Overload protective system and method of excavator working devices and excavator

A working device and overload protection technology, which is applied to mechanically driven excavators/dredgers, earth movers/shovels, construction, etc., can solve problems such as increasing the replacement rate of spare parts, breaking or deforming, and reducing service life. Reach the effect of reducing the requirement of operating skills, reducing the replacement rate of spare parts, and improving the level of intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

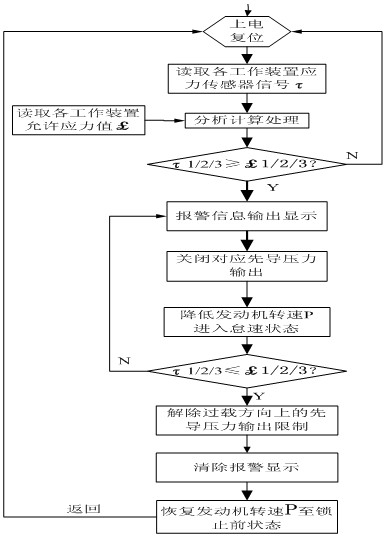

[0024] The present invention will be further described below in combination with principle diagrams and specific operation examples.

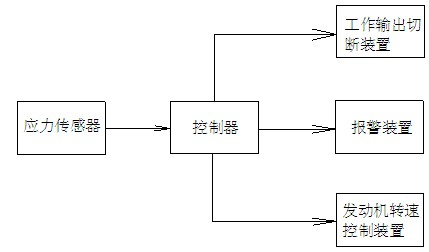

[0025] Such as figure 1 As shown, the embodiment of the present invention includes a controller and several stress sensors, and the controller is connected with several stress sensors in sequence, and also includes an engine speed control device and an alarm device, and the controller is respectively connected with the engine speed control device and the alarm device, and several stress sensors The sensors are respectively installed on multiple working parts of the excavator, and the multiple working parts of the excavator include a bucket, an arm and a boom; and a working output cut-off device connected with a controller.

[0026] The stress sensor relies on the deformation of the extruded material to cause the change of the cross-sectional area and length, and the change of the resistance value, so as to output different voltage values to m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com