Casing pipe driving head suitable for casing pipe well drilling

A casing drive head and casing drilling technology, which is applied in the direction of drilling drive devices, casings, drilling equipment, etc. Ability, increased safety, reduced mutual swing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

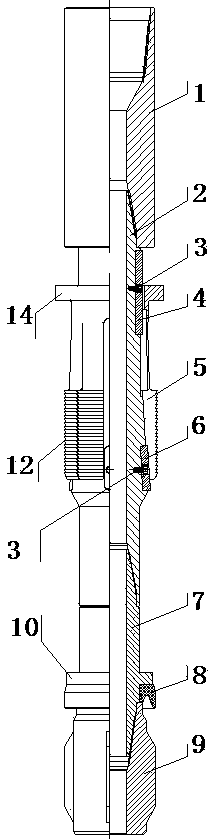

[0041] A casing driving head suitable for casing drilling, including a variable button joint 1, a guiding locking mechanism and a righting sealing mechanism; the guiding locking mechanism cooperates with the casing to lift, lower and rotate the casing; the The righting and sealing mechanism is used to guide and straighten the guiding and locking mechanism that is lowered into the casing and seal the drilling fluid; the variable button joint 1, the guiding and locking mechanism and the righting and sealing mechanism are sequentially connected from top to bottom.

[0042] In the present invention, the guiding and locking mechanism includes a central shaft 2 and slips 5 sleeved on the central shaft 2, and the central shaft 2 cooperates with the casing through the slips 5 for lifting, lowering and rotating the casing.

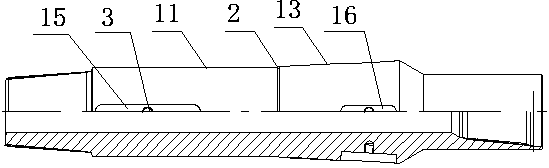

[0043] In the present invention, the central shaft 2 includes a positioning section 11 and a driving section 13 from top to bottom. The positioning section 11 is fi...

Embodiment 2

[0054] The invention includes a variable button joint 1, a guiding and locking mechanism, and a righting sealing mechanism;

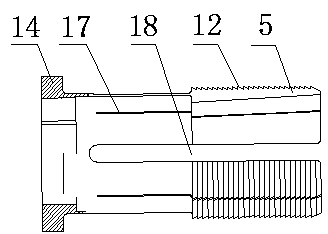

[0055] The guiding and locking mechanism includes the central shaft 2, the positioning key 4, the slips 5, the driving key 6 and the lower joint 7. One end of the central shaft 2 is a male buckle, and the other end is a female buckle. The male buckle and the female buckle end of the central shaft 2 Positioning keyway 15 and driving keyway 16 are respectively provided with, positioning key 4 is arranged in positioning keyway 15, driving key 6 is arranged in driving keyway 16, positioning key 4 is fixed in positioning keyway 15 by fixing bolt 3, driving key 6 The fixed bolt 3 is fixed in the driving keyway 16; the slip 5 is set on the outer circle of the central shaft 2, and the slip 5 is a cylindrical structure, one end of the slip 5 is the snap tooth 12, and the other end is the slip lifter. The shoulder 14 is provided with a slip keyway 18 and a gap 17...

Embodiment 3

[0064] The centralizing sealing mechanism in the present invention can also be used in casing driving heads of other structures. When the casing driving head needs to be used in the downhole, under the guidance of the centralizing sealing mechanism, the casing driving head will enter the casing smoothly. It will play the role of guiding and straightening in the casing. Under the action of the centralizing edge, the centralizer on the inner wall can reduce casing wear, remove cuttings during drilling, and straighten the casing driving head so that the casing driving head is in the casing. The position inside the pipe is in the middle position, so that the sealing ring 8 can achieve the best sealing effect, and prevent the sealing failure caused by the eccentricity of the sealing ring 8, as well as the outflow of downhole circulating mud; The centering function of the mechanism, the sealing ring 8 is in the middle position in the casing, which can seal the inner wall of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com