Anti-abrasion circulating fluidized bed boiler

A circulating fluidized bed and anti-wear technology, which is applied to fluidized bed combustion equipment, fuel burned in a molten state, lighting and heating equipment, etc., can solve the problem of reduced gas and solid flow area and increased wear of both side wall tubes , easy to form eddy currents and other problems, to achieve the effect of reducing speed and concentration, simple and convenient maintenance, and high operating reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

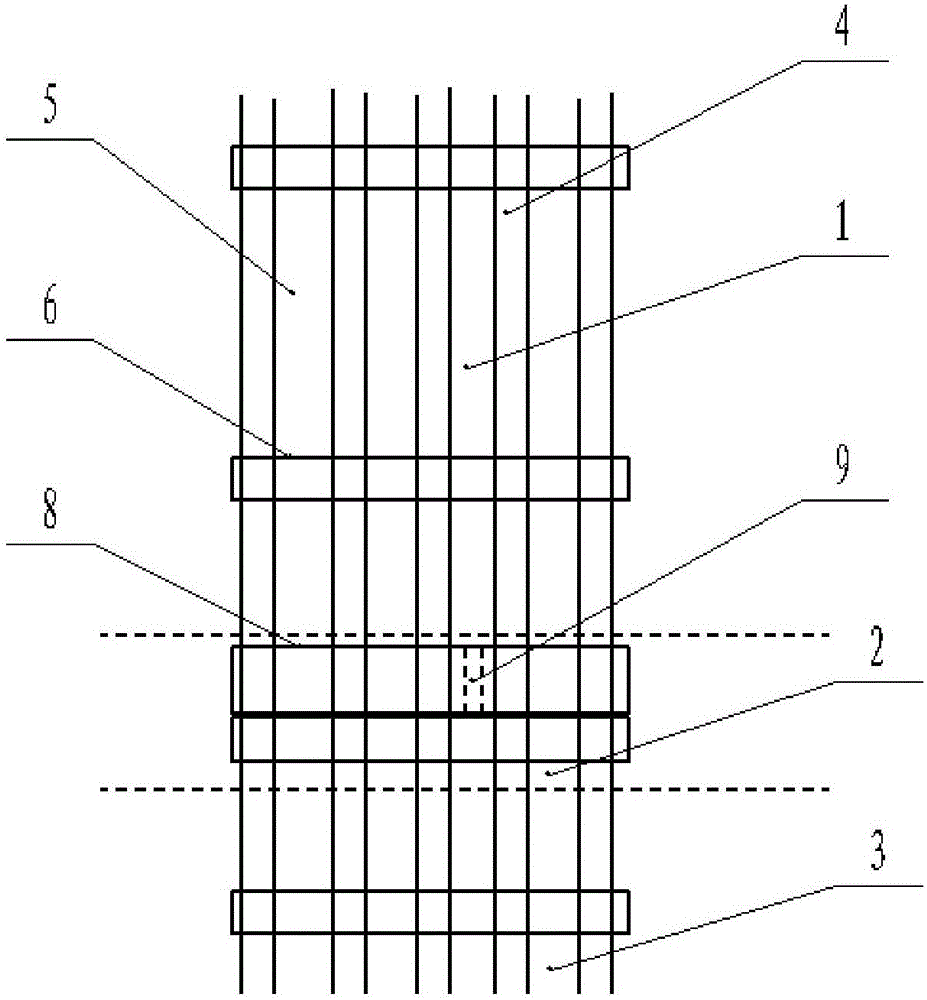

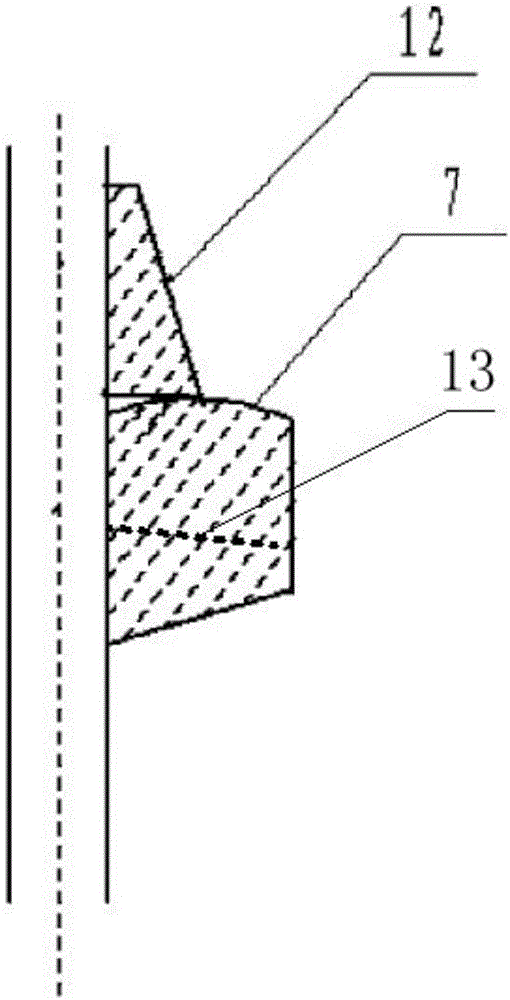

[0032] An anti-wear circulating fluidized bed boiler boiler, comprising a water wall, a dense phase zone 1, a transition zone 2 and a dilute phase zone 3, such as figure 1 and figure 2 As shown, the water cooling wall is formed by connecting the water cooling wall tube 4 and the fins 5, the surface of the water cooling wall is sprayed with a wear-resistant coating with a thickness of 2-5mm, and the water cooling wall is provided with a "V" shaped grip The nail 13 and the anti-wear beam 6 with a semi-trapezoidal cross-section, the grab nail 13 is welded on the fin, the anti-wear beam 6 is laid on the grab nail 13 and covers the grab nail 13, and the height of the laid anti-wear beam 6 is 140- 160mm, width 80-100mm. The anti-wear beam 6 is close to the nail 13 and the water-cooled wall pipe 4, and the anti-wear beam 6 also has a guide slope 7 for changing the direction of the particles.

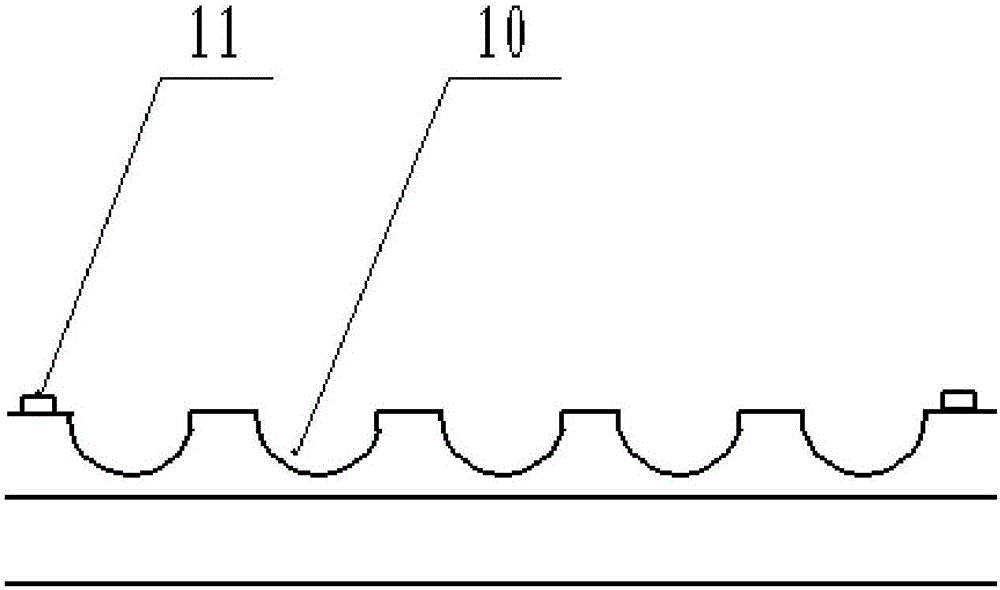

[0033] At the same time, in order to further achieve the anti-wear effect, the present i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com