Patents

Literature

51results about How to "Reduce excessive wear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

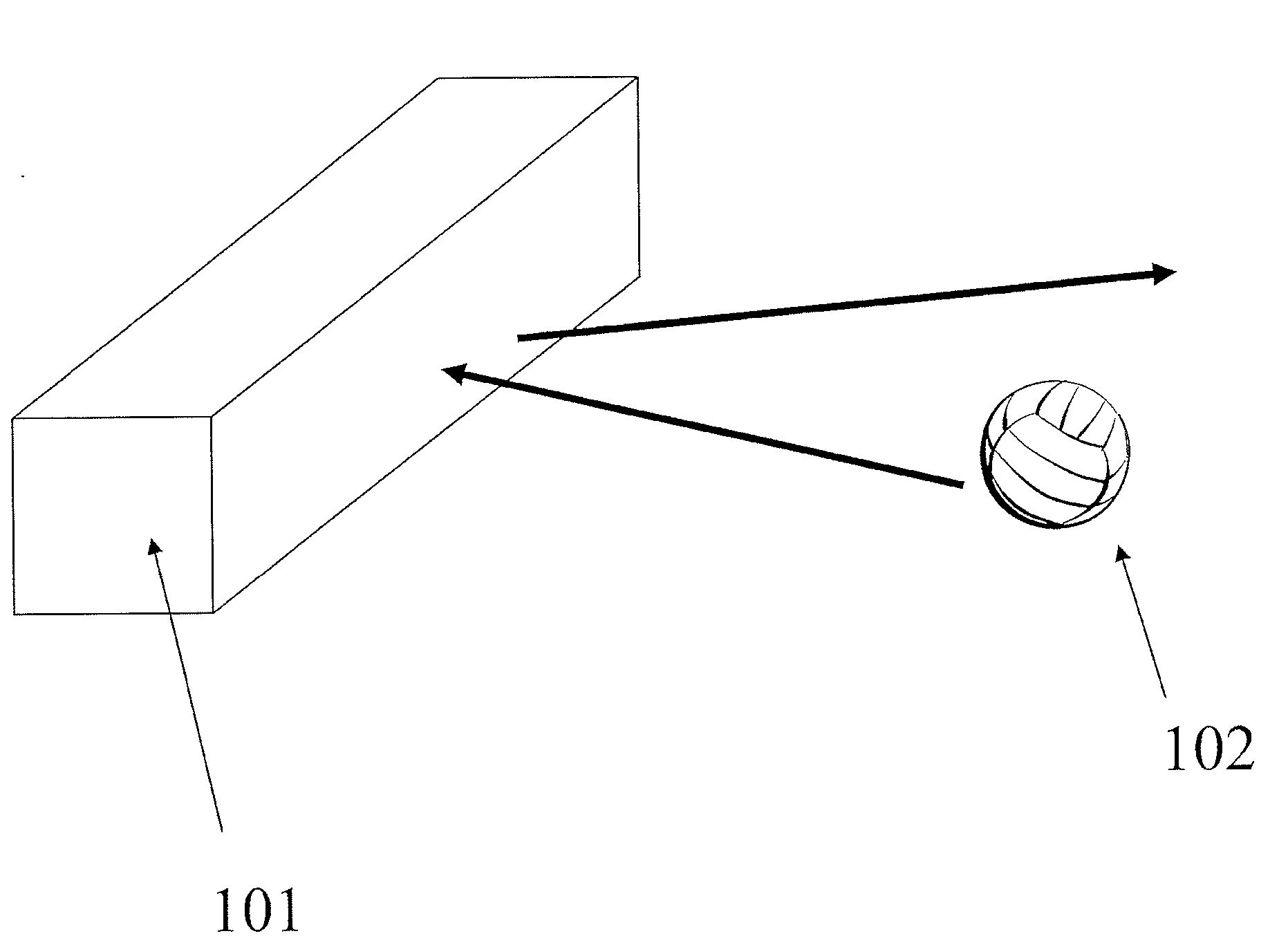

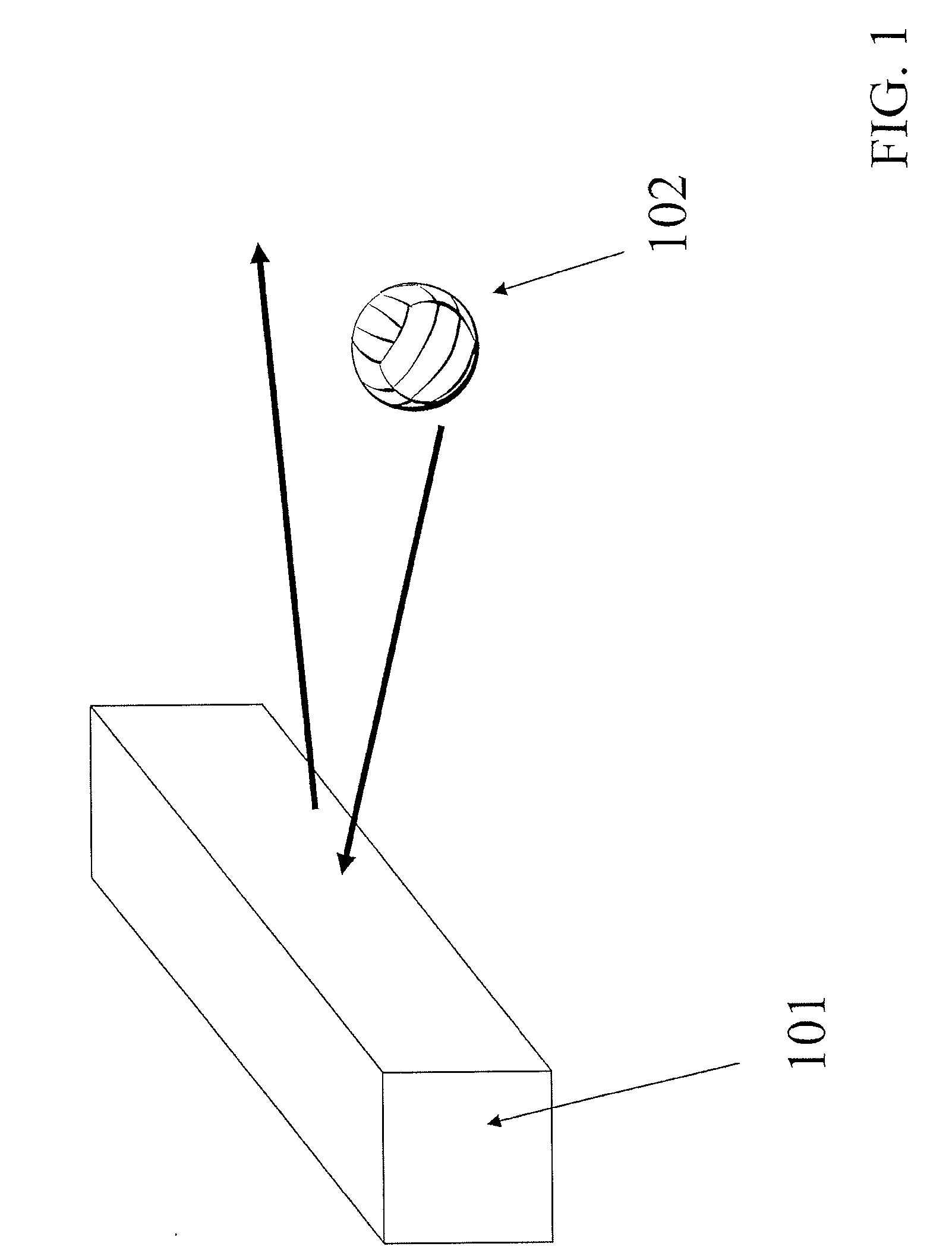

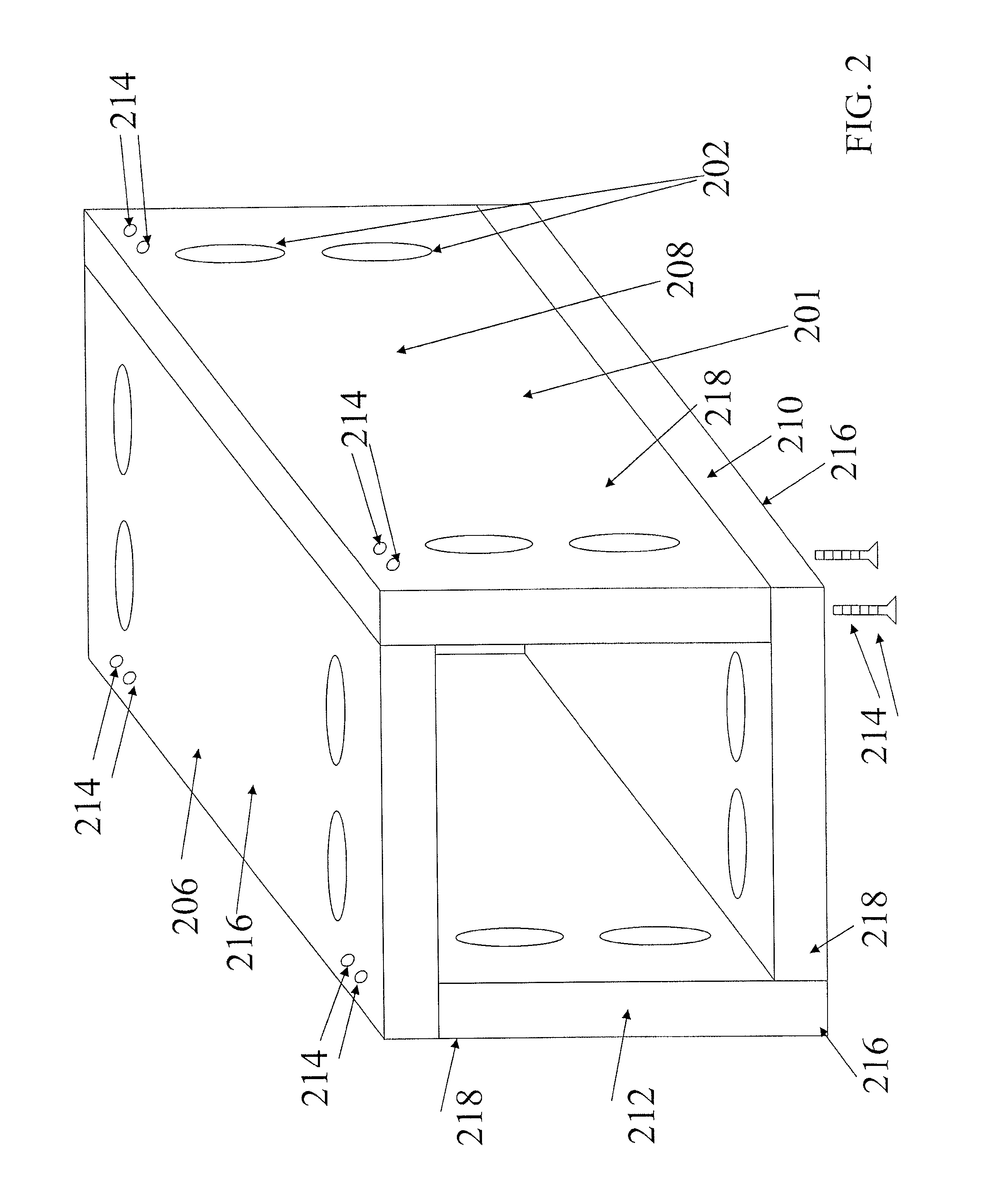

Rebound Sports Training Apparatus

InactiveUS20090069125A1Less spaceReduce excessive wearBall sportsSpace saving gamesSport trainingBiomedical engineering

Owner:PORTER LUKE LEONARD MARTIN

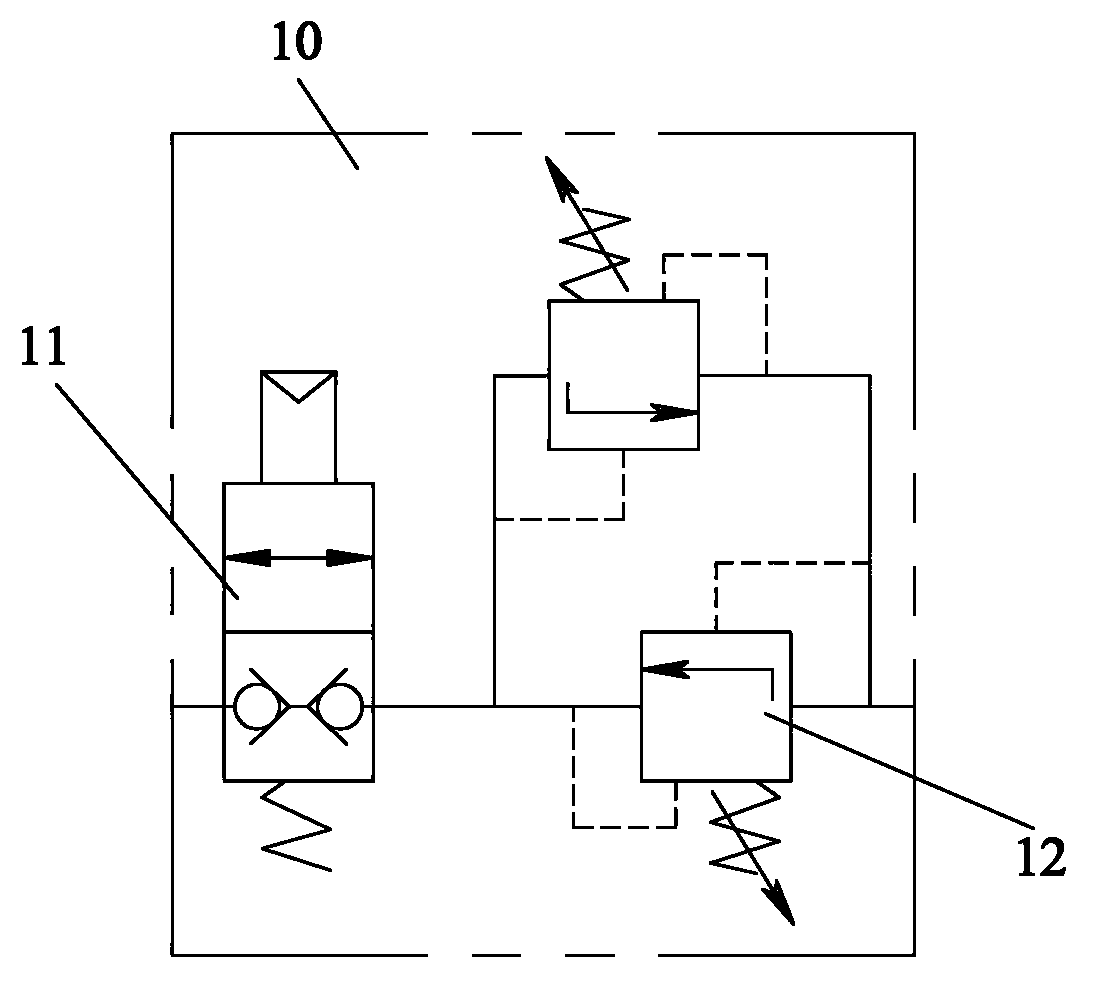

Pressure balancing device, hydro-pneumatic suspension automatic leveling system and engineering vehicle

ActiveCN103204042AReduce distortionReduce excessive wearServomotorsResilient suspensionsEngineeringPressure balance

The invention provides a pressure balancing device, a hydro-pneumatic suspension automatic leveling system and an engineering vehicle. The pressure balancing device comprises a switch valve and a pressure stabilizing circuit which is in series connection with the switch valve to control pressure differences of two terminals of the pressure stabilizing circuit within a preset range. The pressure balancing device has the advantages of being capable of effectively keeping balance of a vehicle and prolonging the service life of axles.

Owner:ZOOMLION HEAVY IND CO LTD

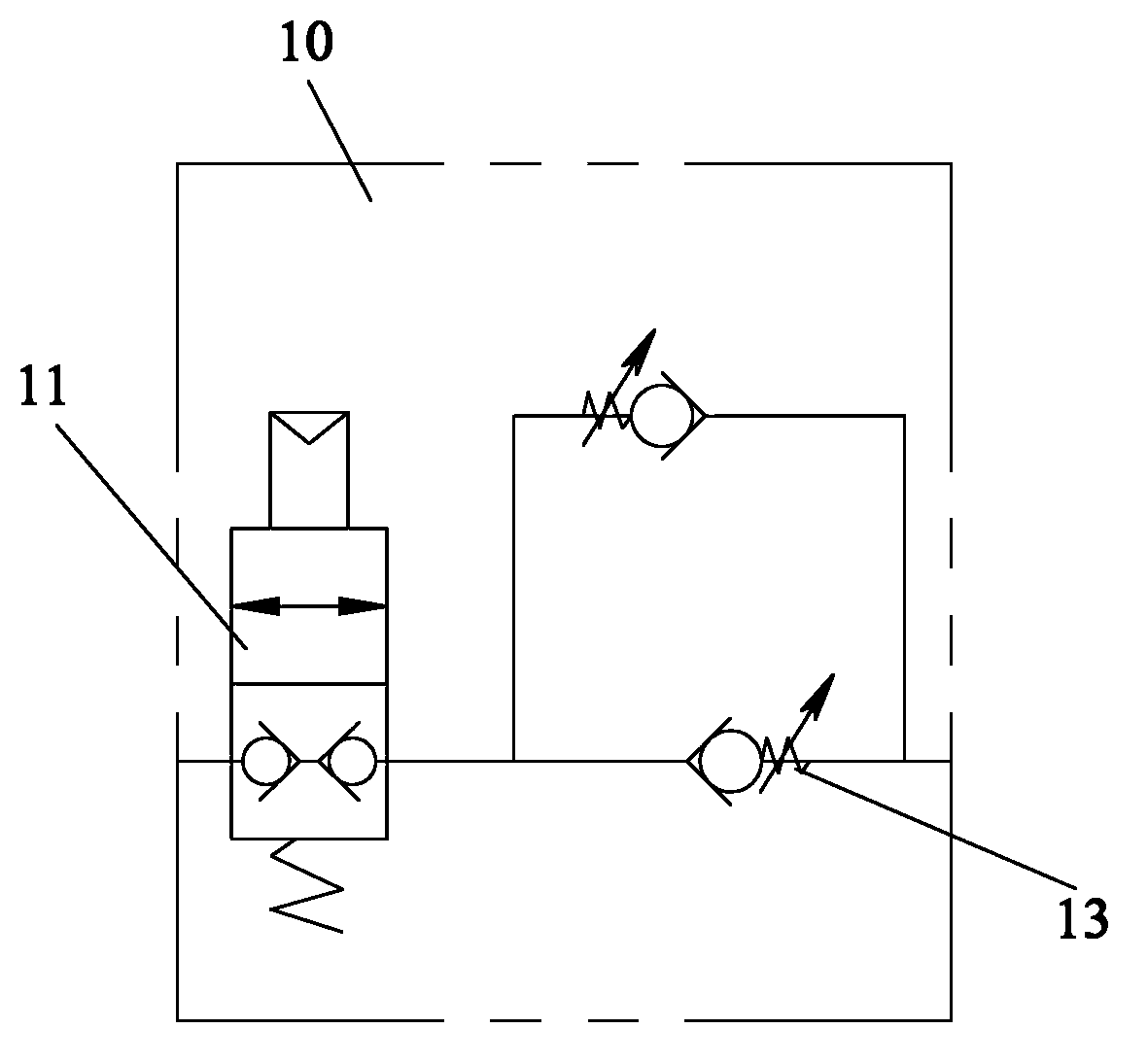

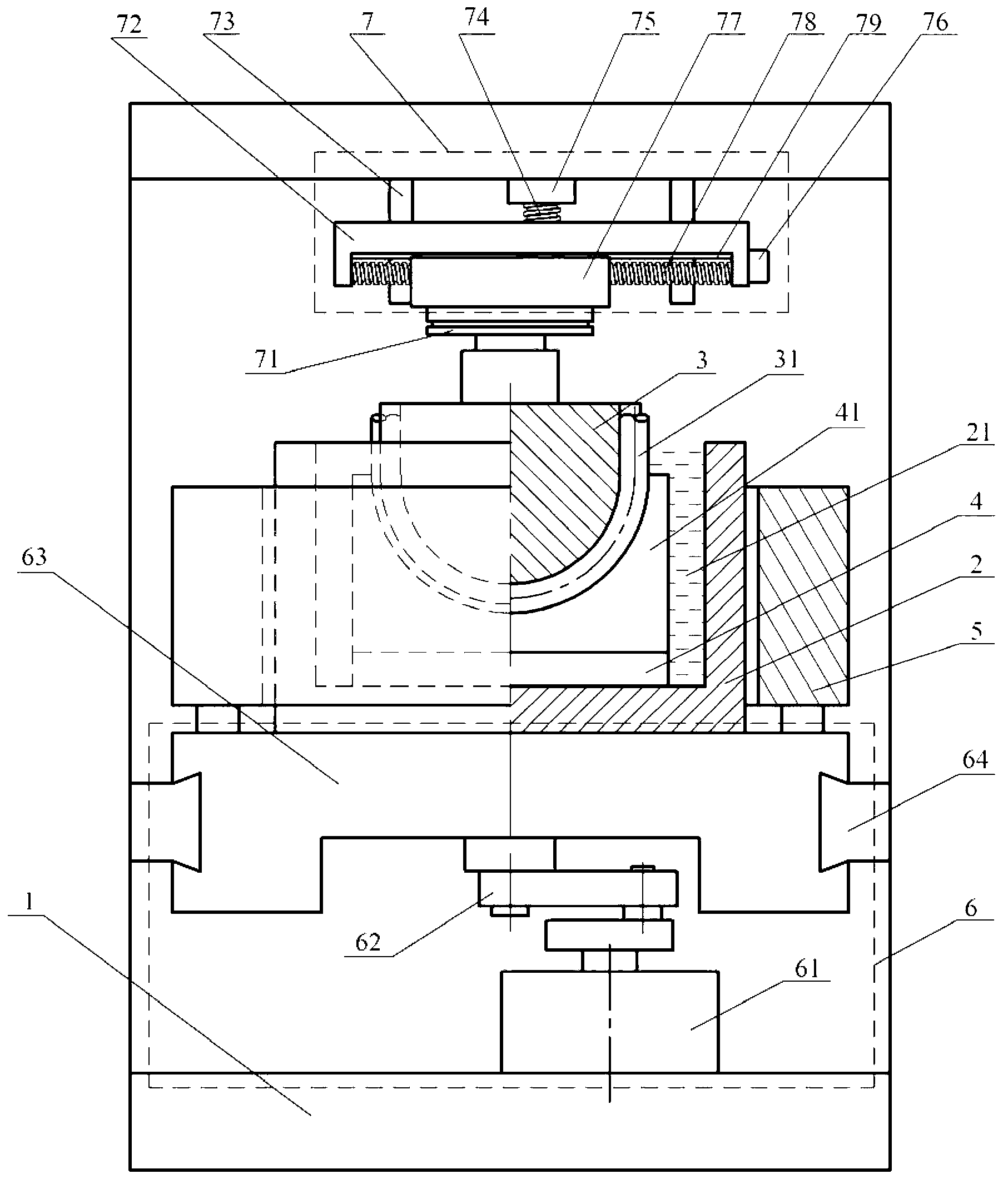

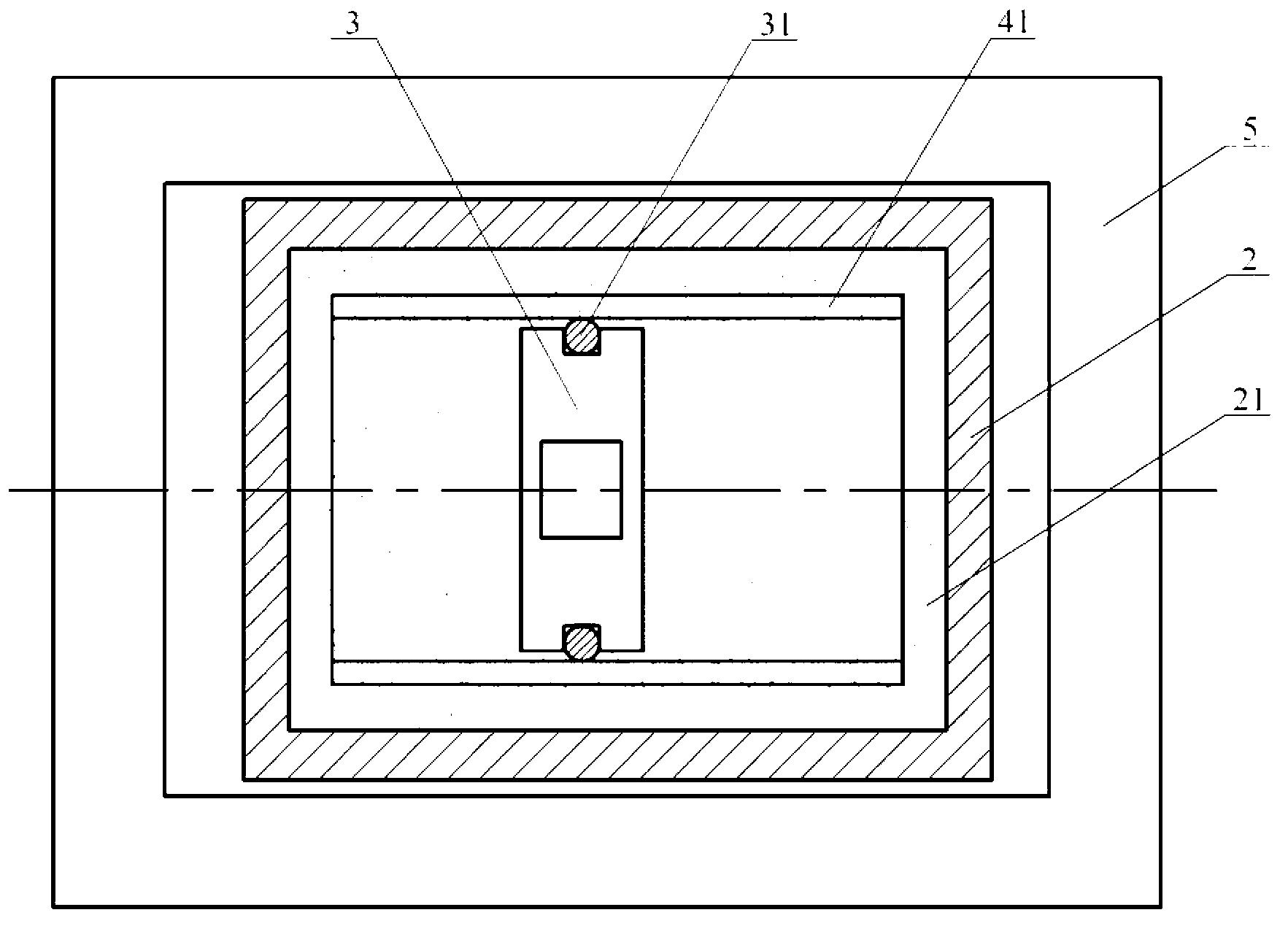

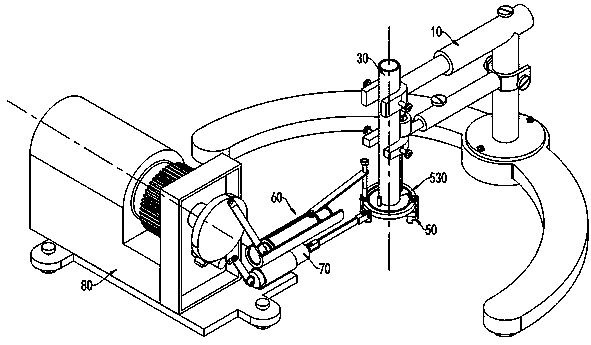

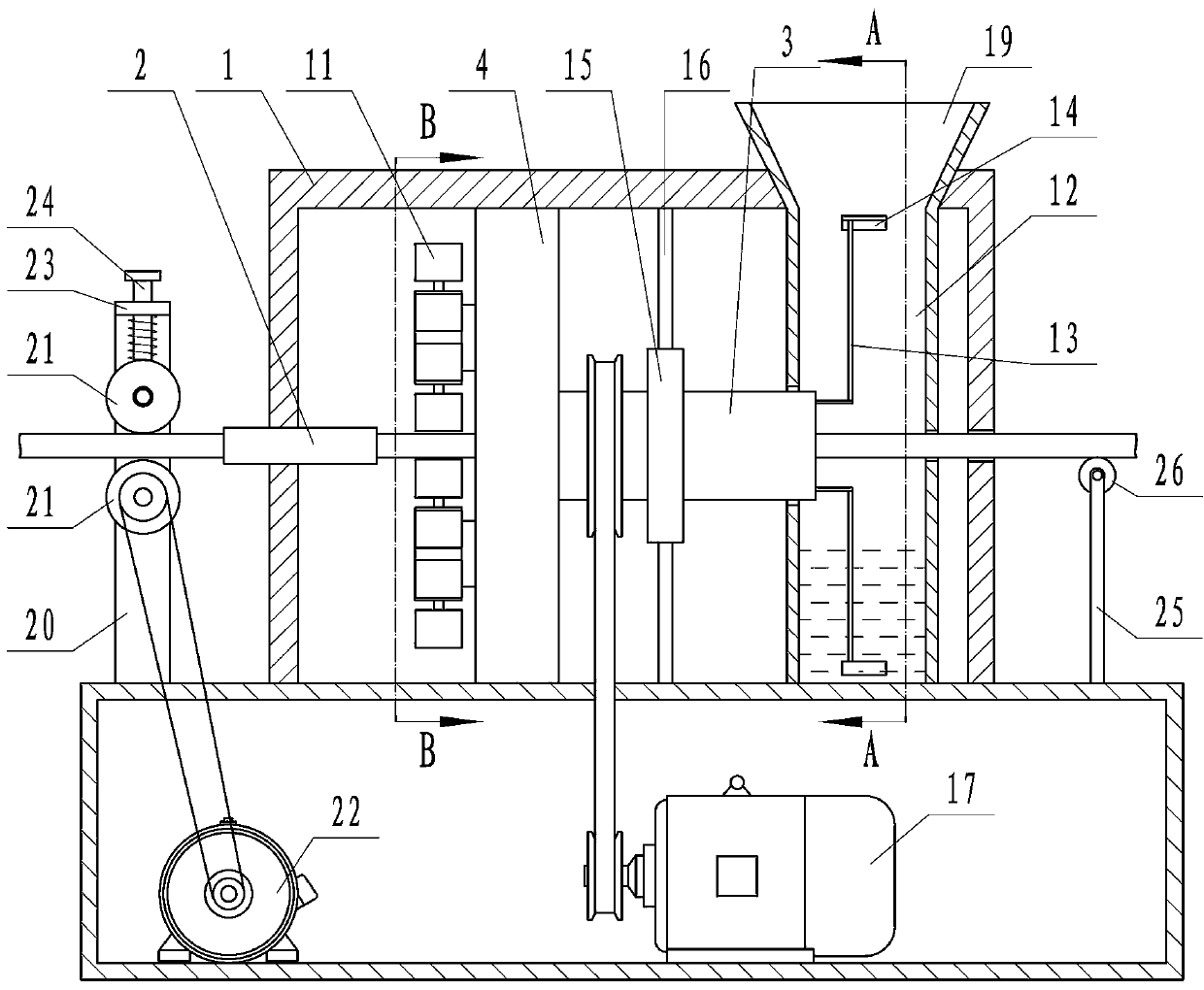

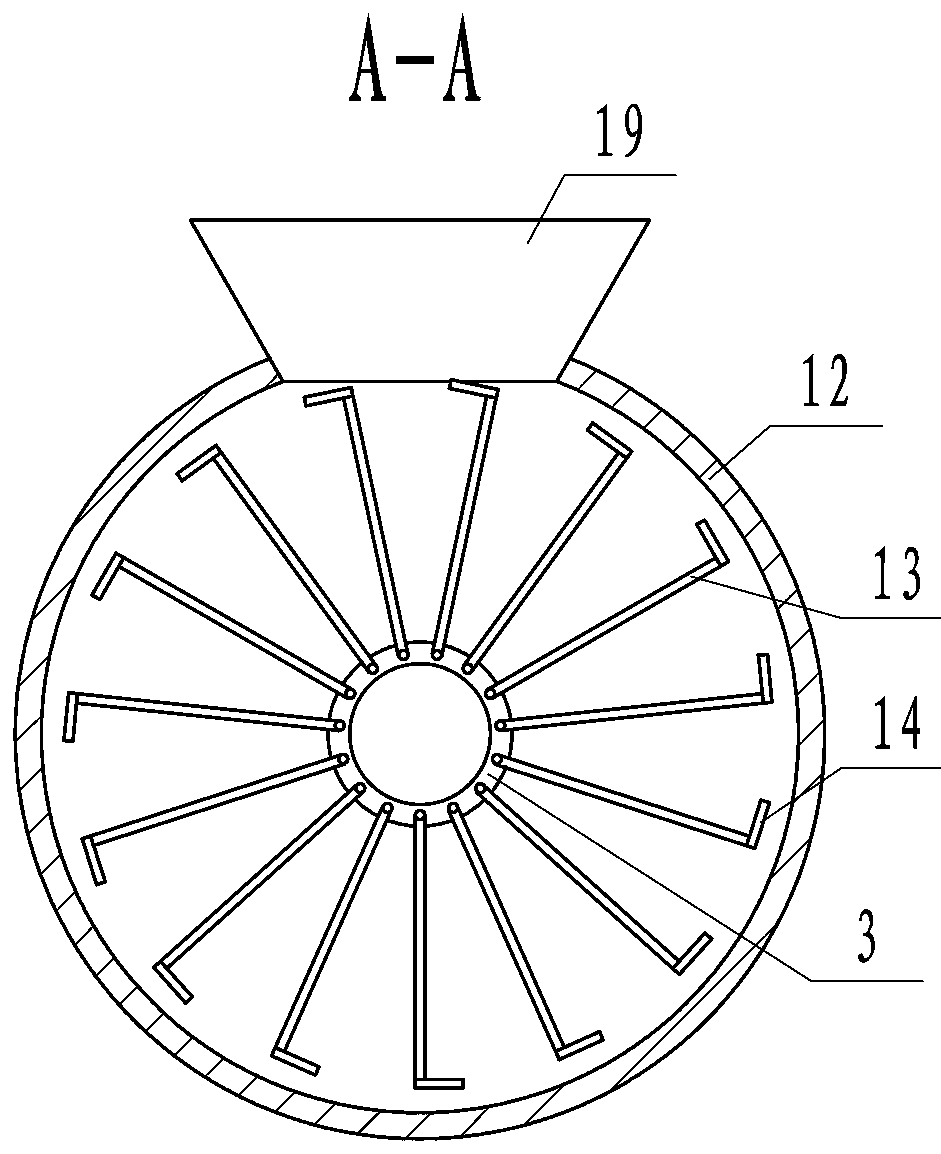

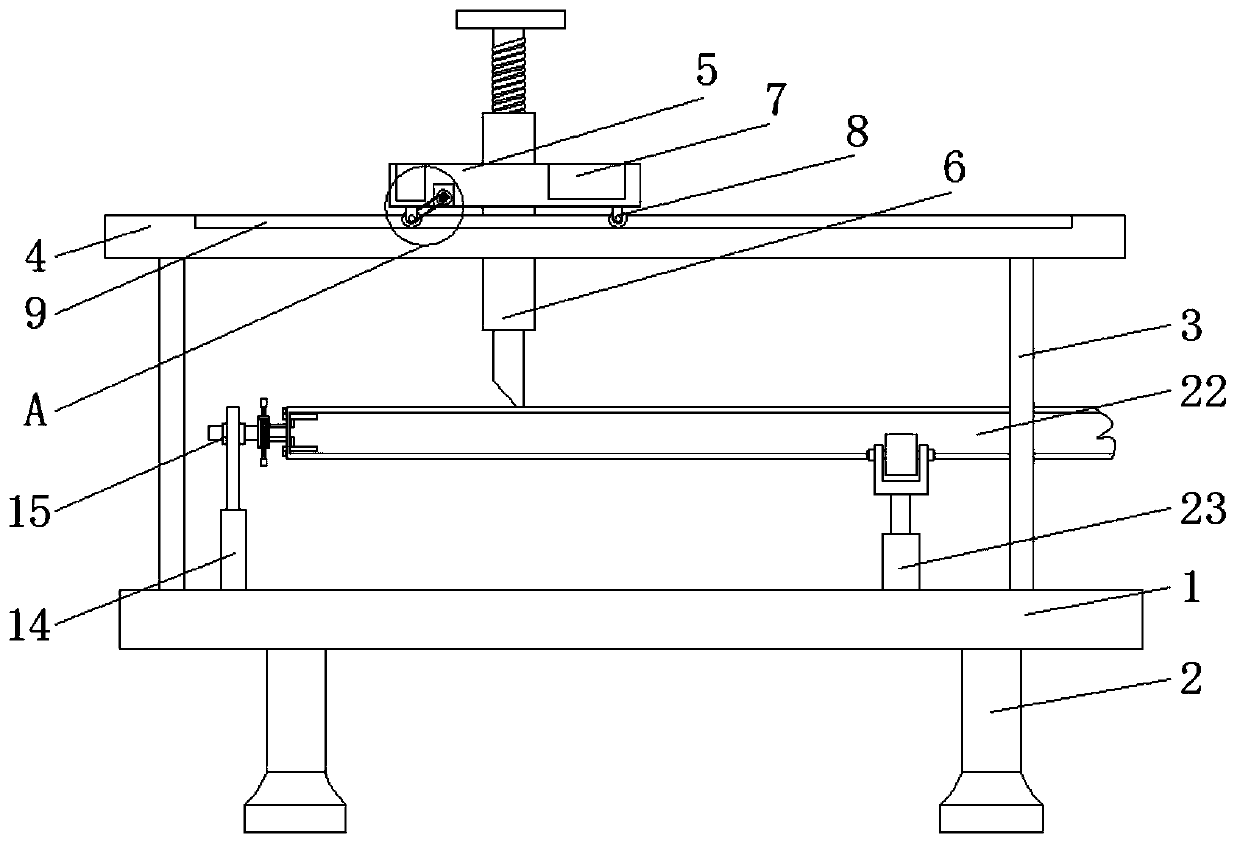

Frictional wear test method and test device for sealing ring

ActiveCN103308410AReduce excessive wearImprove performance and lifeInvestigating abrasion/wear resistanceElectricityEngineering

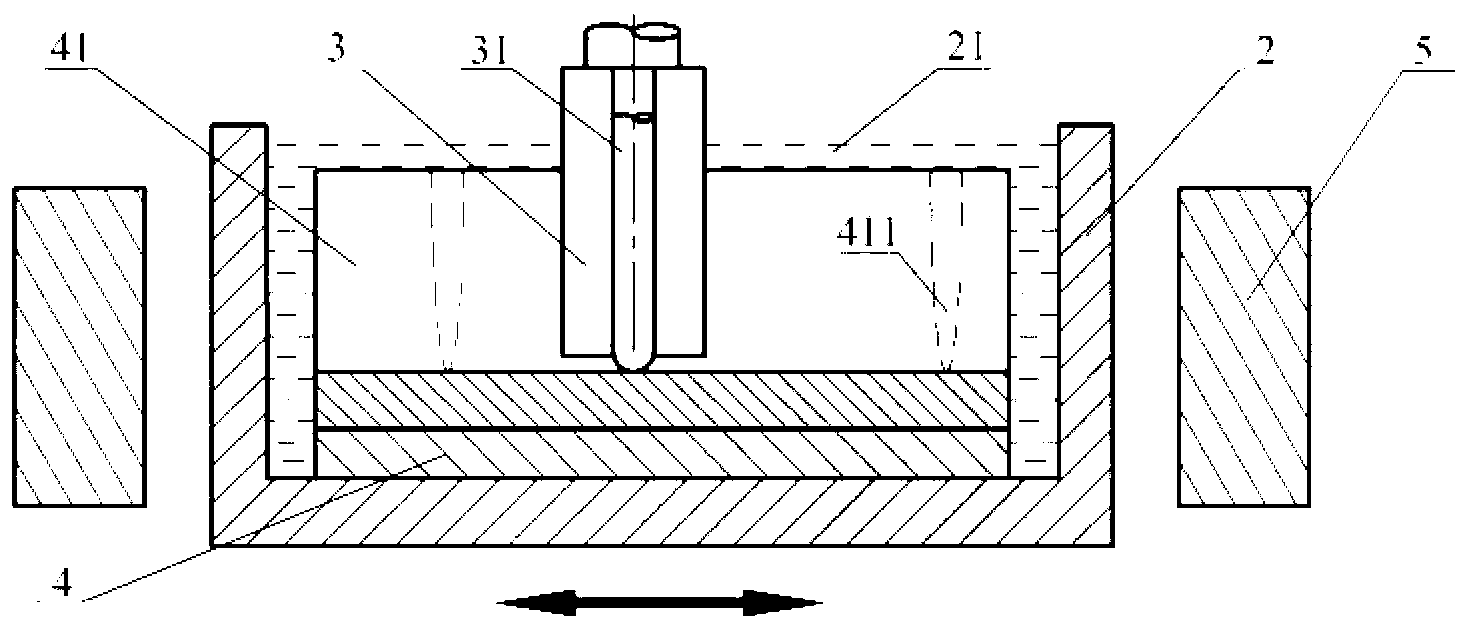

The invention discloses a frictional wear test method and a frictional wear test device for a sealing ring. The method comprises the following steps of: 1) fixing a lower test piece on a lower clamp; 2) embedding an upper test piece into a cambered accommodating slot, and adjusting an adjustment bolt to control the axial compression rate of the upper test piece; 3) adding a test medium into a medium slot, and setting test temperature, a normal load and a friction frequency; and 4) controlling a bidimensional adjustable mobile table and a horizontal reciprocating motion device, and calculating a friction coefficient between the upper test piece and the lower test piece. The device comprises a machine seat, the medium slot, an upper clamp, a lower clamp, a temperature control console, a horizontal reciprocating motion device, the bidimensional adjustable mobile table and a data acquisition control system, wherein the bidimensional adjustable mobile table, the horizontal reciprocating motion device and the temperature control console are electrically connected with the data acquisition control system. The frictional wear test method and the frictional wear test device have the beneficial effects that a working condition of the sealing ring is really simulated; in a test process, the friction is synchronously and dynamically acquired; and the friction interface damage evolution property and the influence rule of the sealing ring are accurately analyzed.

Owner:菏泽建数智能科技有限公司

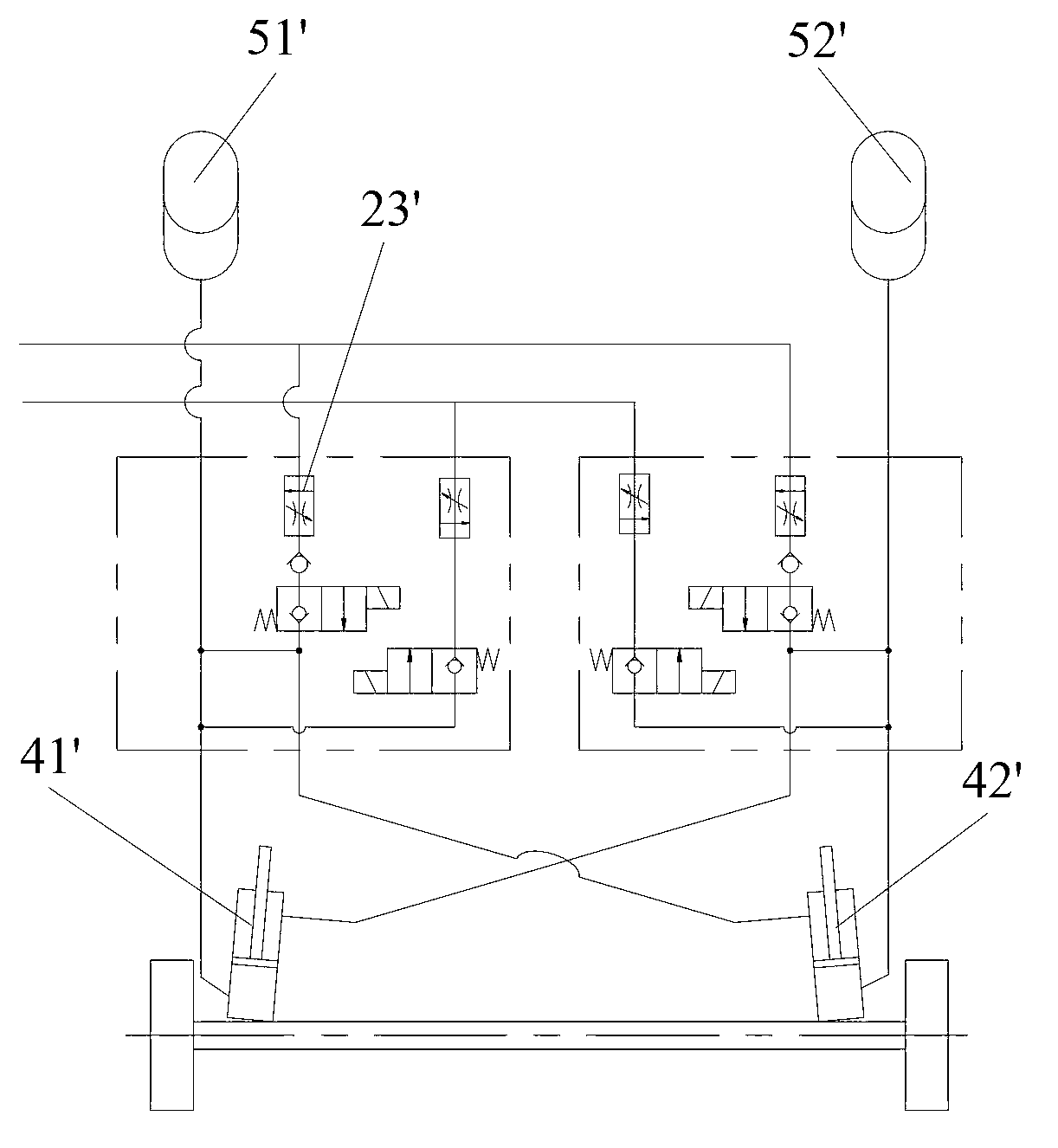

Vehicle, vehicle leveling system, vehicle leveling method and oil-gas suspension leveling device

InactiveCN104129250AReduce distortionReduce excessive wearResilient suspensionsVehicle framePressure balance

The invention provides a vehicle, a vehicle leveling system, a vehicle leveling method and an oil-gas suspension leveling device. In the oil-gas suspension leveling device, a first oil cylinder and a second oil cylinder which are correspondingly arranged are symmetrically mounted between a vehicle shaft and a vehicle frame of the vehicle, a first working oil opening of a control valve group of the first oil cylinder is respectively communicated with a rodless cavity of the first oil cylinder and a rod cavity of the second oil cylinder, and a first working oil opening of a control valve group of the second oil cylinder is respectively communicated with a rodless cavity of the second oil cylinder and a rod cavity of the first oil cylinder; and the oil-gas suspension leveling device also comprises a pressure balancing valve, wherein one end of the pressure balancing valve is communicated with the first working oil opening of the control valve group of the first oil cylinder, and the other end of the pressure balancing valve is communicated with the first working oil opening of the control valve group of the second oil cylinder. The pressure difference between the first oil cylinder and the second oil cylinder is over the set value, the first working oil opening of the control valve group of the first oil cylinder is communicated with the first working oil opening of the control valve group of the second oil cylinder through the pressure balancing valve.

Owner:ZOOMLION HEAVY IND CO LTD

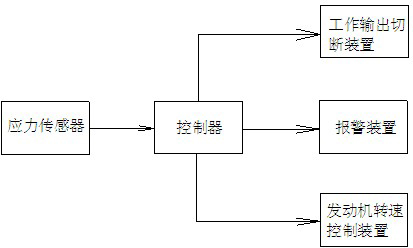

Overload protective system and method of excavator working devices and excavator

InactiveCN102677736AReduce excessive wearReduce replacement rateMechanical machines/dredgersIdle speedEngineering

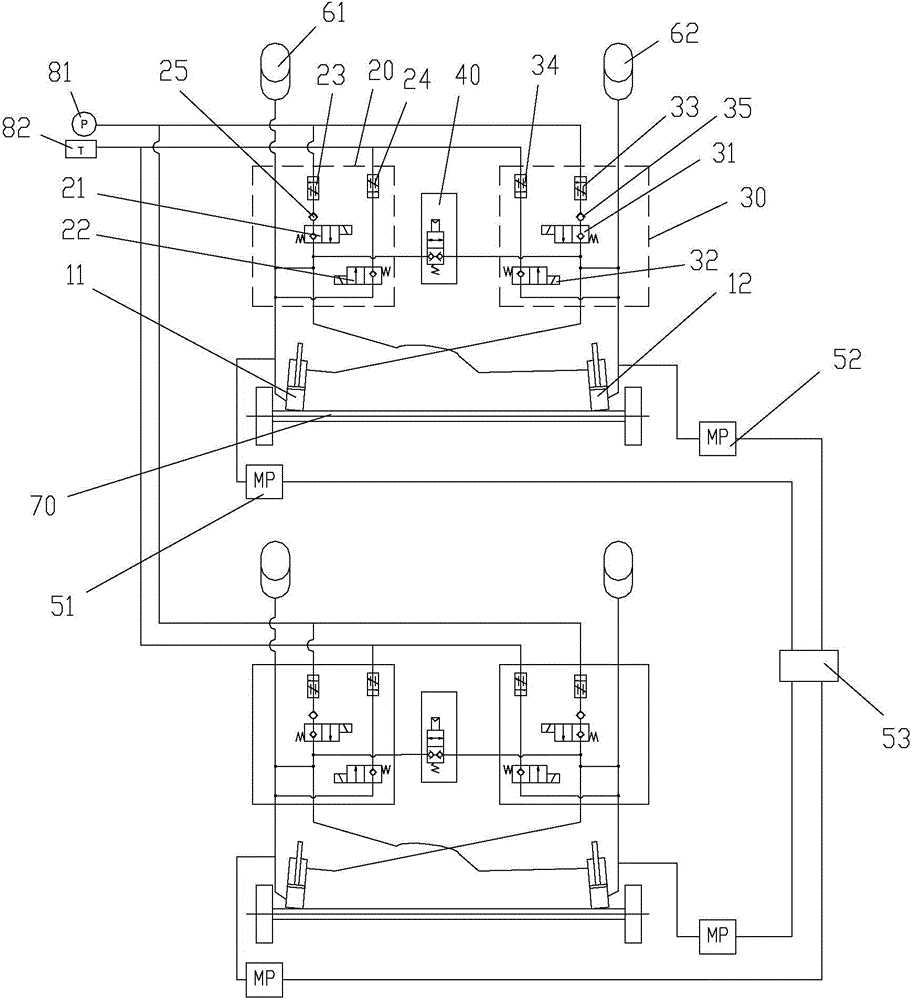

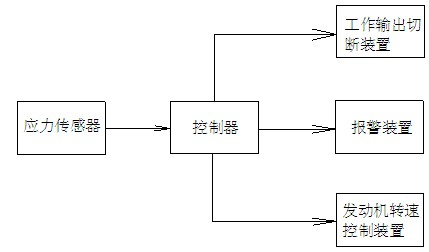

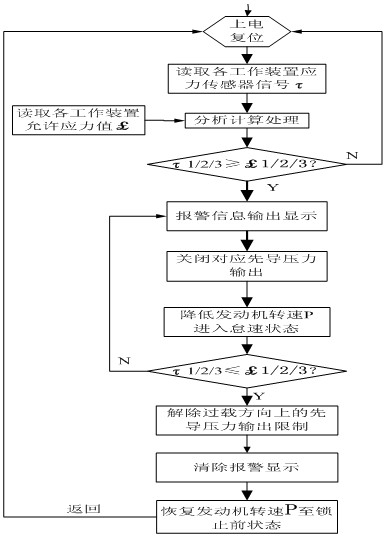

The invention discloses an overload protective system and method of excavator working devices and an excavator, relating to the technical field of interference prevention of large machines. The system comprises a controller, a plurality of stress sensors, an engine rotating speed control device and an alarm device, wherein the controller is sequentially connected with the stress sensors; the controller is respectively connected with the engine rotating speed control device and the alarm device; and the aim of automatic adjustment for overload protection of the excavator working devices is achieved through comparing stresses allowed by all working devices with the actual stress values tau of all the working devices in working to judge whether the working devices overload, and then, cutting off pilot pressure, outputting alarm information, reducing engine rotating speed P to an idle speed state and the like on each working direction based on the judgment result. By using the overload protective system and method of the excavator working devices, the service life of each working device is prolonged, and therefore, the service life of the excavator is prolonged, the work efficiency of the excavator is increased, and the requirement for operating skills is lowered to a certain extent.

Owner:SHANGHAI SANY HEAVY IND

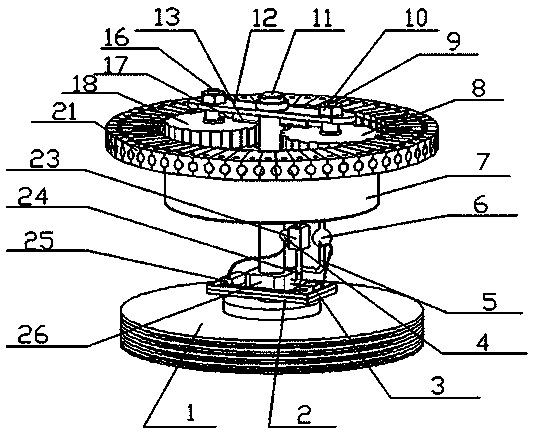

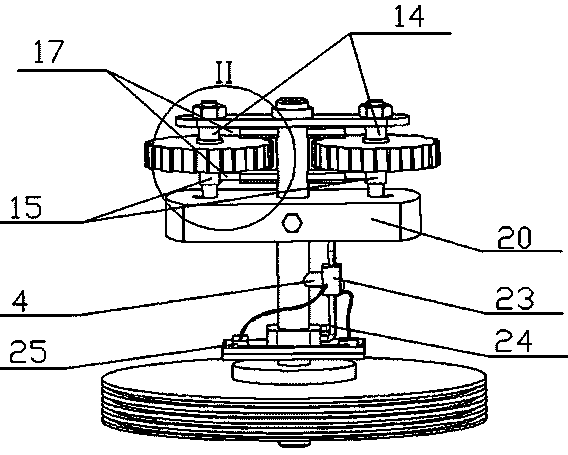

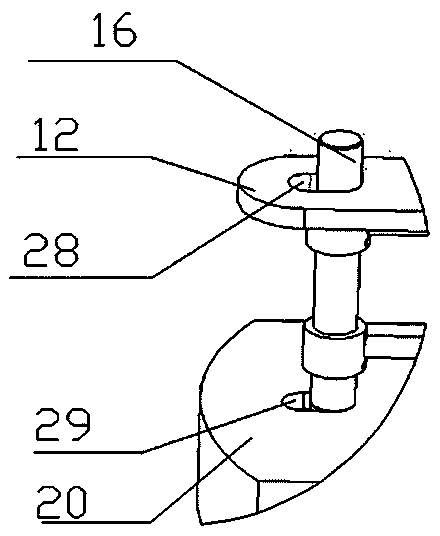

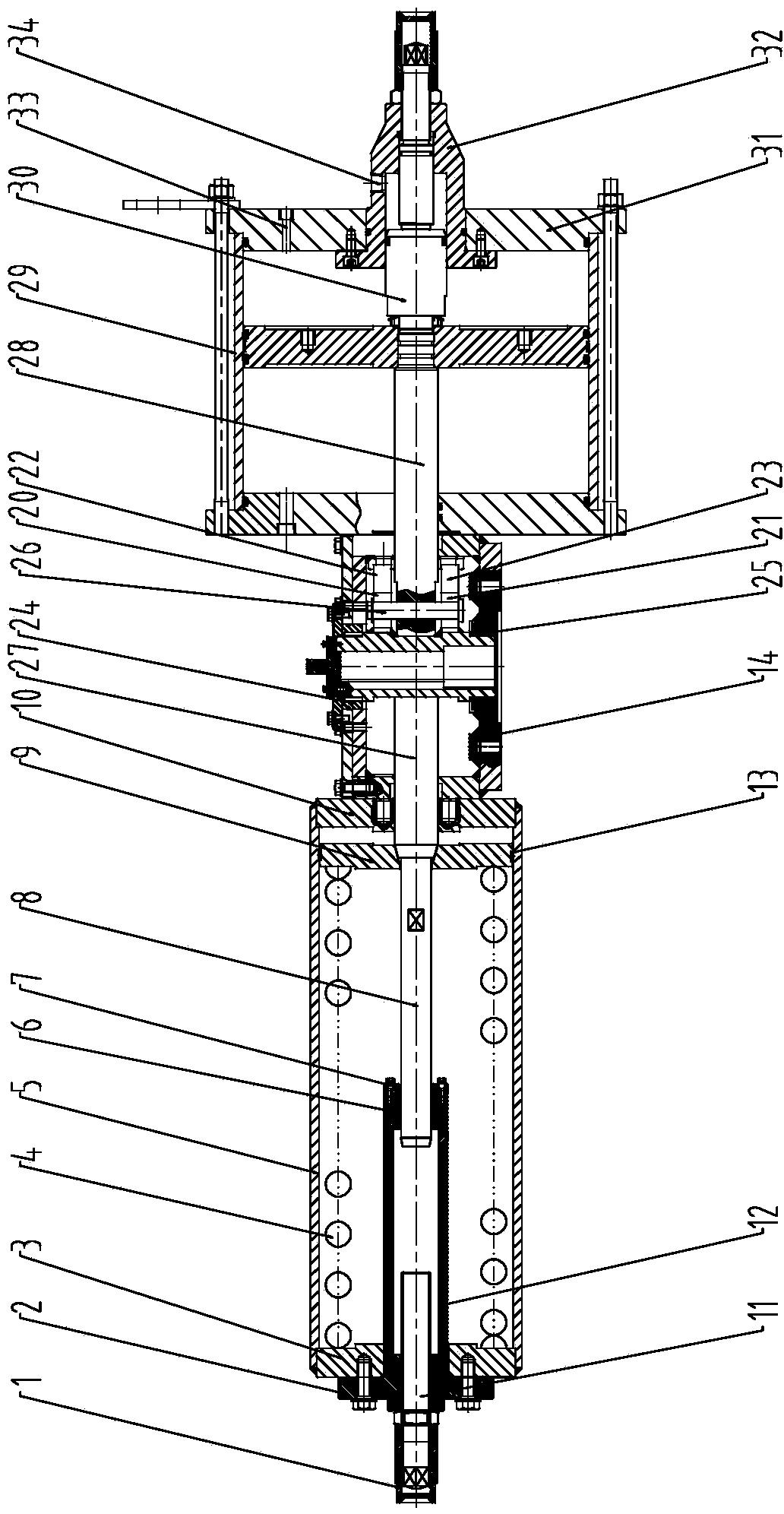

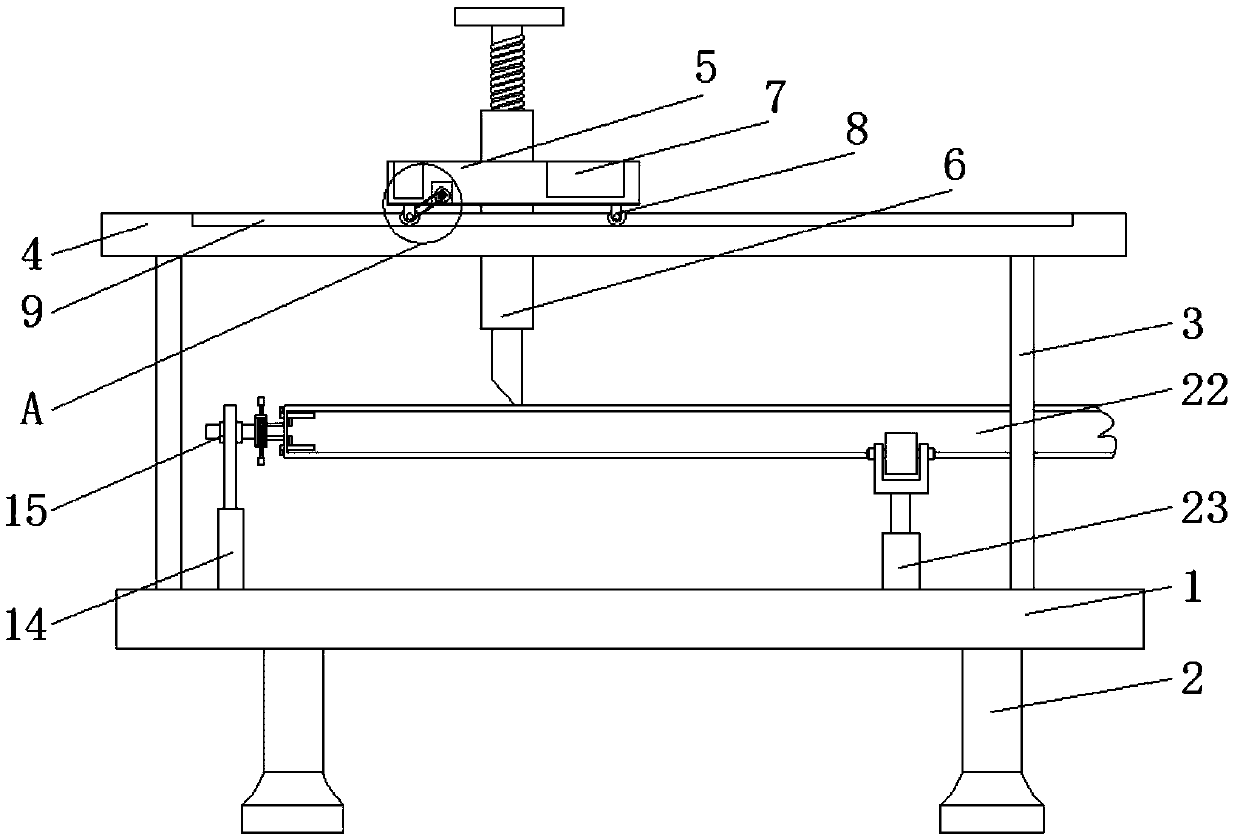

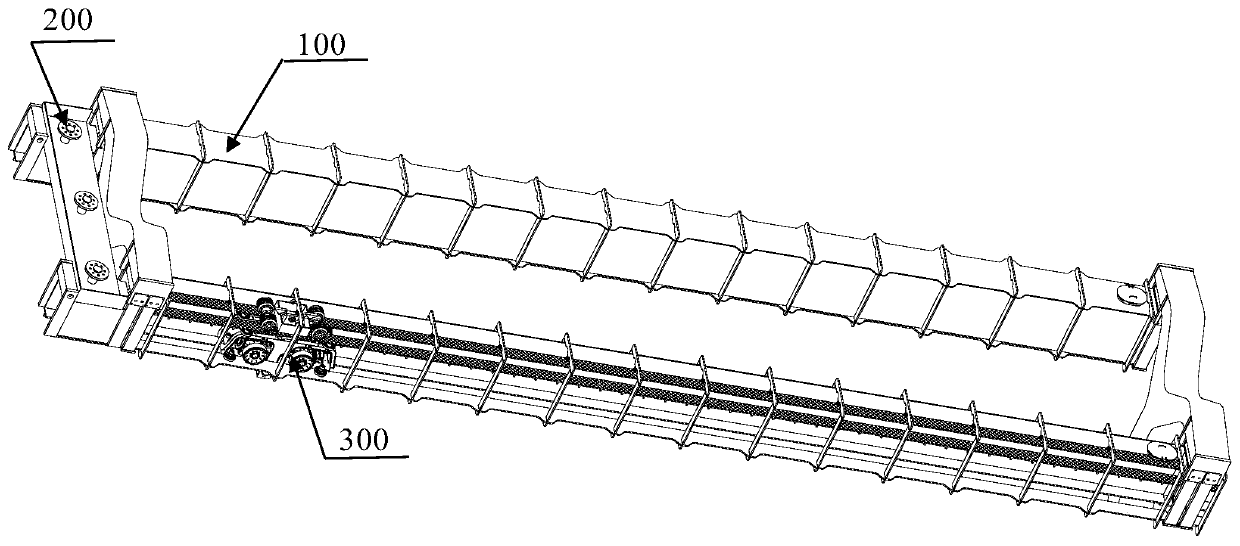

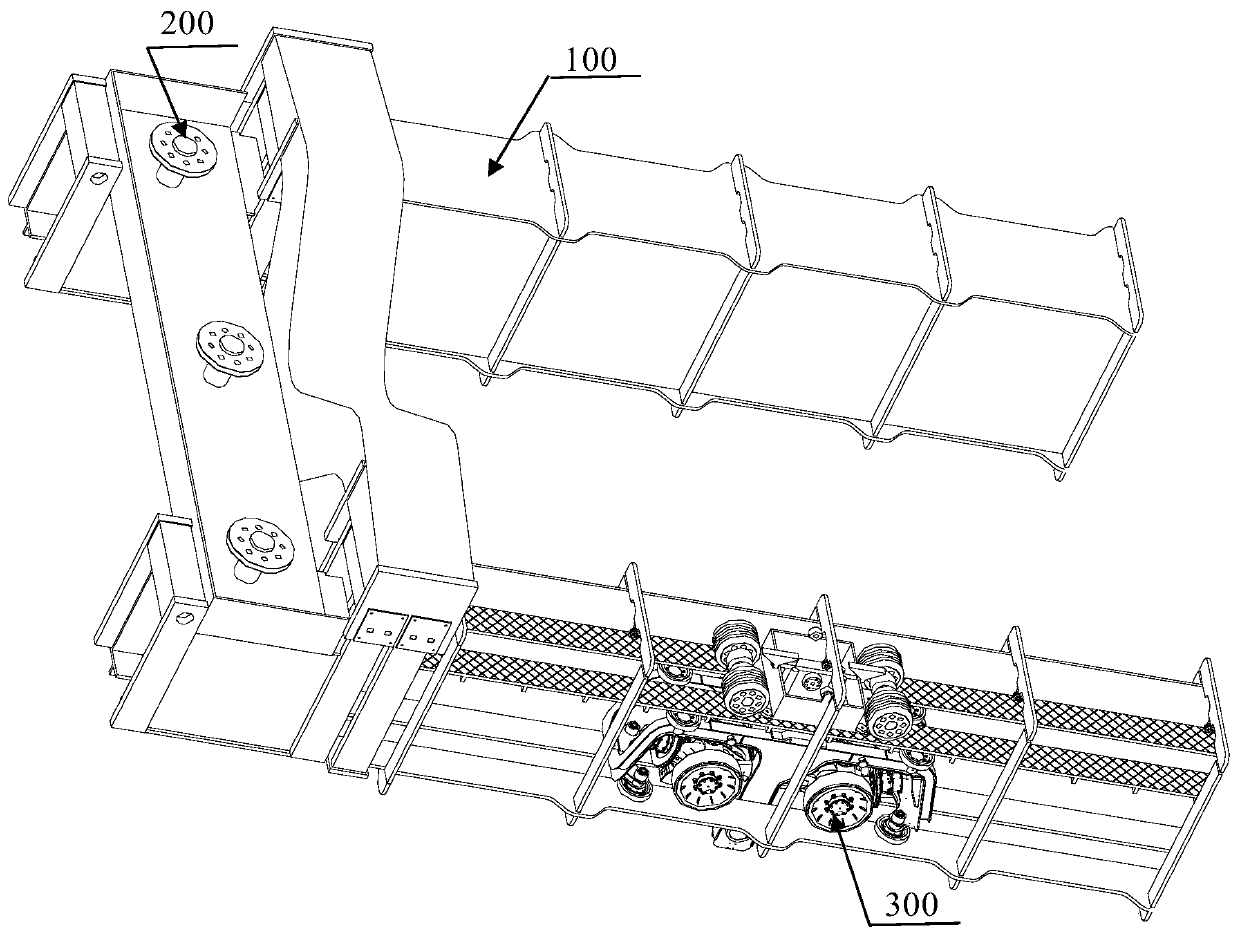

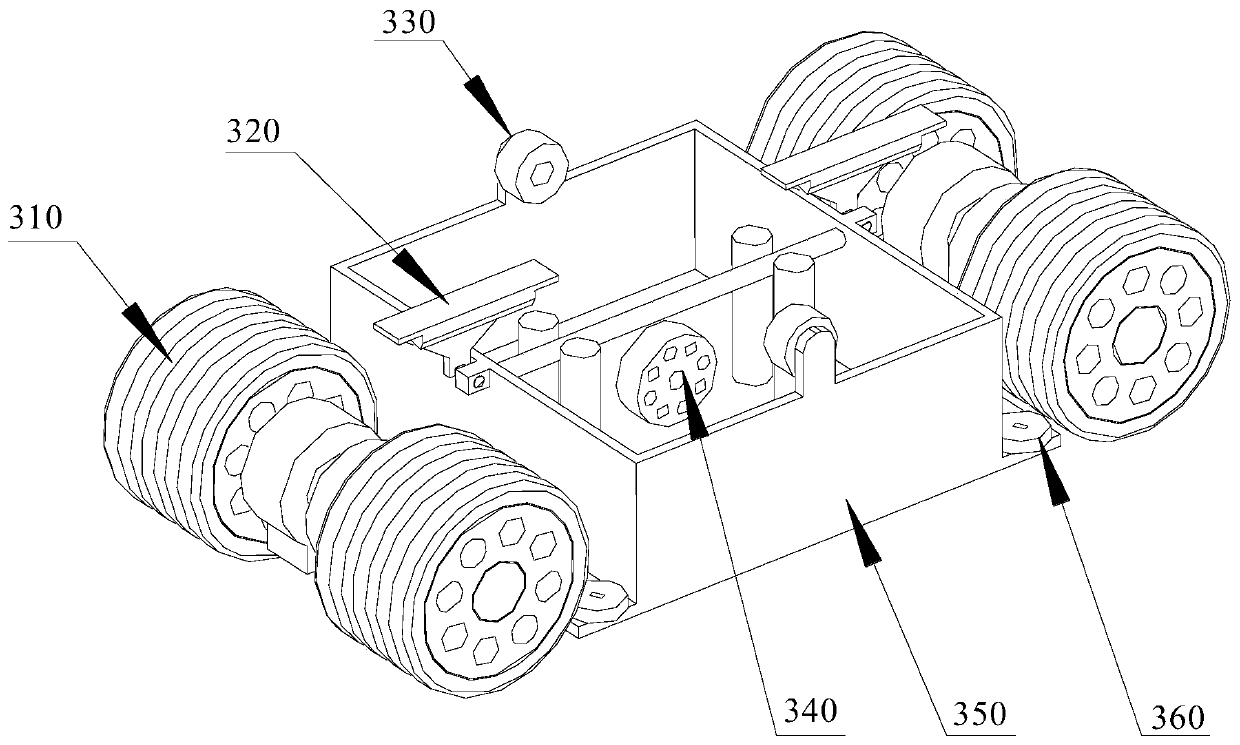

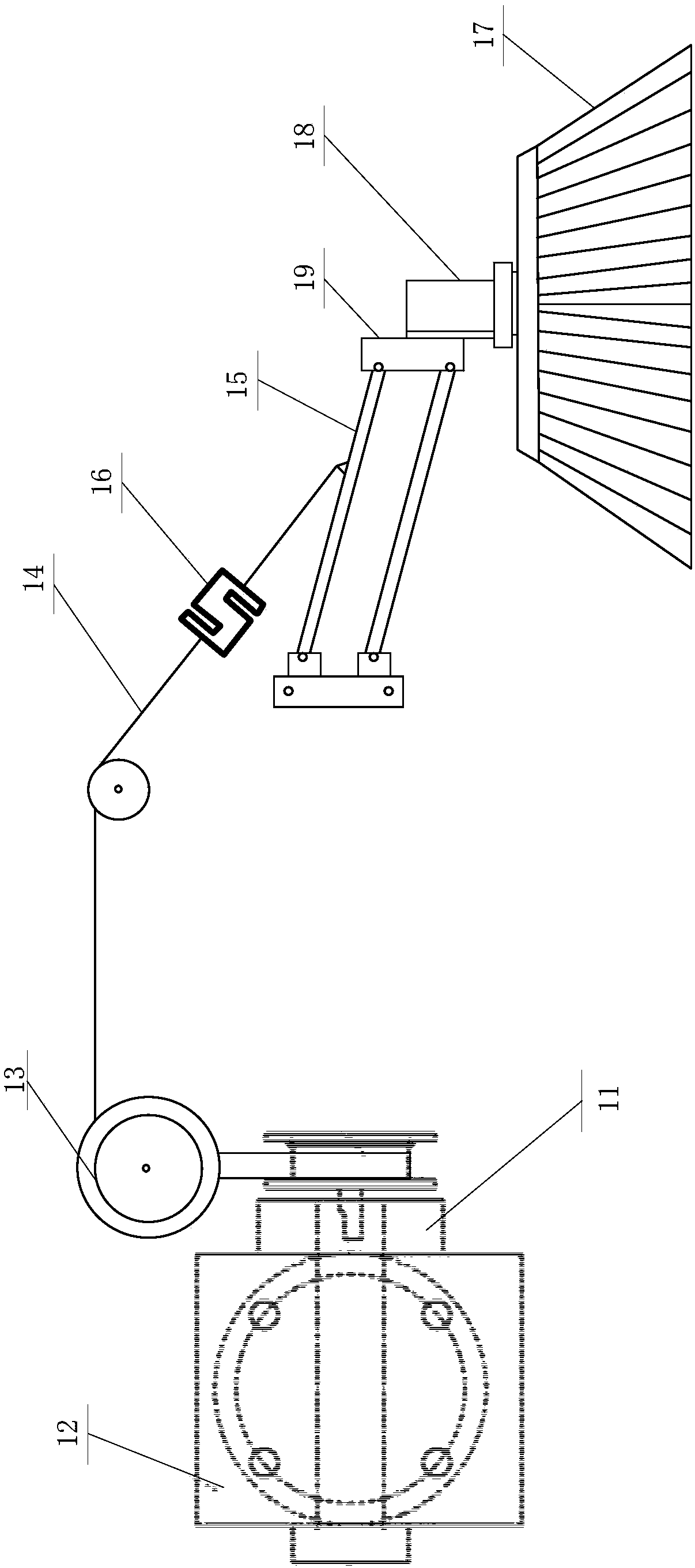

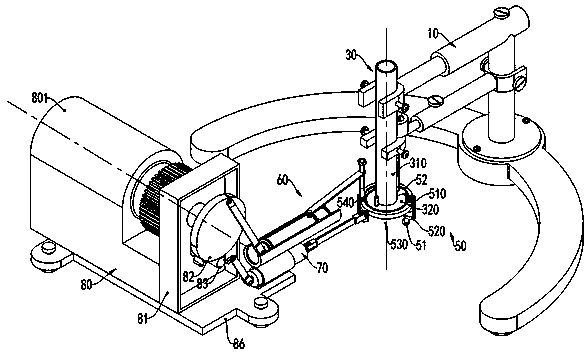

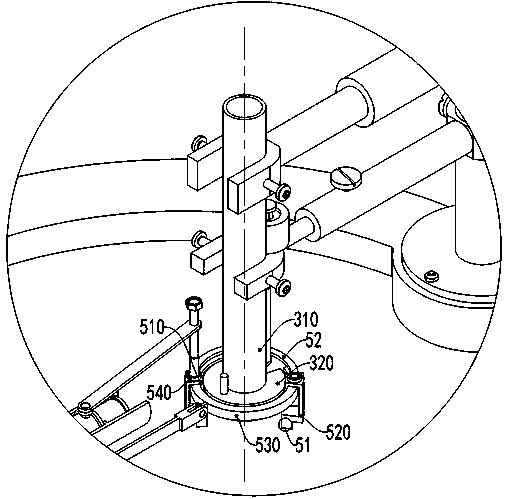

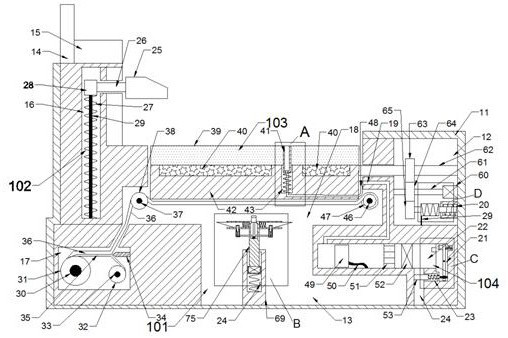

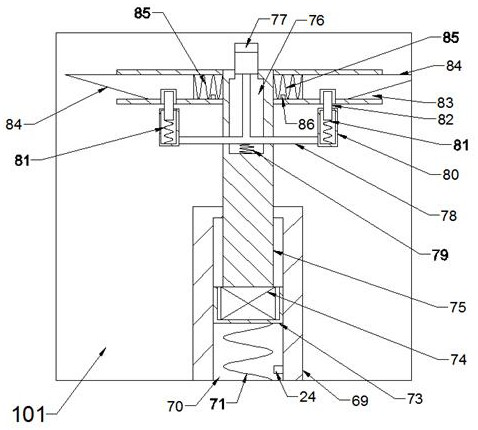

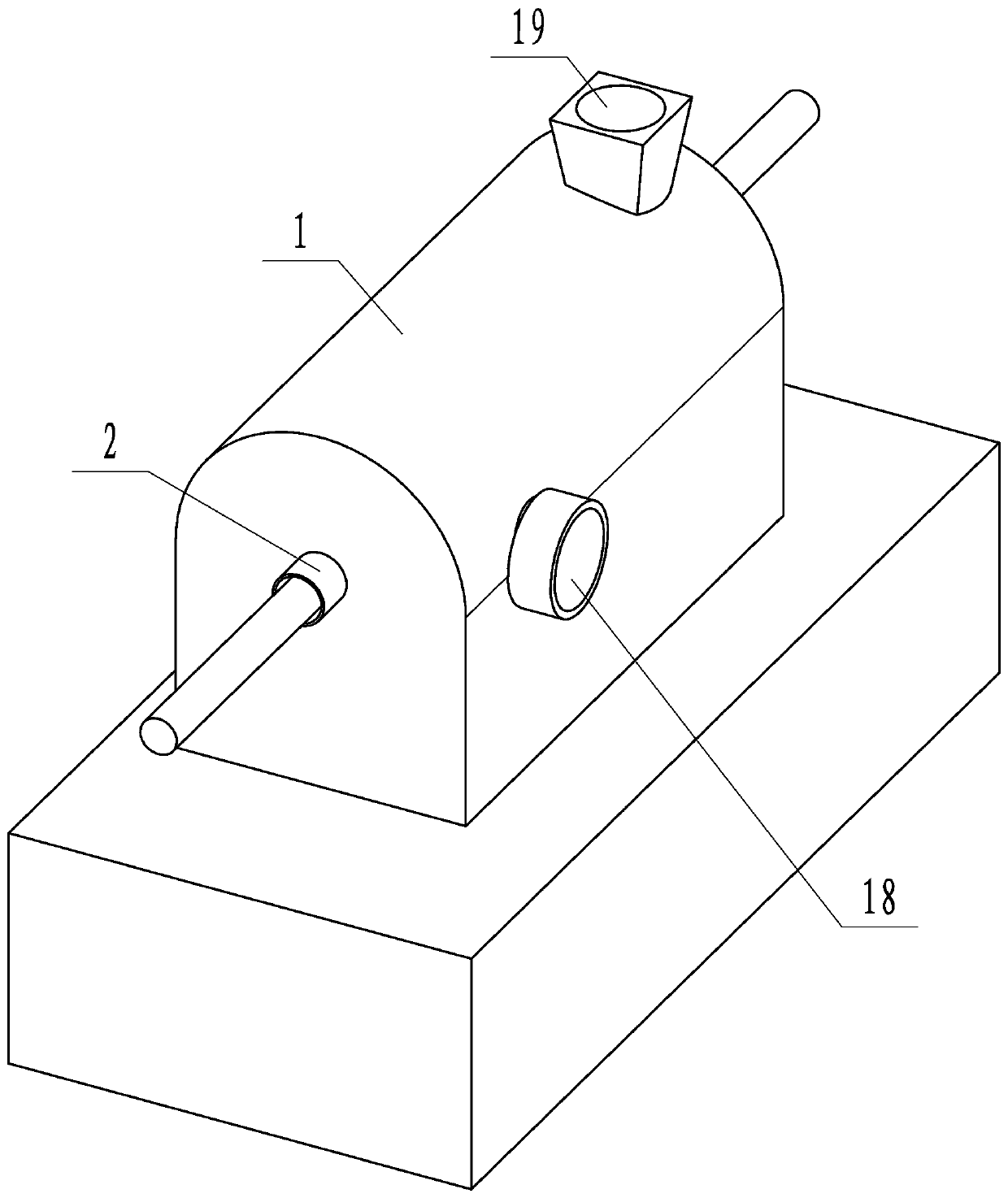

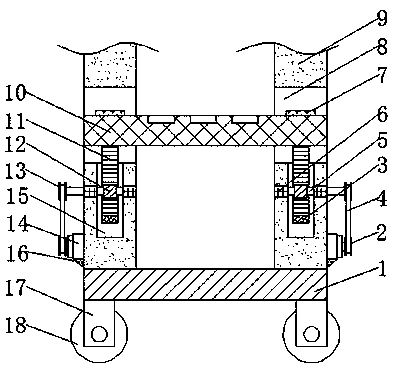

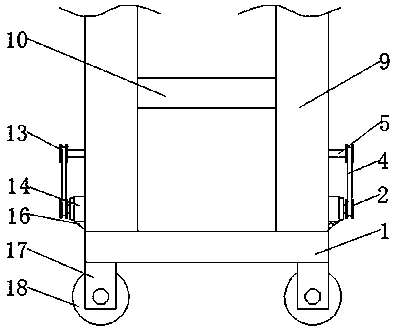

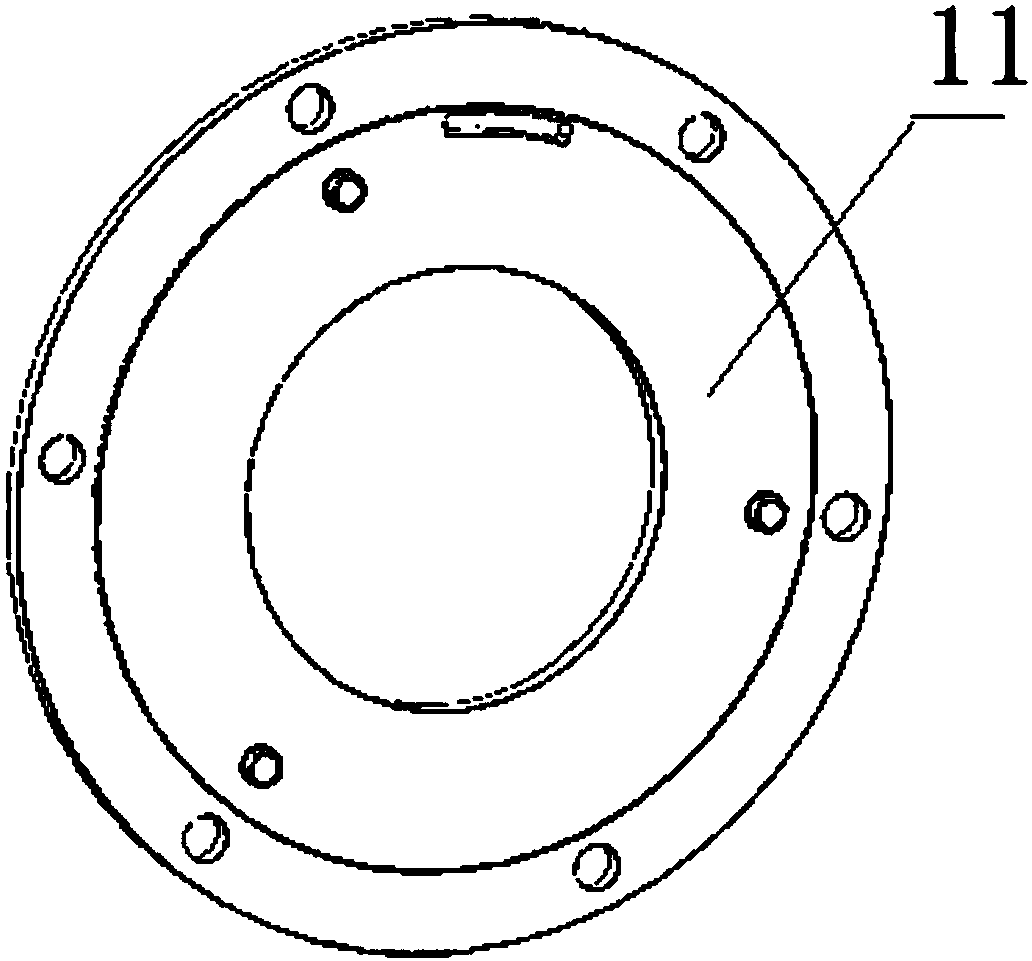

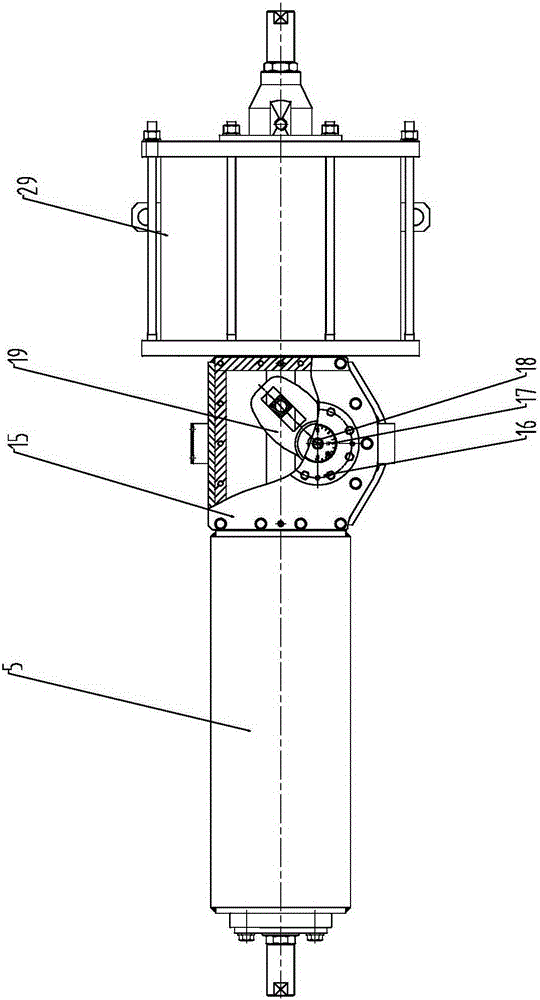

Mold roller gap stepless automatic regulation device of vertical annular mold straw briquetting machine

ActiveCN104228109AReduce excessive wearExtended service lifeShaping pressProgrammable logic controllerEngineering

The invention provides a mold roller gap stepless automatic regulation device of a vertical annular mold straw briquetting machine. The mold roller gap stepless automatic regulation device comprises an upper press plate, a grinding disc, an eccentric shaft A, an eccentric shaft B, a vertical main shaft, a PLC (programmable logic controller), an intermediate relay, an electromagnetic valve, a miniature hydraulic pump, an oil tank, a branch oil pipe A, a branch oil pipe B, a push rod and a tray. Strain force sensors sense strain of the eccentric shaft A and the eccentric shaft B in real time and transmit information to the PLC, the PLC controls the electromagnetic valve and the intermediate relay to work, further, the extension and retraction of the push rod are controlled through oil pressure, a mold roller gap is automatically regulated in a stepless way, the effective regulation on the mold roller gap is realized, the stability of forming extrusion force among grinding rollers is ensured, in addition, the briquette forming quality and the briquette forming uniformity are improved, meanwhile, the excessive abrasion among mold rollers is also reduced, the service life of each mold roller is prolonged, and the energy consumption during the production is also reduced.

Owner:万华禾香生态科技股份有限公司

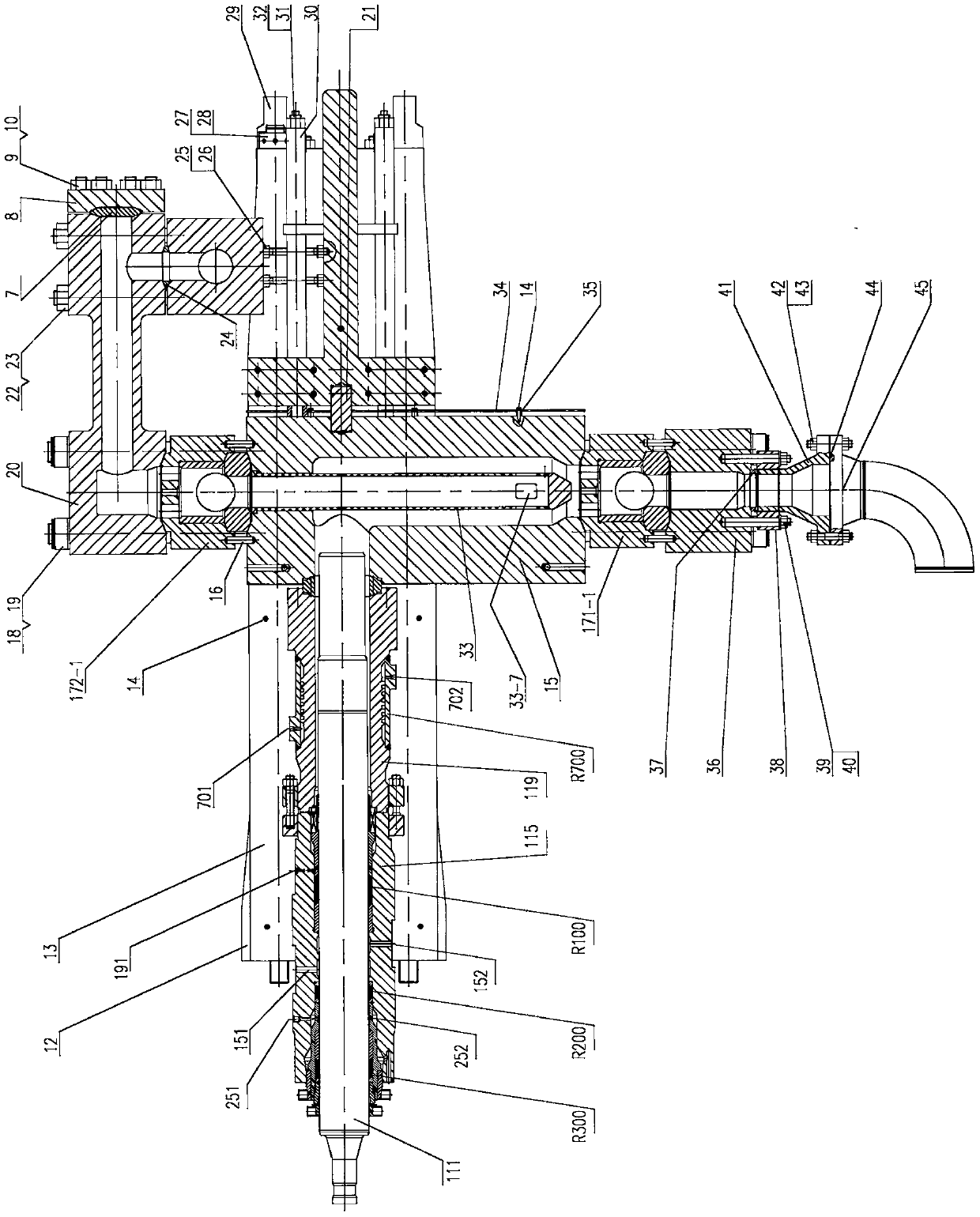

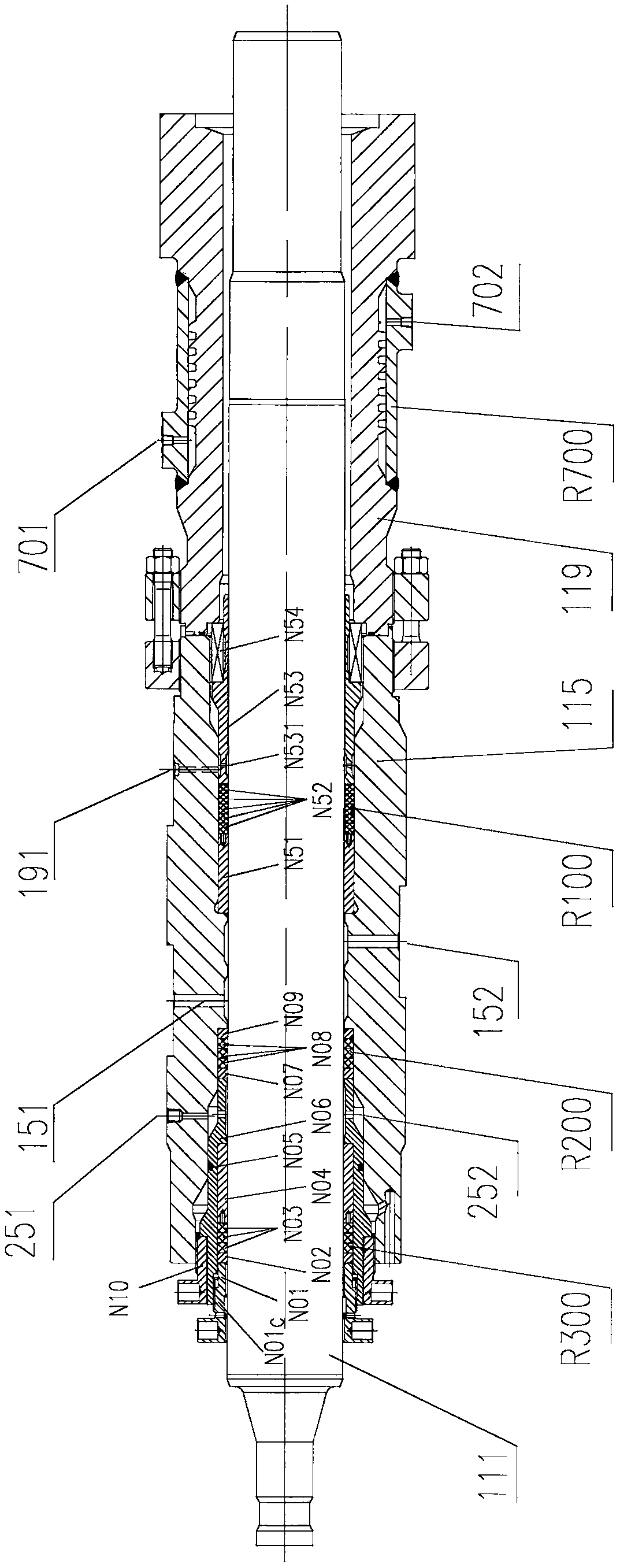

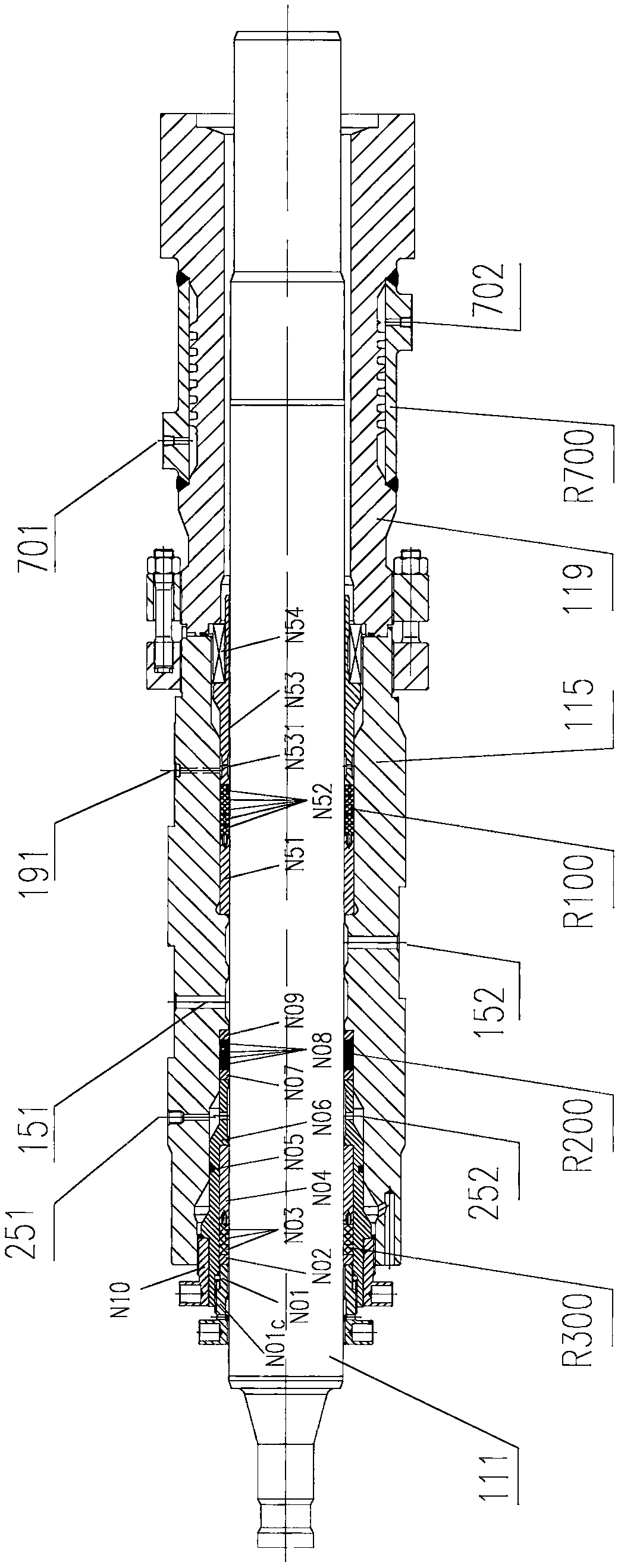

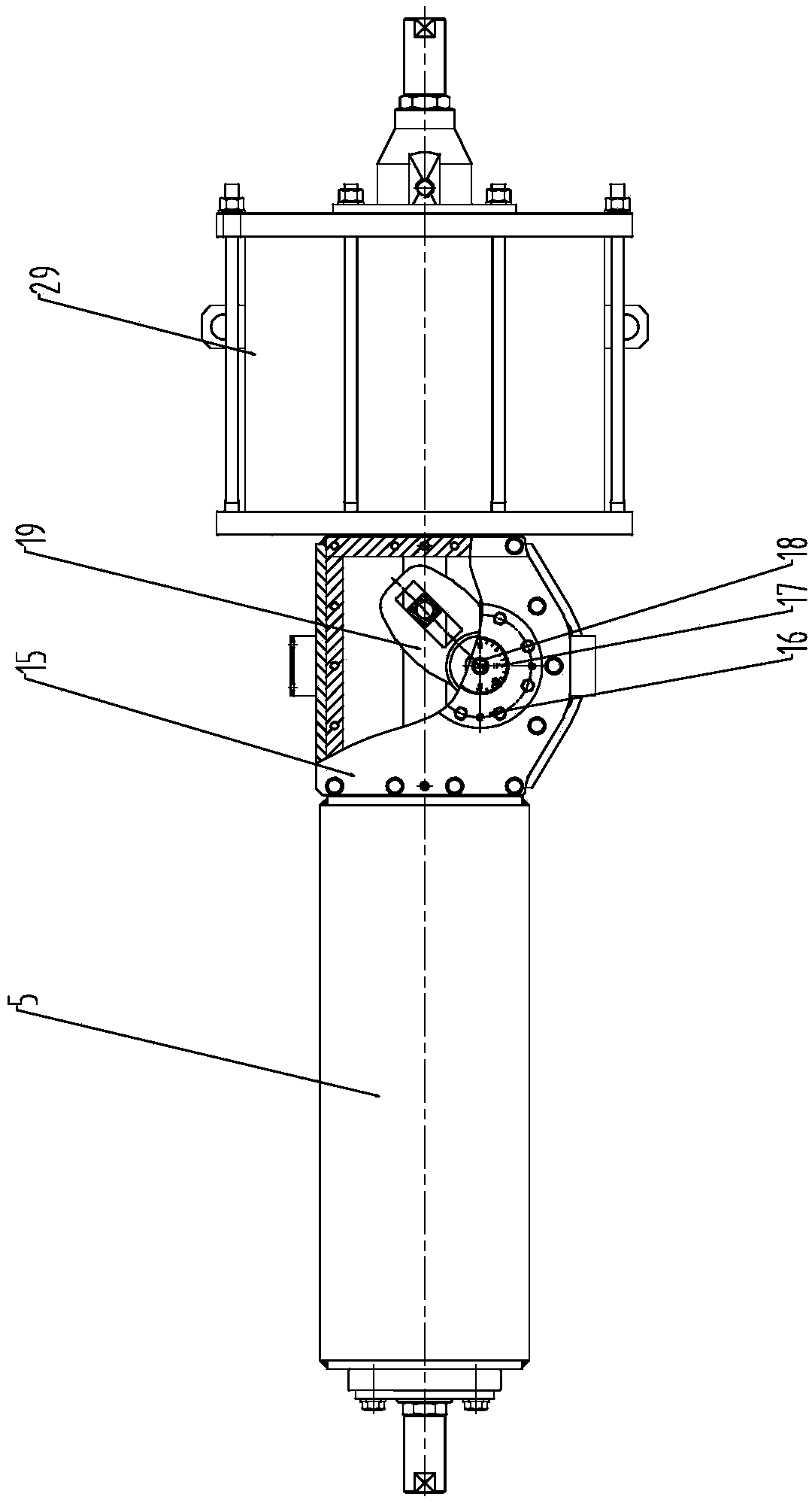

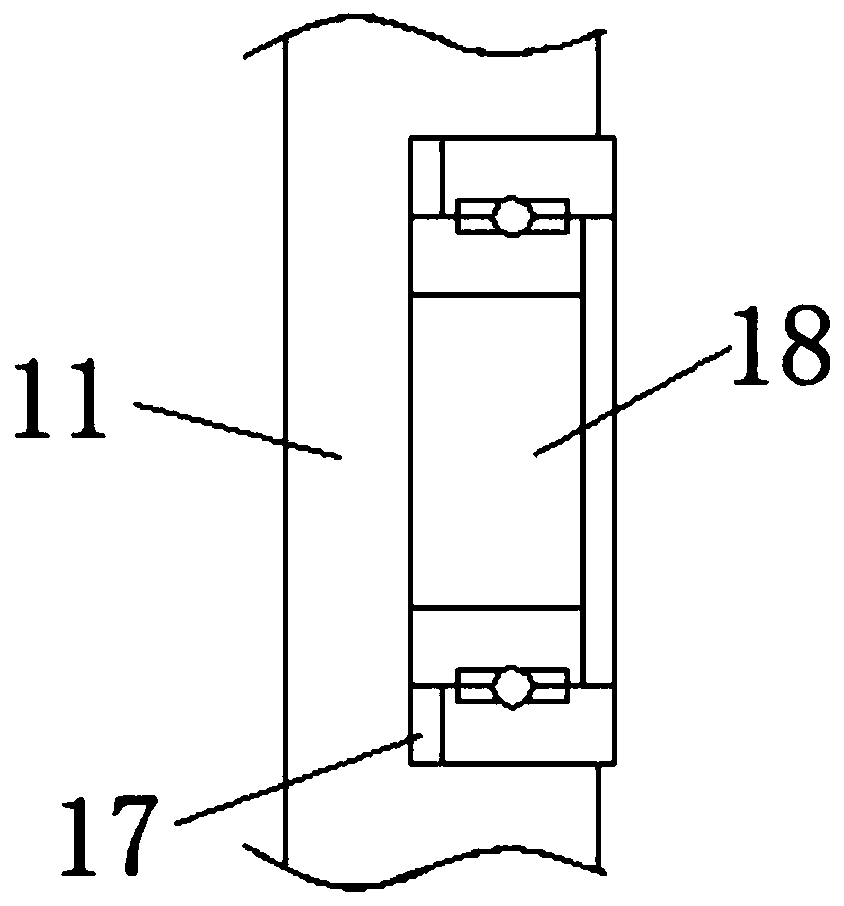

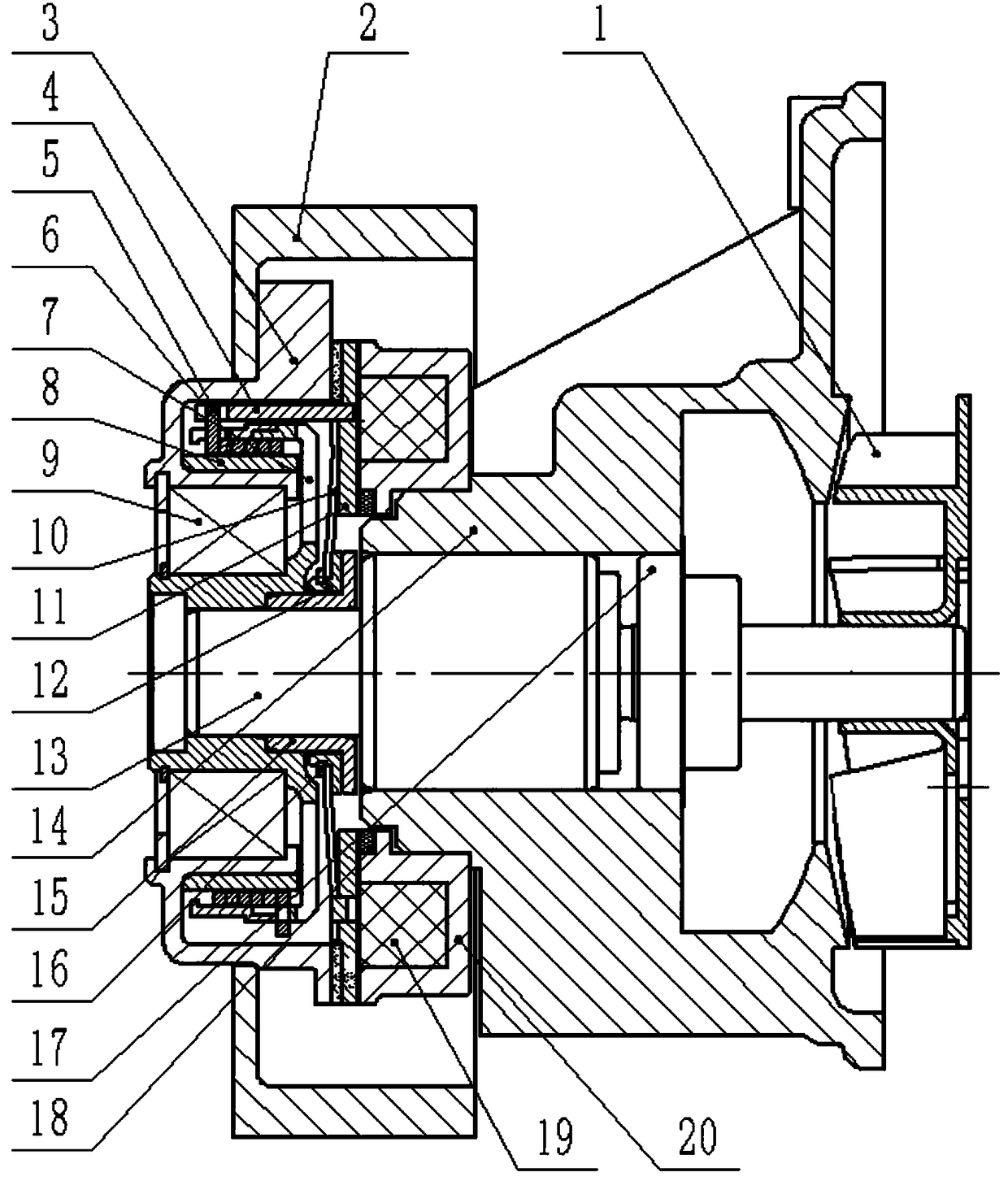

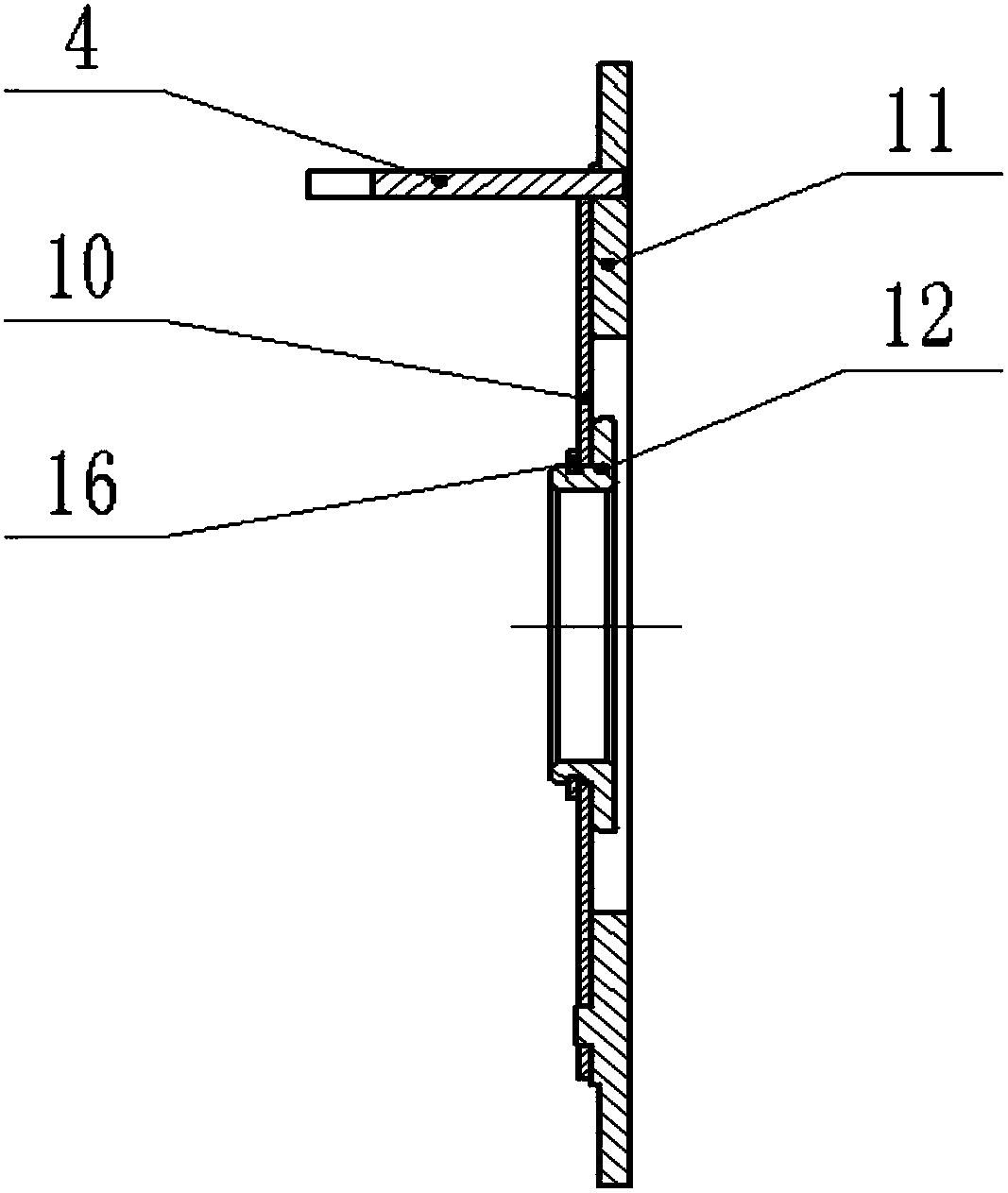

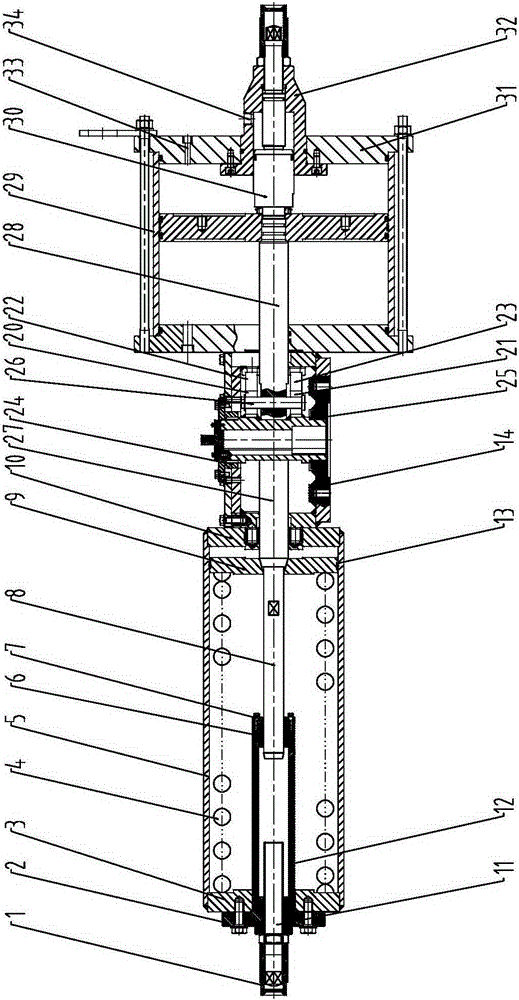

Three-filler type reciprocating seal using pressurizing middle flushing cavity and reciprocating pump thereof

InactiveCN110017269AReduced preload differentialReduce excessive wearPositive displacement pump componentsLiquid fuel engine componentsEngineeringHigh pressure

The invention discloses a three-filler type reciprocating seal using a pressurizing middle flushing cavity and a reciprocating pump thereof. The three-filler type reciprocating seal is suitable for transportation of high-temperature oil coal slurry pressurized to 7.0-25.0MPa; two-filler seal is arranged at the rear end (far away the pump cylinder end) of a stuffing box; a first filler seal (high pressure filler seal) is arranged in a pressure-bearing sealing cavity formed by a cavity at the front end of the stuffing box and the cavity at the rear end of a plunger sleeve; a flushing cavity system between the first filler seal and a middle filler seal adopts pressurizing flushing; compared with the traditional low-pressure flushing, pressurizing flush enables the probability that the main liquid harmful matters (high temperature liquid, high solid concentration slurry, corrosive or flammable and explosive or toxic or radioactive components with fierce deleterious effect) of the pump cylinder penetrate through the first filler seal to leak into the middle flushing cavity to be nearly reduced to zero, middle flushing fluid is also enabled to enter the gap between the first filler sealand a plunger to lubricate and cool the first filler seal and the plunger, so that consumption of high pressure filling oil is reduced favorably, the operating safety of the plunger end is remarkablyimproved, and the application range of the plunger reciprocating pump is enlarged.

Owner:何巨堂

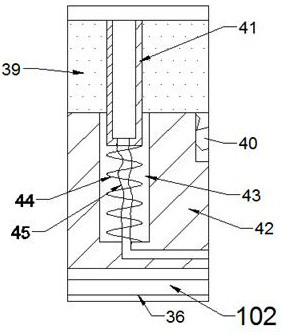

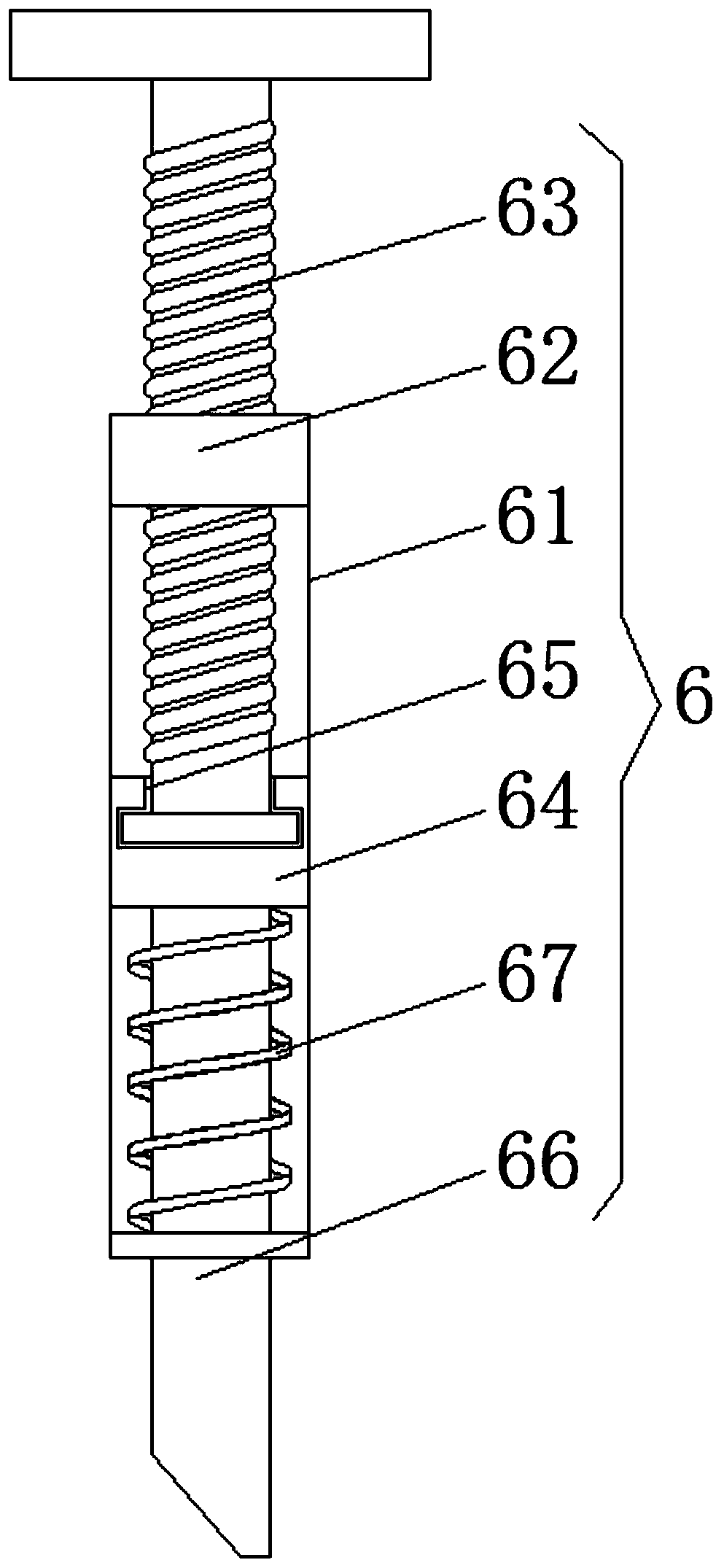

Buffer type large-torque spring restoration executing mechanism

ActiveCN103672123AExtended service lifeReduce excessive wearOperating means/releasing devices for valvesValve members for absorbing fluid energyEngineeringCylinder block

The invention relates to a pneumatic executing mechanism, in particular to a buffer type large-torque spring restoration executing mechanism with a final position pneumatic buffer structure, and belongs to the technical field of pneumatic executing mechanisms. The buffer type large-torque spring restoration executing mechanism comprises a cylinder body. The outer side of a left cylinder cover is connected with a left cylinder cover pressing plate through bolts. A guide sleeve is disposed in the cylinder body. The guide sleeve is tightly pressed on the left cylinder cover through the left cylinder cover pressing plate. The right side of a right cylinder cover is connected with a converting box through bolts. The rear end of the converting box is connected with a buffer air chamber. The rear end of the buffer air chamber is connected with the rear cylinder cover of the buffer air chamber. A buffer seat is connected to the rear cylinder cover of the buffer air chamber. A buffer plunger is slidably mounted in the buffer seat. The buffer type large-torque spring restoration executing mechanism has the advantages that the drive requirements of a valve acting frequently can be satisfied, internal component damage, caused by frequent acting, of the executing mechanism can be avoided effectively, and accordingly maintenance frequency can be lowered, and economical benefits can be increased.

Owner:WUXI SMART AUTO CONTROL ENG CO LTD

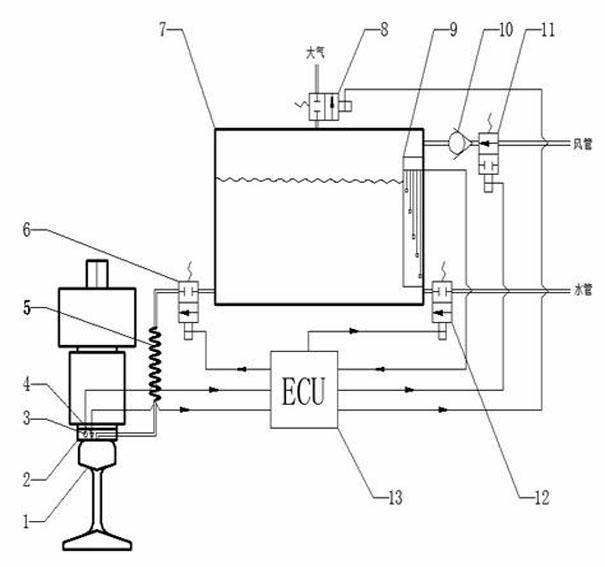

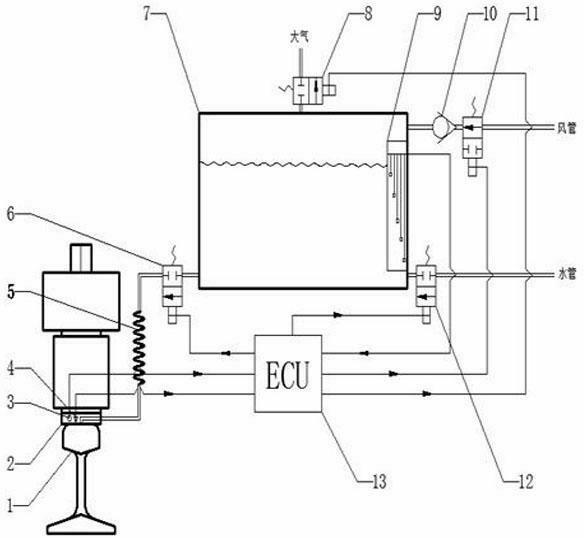

Device for controlling temperatures of pole sole of magnetic track brake and track as well as control method thereof

ActiveCN102673601AEffective coolingAvoid excessive wearTrack-braking member co-operationBrake safety systemsSolenoid valvePole piece

The invention discloses a device for controlling temperatures of a pole sole of a magnetic track brake and a track as well as a control method thereof. A first non-contact temperature sensor and a second non-contact temperature sensor are respectively used for detecting the temperature of the pole sole of the magnetic track brake and the steel track; a water through hole is formed in the side face of the pole sole of the magnetic track brake; small water spraying holes are formed at the bottom of the pole sole of the magnetic track brake; the water through hole and the small water spraying holes are communicated inside the pole sole of the magnetic track brake; the water through hole is connected with the lower part of a water tank in a sealed manner by passing through a spiral elastic hose and a first solenoid valve in sequence; a liquid meter is arranged in the water tank; the top of the water tank is communicated with atmosphere through a second solenoid valve; the side part of the water tank is connected with a water pipe connected on a train through a fourth solenoid valve; the side part of the water tank is sequentially connected with an air duct on the train through a one-way valve and a third solenoid valve in sequence; and the liquid meter and the solenoid valves are connected with an electronic control unit. The device provided by the invention can effectively cool the pole sole and the steel track, so that the excessive abrasion and the adhesive welding of the pole sole and the steel track can be prevented when the magnetic track brake works.

Owner:江苏大学扬州(江都)新能源汽车产业研究所

Anticorrosive paint spraying and grinding equipment for production and processing of buried pipe

ActiveCN109623622AAdjust arcStable supportPolishing machinesGrinding drivesEngineeringMechanical engineering

The invention relates to the technical field of pipe processing equipment and discloses anticorrosive paint spraying and grinding equipment for production and processing of a buried pipe. The anticorrosive paint spraying and grinding equipment comprises a machine table; supporting legs are fixedly installed at the bottom end of the machine table; fixing rods are fixedly installed at the top end ofthe machine table; the top ends of the fixing rods are fixedly connected with a horizontal plate; a transmission machine is placed on the horizontal plate; the middle part of the transmission machineis fixedly provided with a fixed point grinder in a sleeving manner; a component positioned at the side surface of the fixed point grinder is fixedly installed inside the transmission machine; movingwheels are arranged at the bottom end of the transmission machine; and the moving wheels are matched with fixing grooves which are formed in the top of the horizontal plate. According to the anticorrosive paint spraying and grinding equipment for production and processing of the buried pipe, a transmission driven plate is moved toward a direction corresponding to a screw handle by twisting the screw handle so that two externally connected rods are used for driving two contact plates to expand; by regulating the radian of the two contact plates, material pipes which are different in diameter can be conveniently supported and positioned; and a bearing frame device is used for auxiliary support for the position, thereby effectively guaranteeing processing of the material pipes which are different in length.

Owner:苏州福祺互联网科技有限公司

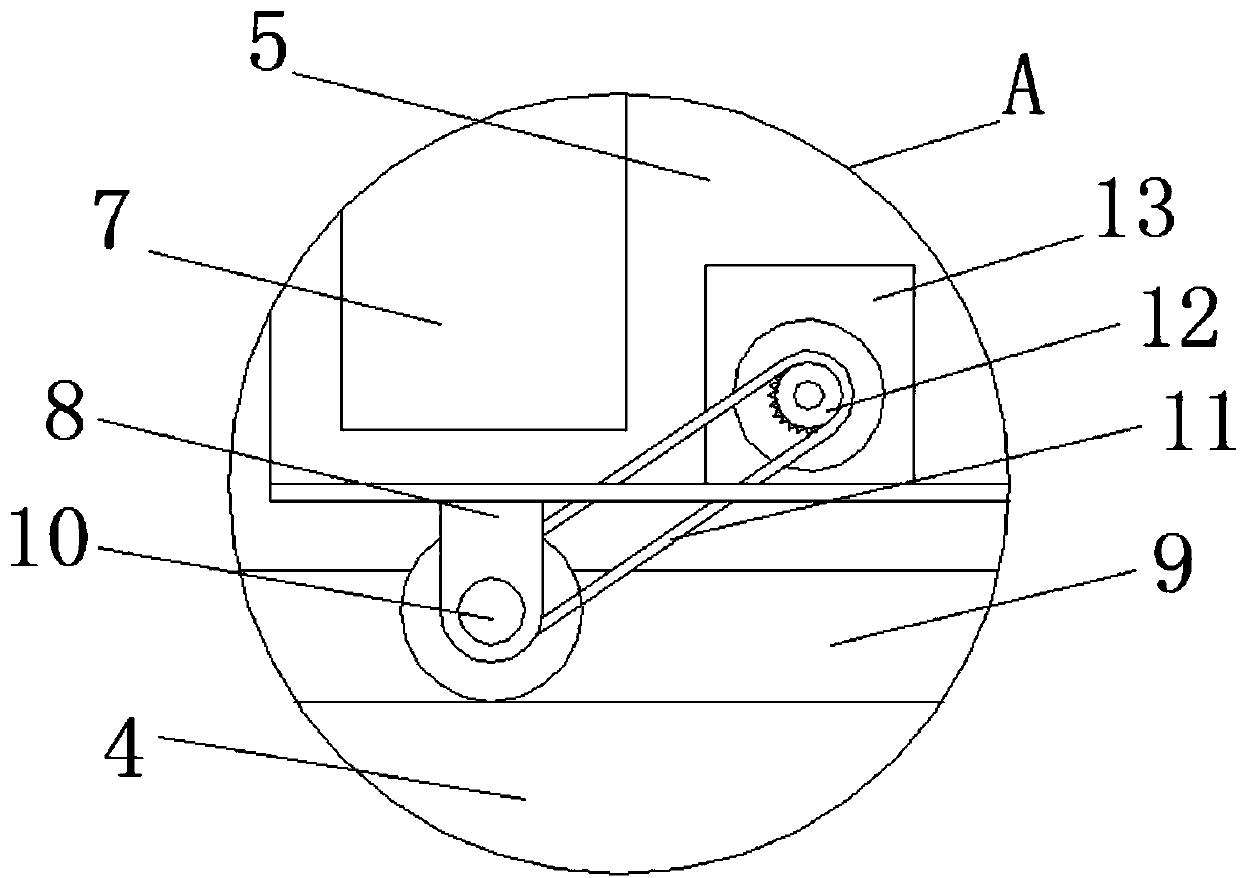

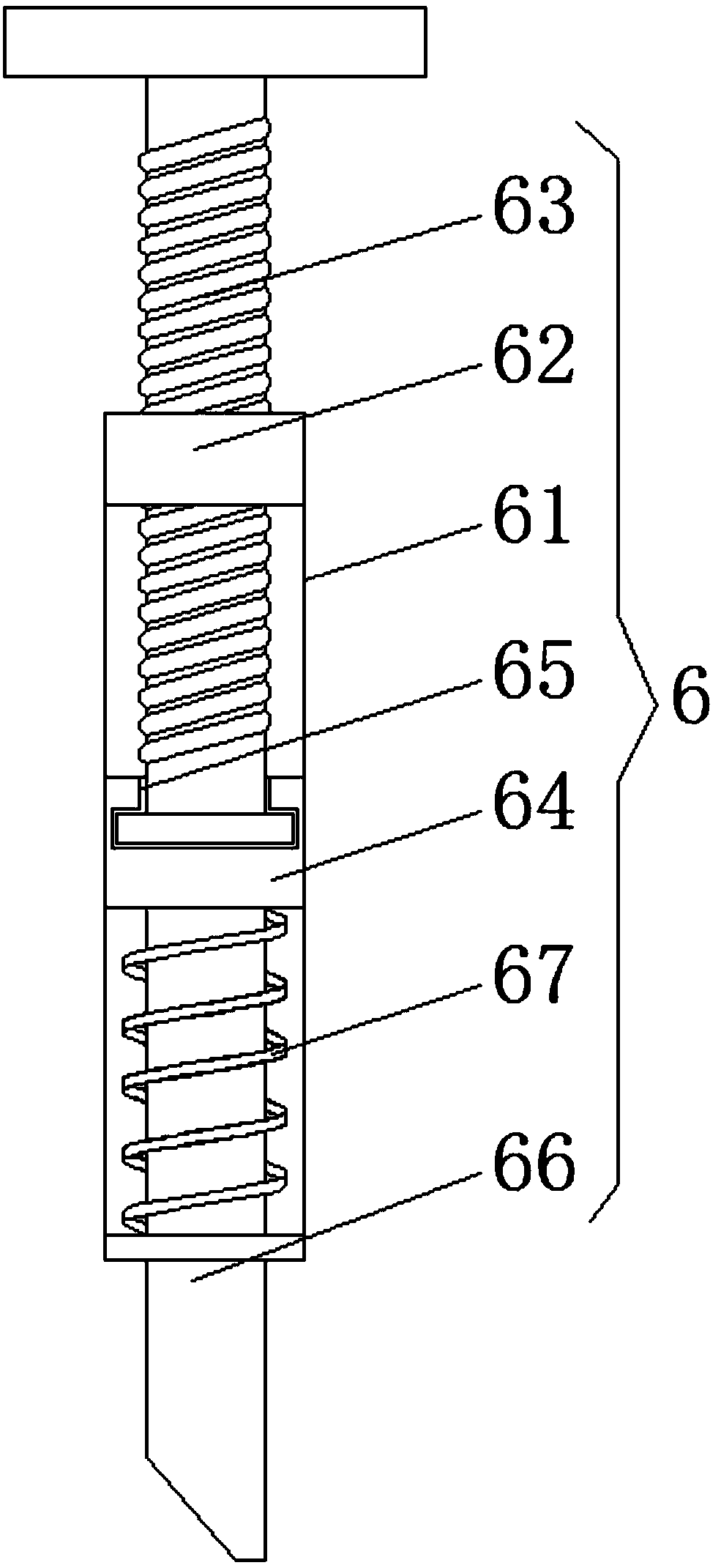

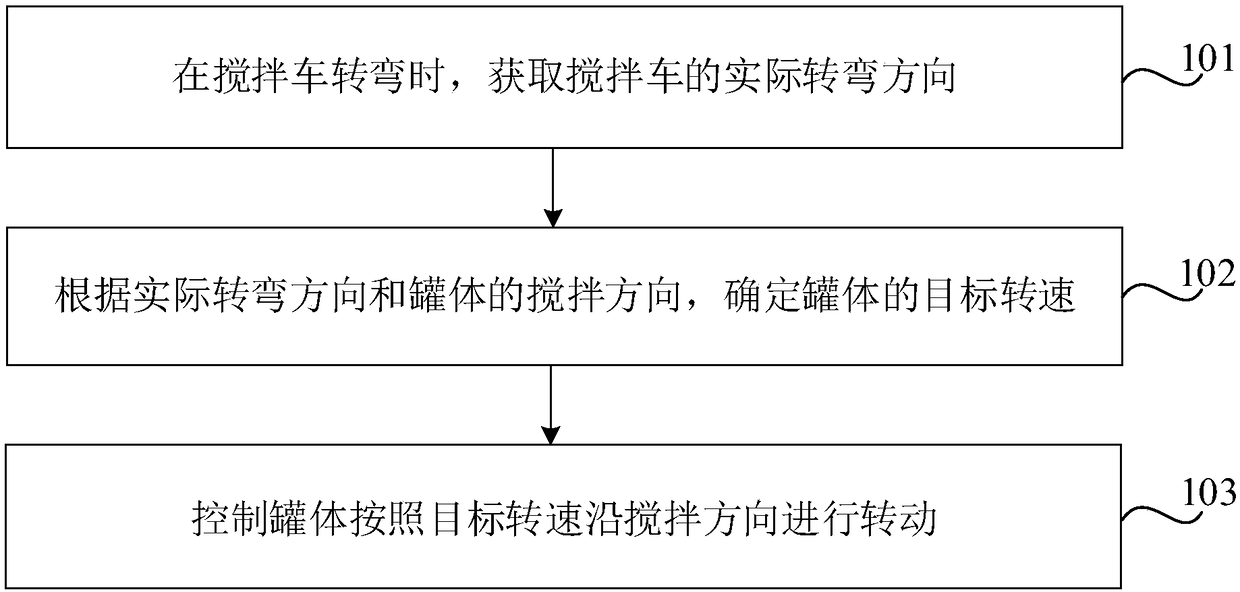

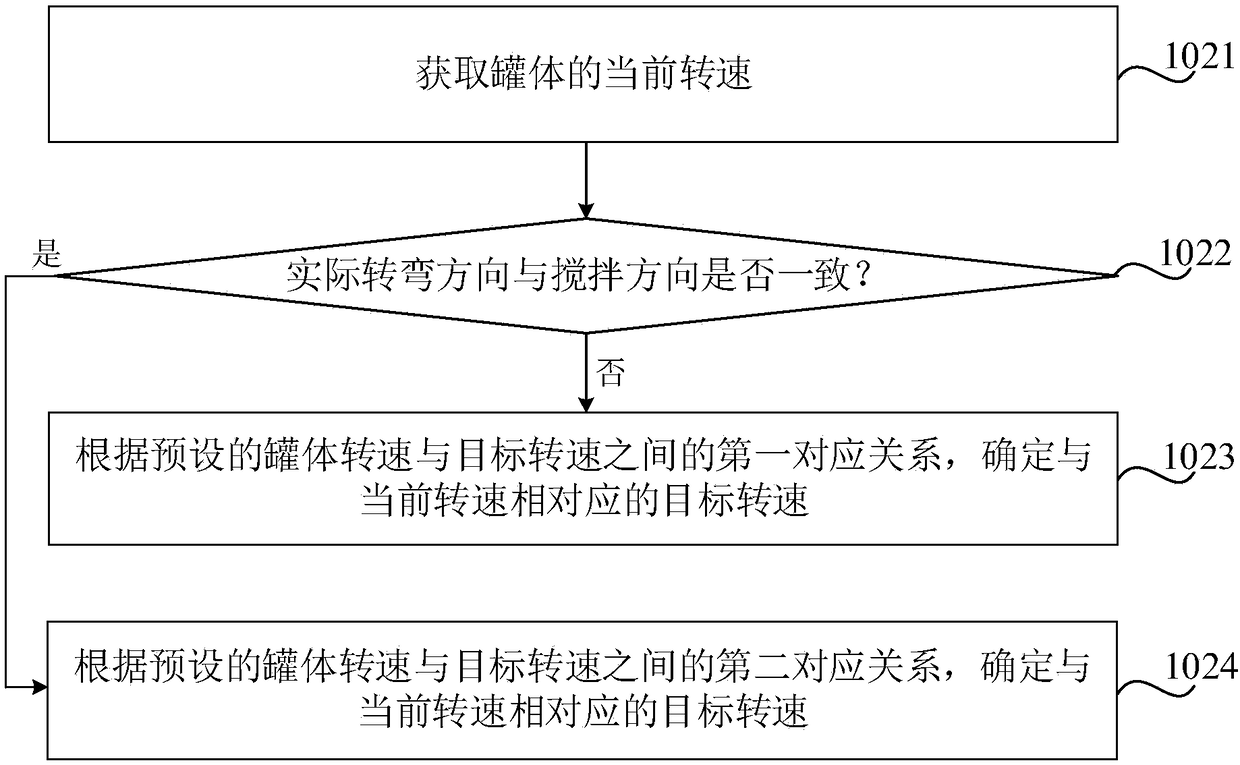

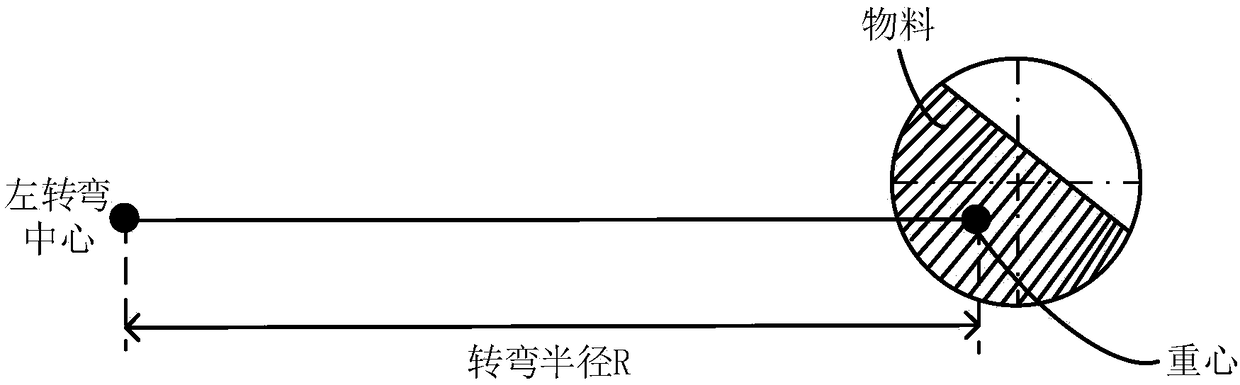

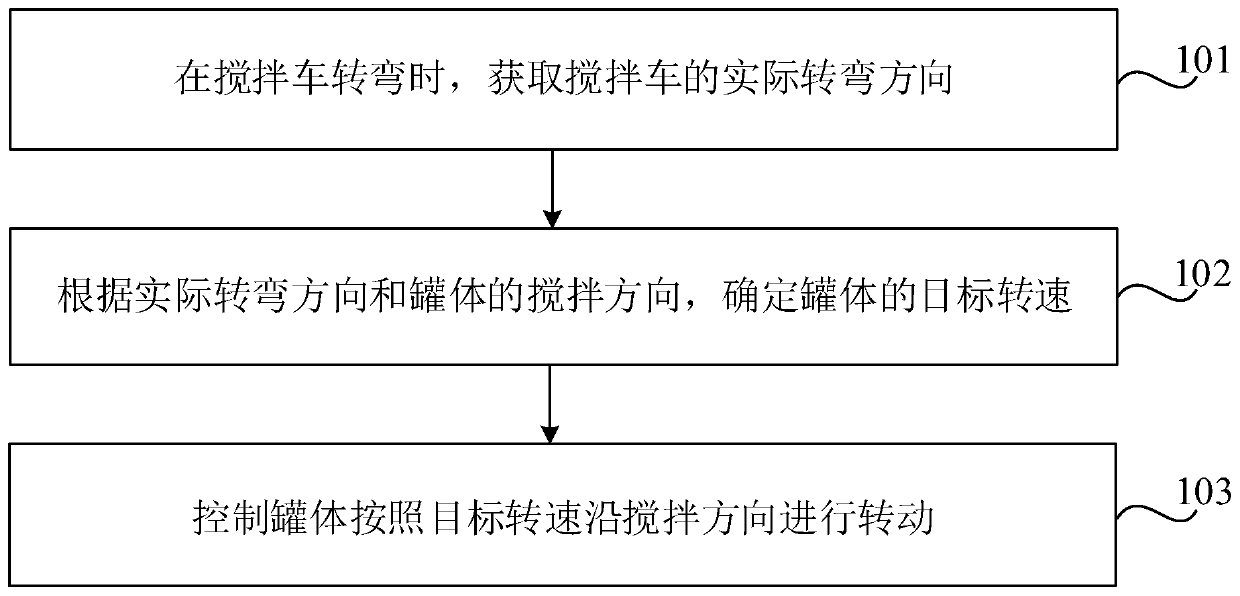

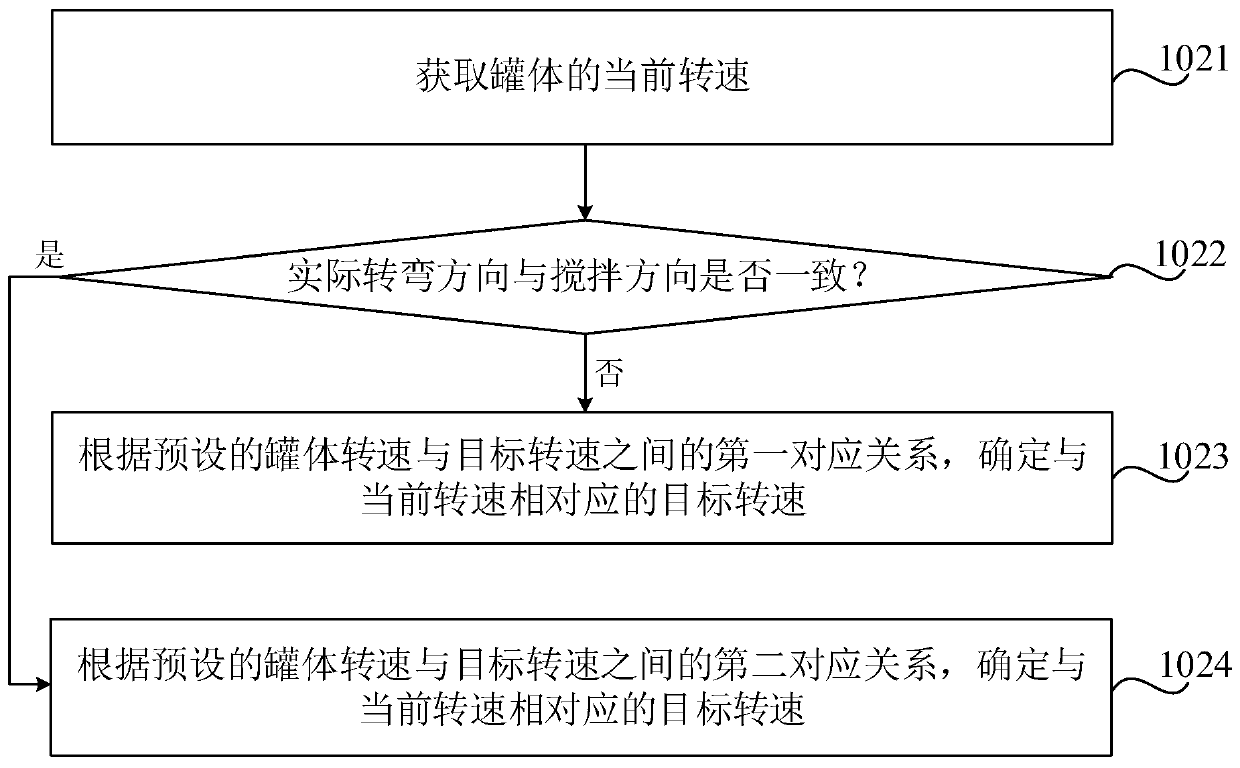

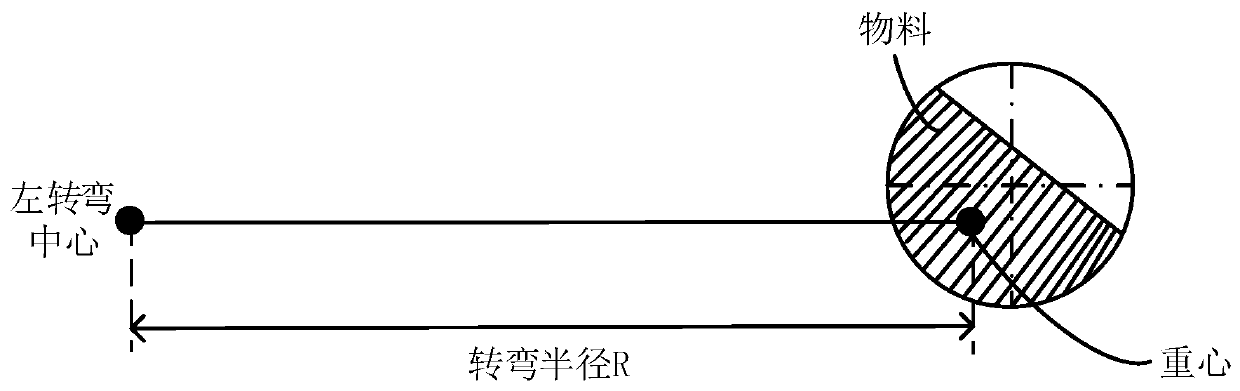

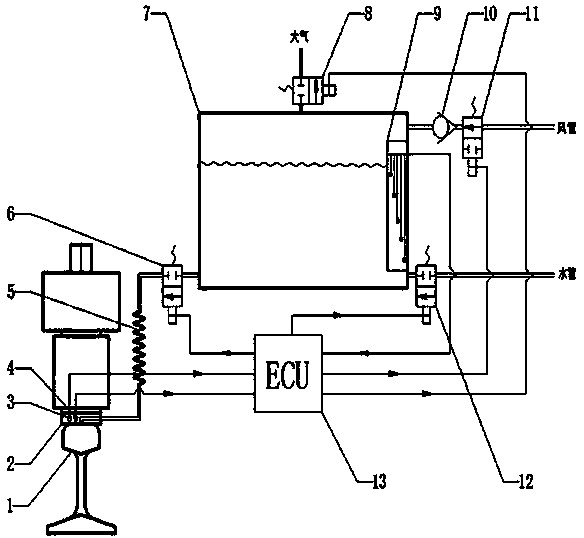

Turning control method, device, and mixer truck

ActiveCN108422558AImprove stabilityImprove driving safetyCement mixing apparatusDriver/operatorEngineering

The invention relates to a turning control method, a device, and a mixer truck. The turning control method is used for the mixer truck. The mixer truck comprises a tank body. The turning control method comprises following steps: in turning of the mixer truck, the practical turning direction of the mixer truck is obtained; a target rotating speed of the tank body is determined based on the practical turning direction and the stirring direction of the tank body; the tank body is controlled to rotate at the target rotating speed along the stirring direction, so that in turning of the mixer truck,automatic adjusting of the rotating speed of the tank body is realized based on the relationship of the practical turning direction of the mixer truck and the stirring direction of the tank body, dependent on single speed reduction by drivers is avoided, the stability and driving safety of the mixer truck are improved, driver labor intensity is reduced; and in addition, the mixer truck is more stable, so that excess wearing caused by aggressive vibration is avoided, and the service life of the mixer truck is prolonged.

Owner:雷萨股份有限公司

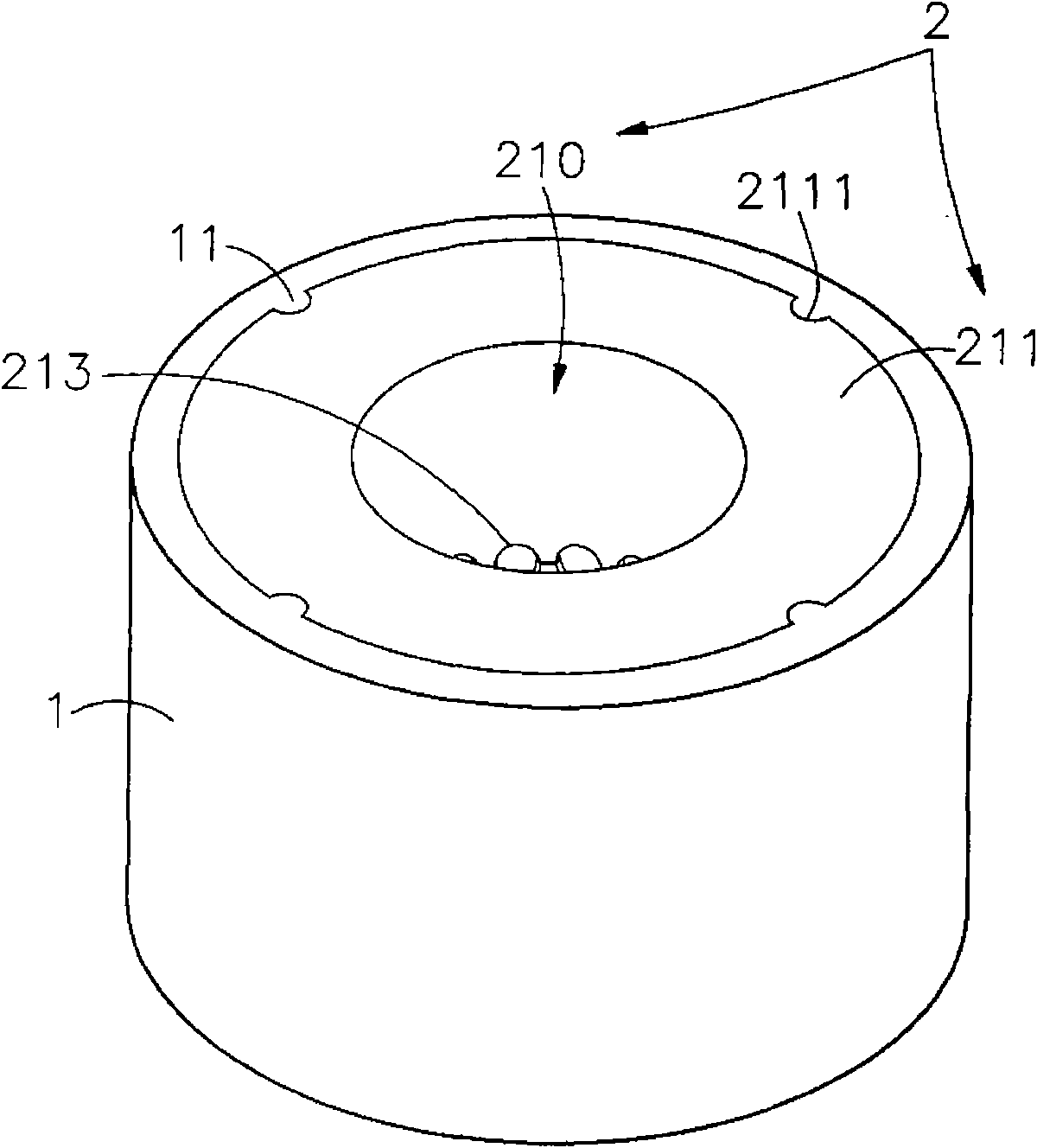

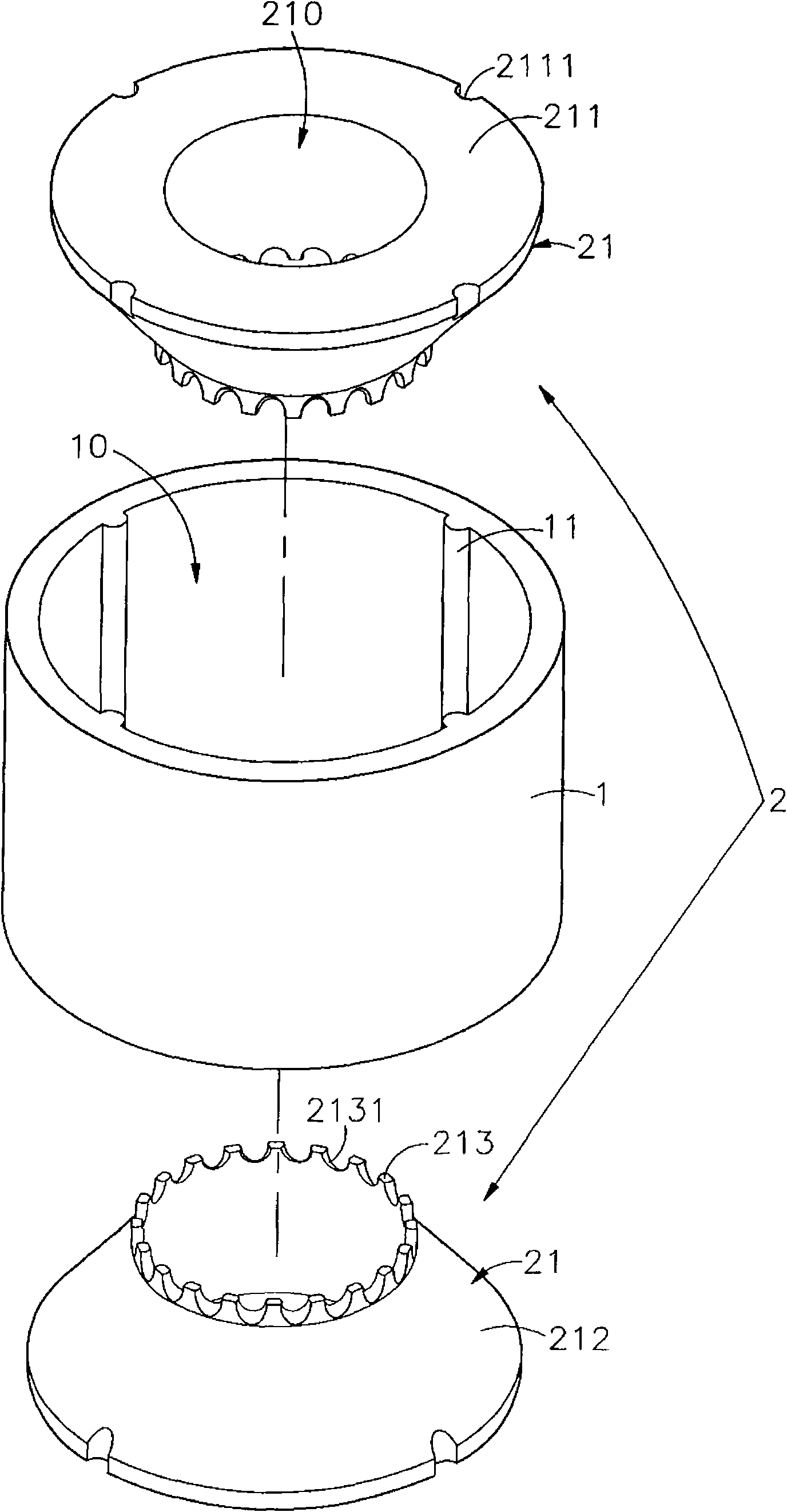

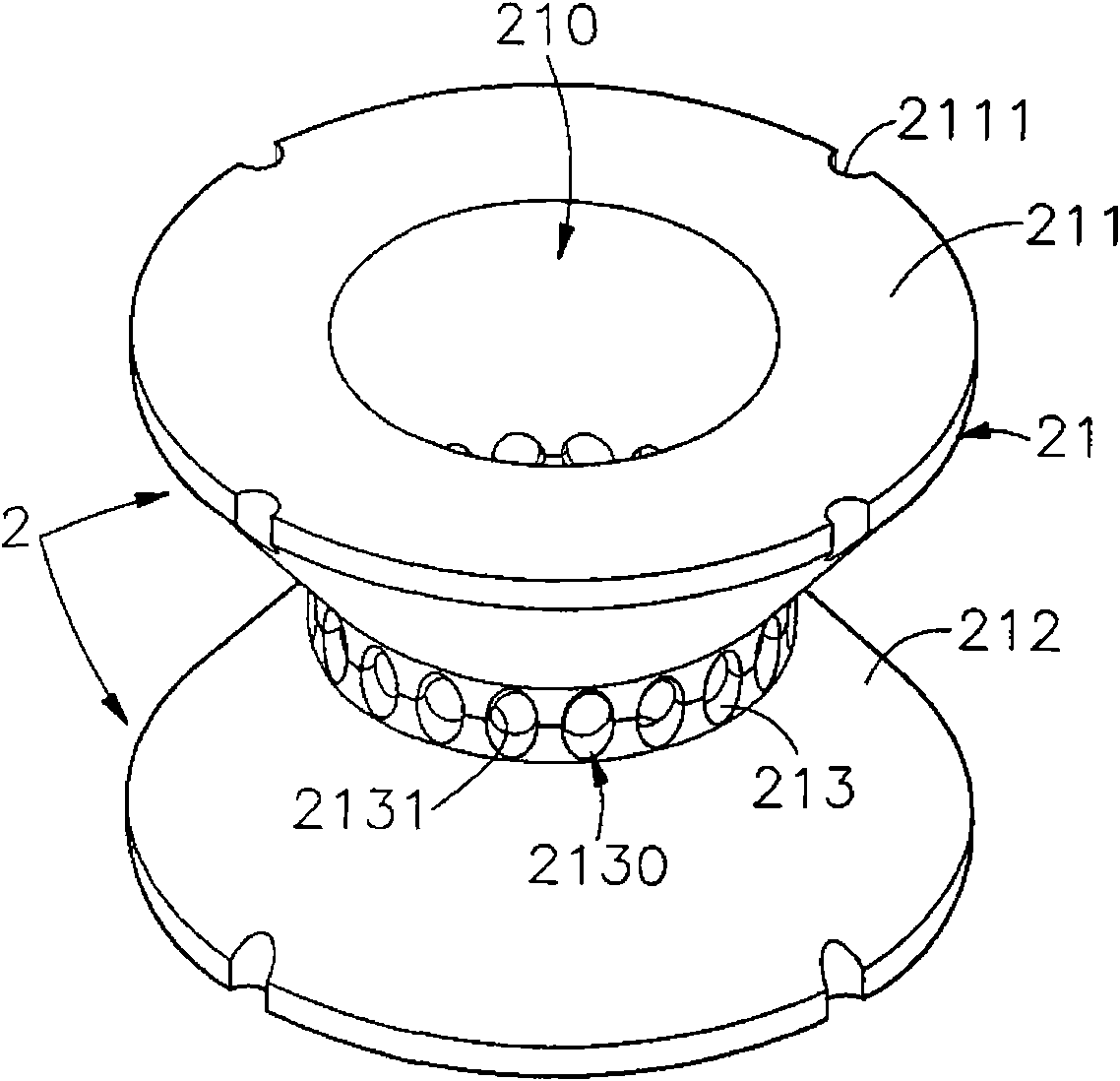

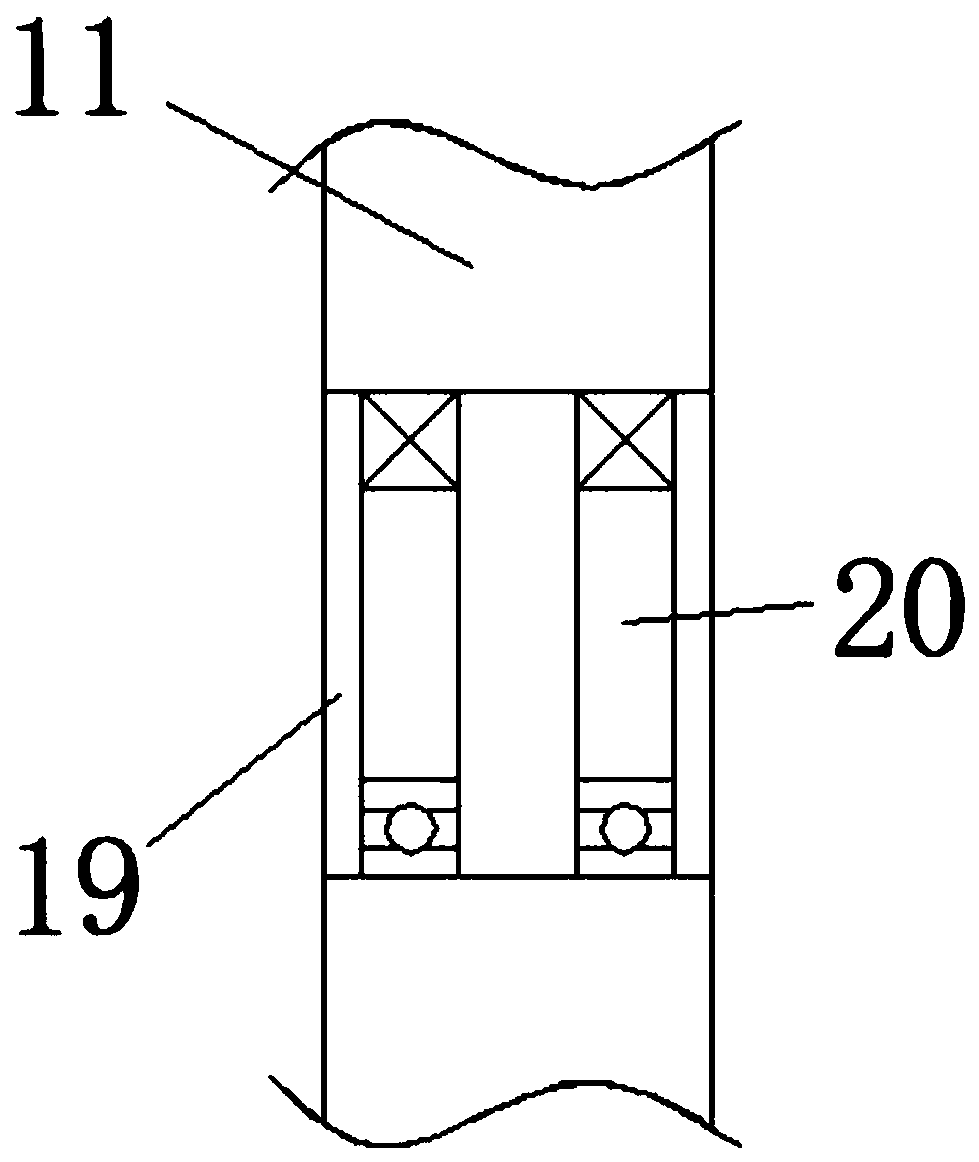

Composite self-lubricating bearing

ActiveCN101922502AExtend and optimize usage limitsSimplify the mass production processBearing componentsSliding contact bearingsEngineeringLubrication

The invention relates to a composite self-lubricating bearing which comprises a bearing group and a shell, wherein the bearing group is formed by assembling at least one bearing unit, and the bearing unit is provided with an axially-perforative axial hole in which an axial core passes through; the shell is a hollow tube body which is used for sleeving on the outer edge of the bearing group along the axial core direction in a sealing way, and at least one storage tank for storing a lubricating medium is defined by the bearing group and the shell. At least one microgap runner communicated with the axial hole is arranged round the storage tank so as to continuously supply the lubricating medium. The lubricating medium exerts the efficacy of high-quality lubrication between the axial core and the axial hole.

Owner:NEWCERA TECH

Steep slope running assisting system

PendingCN110562273AImprove stabilityEnsure driving safetyRailway tracksElevated railway with suspended vehicleEngineeringSteep slope

Owner:ZHONGJIAN AIR TRAIN BEIJING TECH CO LTD

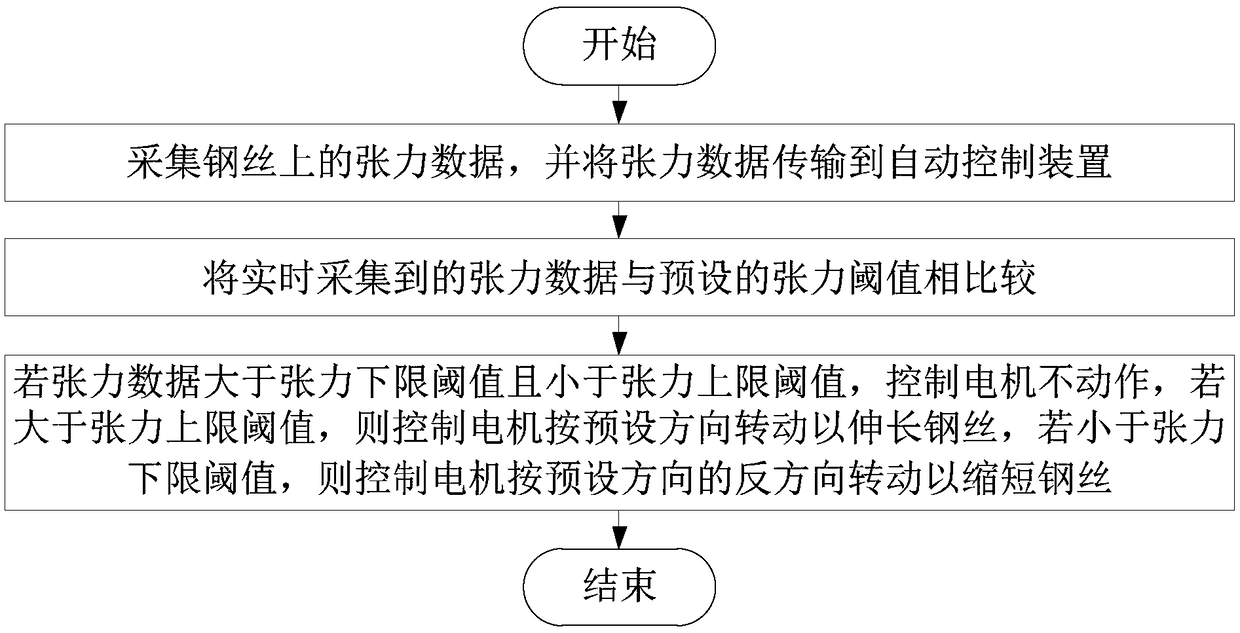

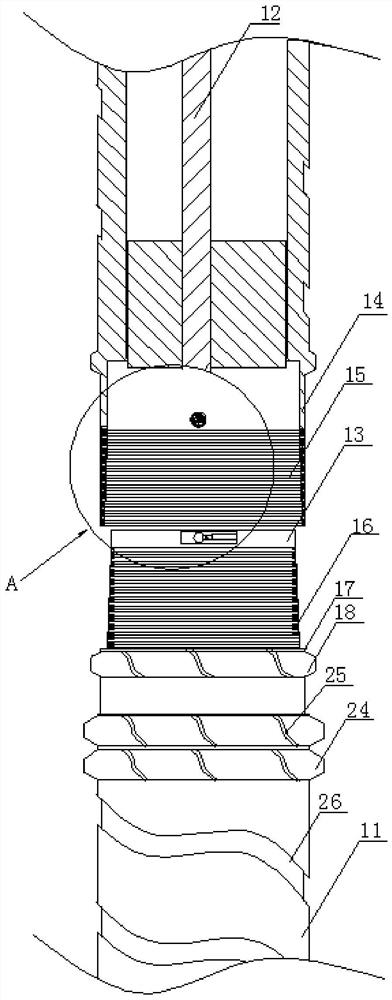

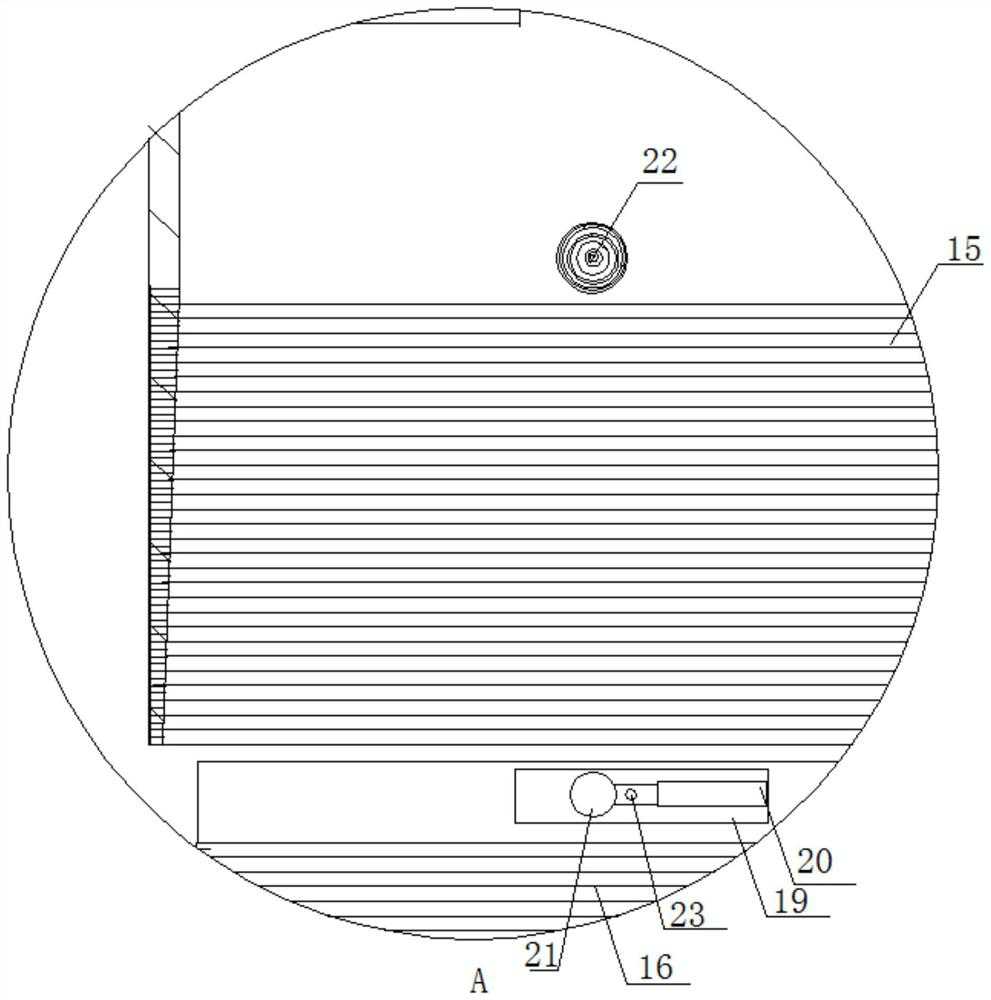

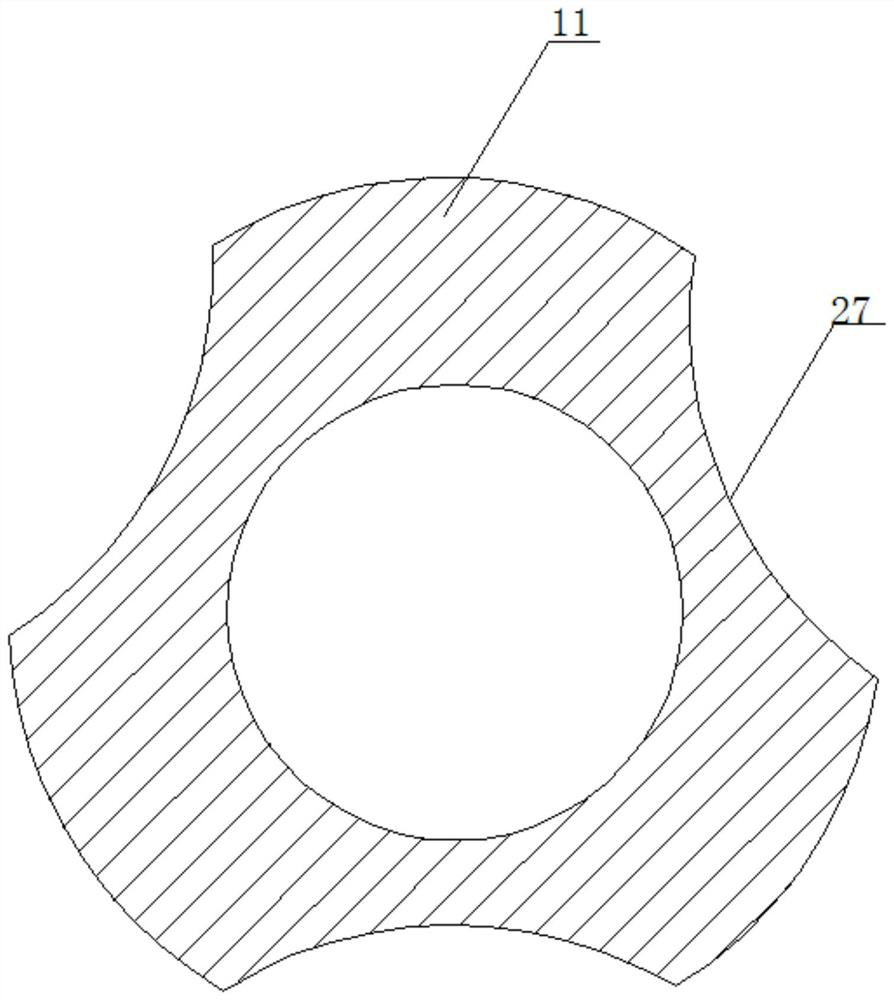

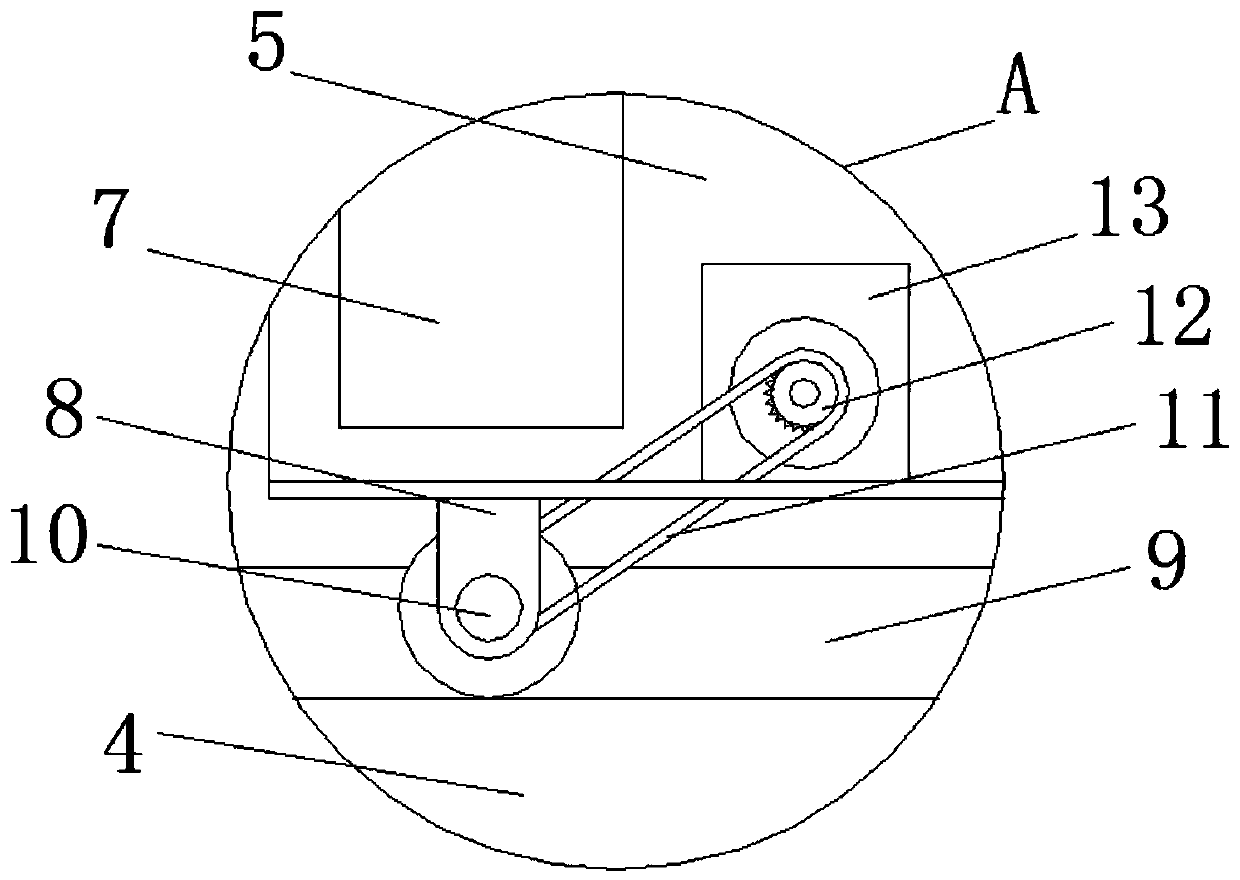

Disk sweeping automatic position adjusting device and adjusting method of sweeping machine

PendingCN108149612AImprove cleaning efficiency and control accuracyReduce excessive wearRoad cleaningAutomatic controlElectricity

The invention discloses a disk sweeping automatic position adjusting device of a sweeping machine and an adjusting method of the sweeping machine. The disk sweeping automatic position adjusting devicecomprises a deflecting reduction case, a motor, a winding roll wheel, a steel wire, a sweeping disk adjusting rod, a sweeping disk component, a tension sensor and an automatic control device; the disk sweeping component is hinged on a chassis of the sweeping machine through the sweeping disk adjusting rod, both ends of the steel wire are connected with the sweeping disk adjusting rod and the winding roll wheel; the motor is connected with the winding roll wheel through the deflecting reduction case, and the tension sensor is arranged at one side of the steel wire closing to the tail end; thetension sensor is electrically connected with the automatic control device, and the automatic control device is electrically connected with the motor controller. Through the technical scheme, the disksweeping position is automatically adjusted, the labor work is saved while the excessive wear of a sweeping brush is reduced, the cleaning efficiency and control precision are improved; thus a working vehicle can keep the best working state at any time.

Owner:SHANGHAI ZHAHUAN BEIZHAN ENVIRONMENT HEALTH ENG CO LTD

Drill rod for directional branch drilling

PendingCN114592804ASimple structureAvoid debris from abrading jointsDrilling rodsFlushingDirectional boringDrill hole

The invention discloses a drill rod for directional branch drilling, and relates to the field of directional drilling, the drill rod comprises a drill rod body, the drill rod body comprises a pipe body and a cable, one end of the pipe body is provided with a male joint, the other end of the pipe body is provided with a female joint, the inner circumferential wall of the female joint is provided with an internal thread, the outer circumferential wall of the male joint is provided with an external thread, and the joint of the external thread of the male joint and the pipe body is provided with a butt joint table; a reinforcing protrusion is arranged on the periphery of the butt joint table, an anti-loosening clamping assembly is arranged between the male connector and the female connector and comprises an embedded groove, a supporting rod and an anti-loosening protrusion are arranged in the embedded groove, and an embedded groove is formed in the female connector. The strength of the butt joint table and the joint of the male joint external thread and the pipe body can be further enhanced by arranging the reinforcing protrusions, the reinforcing protrusions can be abraded firstly, excessive abrasion of the butt joint table is avoided, the male joint and the female joint can be stably fixed by arranging the anti-loose clamping assemblies during drilling vibration and rotation, thread abrasion is reduced, and the service life of the male joint and the female joint is prolonged. The probability of fracture or deformation at the male and female joints is reduced, and the service life of the drill rod is prolonged.

Owner:SHAANXI TAIHE TECH CO LTD

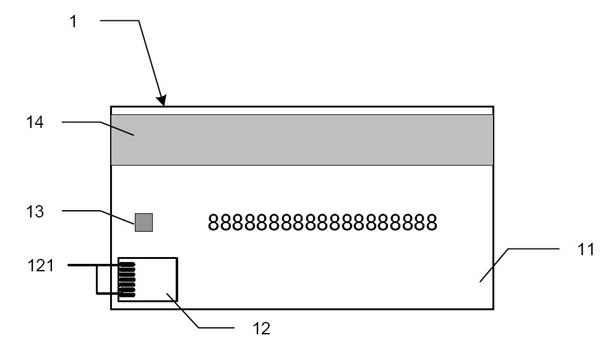

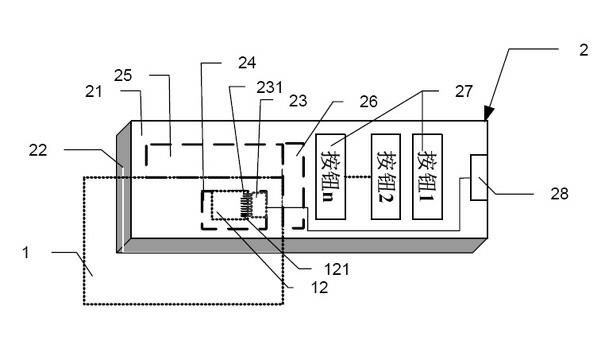

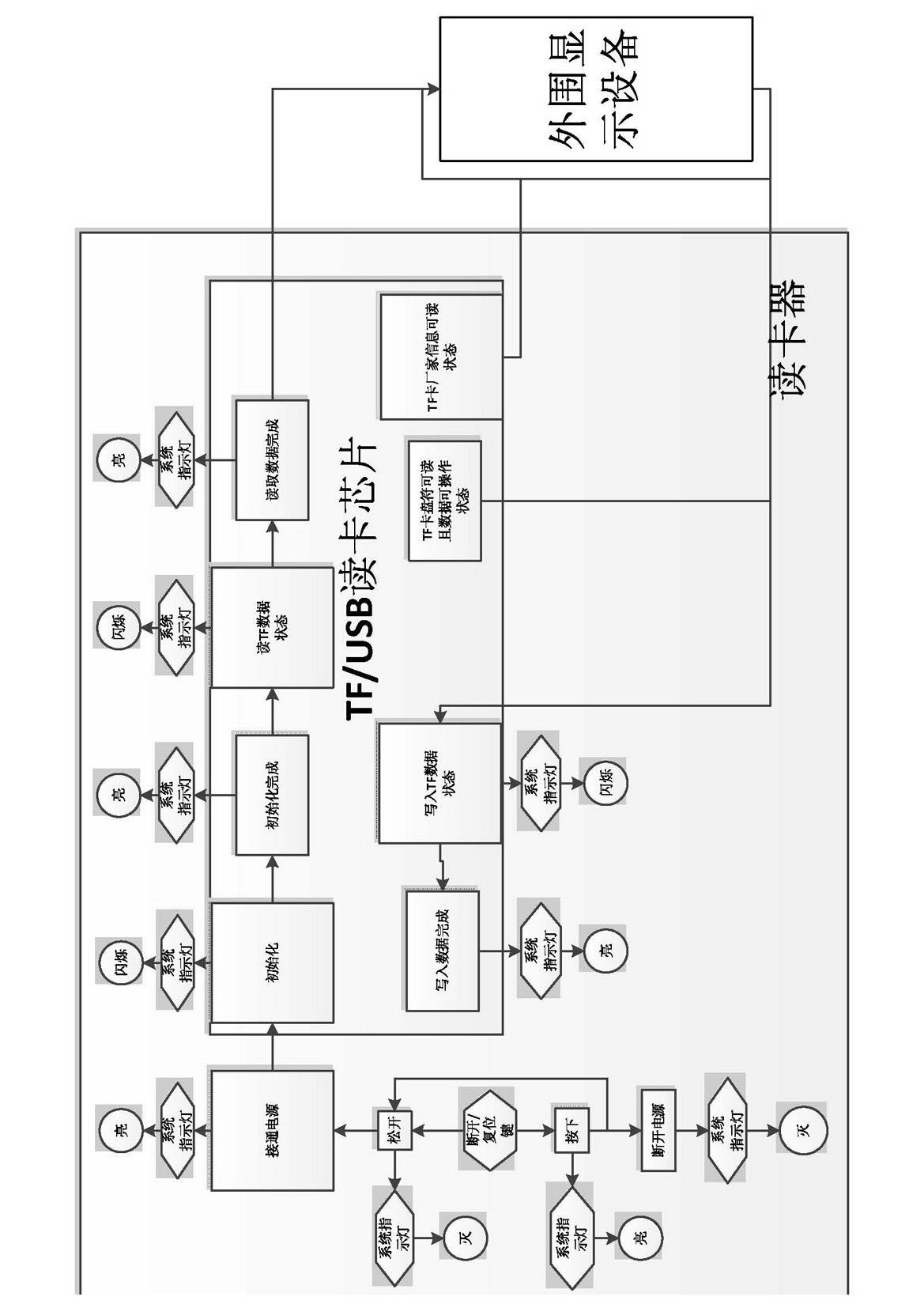

Integrated card, card reader and integrated card combination

InactiveCN102663470AImprove reading and writing qualityQuick dockingSensing record carriersRecord carriers used with machinesCard readerComputer science

The invention relates to a mobile storage device, in particular to an integrated card, a card reader and an integrated card combination. The integrated card comprises a sheet card and a storage card, wherein the storage card is fixed on the sheet card; a lug protruded from the surface of the sheet card is arranged on the sheet card; a groove matched with the lug is formed in the card reader; a card reading device in the card reader also comprises a confidential auxiliary circuit; buttons for controlling the card reader and the storage card to work are arranged on the surface of a sheet card seat; when the integrated card is inserted into the card reader, the lug is clamped into the groove, so that an output interface of the storage card and an input interface of the card reading device are positioned quickly and precisely; and therefore, because of ineffective contact between the integrated card and the card reader when the integrated card is inserted into the card reader, the risk that the storage card fails to read and write data, or circuits of the storage card and the card reader are damaged can be effectively reduced, and the integrated card cannot be excessively abraded during positioning A user can read and safely manage and control information in the storage card through the buttons conveniently and quickly.

Owner:DONGGUAN MATHEMATICAL ENG ACAD OF CHINESE MEDICINE GUANGZHOU UNIV OF CHINESE MEDICINE

Clamping device for polishing metal material

ActiveCN111438622AShorten the timeReduce manual operationsGrinding carriagesPolishing machinesPolishingMetallic materials

The invention relates to the technical field of metal material processing, in particular to a clamping device for polishing a metal material, which solves the problem that no devices that can guarantee the application of a controllable loading force to the polishing metal material and can periodically switch the polishing direction of the metal material are existed in the prior art. The clamping device for polishing the metal material specifically includes a bracket assembly; a force applying mechanism is detachably fixed on the working end of the bracket assembly; a clamping assembly can slide along a track and is also used for clamping the circumferential direction of the metal material to be processed; a first transmission mechanism drives and controls the clamping assembly to slide along the track within a preset sliding track scope; a driving mechanism is used for driving the first transmission mechanism to drive and control the clamping assembly to slide along a preset rotation track; a second end can be detachably connected to the driving mechanism or can be maintained in transmission connection with the driving mechanism; and the driving mechanism can intermittently drive asecond transmission mechanism. The clamping device for polishing the metal material can provide a controllable loading force and can prevent partial polishing; and the polishing process does not require manual contact with the polishing material, and is safe and reliable.

Owner:JILIN UNIV

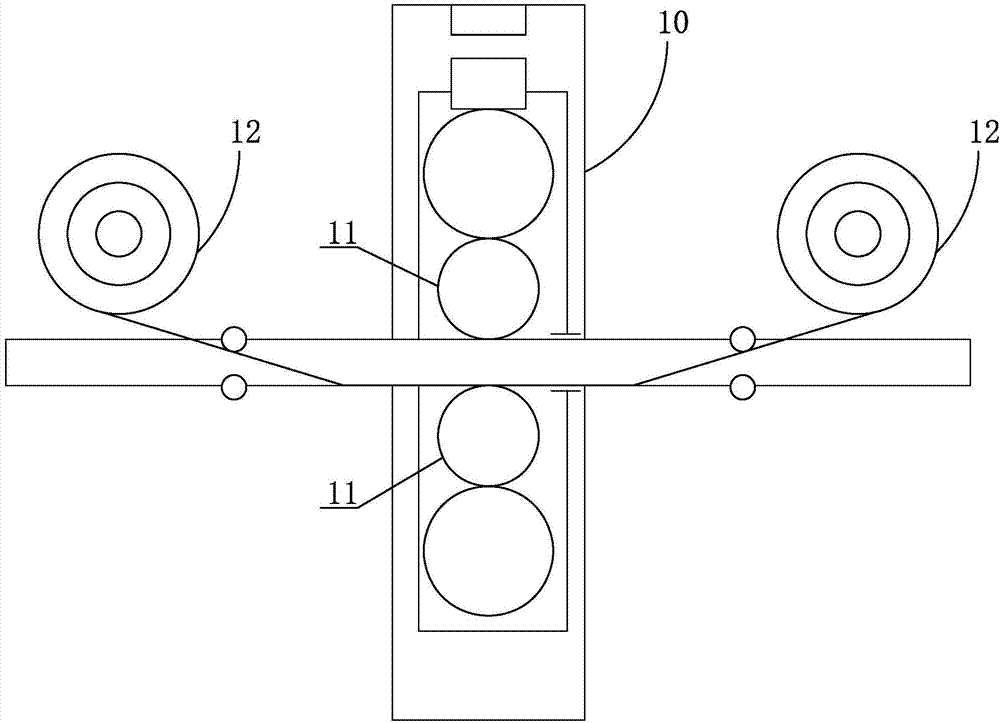

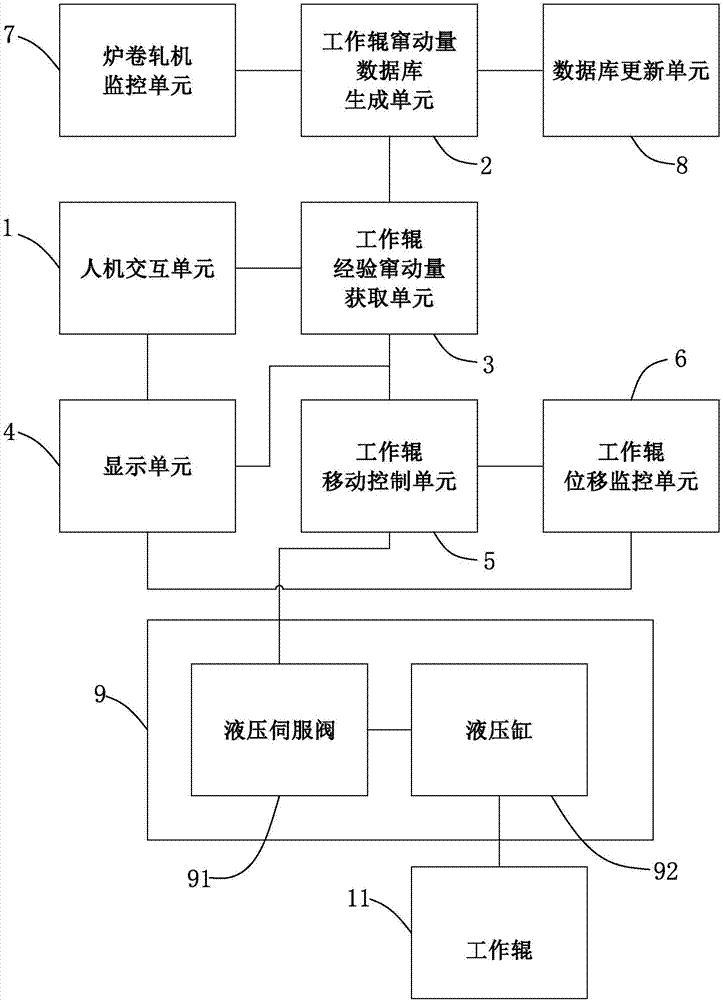

Control method and device for working roll bouncing between passes of steckle mill

ActiveCN107537862AReduce wearReduce excessive wearProfile control deviceMetal rolling arrangementsWork rollControl theory

The invention relates to a control method for working roll bouncing between passes of a steckle mill. The control method comprises the steps that working roll experience displacement of the passes corresponding the variety of a current blank is acquired from a preset working roll displacement database; the working roll experience displacement of the current pass is determined according to the working roll experience displacement of the passes; the position of a working roll is adjusted according to the working roll experience displacement of the current pass, wherein before rolling of the current pass is carried out on the blank, the working roll is driven to move in the axis direction of the working roll; and when the moving displacement of the working roll reaches the working roll experience displacement of the current roll, the working roll is controlled to stop moving. According to the control method, control over displacement of each pass of the working roll can be automatically carried out, and therefore the product quality is improved, the surface quality of the product is guaranteed, in addition, the bending effect of the working roll can also be improved, and excessive abrasion to the working roll is reduced.

Owner:ZHANGJIAGANG POHANG STAINLESS STEEL

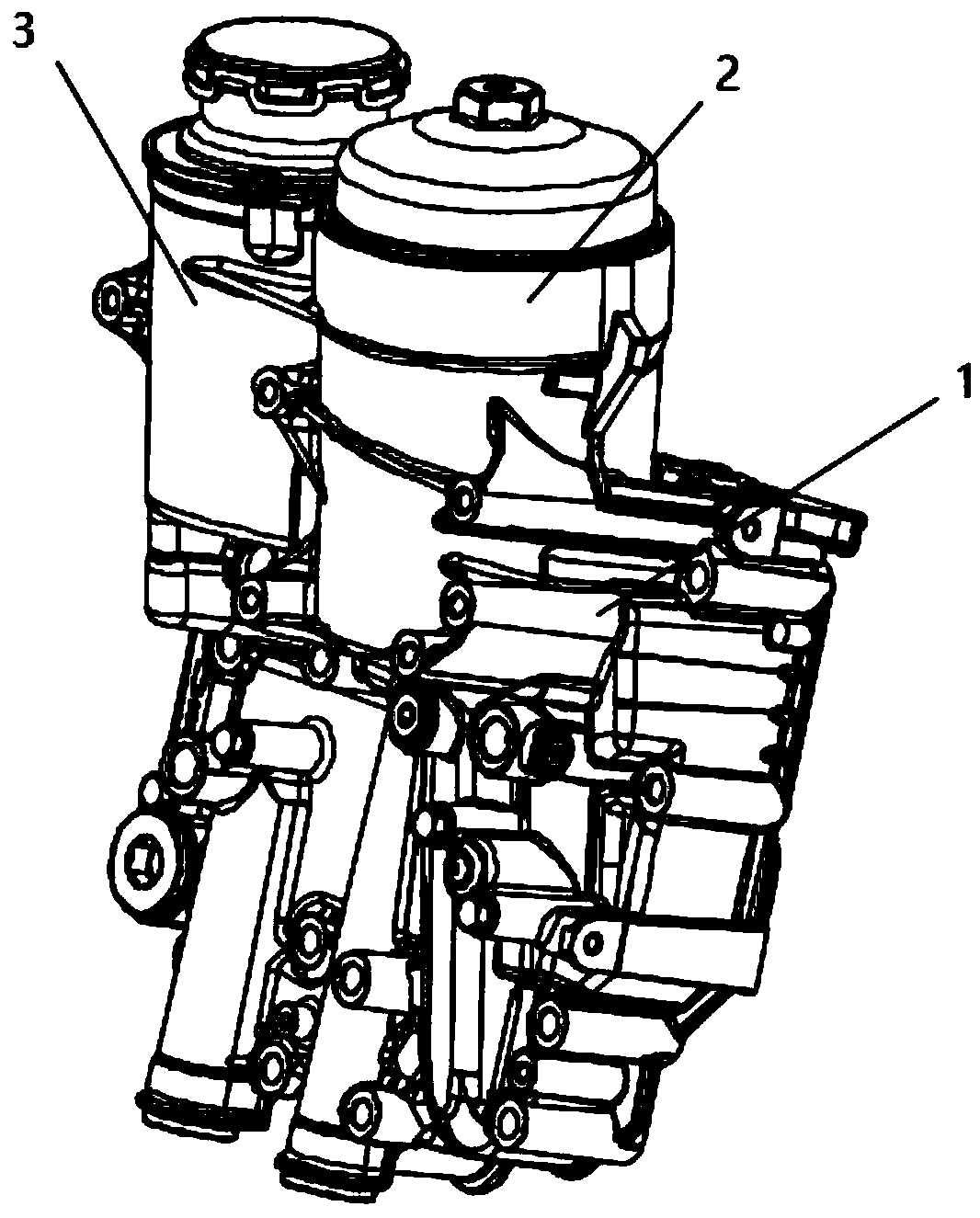

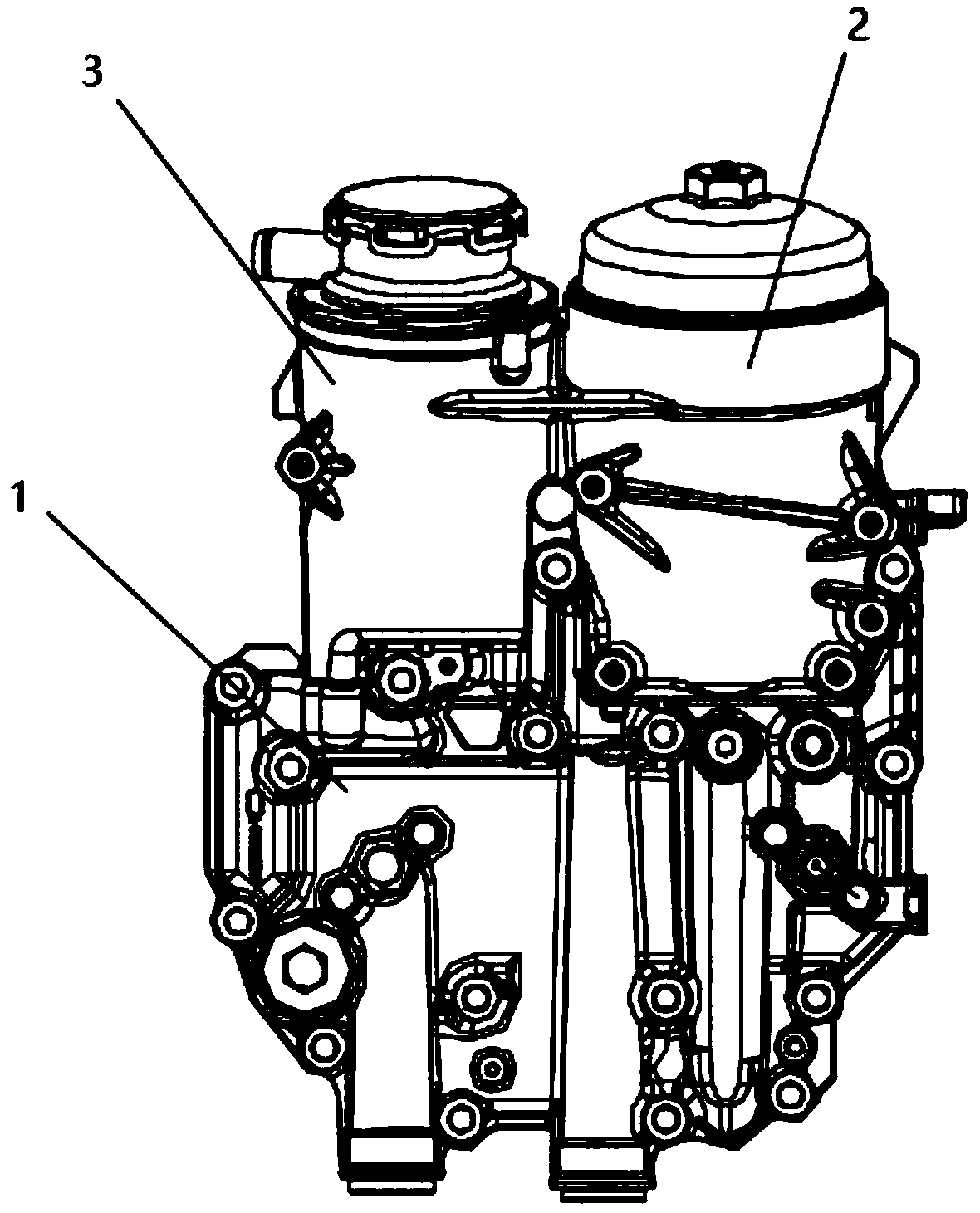

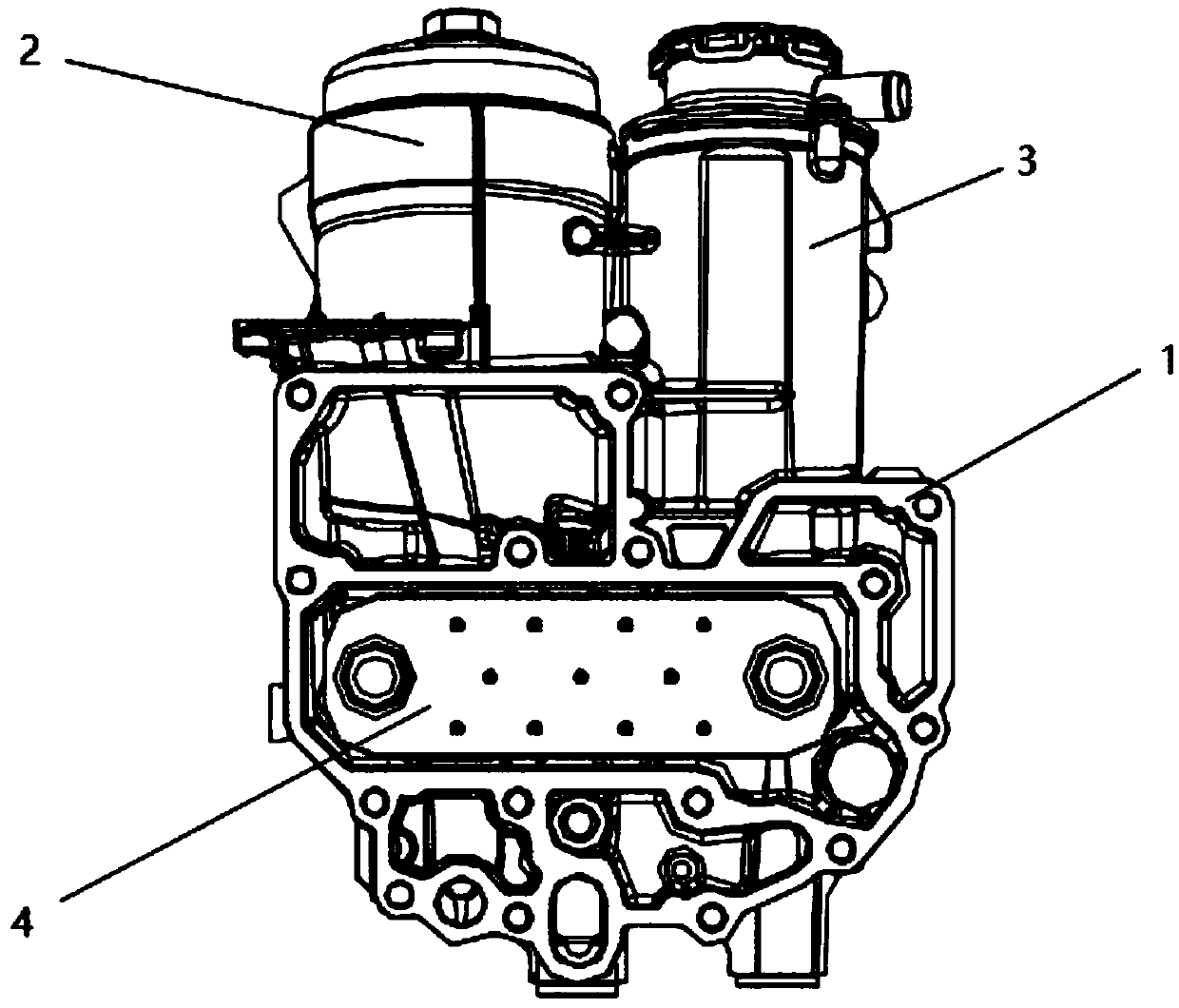

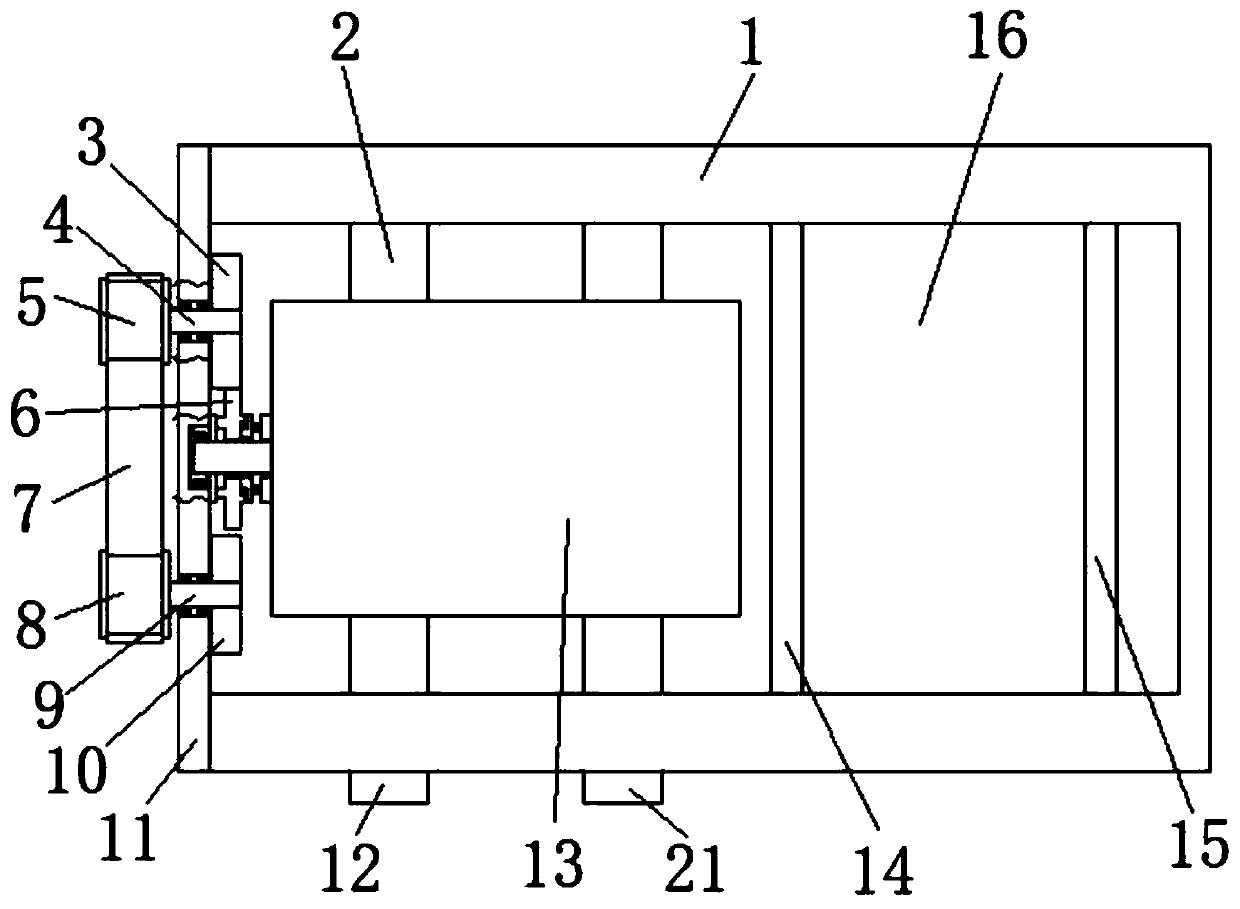

Integrated engine oil filter

PendingCN109630233AExtend your lifeImprove emission effectMachines/enginesPressure lubricationPaper filterSafety valve

The invention discloses an integrated engine oil filter. The integrated engine oil filter comprises a casing, an engine oil filtering module, an oil-gas separation module, an oil cooler, a paper filter element, a bypass valve, a service valve and a safety valve; the engine oil filtering module and he oil-gas separation module are arranged at the top of the casing; the oil cooler is mounted on thecasing and located below the engine oil filtering module and he oil-gas separation module; the paper filter element is mounted inside the engine oil filtering module; the bypass valve is arranged on the engine oil filtering module and located at the top of the center of the paper filter element; the service valve is arranged at the bottom of the center of the engine oil filtering module; the safety valve is mounted inside the casing and located below the oil cooler; the back surface of the casing is a flange surface; and a connecting opening is reserved in the flange surface. The integrated engine oil filter has the characteristics that the integrated engine oil filter is convenient to replace, capable of prolonging the life of an engine, highly integrated and high in overall ability.

Owner:HENGST FILTER SYST (KUNSHAN) CO LTD

Grinding equipment for aluminum profile fracture

The invention provides grinding equipment for an aluminum profile fracture. The equipment comprises a storage shell, a main motor is fixedly installed in the storage shell, a fixing plate is fixedly installed at the left end of the storage shell, the upper end and the lower end of the fixing plate are symmetrically provided with rotating shaft holes, a transmission shaft is rotationally installedin the rotating shaft hole in the upper end, a driving belt wheel is spirally installed at the left end of the transmission shaft, a transmission gear is clamped to the right end of the transmission shaft, and a positioning shaft is rotationally installed in the rotating shaft hole in the lower end. Abrasive paper is replaced with an abrasive belt, toughness is improved, the abrasive belt is softer compared with a corner grinding sheet, excessive abrasion to the fracture is reduced, the device has the convenience and fastness of operation of the corner grinding machine and the characteristic of excessive abrasion prevention for the fracture, and by means of a clutch mechanism of the driving gear, the main motor can be in a working state all the time after being started, and the problem that starting current is too large due to repeated starting is avoided.

Owner:天津市众联铝业有限公司

Sole film pasting equipment using novel material

InactiveCN111874712AReduce excessive wearWear will notApparel holdersArticle deliveryEngineeringStructural engineering

The invention discloses sole film pasting equipment using a novel material. The equipment comprises a shell, a first transmission space is arranged at the right side of the shell, a main space is arranged at the lower side of the first transmission space, a backrest is fixedly arranged on the upper side surface of the shell, a person can sit on the backrest through the backrest, a seat is fixedlyarranged at the right side of the backrest, and the seat is a position where the person can sit. A first sliding space is formed at the left side of the shell, a winding space is formed at the lower side of the first sliding space, and a working space is formed at the upper side of the winding space. Before mountain climbing, memory metal and a high-friction material can be used for jointly manufacturing a friction film meeting different soles, the film is pasted on a sole, excessive abrasion of a shoe due to terrain and other factors can be greatly reduced during mountain climbing, the shoe can be greatly protected against abrasion during climbing, the friction force between the shoe and the ground can be increased, the climbing process can be safer, and the phenomena of slipping and thelike can be avoided.

Owner:ZHEJIANG DA BO WEN SHOES CO LTD

A reprocessing device for construction waste steel bars

ActiveCN110170905BHigh speed rotationGuaranteed mixing needsGrinding carriagesLiquid surface applicatorsWater storageWater storage tank

The invention relates to a construction waste steel bar reprocessing device. The construction waste steel bar reprocessing device effectively solves the problems related to steel bar daubing cement, rust removal and the like; the technical proposal is to include a shell, wherein the left side of the shell is provided with a steel bar propelling device and a guide cylinder, a sleeve which is coaxial with the guide cylinder and can rotate is arranged inside the shell, a planetary gear set is arranged at the left end of the sleeve in a sleeved mode, the outer gear ring of the planetary gear set is fixedly connected with the shell, and a sun gear of the planetary gear set is arranged on the sleeve in a sleeved mode; the sleeve can drive the sun wheel to rotate, a plurality of sector-shaped rust removal brushes are uniformly distributed on the circumference of each planetary gear of the planetary gear set, a water storage tank which is positioned on the right side of the planetary gear setis fixedly arranged inside the shell, the right end of the sleeve is not in contact with and is arranged inside the water storage tank, the plurality of radial connecting rods are uniformly distributed on the circumference of the right end of the sleeve, and the other end of the connecting rods are connected with a scraper. The construction waste steel bar reprocessing device is not only convenient for rust removal but also conducive to coating cement.

Owner:华新建工集团有限公司 +1

Flower and plant seedling cultivating frame convenient for adjusting

InactiveCN108377798AEasy to adjustSolve the problem that it needs to be folded to adjust the height between layersClimate change adaptationGreenhouse cultivationDrive shaftGear wheel

The invention discloses a flower and plant seedling cultivating frame convenient for adjusting. The flower and plant seedling cultivating frame comprises a bottom base. The upper surface of the bottombase is fixedly connected with two symmetrical support rods. The upper part of one side face, mutually adjacent to each other, of each of the support rods is provided with a through channel. A seedling cultivating plate matched with the through channels is placed above the bottom base. The left and right ends of the seedling cultivating plate are locked and connected in two through channels. Themiddle of the bottom wall in each of the through channels is provided with a groove. The interior of each of the grooves is locked and connected with a rack matched with the groove. The upper surfacesof two racks pass through two grooves and are extended to the interior of the through channels, and the upper surfaces of the two racks are fixedly connected with the bottom face of the seedling cultivating plate. The flower and plant seedling cultivating frame convenient for adjusting is capable of, through installing the racks, and under the combined action of a gear, a transmission shaft, a first driving wheel, a conveying belt, a second driving wheel and a speed reducing motor, enabling the seedling cultivating plate to be upwards and downwards moved, and solving a problem that an interlayer height can be adjusted only if the traditional seedling cultivating plate is detached and assembled.

Owner:XISHAN XIANFENG FAMILY FARM

Switch water pump based on electromagnetic torsional spring type clutch

PendingCN108331852AAvoid damageReduce coefficient of frictionCoolant flow controlMagnetically actuated clutchesImpellerDrive wheel

The invention relates to an electromagnetic torsional spring type clutch, a switch water pump based on the electromagnetic torsional spring type clutch and a vehicle. The electromagnetic torsion spring type clutch comprises a driving wheel assembly, a driven wheel assembly and a control device, wherein the driving wheel assembly and the driven wheel assembly are connected through a bearing, and relative rotation can be achieved between the driving wheel assembly and the driven wheel assembly; a friction sleeve is arranged outside a support in the driving wheel assembly and is tightly clamped with a spiral part of a torsional spring in the driven wheel assembly; the switch water pump comprises the electromagnetic torsional spring type clutch, an iron core assembly and a pump body assembly;and by means of connection or disconnection between a coil and a power supply, a power output part of the clutch part is controlled to transmit the rotary motion to an impeller or not so as to controlthe motion of the impeller. According to the switch water pump based on the electromagnetic torsional spring type clutch, the problem that the torsional spring is abraded too fast is solved, and a device in which a cooling system of an engine is controlled to work according to the temperature of the automobile engine is formed.

Owner:LONGKOU ZHONGYU THERMAL MANAGEMENT SYST SCIAND TECH

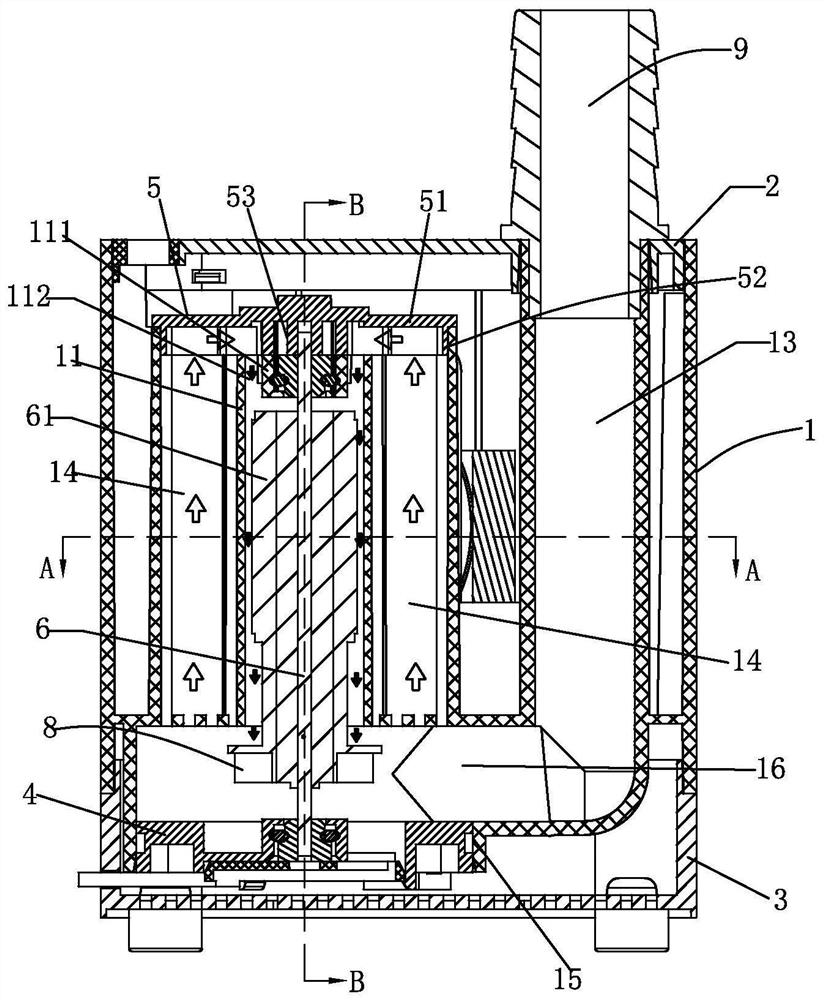

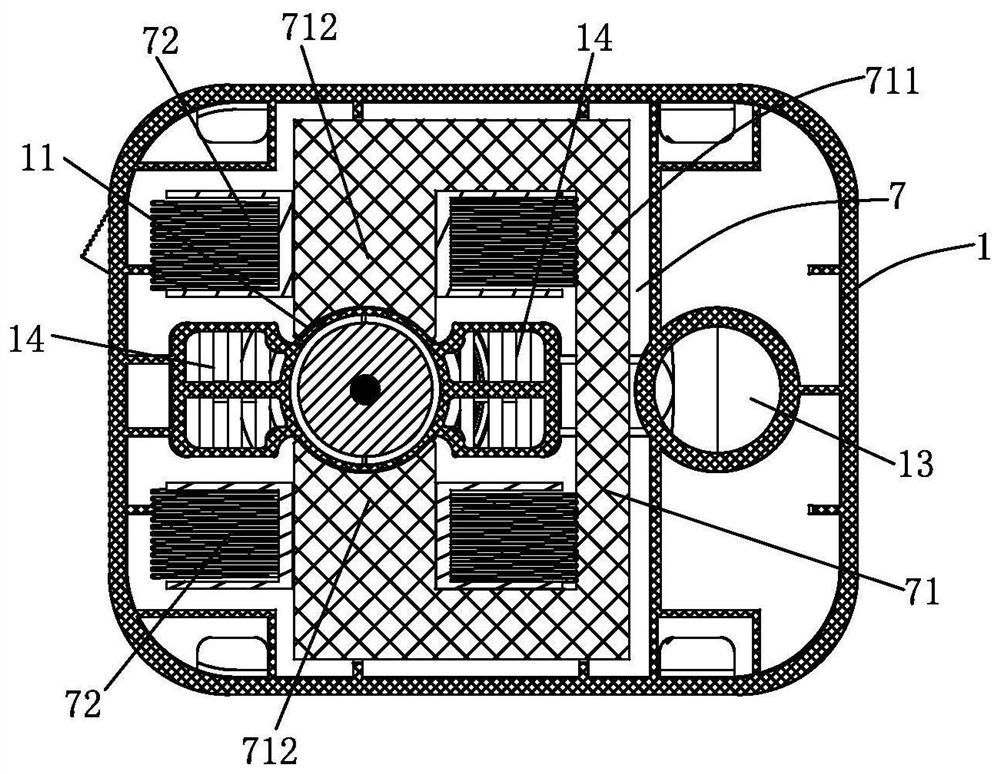

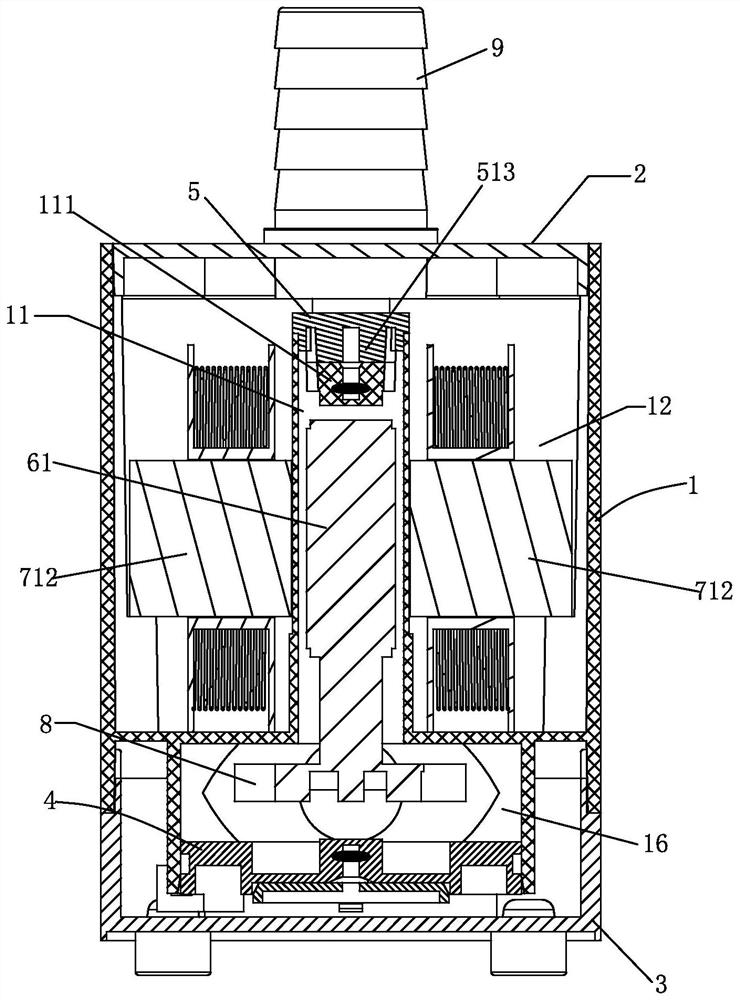

Brushless magnetic drive submersible pump with built-in water cooling system

PendingCN111622960AExtended service lifeReduce temperature risePump componentsMagnetic circuit stationary partsImpellerElectric machinery

The invention relates to a brushless magnetic drive submersible pump with a built-in water cooling system. The brushless magnetic drive submersible pump comprises a pump body, a pump cover, a water inlet housing, an upper end cover, a lower end cover, a motor shaft, a rotor, a stator, an impeller and a water outlet pipe, and a rotor cavity, a stator cavity, a pump pressure cavity, a pump water inlet and a water outlet pipeline are arranged on the pump body; the shell further comprises two longitudinal water channels arranged in the stator cavity and a mounting hole in the upper end cover of the bottom plate, the upper parts of the longitudinal water channels are in communication with the upper part of the rotor cavity, and a water inlet hole is formed in the upper end cover; the lower endcover is buckled with the rotor cavity and the upper ends of the longitudinal water channels and is in liquid sealing with the rotor cavity and the upper ends of the longitudinal water channels, and awater flow heat exchange gap is formed between the rotor and the rotor cavity; and water enters from the bottom ends of the longitudinal water channels, flows through the longitudinal water channels,the water inlet holes in the upper end cover and the rotor cavity, and then is discharged from the bottom end of the rotor cavity to flow into the pump pressure cavity to form a water cooling system.Flowing water absorbs heat on a coil and the rotor, so that the temperature rise of rotating shafts of the coil and the rotor is effectively reduced, and the service life of the submersible pump is prolonged.

Owner:ZHONGSHAN JINGBAO ELECTRICAL

Turning control method, device and mixer truck

ActiveCN108422558BImprove stabilityImprove driving safetyCement mixing apparatusDriver/operatorEngineering

The invention relates to a turning control method, a device, and a mixer truck. The turning control method is used for the mixer truck. The mixer truck comprises a tank body. The turning control method comprises following steps: in turning of the mixer truck, the practical turning direction of the mixer truck is obtained; a target rotating speed of the tank body is determined based on the practical turning direction and the stirring direction of the tank body; the tank body is controlled to rotate at the target rotating speed along the stirring direction, so that in turning of the mixer truck,automatic adjusting of the rotating speed of the tank body is realized based on the relationship of the practical turning direction of the mixer truck and the stirring direction of the tank body, dependent on single speed reduction by drivers is avoided, the stability and driving safety of the mixer truck are improved, driver labor intensity is reduced; and in addition, the mixer truck is more stable, so that excess wearing caused by aggressive vibration is avoided, and the service life of the mixer truck is prolonged.

Owner:雷萨股份有限公司

Device for controlling temperatures of pole sole of magnetic track brake and track as well as control method thereof

ActiveCN102673601BEffective coolingAvoid excessive wearTrack-braking member co-operationBrake safety systemsSolenoid valvePole piece

The invention discloses a device for controlling temperatures of a pole sole of a magnetic track brake and a track as well as a control method thereof. A first non-contact temperature sensor and a second non-contact temperature sensor are respectively used for detecting the temperature of the pole sole of the magnetic track brake and the steel track; a water through hole is formed in the side face of the pole sole of the magnetic track brake; small water spraying holes are formed at the bottom of the pole sole of the magnetic track brake; the water through hole and the small water spraying holes are communicated inside the pole sole of the magnetic track brake; the water through hole is connected with the lower part of a water tank in a sealed manner by passing through a spiral elastic hose and a first solenoid valve in sequence; a liquid meter is arranged in the water tank; the top of the water tank is communicated with atmosphere through a second solenoid valve; the side part of the water tank is connected with a water pipe connected on a train through a fourth solenoid valve; the side part of the water tank is sequentially connected with an air duct on the train through a one-way valve and a third solenoid valve in sequence; and the liquid meter and the solenoid valves are connected with an electronic control unit. The device provided by the invention can effectively cool the pole sole and the steel track, so that the excessive abrasion and the adhesive welding of the pole sole and the steel track can be prevented when the magnetic track brake works.

Owner:江苏大学扬州(江都)新能源汽车产业研究所

Buffer type large torque spring return actuator

ActiveCN103672123BAvoid forceRealize the buffering effectOperating means/releasing devices for valvesValve members for absorbing fluid energyEngineeringCylinder block

The invention relates to a pneumatic executing mechanism, in particular to a buffer type large-torque spring restoration executing mechanism with a final position pneumatic buffer structure, and belongs to the technical field of pneumatic executing mechanisms. The buffer type large-torque spring restoration executing mechanism comprises a cylinder body. The outer side of a left cylinder cover is connected with a left cylinder cover pressing plate through bolts. A guide sleeve is disposed in the cylinder body. The guide sleeve is tightly pressed on the left cylinder cover through the left cylinder cover pressing plate. The right side of a right cylinder cover is connected with a converting box through bolts. The rear end of the converting box is connected with a buffer air chamber. The rear end of the buffer air chamber is connected with the rear cylinder cover of the buffer air chamber. A buffer seat is connected to the rear cylinder cover of the buffer air chamber. A buffer plunger is slidably mounted in the buffer seat. The buffer type large-torque spring restoration executing mechanism has the advantages that the drive requirements of a valve acting frequently can be satisfied, internal component damage, caused by frequent acting, of the executing mechanism can be avoided effectively, and accordingly maintenance frequency can be lowered, and economical benefits can be increased.

Owner:WUXI SMART AUTO CONTROL ENG CO LTD

A kind of anti-corrosion painting and polishing equipment for underground pipe production and processing

Owner:苏州福祺互联网科技有限公司

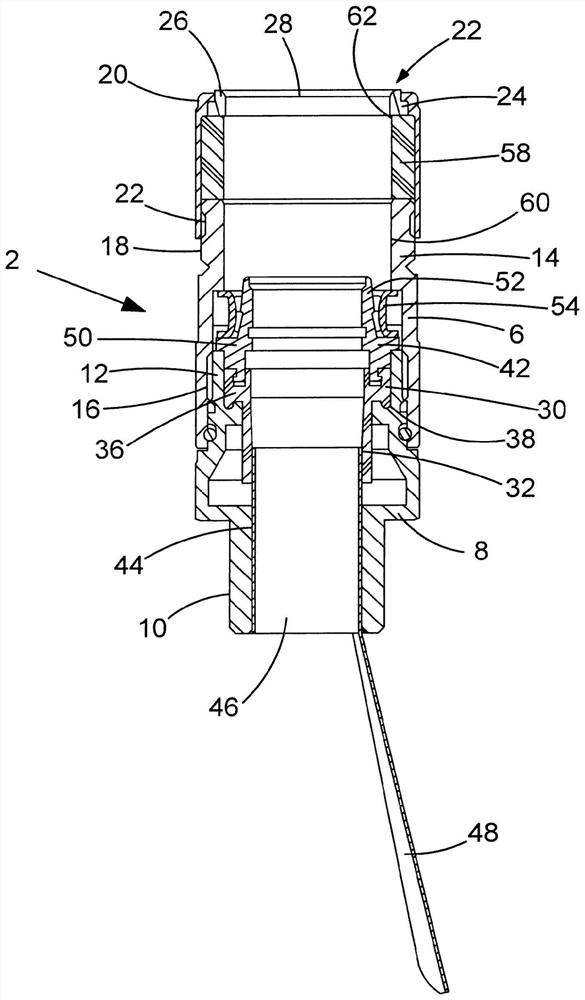

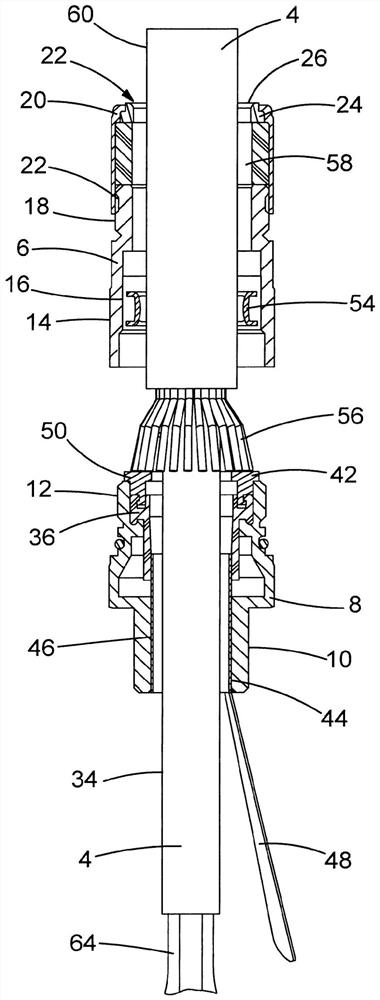

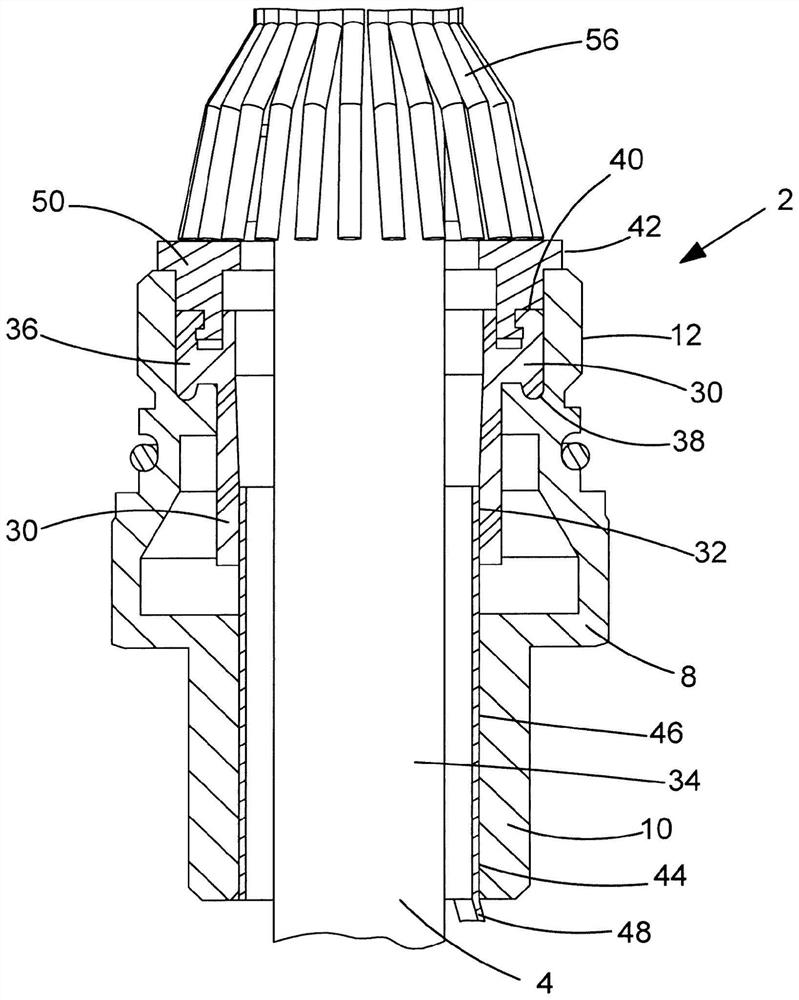

cable connector assembly

ActiveCN110178279BAvoid distortionPrecise positioningCable inlet sealing meansCable terminationsStructural engineeringElectric cables

A cable connector assembly (2) includes a connector body (6) for being installed on a cable, a first elastic sealing member (30) for forming a seal between the cable and the connector body and having a first through hole ), a seal opening device (44) for penetrating and enlarging the first through hole, the seal opening device (44) has a hollow body (46) so that part of the cable can The case passes through the first through hole, wherein the seal opening device can be removed from the connector body so that the first seal and the cable can be elastically combined.

Owner:CMP PRODS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com