A packaging carton making corrugated cardboard stereotypes cutting processing method

A corrugated cardboard and processing method technology, which is applied in the field of corrugated cardboard shaping and cutting processing for packaging carton production, can solve the problems of staggered offset, internal offset of cutter incision, and different positions of corrugated cardboard incisions, and can prevent deviation and internal biased effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the techniques of the present invention, the creation characteristics, the purpose and efficacy are readily understood, and the present invention is further illustrated in connection with the specific illustration. It should be noted that the features of the present application and the features in the embodiments in the present application can be combined with each other in the case of an unable conflict.

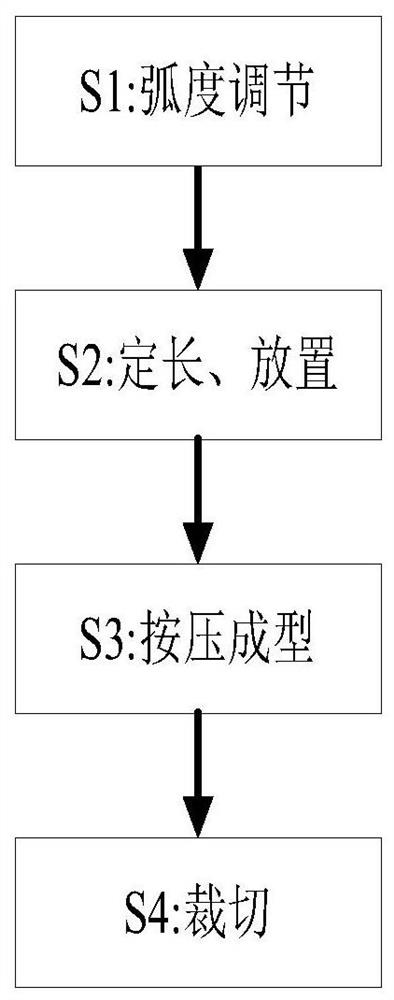

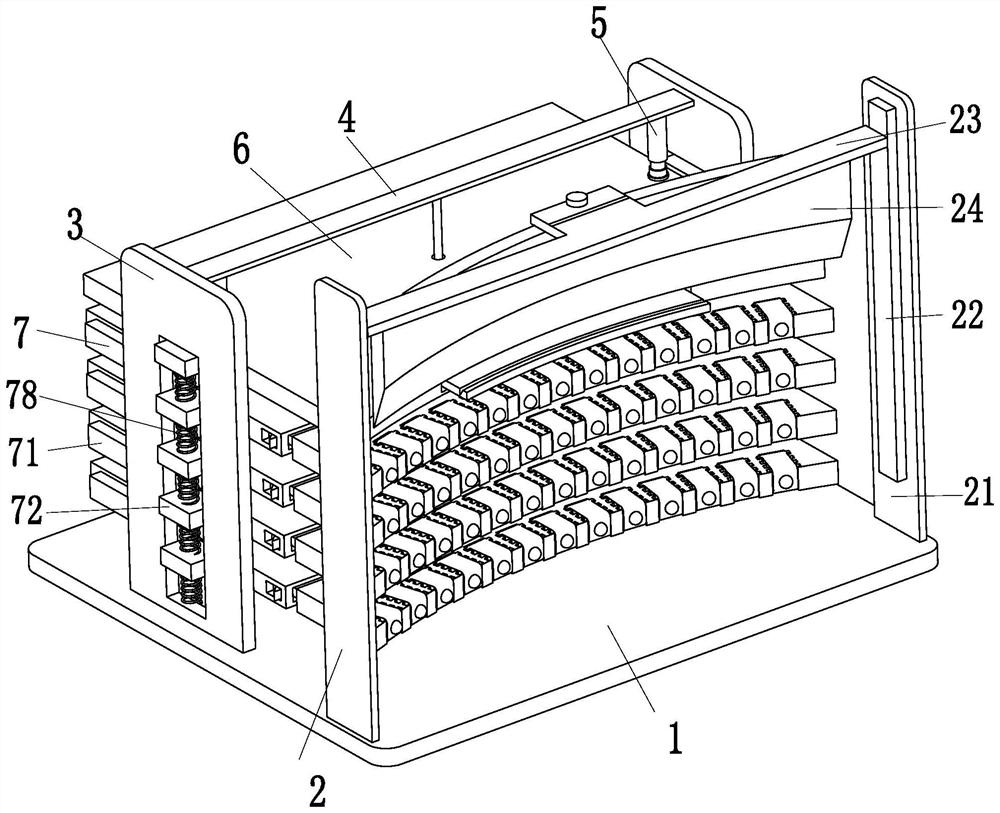

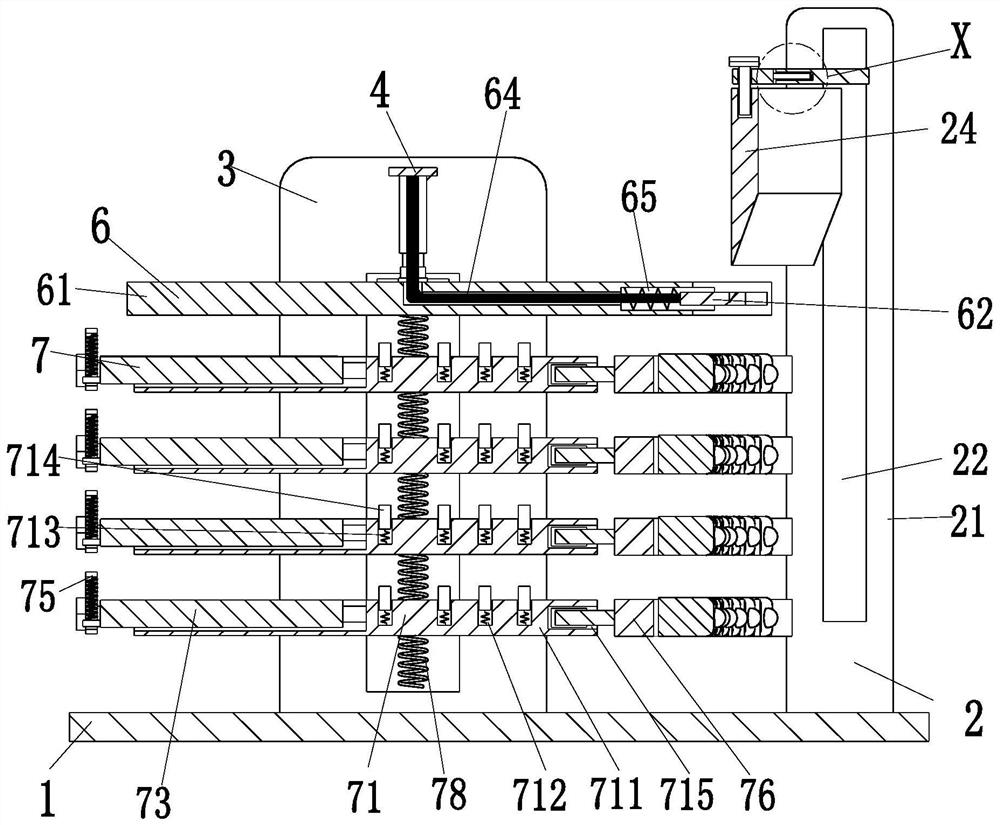

[0034] Such as Figures 1 to 7 As shown, a packaging carton is made of corrugated cardboard type cutting processing method, which is pressed against cutting equipment including a bottom plate 1, a cutting device 2, two support frames 3, a connecting plate 4, Pressing the cylinder 5, the lower press plate group 6, and the press plate group 7, the specific critic method of the corrugated board is used in the above-described pressing cutting equipment as follows:

[0035] S1, radian adjustment: Plug the socket 77 into the detachable plate 76 such that the ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com