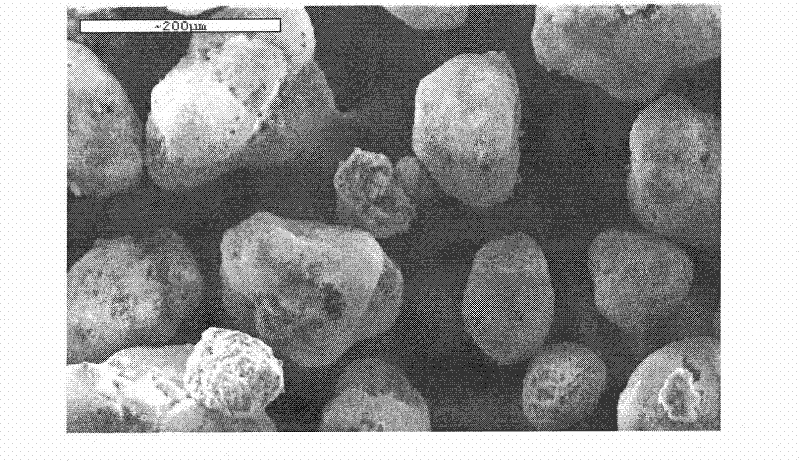

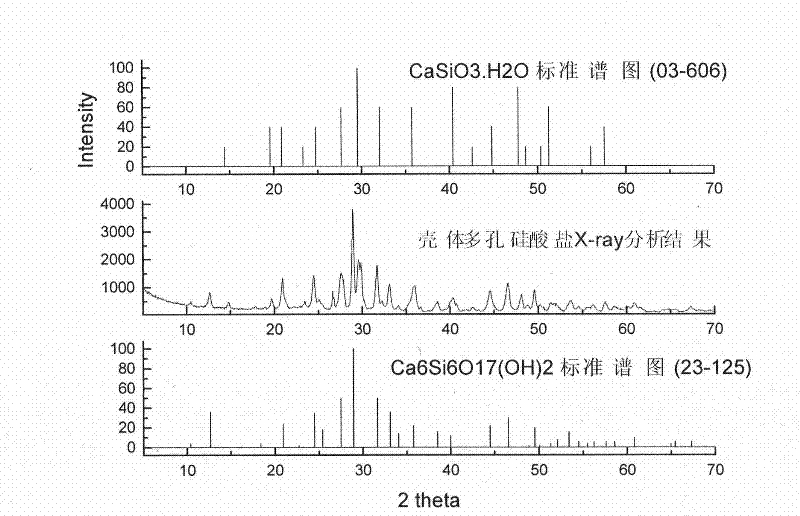

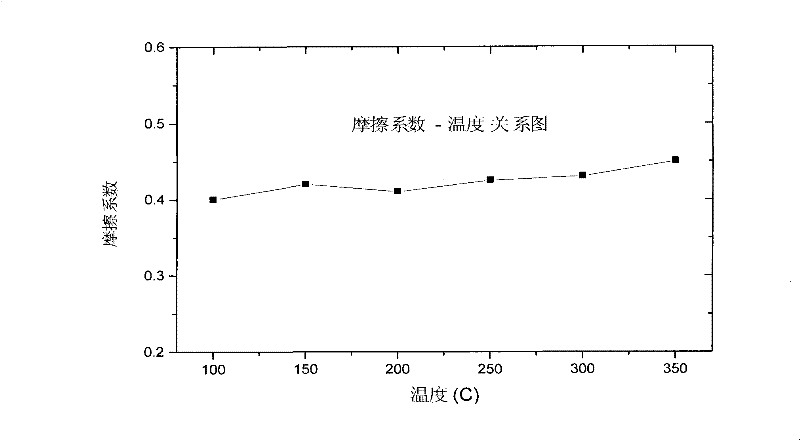

Shell porous silicate, preparation method thereof and friction material containing same

InactiveCN101804991BImprove heat resistanceImprove wear resistanceAlkaline-earth metal silicatesFiberHigh pressure

The invention discloses silicate of special crystal morphology, in particular a porous spherical material enclosed by closed shells woven by needle-like crystal chopped fibers. The bulk density of the material is 20 to 200g / L, the average size of the material is 1 to 1,000 micrometers, the main ingredient of the material is Ca6Si6O17(OH)2, and the material also contains 1 to 20 weight percent of CaSiO3.H2O. The material of the invention is manufactured by using a calcium compound and a silicon compound as raw materials, wherein the raw materials are uniformly mixed in a mol ratio of Ca<2+> to Si<4+> of 0.8 to 1.2; metal powder and water, which serve as reaction promoters are added into the raw materials; and the hydro-thermal synthesis is performed for 30 to 24 hours in a high-pressure reaction kettle under the conditions of stirring, a temperature rise speed of 0.2 to 3 DEG C / min, a constant temperature of 160 to 280 DEG C and a constant pressure of 6 to 68 Kg / cm<2>, and the product of the reaction is washed, filtered out and dried to give the finished product. The shell porous silicate of the invention has high heat resistance, high wear resistance, little wear and no noises, can be used as the friction material of the braking devices of automobiles, trains and air planes and is the optimal product for substituting asbestos. The material and the preparation process of the invention cause little environmental pollution and are suitable for industrial production.

Owner:隗学礼

Automatic continuous layering conveyor for planks

ActiveCN104261160BReduce travel resistanceReduce work intensityArticle feedersFriction effectEngineering

The invention discloses an automatic board continuous layer conveyor and belongs to the technical field of sheet board conveying machinery. The board continuous layer conveyor comprises a machine frame, a pair of revolving platform elevating mechanisms which are mutually corresponding, a revolving type layered board sending mechanism, a first revolving frame driving action cylinder and a second revolving frame driving action cylinder; the machine frame comprises a first wallboard, a second wallboard, a revolving platform elevating mechanism connecting shaft and a bottom beam; the revolving type layered board sending mechanism is supported between central shafts of a first revolving frame and a second revolving frame; the pair of revolving platform elevating mechanisms comprise revolving platform lifting action cylinder chains and chain wheels; the revolving type layered board sending mechanism comprises a first revolving frame, a second revolving frame, a sheet wood conveying platform panel, an input roller, an input pressing roller, an output roller and an output pressing roller; front ends of the first revolving frame and the second revolving frame are provided with sheet wood input pressing roller lifting and pressing mechanisms; a power transmission mechanism is arranged on the first revolving frame; a sheet wood deflection proof mechanism is arranged between a first bearing beam fixing base and a second bearing beam fixing base; sheet wood input and output pressing rollers are rubber rollers. The board continuous layer conveyor reduces the operation intensity, saves manpower, guarantees a friction effect between sheet wood and reduces movement resistance to the sheet wood.

Owner:常熟市力恒木业机械厂

A preparation method of ceramic reinforced carbon/carbon composite brake disc

ActiveCN109372916BImprove fracture toughnessAvoid catastrophic consequencesBraking discsActuatorsCarbon compositesCarbon fibers

The invention discloses a preparation method of a ceramic reinforced carbon / carbon composite material brake disc. The preparation method comprises the following steps that a carbon fiber prefabricatedbody is put into a deposition furnace, firstly, a chemical vapor-phase permeation process is adopted, then liquid-phase resin or liquid-phase asphalt is used for carrying out a dipping-carbonizationprocess, and a carbon / carbon composite material brake disc blank body is obtained; a liquid-phase siliconizing treatment is carried out on the blank body so as to obtain a disc body with the density of 2-2.2 g / cm<3>; and machining is carried out according to the shape and the size of the required brake disc so as to obtain the ceramic reinforced carbon / carbon composite material brake disc. According to the preparation method, the reasonable composition proportion and the preparation process are adopted, so that the high-quality ceramic reinforced carbon / carbon composite material brake disc with excellent mechanical property, oxidation resistance, friction resistance and wear resistance is prepared; the bake disc is light in weight, good in braking performance, short in production period and capable of realizing industrial production, the brake performance of a brake system of a transport vehicle can be improved, the weight of the brake system can be reduced, the service life of the brake disc is prolonged, and a good market prospect is achieved.

Owner:HUNAN JINTIAN ALUMINUM HI TECH CO LTD

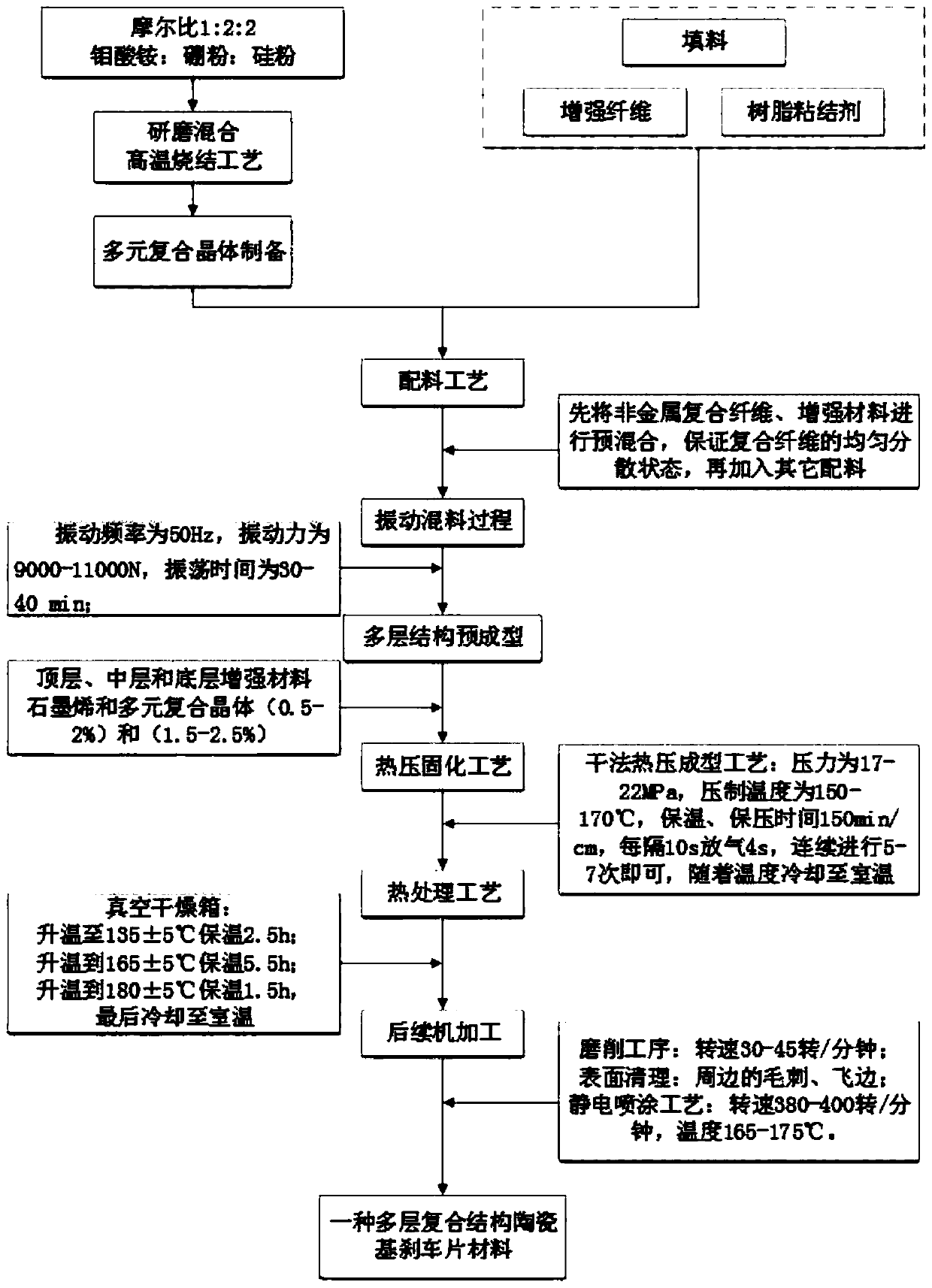

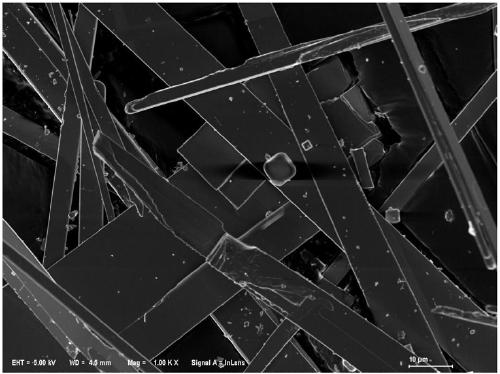

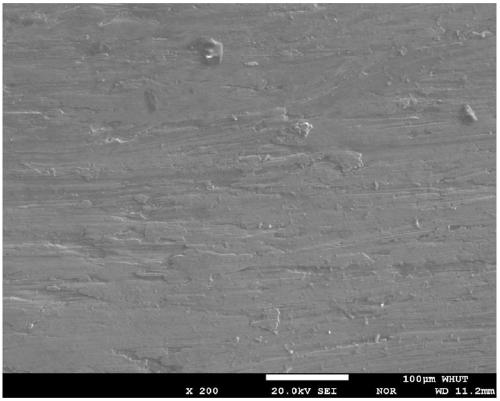

A kind of multilayer composite structure ceramic brake pad material and preparation method thereof

ActiveCN108412924BImprove wear resistanceReduce wear rateOther chemical processesFriction liningMixed materialsLayer thickness

The invention relates to a multi-layer composite structure ceramic brake pad material and a manufacturing method of the multi-layer composite structure ceramic brake pad material. Ceramic brake pad material powder, reinforced performance material graphene and multi-component composite crystals serve as raw materials, and calculation and preparation of material powder of various layers, vibration of mixed materials of various layers, multi-layer structure preforming, the hot-press curing technology, the heat treatment technology and the follow-up machining working procedure are conducted in sequence, so that the multi-layer composite structure ceramic brake pad material is manufactured. The high utilization ratio of the brake pad layer thickness is achieved through ceramic multi-layer gradient distribution, and compared with a uniformly-distributed brake pad, a multi-layer composite structure ceramic brake pad has the advantages that the relative consumption of the reinforced performance material can be reduced, and the friction performance can be guaranteed. Meanwhile, a large number of heavy metal raw materials are not used, and the multi-layer composite structure ceramic brake pad material has the advantages of being green and environmentally friendly, stable in friction performance at the high temperature, long in service life and the like.

Owner:WUHAN UNIV OF TECH

A kind of curved hole channel ceramic base brake pad composite material and its preparation method

ActiveCN110723925BImprove bearing capacityReduced propensity for frictional self-excited squealFriction liningActuatorsVacuum pressureGraphite

The invention discloses a ceramic-based brake pad composite material with a curved hole flow channel and a preparation method thereof. The ceramic matrix of the curved hole flow channel is manufactured by using the light-curing forming technology (SLA), and a composite filler of graphene and Sn-Ag-Cu is prepared. , using vacuum pressure infiltration technology to fill the composite filler into the curved hole flow channel, and then using the hot pressing process to prepare the curved hole flow channel ceramic-based brake pad composite material. Compared with traditional brake pad materials, the unique structural design and optimized filler formula of the present invention combined with advanced preparation technology make the brake material of the present invention have an average friction coefficient greater than 0.402 during operation, and the friction coefficient changes stably, and the material wear rate is low at 1.15×10 ‑7 cm 3 • N ‑1 •m ‑1 , All performance parameters are superior to national standards and traditional brake pad products.

Owner:WUHAN UNIV OF TECH

Lemon-flavor liquid detergent and packaging container thereof

InactiveCN111893001AImprove degreasing effectStrong antibacterial effectInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsChemistryLimonene

The invention discloses a lemon-flavor liquid detergent and a packaging container thereof. The lemon-flavor liquid detergent comprises the following main active components: deionized water, disodium ethylene diamine tetraacetate, sodium dimethyl benzene sulfonate, propylene glycol, sodium alcohol ether sulphate, alkyl glycoside, tea saponin, fatty alcohol-polyoxyethylene ether, granular plastic balls, D-limonene and citric acid. The lemon-flavor liquid detergent packaging container comprises a bottle body, a solution cavity and a placement groove are respectively formed in the left part and the right part of the bottle body; the front end and the rear end of the solution cavity are each fixedly connected with a transparent plate, a heat preservation layer is jointly pasted to the peripheryof the inner wall of the solution cavity, a water collecting groove is formed in the lower groove wall of the placement groove, a draining plate is embedded in the bottom end of the placement groove,and a blocking plug is clamped to the right end of the placement groove. The lemon-flavor liquid detergent is obvious in decontamination effect, free of stimulation, small in harm to human bodies, easy to clean and environmentally friendly, and the packaging container is simple in structure, diversified in function and capable of being used and popularized.

Owner:安徽共盈日化有限公司

Maintenance and Construction Method of Infiltrating Wear Layer of Asphalt Pavement

ActiveCN108003639BFast constructionRepair early diseaseIn situ pavingsBuilding insulationsStructural engineeringRoad surface

The invention discloses a maintenance construction method of an asphalt road surface solid permeability wearing layer. The construction method includes the following steps that the spreading amount ofa solid permeability agent is surveyed; a road surface is cleaned; the road surface is pre-processed; the solid permeability agent is sprayed; a wearing layer is spread; manual trimming is carried out; preliminary maintenance is carried out. According to the maintenance construction method, the solid permeability agent is demulsified immediately after being atomized or smeared on the original road surface, heavy cycloparaffin distilled oil rapidly infiltrates to restore old asphalt performance, early diseases of the original asphalt road surface are repaired, and meanwhile a matrix asphalt and tackifier mixture is left on the road surface to form a binding layer. A solid permeability layer is formed by the repaired original asphalt road surface and the binding layer. The maintenance construction method is high in construction speed and efficiency.

Owner:江苏瑞文戴尔交通科技有限公司

Swing bolster assembly and bogie

PendingCN114750798AAvoid enteringGuaranteed friction performanceBogie-underframe connectionsClassical mechanicsTruck

The invention belongs to the technical field of railway wagons, and discloses a swing bolster assembly and a bogie. The swing bolster assembly comprises a swing bolster, a lower center plate, a sand prevention ring and a side bearing; the lower center plate is arranged on the swing bolster, and the side bearings are arranged on the swing bolster and located on the two sides of the lower center plate. The sand prevention ring is arranged on the swing bolster and annularly arranged outside the lower center plate in a sleeving mode, and the sand prevention ring is higher than the lower center plate. According to the swing bolster assembly and the bogie, sand and dust can be effectively prevented from entering the space between the upper center plate and the lower center plate, and the safety of a vehicle is guaranteed.

Owner:CRRC YANGTZE CO LTD +1

Fixed device used for air conditioner

InactiveCN109059239AAvoid wear and tearGuaranteed friction performanceMechanical apparatusLighting and heating apparatusControl engineeringDistance sensors

The invention discloses a fixed device used for an air conditioner. A fixed shell is included, and a rubber pad is arranged on the inner side of the fixed shell; rolling wheels are arranged at the bottom of the fixed shell; a fixed base is arranged at the bottom of each rolling wheel; a control panel is arranged on the front side of each fixed base; a cooling block is arranged on the back side ofthe fixed shell; the middle of the cooling block is provided with a water outflow pipe opening; the top end of the cooling block is provided with a refrigerating pipe opening; when temperature is toohigh, a bearing controller is used for controlling the opening and closing degree of the cooling block, the air conditioner is coordinated to perform cooling; a distance sensor and a pressure sensor of a trigger detect whether the air conditioner is fixed firmly or not, so that operation is easy and convenient; when fixation is not firm, a buzzer sends out an alarm, a worker can perform manual adjusting through the control panel, the purpose of enhancing the fixing effect is achieved, and the safety is guaranteed; and a fixed circuit passes through a circuit interface, and the potential safetyhazard is effectively lowered.

Owner:JIANGSU UNIV OF SCI & TECH

Waste paper treatment device of adhesive sticker machine

InactiveCN110607707AShort processOptimize environmental protection processRaw material pretreatmentPaper tapePulp and paper industry

The invention relates to non-setting adhesive process production. The waste paper treatment device of the non-setting adhesive machine comprises a machine body, including a machine frame, wherein an ink removing cavity and an ink washing cavity are formed in the rack; a movable frame and a fixed frame are respectively mounted in the printing ink removing cavity; a movable friction roller is mounted on the movable frame; a fixed friction roller is mounted on the fixed frame; the movable friction roller and the fixed friction roller are installed in an inner cavity of the ink removing cavity through a movable roller shaft and a fixed roller shaft correspondingly. Guide rails are further arranged on the left side wall and the right side wall of the ink removing cavity, guide blocks are installed at the two ends of the movable roller shaft and installed in the corresponding guide rails in an embedded mode, an electric push rod is installed at the top of the ink removing cavity, and the bottom end of the electric push rod extrudes downwards to make contact with the movable frame. Ink stains and paper tapes are effectively separated through clamping friction, subsequent classification treatment is facilitated, and the environmental protection process of an enterprise is optimized.

Owner:云和县宏峰模具厂

A printing product drying device

ActiveCN112937115BAvoid osmosisAvoid drippingCylinder pressesPlaten pressesEngineeringMechanical engineering

Owner:山东润声印务有限公司

Composite bearing deflection limiting device for stirring shaft

ActiveCN104533965BAvoid bitesAvoid collisionRotary bearingsMixer accessoriesEngineeringMechanical engineering

The invention belongs to the field of structural design of stirring equipment, and in particular relates to a composite bearing deflection limiting device for a stirring shaft. The composite bearing deflection limiting device comprises a bearing block and a support frame, wherein the bearing block comprises an outer ring sleeve directly sleeving a shaft body of the stirring shaft, and a hole wall of the outer ring sleeve is spaced from the shaft body of the stirring shaft; a plurality of roll shaft parts are annularly arranged on the hole wall of the outer ring sleeve along the axial line of the hole wall, each roll shaft part comprises a stator shaft and a rotating sleeve, and the axial line of the outer ring sleeve, the axial line of a stator shaft and an ideal axial line of the stirring shaft are coaxially and vertically arranged; a section, matched with the rotating sleeve, of the stator shaft has a spindle-shaped structure, and the rotating sleeve correspondingly has a sleeve structure with a concave spherical inner cavity; on the axial cross section passing through the axial line of the stator shaft, the diameters of generatrixes of the stator shaft and the rotating sleeve at sections matched with each other are consistent and the circle centers are positioned on the same horizontal plane, and the diameter of the generatrix at a hole cavity of the rotating shaft is greater than that of the generatrix of the stator shaft. By adopting the composite bearing deflection limiting device provided by the invention, the effect of fixing the shaft body of the stirring shaft within an allowed deflection quantity range can be realized.

Owner:合肥华升泵阀股份有限公司

Printed product drying device

ActiveCN112937115AAvoid osmosisAvoid drippingCylinder pressesPlaten pressesEngineeringMechanical engineering

The invention discloses a printed product drying device. The device comprises a seat box plate, wherein a partition plate is fixedly connected to the top of the seat box plate, an airflow hole is formed in the middle of the top of the partition plate, a temperature rising mechanism is movably connected to a position, located on the outer side of the airflow hole, of the top of the partition plate, a flow dividing frame plate is movably connected to a lower middle position of the inner surface of the temperature rising mechanism, the top of the flow dividing frame plate is movably connected with an airflow fan, a portion, located on the outer side of the temperature rising mechanism, of the top of the partition plate is movably connected with conveying rollers, and air hole grooves are formed in a position, located on the outer side of the temperature rising mechanism and between the conveying rollers, of the top of the partition plate. The invention relates to the technical field of printing. According to the device, a printed product is vertically placed, airflow is used for blowing upwards continuously, wind resistance generated by blowing of wind inhibits falling of printing dye due to the weight of the printing dye, the printing dye is prevented from permeating or dripping towards the periphery, damage of the printing dye to the quality of the product is reduced, and safety of the surrounding environment is guaranteed.

Owner:山东润声印务有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com