Patents

Literature

69results about How to "Solve obstacles" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

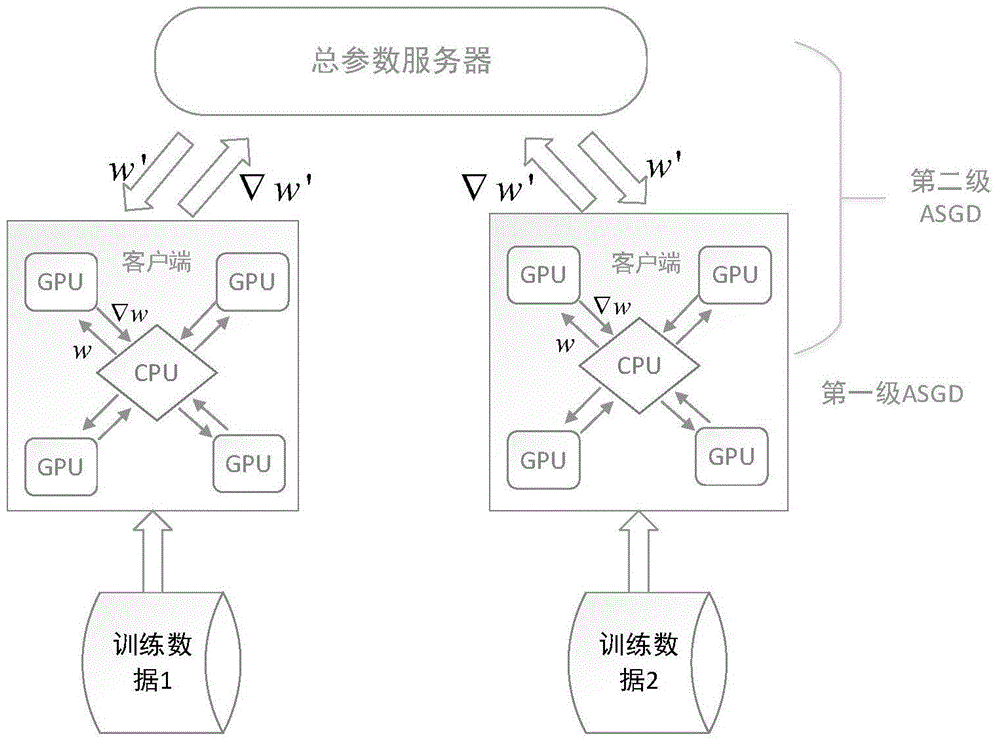

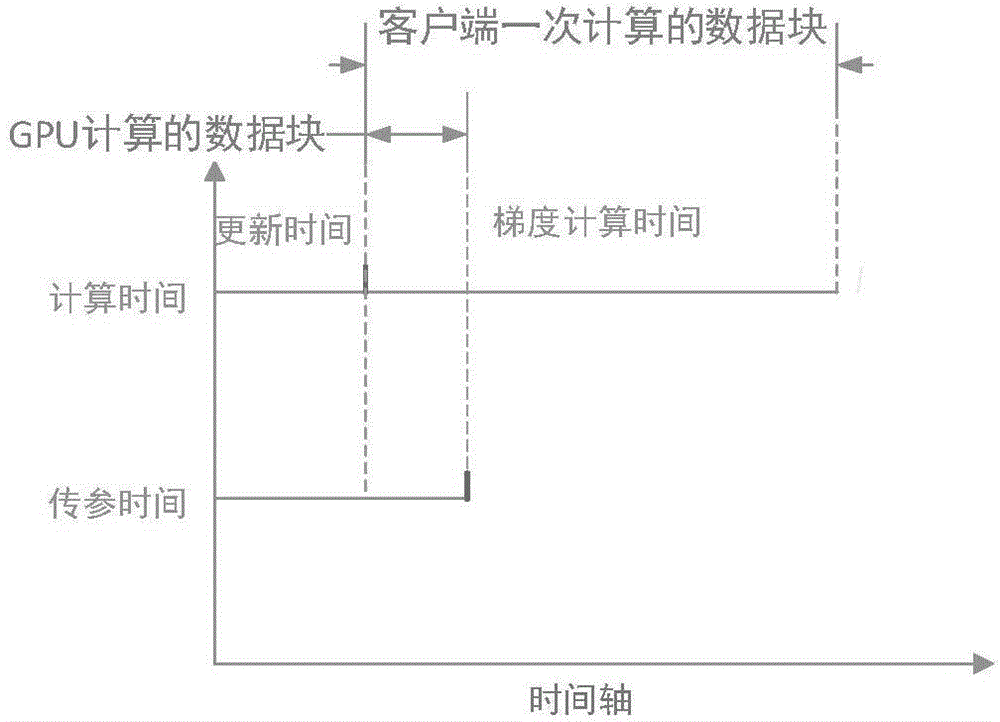

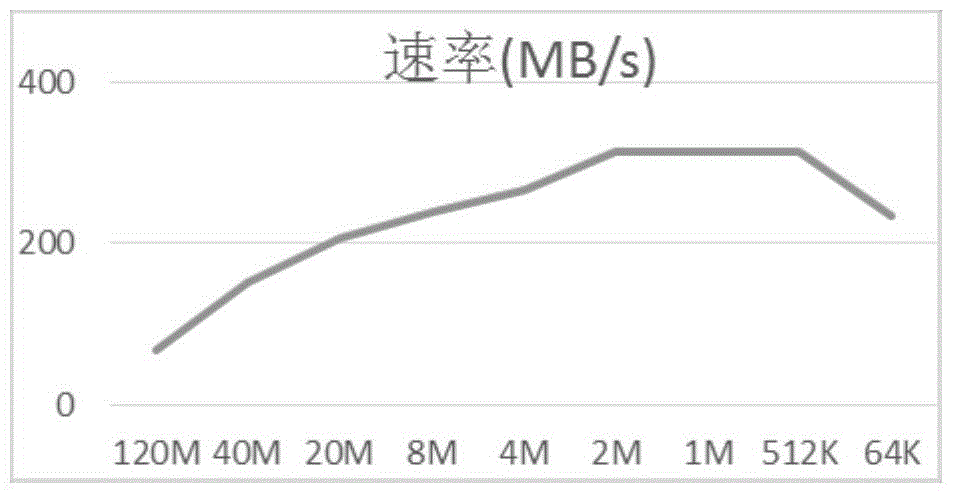

Distributed parallel training method and system for neural network acoustic model

ActiveCN106297774AReduce frequencyAvoid divergenceBiological neural network modelsSpeech recognitionAlgorithmAcoustic model

The invention provides a distributed parallel training method and system for a neural network acoustic model. The distributed parallel training method comprises the steps that 101) each group of training data is inputted into a client respectively; 102) each of the client receives the inputted training data, and transmits parameters between a plurality of GPU and a first CPU, which are arranged in the client, by adopting a bus, wherein the parameters comprise the model weight and the gradient; each GPU calculates the gradient based on the inputted model weight parameter and inputs the calculated gradient into the first CPU; the first CPU updates a model copy in the corresponding client by using the gradient uploaded by the GPUs, transmits an updated weight parameter back to each GPU so as to be used for carry out gradient calculation again, and meanwhile, the first CPU accumulates the gradient inputted by each GPU and updates a model in a parameter server according to a accumulation result; and 103) latest gradient information acquired by accumulation carried out by the CPU of each client is inputted into the server by adopting network resources, and then a neural network acoustic model stored in the server is updated.

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI +1

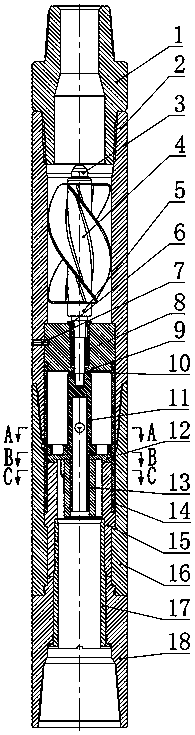

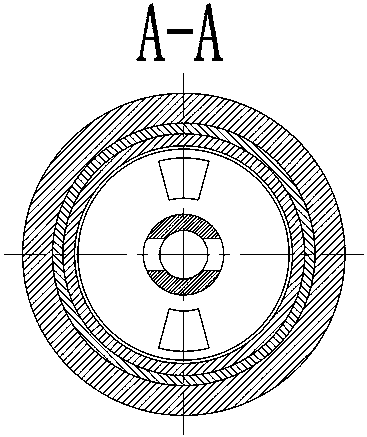

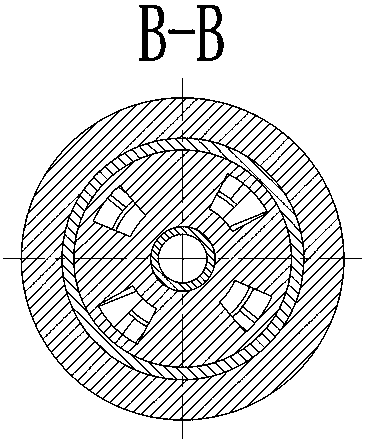

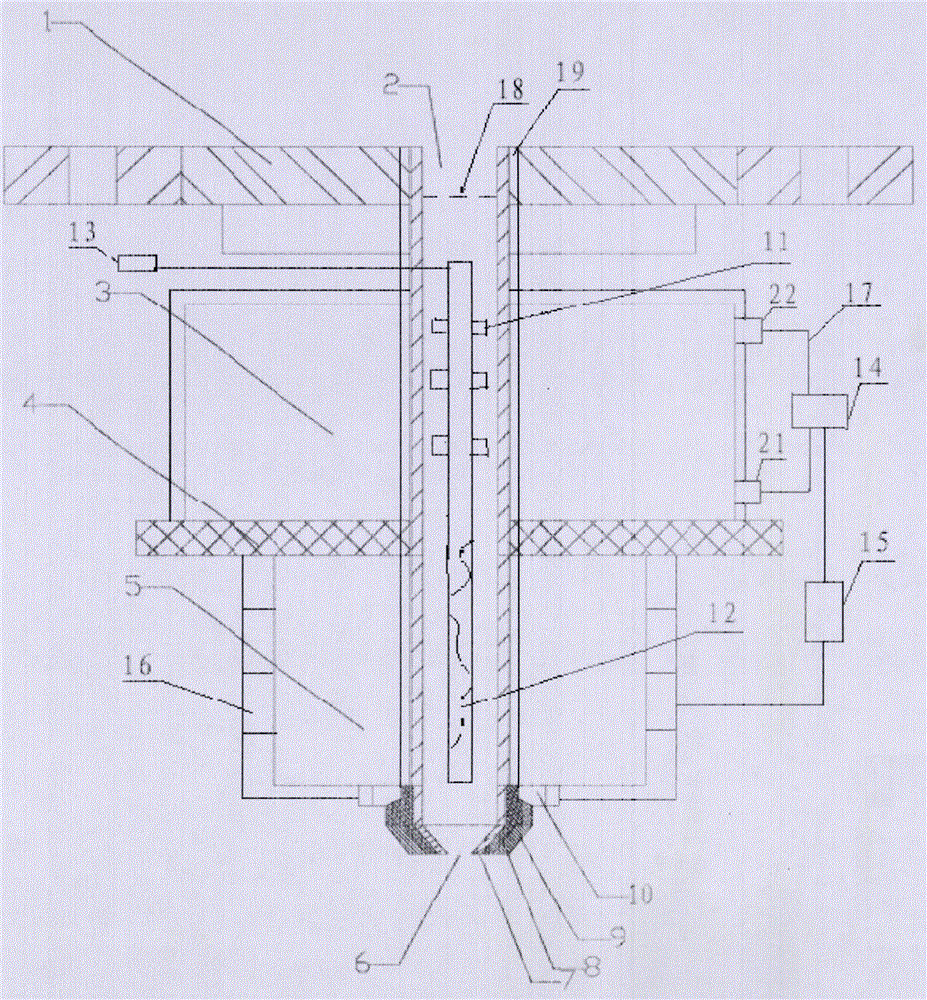

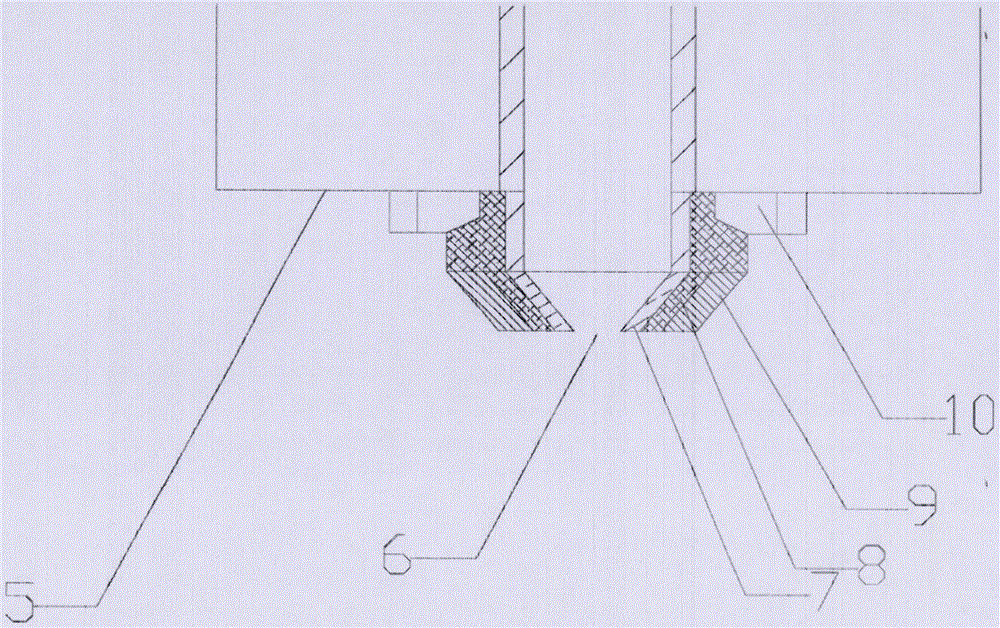

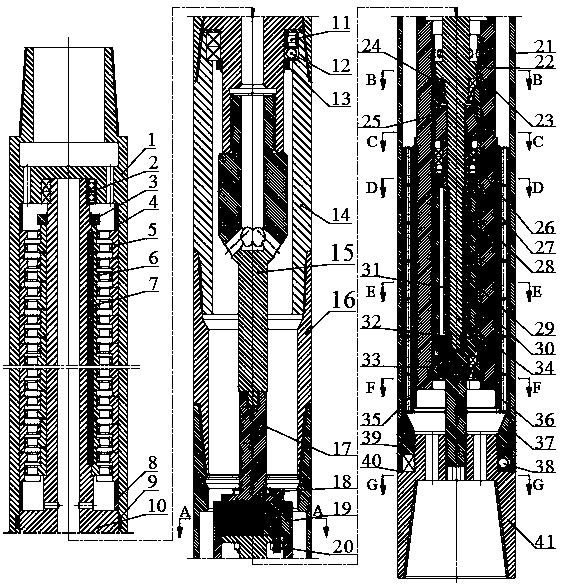

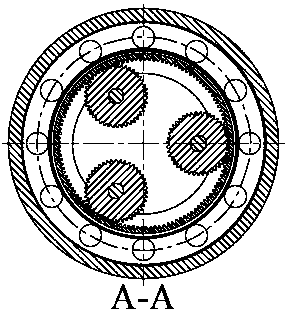

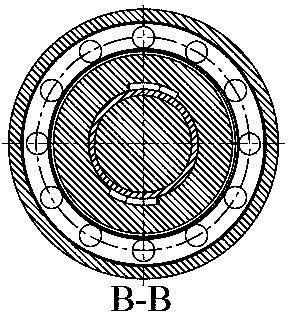

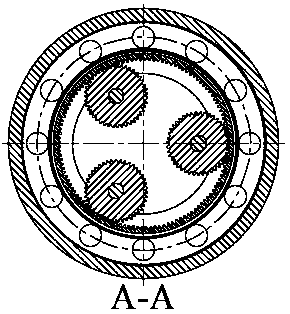

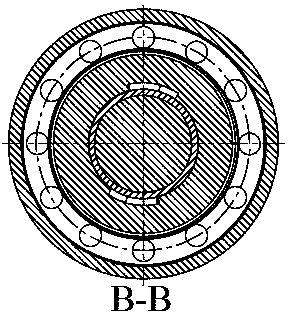

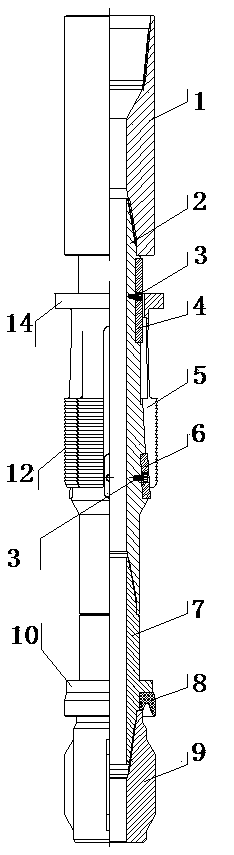

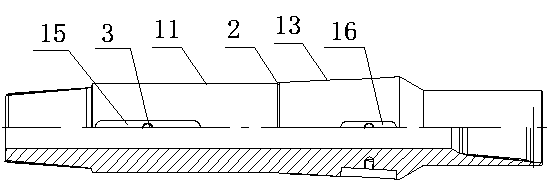

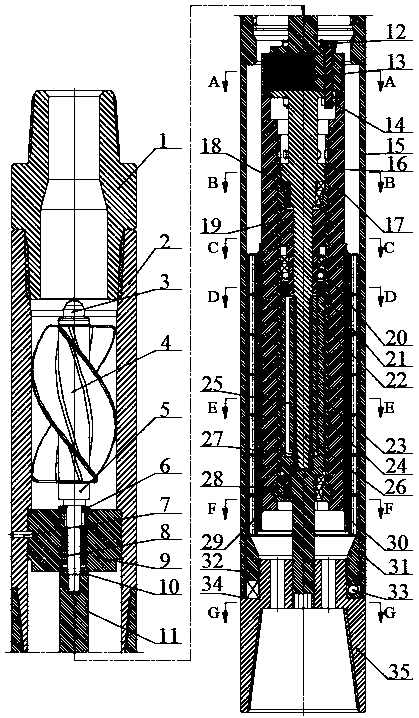

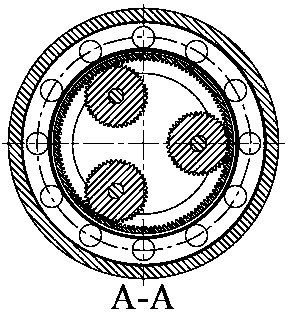

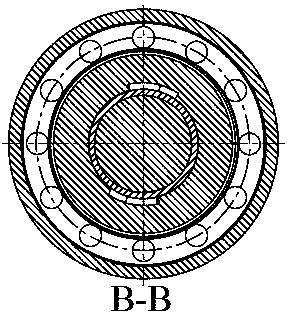

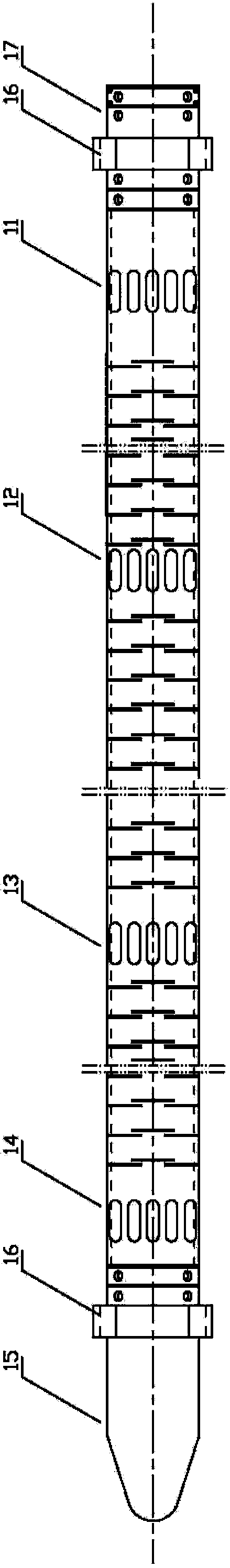

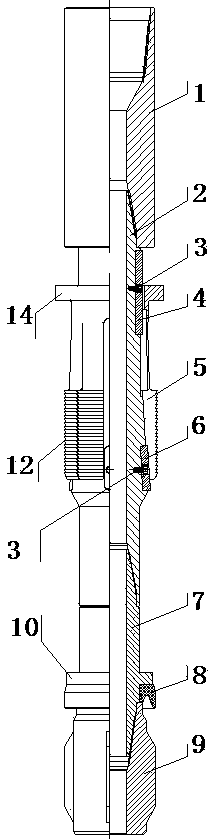

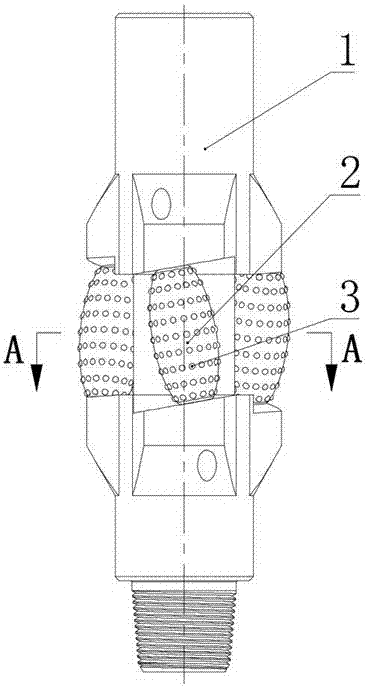

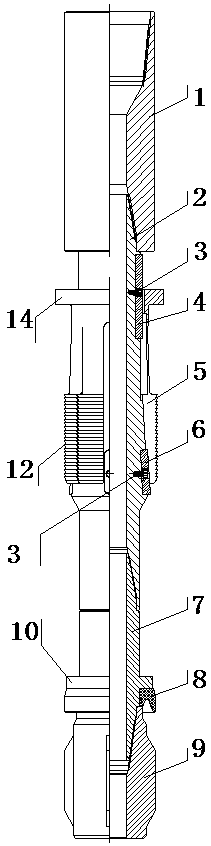

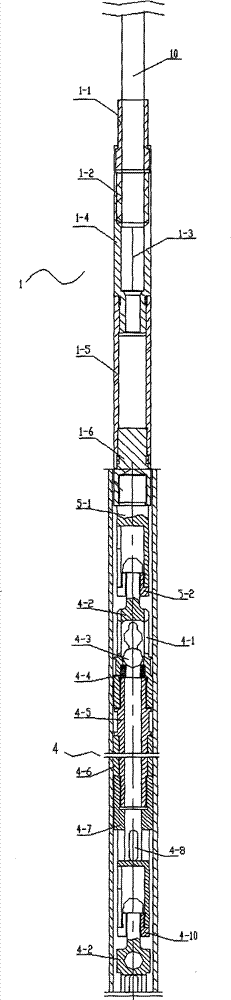

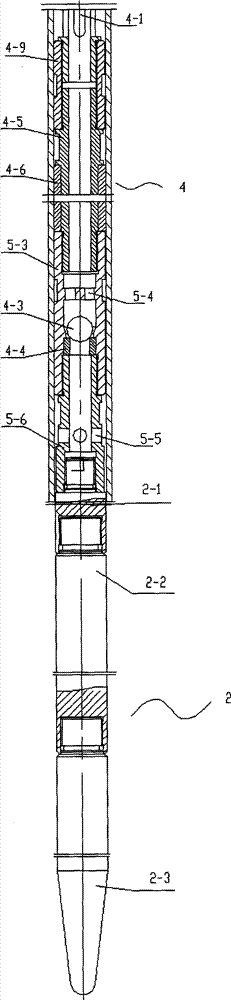

Impeller type axial and circumferential compound impactor

PendingCN107664013AReasonable designReliable performanceBorehole drivesClimate change adaptationImpellerRotary valve

The invention provides an impeller type axial and circumferential compound impactor. The impeller type axial and circumferential compound impactor comprises a conversion adapter, a motor assembly andan impact assembly. The front end of the motor assembly is connected with the impact assembly; the rear end of the motor assembly is connected with the conversion adapter; liquid energy is converted into rotating mechanical energy through an impeller of the motor assembly so that a rotating valve of the impact assembly is driven to rotate; holes are formed in the rotating valve and a valve cover,so that drilling liquid enters a hammer head and a hammer body cylinder cavity periodically; the hammer head impacts a hammer body cylinder to produce circumferential vibration under the pushing of the liquid; meanwhile, axial holes of the rotating valve and the valve cover are staggered periodically to change the pressure of the liquid, so that high-frequency axial vibration is produced; axial and circumferential impact force is transferred to a drilling bit through a lower connector, a stick slip phenomenon is eliminated, and the drilling bit is protected, so that the rock breaking efficiency of the drilling bit is improved. According to the impeller type axial and circumferential compound impactor disclosed by the invention, axial and circumferential impact is produced by utilizing thedrilling liquid, so that the drilling efficiency can be effectively improved.

Owner:SOUTHWEST PETROLEUM UNIV

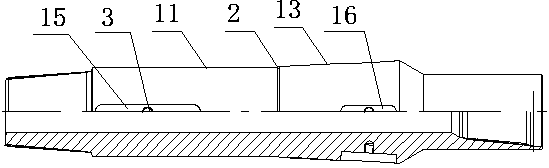

Cyclic heating high efficiency 3D printer nozzle device

InactiveCN106426912ANot easy to cureSolve obstaclesManufacturing heating elements3D object support structuresHeat conductingThermal insulation

The invention relates to a cyclic heating high efficiency 3D printer nozzle device, including a base plate, the middle of the base plate is provided with a feeding tube, the main body of the feeding tube is located below the base plate, the lowermost of the feeding tube is a nozzle, the upper outer side of the feeding tube is provided with a heat dissemination component, the outside of the lower part of the feeding tube is a heating component, the outer wall of the nozzle is constructed from multiple layered structures, the inner layer is a main heat conducting layer, which is touched and fixed with an elastic thermal preservation layer outside the main heat conducting layer, the outer side of the elastic thermal insulation layer is an outer wall, the top of the elastic thermal preservation layer is provided with a compression rod, the inside of the feeding tube is provided with a rotating shaft, the rotation of which is driven by a motor, the heat dissemination component includes a heat dissemination tube and a liquid heat dissemination device connected with the heat dissemination tube, the liquid heat dissemination device is connected with a control device, the control device through controlling a temperature sensor provided on the heat dissemination tube performs a heat disseminating control to the materials in the feeding tube. The device has good performance on heating and disseminating heat, and has obvious effect on anti clogging.

Owner:HUNAN RUIDU TECH

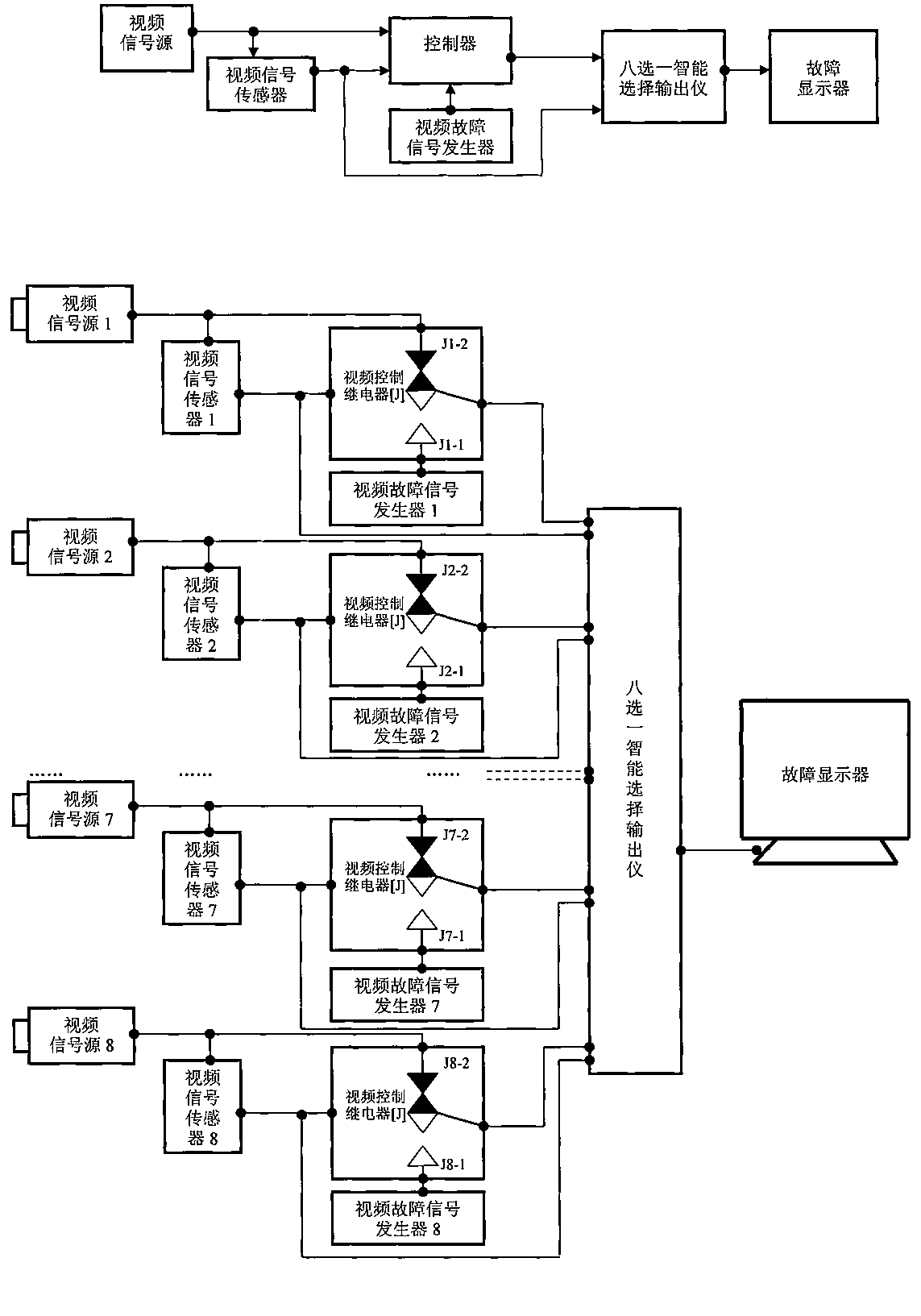

Real-time on-line self-diagnosis method and system for video monitoring equipment failure

InactiveCN103517064AReal-time online monitoring and running real-time statusSolve obstaclesClosed circuit television systemsVideo monitoringDisplay device

The invention belongs to a real-time on-line self-diagnosis method and system for a video monitoring equipment failure. A real-time on-line self-diagnosis system is formed by a video signal sensor, a video signal control relay, a video failure signal generator, an intelligent one-out-of-eight selection output instrument and a failure displayer. The video signal sensor additionally installed on a video signal source is adopted to induce and detect the state of a video signal in real time, and automatic induction detection, failure precise warning, real-time displaying of failure equipment related information and other functions of the video monitoring equipment failure are achieved. The method comprises the following steps that (1) the video signal sensor induces the video signal; (2) the video signal control relay carries out gating control; (3) the video failure signal generator is closed and powered on; (4) the intelligent one-out-of-eight selection output instrument selects failure information needing to be output; (5) the video failure information is output and displayed. According to the real-time on-line self-diagnosis method and system, an existing failure maintenance mode is innovated to an on-line real-time self-diagnosis mode, lots of manpower, material resources and maintenance cost are saved, and far-reaching influences on social management innovation are achieved.

Owner:支录奎

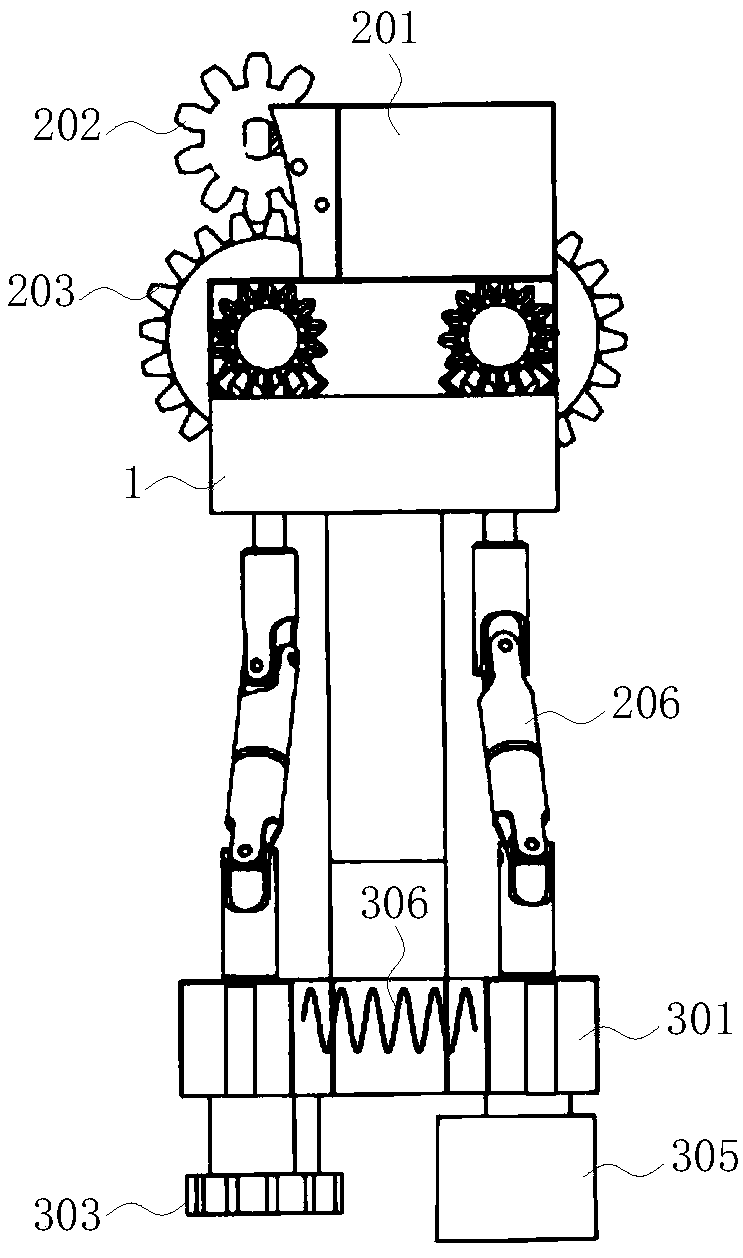

Torsion impactor based on turbine and gear

ActiveCN108104715ASolve obstaclesEliminate stick-slipBorehole drivesMachines/enginesGear wheelDrive shaft

The invention provides a torsion impactor based on a turbine and a gear, which solves the sticky-slip vibration produced by a drill bit in a drilling process. The torsion impactor based on the turbineand the gear is characterized in that the torsion impactor consists of a turbine assembly, an adapter substitute and an impact assembly, wherein the turbine assembly generates high-speed rotary motion under the impact effect of drilling fluid to further drive a flange driving shaft to rotate; on one hand, the flange driving shaft drives an eccentric impact hammer to rotate at a high speed by virtue of a driving shaft and a driving pin; on the other hand, the flange driving shaft drives an outer gear to rotate to be engaged with an inner gear shell, a lower rotation speed is transferred to the inner gear shell to drive the impact driving shaft to rotate at a lower rotation speed; and a rotation speed difference is formed between the impact driving shaft and an eccentric impact block, an impact effect is generated, and the torsion vibration produced by the collision is transferred to a lower joint by virtue of the impact driving shaft. The torsion impactor can continuously produce thetorsion impact vibration, so that the rock breaking efficiency of the drill bit is increased, and the jamming of drilling tool and the sticky-slip phenomenon can be effectively avoided.

Owner:SOUTHWEST PETROLEUM UNIV +2

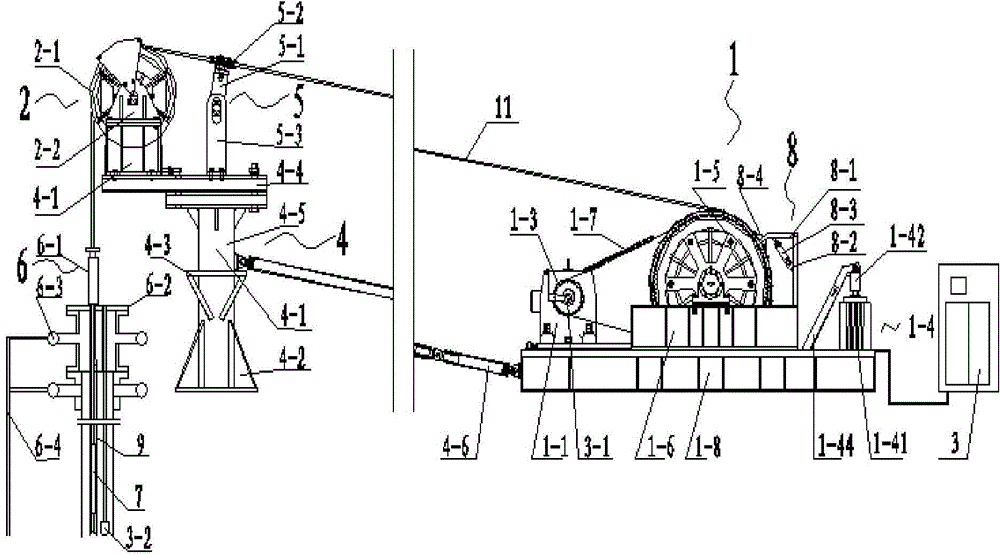

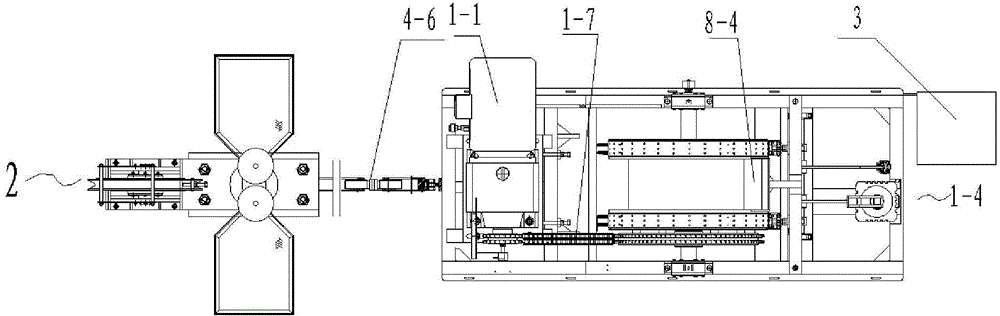

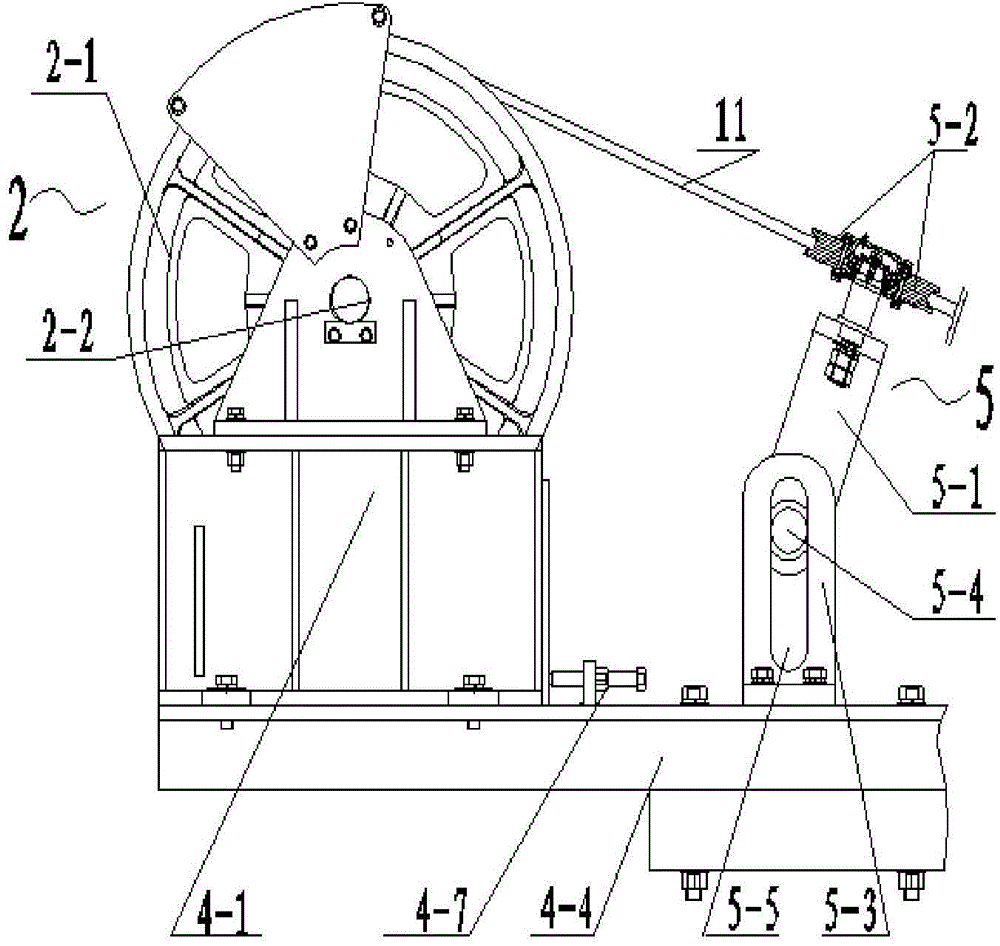

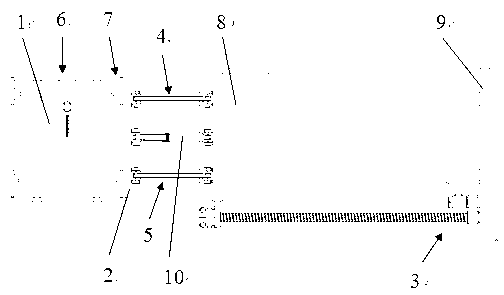

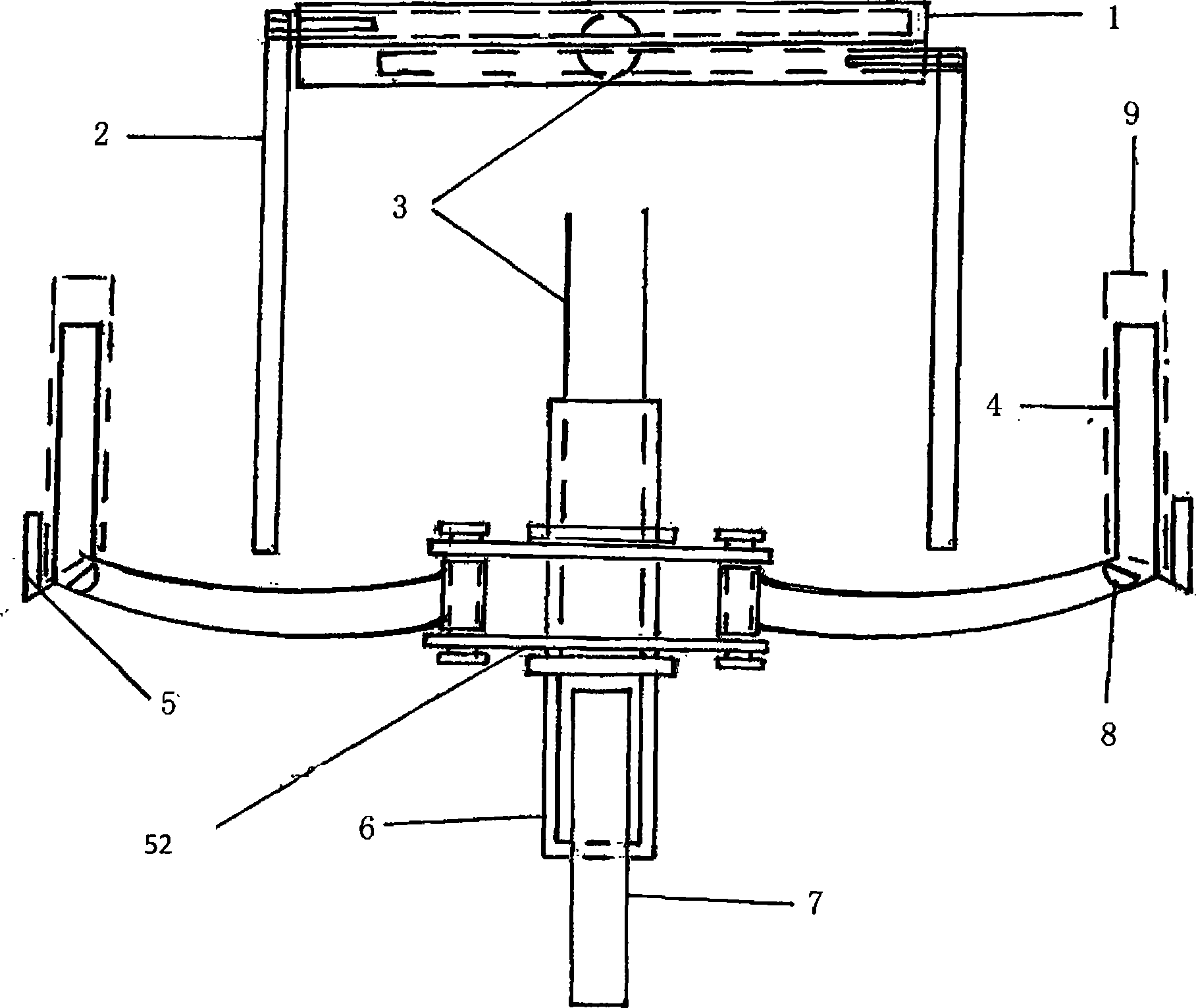

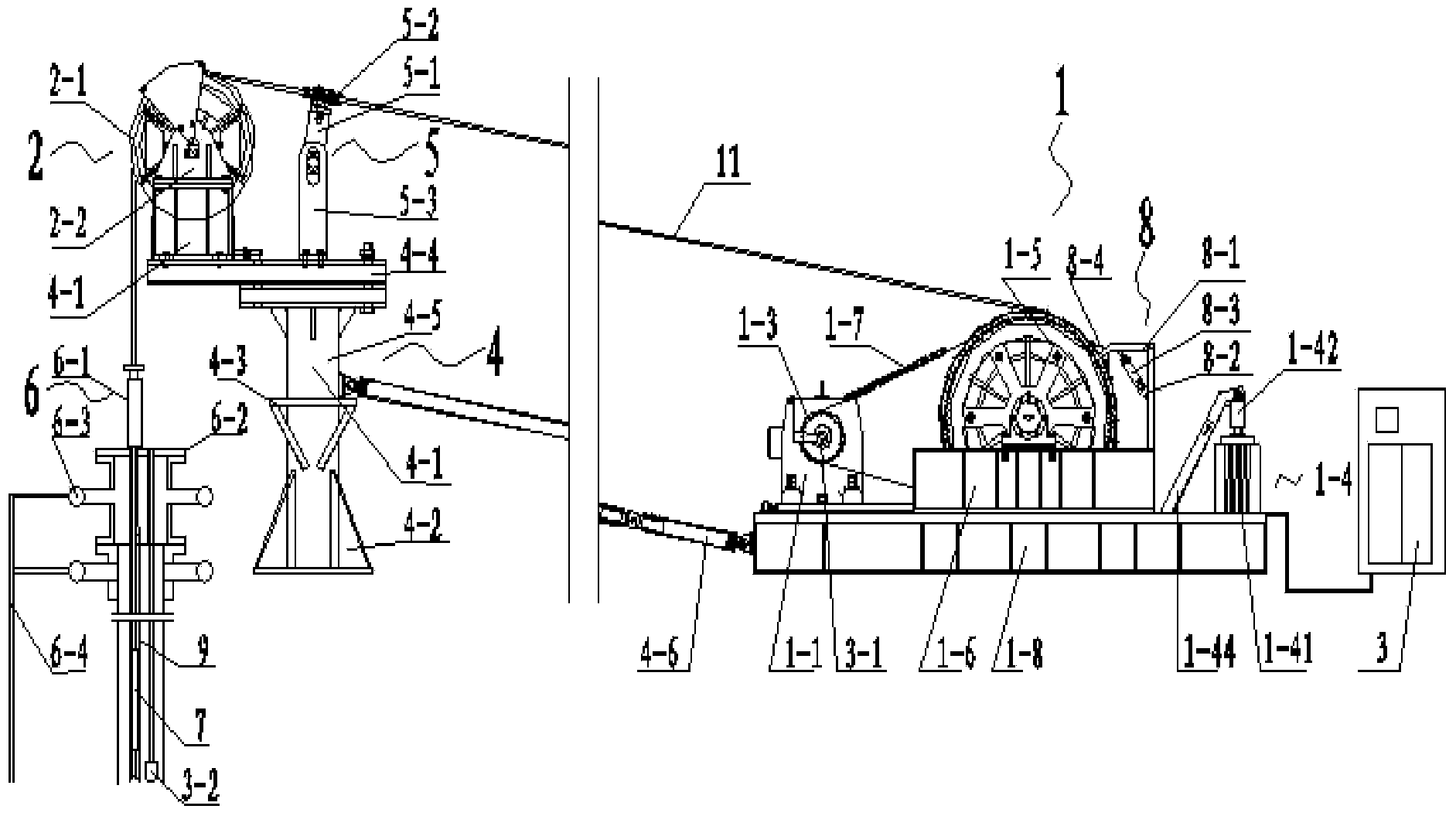

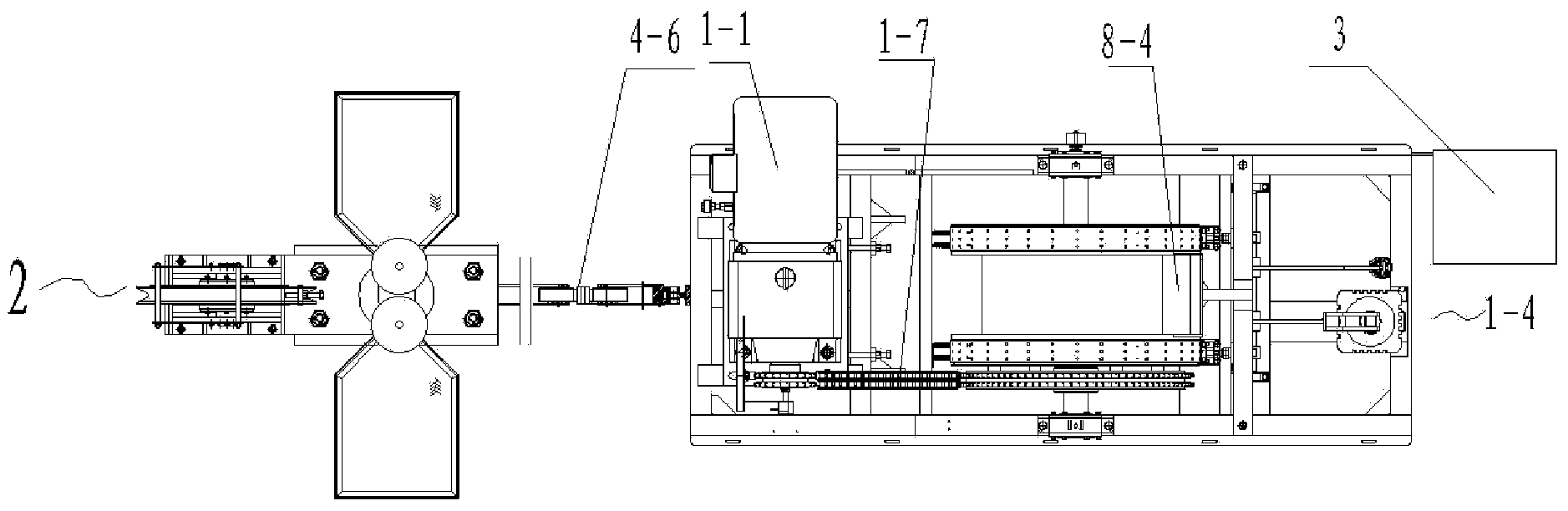

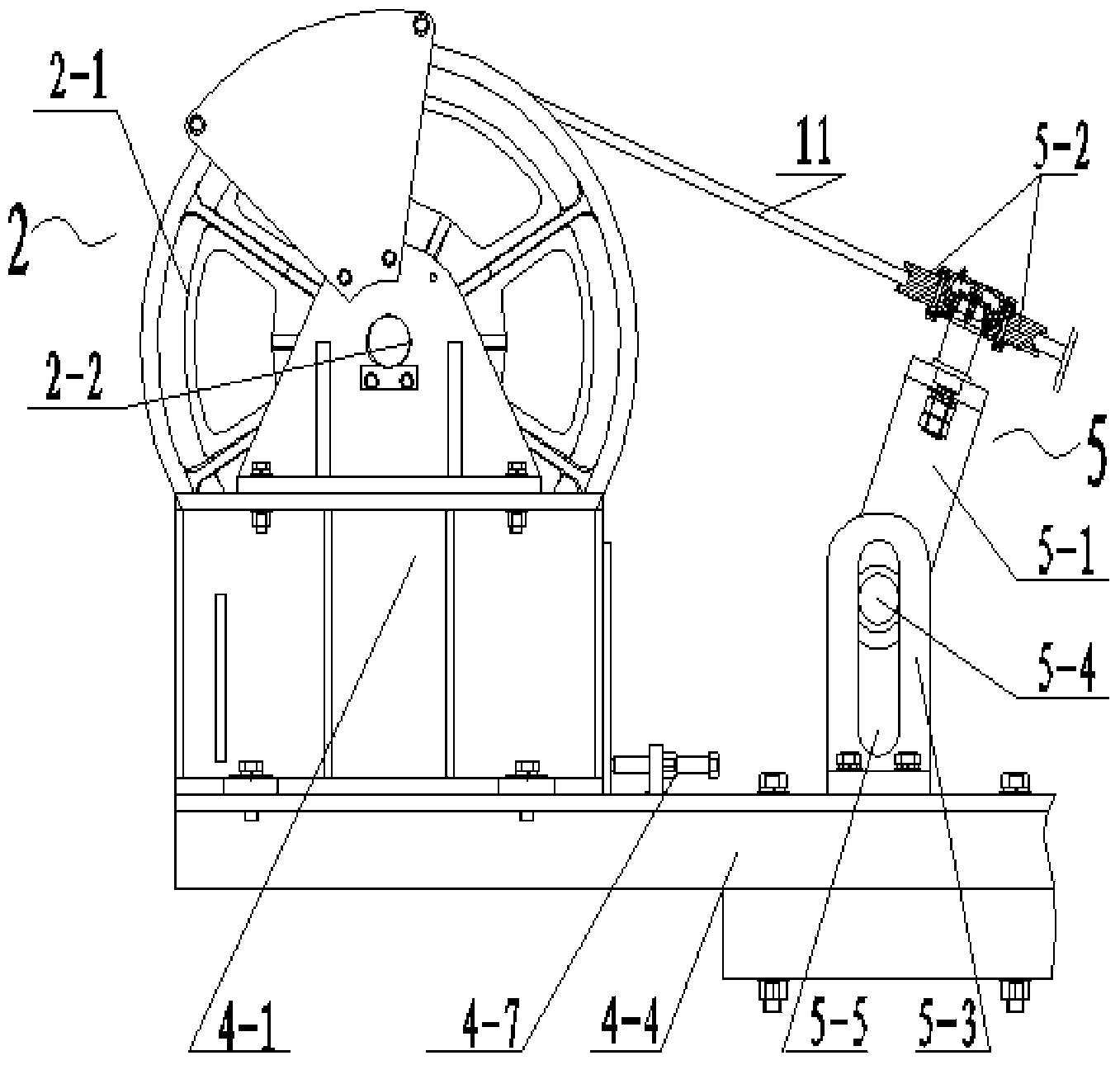

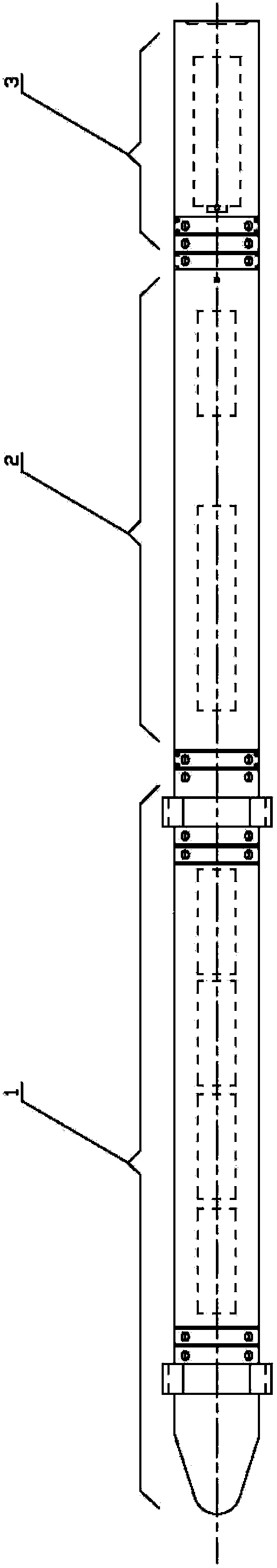

Low-rise super-long stroke intelligent control winding type pulling oil production system and working method

ActiveCN104033134ASolve obstaclesSave crafting materialsConstructionsFluid removalMaterial consumptionWorking set

The invention relates to a low-rise super-long stroke intelligent control winding type pulling oil production system. The low-rise super-long stroke intelligent control winding type pulling oil production system comprises a power drive assembly, a control assembly, a derrick assembly, a well mouth device, an underground tubular column and an underground multi-stage plunger super-long stroke oil well pump. A flexible oil pumping rope driven by the power drive assembly sequentially passes through a blowout prevention box of the well mouth device, an eccentric well mouth and the underground tubular column and is then connected with a steel wire rope in the tubular column or an oil pumping rod through a hoop, and therefore a full-well oil pumping rope is formed. The steel wire rope or the oil pumping rod is connected with the multi-stage plunger of the oil well pump. A fixed pulley assembly and a sliding and swinging device are arranged on the derrick assembly. The well mouth device is connected with the tubular column. The tubular column is connected with a super-long pump cylinder of the underground multi-stage plunger super-long stroke oil well pump. The low-rise super-long stroke intelligent control winding type pulling oil production system can overcome the defects that the stroke of a beam-pumping unit is limited, the beam-pumping unit is not suitable for low-yield oil wells, deep wells and gas-contained large wells, and can solve the problems that according to an existing winding type pulling oil production device, due to the full-well running mode, the size and the weight of the complete machine are large, material consumption is high, and transportation is not convenient.

Owner:瑞燕(上海)能源科技有限公司

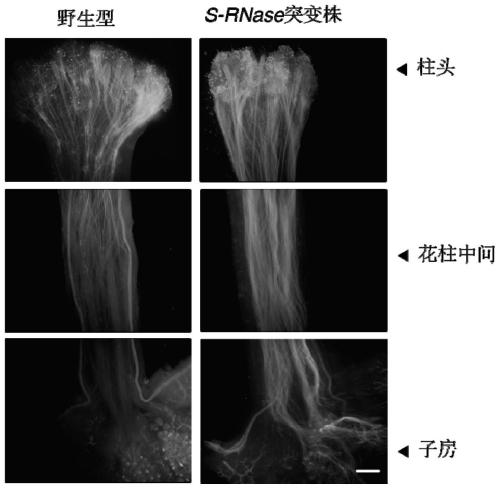

StSCI protein for changing self-incompatibility of diploid potato material

ActiveCN110938120AOvercome defectsAchieve seed breedingMicrobiological testing/measurementPlant peptidesBiotechnologyHomologous Sequences

The invention provides a StSCI protein for changing the self-incompatibility of a diploid potato material. The StSCI protein has an amino acid sequence which comprises or is composed of the followingsequences: 1) an amino acid sequence as shown in SEQ ID NO. 1; or 2) a functional homologous sequence with at least 95% of sequence identity with the amino acid sequence as shown in the SEQ ID NO. 1;or 3) a sequence which is obtained by adding, deleting and replacing one or more (such as 1-10) amino acids in the amino acid sequence as shown in the SEQ ID NO. 1 and has a protein capable of inhibiting self-incompatible activity. The StSCI protein provided by the invention has the following advantages: the StSCI protein can inhibit the cytotoxic effect of various types of S-RNase, has heredity,fundamentally overcomes the defect of self-incompatibility of diploid potatoes, and facilitates realizing cultivation of diploid potato high-generation homozygous selfing lines.

Owner:AGRI GENOMICS INST CHINESE ACADEMY OF AGRI SCI +1

Bluetooth 4.0-based inertia motion capturing system used for realizing low-power wireless data transmission, and data transmission method thereof

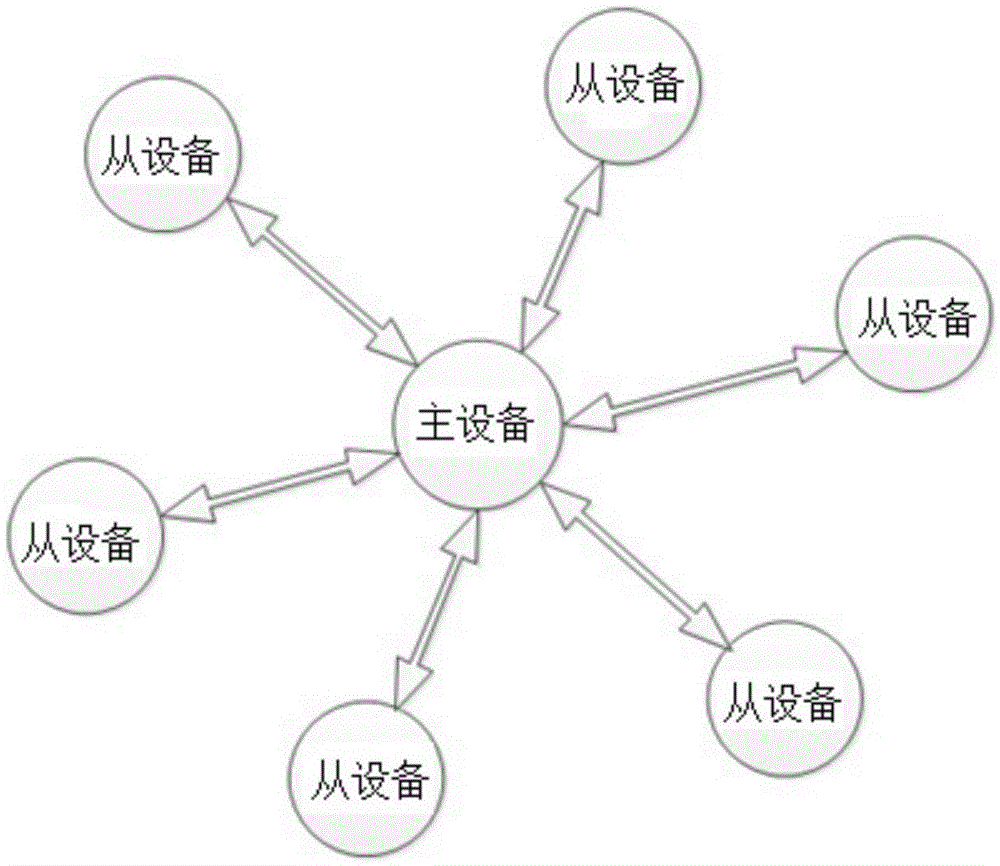

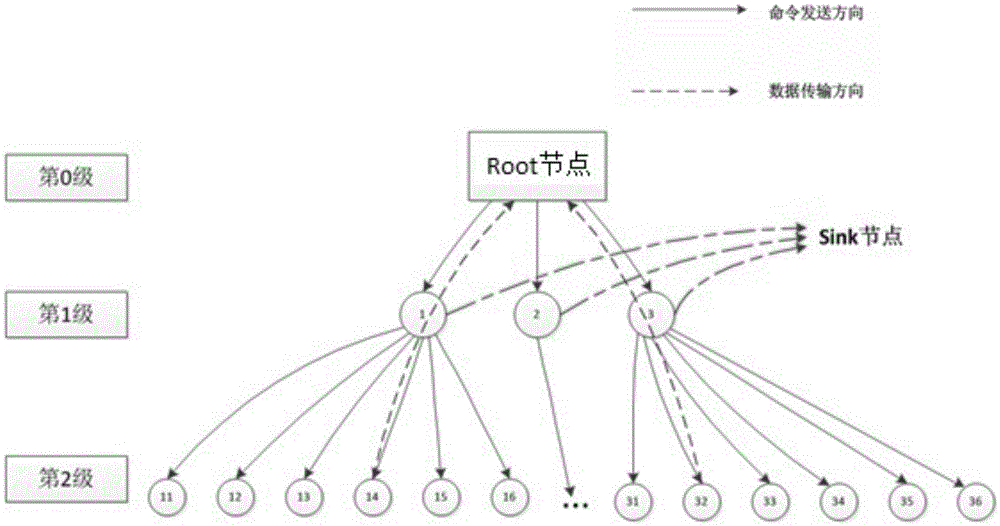

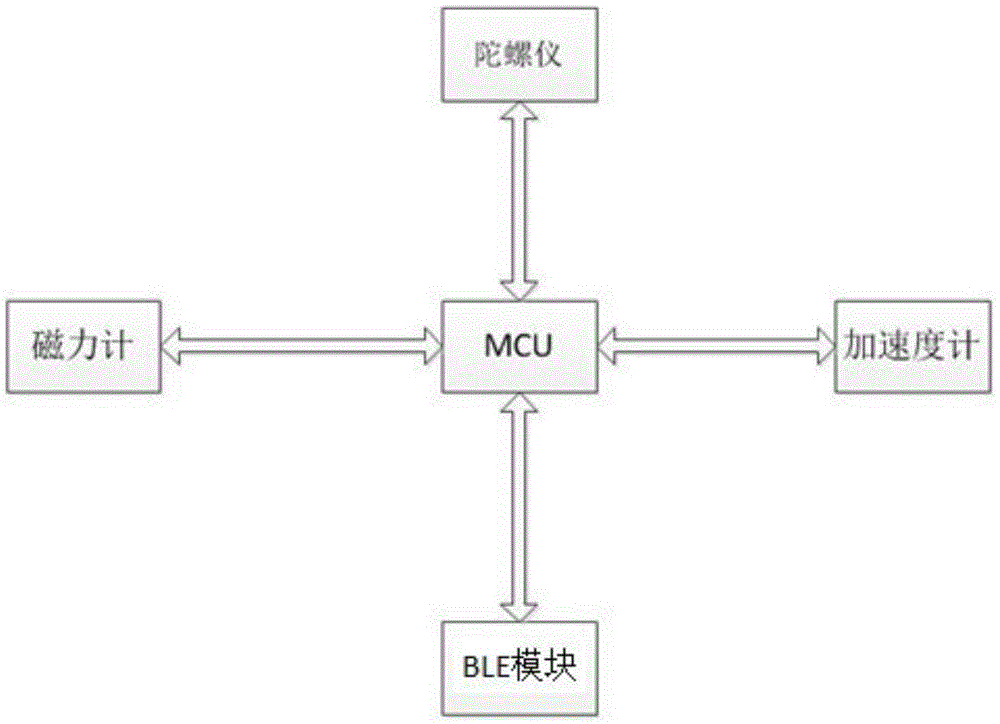

InactiveCN105592535AImprove experienceGet rid of the bondagePower managementTransmission systemsTree shapedMotion capture

The invention relates to a Bluetooth 4.0-based inertia motion capturing system used for realizing low-power wireless data transmission, and a data transmission method thereof. A BLE (Bluetooth Low Energy) module is arranged at each joint of a collection object, allowing each joint to employ the Bluetooth technology to communicate with a sink node; all joints are divided into a plurality of sets, and each set is in connection with a sink node; the joint in each set can transmit data with an own sink node; the sink node performs data transmission with a Root node through a serial port, thereby forming a tree-shaped transmission network. The tree-shaped transmission network based on Bluetooth effectively overcomes the deficiency of the WiFi and Zigbee wireless technology in a motion capturing system, emancipates users from data line constraints, improves user experience and reduces the power consumption of a whole system.

Owner:SHANDONG UNIV

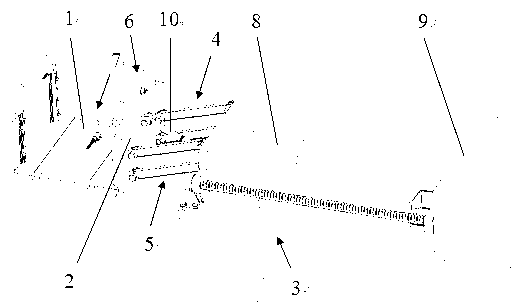

Device for enabling wheelchair to get on or off vehicle

InactiveCN103057479AGuaranteed stabilityImprove stabilitySteps arrangementWheelchair positioningEngineering

The invention discloses a device for enabling a wheelchair to get on or off a vehicle. The device is characterized by mainly comprising a movable platform, a suspension platform, a sliding block guiding branch chain, a first intermediate branch chain, a second intermediate branch chain, a wheelchair positioning fastening device, a sliding block, a machine frame and an electric push rod. The structural layout of the whole device is that the sliding block is connected with the machine frame through the sliding block guiding branch chain, the suspension platform and the sliding block are in symmetric connection through the first intermediate branch chain and the second intermediate branch chain, the movable platform is connected with the suspension platform through a movable platform guiding branch chain, the wheelchair positioning fastening device is installed on the movable platform and used for being connected with an electric wheelchair, and the electric push rod is connected between the suspension platform and the sliding block. The first intermediate branch chain and the second intermediate branch chain are identical in structure and form double parallelogram mechanisms. Under the conditions of guaranteeing that the sliding block is horizontal, movement of the suspension platform is in a translation process and is always kept in a horizontal state, simultaneously two parallelograms are matched to be used, and horizontal movement stability of the movable platform is also guaranteed.

Owner:HEBEI UNIV OF TECH

Silk printed fabric and preparation method thereof

ActiveCN108660815ARealistic patternEasy to operateTransfer printing processDyeing processPre treatmentWater soluble

The invention relates to a preparation method of a silk printed fabric. The preparation method comprises the following steps of applying a macromolecular modifier to the surface of paper, and treatingat the temperature of 60 DEG C, so as to obtain the transfer printing paper, wherein the weight increasing amount of the paper is 10 to 20g / m<2>, and the macromolecular modifier is prepared from thefollowing components in percentage by mass: 0.5 to 5% of water-soluble hot melt glue, 2 to 12% of thickener, 0.5 to 3% of acid and alkaline agent, 2 to 8% of moisture absorber, and the balance of water; performing ink jetting and printing onto the transfer printing paper by active dye ink or acid dye ink, and drying, so as to obtain the transfer printing paper jetted with ink; soaking and rollingthe silk fabric, wherein the liquid entrapping rate of the fabric is 80 to 90%; laminating the transfer printing paper jetted with ink and the pretreated silk fabric in a hot press way, steaming by vapor, and washing by water, so as to obtain the silk printed fabric, wherein the permeation hot press temperature is 100 to 160 DEG C, and the hot press pressure is 3 to 6MPa. The preparation method has the advantages that the technology is simple and environmentally friendly; the color depth value of the prepared silk printed fabric is 4 to 7, the permeation rate of dye is 90% to 111%, and the color fixation rate is 79 to 90%.

Owner:SUZHOU UNIV

Differential torsion impactor based on screw and gear

PendingCN108104714AResolve easily-caused obstaclesSolve the problem of encountering cardsBorehole drivesMachines/enginesDrive shaftTorsional vibration

The invention provides a differential torsion impactor based on a screw and a gear, which solves the sticky-slip and vibration phenomenon produced by a drill bit in the drilling process. The differential torsion impactor based on the screw and the gear is characterized in that the differential torsion impactor consists of a power assembly, an universal shaft assembly, a drive assembly and an impact assembly, wherein the upper portion of the power assembly is connected with a drill stem, the lower portion is successively connected with the universal shaft assembly, the drive assembly and the impact assembly, and the power assembly drives a flange driving shaft to rotate; and on one hand, the flange drive shaft drives an eccentric impact hammer to rotate at a high speed by virtue of a driveshaft and a drive pin, on the other hand, an outer gear is driven to rotate and engage with an inner gear shell, a lower rotation speed is transferred to the inner gear shell to drive the impact driveshaft to rotate at a lower rotation speed, so that the drive shaft forms a rotation speed difference with an eccentric impact block to generate an impact effect, and the torsion vibration generated by the collision is transferred to a lower connector by virtue of the impact drive shaft. The differential torsion impactor can continuously produce torsion impact vibration, so that the rock breakingefficiency of the drill bit can be increased, and the jamming of drill tool and sticky-slip phenomenon can be effectively avoided.

Owner:SOUTHWEST PETROLEUM UNIV

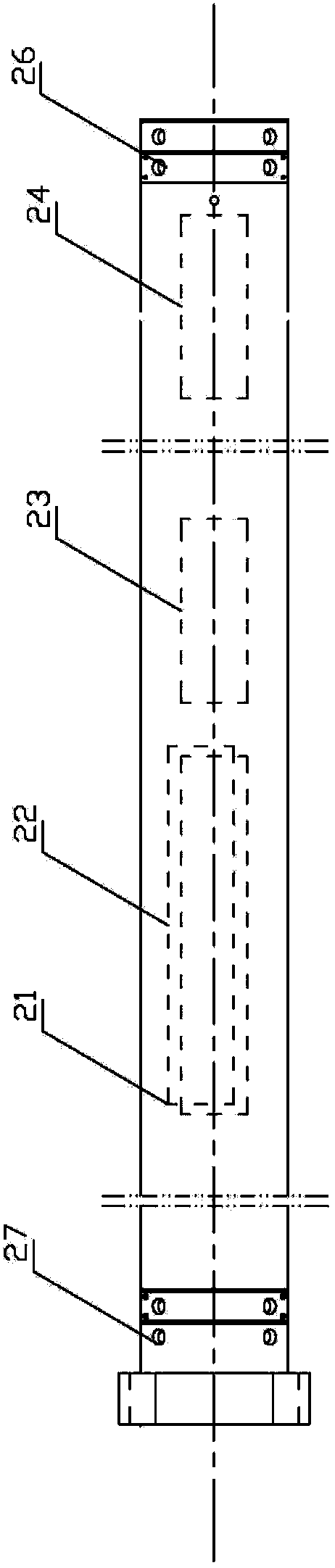

Method for casing pipe downward running operation through casing pipe driving head

ActiveCN103437709ASolve obstaclesImprove downloading abilityDrilling machines and methodsEngineeringPipe

The invention discloses a method for conducting casing pipe downward running operation through a casing pipe driving head. the method comprises the steps that a first casing pipe is lifted up, and is clamped to the interior of a rotating plate, and the casing pipe driving head is then connected to a drilling tool; the casing pipe driving head is inserted into the first casing pipe to ensure that a clamping tile on the casing pipe driving head is locked on the inner diameter of the first casing pipe; the clamping tile of the casing pipe is taken out, a square drilling rod is inserted into the rotating plate, and a pump is started to carry out casing pipe drilling until drilling of the first casing pipe is finished; unlocking is carried out to release the clamping tile on the casing pipe driving head, and the casing pipe driving head is lifted out; a second casing pipe is lifted up through a clamping lifter again, and is inserted into the first casing pipe arranged in the rotating plate in a clamped mode; the casing pipe driving head is then inserted into the second casing pipe to ensure that the clamping tile on the casing pipe driving head is locked on the inner diameter of the second casing pipe, the second casing pipe runs downwards until the second casing pipe reaches the bottom of a well, and the pump is started to carry out casing pipe drilling until the second casing pipe is completely drilled. The method for conducting casing pipe downward running operation through the casing pipe driving head can improve the downward running capability of the casing pipes in the complex well and casing pipe downward running safety and reduce operation risks.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Combined multifunctional modified power vehicle instead of walk

InactiveCN101412419ARemove traffic barriersHigh market demandAmphibious vehiclesWheelchairs/patient conveyanceEnergy deviceAutomotive engineering

The invention discloses a combination multifunctional body capable of changing power instead-of-walking vehicle. The vehicle overcomes the obstacles existing in the prior instead-of-walking vehicles such as wheel chair vehicles, tricycles and bicycles that the characteristic functions of the shape can not be mutually changed, overcomes the existed obstacle existed when the vehicle runs on the road and the water surface, overcomes the obstacle existing in the tool application between a normal person and an abnormal person, and has the advantages of having reasonable structure, convenient use, and various types and meeting needs of different people in different places by changing the shape. The structure of the vehicle is as follows: the vehicle comprises a guide connecting part connected with a wheel box, the lower part of the wheel box is provided with a cymbal-type combined wheel, the wheel box is also provided with a seat rest part, the outer part of the wheel box is provided with telescopic combination type paddles, the bottom of the wheel box is provided with an inflatable packer, and the front part of the wheel box is also provided with an energy device part and a wheel chair auxiliary wheel respectively.

Owner:马升昊

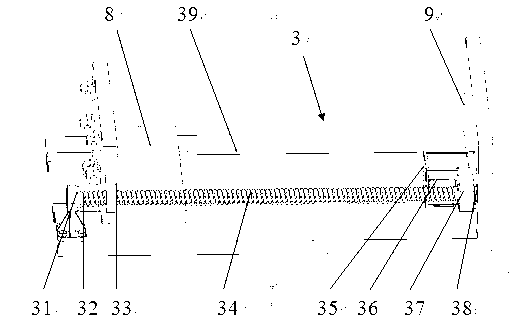

Short intelligent-control hoist type lifting oil extraction system with ultra long stroke and working method

The invention relates to a short intelligent-control hoist type lifting oil extraction system with an ultra long stroke and a working method. The oil extraction system comprises a motor, a winding drum, a fixed pulley, a derrick, a slide and swing device, a control assembly, an oil extraction rope and a down-hole multi-stage plunger ultra long stroke oil well pump; the control assembly controls the motor to start, rotate forwards and backwards and halt for waiting according to set parameters such as the stroke, down-hole liquid pressure, halt waiting time and the like; the winding drum is driven to rotate forwards and backwards and halt, the oil extraction rope on the winding drum drives multi-stage plungers of the down-hole multi-stage plunger ultra long stroke oil well pump to reciprocate at the set stroke in an ultra long pump cylinder, a whole well operation mode that a plunger of a conventional hoist type bailing oil extraction device lifts a well liquid from the well bottom to the well mouth is changed, a non whole well operation mode is realized, the whole unit structure is compact, the size is small, material consumption is reduced, energy is saved, the cost is reduced remarkably, and one-time investment of an oil well can be reduced by almost 40%. The short intelligent-control hoist type lifting oil extraction system with the ultra long stroke is applicable to a deep well, a stripper well and a heavy oil well, and the oil well yield-increasing effect is improved remarkably.

Owner:鄂德刚

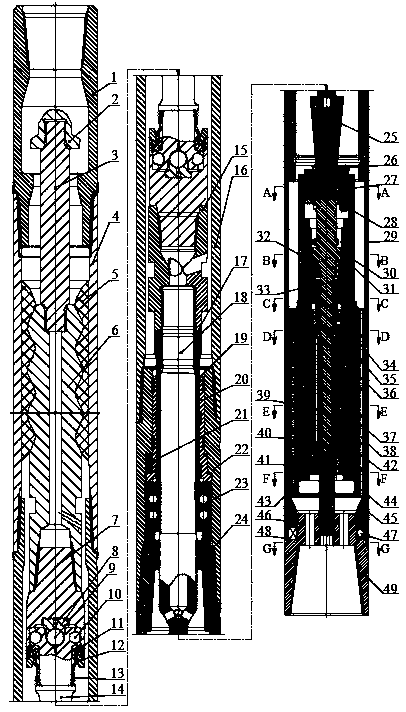

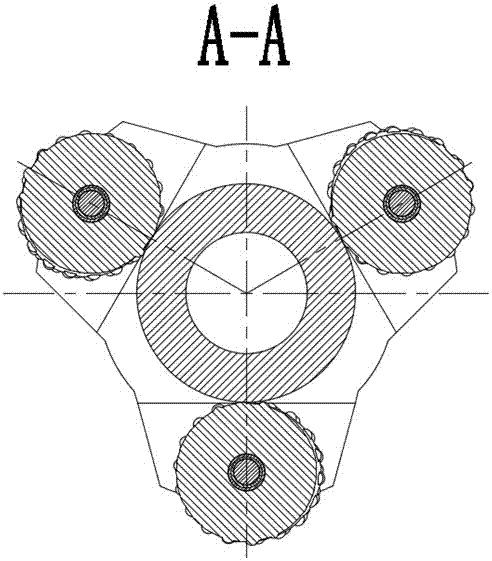

Impeller type differential torque impactor

ActiveCN108049803AResolve easily-caused obstaclesSolve the problem of encountering cardsBorehole drivesUpper jointEngineering

The invention provides an impeller type differential torque impactor, and solves the phenomenon of sticky slip and vibration produced by a drilling bit in a drilling process. The technical scheme of the impeller type differential torque impactor is that the impeller type differential torque impactor consists of an upper joint, a power assembly, an impact assembly and a lower joint, wherein the upper part of the upper joint is connected with a drilling rod while the lower part of the upper joint is connected with the power assembly; the power assembly produces high-speed rotation motion under an impact effect of drilling fluid so as to drive a flange transmission shaft to be rotated; the flange transmission shaft drives an eccentric impact hammer to be rotated at high speed through a transmission shaft and a transmission pin and also drives an outer gear to be rotated, the outer gear is meshed with an inner gear shell, and lower rotation speed is transmitted to the inner gear shell, sothat an impact transmission shaft is driven to be rotated at lower rotation speed, a rotation speed difference between the impact transmission shaft and an eccentric impact block is formed, and an impact effect is produced to transmit torsional vibration produced by collision to the lower joint through the impact transmission shaft. According to the impeller type differential torque impacter disclosed by the invention, torsional impact and vibration can be continuously produced, so that the rock breaking efficiency of the drilling bit is improved, and the phenomenon of drilling sticking and sticky slip can be effectively avoided.

Owner:SOUTHWEST PETROLEUM UNIV +2

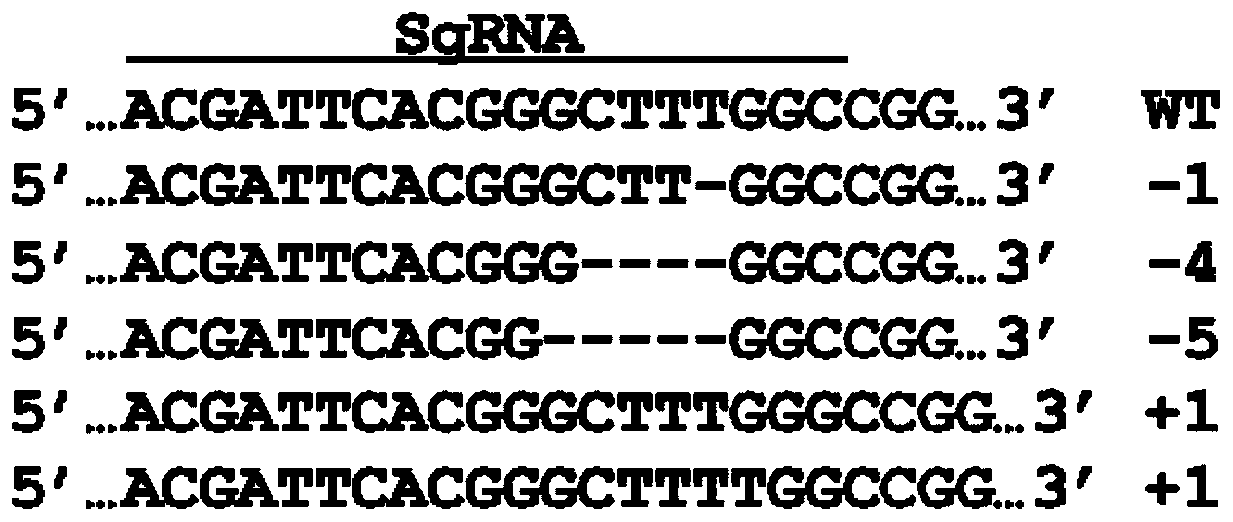

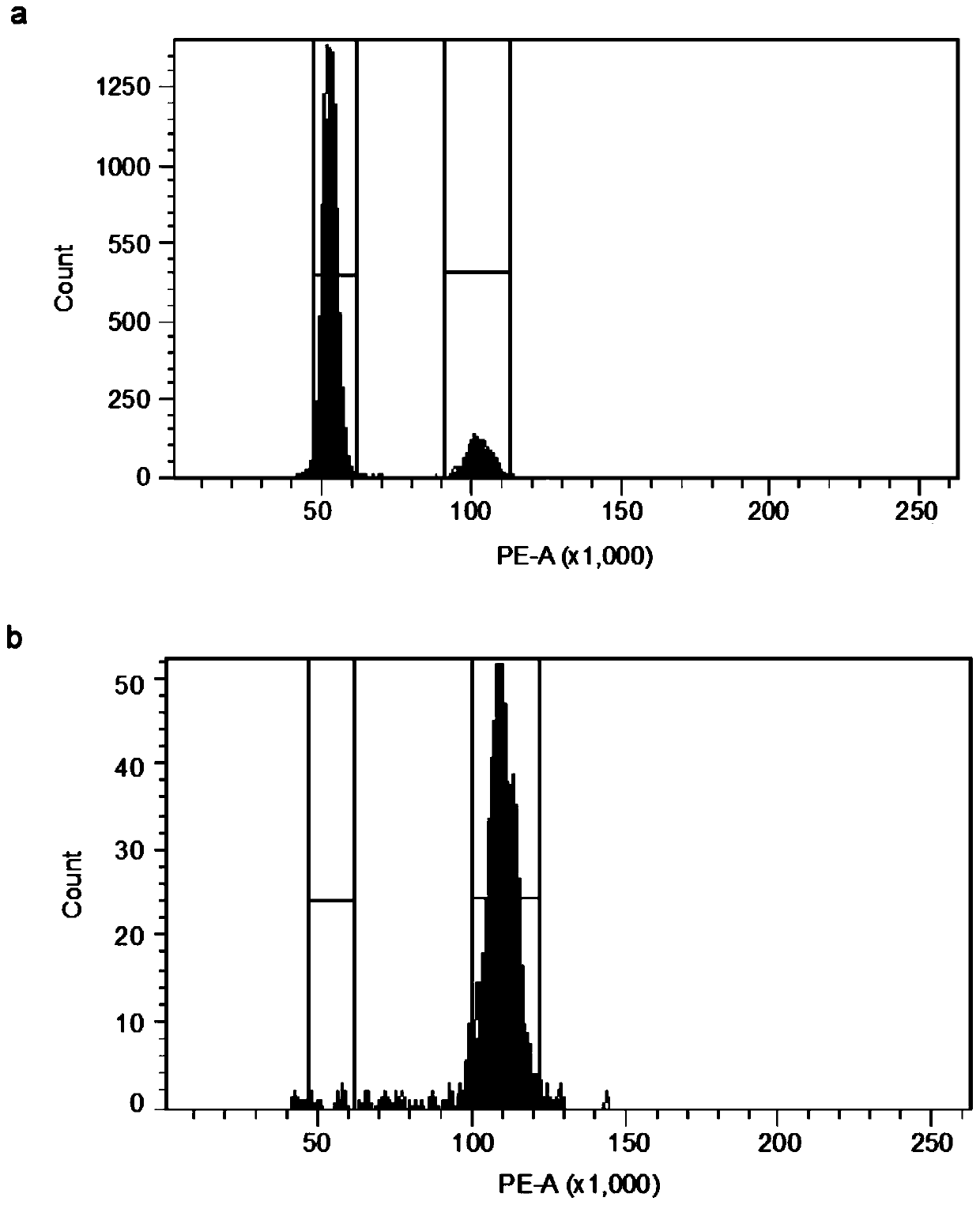

Method for overcoming diploid potato self-incompatibility

ActiveCN109750061AShort breeding cycleEasy to operateHydrolasesMicrobiological testing/measurementGene targetsA-DNA

The invention discloses a method for overcoming diploid potato self-incompatibility. The method comprises the steps of 1, selecting a target fragment; 2, constructing a gene target shooting recombinant vector; 3, achieving function deletion mutation of a S-RNase gene inside a cell; 4, regenerating a plurality of potato plants; 5, specifically amplifying a DNA block containing the target fragment of the S-RNase gene in the regeneration plant; 6, selecting the regeneration plant edited by the S-RNase gene; 7, further screening out a diploid gene editing strain from the gene edited plant; 8, performing expanding propagation and planting on the gene edited strain, and performing self-incompatibility phenotype identification on the blooming stage; 9, amplifying product sequencing on the harvested self-compatible plant later generations, and detecting heredity and separation of the edited target gene for later generations. The method has the advantages that the simple, accurate and efficiency method is found for overcoming diploid potato self-incompatibility.

Owner:AGRI GENOMICS INST CHINESE ACADEMY OF AGRI SCI +1

Oil-water distribution tester and oil-water distribution test method

ActiveCN103485765AReduce moisture contentIncrease oil productionConstructionsProduction effectEngineering

The invention provides an oil-water distribution tester and an oil-water distribution test method. The tester comprises a sonic system, a main machine consisting of an electronic circuit and a battery, wherein the sonic system, the main machine and the battery are in thread connection with one another and respectively provided with a centering guide so as to guarantee the concentricity of the tester and a shaft. The storage-type amplitude log is carried out by adopting a double-transmission and four-receiving way, the distribution of oil and water in a horizontal section is determined through the micro sound difference, the periodic injection-production effect of a thermal-recovery horizontal well can be analyzed collectively by utilizing the micro sound difference method, the micro-temperature-difference water finding method and a temperature pressure sectional curve of the horizontal section, when the cementing quality is detected, the distribution situation of the oil and water can be judged by detecting the tiny time difference through the difference of the spreading speed of sound wave in different media such as oil, formation water and injected water, the tiny difference of the medium temperature can be detected through a micro-temperature-difference instrument, the location and source of the water can be collectively determined by combining the tiny temperature difference and micro sound difference, so that the reliability of the logging data can be greatly improved, and the measurement precision of the instrument is higher.

Owner:PANJIN LIAOHE OILFIELD YULONG RUIDA PETROLEUM TECH CO LTD

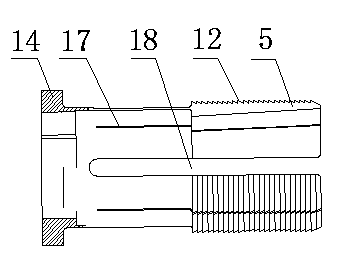

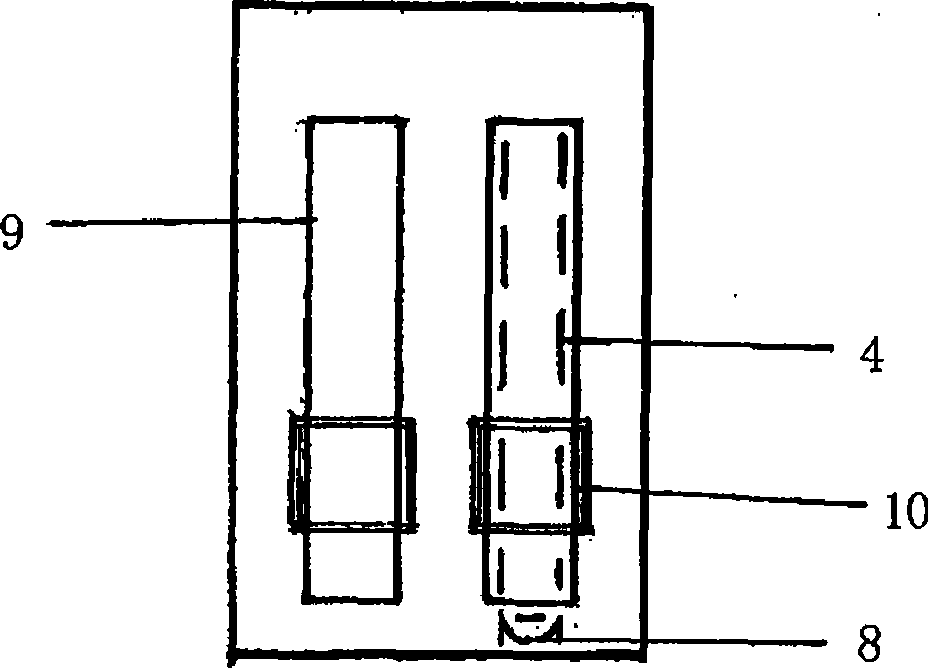

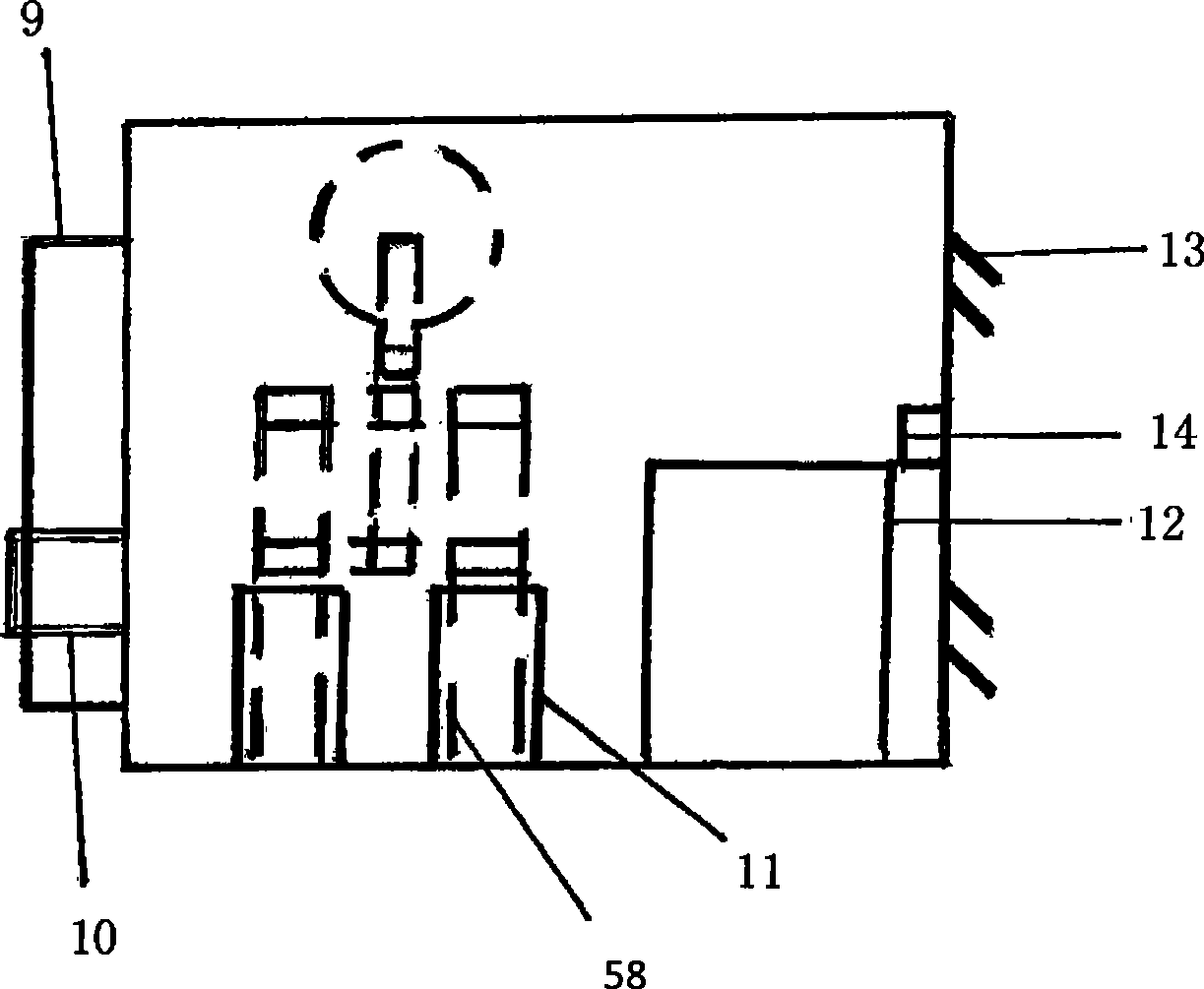

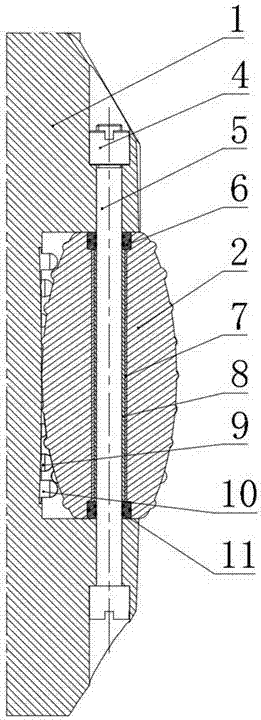

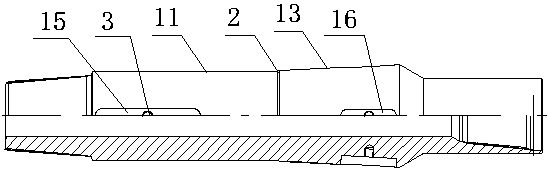

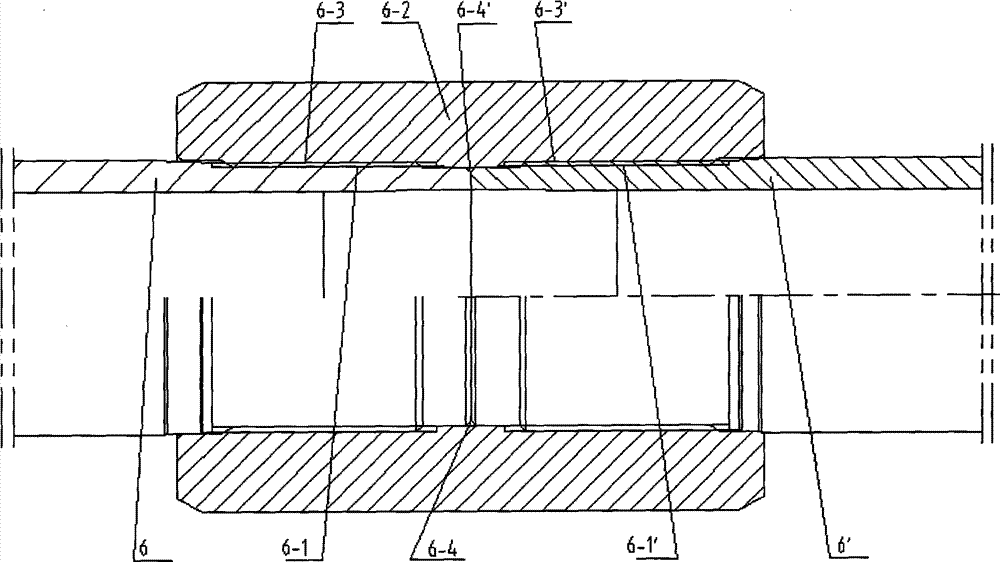

Casing pipe driving head suitable for casing pipe well drilling

ActiveCN103437708ASolve obstaclesImprove downloading abilityDrilling rodsBorehole drivesWell drillingStructural engineering

The invention discloses a casing pipe driving head suitable for casing pipe well drilling. The casing pipe driving head comprises an adapter connector, a guiding and locking mechanism and a centering and sealing mechanism. The guiding and locking mechanism is matched with a casing pipe for lifting, dropping and rotating the casing pipe. The centering and sealing mechanism is used for guiding and centering the guiding and locking mechanism inside the set casing pipe and sealing drilling fluid. The adapter connector, the guiding and locking mechanism and the centering and sealing mechanism are sequentially connected from top to bottom. By adopting the casing pipe driving head, the setting ability of the casing pipe inside a complex well can be improved, the safety of the set casing pipe can be improved, and operating risk can be lowered.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

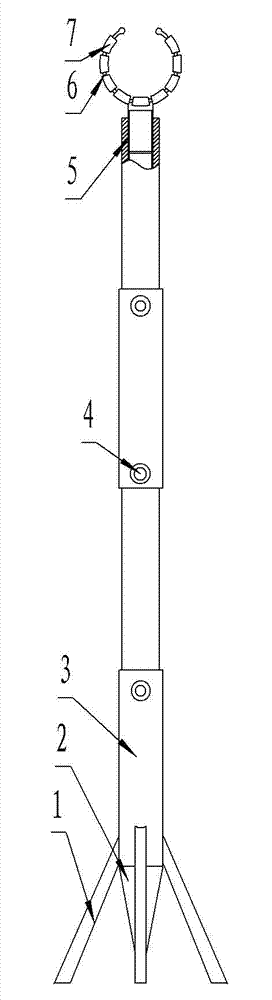

Water pipe redirection rod

InactiveCN104500841ASolve the entanglementSolve obstaclesPipe supportsWeed killersEngineeringConductor Coil

The invention discloses a water pipe redirection rod, and relates to the technical field of agricultural tool machining. The water pipe redirection rod comprises at least two round pipes embedded with each other and vertically arranged, wherein every two embedded round pipes are locked through locking screws; an inverted cone part with a big top and a small bottom is arranged at the lower end of the lowest round pipe; and a vertical ring is mounted at the top end of the highest round pipe. The water pipe redirection rod can solve the problem of inconvenience for use due to easy winding or blocking of spraying equipment with a flexible water pipe used in a mountainous region.

Owner:陈蓝天

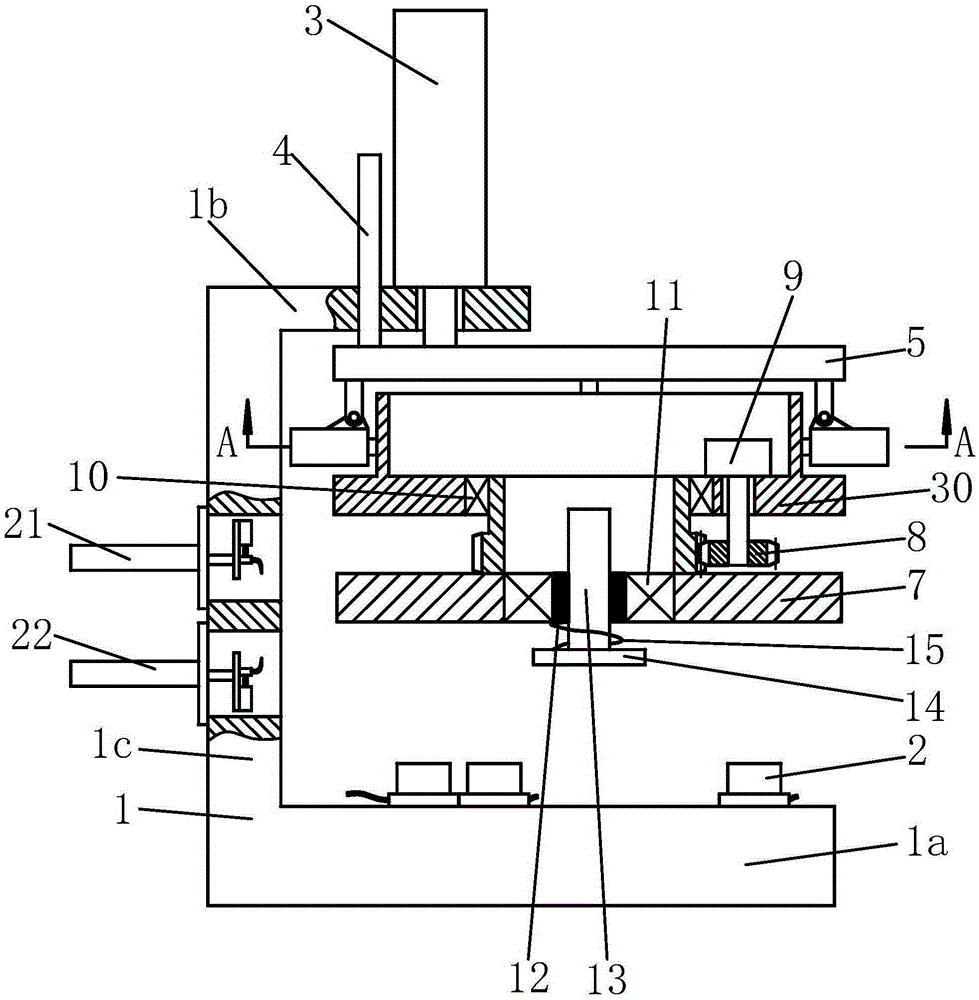

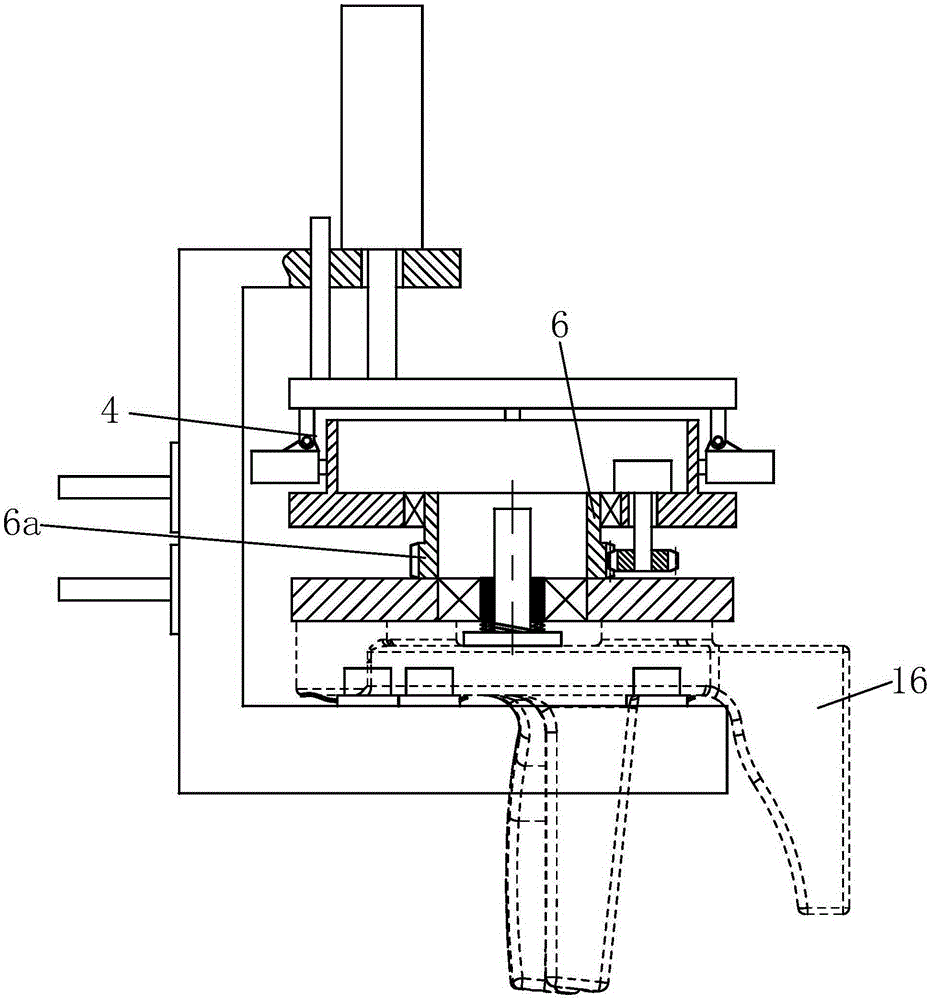

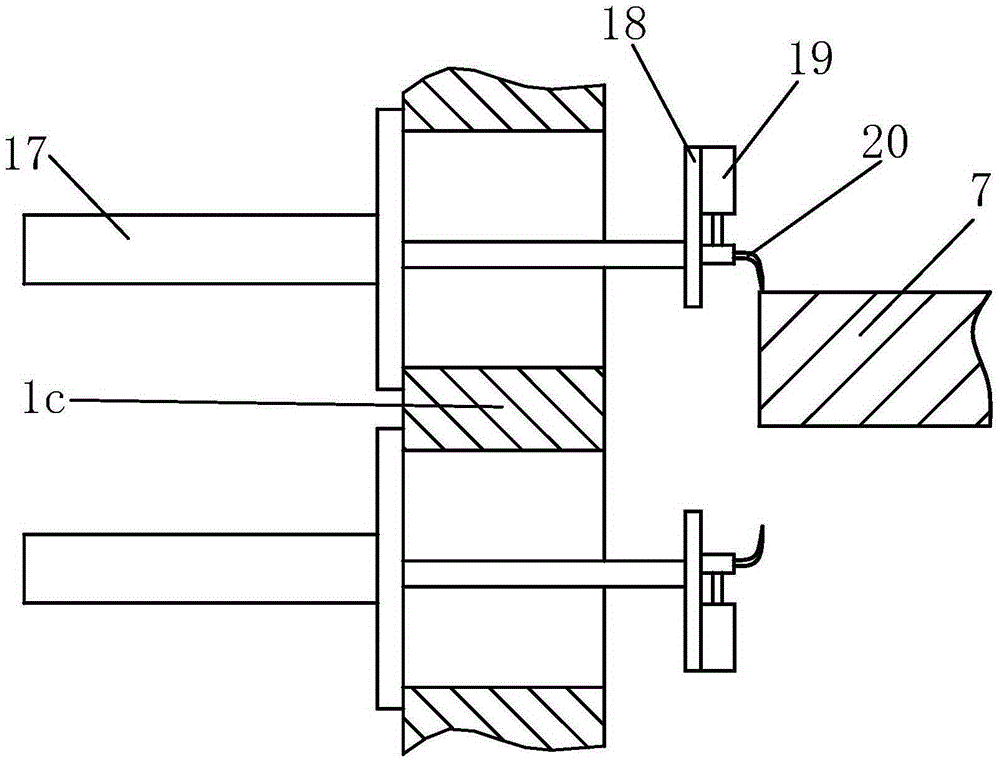

Automatic end surface milling device for automobile flexible shaft brackets

InactiveCN105345107AReasonable structural designReduce production costMilling equipment detailsPositioning apparatusMechanical engineeringEngineering

The invention relates to an automatic end surface milling device for automobile flexible shaft brackets. The automatic end surface milling device comprises a base, a locating device, a lifting regulation device, a milling position regulation device, a rotary milling device, a pressing device and an abrasion detector. The locating device is placed on the upper end surface of a work table, the lifting regulation device is installed on a cross beam, the milling position regulation device is installed in the middle of the lower end of the lifting regulation device, the rotary milling device is installed in the middle of the milling position regulation device, the pressing device is installed in the middle of the lower end of the rotary milling device, the abrasion detector is installed in the middle of a supporting beam, and the lower left part of the rotary milling device is located in the middle of the abrasion detector. The automatic end surface milling device has the advantages of being reasonable in structural design, low in producing and manufacturing cost, convenient to operate, capable of milling the upper end surfaces of the flexible shaft brackets and greatly improving the milling efficiency of the automobile flexible shaft brackets, capable of compensating for abrasion so as to guarantee the machining precision, capable of being regulated according to the automobile flexible shaft brackets of different dimensions, high in flexibility and wide in application range.

Owner:WUHU YINXING AUTO PARTS

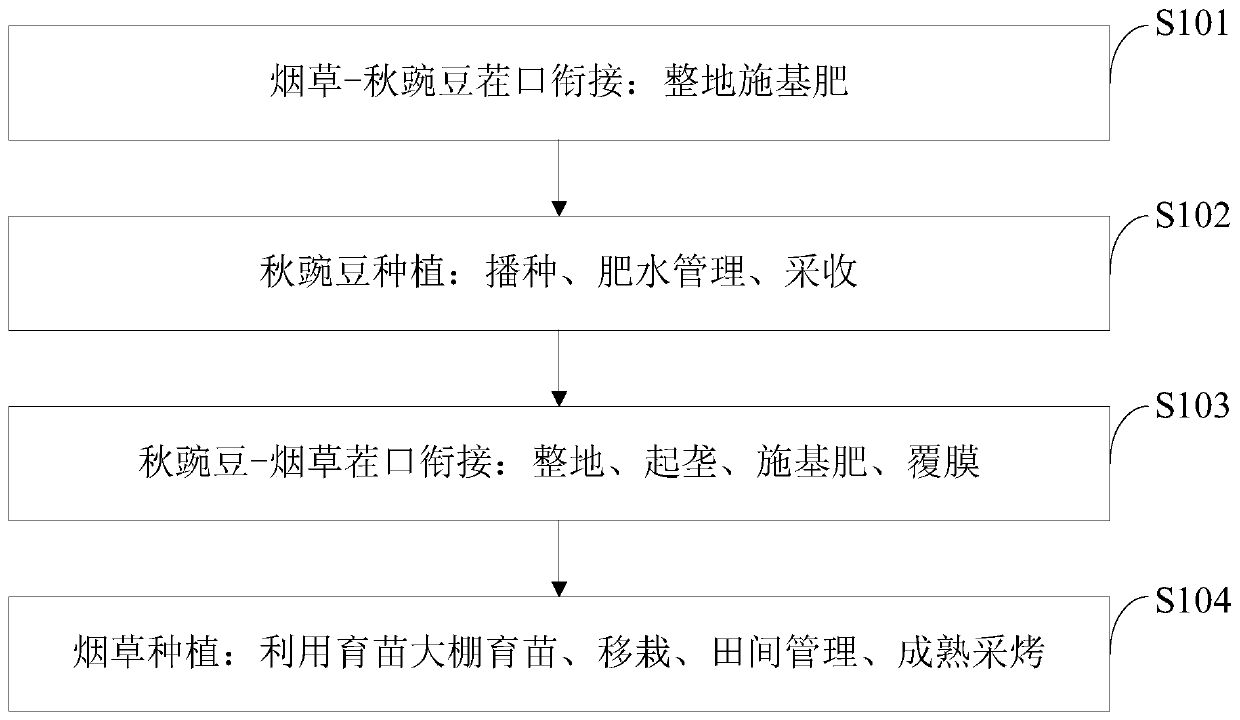

Double-cropping planting method for tobacco plants and autumn peas

InactiveCN111226727AQuality improvementOptimizing the Hierarchy StructureFabaceae cultivationTobacco cultivationBiotechnologyNicotiana tabacum

The invention belongs to the technical field of crop-rotation planting of tobacco plants and discloses a double-cropping planting method for tobacco plants and autumn peas. The method comprises the steps: tobacco plant-autumn pea crops-for-rotation link: carrying out land preparation, and carrying out basal fertilizer application; autumn pea planting: carrying out sowing, carrying out fertilizer and water management, and carrying out harvesting; autumn pea-tobacco plant crops-for-rotation link: carrying out land preparation, carrying out ridge forming, carrying out basal fertilizer application, and carrying out mulching; and tobacco plant planting: carrying out seedling raising, carrying out transplanting, carrying out field management, and carrying out mature picking and curing. Accordingto the method, the problem on tobacco field soil obstacle caused by the existing tobacco plant planting single-cropping continuous-cropping mode can be effectively solved, soil nutrients are balanced, root system development is promoted, accumulation of harmful substances and plant diseases and insect pests are reduced, the yield and quality of tobacco leaves and comprehensive economic results ofa tobacco field are improved. Shown by experiments, by the method, organic matters of soil can be increased by 10%-20%, the structure of an arable layer is improved obviously, the incidence rate of diseases is lowered by 55%, the first-class tobacco ratio of the tobacco leaves is increased by 5%-7%, the chemical ingredient coordination and sensory evaluation score of the tobacco leaves are improved obviously, and the comprehensive economic results of farmers are increased by 15%-20%.

Owner:TOBACCO RES INST CHIN AGRI SCI ACAD

Anti-friction centralizer having anti-balling and boosted propelling functions

ActiveCN107130925ASolve obstaclesSolve the problem of encountering cardsDrilling rodsBorehole drivesRolling resistanceEngineering

The invention relates to an anti-friction centralizer having anti-balling and boosted propelling functions. The anti-friction centralizer comprises a body and roller assemblies, wherein the body is connected between underhole tools through threads, and the roller assemblies are arranged on prisms which are uniformly distributed outside the body along the circumferential direction; a certain included angle exists between the roller shaft of each roller assembly and the axial direction of the body; the body rotates in the drilling process, and the rollers spirally roll on a well wall to push an underhole tool to move forward and supply drilling pressure to a drill bit; alloy teeth are embedded to the outer surfaces of the rollers and positions, provided with the roller assemblies, of the body, so that the friction mode is changed into rolling friction, friction resistance of the underhole drill with the well wall in the drilling process can be reduced, and failure of roller balling can be prevented. The anti-friction centralizer has a relatively simple structure, low cost, high strength and long service life, and can be used for solving the technical problems of poor resistance reduction effect, complicated structure, low strength and short service life in the prior art.

Owner:DAQING DANNUO PETROLEUM TECH DEV

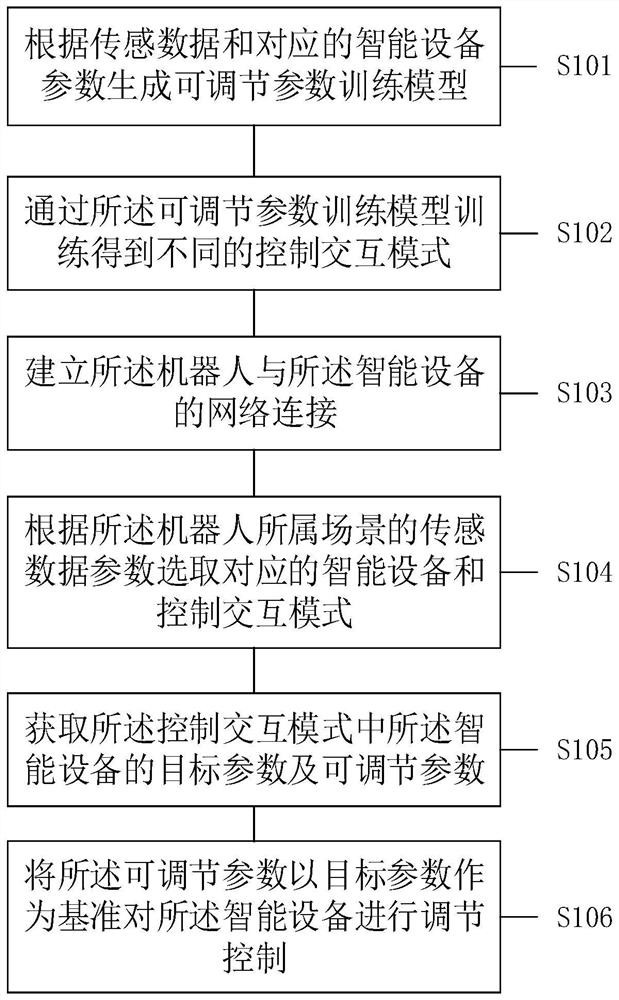

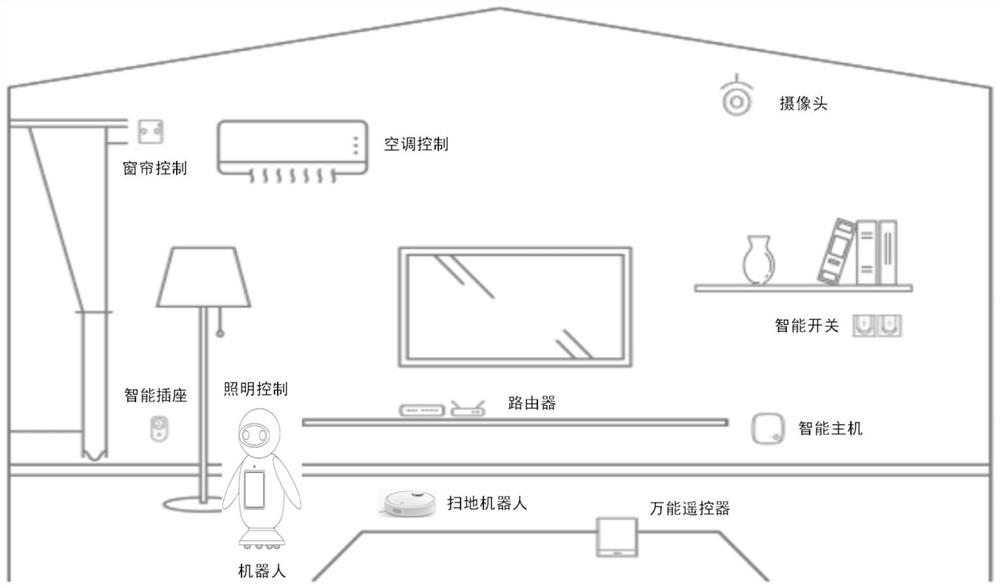

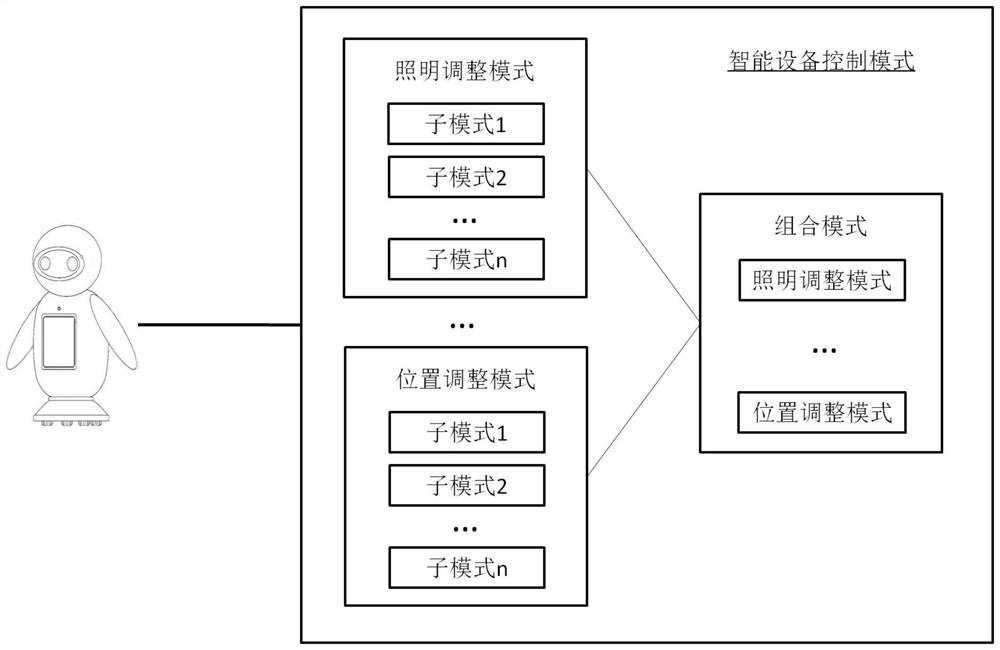

Robot and intelligent equipment interaction method and device and electronic equipment

PendingCN113900384ASolve obstaclesReduce or eliminate distracting factorsComputer controlTotal factory controlSensing dataSimulation

The invention provides a robot and intelligent equipment interaction method and device and electronic equipment. The method comprises the steps of; generating an adjustable parameter training model according to sensing data and corresponding intelligent equipment parameters; training through the adjustable parameter training model to obtain different control interaction modes; establishing a network connection between a robot and the intelligent equipment; selecting corresponding intelligent equipment and a control interaction mode according to the sensing data parameters of the scene to which the robot belongs; obtaining a target parameter and an adjustable parameter of the intelligent equipment in the control interaction mode; and performing adjustment control on the intelligent equipment by taking the adjustable parameter as a reference. Through interaction between the robot and the intelligent hardware, the intelligent equipment can be controlled to reach the optimal environment mode, the problem of obstacles encountered in the task execution process of the robot can be solved, and interference factors in the task execution process of the robot can be weakened or eliminated.

Owner:CLOUDMINDS BEIJING TECH CO LTD

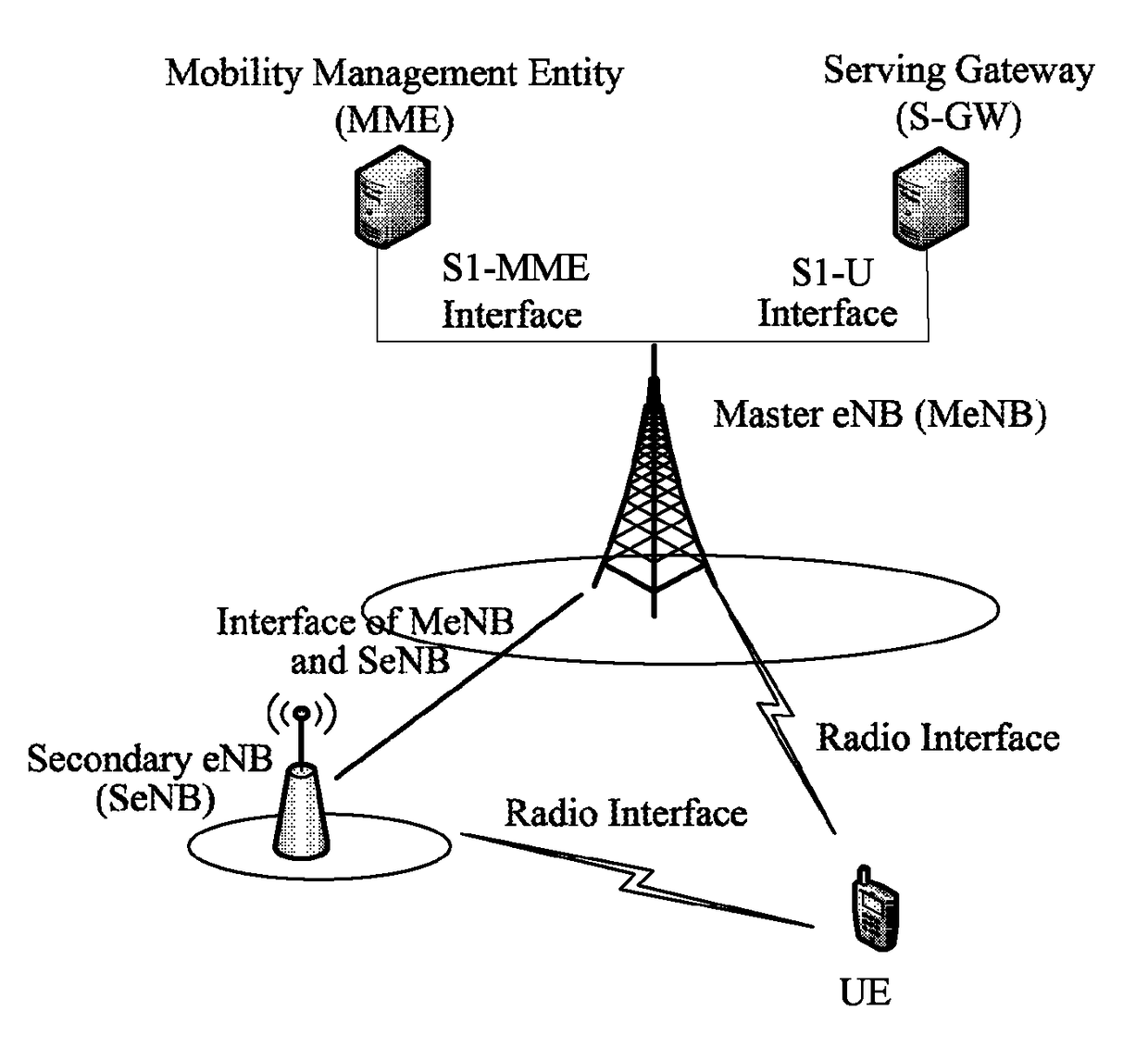

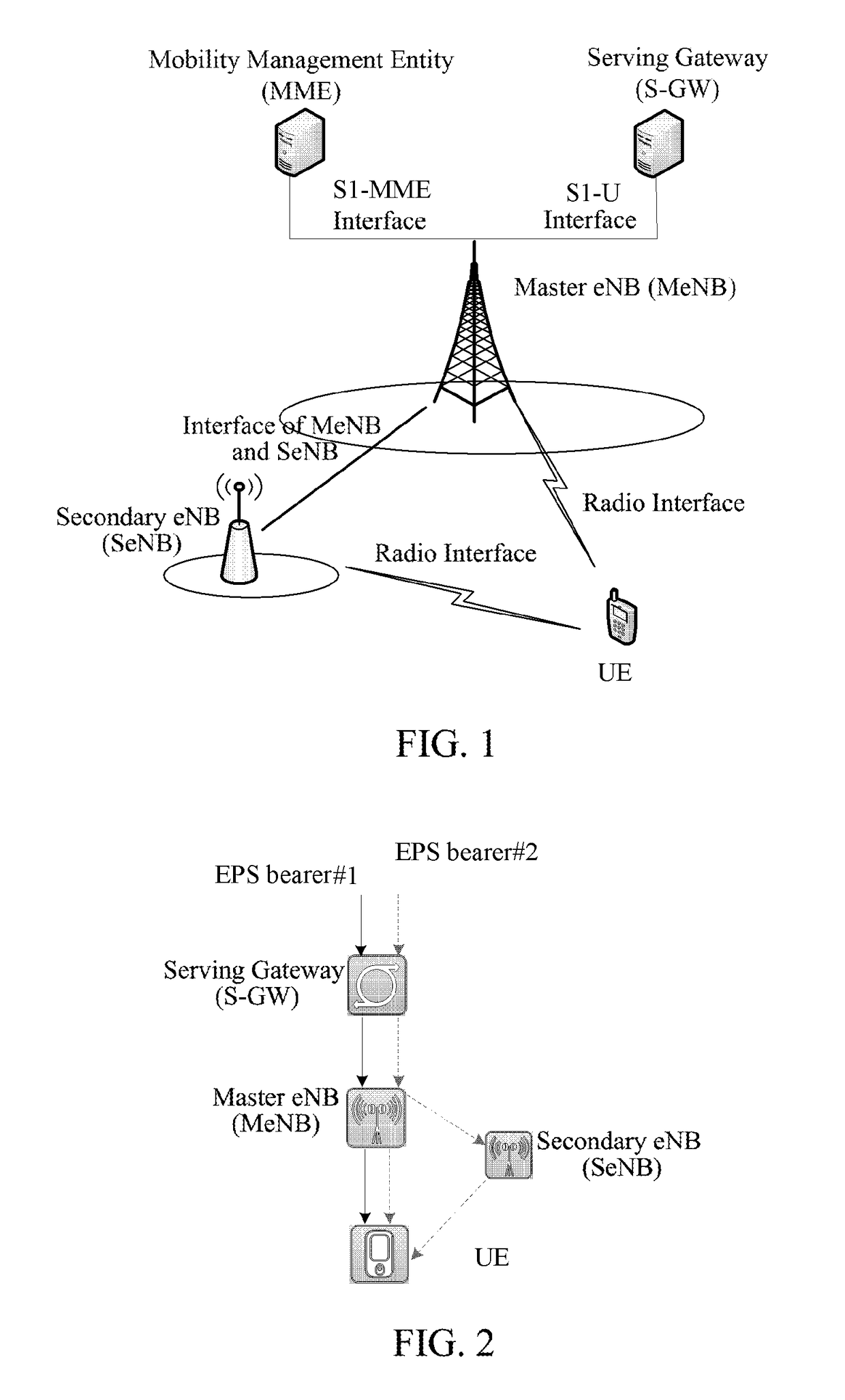

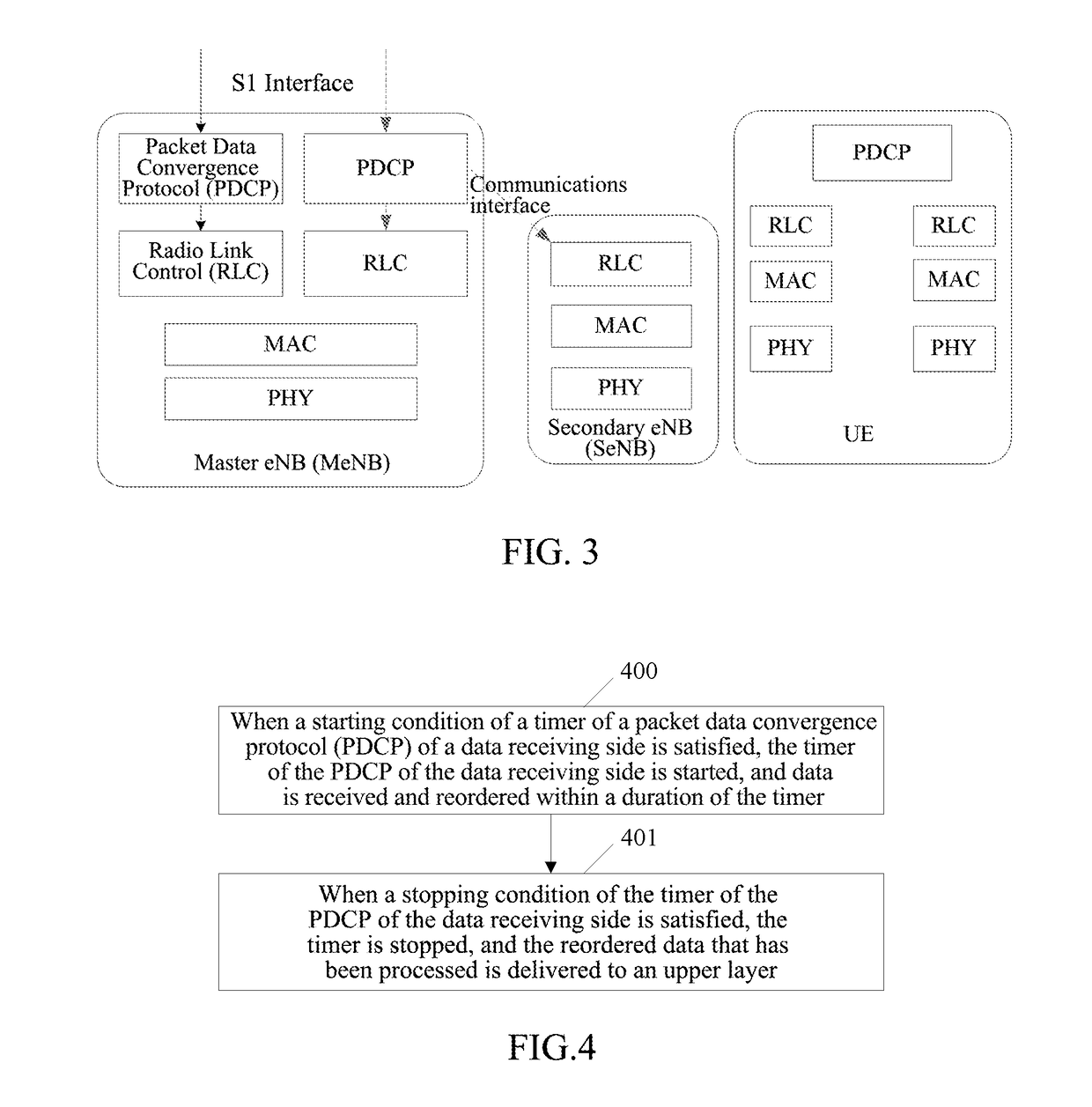

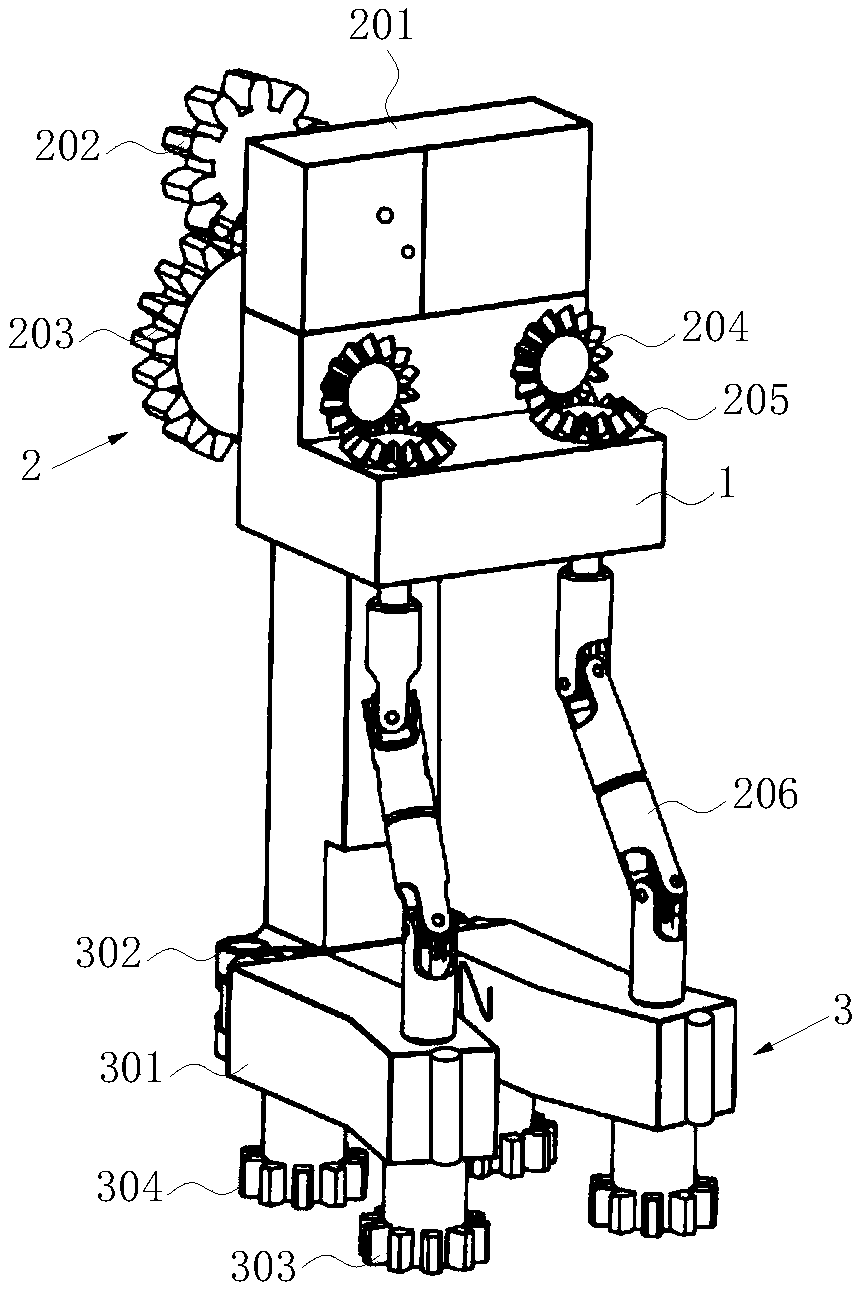

Method and device for realizing data transmission

InactiveUS10021663B2Efficiently re-orderingSolve obstaclesError prevention/detection by using return channelSynchronisation arrangementNetwork packetRadio Link Control

A method and device for realizing data transmission, including: when a starting condition of a timer of a packet data convergence protocol (PDCP) of a data receiving side is satisfied, starting the timer of the PDCP of the data receiving side, and receiving and reordering data within a duration of the timer; and when a stopping condition of the timer of the PDCP of the data receiving side is satisfied, stopping the timer, and delivering to an upper layer the reordered data that has been processed; wherein the duration of the timer is related to a radio link control (RLC) mode of an offloading bearer. In embodiments of the present document, by setting the starting condition of the timer of the PDCP at the data receiving side, data packets are received and reordered within the duration of the timer when the data packets are received, and the timer is stopped while the data packets are continuously delivered when the stopping condition of the timer is satisfied, which realizes efficient ordered transmission of the data packets of the PDCP.

Owner:ZTE CORP

Friction-type pineapple picking device

The invention relates to a friction-type pineapple picking device and belongs to the technical field of agricultural machinery. The problems are solved that in the prior art, the damage rate of pineapple picking is high, and the device cannot adapt to pineapples different in size. The friction-type pineapple picking device comprises a main rack, a driving mechanism arranged on the main rack and afriction picking mechanism arranged at the lower end of the main rack. The friction picking mechanism comprises two symmetrically-arranged picking heads of the same structure and a spring connected between the two picking heads; each picking head comprises a picking head, a drive gear, a driven gear and a friction band, one end of the picking rack is hinged to the main rack through a hinge, the drive gear and the driven gear are arranged on the lower end face of the picking rack and meshed with each other, and the friction band is connected between the drive gear and the driven gear; the two ends of the spring are connected with the opposite side faces of the two picking racks respectively, and when the spring is in a natural state, the two picking racks are relatively close to each other;the driving mechanism drives the two drive gears of the two picking heads to rotate in different directions.

Owner:CHANGCHUN UNIV OF SCI & TECH

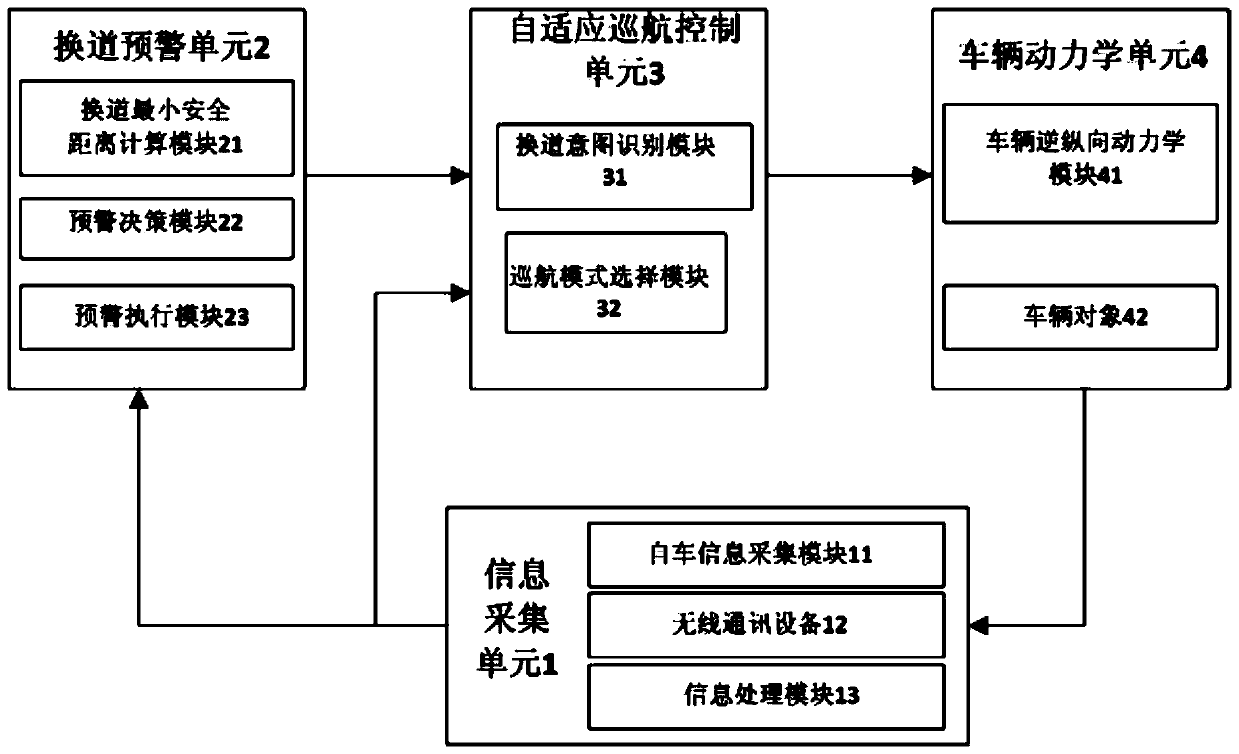

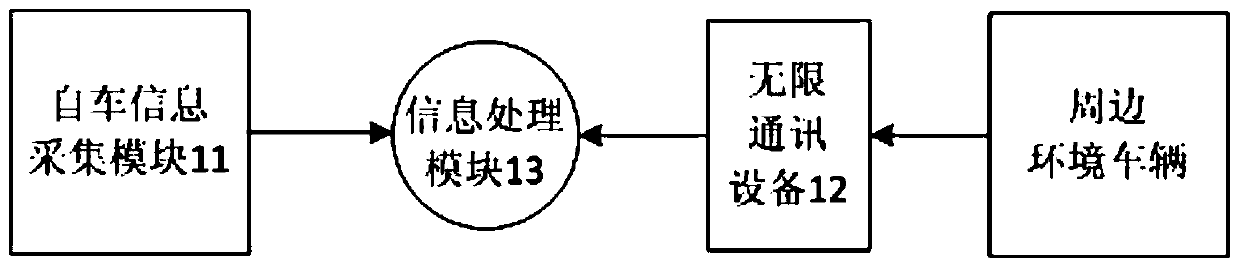

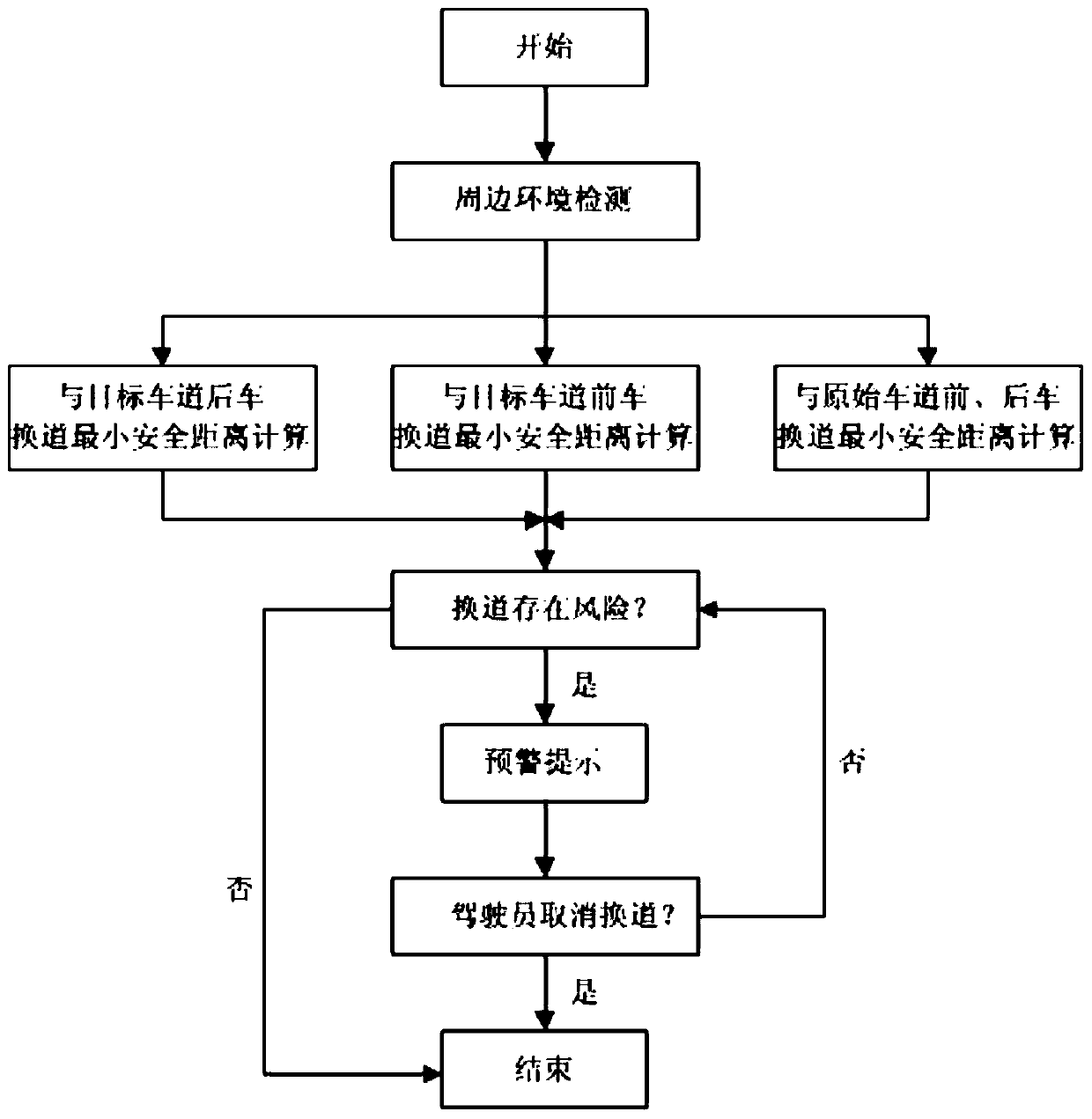

A vehicle adaptive cruise control system

ActiveCN103754221BEnsure lane change safetyImprove functional limitationsExternal condition input parametersVehicle dynamicsCruise control

The invention relates to a vehicle adaptive cruise control system. The vehicle adaptive cruise control system is characterized in that an information collecting unit, a lane changing early warning unit, an adaptive cruise control unit and a vehicle dynamics unit are included; the information collecting unit collects and processes the driving state information of a vehicle, and sends the driving state information to the lane changing early warning unit and the adaptive cruise control unit; the lane changing early warning unit calculates the lane changing minimum safety distance between the own vehicle and surrounding vehicles according to the received effective vehicle movement information, and judges lane changing risks according to a calculation result, an early warning is carried out on the vehicle according to a judgment result, and the judgment result is sent to the vehicle adaptive cruise control unit; the vehicle adaptive cruise control unit selects a control mode according to the vehicle movement information and the lane changing risk judgment result, calculates expected longitudinal acceleration needed by vehicle longitudinal driving, and sends the calculated expected longitudinal acceleration to the vehicle dynamics unit; the vehicle dynamics unit converts the expected longitudinal acceleration into an expected air valve opening degree or braking pressure and sends the expected air valve opening degree or the braking pressure to a vehicle object, and the longitudinal control over the vehicle object is completed.

Owner:TSINGHUA UNIV

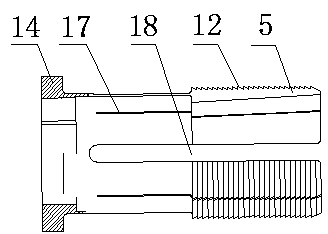

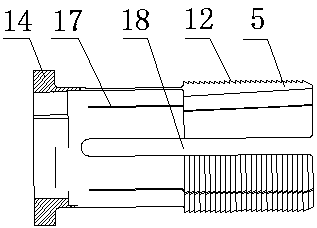

Guided locking mechanism for casing drive heads

ActiveCN103437707BSolve obstaclesImprove downloading abilityDrilling rodsDrilling casingsLocking mechanismEngineering

The invention discloses a guiding and locking mechanism suitable for a casing pipe driving head. The guiding and locking mechanism comprises a center shaft and a clamping tile, wherein the center shaft is sleeved with the clamping tile. The center shaft is used for lifting, dropping and rotating a casing pipe through matching of the clamping tile and the casing pipe. By adopting the clamping tile, due to a key groove of the clamping tile and a gap, a tool can be set for driving the casing pipe to rotate or a driving mechanism can be taken out according to needs, locking or unlocking between the tool or the driving mechanism and the casing pipe can be changed, and the mode of drilling through the casing pipe can be implemented conveniently. Clamping teeth have good adhesive force, can achieve locking with the underground casing pipe wall effectively and can be attached to the casing pipe wall after being inserted into the casing pipe, and therefore mutual swing between the casing pipe and the casing pipe driving mechanism can be reduced, the clamping teeth can be attached to the casing pipe inner wall closely when being connected with the casing pipe completely, and the effect of preventing the casing pipe from dropping can be achieved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

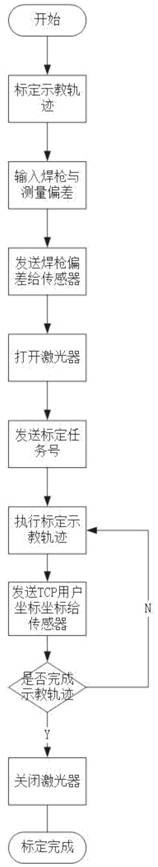

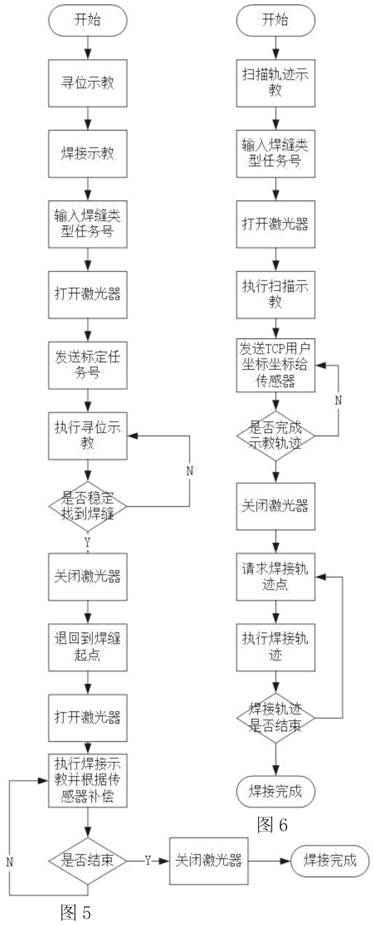

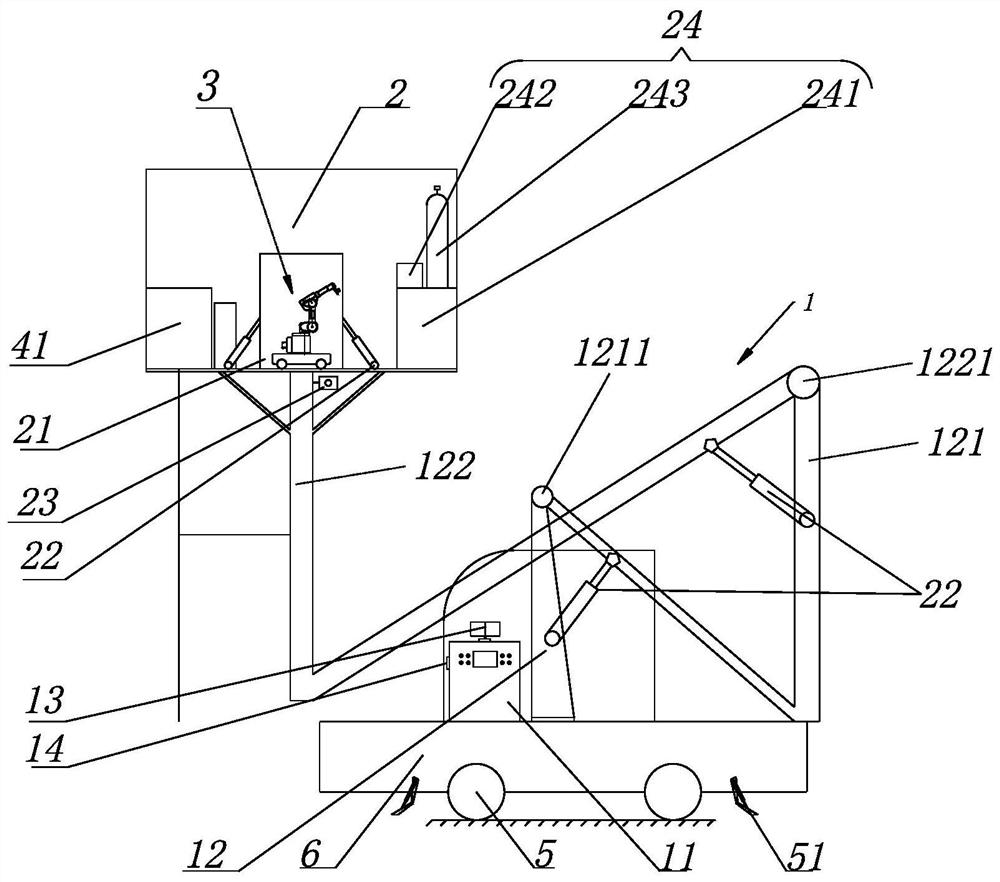

Auxiliary welding device of crawling welding robot, control method and welding method of auxiliary welding device

ActiveCN113199175ASolve the load problemSolve the problem of not being able to carry peripheral devicesProgramme-controlled manipulatorWelding/cutting auxillary devicesCrankEngineering

The invention relates to an auxiliary welding device of a crawling welding robot, a control method and a welding method of the auxiliary welding device. The welding device comprises a crank arm type lifting mechanism assembly for controlling an operation room to flexibly move to the surface and the periphery of any operation position of a large component, the crawling welding robot is arranged in the operation room, and whole machine electric control equipment and peripheral equipment are arranged in the operation room; and the crank arm type lifting mechanism assembly comprises a combined general control operation table and a crank arm lifting mechanism which are arranged on a carrying tool. The crank arm lifting mechanism is rigidly connected with the tail end operation room by adopting a three-section hydraulic folding type working arm; the crank arm lifting mechanism comprises a welding operation arm pivoted to the combined general control operation table through a first pivot and a first crank arm pivoted to the end of one end of the welding operation arm through a second pivot; and each crank arm is driven by a cylinder.

Owner:SHENZHEN CIMC SECURITY & SMART TECH

Multistage plunger super-long-stroke oil well pump

InactiveCN104728098AAchieve ultra-long connectionAchieve ultra-long strokePositive displacement pump componentsFlexible member pumpsSingle stageButt joint

The invention relates to a multistage plunger super-long-stroke oil well pump which is composed of a multistage rigid plunger and a super-long pump cylinder. The multistage rigid plunger comprises a sealed cavity part, a weighting part and multiple single-stage rigid plungers which are connected in series. The single-stage rigid plungers are in loose joint so that the multistage rigid plunger can be freely adjusted to adapt to the axial deviation of the super-long pump cylinder and solve the problem that the plunger is stopped. The super-long pump cylinder is formed by linearly connecting multiple finish-rolled and honed pump cylinder bodies through couplings. The middle of each coupling is provided with a spigot. Every two pump cylinder bodies are in threaded connection with the corresponding coupling, the fit clearance is smaller than or equal to 0.01 mm, each spigot is aligned so as to be located, the largest gap between the end faces of every two pump cylinder bodies which are in butt joint ranges from 0.1 mm to 0.2 mm, the straightness of the two butt-joint pump cylinder bodies is smaller than or equal to 0.04 mm each meter, connecting gaps of the super-long pump cylinder are small due to the connection mode between the pump cylinder bodies, and connecting faces are smooth. The multistage plunger super-long-stroke oil well pump has the advantages that the stroke of the oil well pump can be set at will according to the requirement of an oil well, and the range is from tens of meters to hundreds of meters.

Owner:瑞燕(上海)能源科技有限公司

English character string input technique applied to English input method and implementation method

InactiveCN103455159ASolve problemsSolve obstaclesSpecial data processing applicationsInput/output processes for data processingTypingConfusion

The invention discloses an English character string input technique applied to an English input method and an implementation method. Related words of various words are arranged into a character string library, and wanted English words are obtained by input, comparison and judgment. The problems of difficulty and impediment in input English usage can be effectively solved for English beginners or people with limited English level, input speed and accuracy are increased, the English character string input technique can help Chinese people with limited English level to distinguish various morphological changes when being applied to the English input method, so that efficiency and accuracy are improved, the problems and confusion of a plurality of English beginners or people with limited English knowledge in China can be solved, particularly, the problem of change of irregular verbs, irregular nouns, irregular adjectives, irregular adverbs and the like can be solved, and typing speed can be increased.

Owner:SUZHOU HEALTH COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com