A large-area curtain wall steel keel installation method

An installation method and steel keel technology, applied in the direction of walls, buildings, building components, etc., can solve the problems that the surface wall layer has a great influence on the forming accuracy, affect the quality and appearance of the project, and the curtain wall layer is uneven, and achieves low cost. , The effect of saving materials and clear installation direction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

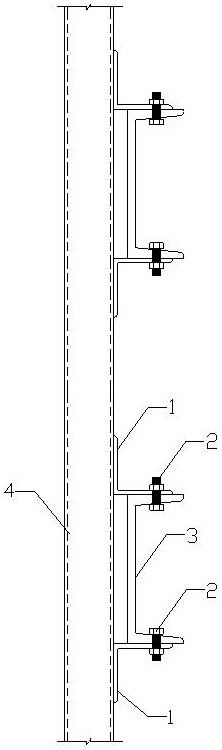

[0023] see figure 1 , a large-area curtain wall steel keel installation method, the curtain wall steel keel includes several main pipes 3 and several surface layer steel keels 4, each main pipe 3 is arranged horizontally, all main pipes 3 are evenly arranged in the vertical direction, and each surface layer steel The keel 4 is vertically fixed on corresponding several main pipes 3; its installation method specifically includes the following steps:

[0024] (1) Prepare several main pipes 3, several surface steel keels 4, several corner codes 1 and several bolts 2. The corner codes 1 include vertical sides and horizontal sides. The adjustment hole is perpendicular to the connection line between the vertical and horizontal sides; according to the fixed position of each surface steel keel 4 in the design, the fixed point is determined at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com