Patents

Literature

38results about How to "Adjust arc" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

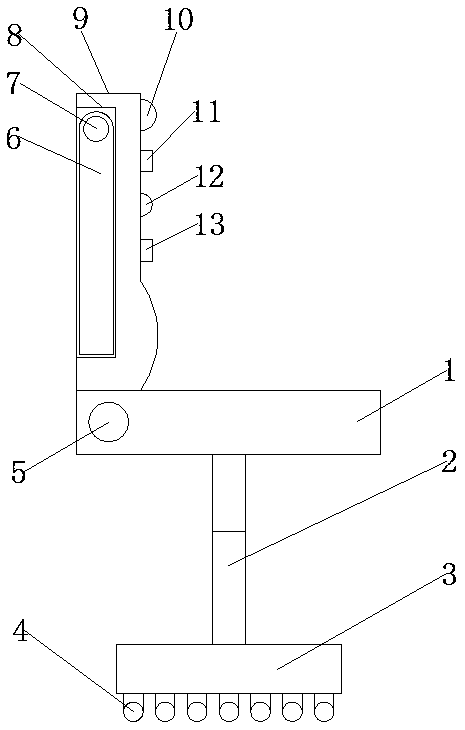

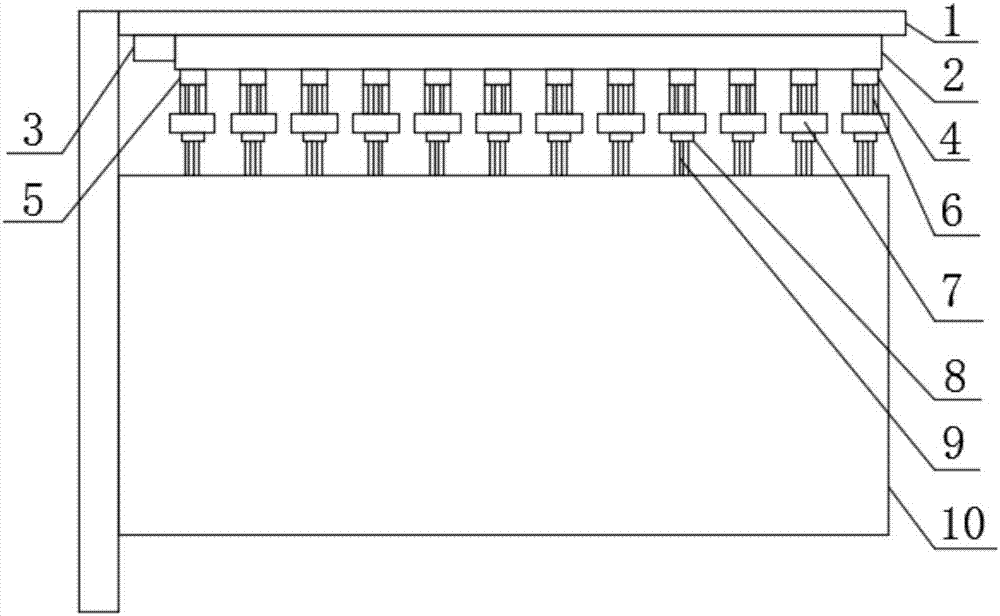

Bending machine for curtain wall metal plate production

The invention discloses a bending machine for curtain wall metal plate production, and belongs to the field of curtain walls. The bending machine comprises a base, wherein a bottom plate is arranged at the top surface of the base, a pressing plate is arranged above the bottom plate, pressing studs are fixed on the two opposite side walls of the base, and through holes matched with the pressing studs are formed in the pressing plate; the two opposite side walls of the base are rotationally connected with an adjusting base, and the base is also provided with an adjusting motor for driving the adjusting base to rotate; the adjusting base is slidingly connected with a pressing base, and the adjusting base is also provided with an adjusting mechanism for driving the pressing base to slide; a bending plate is rotationally connected between the two pressing bases, and bending motors for driving the bending plate to rotate are also installed on the pressing bases. The bending machine has reasonable design, and in terms of use, the bending machine can not only prevent the deviation of the curtain wall metal plate during the bending process, but also flexibly bend out the curtain wall metalplate with different arcs and angles.

Owner:安徽国天节能科技有限公司

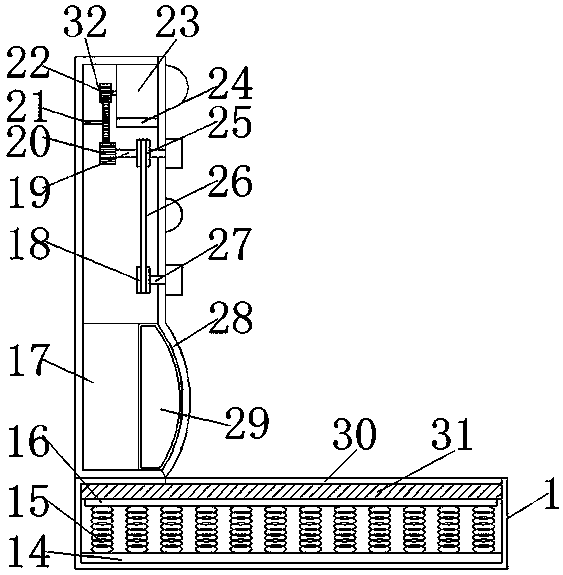

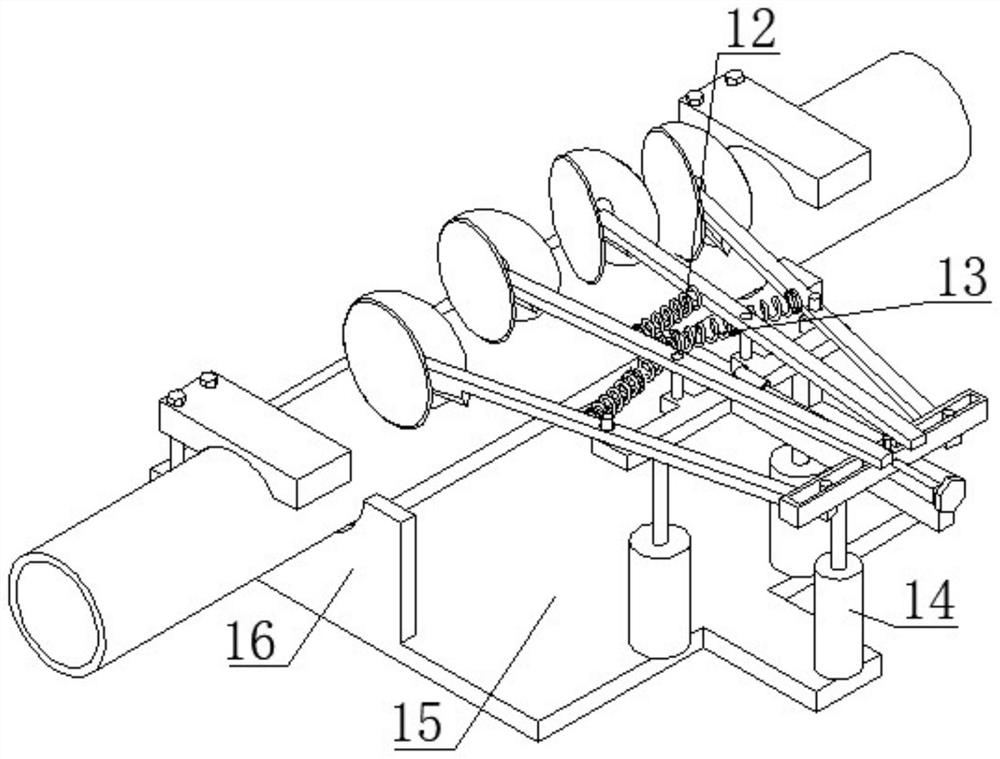

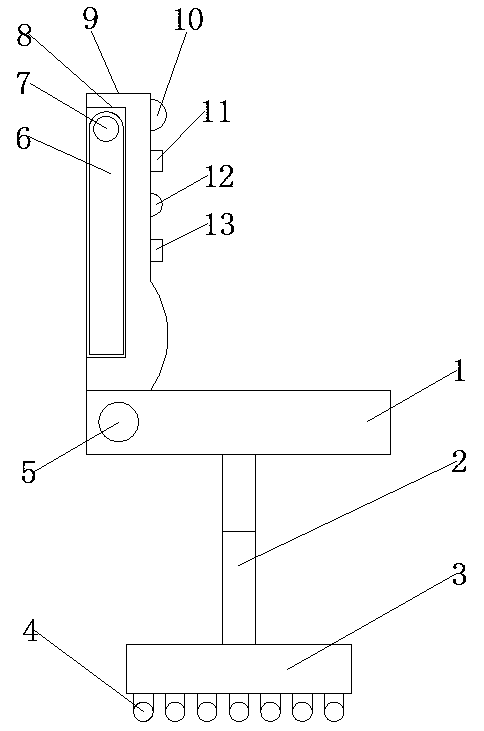

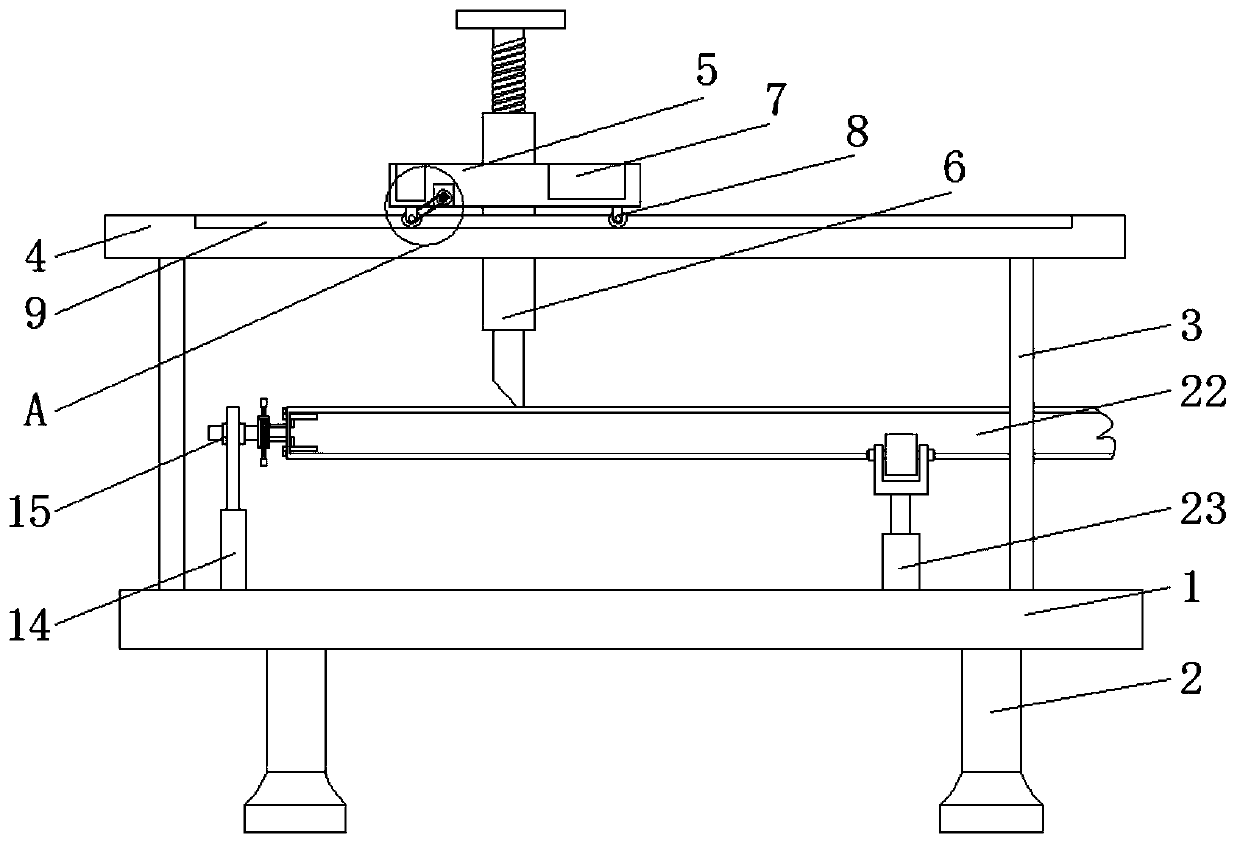

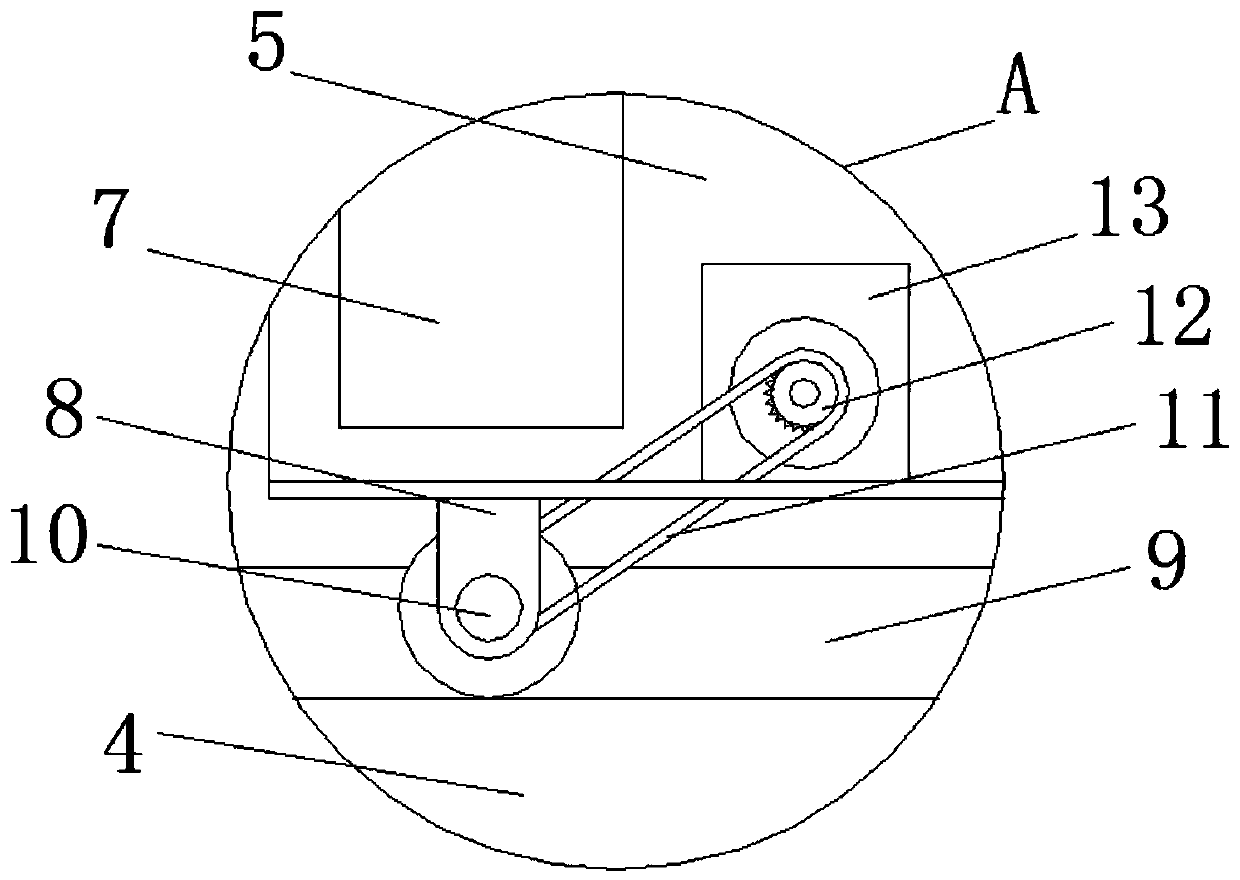

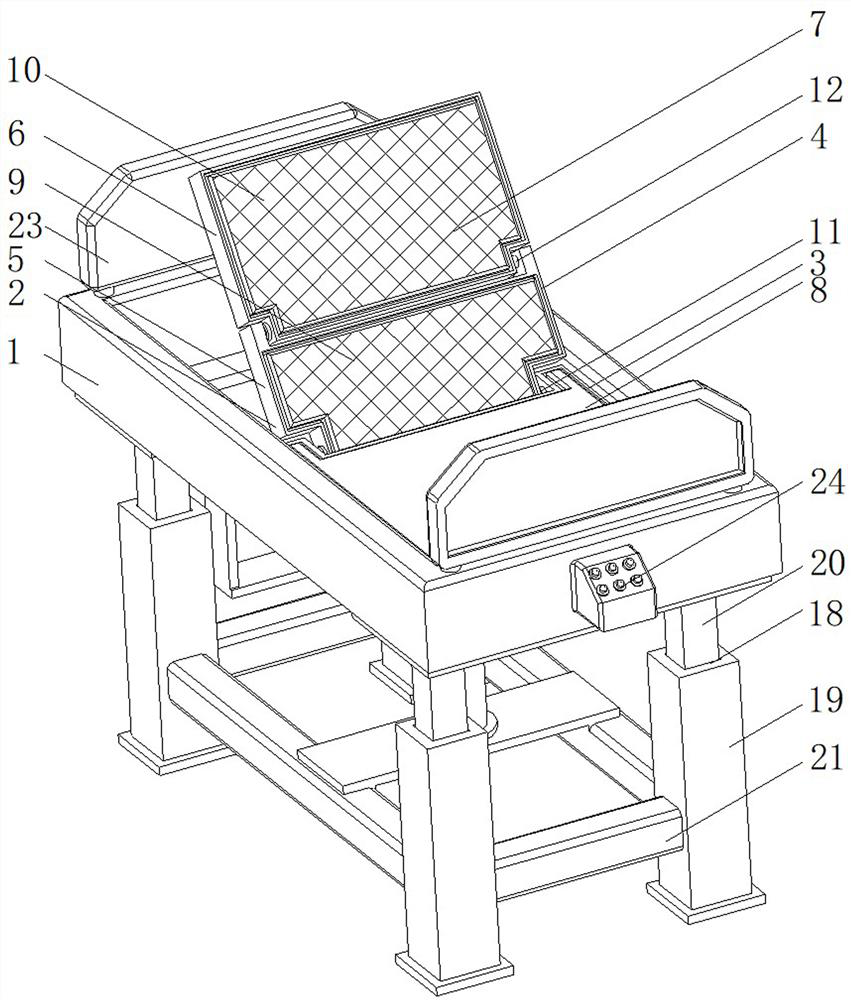

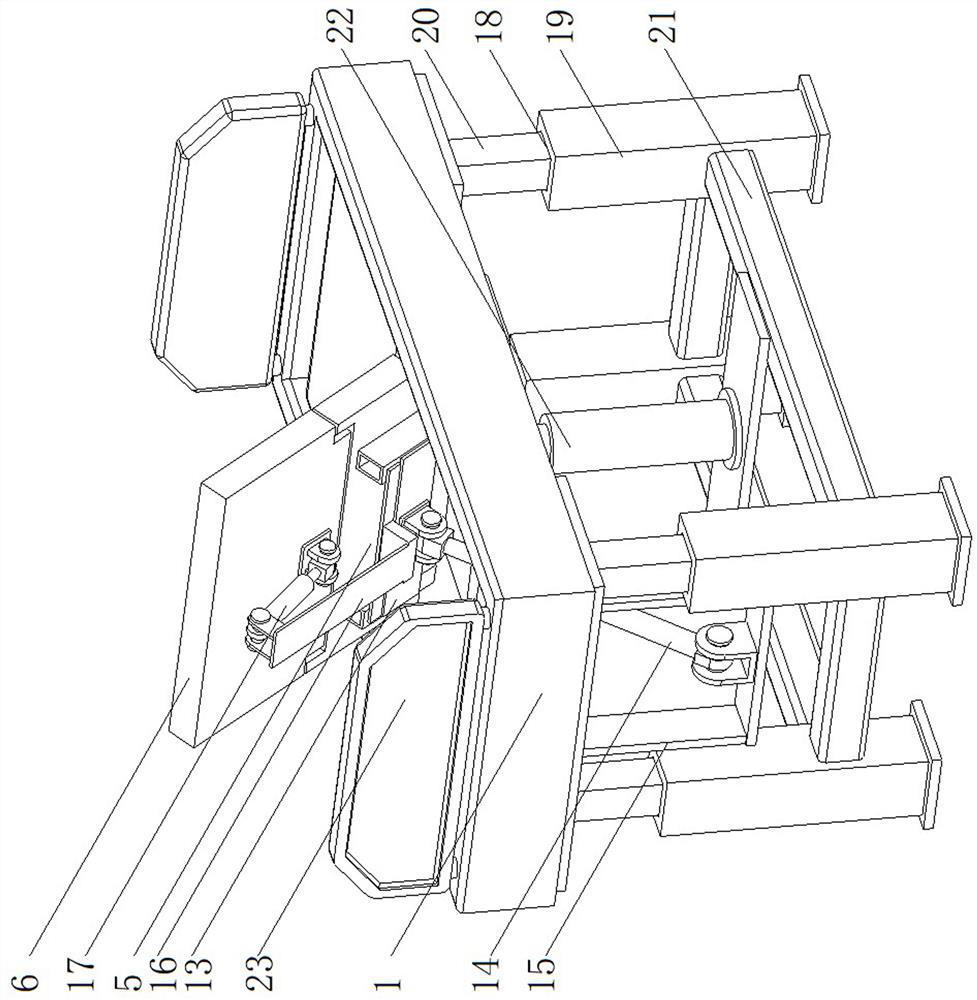

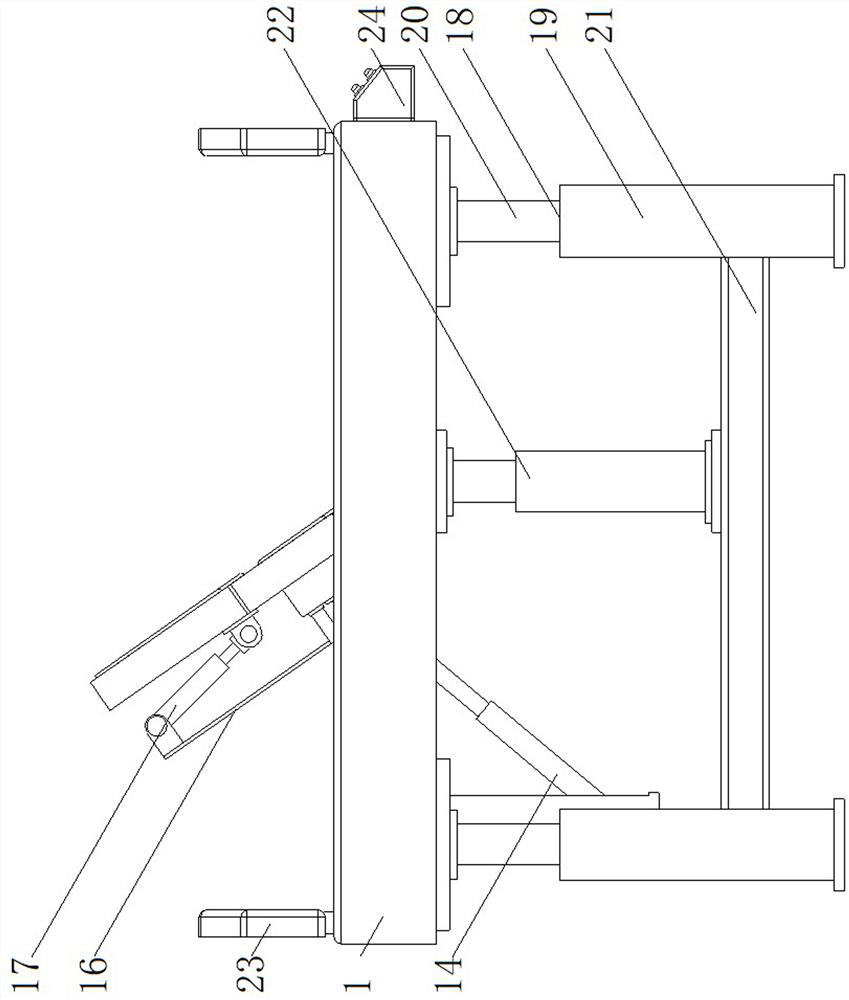

Anticorrosive paint spraying and grinding equipment for production and processing of buried pipe

ActiveCN109623622AAdjust arcStable supportPolishing machinesGrinding drivesEngineeringMechanical engineering

The invention relates to the technical field of pipe processing equipment and discloses anticorrosive paint spraying and grinding equipment for production and processing of a buried pipe. The anticorrosive paint spraying and grinding equipment comprises a machine table; supporting legs are fixedly installed at the bottom end of the machine table; fixing rods are fixedly installed at the top end ofthe machine table; the top ends of the fixing rods are fixedly connected with a horizontal plate; a transmission machine is placed on the horizontal plate; the middle part of the transmission machineis fixedly provided with a fixed point grinder in a sleeving manner; a component positioned at the side surface of the fixed point grinder is fixedly installed inside the transmission machine; movingwheels are arranged at the bottom end of the transmission machine; and the moving wheels are matched with fixing grooves which are formed in the top of the horizontal plate. According to the anticorrosive paint spraying and grinding equipment for production and processing of the buried pipe, a transmission driven plate is moved toward a direction corresponding to a screw handle by twisting the screw handle so that two externally connected rods are used for driving two contact plates to expand; by regulating the radian of the two contact plates, material pipes which are different in diameter can be conveniently supported and positioned; and a bearing frame device is used for auxiliary support for the position, thereby effectively guaranteeing processing of the material pipes which are different in length.

Owner:苏州福祺互联网科技有限公司

Construction method of special-shaped curved surface concrete roof

ActiveCN111962870AReduce quality problemsAdjust arcRoof covering using sealantsForms/shuttering/falseworksRebarHorizontal projection

The invention relates to a construction method of a special-shaped curved surface concrete roof, which comprises the following steps of: dividing arc-shaped sections of the roof, namely dividing the sections of the roof into a plurality of arc-shaped surfaces in the transverse and longitudinal directions on the arc-shaped roof according to a design drawing; performing computer pre-arranging, positioning the whole arc-shaped surface according to the divided arc-shaped surfaces and the four points of each arc-shaped surface, and modeling the arc-shaped roof; positioning and paying off: positioning the arc-shaped roof by adopting a three-dimensional horizontal projection method; positioning and erecting the support frames, namely positioning the support frames on the lower-layer structure surface in a longitudinal and transverse arrangement line manner according to the positioning result of the computer, and marking the positioning coordinates and height of each support point on the lower-layer structure surface; mounting a template and reinforcing steel bars; pouring concrete; maintaining; and removing the template. The construction method of the special-shaped curved surface concrete roof has the effect of improving the quality of the special-shaped curved surface concrete roof.

Owner:SUZHOU JINXIN CONSTR GRP

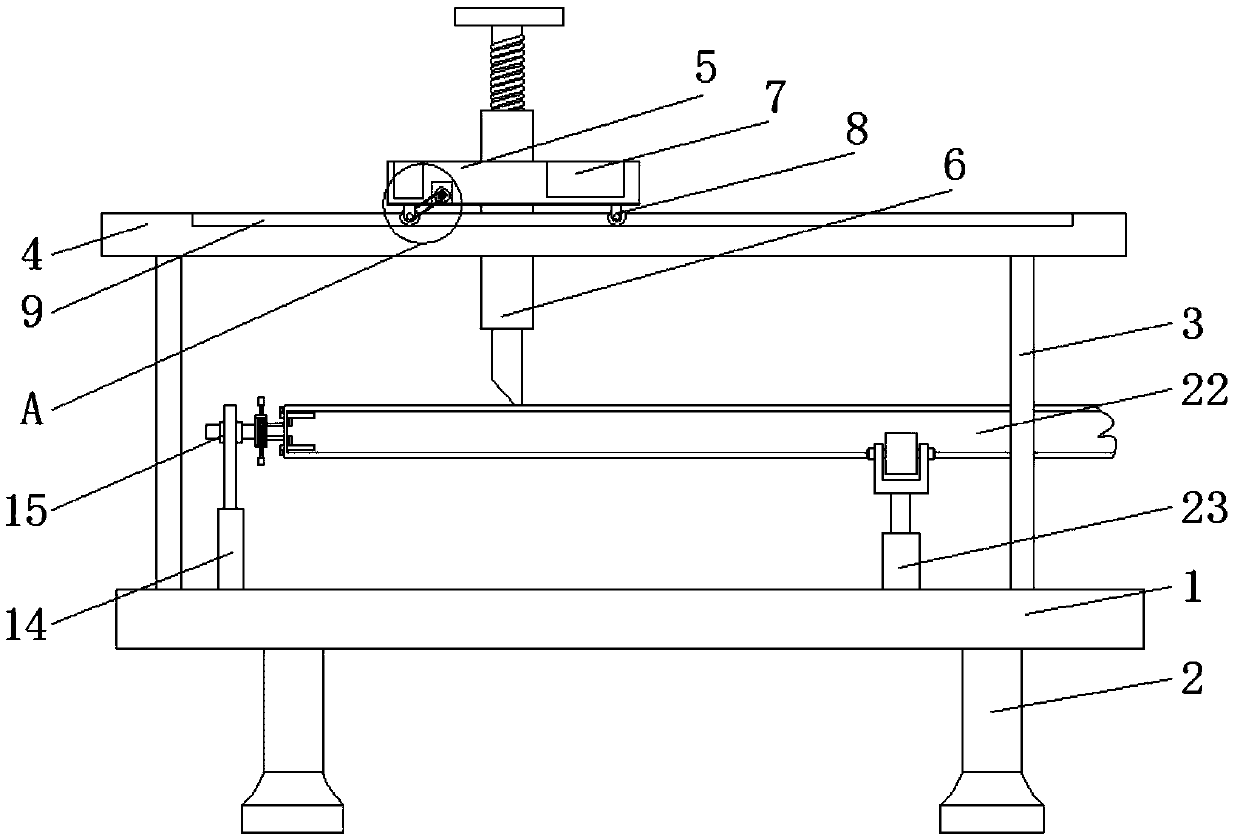

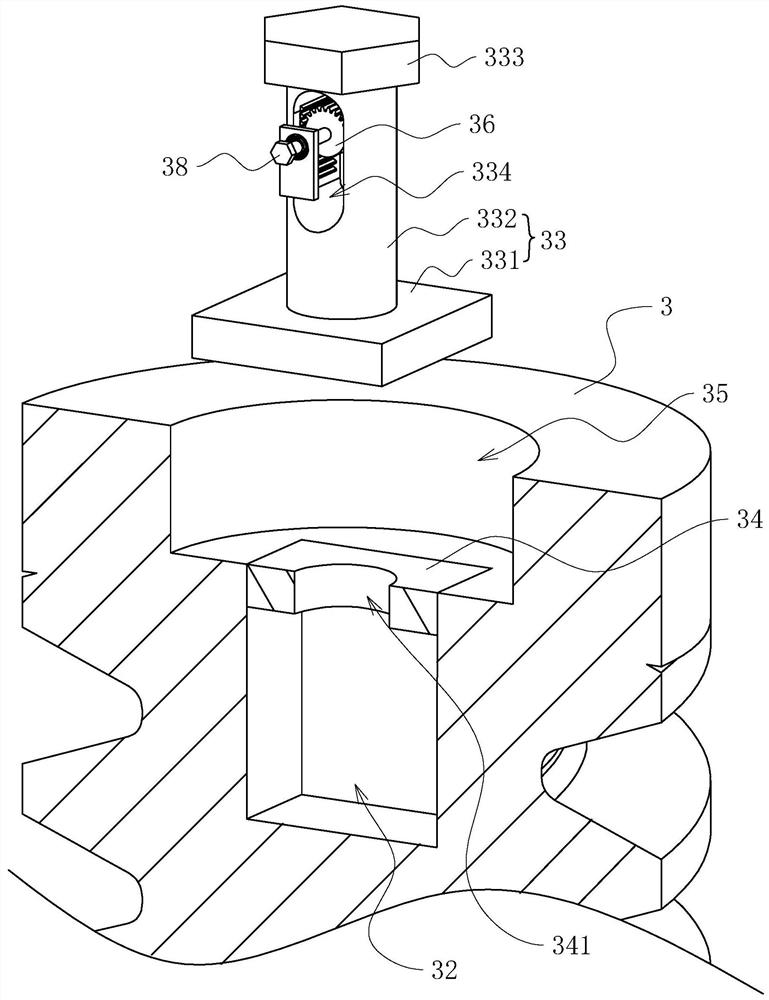

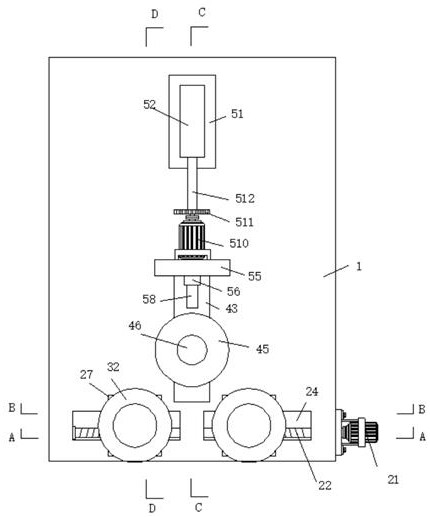

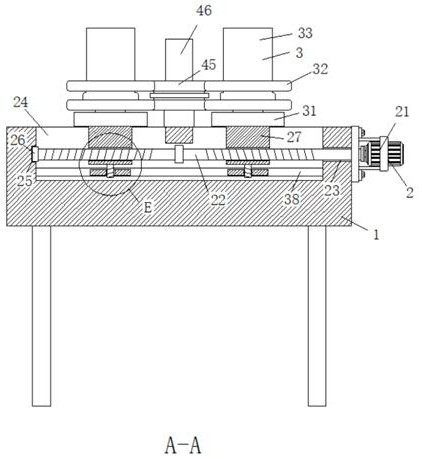

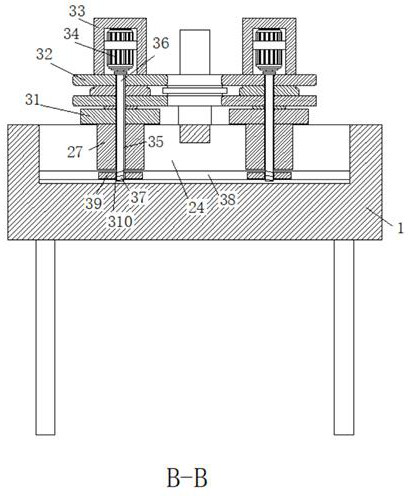

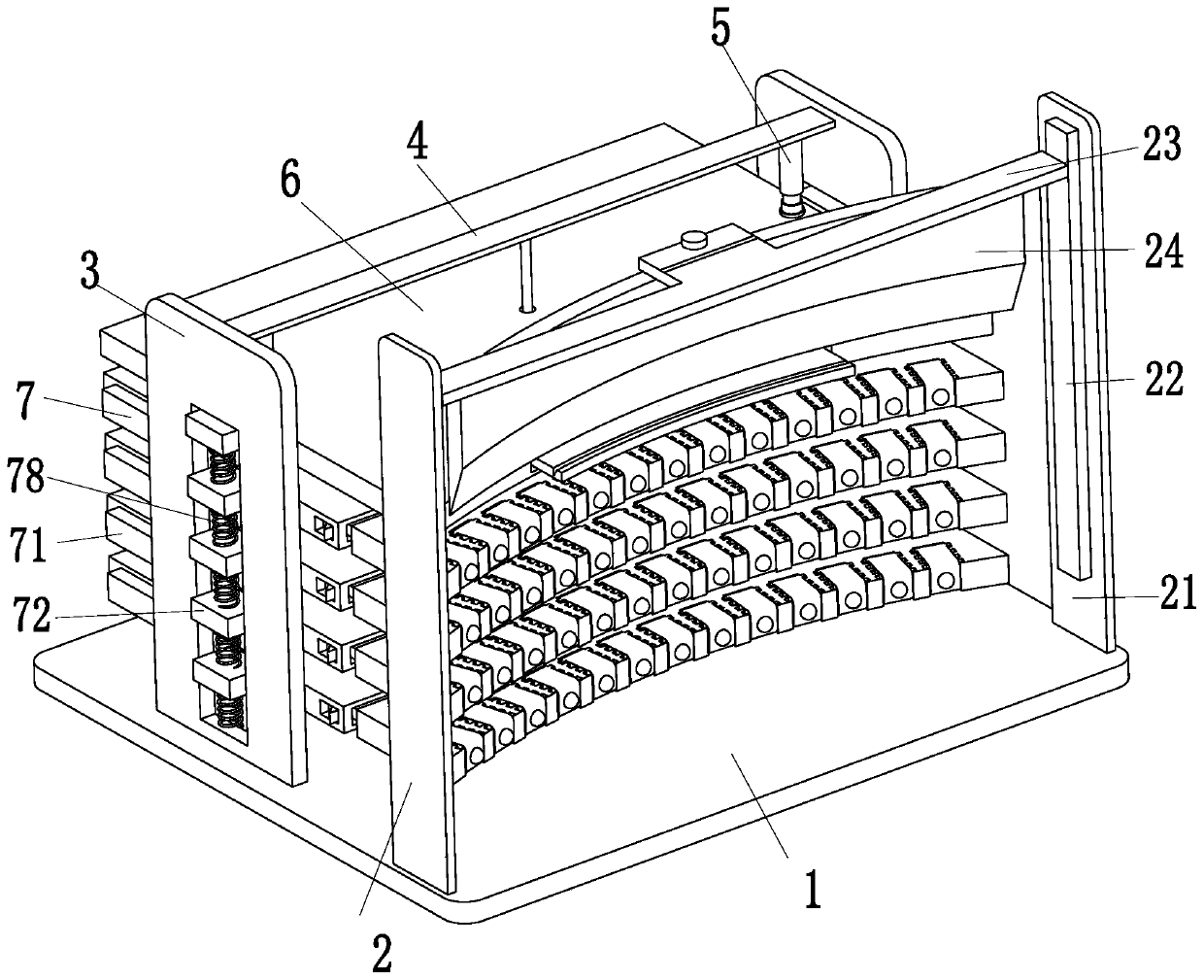

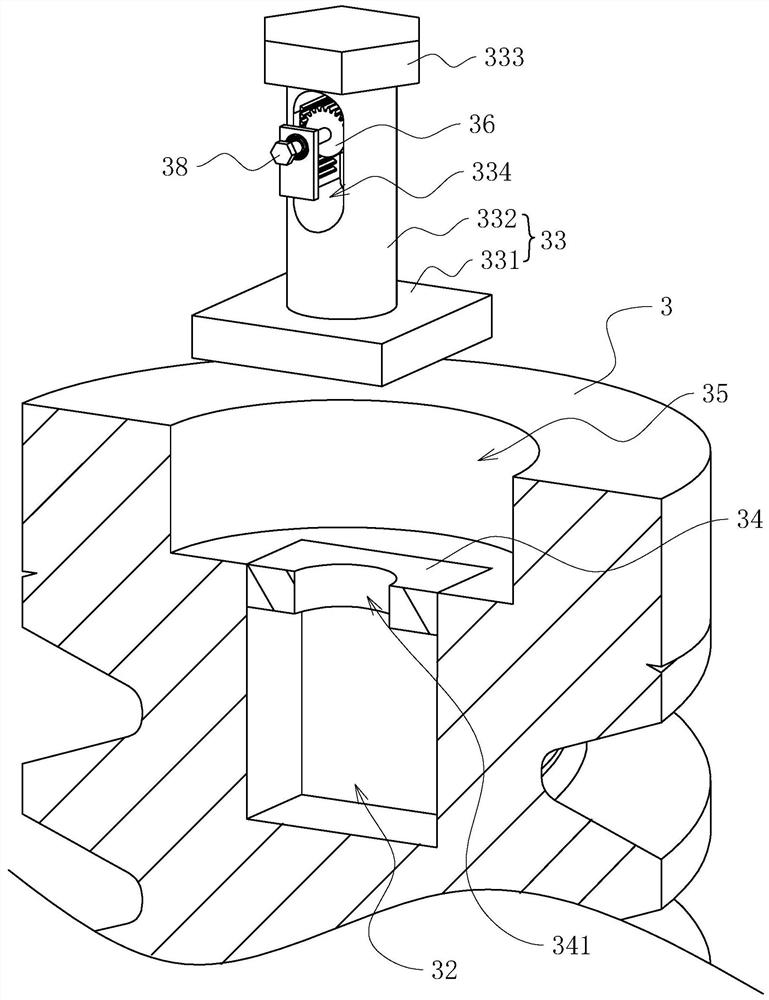

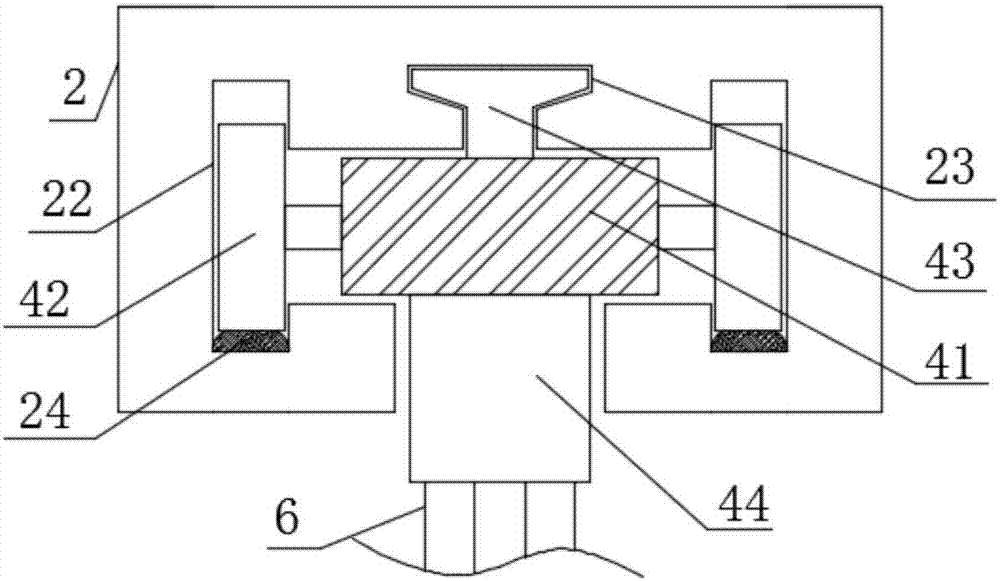

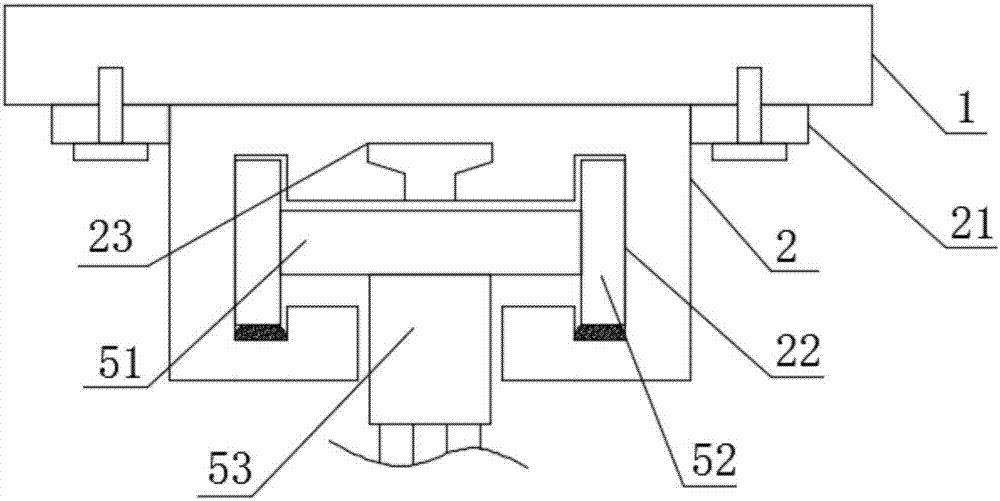

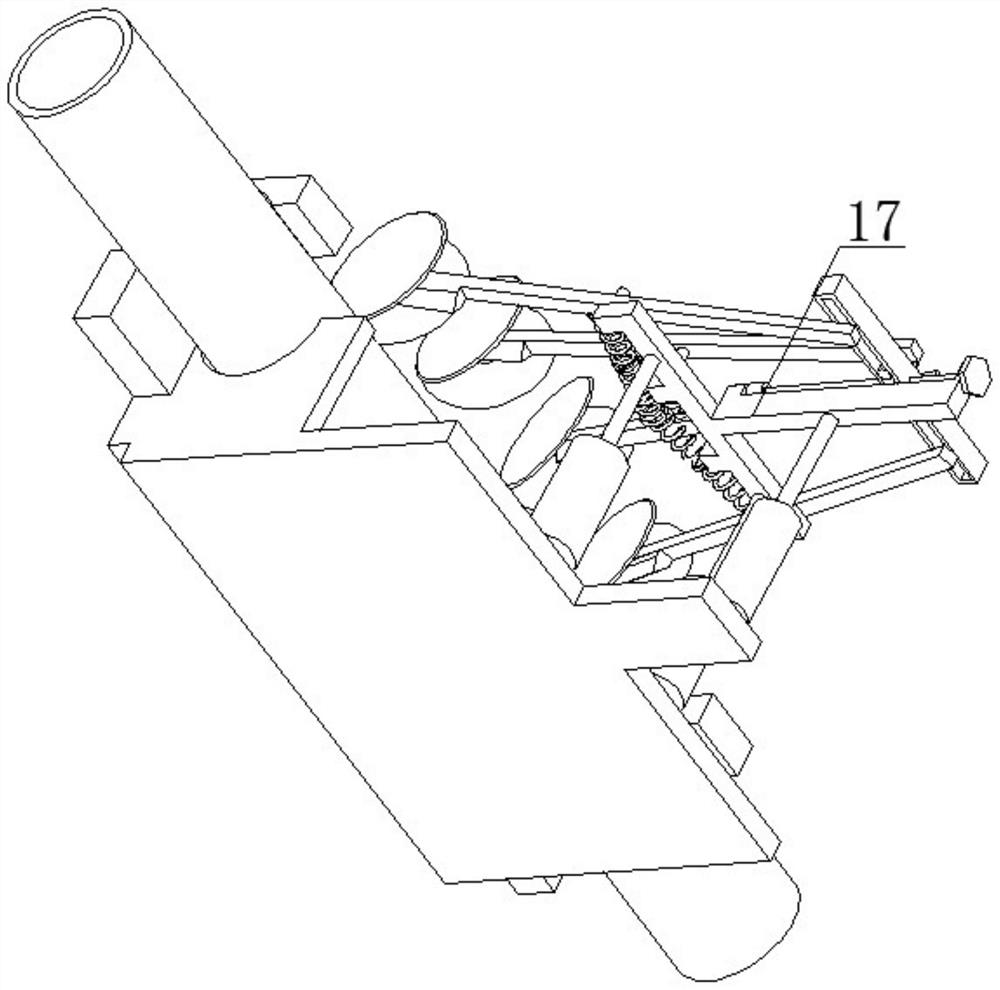

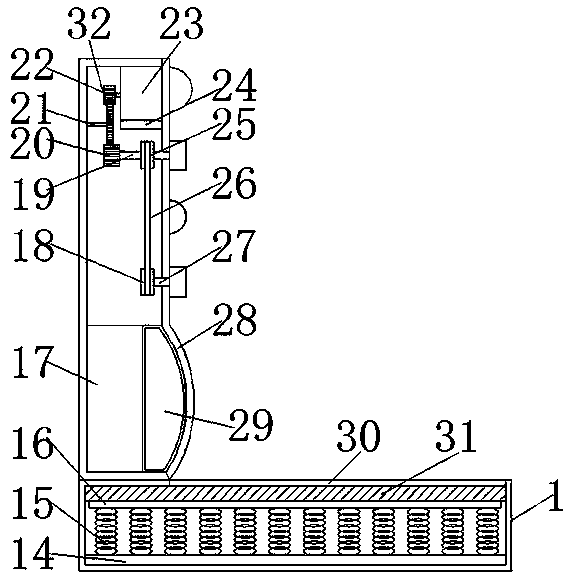

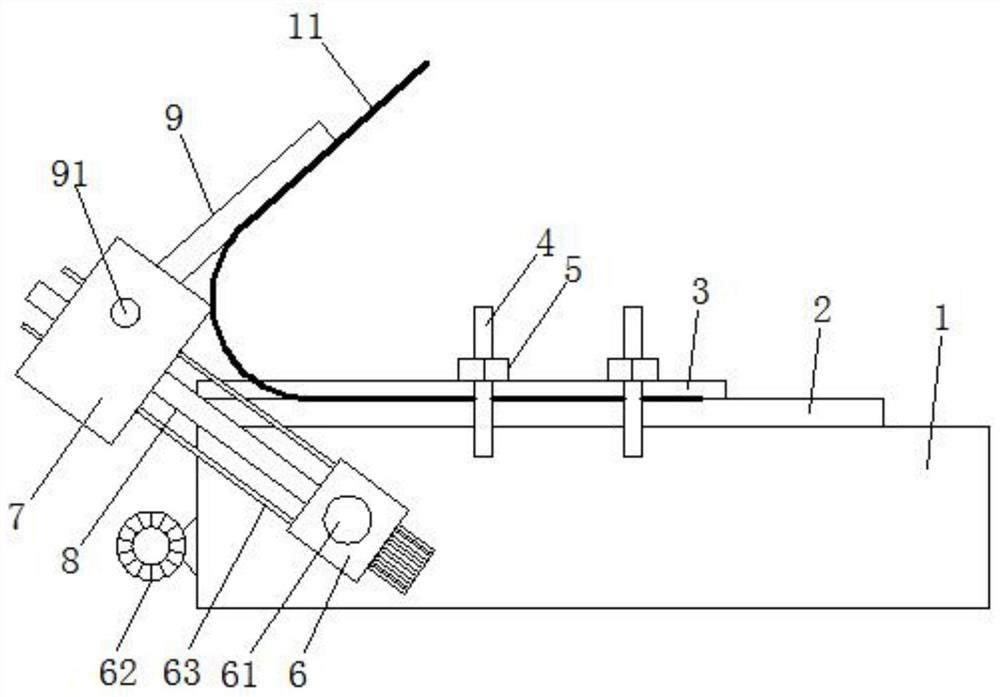

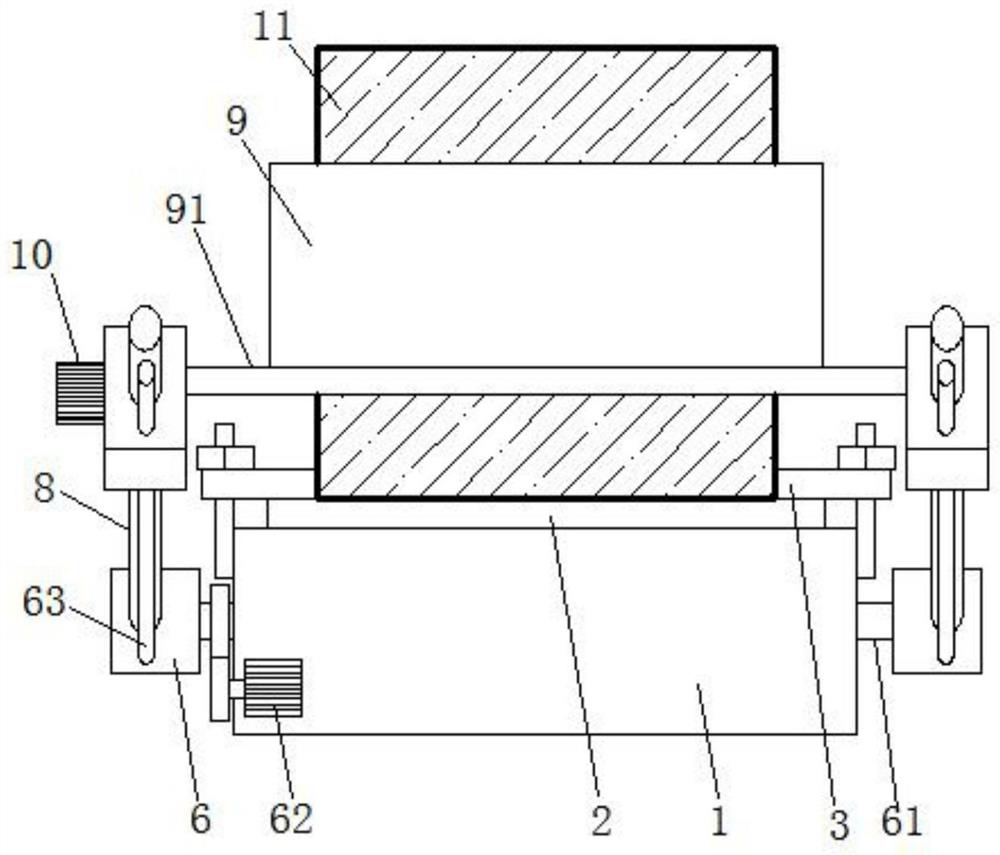

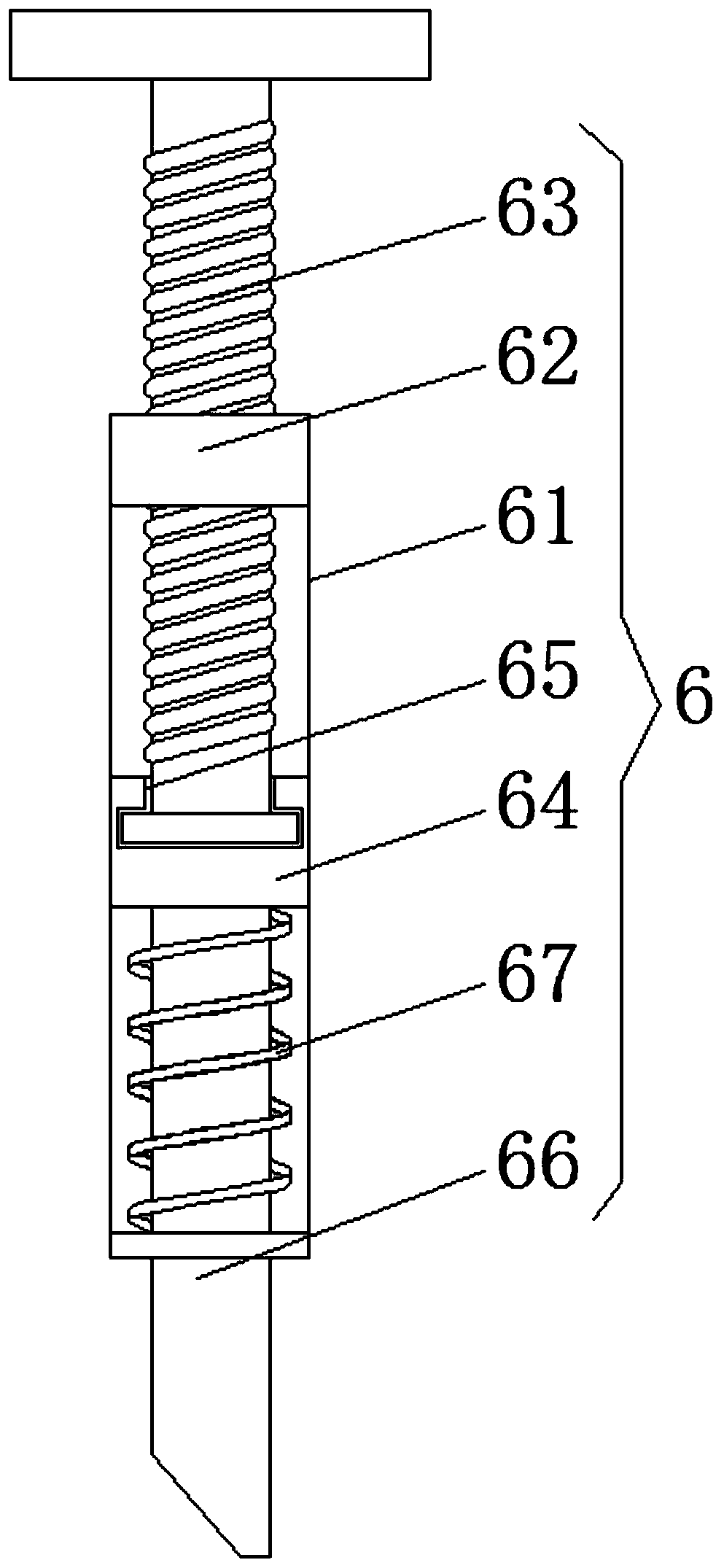

Numerical-control roller bending device used for step guide rail bending, molding and processing

PendingCN112122418APrecise Control of SpacingAdjust the amount of bendingElectric machinerySlide plate

The invention discloses a numerical-control roller bending device used for step guide rail bending, molding and processing. The numerical-control roller bending device used for step guide rail bendingcomprises a main body, wherein a spacing regulating mechanism is arranged inside the main body; two fixed mold mechanisms are arranged at the upper end of the spacing regulating mechanism; a movablemold mechanism is arranged on the upper surface of the main body; and one end of the upper surface of the main body is equipped with a pressure mechanism. The numerical-control roller bending device disclosed by the invention has the beneficial effects that: spacing regulation between the two fixed mold mechanisms is more synchronous by the spacing regulating mechanism via a two-way threaded rod,and manual operation is not needed; step guide rails of different bending amplitudes are rolled by regulating different spacings, and contact points between fixed molds of the two fixed mold mechanisms and the step guide rails change, so that a slide block can be effectively fixed through a slide plate and a limiting slot without sliding; and a third motor is used for regulating, so that a strokeof a hydraulic rod can be changed to change movement amount of the movable molds to change depth of roller-pressing, and thus, roller-pressing radian of the step guide rails can be freely regulated.

Owner:JIANGSU TONGLI MACHINERY

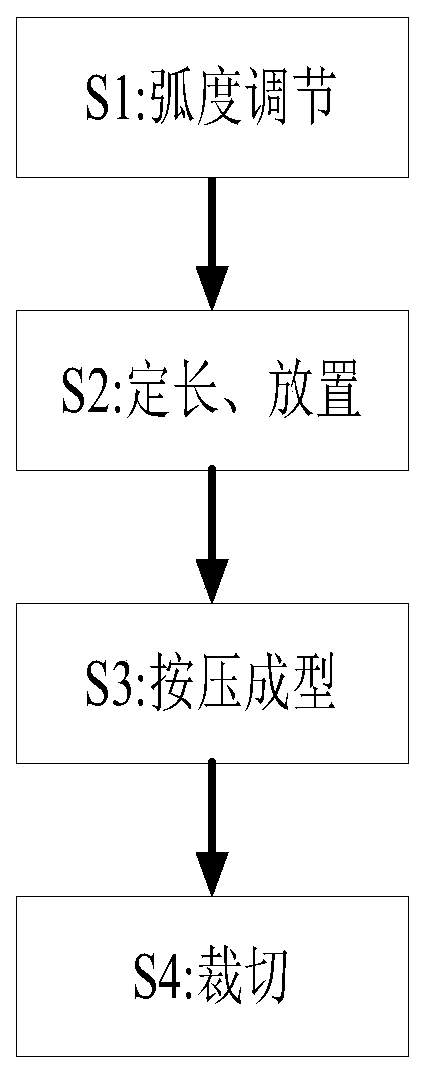

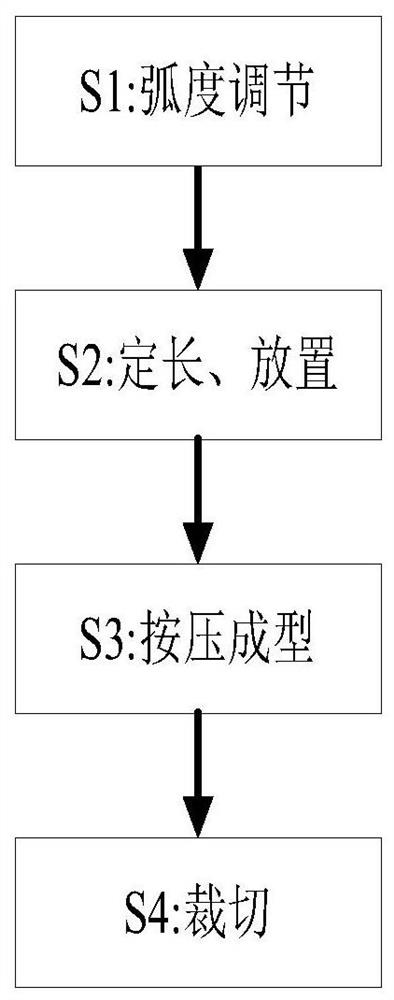

Shaping and cutting processing method for corrugated board for manufacturing packaging carton

InactiveCN111231410AAvoid Scratching DeviationsAct as a guidePaper-makingBox making operationsCartonStructural engineering

The invention provides a shaping and cutting processing method for a corrugated board for manufacturing a packaging carton. The shaping and cutting processing method is operation completed by matchinga bottom plate, a cutting device, two supporting frames, a connecting plate, a pressing air cylinder, a lower plate pressing set and a plate pressing set; the shaping and cutting processing method can solve the problems that stagger and deviation situations between stacked corrugated boards are likely to be caused by pressure when the stacked corrugated boards are pressed downwards and cut due tothe fact that the stacked corrugated boards have a certain thickness, so that cutting opening positions of the cut corrugated boards are different; and when existing arc-shaped cutters carry out downward-pressing and cutting, due to the fact that various cutters are different in radian, corresponding dies for guiding the cutters are difficult to be provided, and due to the fact that certain resistance exists in the downward-cutting process, the problems that cutting openings deviate inwards when the cutter is pressed downwards and the like are prone to occur.

Owner:许昌京昌包装有限公司

Shaping plate and shaping mold for civil engineering

ActiveCN113090002AVersatileImprove general performanceAuxillary members of forms/shuttering/falseworksForming/stuttering elementsStructural engineeringMechanical engineering

The invention provides a shaping plate and a shaping mold for civil engineering, and belongs to the technical field of pouring molds. The shaping plate comprises a first mounting assembly, a second mounting assembly and the shaping plate, wherein both ends of the second mounting assembly are respectively connected with adjacent first formworks; a plurality of shaping plates include first formworks, second formworks and at least two adjusting assemblies; the second formworks are of an arc-shaped structure and are located on one side of the first formworks; and the convex surfaces of the second formworks make contact with the first formworks. When a cylindrical concrete member needs to be poured, a plurality of second formworks are spliced so as to form a cylindrical pouring cavity; and when a prismatic concrete member needs to be poured, a corresponding number of first formworks are selected according to the shape of a prism which needs to be poured, the first formworks are spliced so as to form a prismatic pouring cavity, and therefore, the prismatic concrete member can be poured conveniently.

Owner:XINGTAI POWER SUPPLY +2

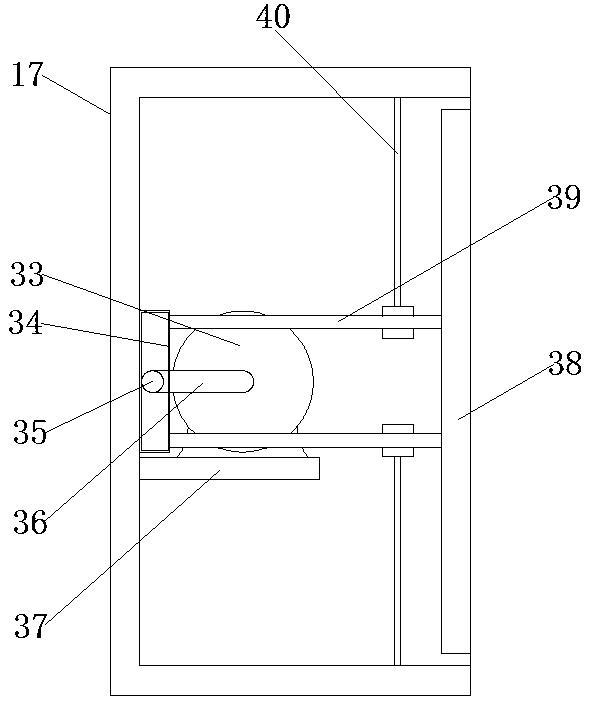

Pressing and rounding mechanism for steel plate

InactiveCN106001200AAccurately placed horizontallyAdjust arcMetal-working feeding devicesPositioning devicesHydraulic cylinderSheet steel

The invention discloses a steel plate rounding mechanism, which belongs to the field of steel processing mechanical equipment. The invention includes a pressure circle support, a support plate support, a support plate roller, a support plate hydraulic cylinder, a lifting support, a steel plate pressure roller, and a lifting hydraulic cylinder. The support plate supports are symmetrically arranged on both sides of the pressure circle support, and the upper end of the support plate support rotates horizontally. The bearing plate roller is connected, and the bearing plate hydraulic cylinders are arranged symmetrically on both sides of the lower side of the bearing plate support. Lifting hydraulic cylinders are arranged vertically downward on both sides of the middle part above the support, the lifting support is horizontally arranged at the output end of the lifting hydraulic cylinder, and the steel plate pressing roller is horizontally connected to the lifting support. The invention has a reasonable structural design, can quickly and efficiently round steel plates of various sizes and specifications smoothly and conveniently, and meets the needs of production and use.

Owner:钟彩凤

Electric massage chair for medical care

The invention provides an electric massage chair for medical care, and relates to the field of medical care devices. The electric massage chair comprises a base, a first outer sleeve is arranged at the top of the base, a sponge mat is arranged at the bottom of the bottom of the first outer sleeve, a supporting plate is fixedly connected at the bottom of the sponge mat, springs are fixedly connected at the bottom of the supporting plate, a damping rubber mat is fixedly connected at the bottom of the spring, a damping rod is fixedly connected at the bottom of the base, and a first rotating shaftis arranged on the left side of the base. The electric massage chair for medical care can be opened to form a bed through a supporting leg on a backrest and is rich in function, the massage chair canbe more conveniently and flexibly moved through universal wheels at the bottom of a supporting seat, a lot of labor and time is saved, people can feel more comfortable when sitting on the chair through springs and the sponge mat in the base, a pushing device pushes an air bag, the arc degree of the waist of the backrest can be adjusted, arc requirements of the back and the waist of different people can be met, and the electric massage chair is more comfortable.

Owner:邓纪英

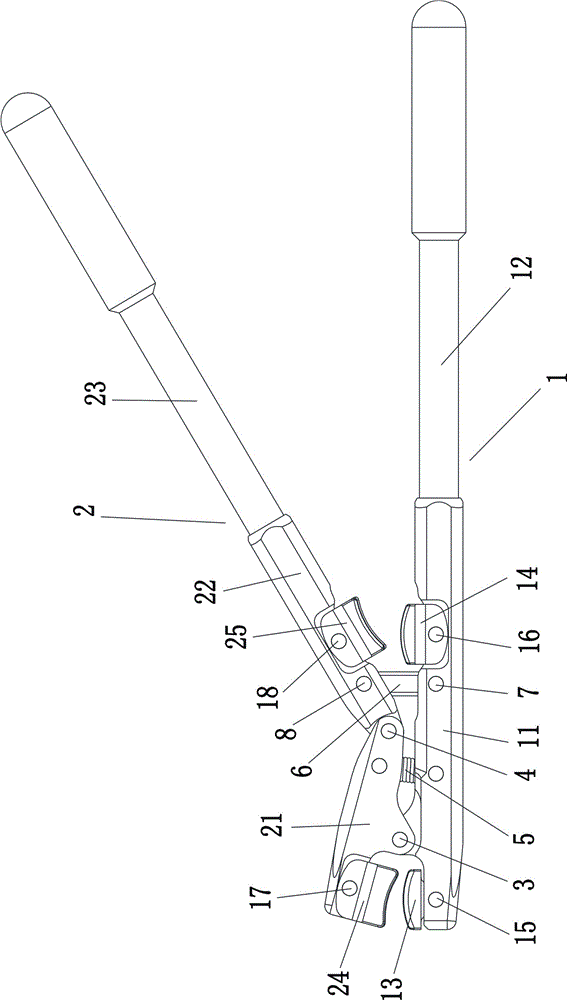

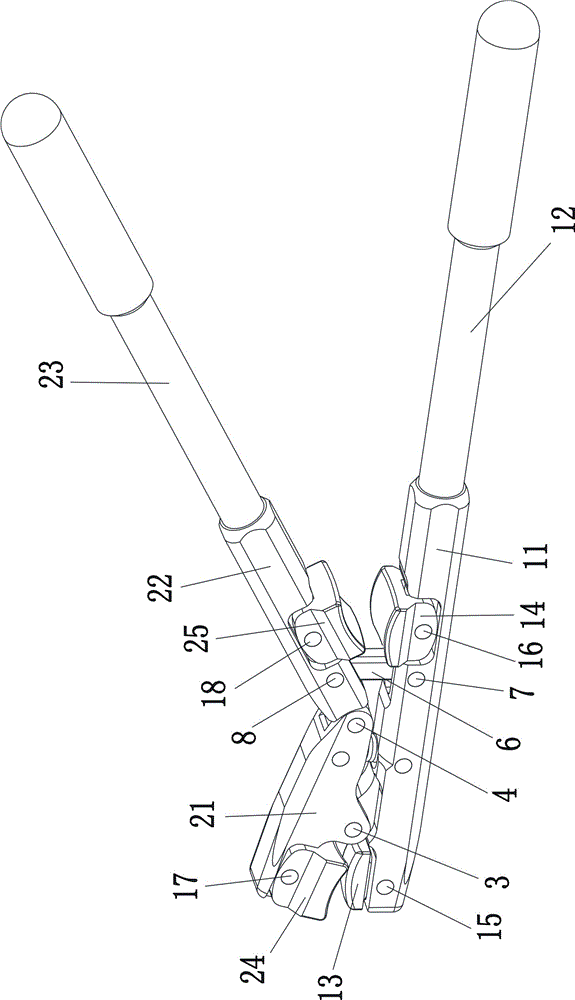

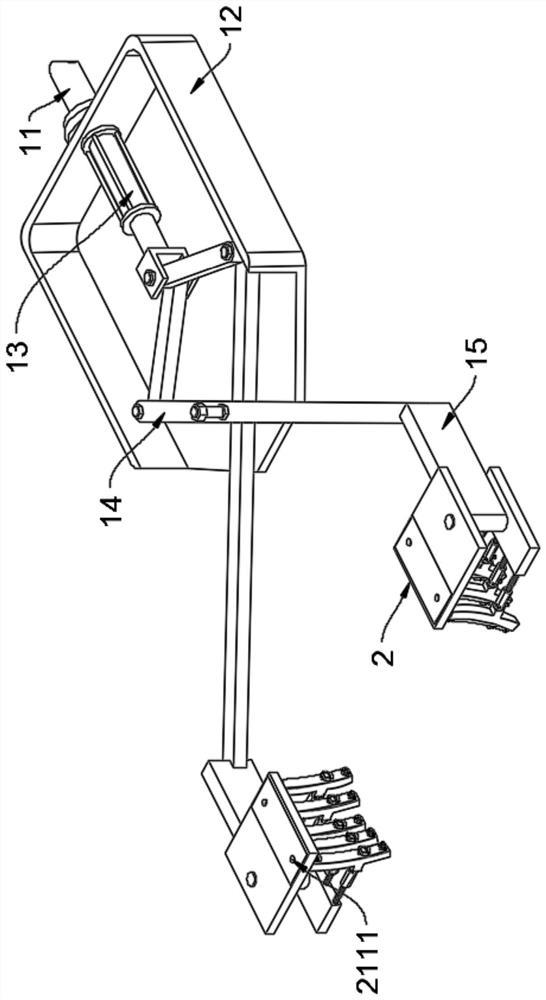

Dual-joint board bending forceps

ActiveCN106236239APress firmlyNot easy to come outSurgical forcepsBone platesCERVICAL FIXATIONOn board

The invention discloses dual-joint board bending forceps being used by cooperating with an anterior cervical fixation system in a spinal fixation operation. The board bending forceps are provided with a left forceps handle and a right forceps handle which are movably connected through a first connecting shaft. The dual-joint board bending forceps are structurally characterized in that the left forceps handle is composed of a left pincer head and a left handle which are fixedly connected; the right forceps handle is composed of a first right forceps head, a second right forceps head and a right handle, one end of the second right forceps head is movably connected with the first right forceps head through a second connecting shaft, and the other end of the second right forceps head is fixedly connected with the right handle; a spring is connected between the first right forceps head and the left forceps head, and a connecting rod is movably connected between the second right forceps head and the left forceps head; the head of the left forceps head is provided with a first left cushion block, and the head of the first right forceps head is provided with a first right cushion block matched with the first left cushion block; a forceps body of the left forceps head is provided with a second left cushion block, and a forceps body of the second right forceps head is provided with a second right cushion block matched with the second left cushion block. The board bending forceps have the advantages of being easy and convenient to operate, accurate in positioning, firm in clamping and high in stability.

Owner:ZHEJIANG KANGCI MEDICAL TECH

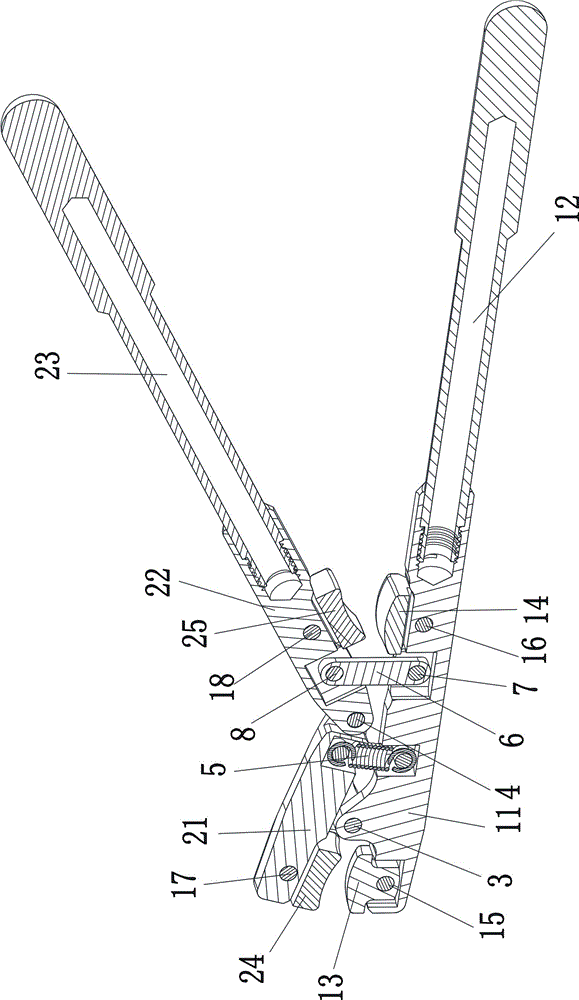

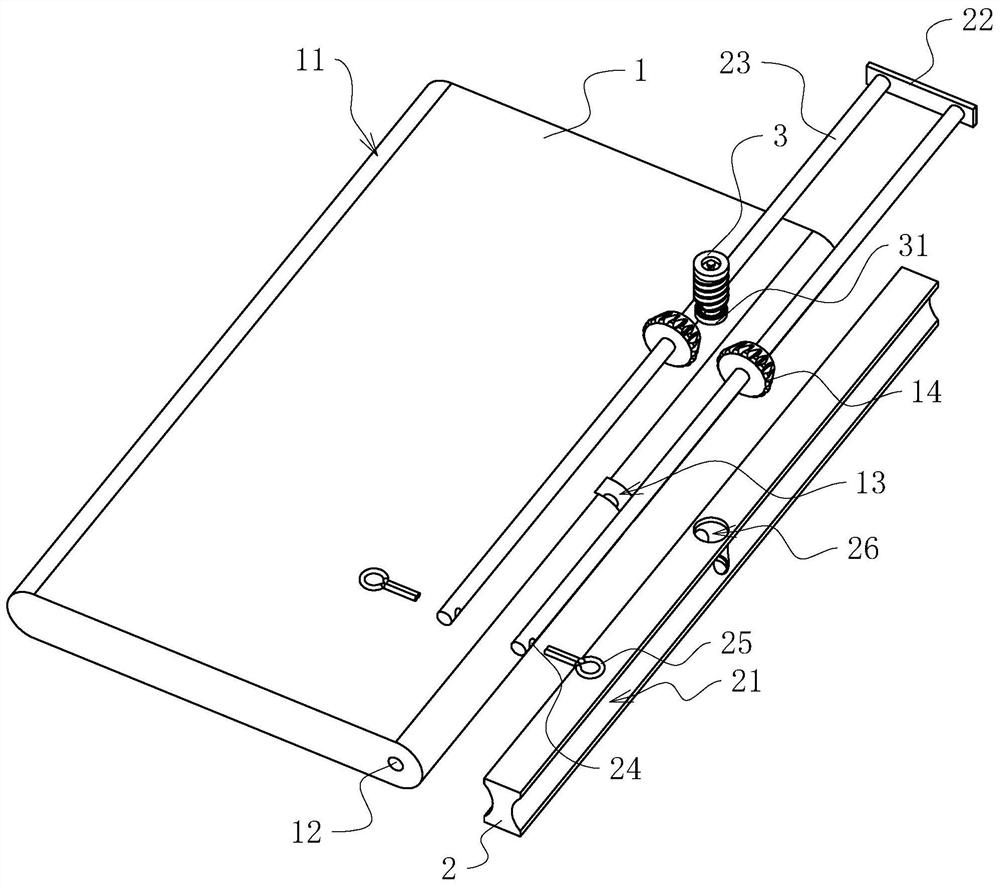

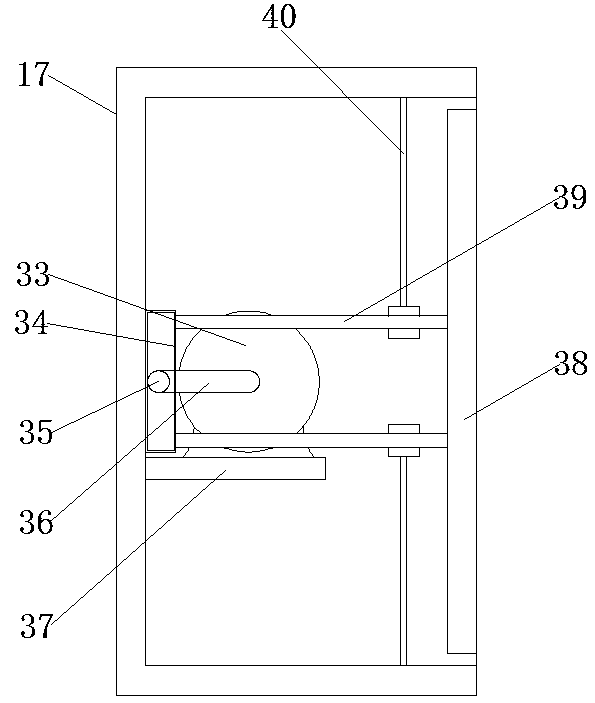

Laser lens polishing device

ActiveCN114571318AAdjust arcGrinding carriagesOptical surface grinding machinesGear wheelEngineering

The invention relates to lens polishing, in particular to a laser lens polishing device which comprises a machining support, a clamping mechanism, a supporting mechanism, a lifting mechanism, a rotating mechanism, a swing mechanism, an expansion mechanism and a polishing mechanism. The machining support comprises a bottom support, a supporting ring and a gear ring frame, and the clamping mechanism comprises a gear ring, a gear and a clamping arc plate; the supporting mechanism comprises a telescopic mechanism I, an arc cavity I, a ball I and a suction cup I, the lifting mechanism comprises a telescopic mechanism I and a lifting support, the rotating mechanism comprises a rotating ring, a sliding column and a threaded rod, and the swinging mechanism comprises a swinging support, a rotating motor, a swinging connecting rod, a sliding connecting rod and an arc cavity II. The expansion mechanism comprises a ball II, a telescopic mechanism III, a telescopic mechanism IV, a ball III, a telescopic mechanism V and a ball IV, the grinding mechanism comprises a grinding frame, an arc cavity III and an arc cavity IV, and the grinding radian of the lens can be adjusted according to different use requirements.

Owner:HARBIN UNIV

Construction method of special-shaped curved concrete roof

ActiveCN111962870BReduce quality problemsAdjust arcRoof covering using sealantsForms/shuttering/falseworksArchitectural engineeringRebar

This application relates to a construction method for a special-shaped curved concrete roof, which includes the division of roof arc sections, according to the design drawings on the arc roof, the roof is divided into sections in the transverse and longitudinal directions, and divided into several arc surfaces; computer pre-arrangement , according to the divided arc surface, the entire arc surface is positioned according to the four points of each arc surface, and the arc roof is modeled; the positioning is set out, and the arc roof is positioned by the three-dimensional horizontal projection method ;The positioning and erection of the support frame, according to the positioning results of the computer, the vertical and horizontal arrangement lines of the support frame are positioned on the lower structural surface, and the positioning coordinates and heights of each support point are marked on the lower structural surface; formwork and steel bar installation and concrete pouring And maintenance demoulding. The application has the effect of improving the quality of the special-shaped curved concrete roof.

Owner:SUZHOU JINXIN CONSTR GRP

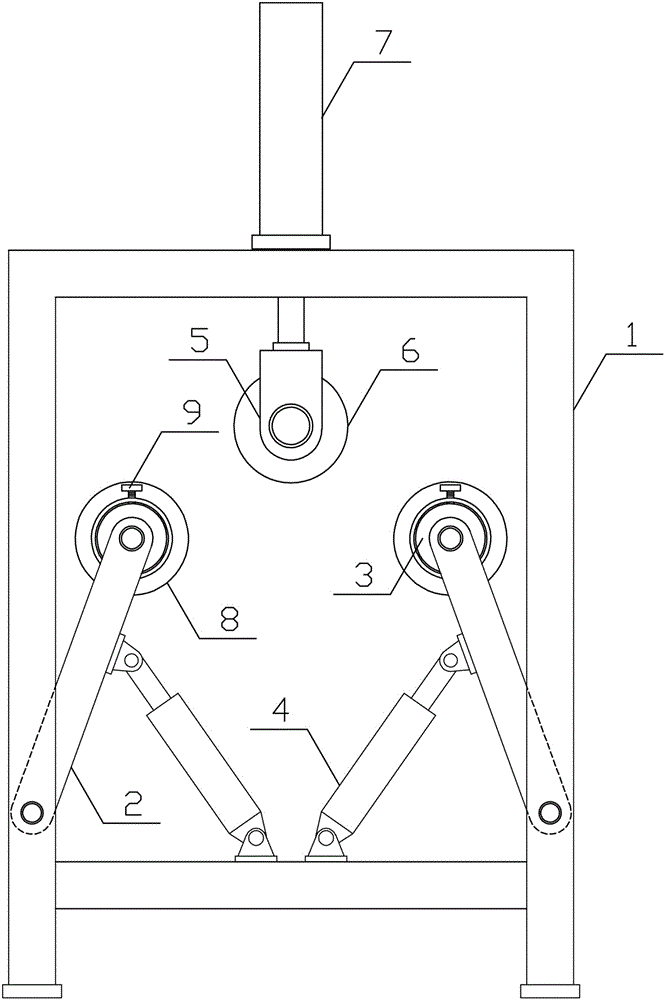

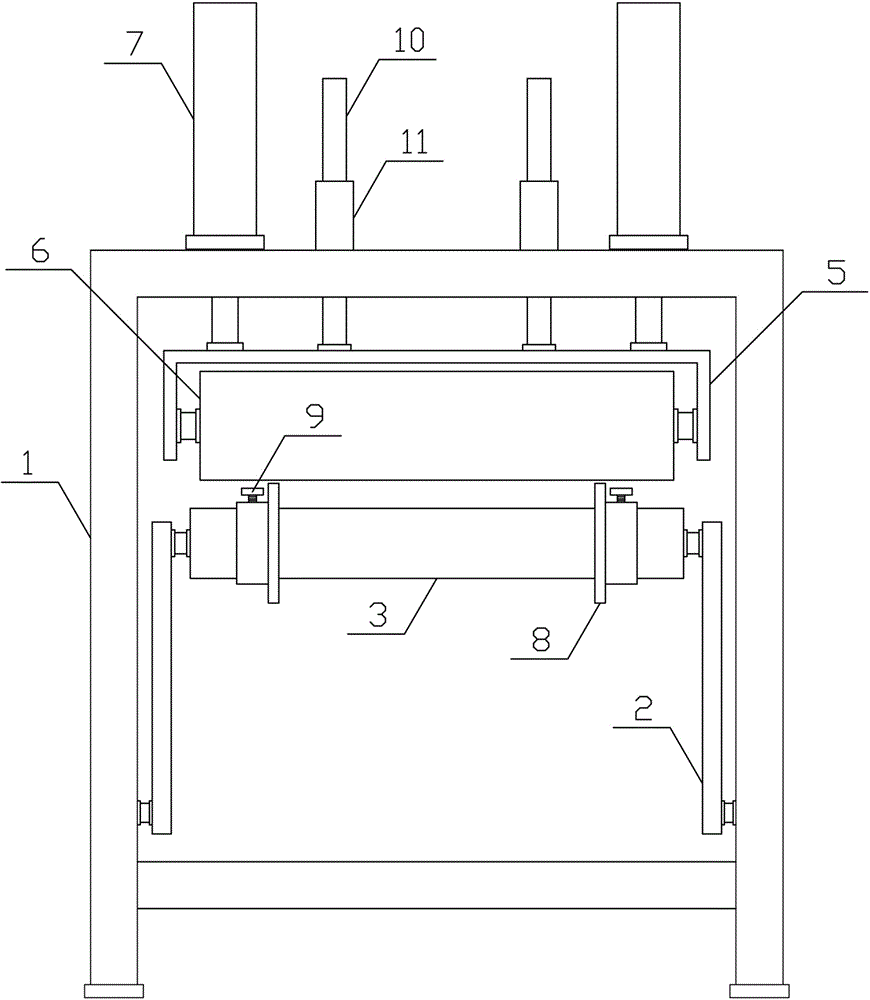

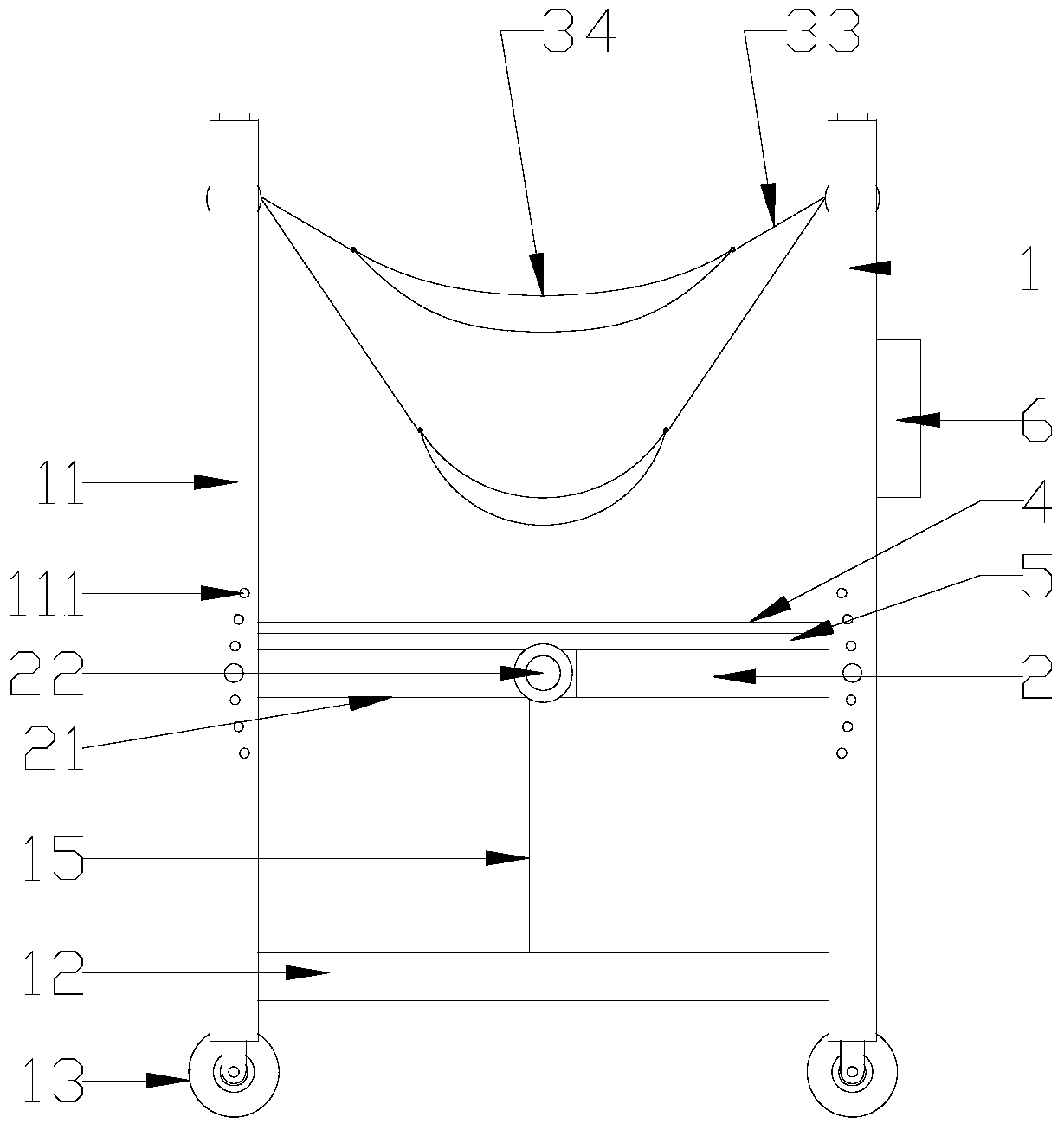

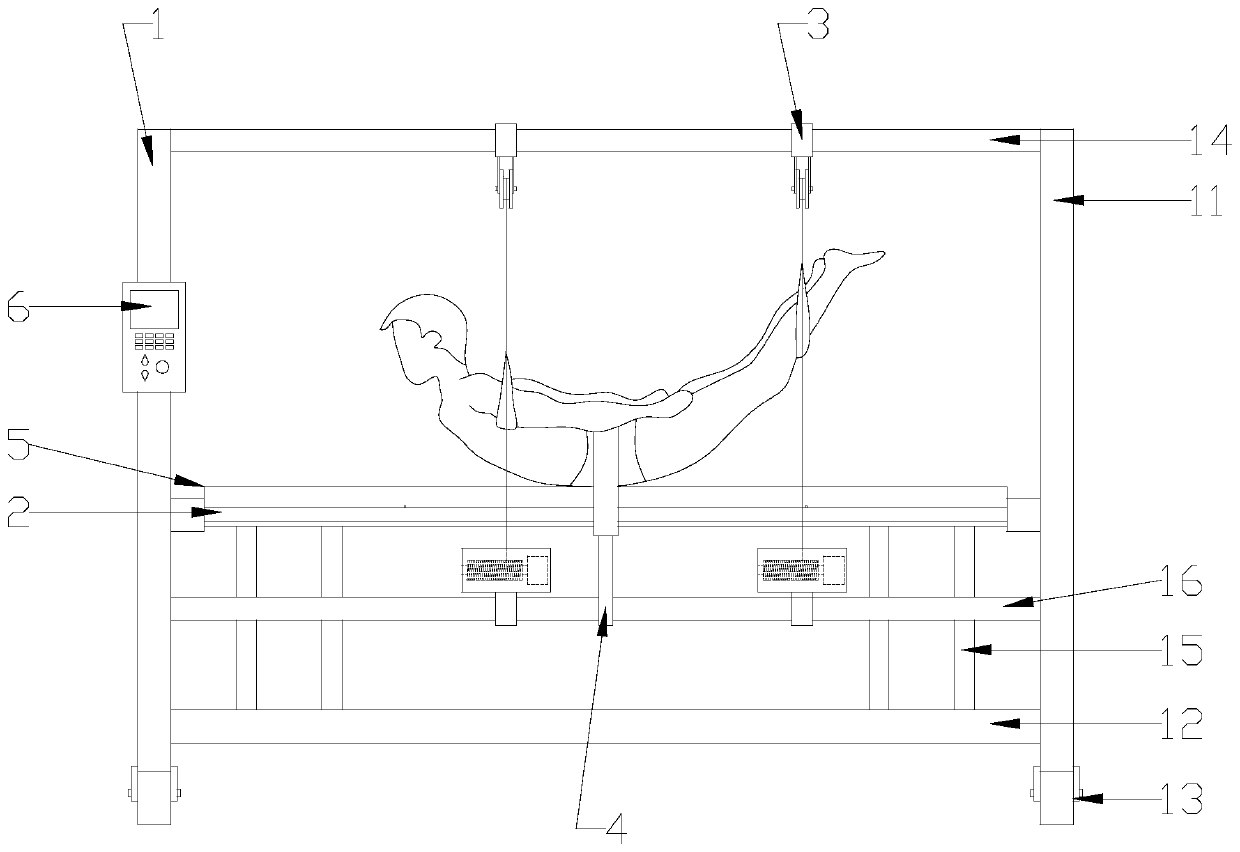

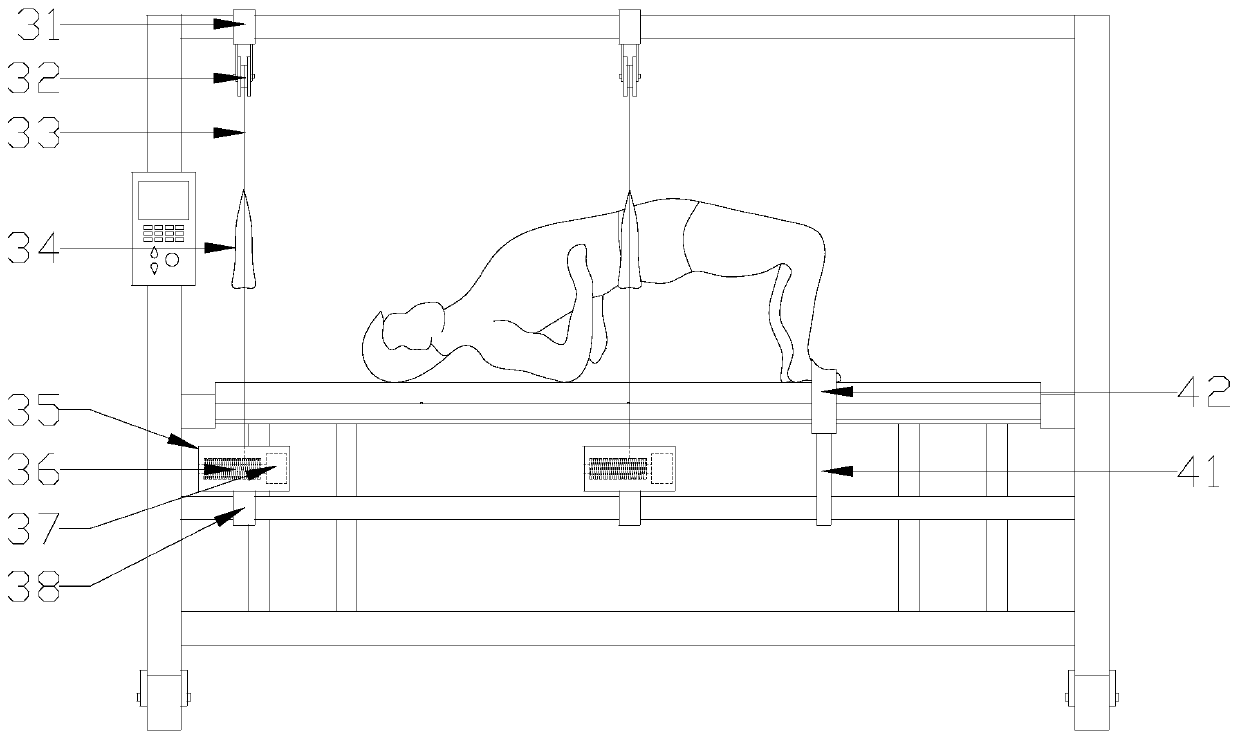

Lumbar and dorsal muscle function exercising device

InactiveCN111068252AMake Your Workout Less DifficultImprove workout confidenceGymnastic exercisingTherapy exerciseElectric machinerySupport belt

The invention discloses a lumbar and dorsal muscle function exercising device. The device comprises a frame, a supporting frame horizontally fixed in the frame, a soft cushion placed on the top face of the supporting frame, lifting mechanisms fixed to the frame and a control device electrically connected with the lifting mechanisms. The lifting mechanism comprises a first sliding block, a fixed pulley, a steel wire, a supporting belt, a rolling and pulling shell, a winding drum, a motor and a second sliding block. The first sliding block and the second sliding block are fixed to a first crossrod and a second cross rod located at the upper ends and the lower ends of the two sides of the long edge of the frame in a sliding mode respectively. The fixed pulley is fixed on the bottom surface of the first sliding block. The rolling and pulling shell is fixed on the top surface of the second sliding block. The motor is located in the rolling and pulling shell, an output shaft of the motor isconnected with the winding drum, one end of the steel wire is fixed to the winding drum, the other end of the steel wire penetrates through the fixed pulley and then is connected with the supportingbelt. The device is suitable for various different lumbar muscle and dorsal muscle exercising actions, human body parts can be assisted in lifting, and therefore the difficulty of the lumbar muscle and dorsal muscle exercising actions is reduced.

Owner:THE THIRD AFFILIATED HOSPITAL OF ZHEJIANG CHIENSE MEDICAL UNIV

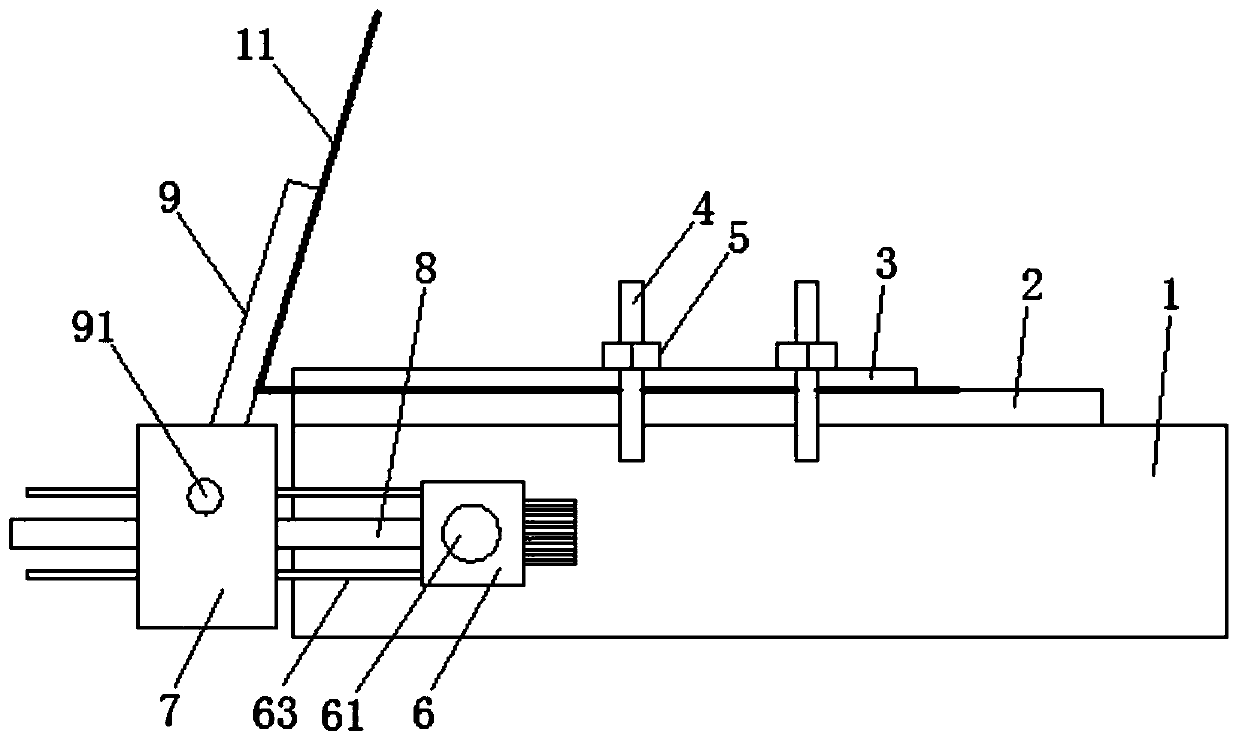

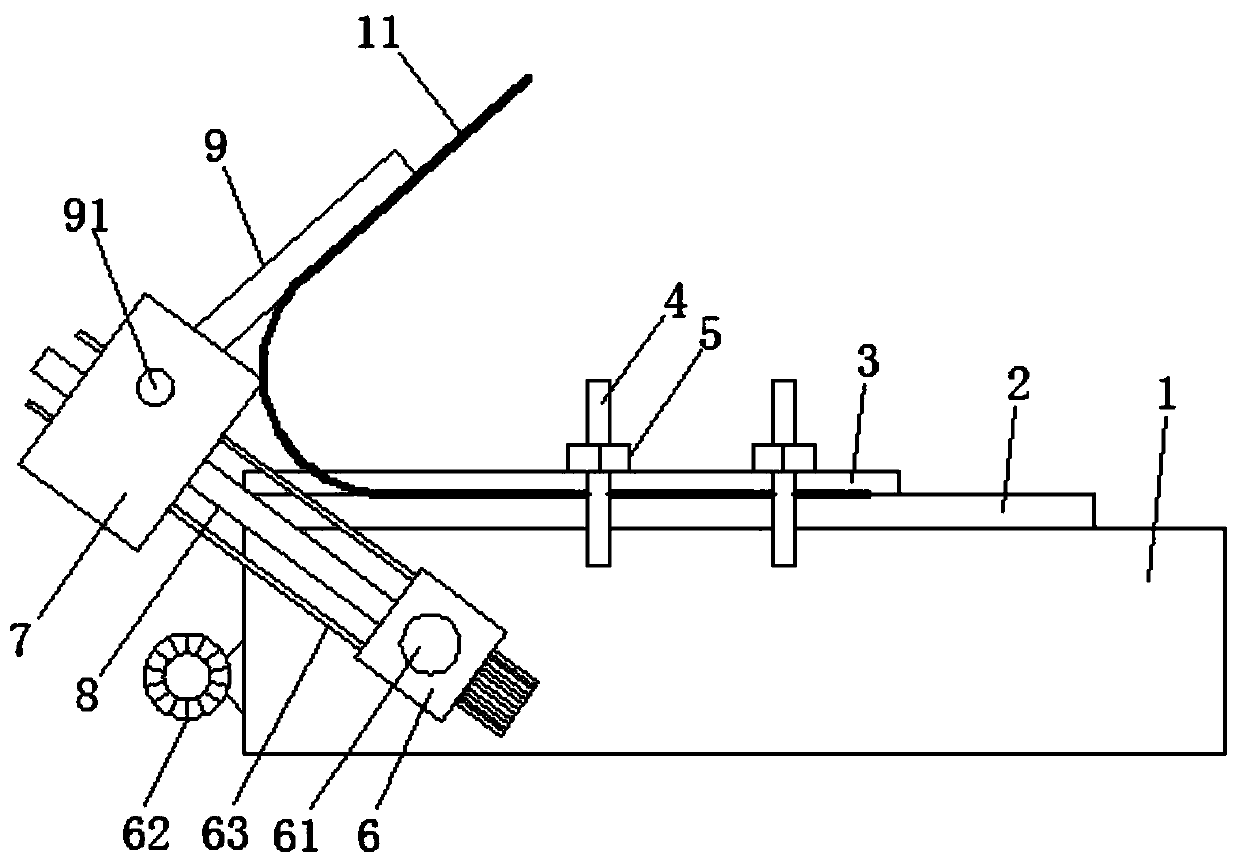

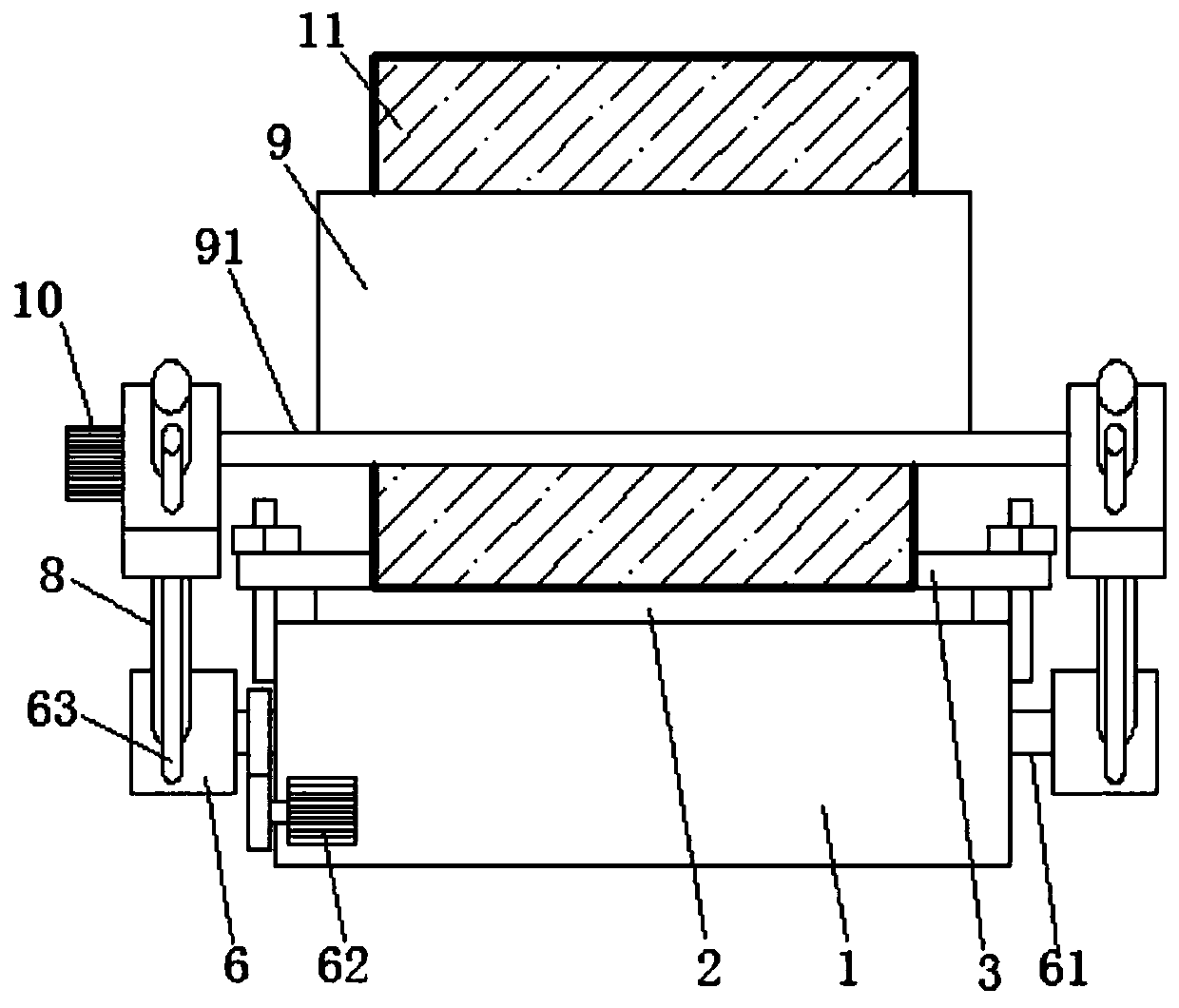

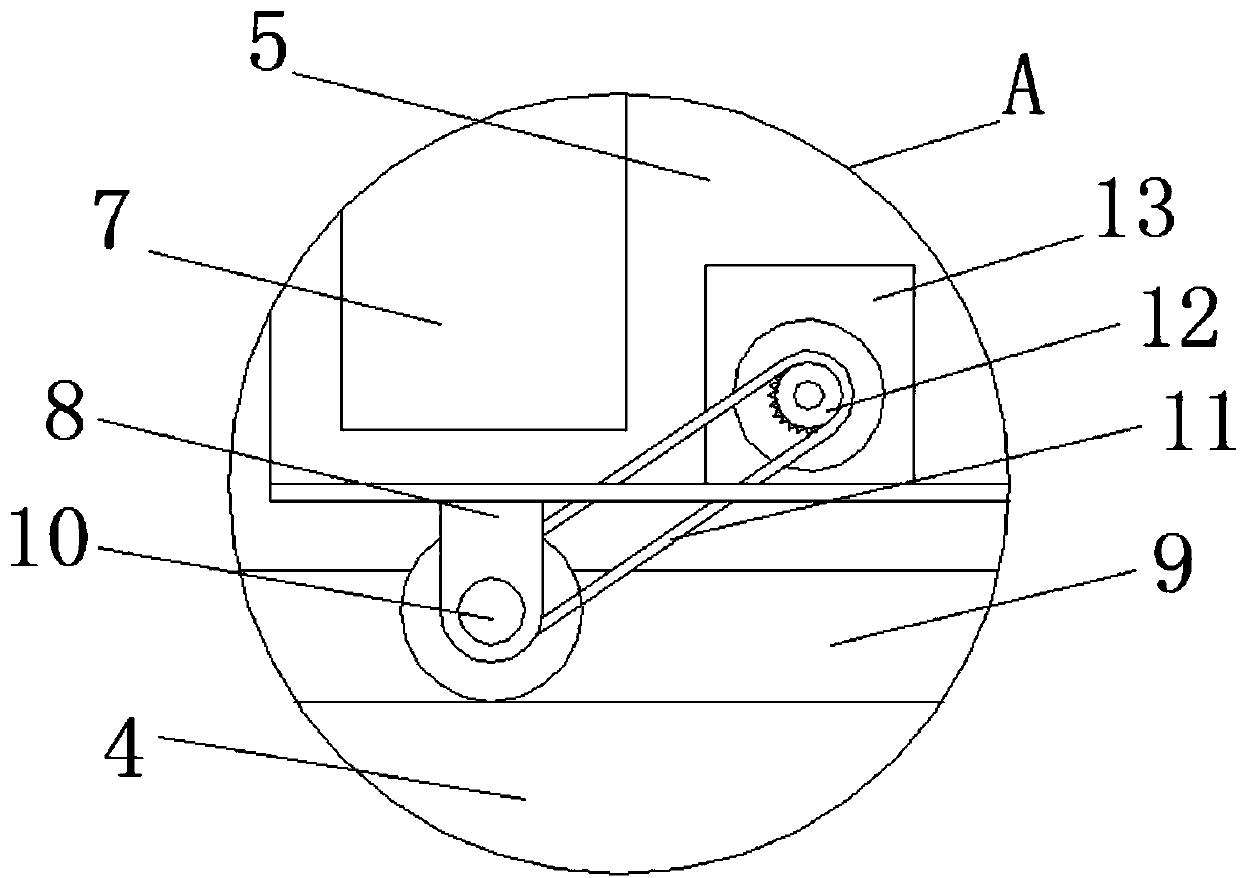

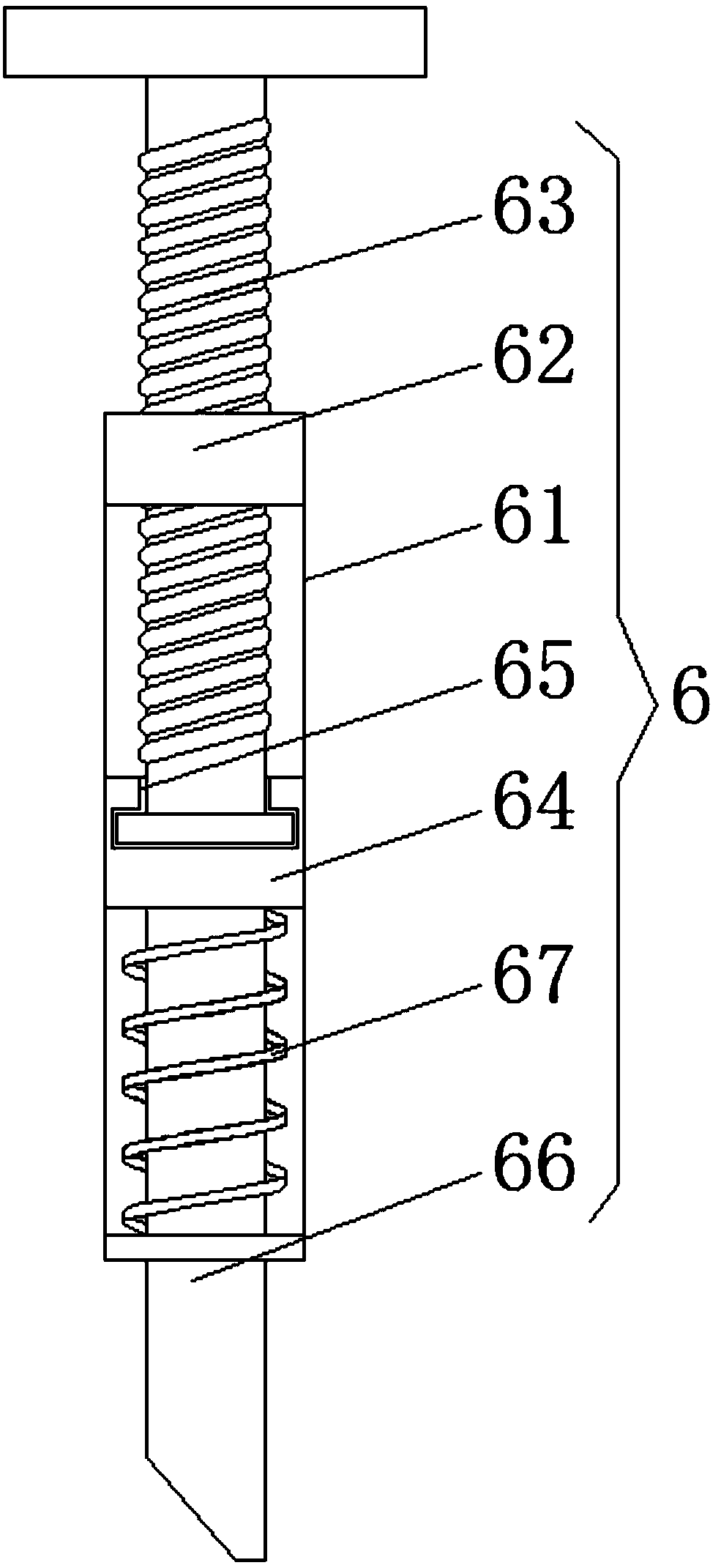

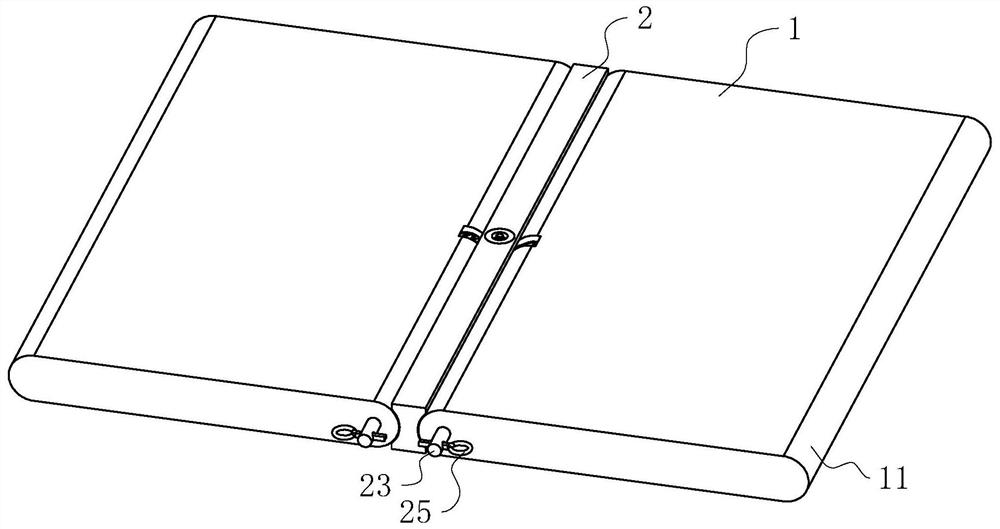

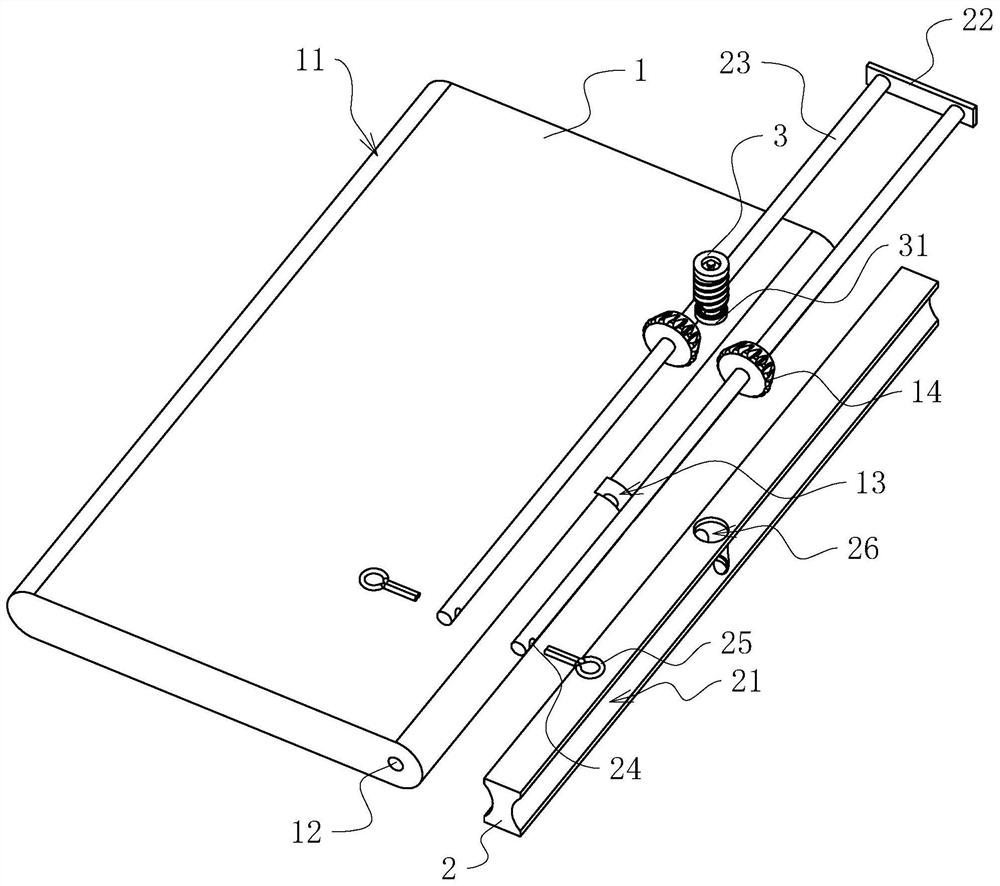

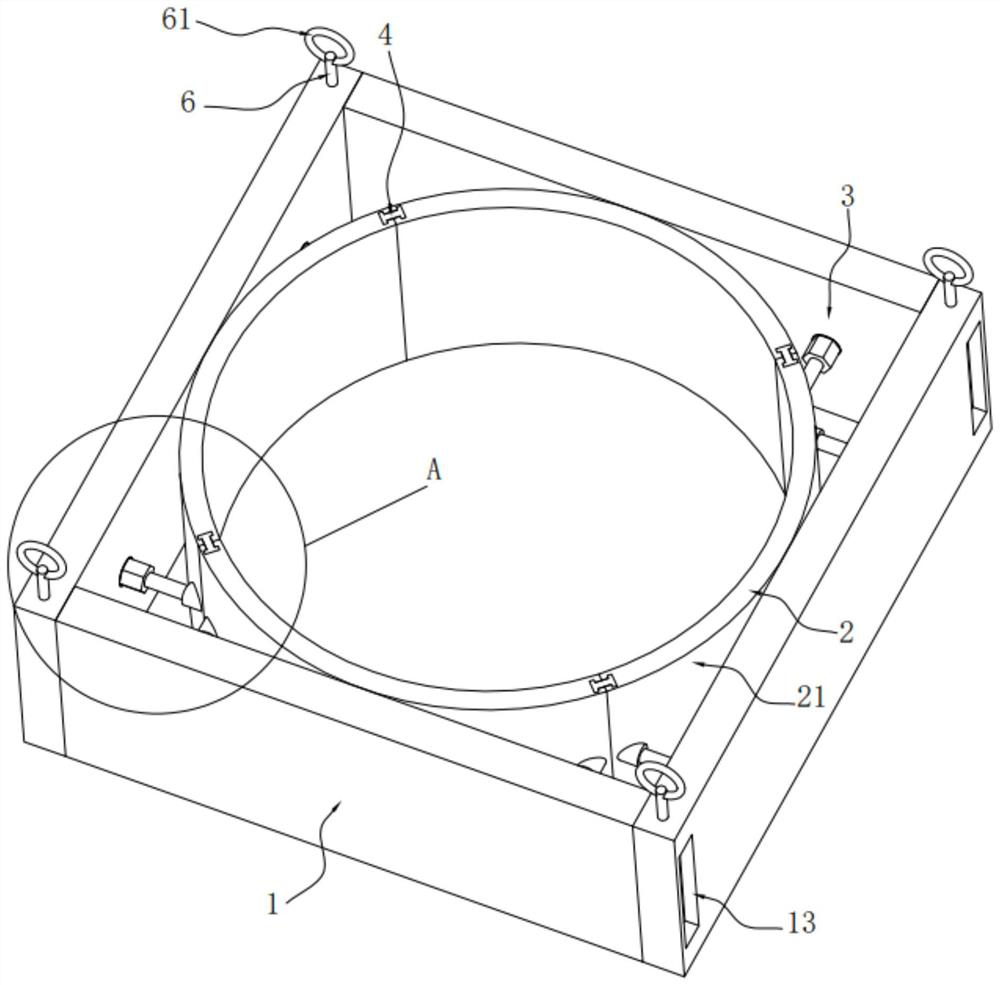

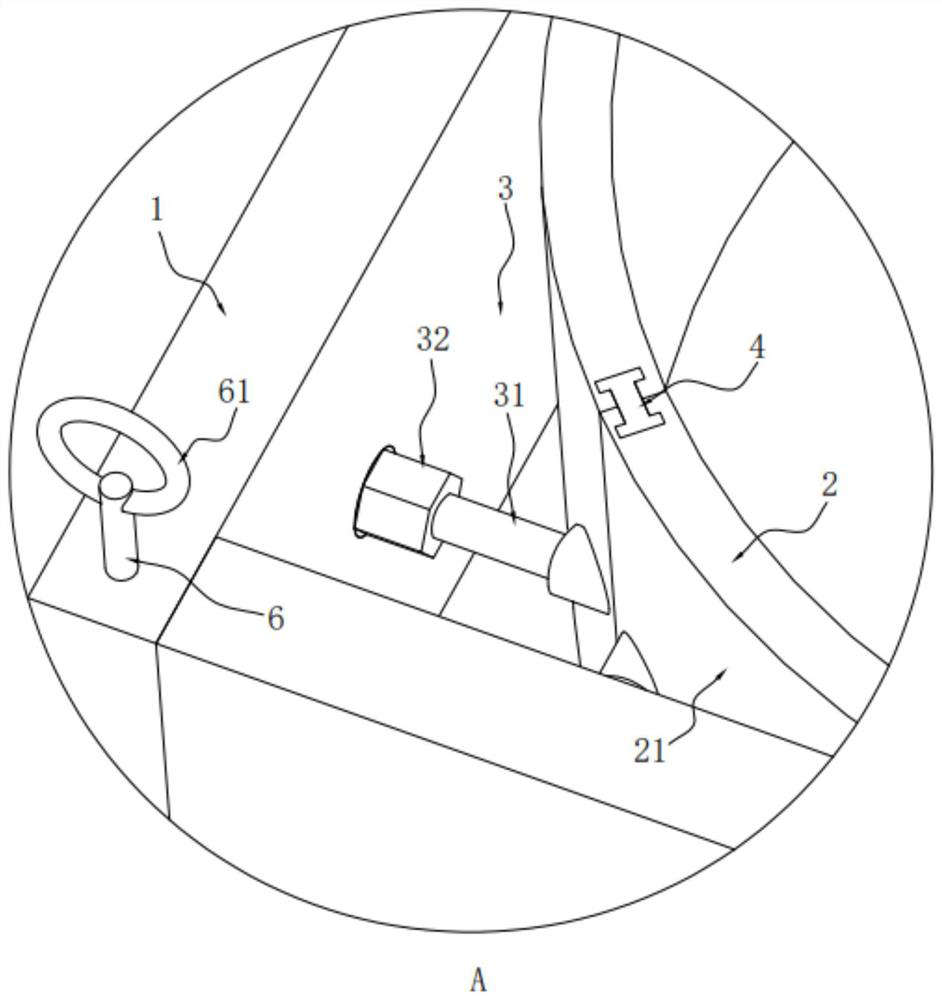

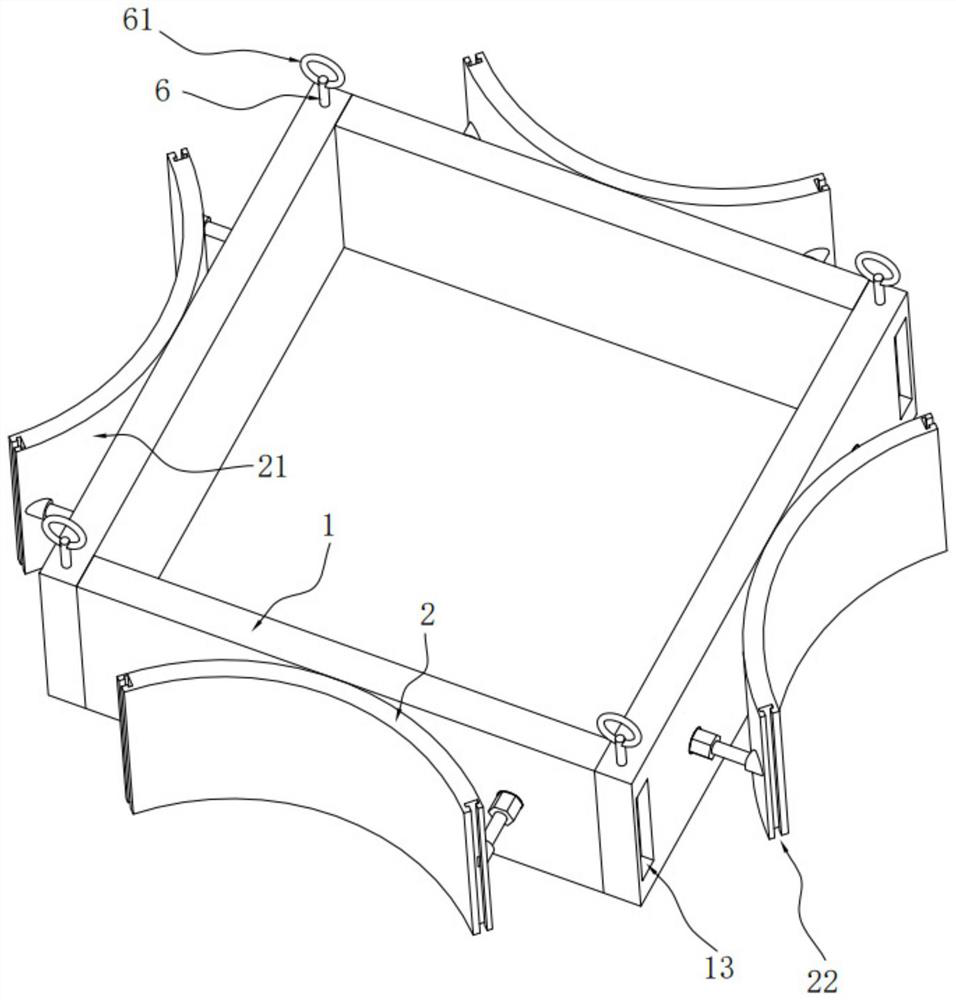

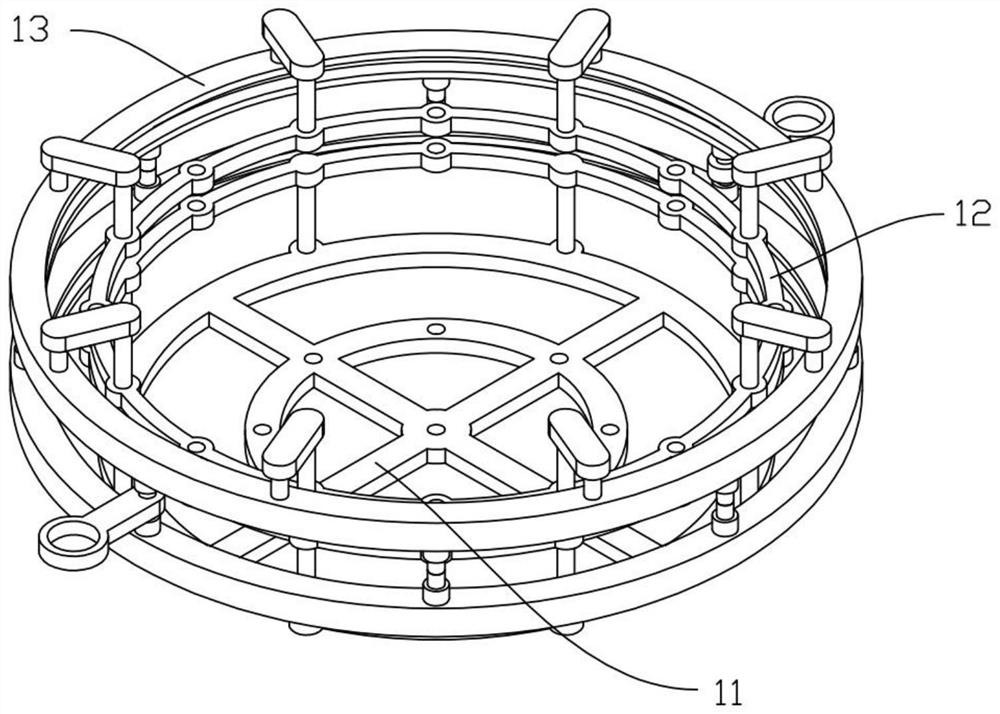

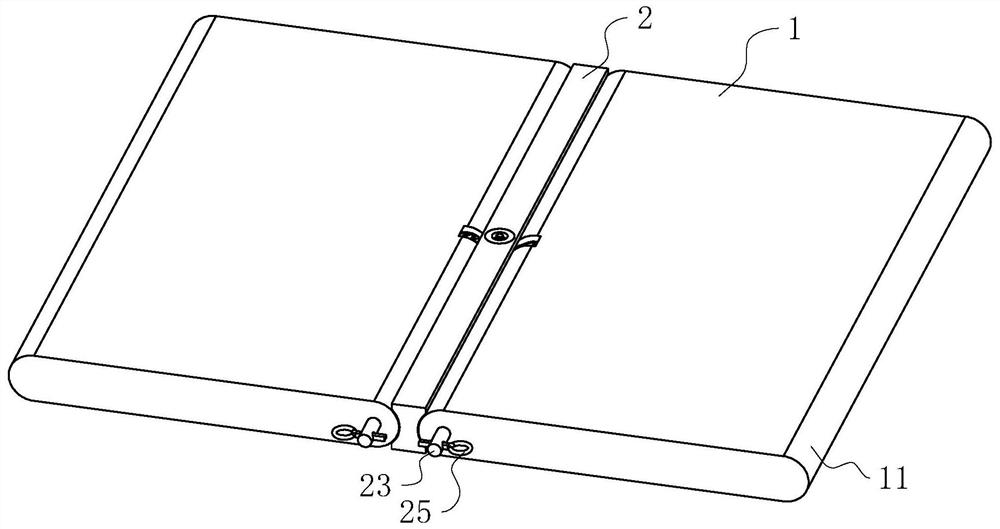

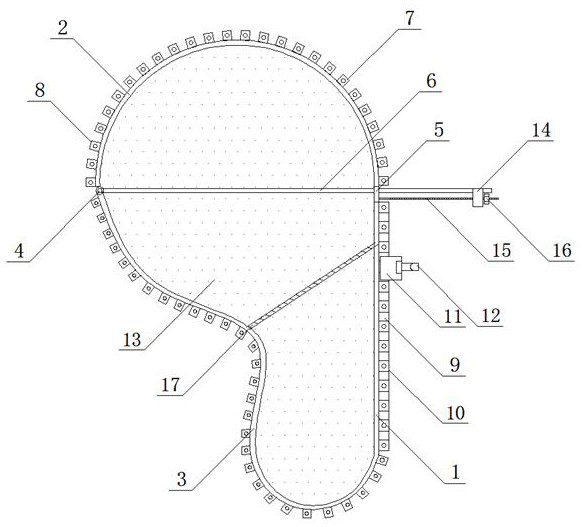

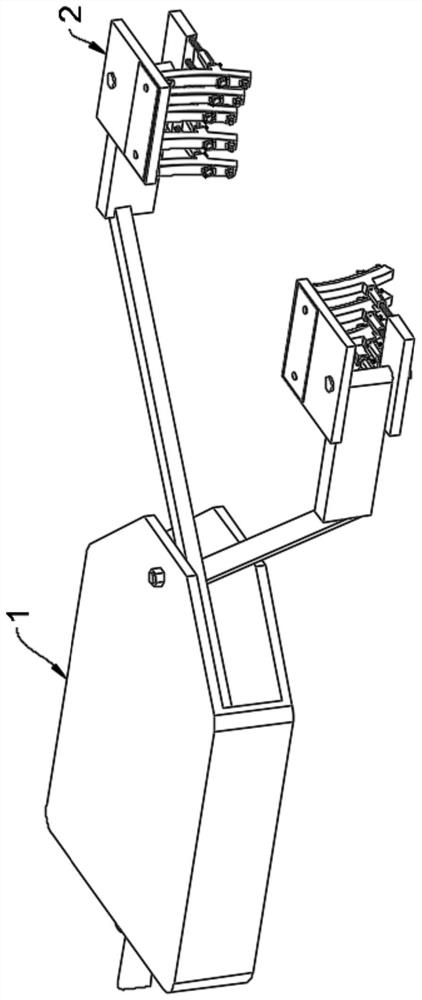

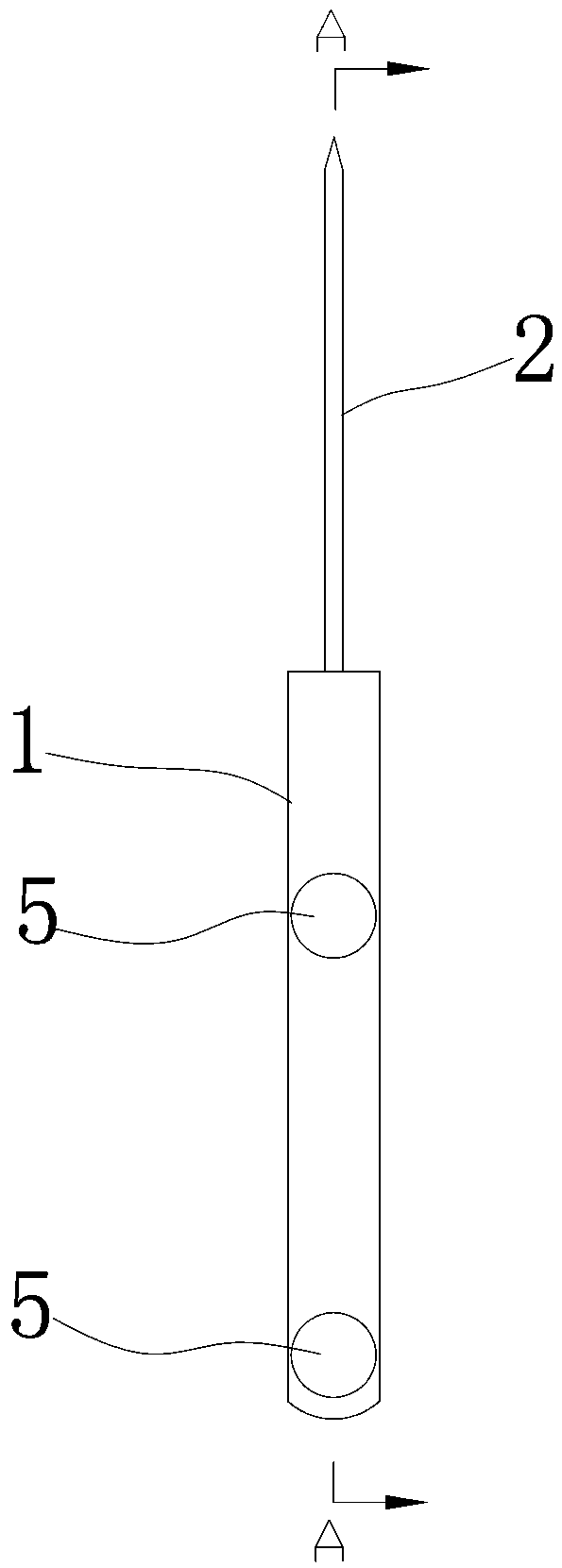

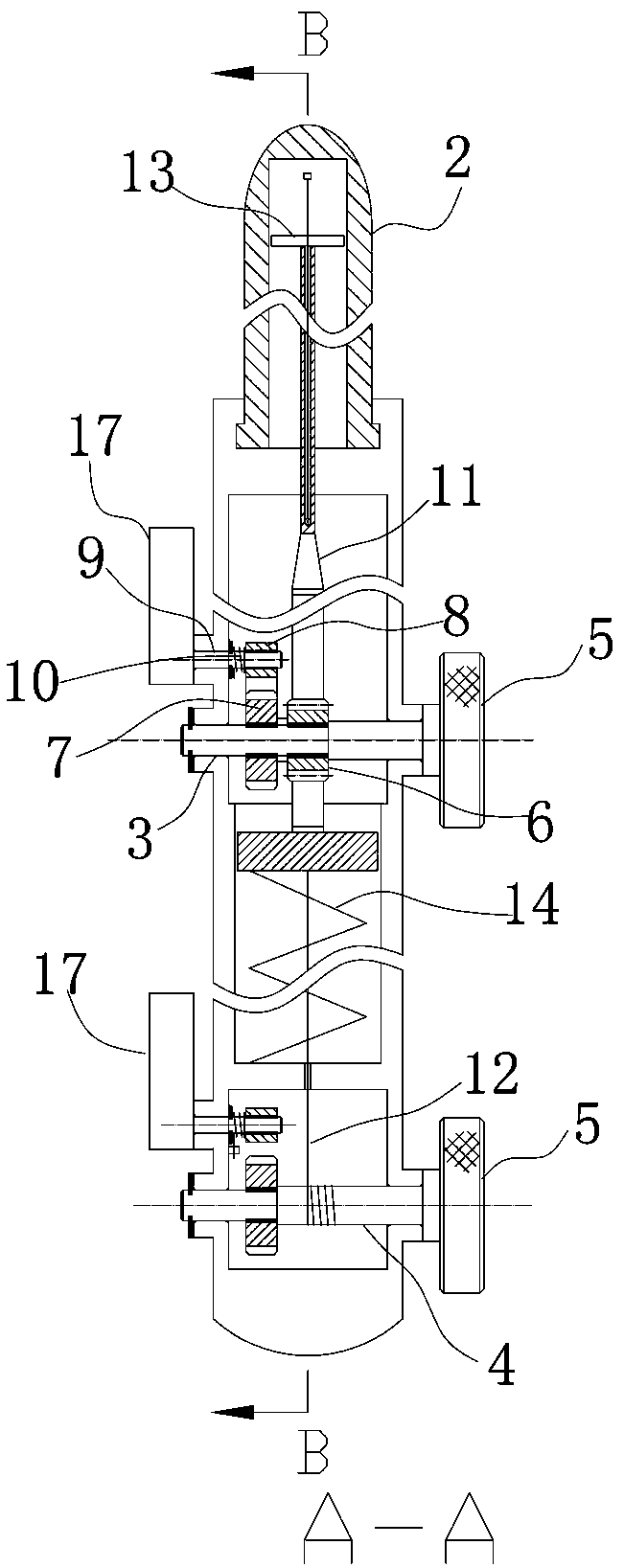

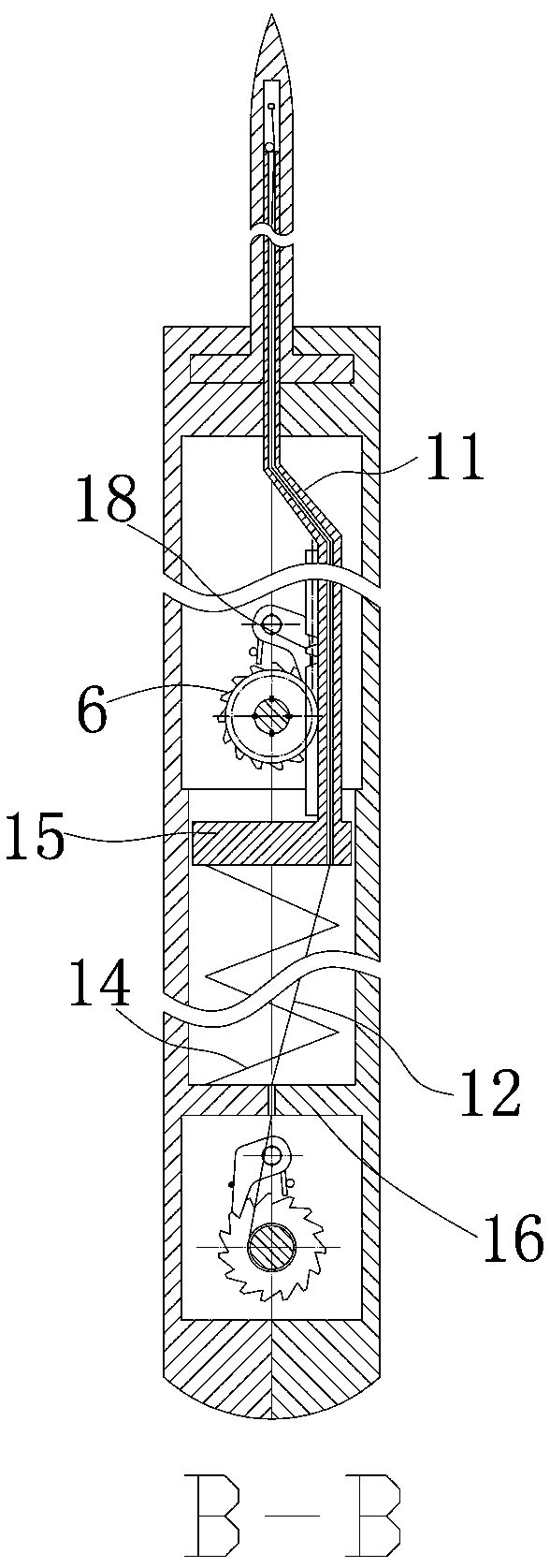

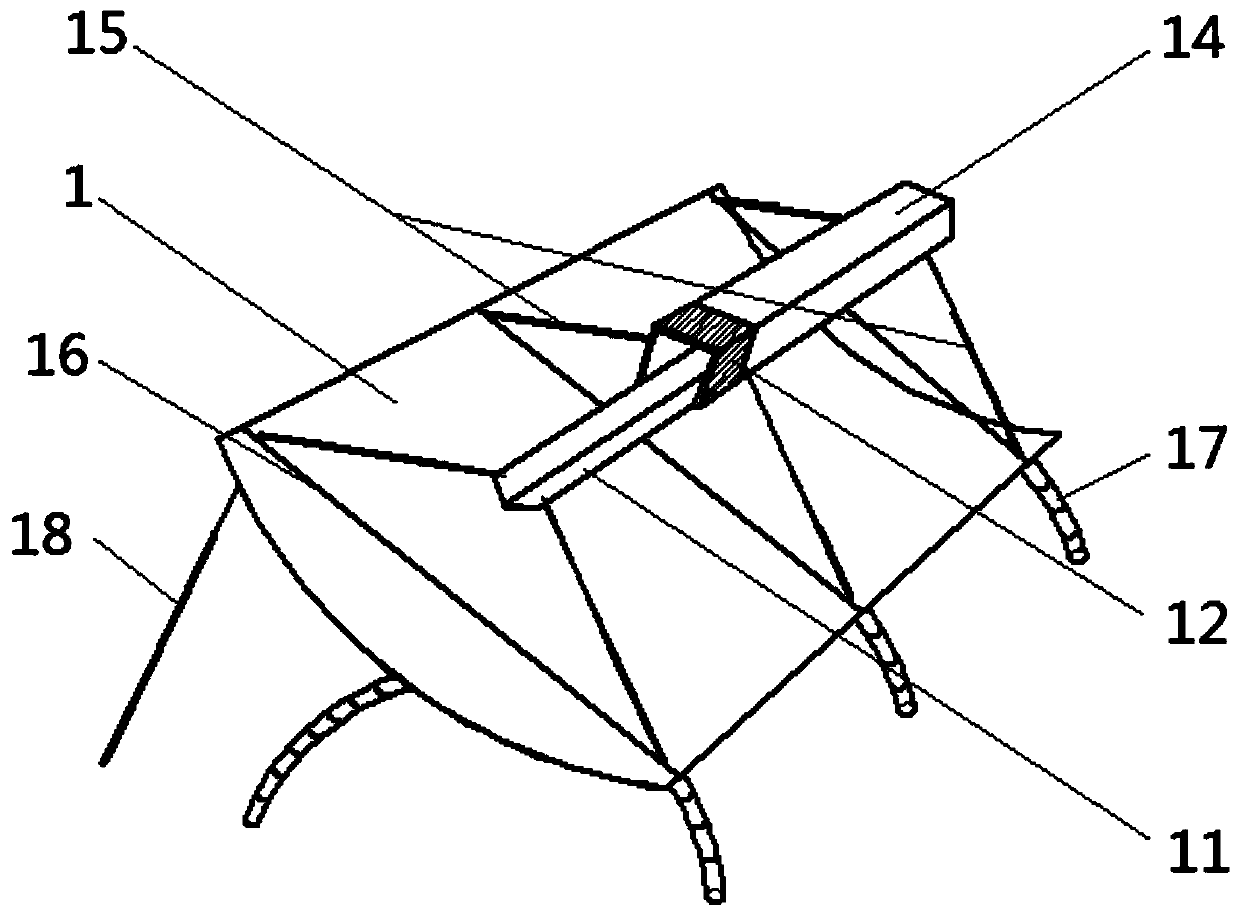

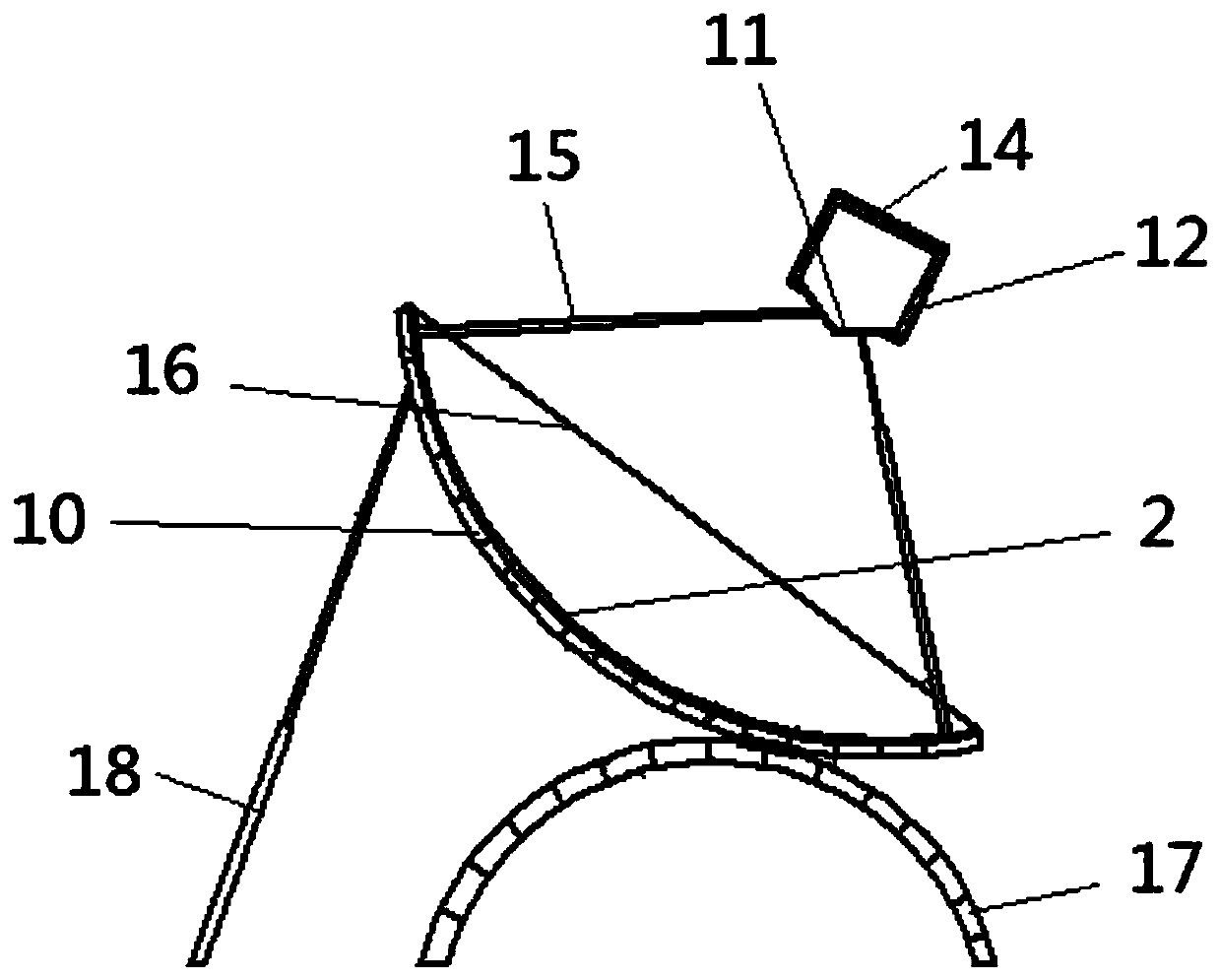

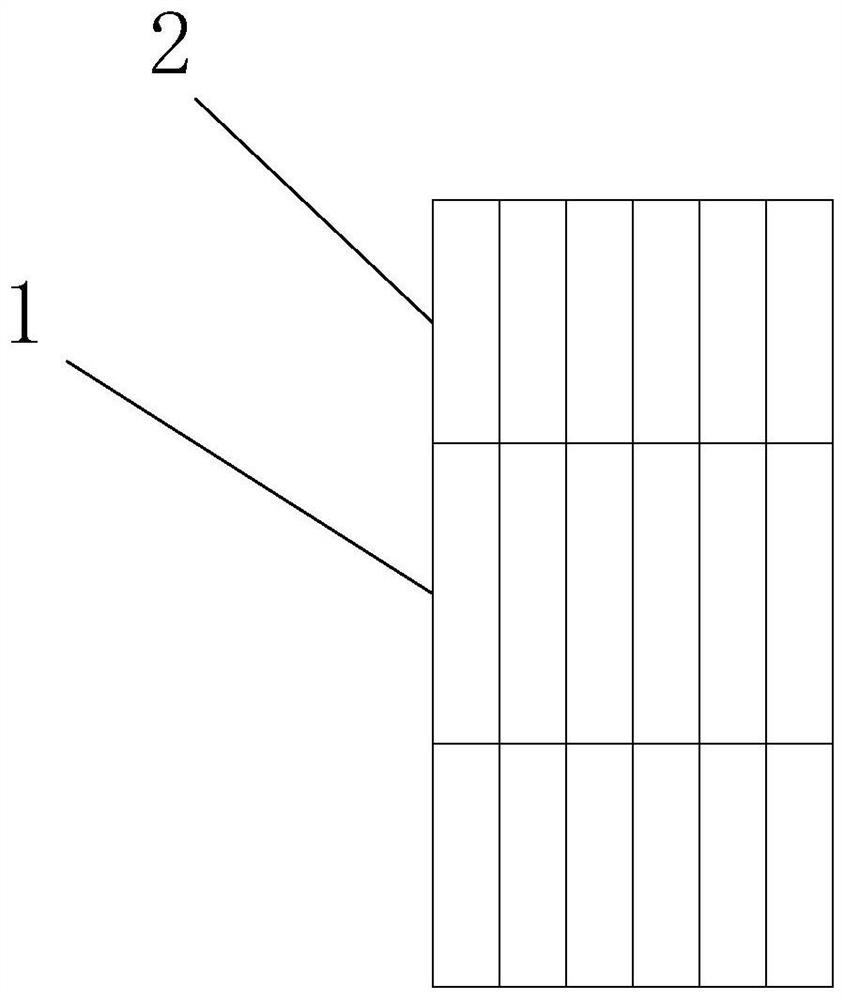

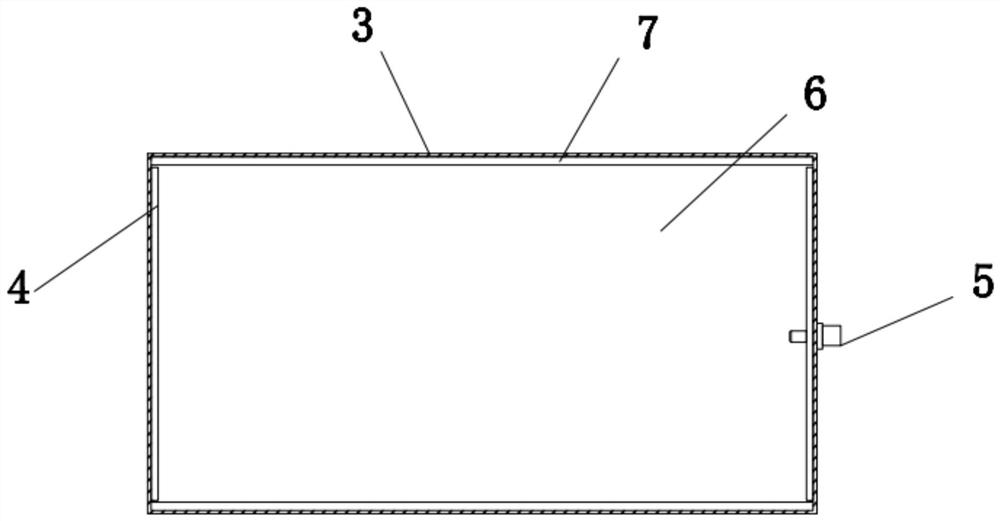

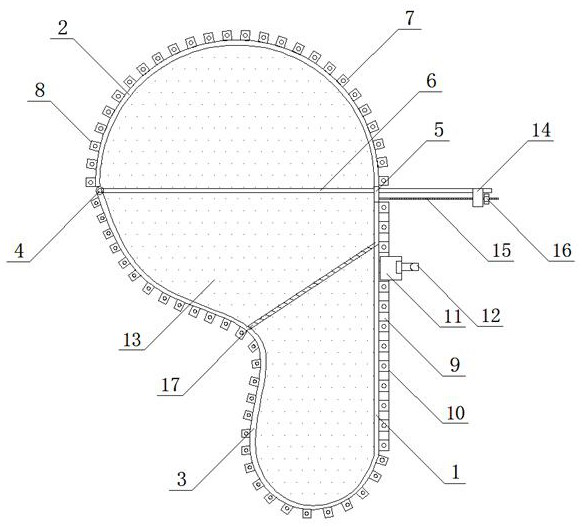

Adjustable outer contour sewing positioning die and wiring guide device

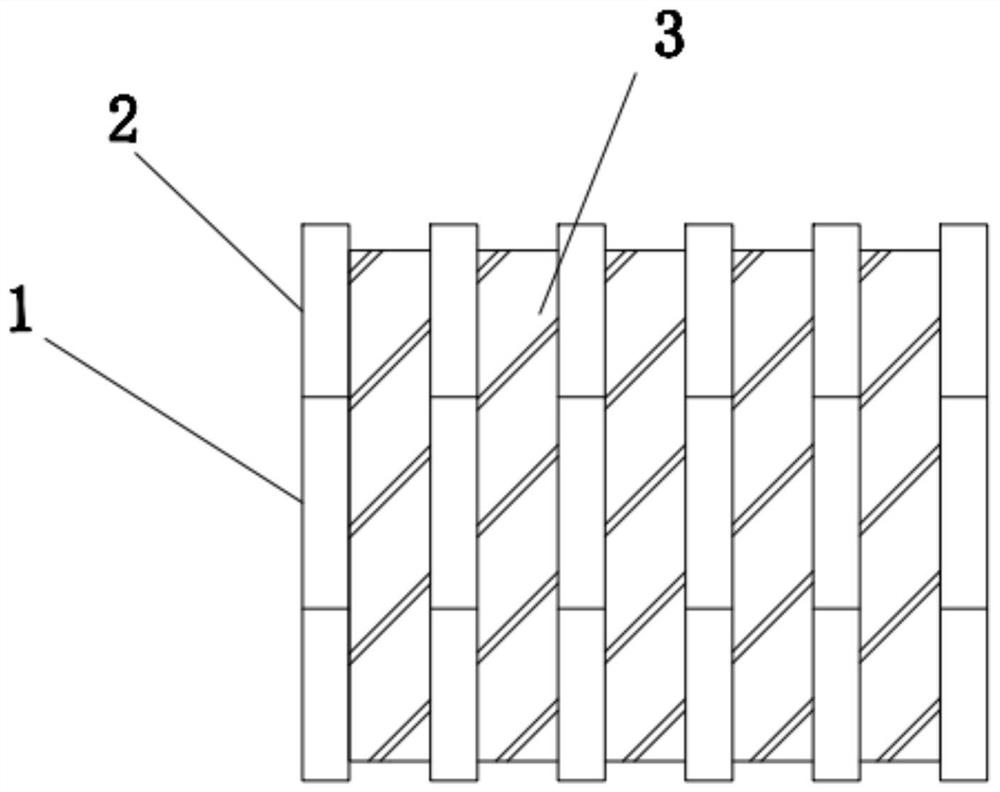

An adjustable outer contour sewing positioning die and wiring guide device comprises an outer contour fixing edge (1) and is characterized in that one end of the outer contour fixing edge (1) is fixedto one end of an arc steel belt (2), a connecting shaft (4) is hinged to a sliding adjusting strip (6), a curved surface steel belt (3) is arranged at the other end, penetrating into the outer contour fixing edge (1) in a sliding hole (5), of the sliding adjusting strip (6), an arc adjusting device is installed between the mounting base (14) and the outer contour fixing edge (1), an arc outer toothed plate (7) and a horizontal plate (9) jointly form an outer contour rail, an outer contour sliding base (11) is mounted on the outer contour rail, and a wiring guide presser foot (12) is mounted on the outer contour sliding base (11). According to the device, the outer contour can be adjusted according to needs, adjustment and fixation are extremely convenient, outer contour sewing positioningand wiring guide are achieved, sewn products are good in consistency, and the attractiveness and the processing efficiency of clothes are improved.

Owner:JIHUA 3506 TEXTILE & APPL

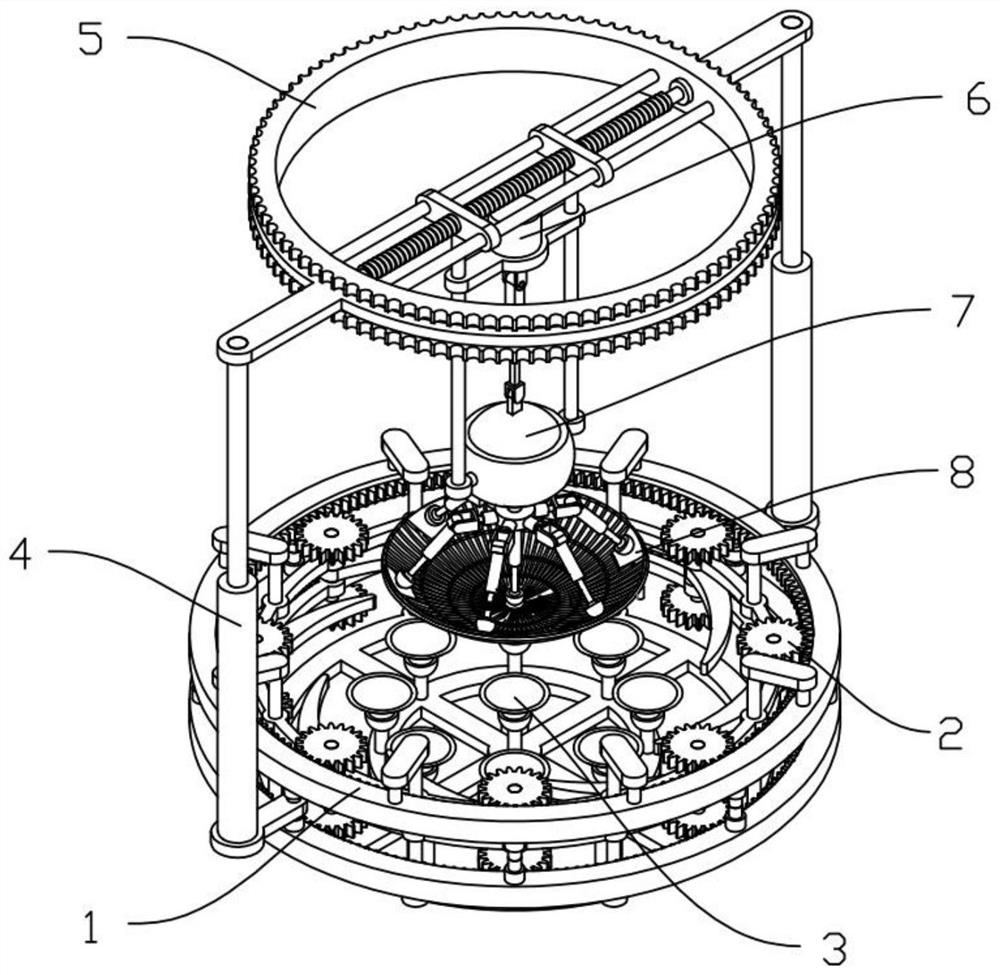

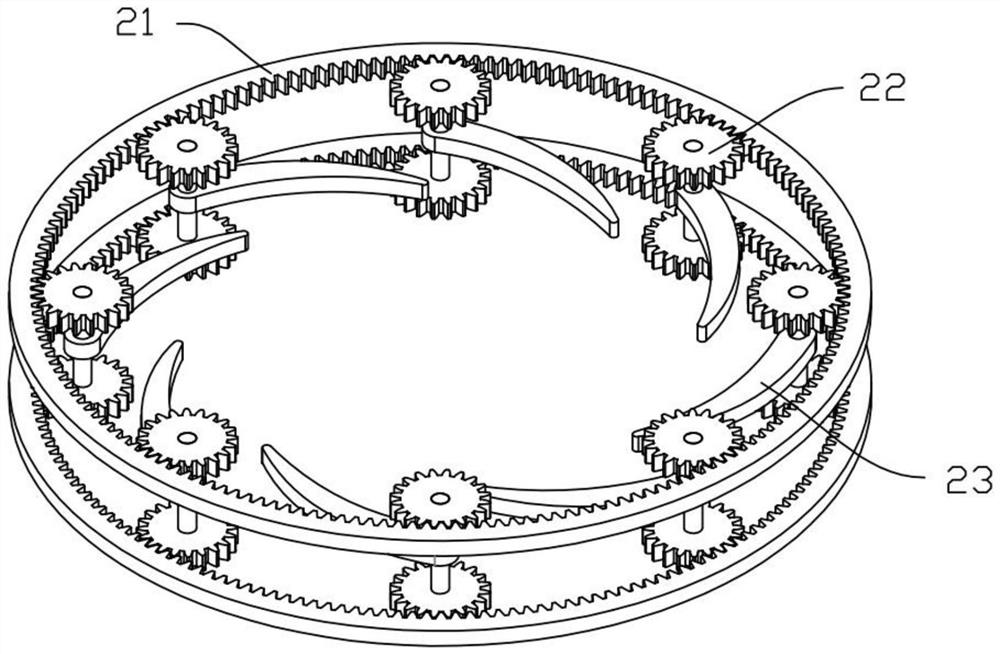

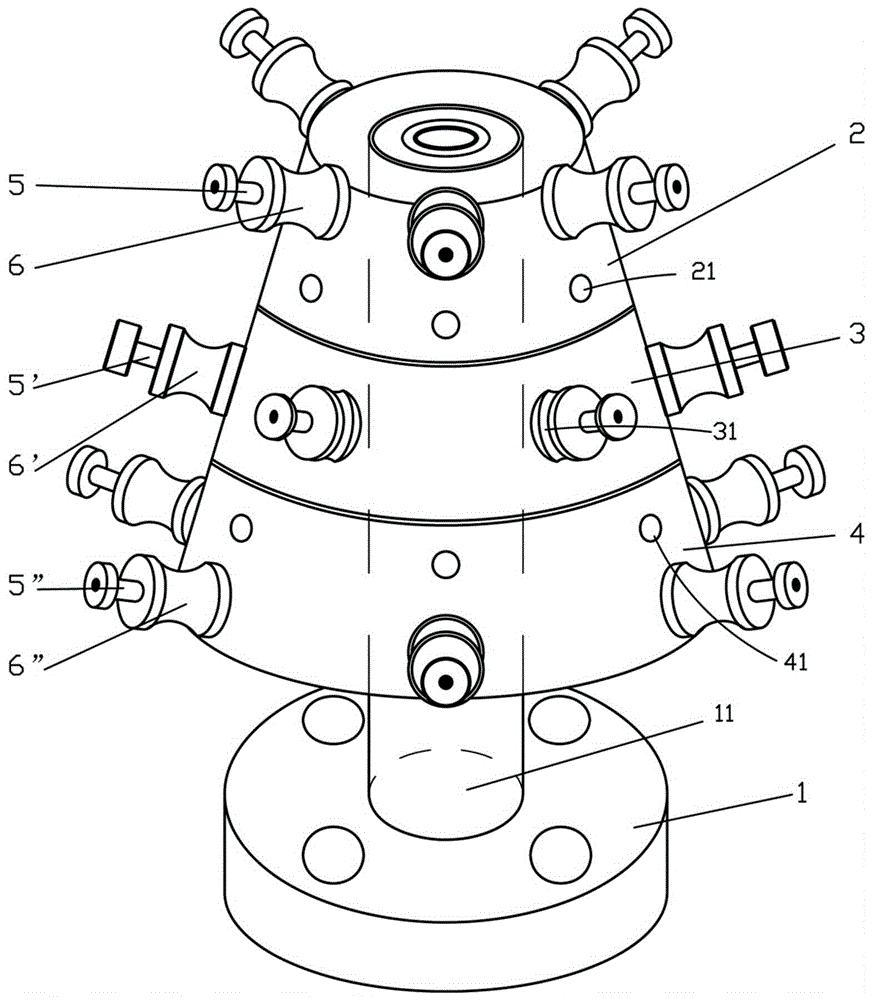

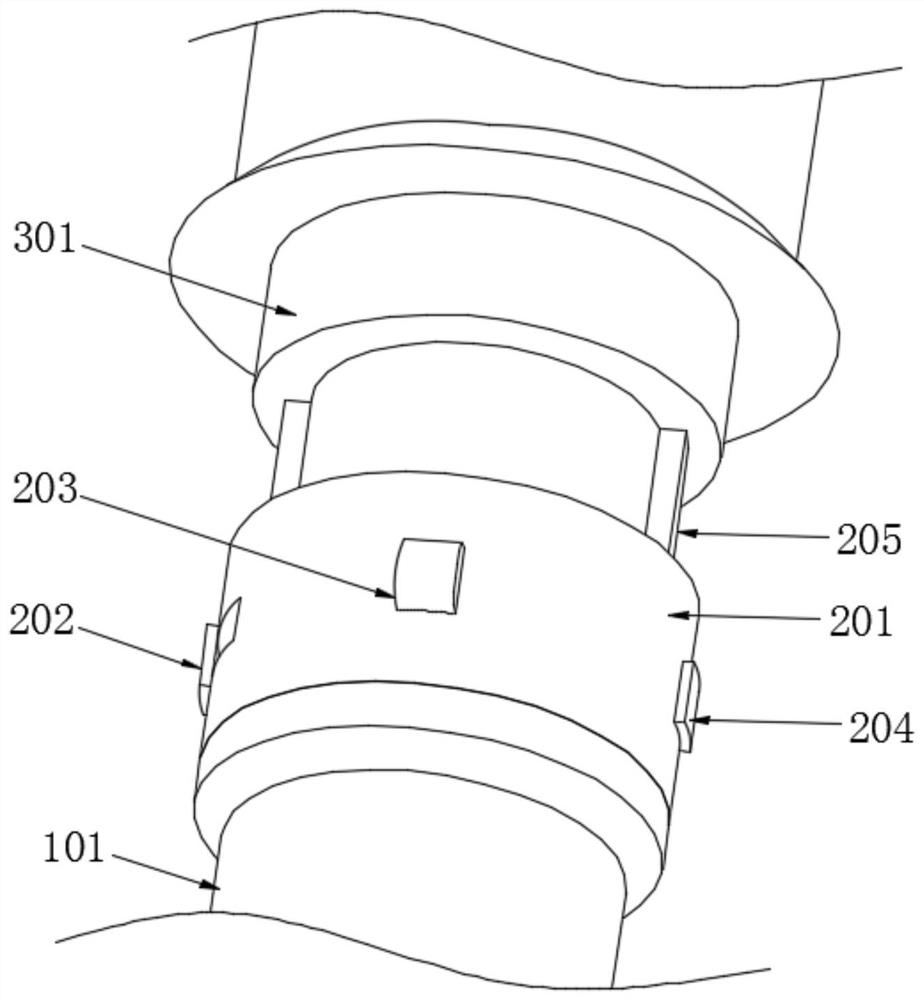

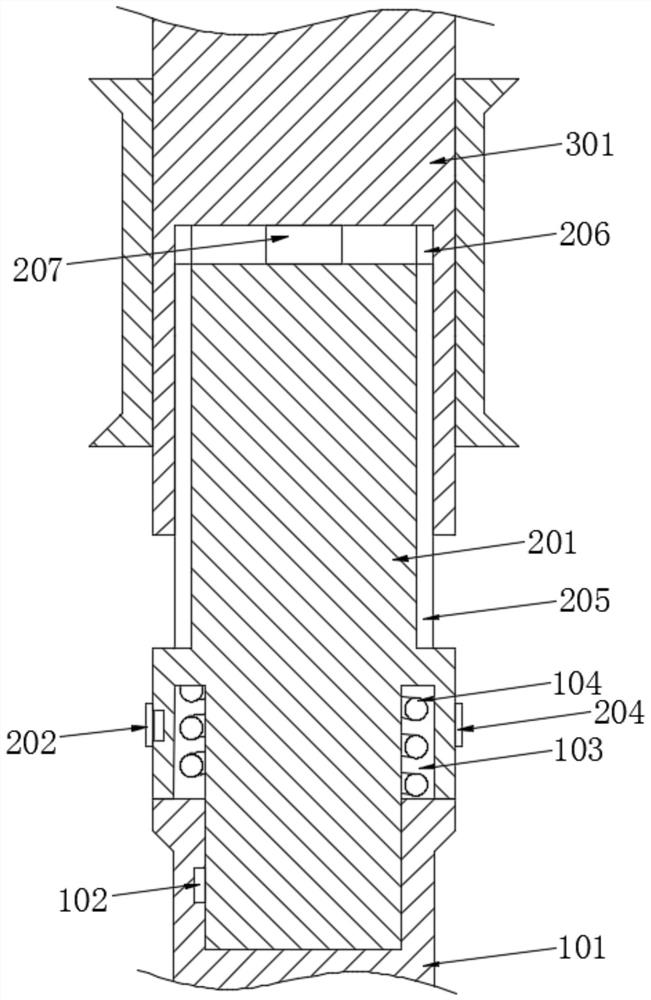

Pre-former for steel cord or steel wire rope

InactiveCN105239433AEasily damagedReduce coefficient of frictionRope making machinesMaterials scienceWire rope

The invention provides a pre-former for a steel cord or a steel wire rope. The pre-former comprises a base, an upper adjusting disc, a middle adjusting disc, a lower adjusting disc and multiple studs. A through hole is formed in the center of the base, and a hollow shaft is arranged in the through hole. The upper adjusting disc, the middle adjusting disc and the lower adjusting disc are each a circular truncated cone with a center hole, the outer surfaces of the three adjusting discs are located on the same straight line, and a circular truncated cone structure with the upper portion larger than the lower portion is formed. The hollow shaft of the base is sleeved with the upper adjusting disc, the middle adjusting disc and the lower adjusting disc, the upper adjusting disc and the lower adjusting disc are fixedly connected to the hollow shaft, and the middle adjusting disc is of a rotatable structure. At least one row of screw holes are evenly formed in the outer side face of each adjusting disc in the circumferential direction, the screw holes of the upper adjusting disc correspond to the screw holes of the lower adjusting disc, in other words, the screw holes of the upper adjusting disc and the screw holes of the lower adjusting disc are located on the same straight line. Each stud is provided with a deformation wheel in a penetrating mode, and is locked through a nut. One ends of the studs are arranged in any rows of screw holes in the outer side faces of the upper adjusting disc, the middle adjusting disc and the lower adjusting disc. By means of the pre-former, free adjustment in all directions can be achieved, and abrasion to a steel wire can be remarkably lowered.

Owner:江苏宝钢精密钢丝有限公司

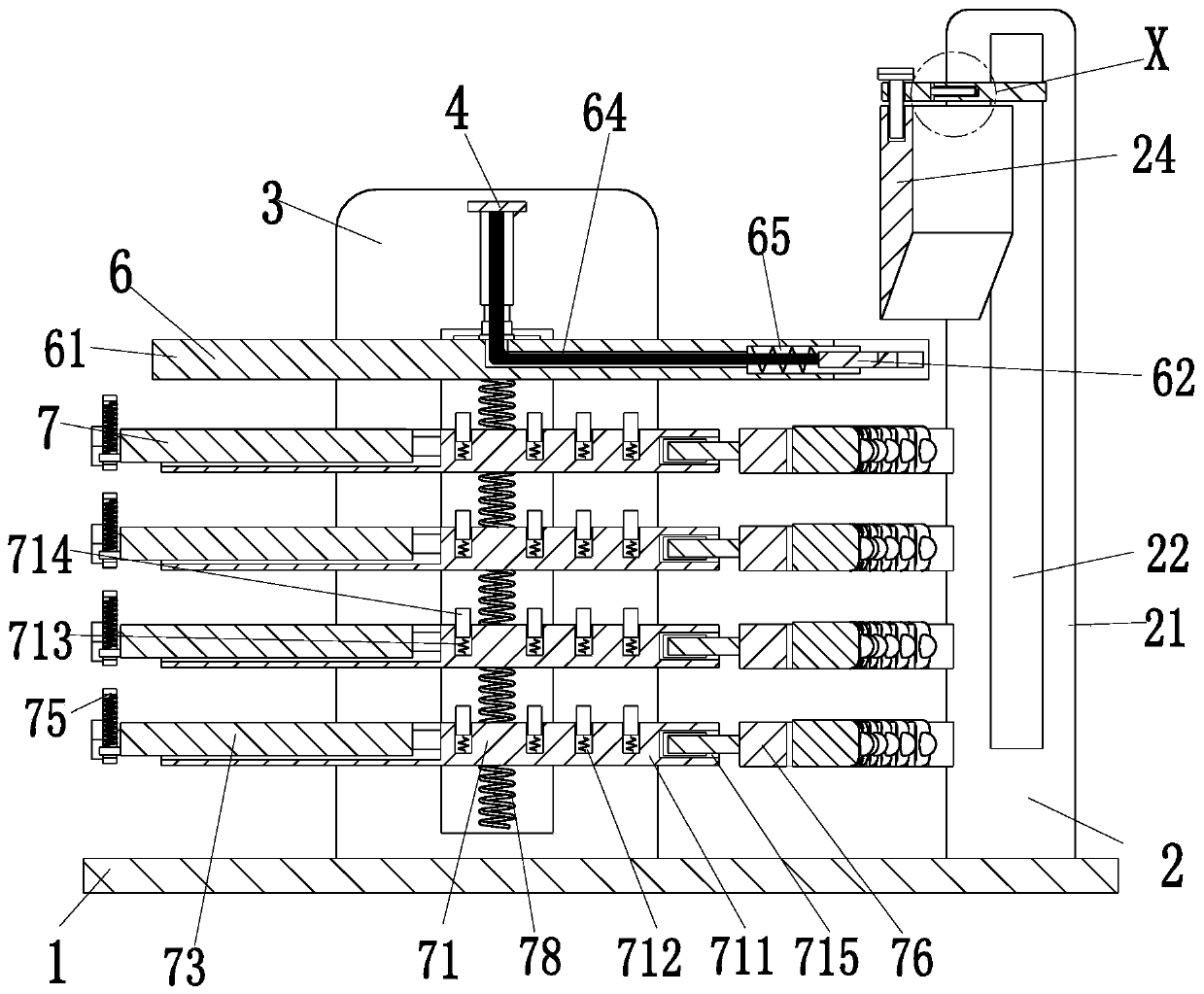

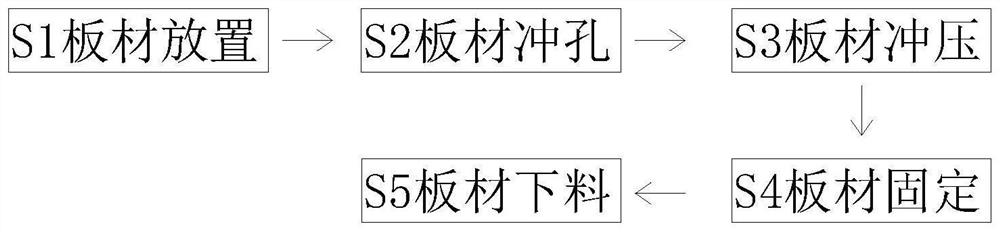

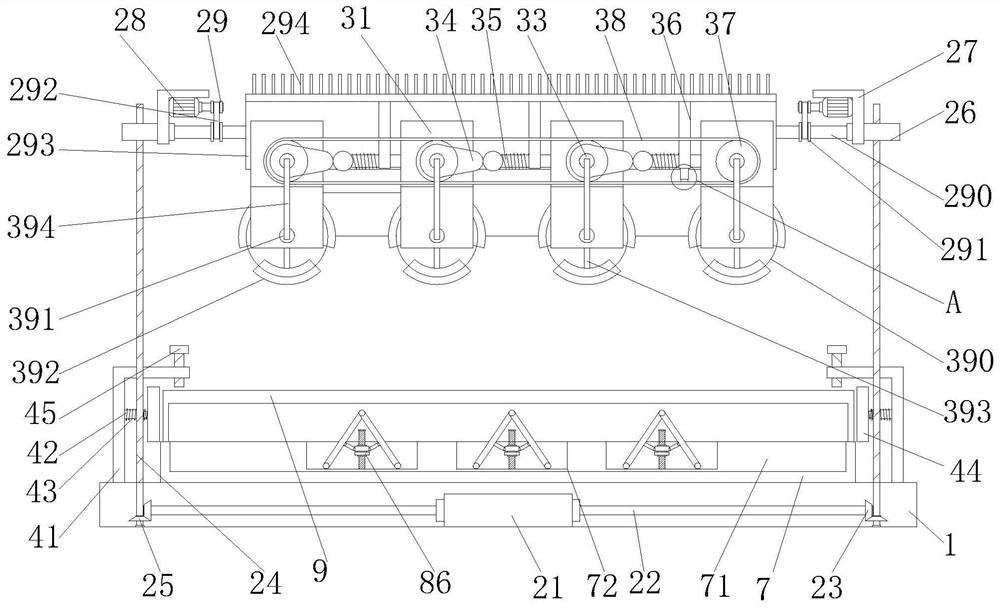

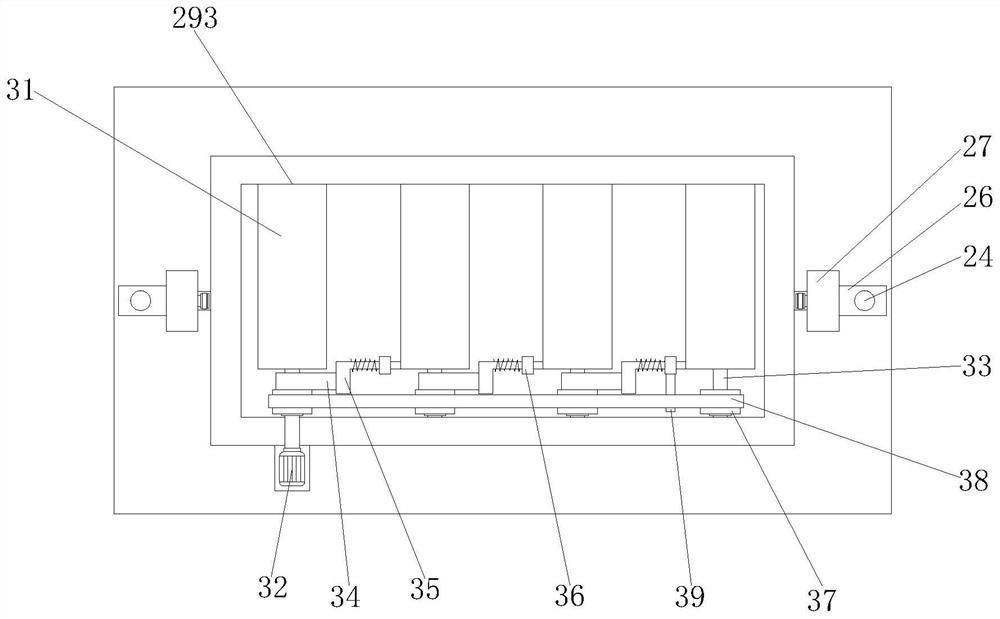

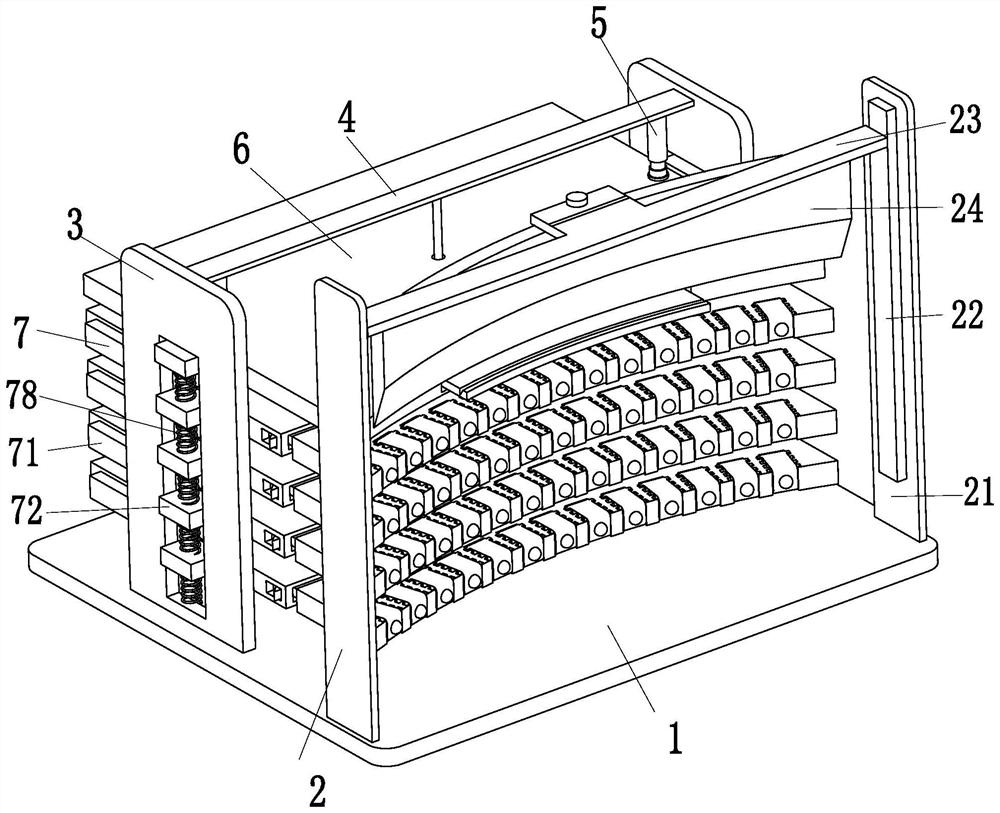

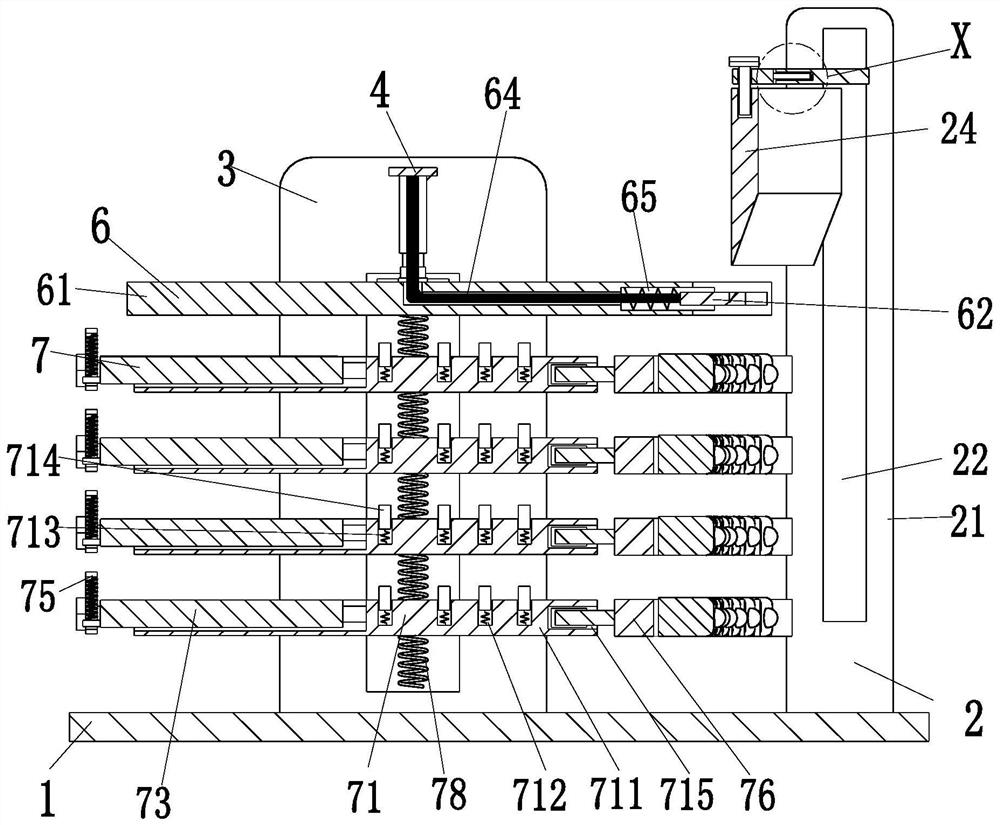

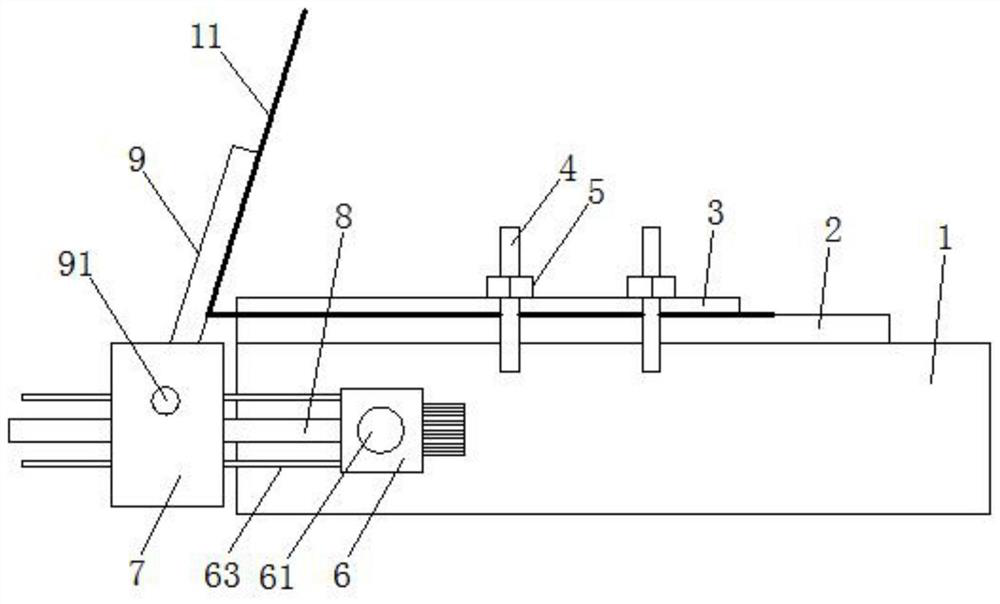

Decorative aluminum-plastic plate forming machining method

PendingCN112475020AAdjustable distanceAdjust arcMetal-working feeding devicesPositioning devicesStampingCam

The invention relates to a decorative aluminum-plastic plate forming machining method. Stamping forming equipment is used and comprises a base, stamping devices, an adjusting device, clamping devicesand a punching table. The adjusting device is arranged in the middle of the upper surface of the base. The stamping devices fixedly connected with the base are arranged on the two sides of the adjusting device. The clamping devices fixedly connected with the base are arranged on the two sides of the stamping devices. The punching table is arranged below the stamping devices. Through the stamping devices, an overturning motor is started and drives a fixture with a right-open-box shape to conduct angle overturning, and punching and stamping are replaced. By starting a double-shaft motor, the fixture with the right-open-box shape is driven to move downwards to conduct punching or stamping on an aluminum-plastic plate. An adjusting motor drives a cam to rotate, the distance of a fixing frame is adjusted, and the distance between radians during stamping is adjusted. Meanwhile, the radians during stamping are adjusted, and through a radian adjusting unit, the radians of the lower surface andthe distance between the radians during aluminum-plastic plate stamping are adjusted.

Owner:张永好

Intelligent curtain apparatus with adjustable radian

The invention discloses an intelligent curtain apparatus with adjustable radian. The intelligent curtain apparatus includes a wall body and a slide rail. Two sides of the slide rail are provided withprotruding blocks. Each protruding block is connected to the wall body through fastening screws. One end of the slide rail is provided with a controller. The bottom part of the slide rail is providedwith a driving slide block and a driven slide block. The driving slide block and the driven slide block are connected to a transverse slide apparatus through a connecting lever at one ends thereof distant from the slide rail. The transverse slide apparatus is connected to the curtain through a connecting rope. According to the invention, the transverse slide apparatus is provided so as to adjust the radian of the curtain, such that the curtain is applicable to various environments and the usage of the curtain is increased; And the controller is disposed to control the transverse slide apparatus, such that the apparatus herein can intelligently adjust the radian of the curtain and adjustment of the curtain is more precise.

Owner:大连函量科技发展有限公司

Bamboo furniture cutting machining device

ActiveCN111805651AAchieve fixationEasy to operateCane mechanical workingWood working apparatusStructural engineeringMachining

The invention relates to the field of bamboo pole cutting equipment, in particular to a bamboo furniture cutting machining device which comprises a bottom plate. The bamboo furniture cutting machiningdevice is characterized in that a vertical plate is fixedly connected to one side of the upper part of the bottom plate, bamboo pole supporting plates with arc-shaped grooves in the upper sides are fixedly connected to two ends of the vertical plate, separately, the two bamboo pole supporting plates are fixedly connected to two ends of the upper side of the bottom plate, separately, the verticalplate is connected to a bamboo pole fixing module, and the upper side of the bottom plate is connected to a bamboo pole cutting module. The bamboo furniture cutting machining device can cut triangularopenings in a bamboo pole conveniently, so that follow-up machining is facilitated.

Owner:金华市和怡休闲用品有限公司

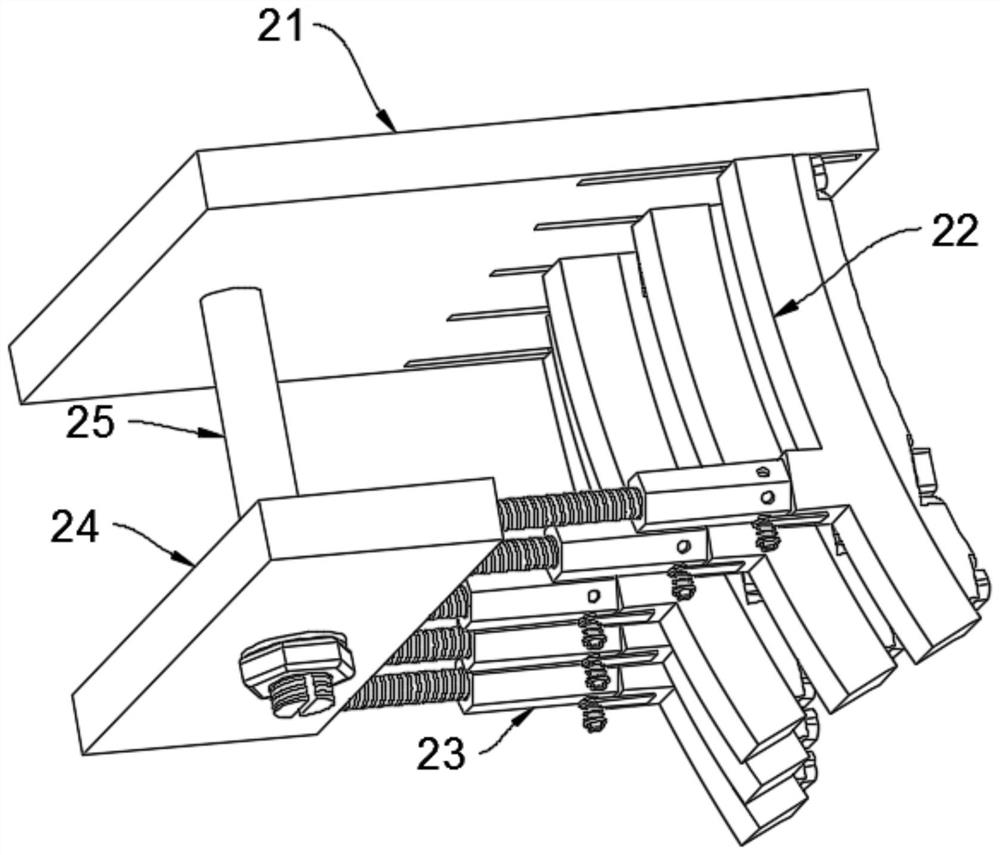

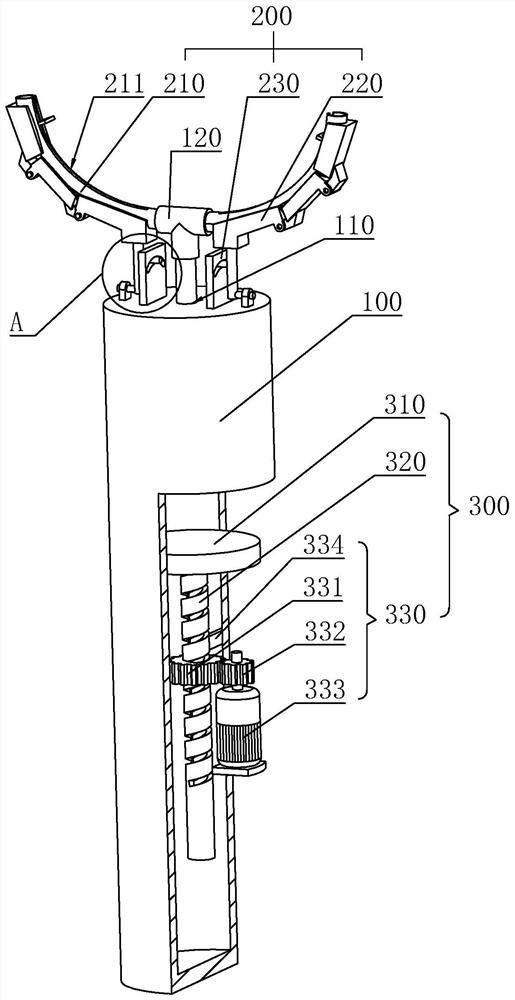

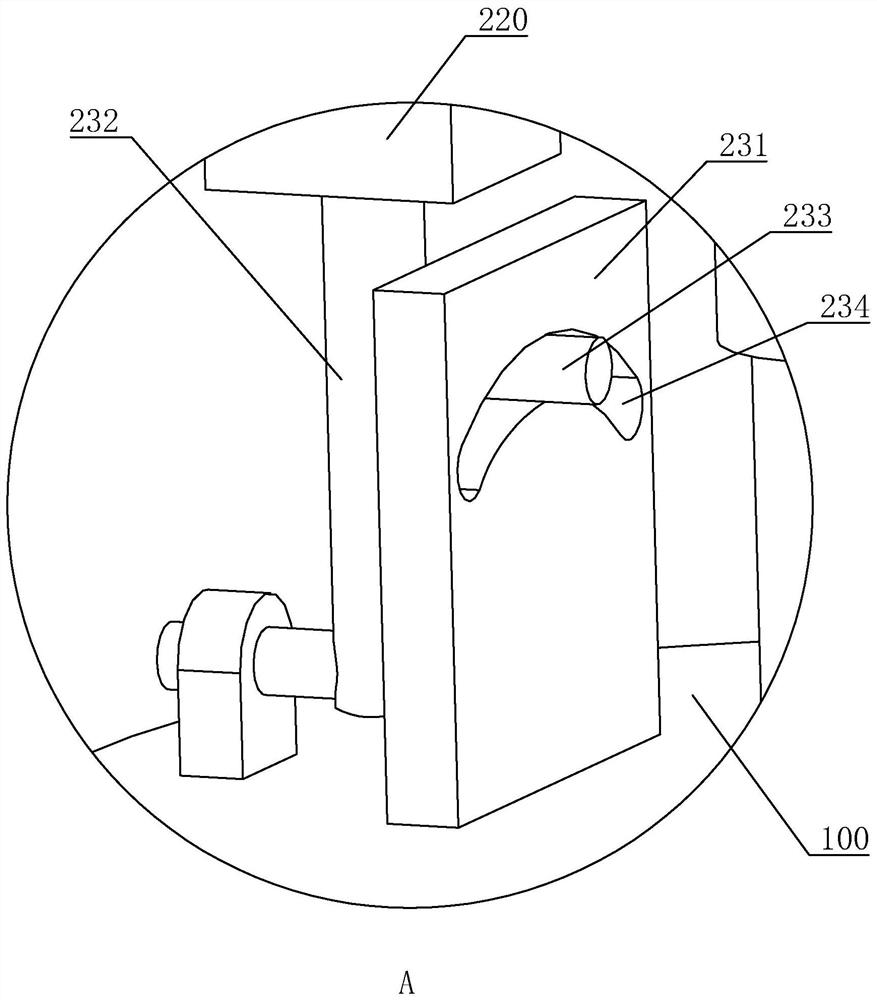

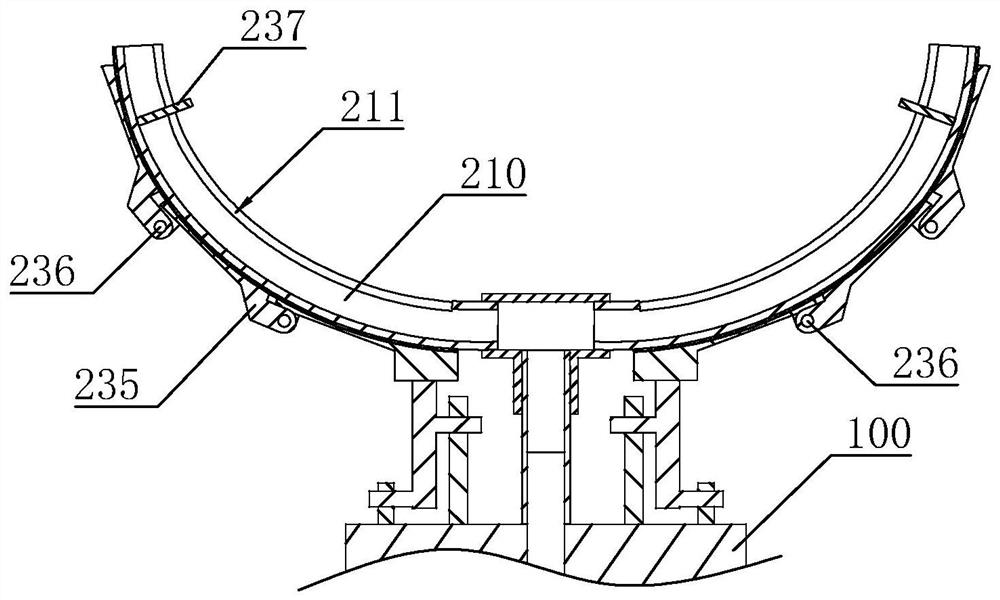

Special fixture for slag stopping cone for manipulator

PendingCN114131642AReduce maintenance costsImprove stabilityGripping headsStacking articlesThreaded pipeManipulator

The invention discloses a special fixture for a slag stopping cone for a manipulator, and belongs to the technical field of slag stopping cone clamping devices.The special fixture comprises the manipulator, one end of the manipulator is sleeved with a fixture assembly, and the fixture assembly is composed of a top plate assembly, a clamping strip assembly, a connecting assembly, a bottom plate assembly and a pin shaft assembly and is convenient to assemble; according to the device, part of components can be replaced conveniently, the maintenance cost is reduced, through a lead screw and a threaded pipe, the position of an arc-shaped strip can be adjusted conveniently, the radian formed between arc-shaped plates can be adjusted conveniently, slag stopping cones of different specifications can be used conveniently, through an air bag strip and an upper fixing plate, the situation that the slag stopping cones fall off during clamping and after overturning is avoided, and the service life of the slag stopping cones is prolonged. And through the limiting disc, during use, rotation of the pin rod is limited, looseness between the clamp assembly and the mechanical arm is avoided, the stability during use is improved, then the stacking position of the slag stopping cone is more accurate, and the production efficiency is effectively improved.

Owner:莱芜钢铁双山陶土福利加工有限公司

An electric massage chair for medical care

The invention provides an electric massage chair for medical care, and relates to the field of medical care devices. The electric massage chair comprises a base, a first outer sleeve is arranged at the top of the base, a sponge mat is arranged at the bottom of the bottom of the first outer sleeve, a supporting plate is fixedly connected at the bottom of the sponge mat, springs are fixedly connected at the bottom of the supporting plate, a damping rubber mat is fixedly connected at the bottom of the spring, a damping rod is fixedly connected at the bottom of the base, and a first rotating shaftis arranged on the left side of the base. The electric massage chair for medical care can be opened to form a bed through a supporting leg on a backrest and is rich in function, the massage chair canbe more conveniently and flexibly moved through universal wheels at the bottom of a supporting seat, a lot of labor and time is saved, people can feel more comfortable when sitting on the chair through springs and the sponge mat in the base, a pushing device pushes an air bag, the arc degree of the waist of the backrest can be adjusted, arc requirements of the back and the waist of different people can be met, and the electric massage chair is more comfortable.

Owner:邓纪英

A packaging carton making corrugated cardboard stereotypes cutting processing method

InactiveCN111231410BAvoid Scratching DeviationsAct as a guideBox making operationsPaper-makingCardboardPressboard

The invention provides a corrugated cardboard stereotype cutting processing method for packaging cartons. The operation is completed by the cooperation of a bottom plate, a cutting device, two support frames, a connecting plate, a pressing cylinder, a lower pressing plate group and a pressing plate group. The present invention can Due to the certain thickness of the stacked corrugated cardboard, when it is pressed down and cut, the stacked corrugated cardboard may be staggered and offset due to pressure, so that the incision position of the cut corrugated cardboard is different. When the shape cutter is pressed down to cut, due to the different radians of various cutters, it is difficult to have a corresponding mold to guide it. Due to the certain resistance when cutting down, the cutter is prone to problems such as incision deviation when it is pressed down. .

Owner:许昌京昌包装有限公司

A bending machine for the production of metal panels for curtain walls

The invention discloses a bending machine used for the production of curtain wall metal plates, belonging to the field of curtain walls, comprising a base, a bottom plate is arranged on the top surface of the base, a pressing plate is arranged above the bottom plate, and pressing plates are fixed on two opposite side walls of the base. Tighten the stud, the pressing plate is provided with a through hole that matches the pressing stud; the two side walls opposite to the base are rotatably connected with the adjustment base, and the base is also installed with a device for driving the adjustment base to rotate. Adjust the motor; the adjustment base is slidingly connected with a compression base, and the adjustment base is also provided with an adjustment mechanism for driving the compression base to slide; a bending plate is connected between the two compression bases, and the compression A bending motor for driving the bending plate to rotate is also installed on the base. The invention is reasonable in design, and in use, can not only prevent the deviation of the metal plate of the curtain wall during the bending process, but also flexibly bend the metal plate of the curtain wall with different radians and angles.

Owner:安徽国天节能科技有限公司

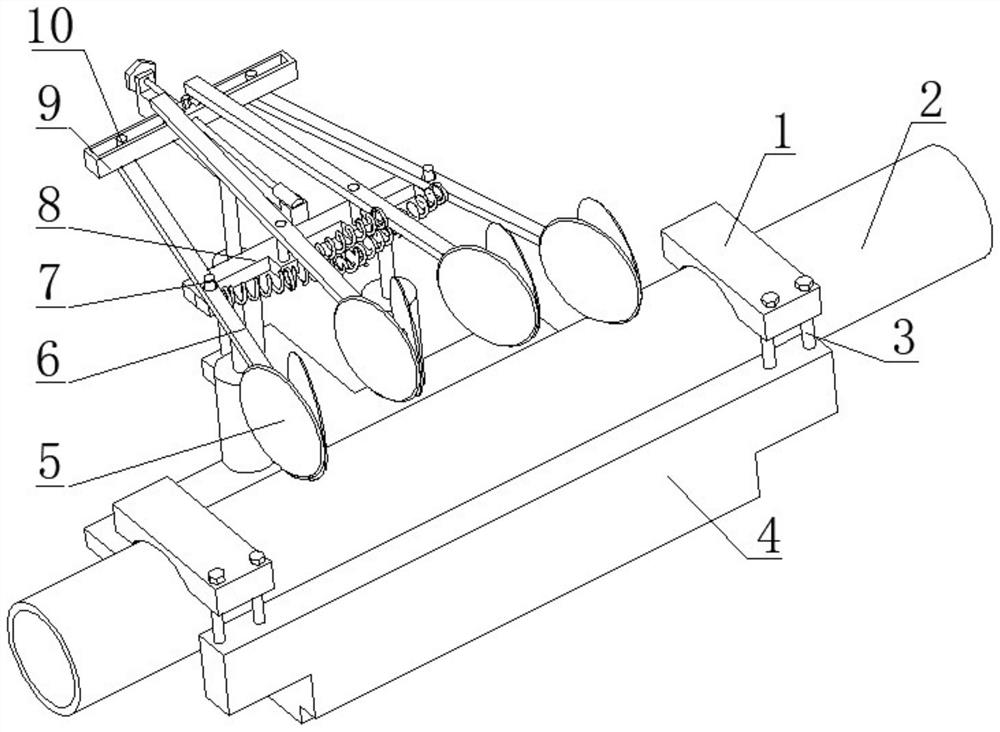

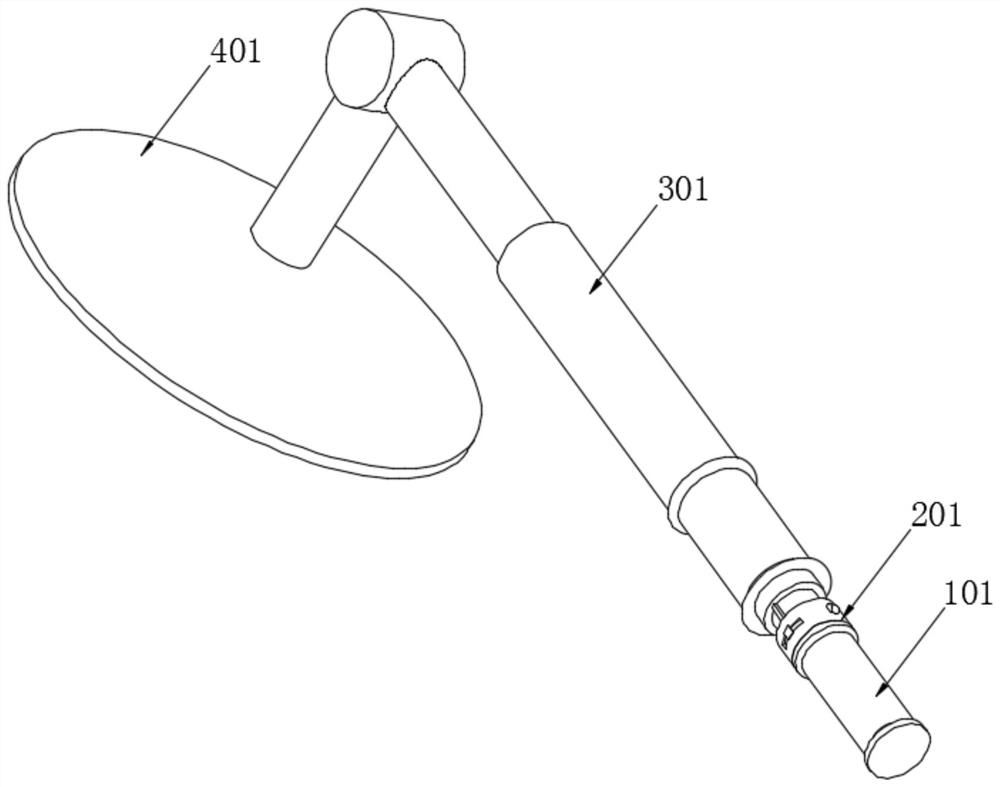

Multi-form pruning and shaping machine for landscaping

PendingCN113170668AWide range of applicationsHigh trimming efficiencyCuttersCutting implementsPruningLandscaping

The invention discloses a multi-form pruning and shaping machine for landscaping, and relates to the technical field of landscaping equipment. According to the technical scheme, the multi-form pruning and shaping machine is characterized by comprising a pruning cutter disc, a hand-held cross rod and a processor, one end of the hand-held cross rod is rotatably connected with a rotary sleeve, and an angle sensor is arranged between the rotary sleeve and the hand-held cross rod; the processor is connected with the angle sensor, the processor generates a sequence control command according to an angle measurement value transmitted by the angle sensor, and the sequence control command is composed of a plurality of sequence sub-commands; the pruning cutter disc comprises a driving rotating shaft and a pruning cutter piece connected with the driving rotating shaft; the pruning cutter piece comprises a plurality of pruning blades and a plurality of driving pieces, and the adjacent pruning blades are rotationally connected through rotating shafts; and the driving parts and the rotating shafts are arranged in a one-to-one correspondence mode, and the driving parts respond to the corresponding sequence sub-commands to independently control the corresponding rotating shafts to rotate. The multi-form pruning and shaping machine for landscaping can meet the pruning requirements of pruning surfaces with different areas in multiple dimensions, and meanwhile can adaptively prune green plants with different thicknesses.

Owner:湖北省城乡建设发展中心

A kind of anti-corrosion painting and polishing equipment for underground pipe production and processing

Owner:苏州福祺互联网科技有限公司

A portable tree spraying device for landscaping

ActiveCN110369203BReduce workloadImprove spraying efficiencySpray nozzlesPlant protectionTree trunkLandscaping

The invention discloses a portable tree spraying device for landscaping. The device comprises a liquid storage bucket with a liquid outlet, a spraying mechanism on the liquid outlet, and a power mechanism used for driving liquid in the liquid storage bucket to be output from the spraying mechanism. The spraying mechanism comprises an elastic spraying pipe connected with the liquid outlet, a supporting rod and a rotating assembly; a spraying opening is formed in the side, facing the trunk, of the elastic spraying pipe, the supporting rod is connected with the elastic spraying pipe, the rotatingassembly comprises a first part connected with the liquid storage bucket, and a second part connected with the supporting rod, the first part and the second part are rotatably connected, and the plane of the elastic spraying pipe is perpendicular to the liquid storage bucket to rotate. Due to the rotating assembly, when the elastic spraying pipe outside the trunk moves upwards or downwards alongthe trunk, a sliding rod on the rotating rod moves along an arc hole, the supporting rod is driven to rotate, the elastic spraying pipe is driven to rotate, a worker does not need to adjust the handheld height of the liquid storage bucket and only needs to carry out rotation to finish the spraying process, workloads of a worker are reduced, and the spraying efficiency is improved.

Owner:广东冠城建设有限公司

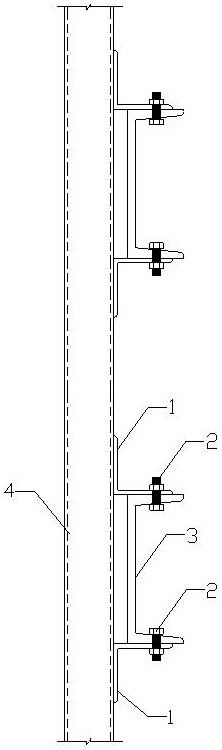

A large-area curtain wall steel keel installation method

The invention discloses a large-area curtain wall steel keel installation method, comprising the following steps: preparing several main pipes, several surface layer steel keels, several corner codes and several bolts, and a long strip-shaped adjustment hole is arranged in the center of the horizontal side and the adjustment hole is vertical The connecting line on the vertical and horizontal sides; then open a connection hole on the upper side or / and lower side of the main pipe corresponding to each fixed point; fix the corner code on the main pipe, and ensure that the vertical side of the corner code is facing outward And the inner surface of the vertical side is far away from the main pipe for a certain distance, and then the main pipe is fixed on the wall surface; the surface steel keel is welded to the outer surface of the vertical side of the corner code, and then the total station is used to detect that the surface steel keel is located at the position of the corresponding main pipe The coordinates of each point; if the error between the point coordinates and the design point coordinates is greater than 5mm, then screw the corresponding angle code to drive the surface steel keel to move to adjust the coordinates of each point, and then tighten the bolts. The method can adjust the radian error of the steel keel on the surface layer of the curtain wall, and improve the installation accuracy of the steel keel on the surface layer of the curtain wall.

Owner:CHINA METALLURGICAL CONSTR ENG GRP

Multifunctional surgical stripper

The invention relates to a multifunctional surgical stripper, which comprises a handle rod and an elastic dial fixedly mounted on the top end of the handle rod, wherein the handle rod and the elasticdial are hollow and communicated. A pulling device for bending the end of the elastic paddle is arranged in the handle rod and the elastic paddle, and a driving device connected with the pulling device is arranged on the handle rod. A brake device is installed on the driving device, and the top end of the elastic paddle is adjusted to the required radian, so that the safety of separation is increased when the tissue is bluntly separated. By adjusting the bending angle and radian of the elastic dial with two first handles, the blood vessel or tissue can be pulled safely, and the surgical fieldaround the blood vessel or tissue can be exposed, and the passage of the endoscopic cutter can be increased, and the damage to the blood vessel or tissue can be reduced.

Owner:THE SECOND HOSPITAL OF HEBEI MEDICAL UNIV

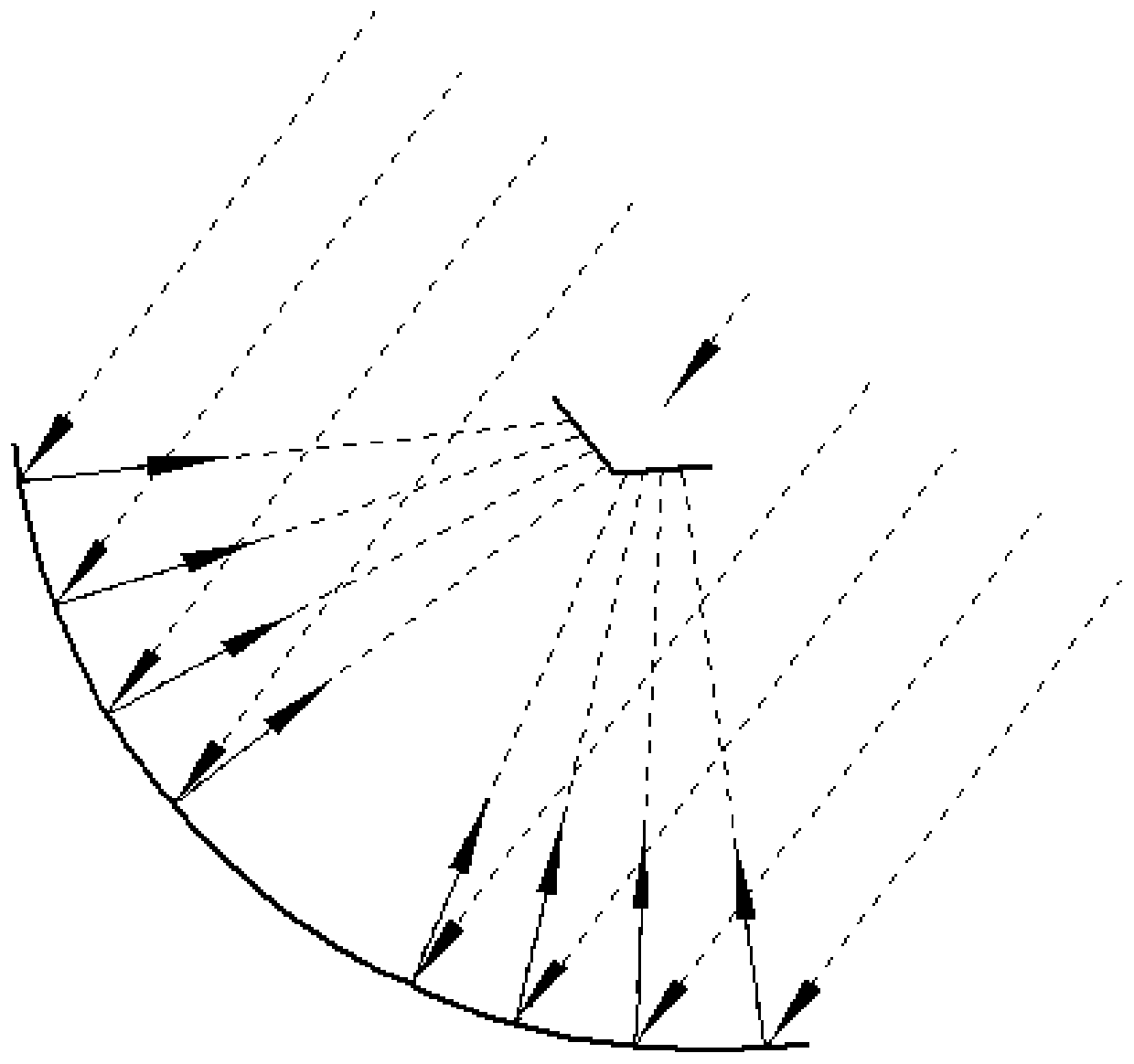

A parabolic cylinder foldable portable solar cooker

ActiveCN108180655BSave spaceEasy to storeSolar heating energySolar heat collector for particular environmentSolar cookerFocal line

The invention discloses a parabolic cylindrical foldable portable solar cooker, which includes a flexible reflective plate arranged at an angle. The flexible reflective plate includes a parabolic cylindrical flexible material bottom plate. The outer wall of the flexible material bottom plate is adhered to multiple layers. There are three arched reflective plate support rods arranged along the length direction of the flexible material base plate. A heat collecting device is provided at the focal line position of the flexible material base plate. There are multiple openings along the flexible material base plate on both sides. The first elastic rope is arranged in the length direction of the flexible material bottom plate. The lower end of the arched reflector support rod is provided with an arched solar cooker bracket, and the upper end of the arched reflector support rod is provided with a solar cooker support rod. The invention has a simple structure and is easy to manufacture. Each component can be combined or folded. The storage volume is small, the weight is light, and it is easy to carry. It is suitable for travel and field work.

Owner:NORTHEASTERN UNIV LIAONING

Composite Building Blocks

ActiveCN110158848BReduce volumeGood flexibilityBuilding componentsArchitectural engineeringStructural engineering

Owner:东阳市天杨建筑工程设计有限公司

Medical flat bed and processing method thereof

The invention discloses a medical flat bed and a processing method thereof.The medical flat bed comprises a bed board frame which is mainly used for a supporting structure of a flat bed device, bed head boards are arranged above the bed board frame, and the two sets of bed head boards are arranged in a bilateral symmetry mode about the vertical center line of the bed board frame; the bed board mechanism is arranged on the inner side of the bed board frame, and the bed board mechanism is mainly used for bearing a lying structure of a patient; the supporting mechanisms are arranged at four corners of the lower end of the bed board frame; the controller is mounted at the right end of the bed board frame; the adjusting mechanism is arranged at the lower end of the bed board mechanism and arranged on the inner side of the bed board frame, according to the medical flat bed, the inclination angle of the bed board mechanism can be conveniently adjusted, and the movable bed board mechanism is divided into a multi-section structure of a first movable bed board and a second movable bed board; the first movable bed plate and the second movable bed plate can be subjected to layered angle adjustment, so that the bed plate mechanism can be better attached to the back of a patient.

Owner:浙江金鹭医疗科技有限公司

An adjustable outer contour sewing positioning and thread guiding device

An adjustable outer contour sewing positioning and routing guide device, including an outer contour fixed edge (1), characterized in that: one end of the outer contour fixed edge (1) is fixed to one end of an arc steel belt (2), The connecting shaft (4) is hinged with the sliding adjustment bar (6), and the sliding adjustment bar (6) penetrates into the sliding hole (5) and the other end of the fixed edge (1) of the inner and outer contours is connected with a curved steel belt (3), and the mounting seat An arc adjustment device is installed between (14) and the fixed side of the outer contour (1). The arc outer tooth plate (7) and the horizontal plate (9) together constitute the outer contour track, and the outer contour slide is installed on the outer contour track. Seat (11), outer contour sliding seat (11) is equipped with routing guide presser foot (12), the invention can adjust the outer contour according to the needs, the adjustment and fixing are very convenient, and the outer contour sewing positioning and routing guidance are realized. The sewn products have good consistency, and the garment aesthetics and processing efficiency have been improved.

Owner:JIHUA 3506 TEXTILE & APPL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com