Curved-hole flow channel ceramic base brake pad composite material and preparation method thereof

A technology of composite materials and base brake pads, which is applied in the field of auto parts, can solve the problems of obvious thermal degradation of friction materials, short service life, high wear rate, etc., achieve excellent frictional thermal stability, reduce regularity, and reduce wear rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A kind of ceramic-based brake pad composite material with curved hole flow channel, its composition is as follows by mass percentage: graphene (1wt.%), Sn-Ag-Cu alloy (4wt.%), nitrile rubber powder (4wt.%) for composite filler), linseed oil modified phenolic resin (5wt.% for composite filler), potassium titanate whiskers (17wt.%), linseed oil modified phenolic resin (18wt.% for matrix), nitrile rubber Powder (7wt.% for matrix), molybdenum disulfide (5wt.%), alumina (8wt.%), silicon oxide (3wt.%), calcium silicate (8wt.%), barite (15wt.%) %), white vermiculite powder (5wt.%). Wherein, the composition of the Sn-Ag-Cu alloy is: Sn (55wt.%), Ag (40wt.%), Cu (5wt.%), and its particle size is 25-45 μm.

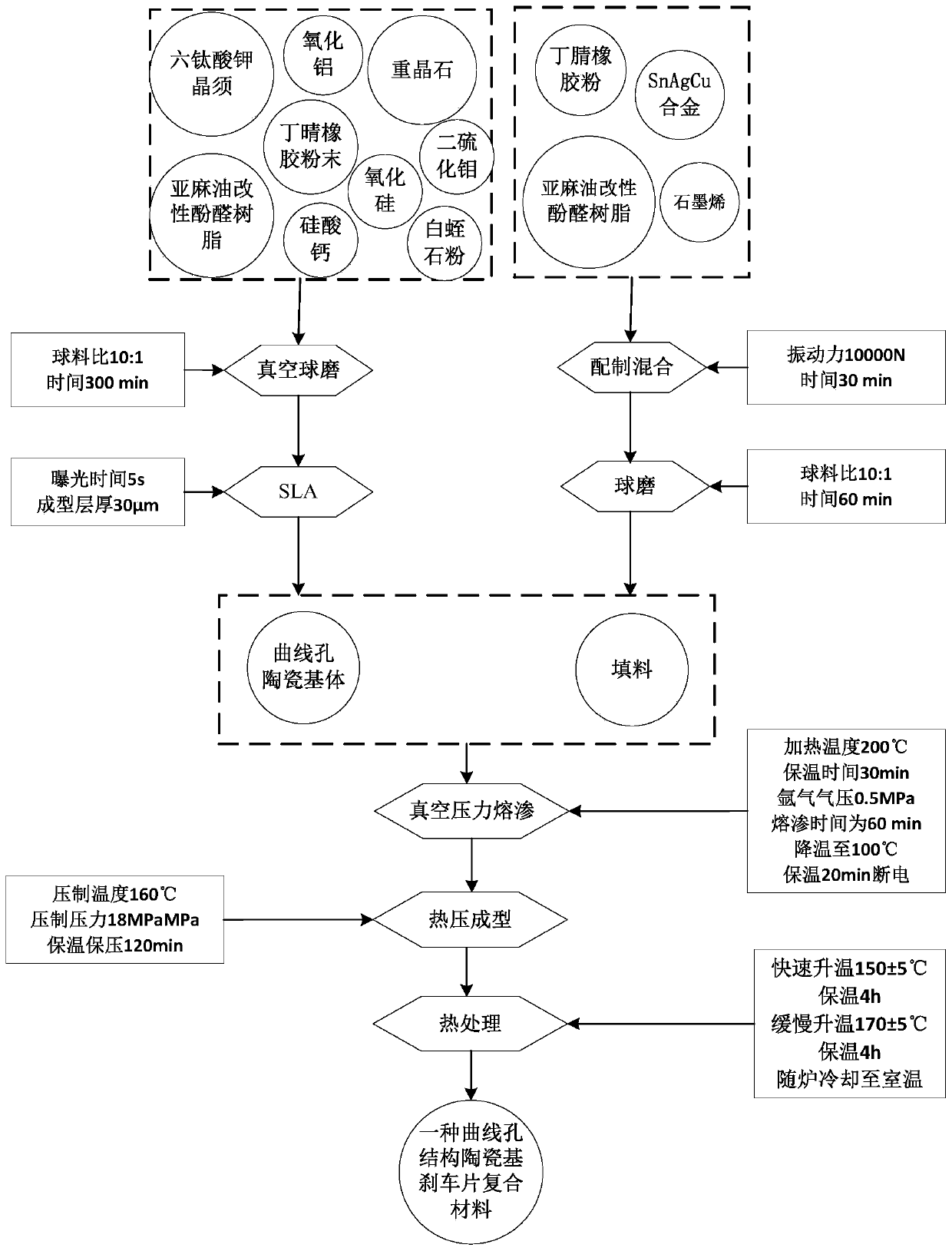

[0039] Such as figure 1 As shown, the preparation method of the above-mentioned curved hole runner ceramic-based brake pad composite material specifically includes the following steps:

[0040] 1) Preparation of ceramic raw materials, the component content is: potassium ti...

Embodiment 2

[0048] A kind of curved hole flow path ceramic base brake pad composite material, its composition is as follows by mass percentage: graphene (1.5wt.%), Sn-Ag-Cu alloy (3.5wt.%), nitrile rubber powder (3wt. % for composite filler), linseed oil modified phenolic resin (3wt.% for composite filler), potassium titanate whiskers (17wt.%), linseed oil modified phenolic resin (25wt.% for matrix), butyl Nitrile rubber powder (6wt.% for matrix), molybdenum disulfide (3wt.%), alumina (8wt.%), silicon oxide (3wt.%), calcium silicate (7wt.%), barite ( 15wt.%), white vermiculite powder (5wt.%). Wherein, the composition of the Sn-Ag-Cu alloy is: Sn (55wt.%), Ag (35wt.%), Cu (10wt.%), and its grain size is 25-45 μm.

[0049] The preparation method of the above-mentioned curved hole channel ceramic-based brake pad composite material specifically includes the following steps:

[0050] 1) Preparation of ceramic raw materials, the component content is: potassium titanate whiskers (34g), linseed...

Embodiment 3

[0057] A kind of curved hole flow path ceramic base brake pad composite material, its composition is as follows by mass percentage: graphene (1.5wt.%), Sn-Ag-Cu alloy (3.5wt.%), nitrile rubber powder (4wt. % for composite filler), linseed oil modified phenolic resin (2wt.% for composite filler), potassium titanate whiskers (13wt.%), linseed oil modified phenolic resin (25wt.% for matrix), butyl Nitrile rubber powder (7wt.% for matrix), molybdenum disulfide (5wt.%), alumina (8wt.%), silicon oxide (3wt.%), calcium silicate (8wt.%), barite ( 15wt.%), white vermiculite powder (5wt.%). Wherein, the composition of the Sn-Ag-Cu alloy is: Sn (60wt.%), Ag (30wt.%), Cu (10wt.%), and its particle size is 25-45 μm.

[0058] The preparation method of the above-mentioned curved hole channel ceramic-based brake pad composite material specifically includes the following steps:

[0059] 1) Preparation of ceramic raw materials, the component content is: potassium titanate whiskers (26g), lins...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| dispersion coefficient | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com