Fruit pre-treatment system for fruit wine

A technology of fruit and pretreatment, applied in application, food processing, food science, etc., can solve the problems of incomplete pretreatment and cleaning, affecting the quality of fruit wine, etc., and achieve the effect of reliable limit, reliable positioning and improved cleaning quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

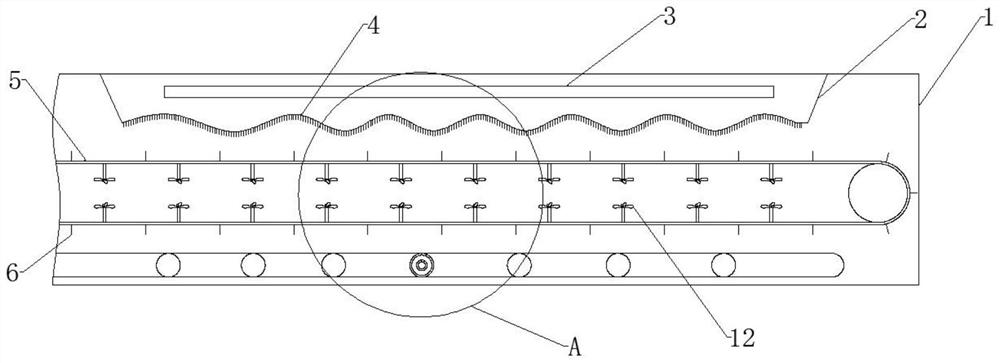

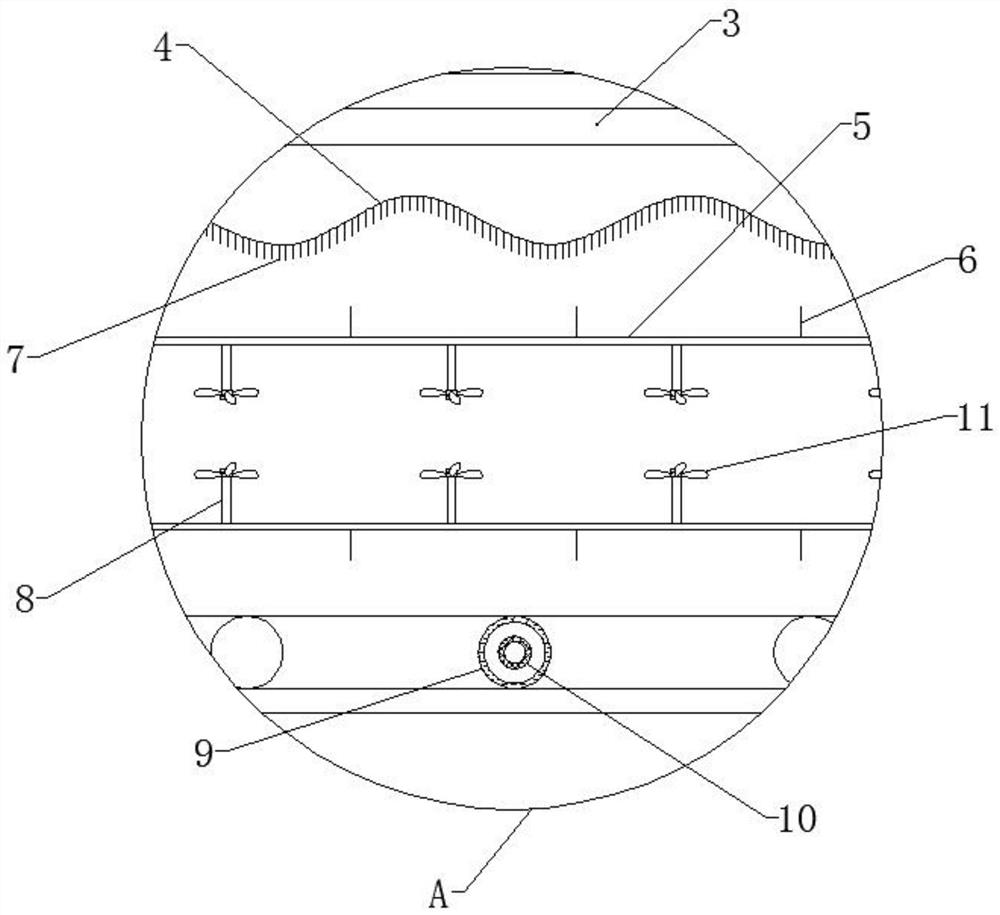

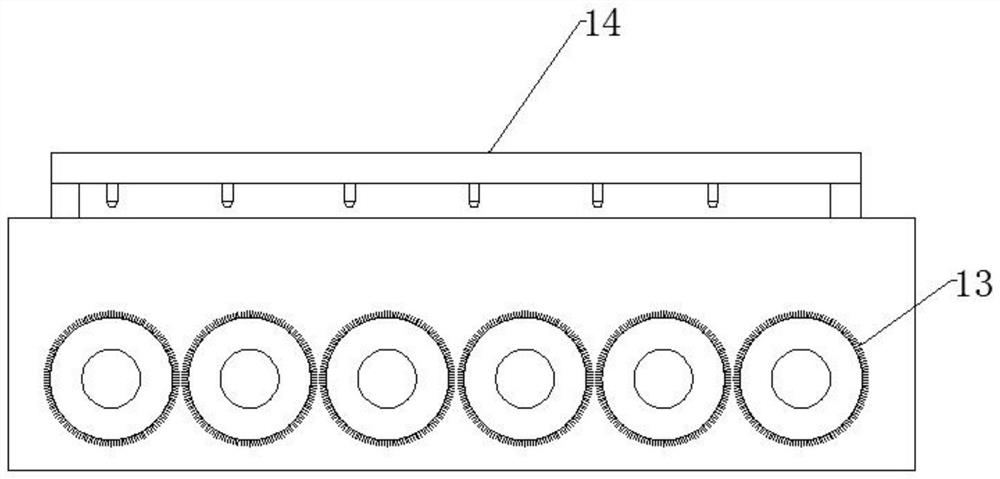

[0021] Embodiment, a kind of fruit pretreatment system for fruit wine, comprises the air bubble cleaning machine, the hair brush cleaning machine and the air dryer arranged in sequence, such as figure 1 , figure 2 As shown, the bubble cleaning machine includes a cleaning tank 1, and the cleaning tank 1 is provided with a conveying mesh belt 5. The conveying mesh belt 5 is hinged with stainless steel mesh plates. Some push pedals 6. Conveyor mesh belt 5 below is provided with water spray pipe 9 and air bubble pipe 10, and air bubble pipe 10 is perforated in water spray pipe 9, and the outlet of air bubble pipe 10 and water spray pipe 9 is arranged concentrically, and the outlet of water spray pipe 9 and air bubble pipe 10 The outlet is arranged obliquely upwards, and the angle between the outlet of the bubble tube 10 and the water spray tube 9 and the horizontal plane is 80°. Conveyor mesh belt 5 inner wall (that is not in contact with the side of the fruit) is rotatably con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com