cable connector assembly

A cable connector and connector technology, which is applied in the direction of cable terminals, electrical components, and cable entry sealing devices, can solve the problems of seal failure, seal bending, and excessive wear of seals, and reduce the risk of excessive wear or damage Risk, the effect of reducing the number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

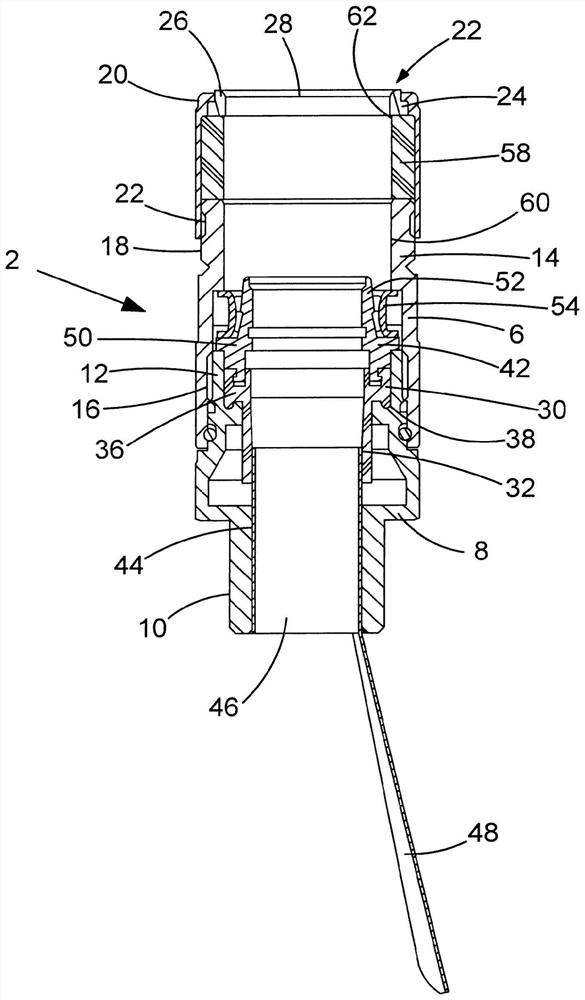

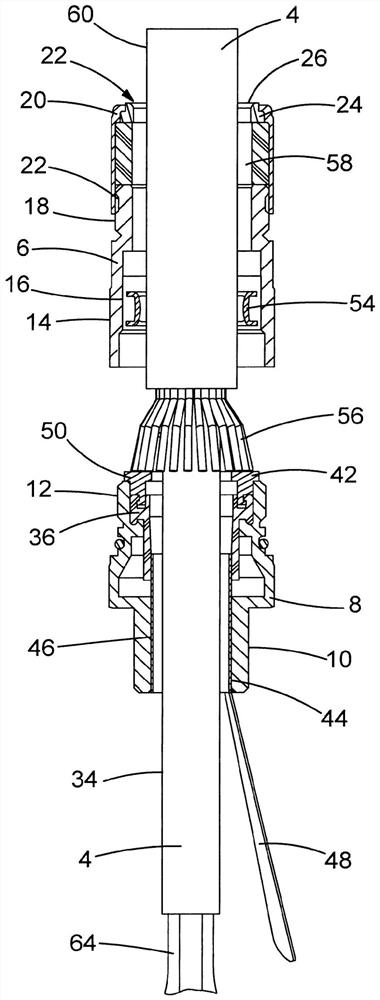

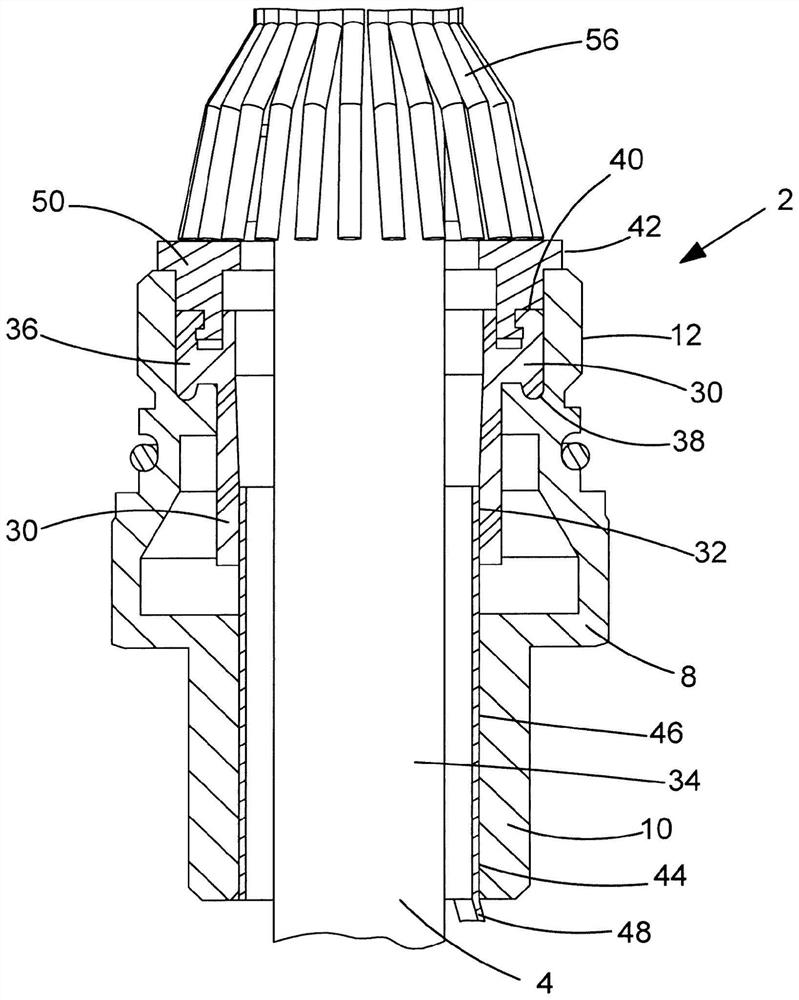

[0051] see figure 1 , used in the first embodiment of the present invention to install cables 4 ( figure 2 ) The cable connector assembly 2 in a housing (not shown) has a connector body 6 , and the connector body 6 includes a first body portion 8 and a second body portion 14 . The first body portion 8 has a first external thread 10 and a second external thread 12 for cooperating with the internal thread of a through hole in the housing (not shown) to install the cable 4 in the housing. The second body portion 14 has an internal thread 16 for cooperating with the second external thread 12 of the first body portion 8 , and an external thread 18 . The third body 20 has internal threads 22 for cooperating with the external threads 18 of the second body 14 and a through hole 22 for cooperating with the shoulder 24 of the ferrule 26 to locate the ferrule 26 . The ferrule 26 has a through hole 28 for the cable 4 to pass through.

[0052] The elastic first seal 30 has a first thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com