Composite self-lubricating bearing

A self-lubricating bearing, compound technology, applied in the direction of bearings, bearing components, shafts and bearings, can solve the problems of self-lubricating bearing bearing capacity limitation, difficult oil supply, weak structure, etc., to meet the needs of industrial applications, Flexible design and application, optimizing the effect of the limit of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The above and other technical features and advantages of the present invention will be described in more detail below in conjunction with the accompanying drawings.

[0021] Refer to the following Figure 1 to Figure 8 , to further illustrate the composite self-lubricating bearing of the present invention.

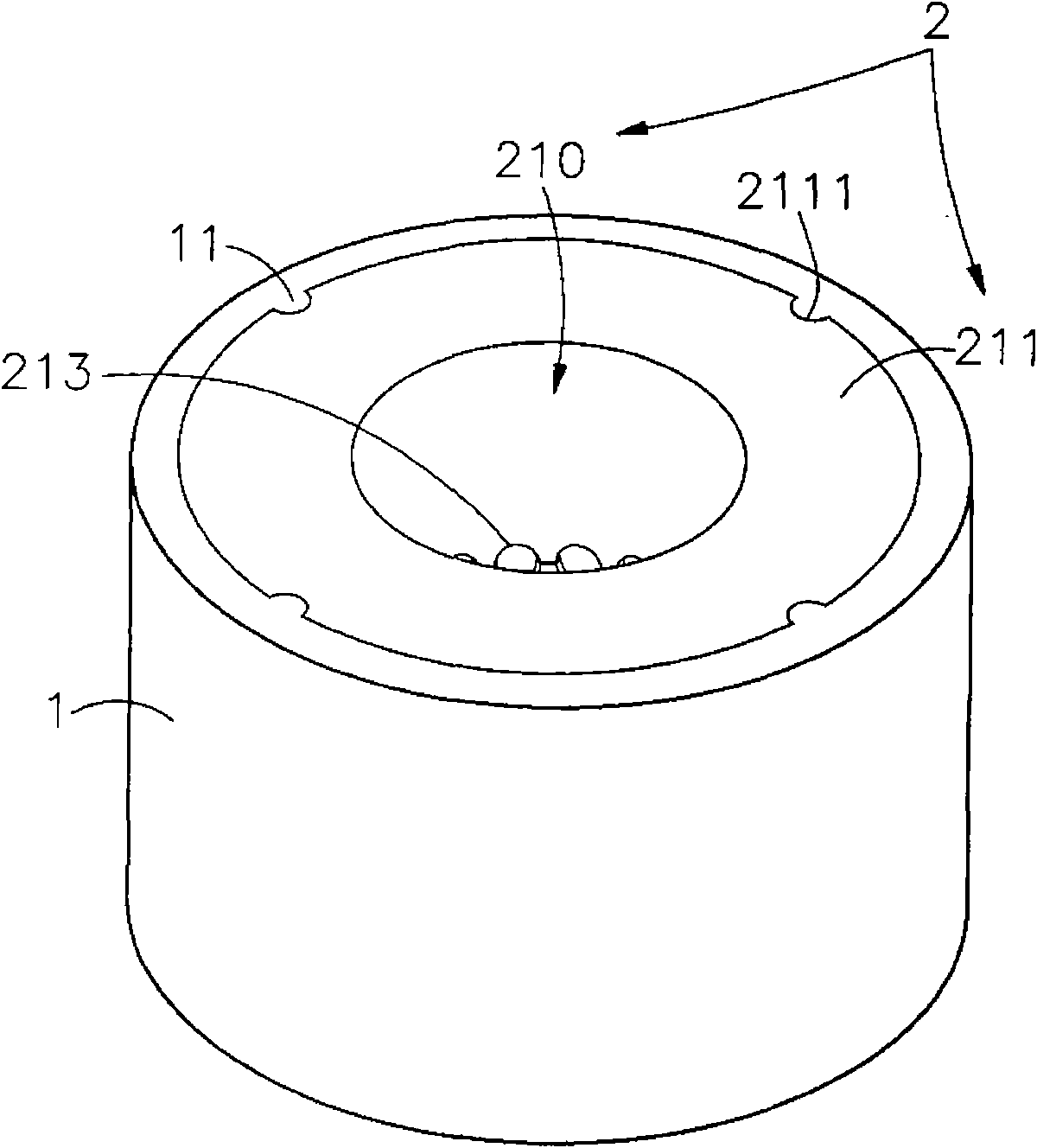

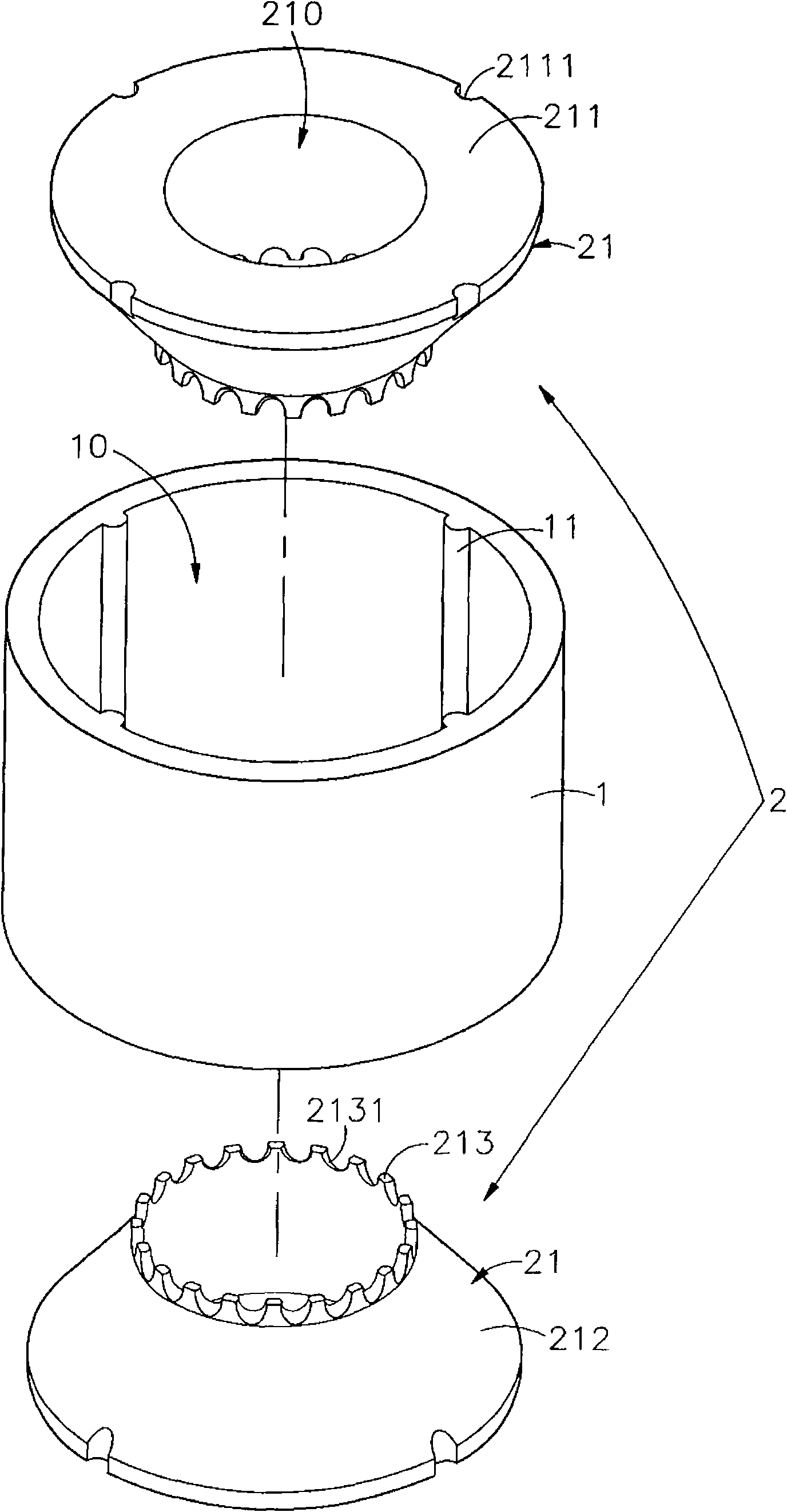

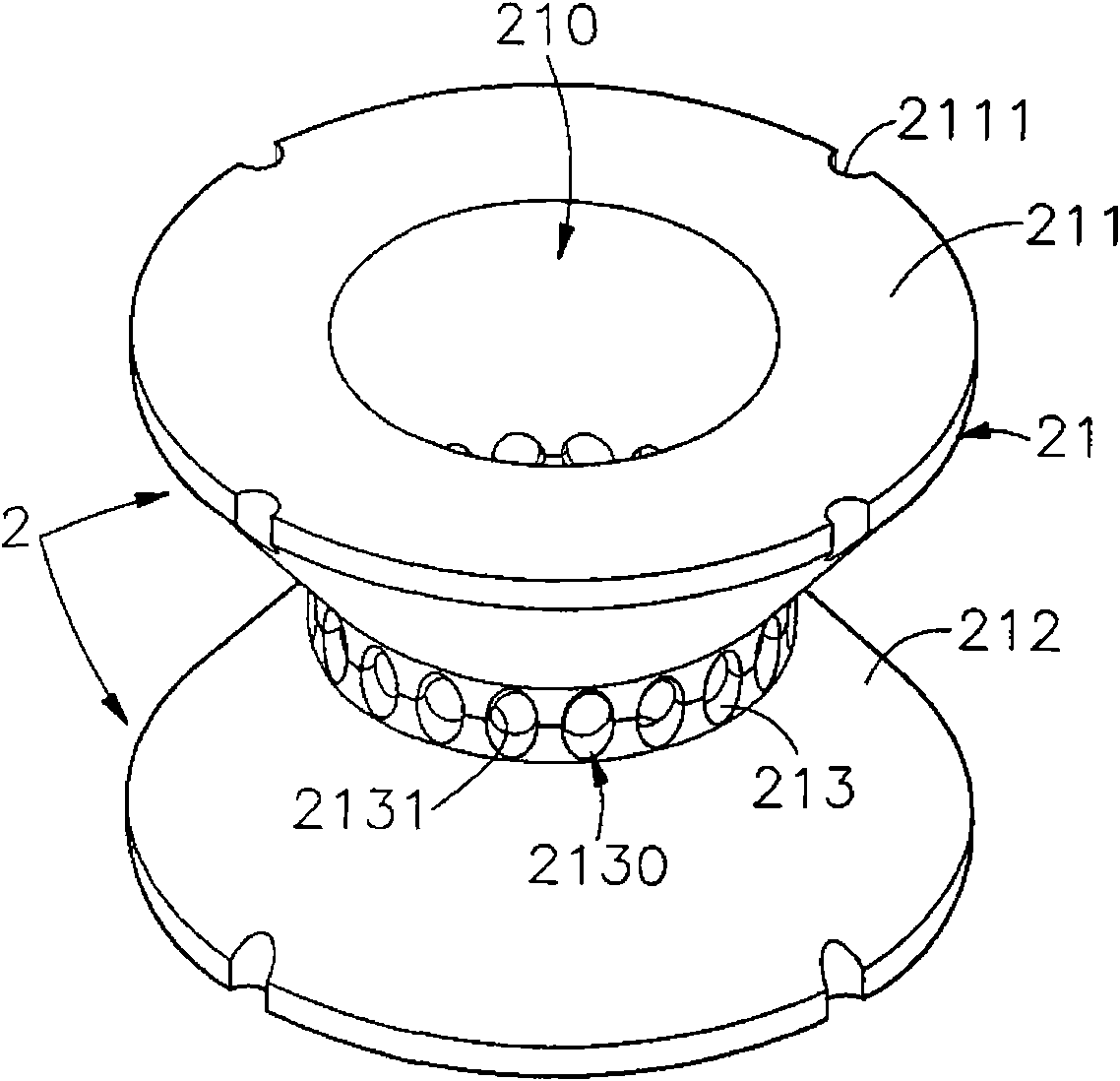

[0022] see Figure 1 to Figure 5 As shown, they are the three-dimensional appearance view, the three-dimensional exploded view, the combined schematic diagram of the bearing unit, the assembly sectional view and the assembly sectional view assembled with the shaft core of the first embodiment of the present invention; the composite self-lubricating bearing is composed of a housing 1 and The bearing set consists of 2, of which:

[0023] The housing 1 is a hollow cylinder penetrating in the axial direction to form an accommodating space 10, which is made of dense solid material or porous material, and the wall surface of the accommodating space 10 is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com