Patents

Literature

56results about How to "Reduce production cost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

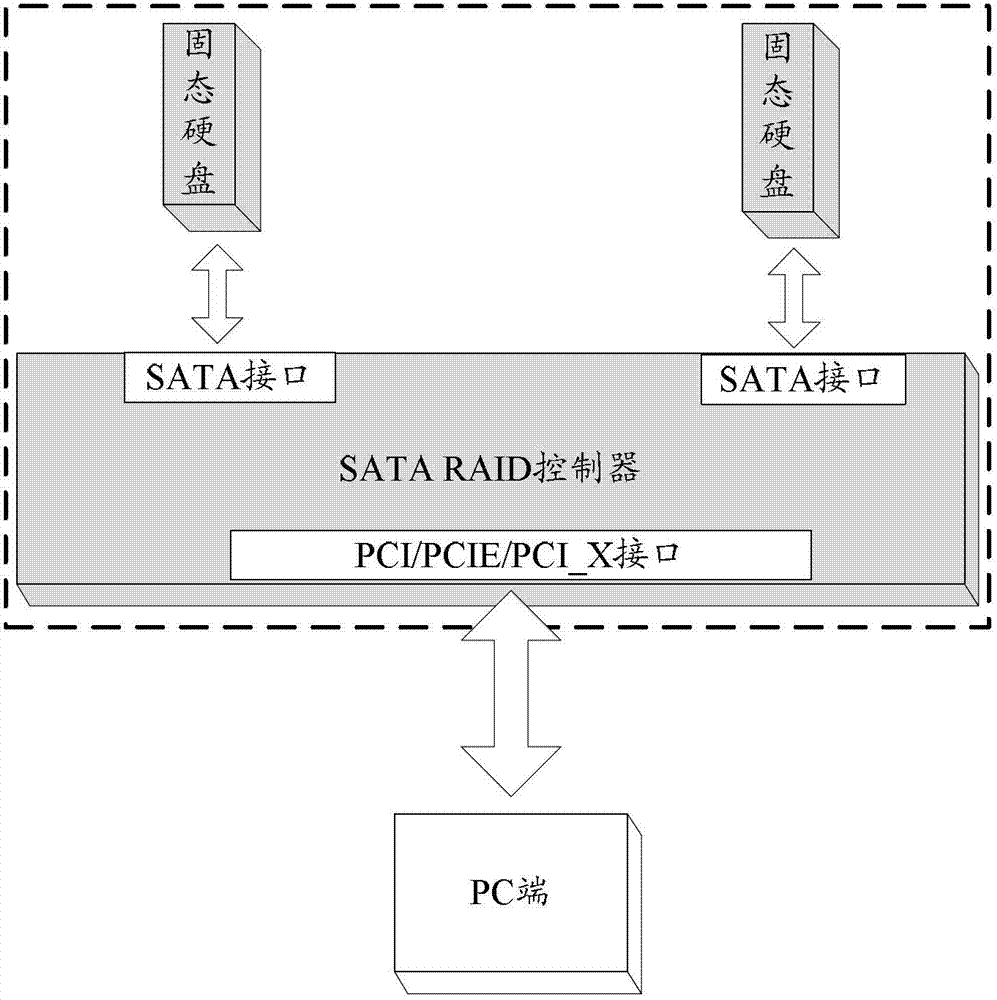

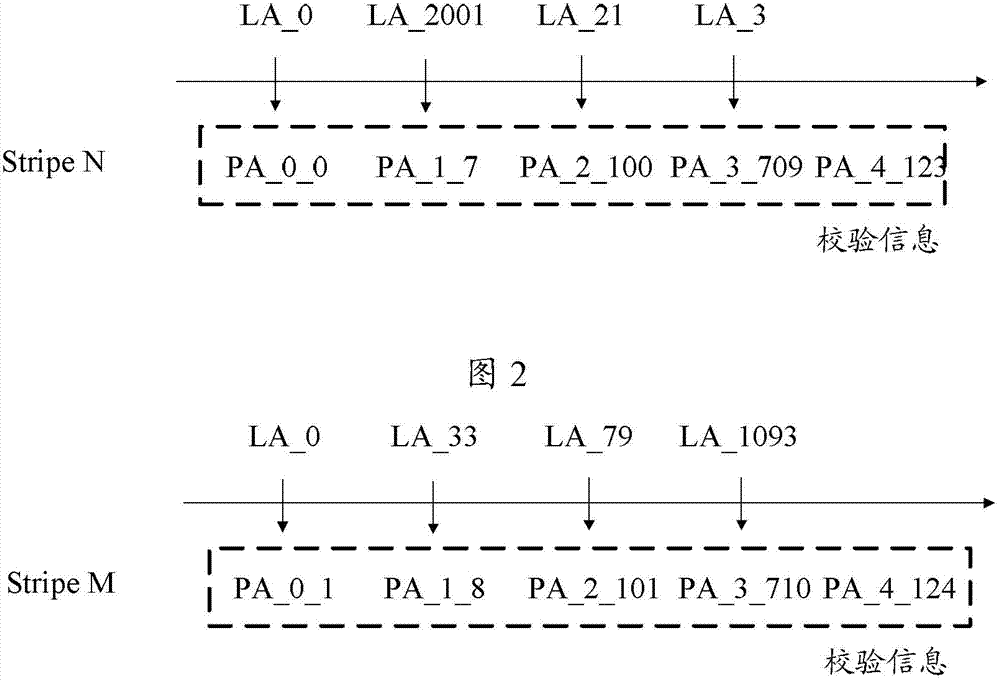

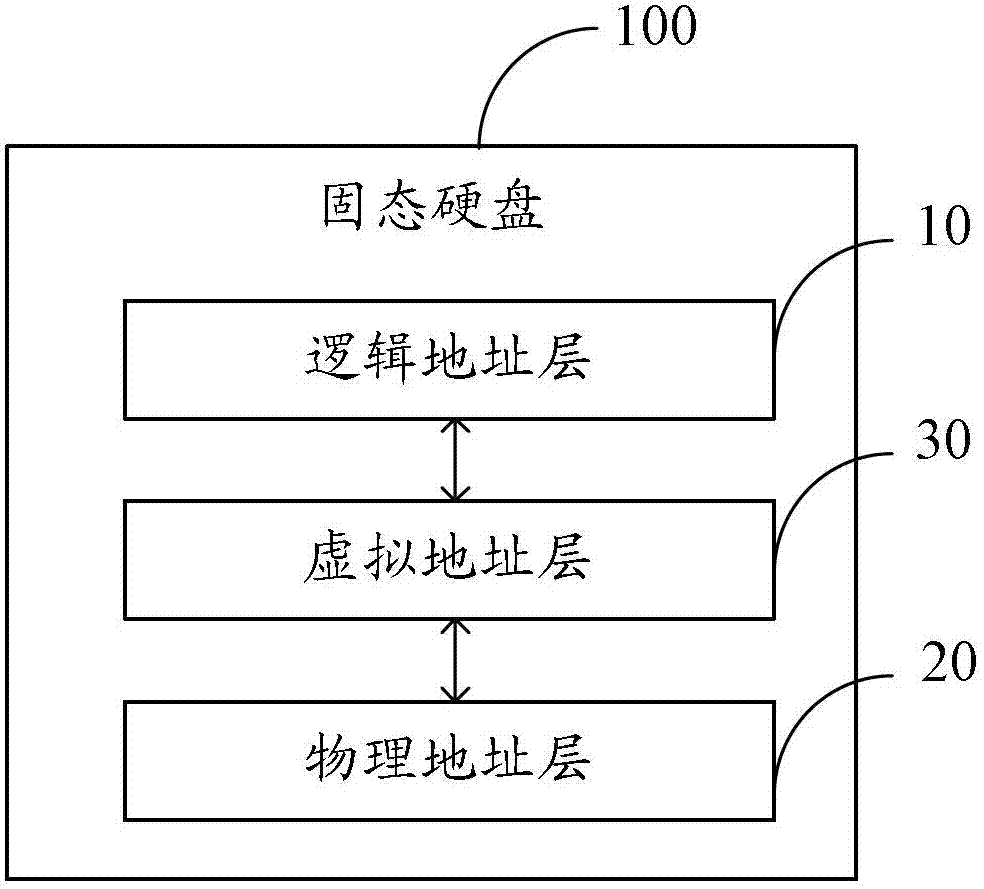

Method for mapping disk array of solid hard disk and solid hard disk

ActiveCN102830942AReduce production costReduce overhead in terms of data management/memory requirements etc.Memory architecture accessing/allocationInput/output to record carriersSolid-state storageSolid-state drive

The invention, which is applicable to the technical field of solid memory, discloses a method for mapping a disk array of a solid hard disk as well as the solid hard disk, wherein the method comprises the steps of setting a virtual address layer between a logic address layer and a physical address layer of the solid hard disk; respectively mapping user data blocks of the logic address layer onto the corresponding virtual address layer; and respectively mapping the user data blocks onto corresponding physical address layer by the virtual address layer. Therefore, the independence of the solid hard disk on the additional transfer interface part is reduced, and the manufacturing cost of the hard disk is lowered.

Owner:RAMAXEL TECH SHENZHEN

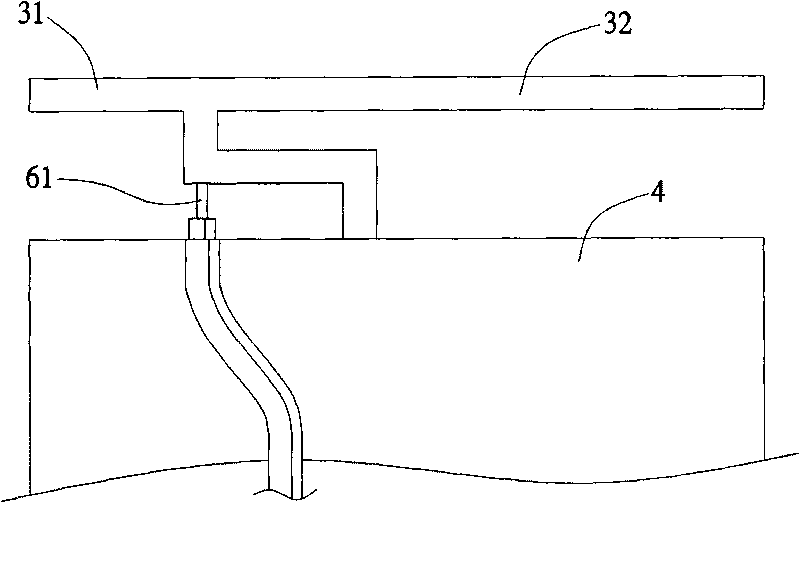

Broadband plane antenna

ActiveCN101740852AReduce production costReduce reflected wavesSimultaneous aerial operationsAntenna supports/mountingsMicrowaveEngineering

The invention relates to a broadband plane antenna which comprises a substrate, a first radiator, a second radiator, a third radiator, a grounding part and a signal source, wherein the substrate is provided with a first surface and a second surface; the first radiator is arranged on the first surface; the second radiator is connected with the first radiator at the connecting part; the third radiator is arranged on the first surface or the second surface; the grounding part is connected with the third radiator; the signal source feeds in positive signals and negative signals; the positive signals are directly fed in through the connecting part so as to excite the first radiator and the second radiator to form a first frequency band mode and a second frequency band mode, and negative signals are in coupling with the grounding part, thereby being in coupling feeding in and exciting the third radiator to form a third frequency band mode. By making use of the design of the first radiator, the second radiator and the third radiator, the antenna can be applied to most advanced communication equipment with worldwide interoperability for microwave storing and fetching at preset. In addition, the broadband plane antenna has the effect of power saving compared with an ordinary broadband antenna, therefore, the antenna is particularly suitable for portable communication equipment.

Owner:WISTRON NEWEB

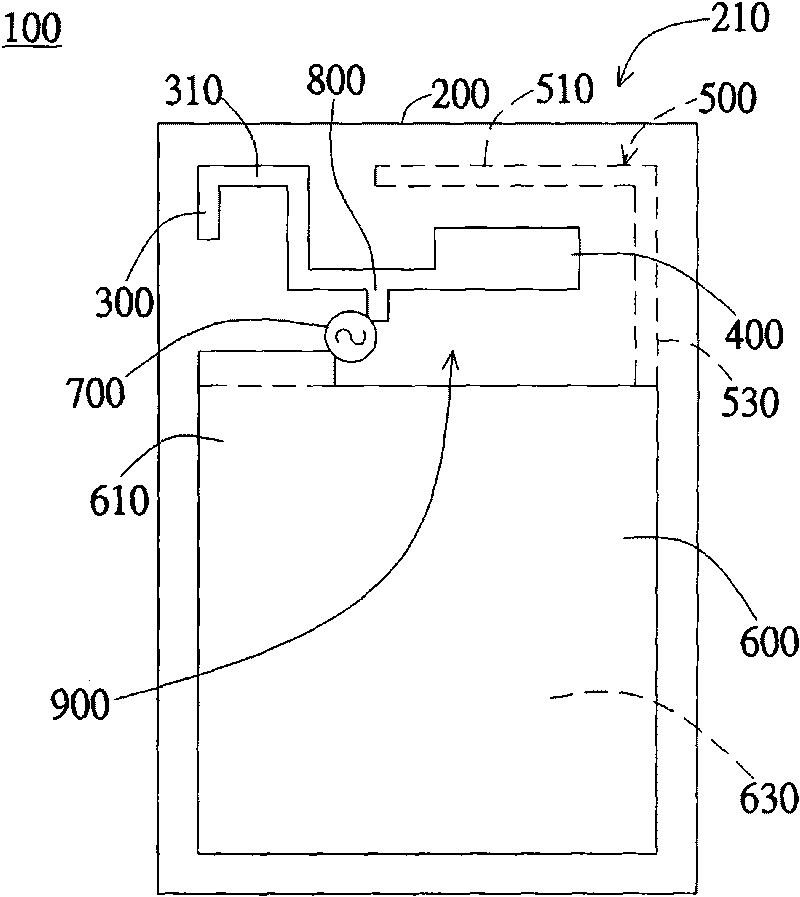

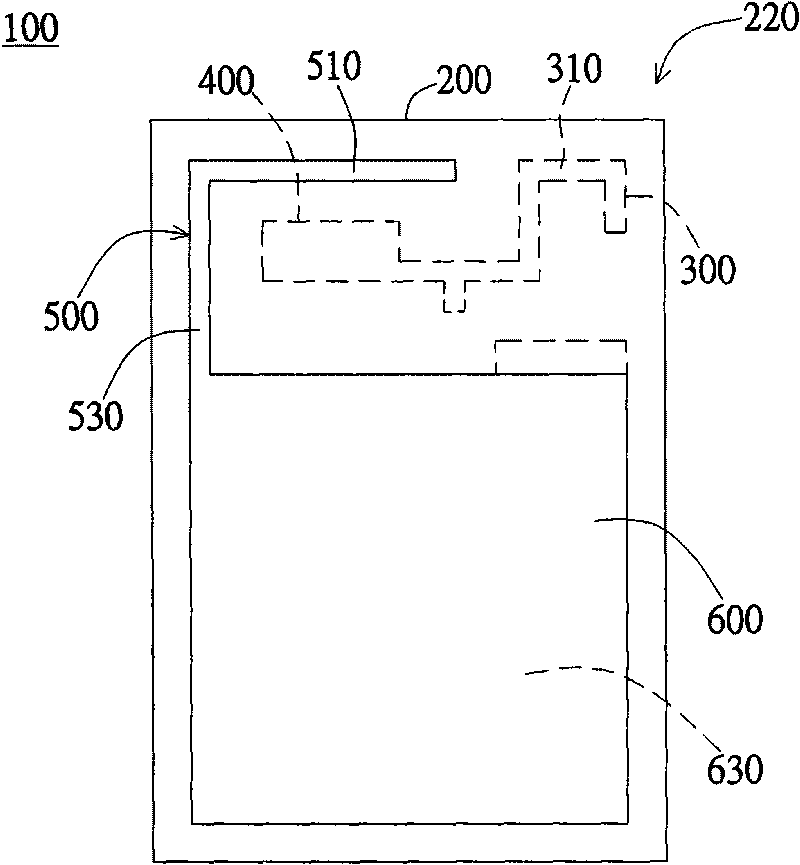

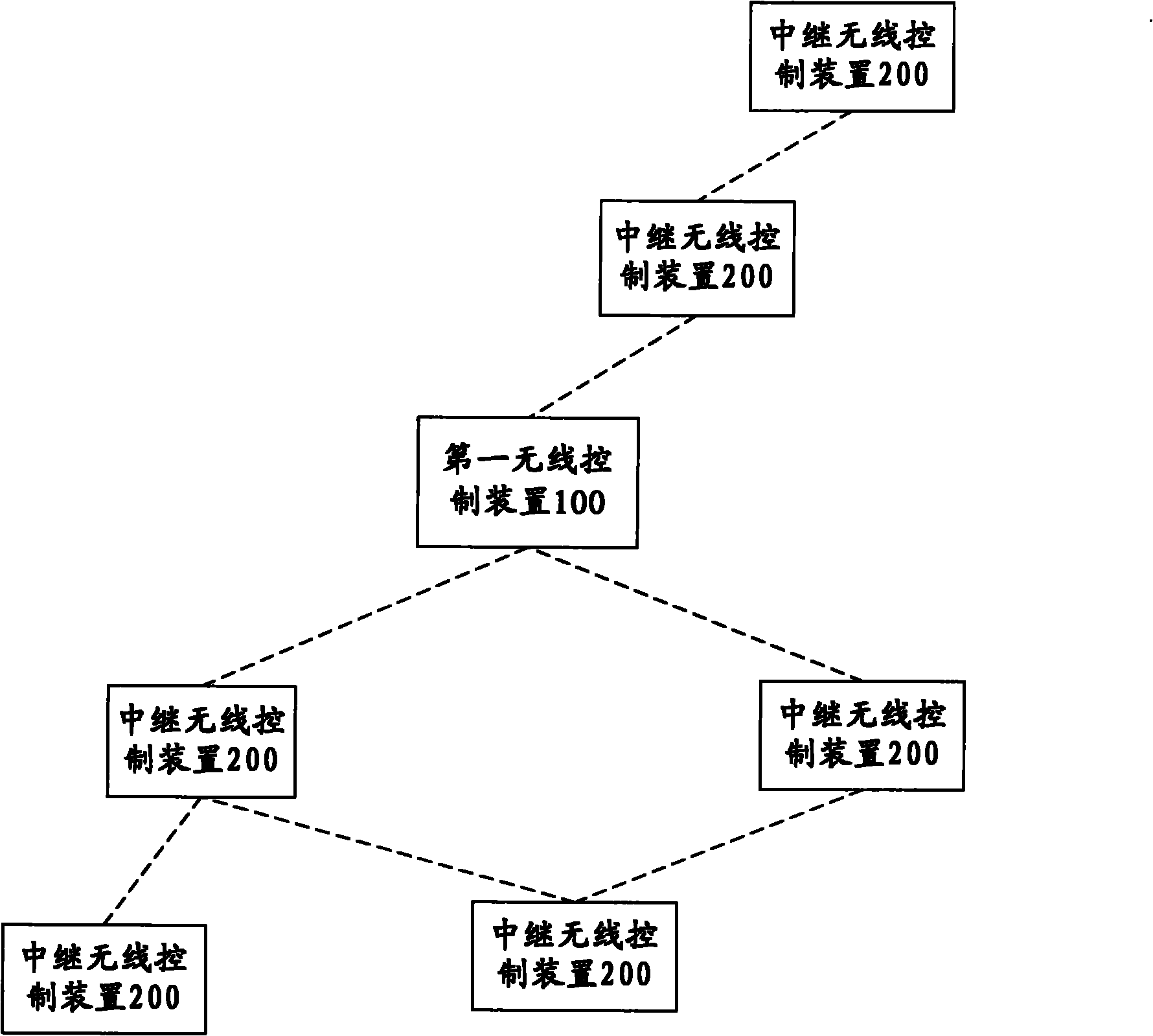

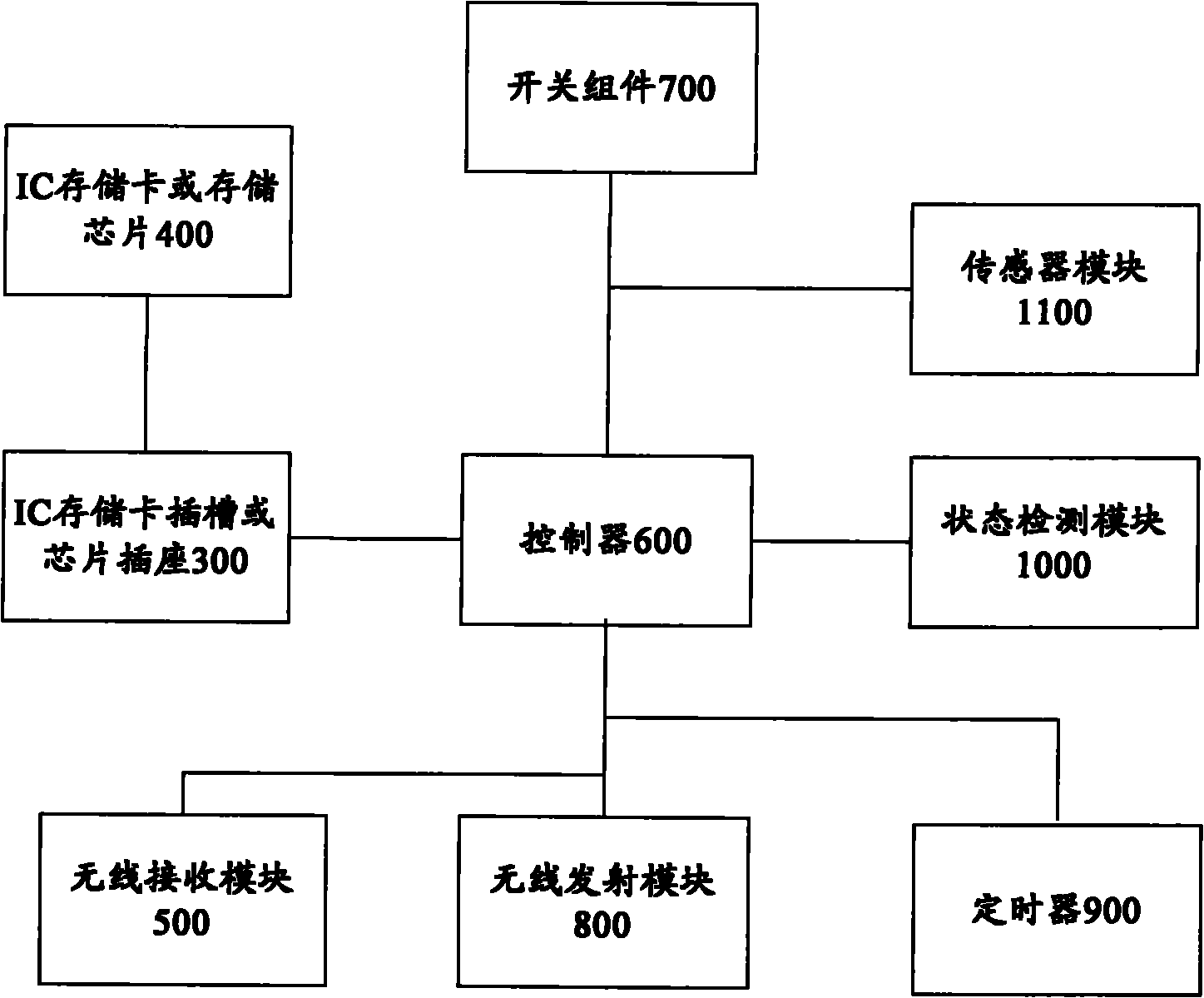

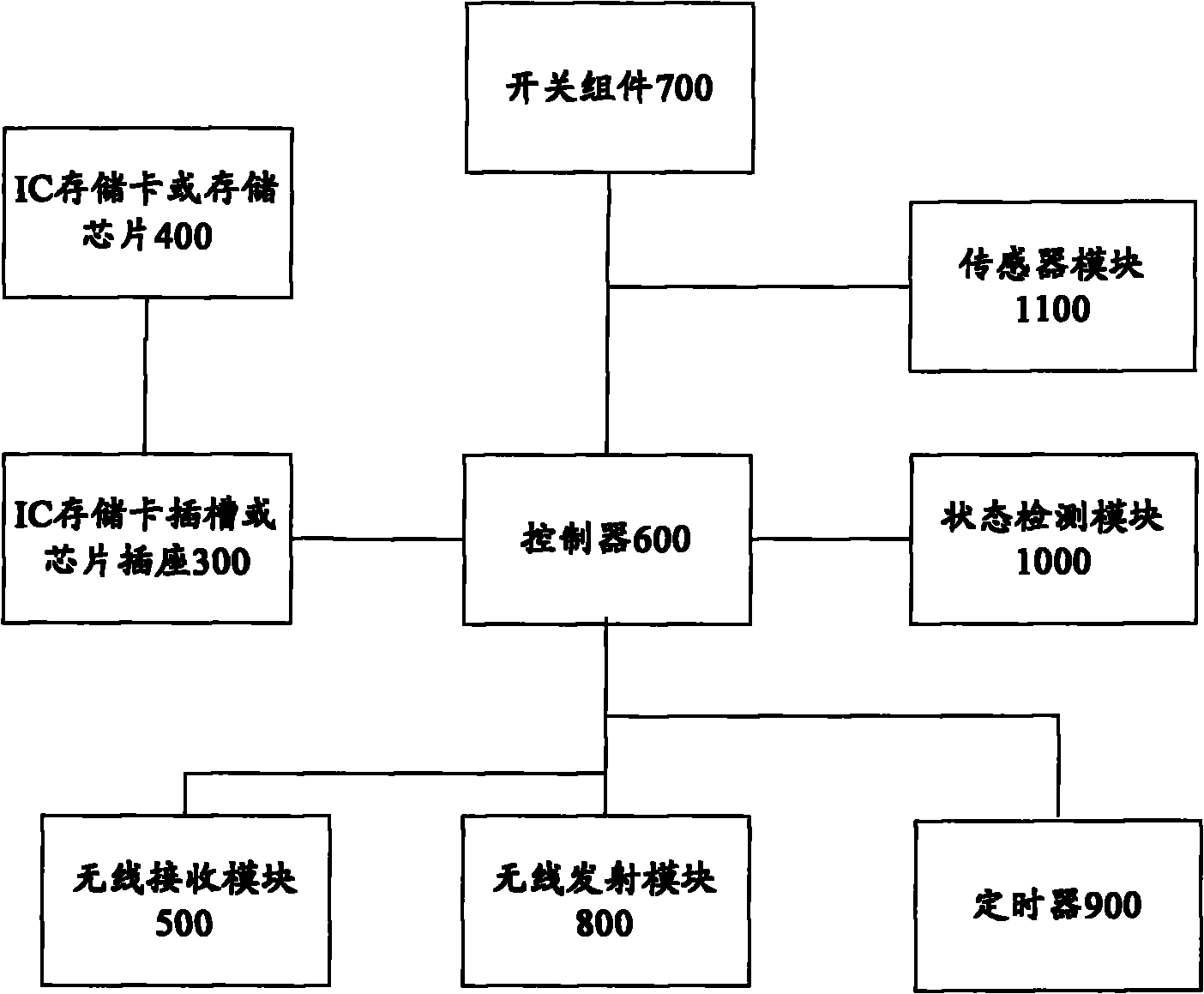

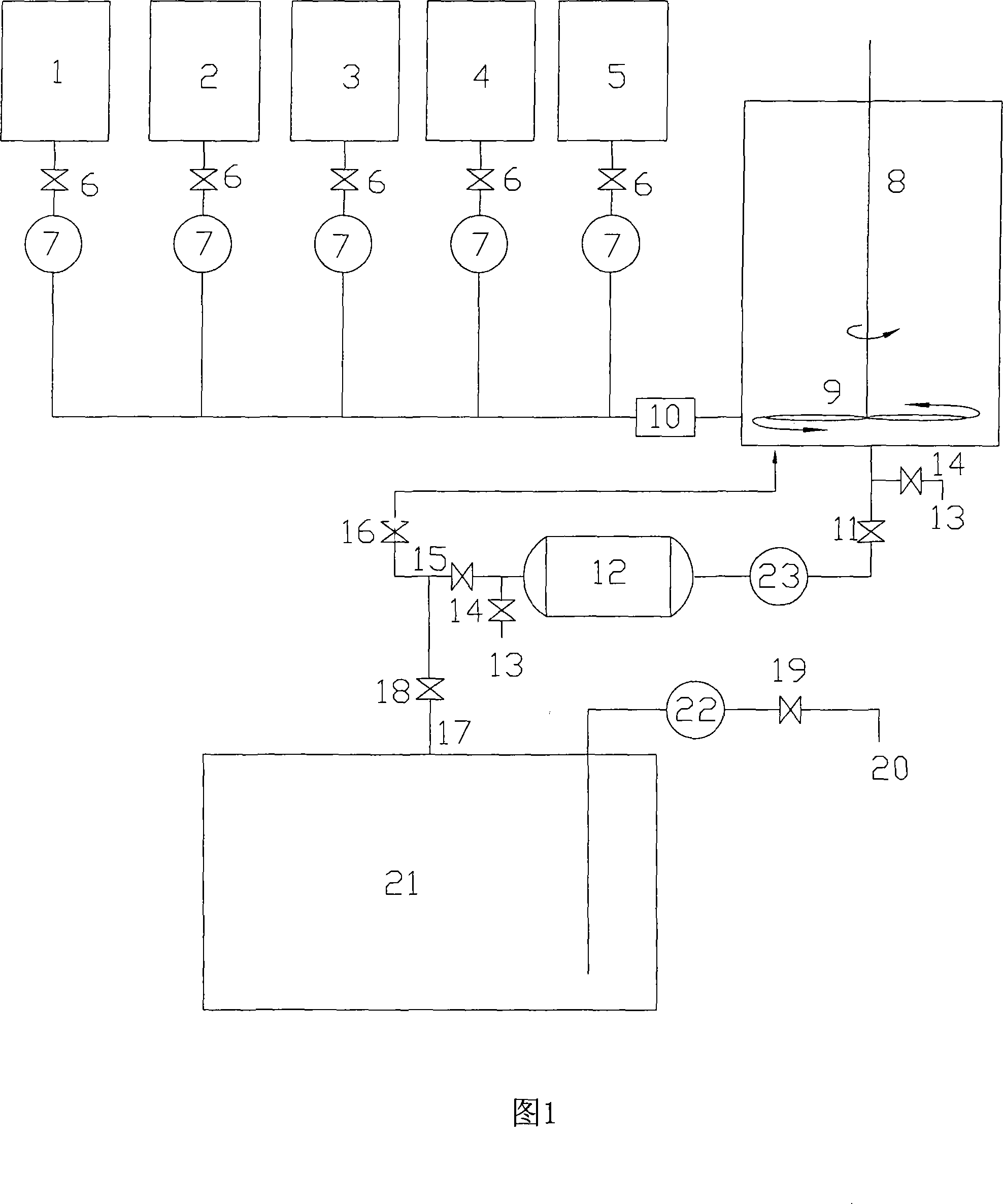

Relay forwarding control system and wireless control device for high current assembly

ActiveCN101958742ALow costReduce production costTransmission control/equalisingActive radio relay systemsHigh currentControl system

The invention provides a wireless control device, which comprises an IC storage card slot or a chip socket, an IC storage card or a storage chip, a wireless receiving module, a controller, a switching assembly and a wireless transmitting module. When the received transmitting identification code is matched with the receiving identification code of the wireless control device, the controller controls the switching assembly according to the control instruction, and controls the wireless transmitting module to transmit the control instruction to the wireless control device of the next hop according to the transmitting identification code of the wireless control device. The control instruction can be transmitted step by step through a plurality of relay wireless control devices so as to avoid using expensive GSM / CMDA modules and greatly reduce the cost.

Owner:苏州云华睿和智能科技有限公司

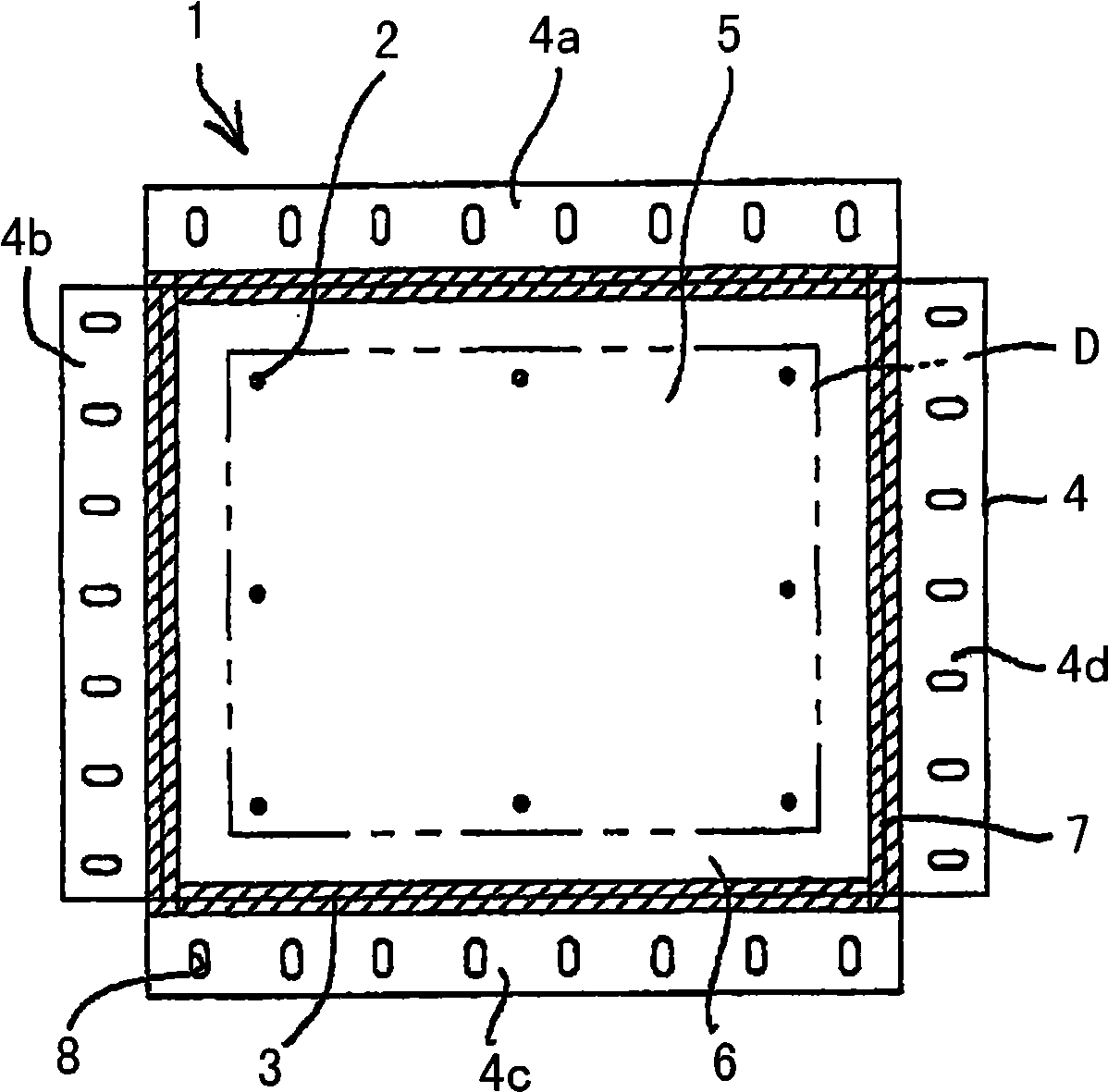

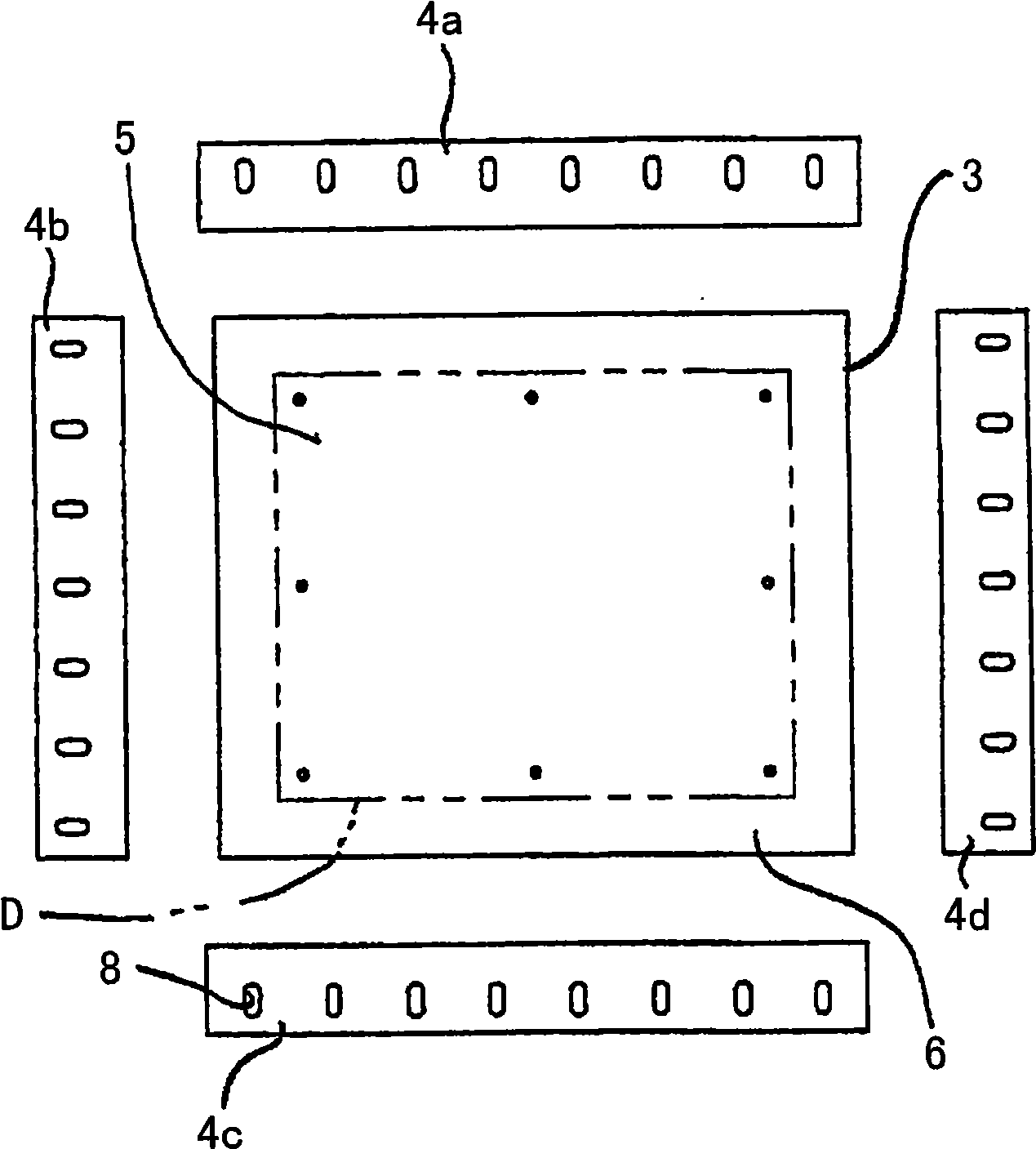

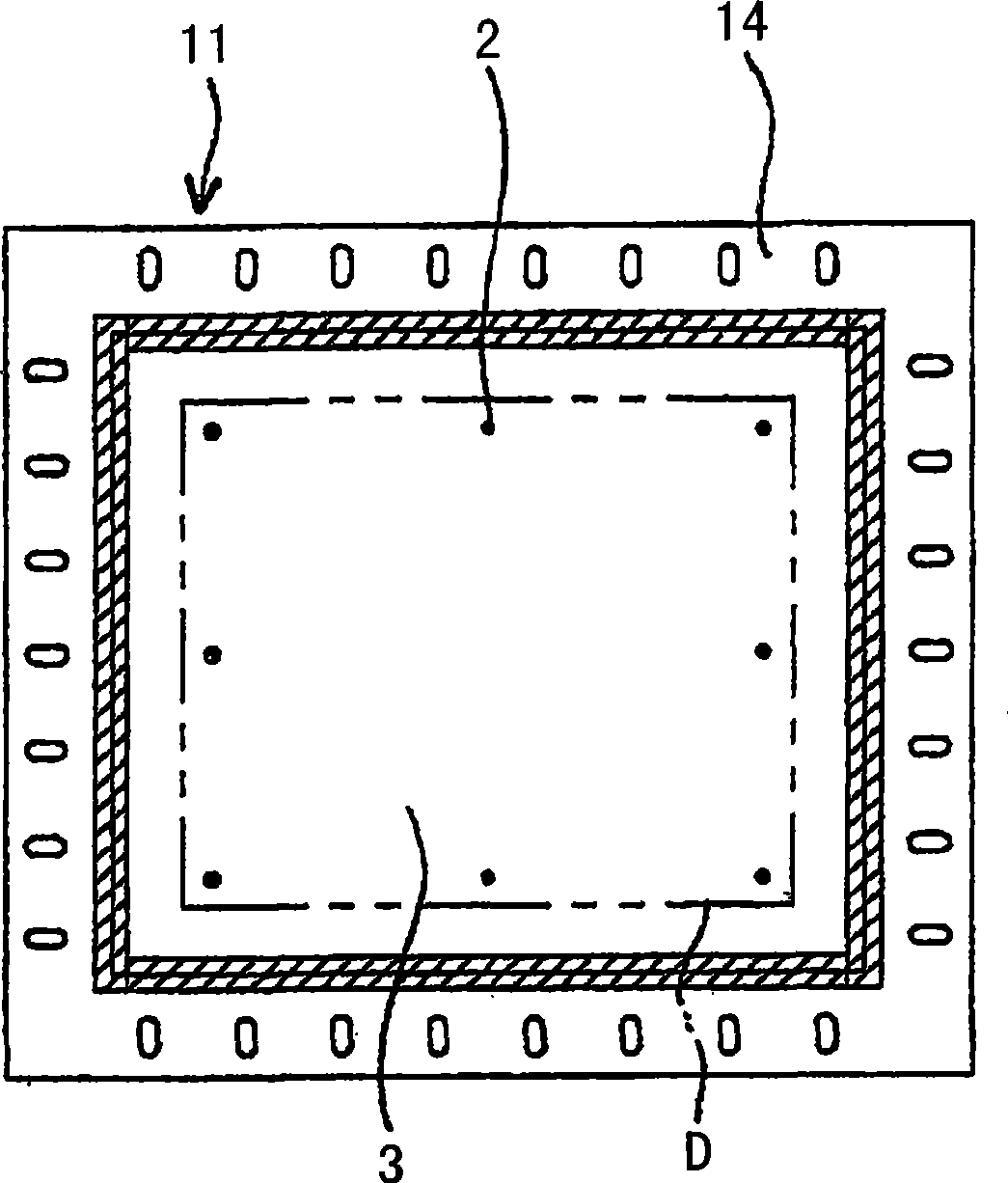

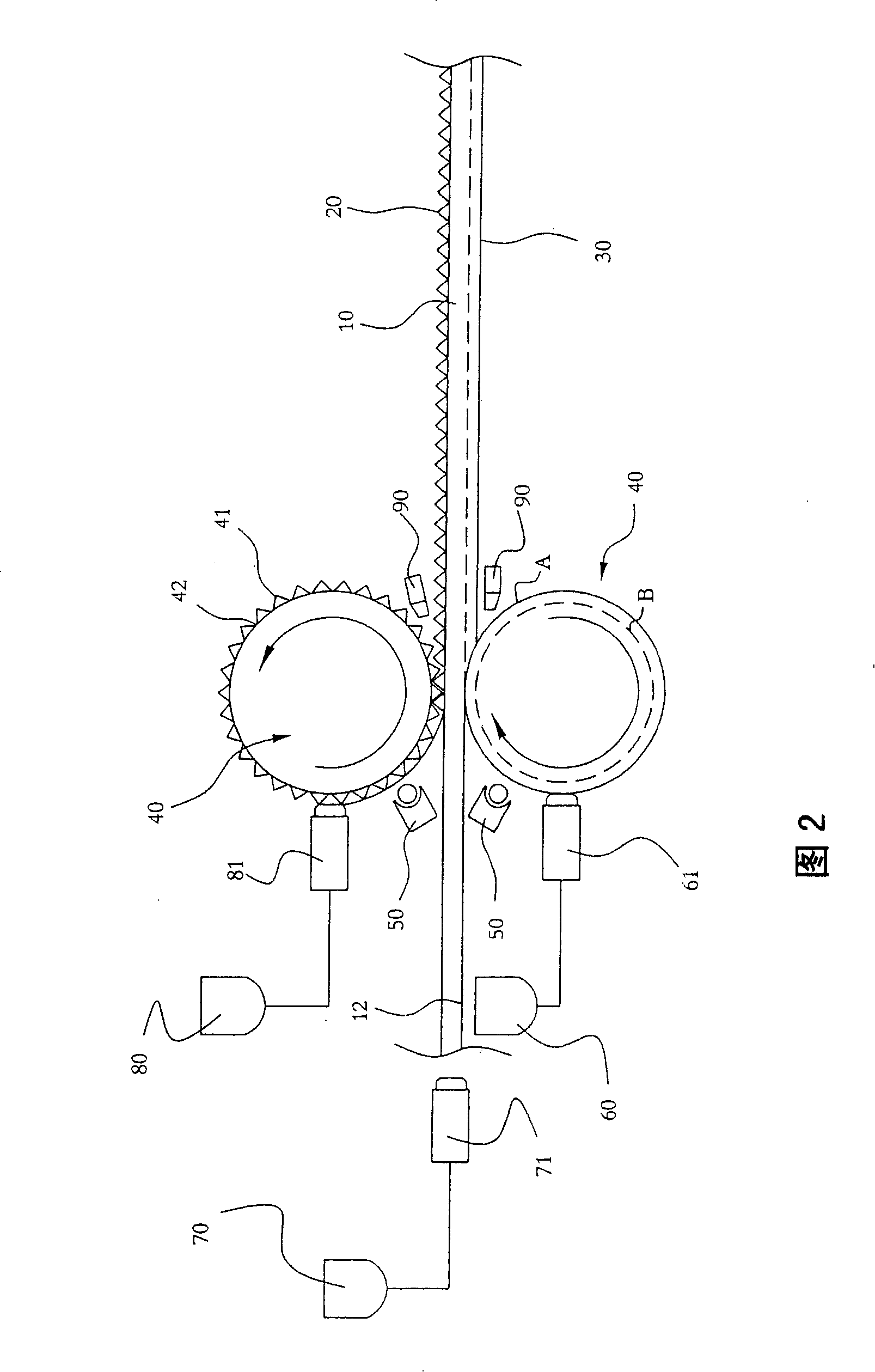

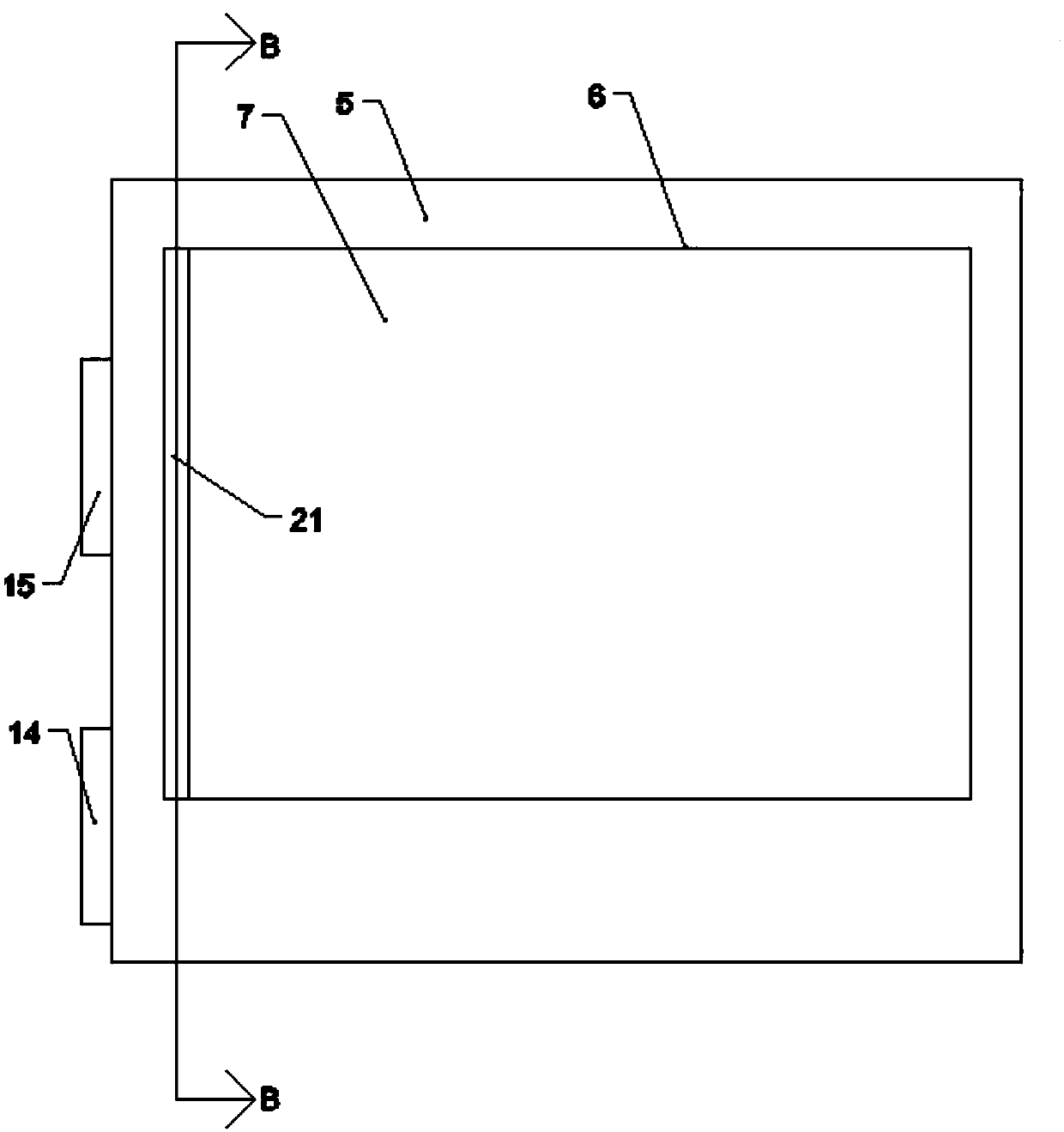

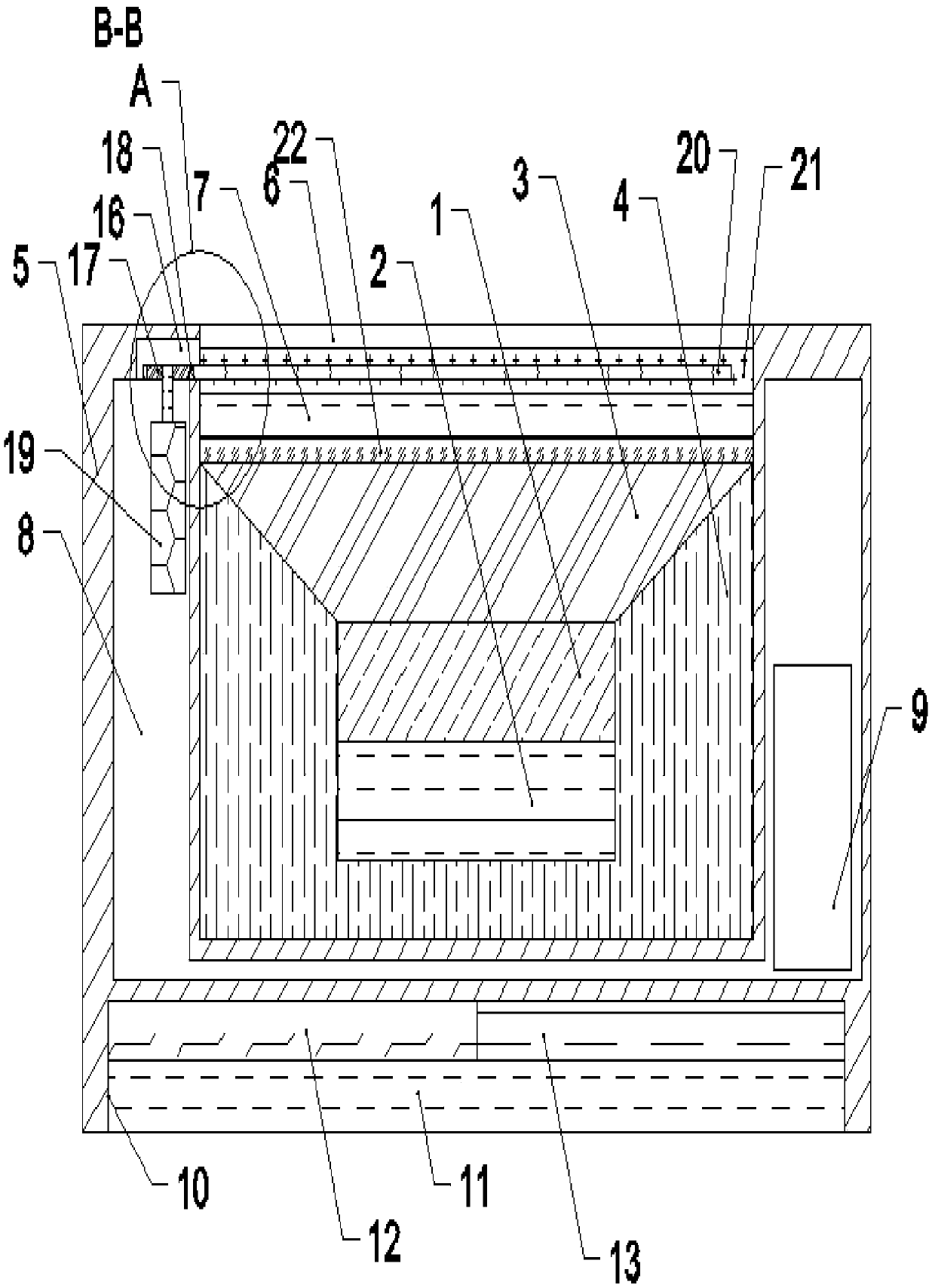

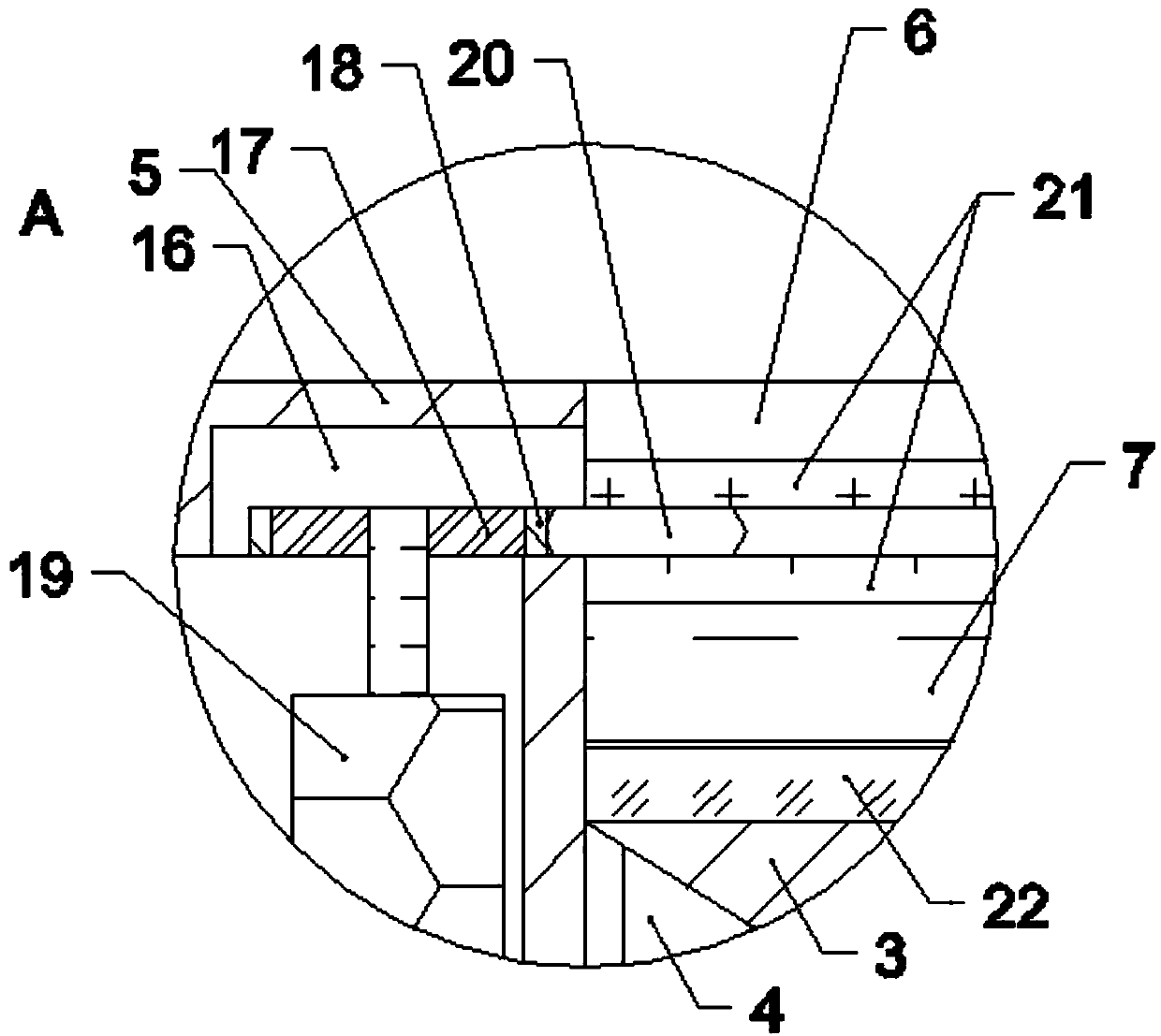

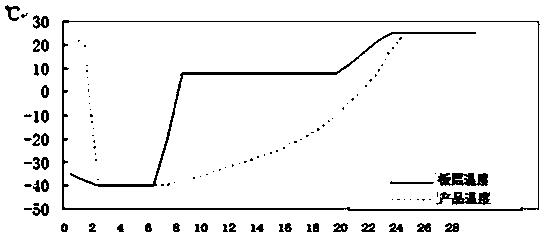

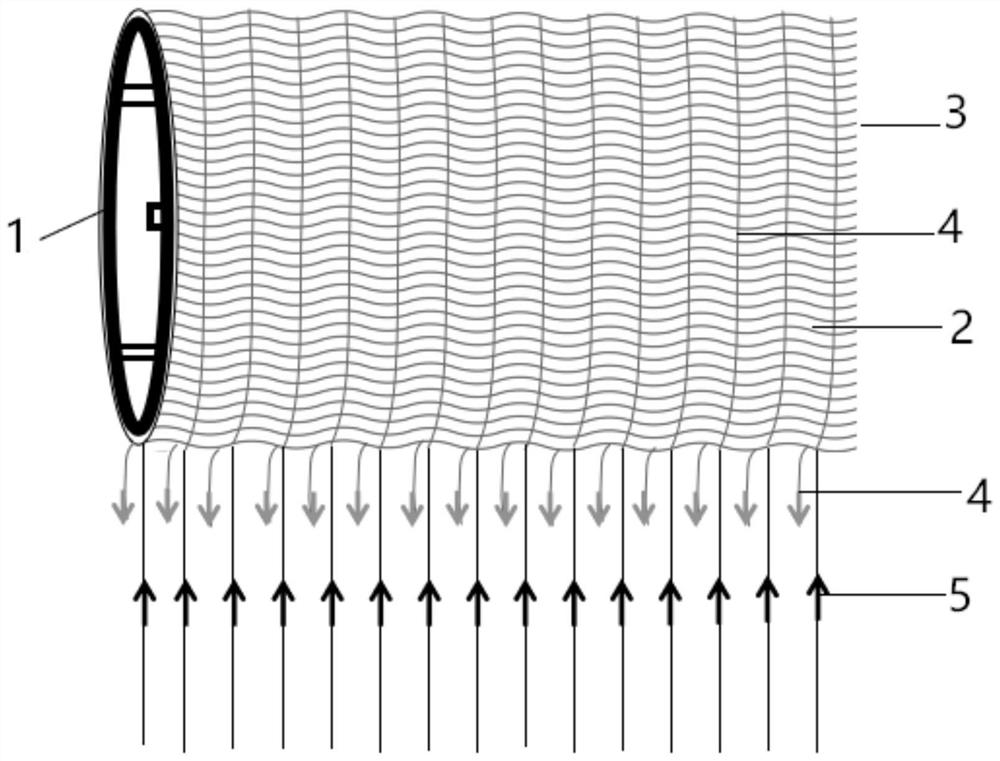

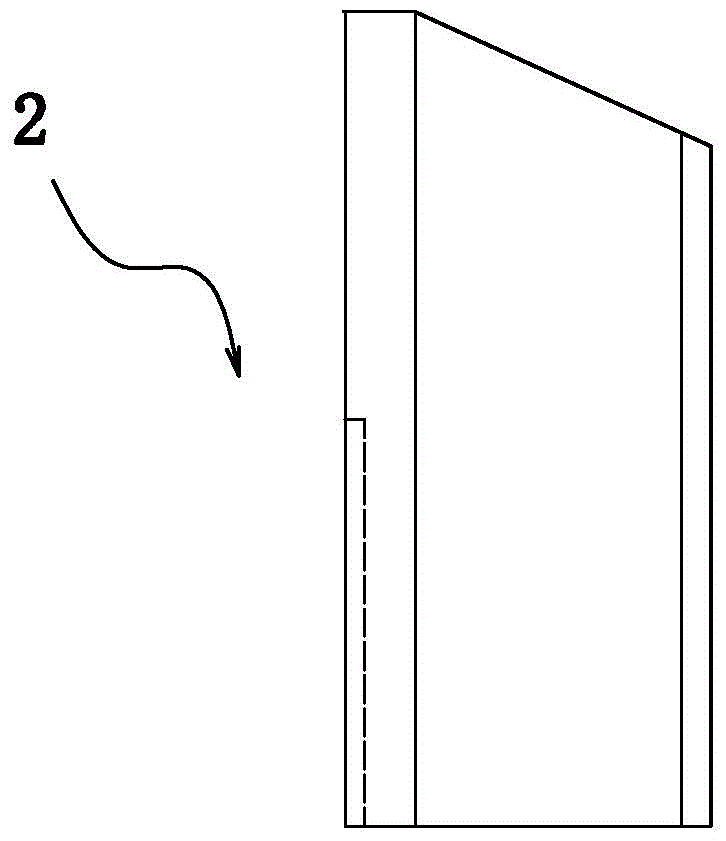

Optical mask for exposure

InactiveCN101482695AReduce partReduce production costPhotomechanical exposure apparatusMicrolithography exposure apparatusEngineeringPhotomask

The invention relates to a photomask, which is formed by dividing the photomask into a central part depicted with patterns and its surrounding force transfer parts, then bonding, so that it can reduce material costs and avoid investment in new facilities. The photomask (1) is divided into a central part(3) including a pattern display area (5), and a force transmission part (4) surrounding the outer peripheral part of the central part (3). The two parts are mutually jionted by the adhesive tape (7). The force transmission part (4) has a jiont part(hole) (8) connected to a force endowing mechanism, for perform elastic deformation to the central part (3).

Owner:SANEI GIKEN

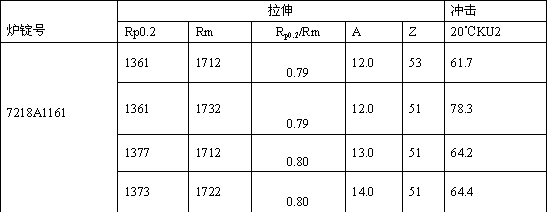

Medium alloy ultrahigh strength and toughness rare earth steel and preparation method thereof

The invention provides a kind of medium alloy ultrahigh strength and toughness rare earth steel and relates to the technical field of rare earth steel, in particular to medium alloy ultrahigh strengthand toughness rare earth steel and a preparation method thereof. The medium alloy ultrahigh strength and toughness rare earth steel is characterized by comprising, by mass, 0.26%-0.31% of C, 0.50%-0.80% of Mn, 1.25%-1.60% of Si, less than or equal to 0.005% of S, less than or equal to 0.010% of P, 3.25%-3.60% of Cr, 0.80%-1.20% of Ni, 0.35%-0.60% of Mo, 0.40%-1.00% of W, 0.02%-0.04% of Nb, 0.20%-0.40% of V, 0.0045%-0.006% of La and 0.0105%-0.014% of Ce. The medium alloy ultrahigh strength and toughness rare earth steel has the characteristics of being high in strength, hardness, toughness andthe like, can also reduce the production cost and achieves a lot of positive effects meeting the application requirements.

Owner:日照市质量检验检测研究院(国家碳素结构钢产品质量检验检测中心(山东)日照市药品不良反应监测中心日照市纺织纤维监测中心

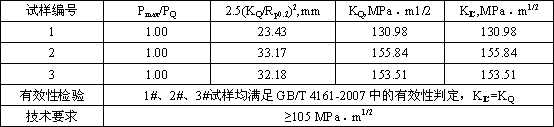

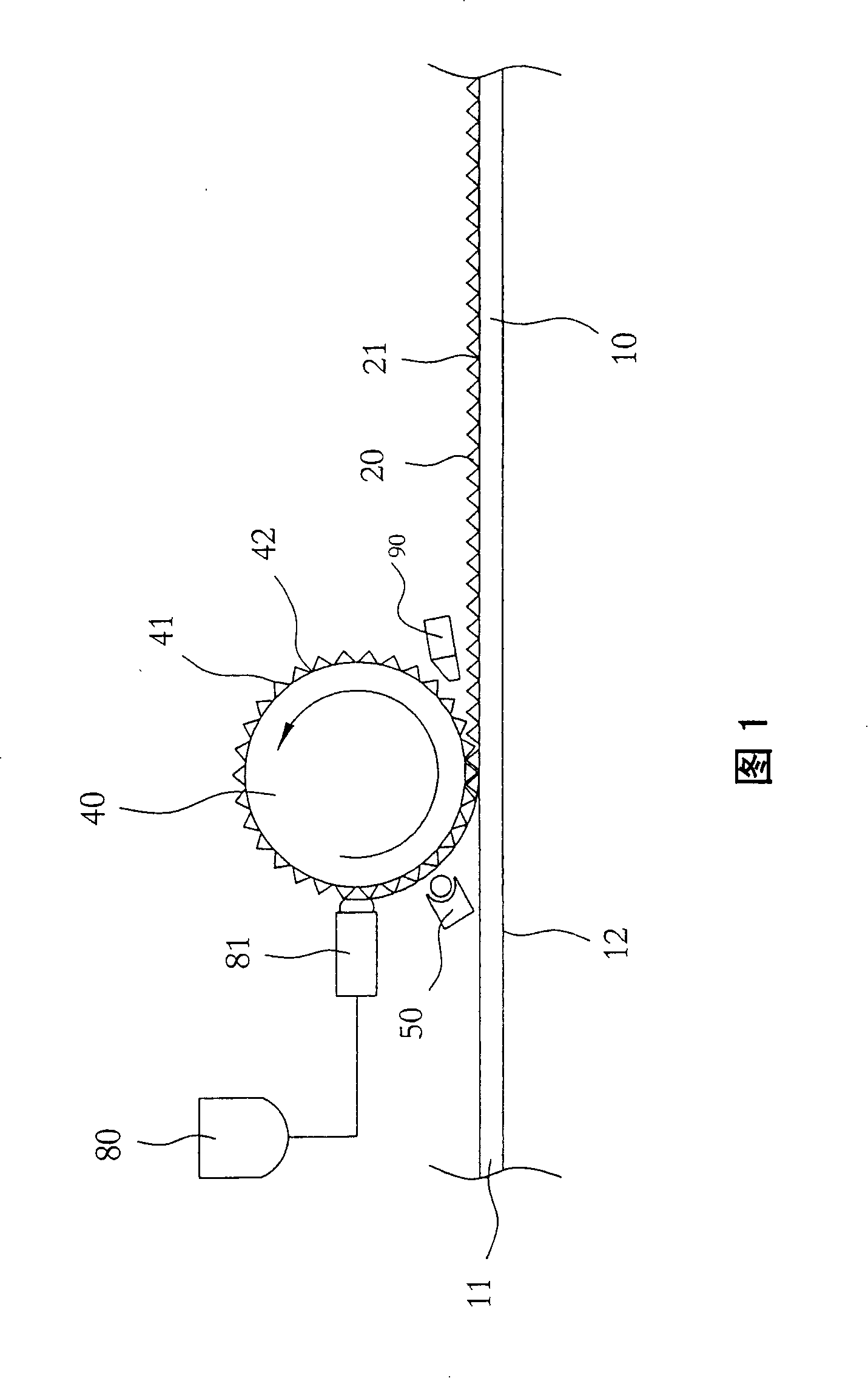

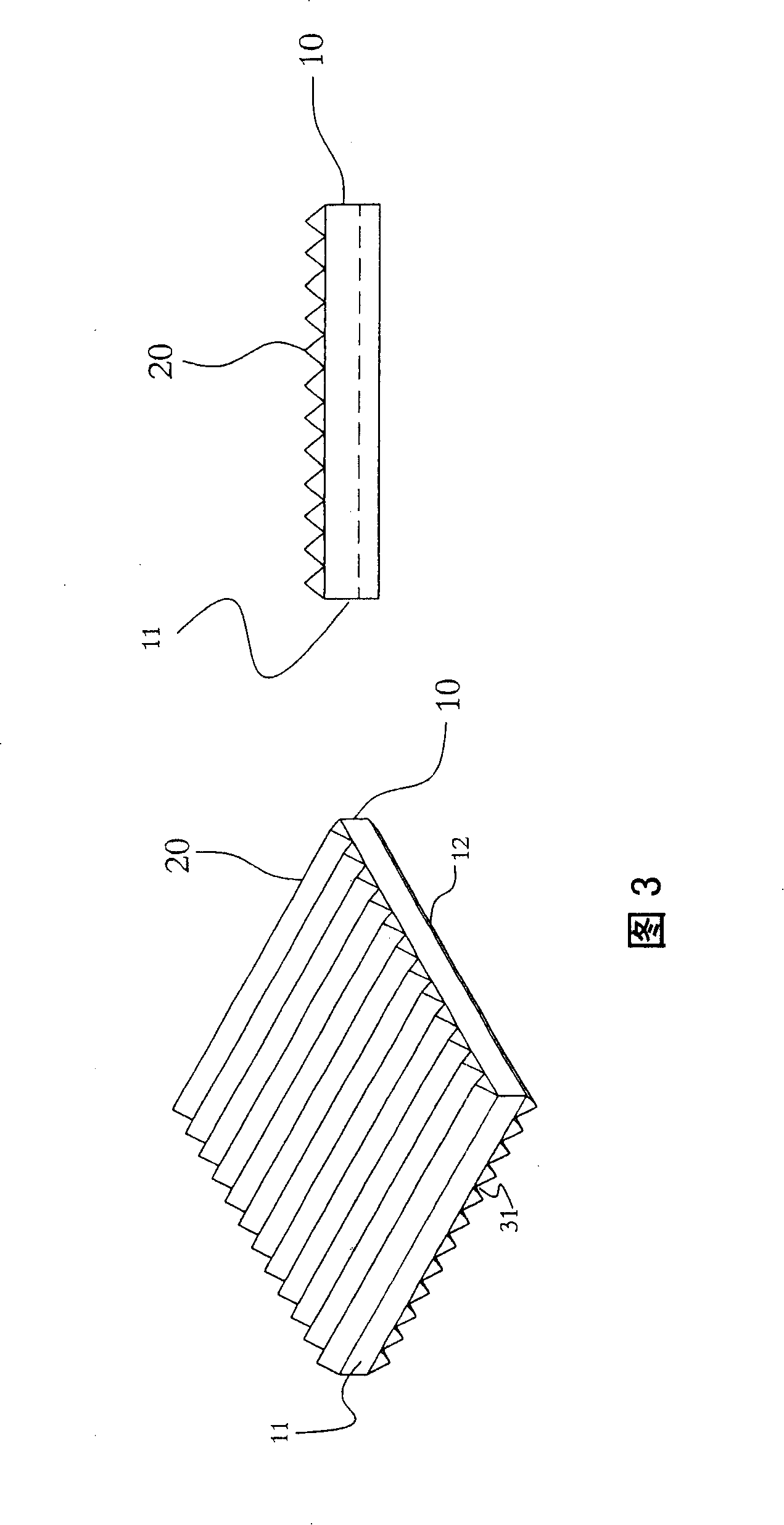

High dispersion ultra-thin light guide board and manufacturing method thereof

InactiveCN101206278AReduce production costImprove product yieldOptical light guidesLight guidePulp and paper industry

The invention provides a high-scattering ultrathin light guide plate and a manufacturing method thereof, including the following steps that: the light guide plate has a body; a bottom surface is arranged below the body; transparent material is daubed on the body by a roller wheel and is formed into a plurality of light outlet bulges after solidifying forming; the body is cut into an appropriate size according to requirements to form the light guide plate; the bottom surface is formed into a reflection convex point and a reflection groove face through synchronous solidifying. In addition, the invention also provides a high-scattering ultrathin light guide plate made through adopting the method.

Owner:PONTEX POLYBLEND

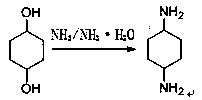

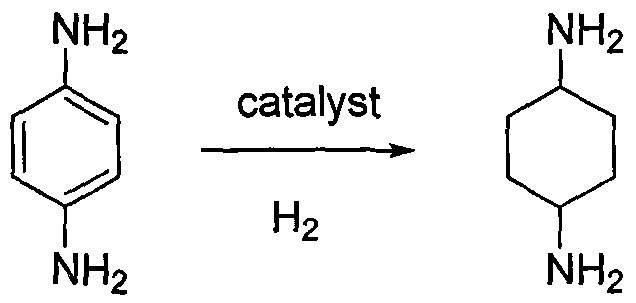

Method for preparing 1,4-cyclohexanediamine at high pressure

InactiveCN103896778AImprove securityAvoid hydrogenOrganic compound preparationAmino compound preparationHexamethylenediamineReaction temperature

The invention discloses a method for preparing 1,4-cyclohexanediamine at high pressure. The method comprises the following steps: adding 1,4-cyclohexanediol and liquid ammonia or 25% ammonium hydroxide to a high-pressure reaction kettle; and reacting at 10-15MPa for 12 hours, wherein the reaction temperature is 220-250 DEG C, so as to obtain a target product 1,4-cyclohexanediamine. The preparation method disclosed by the invention is short in technological process, low in production cost, and high in production security, the product conversion rate is more than 95%, and the product yield is about 93%.

Owner:江苏恒祥化学股份有限公司

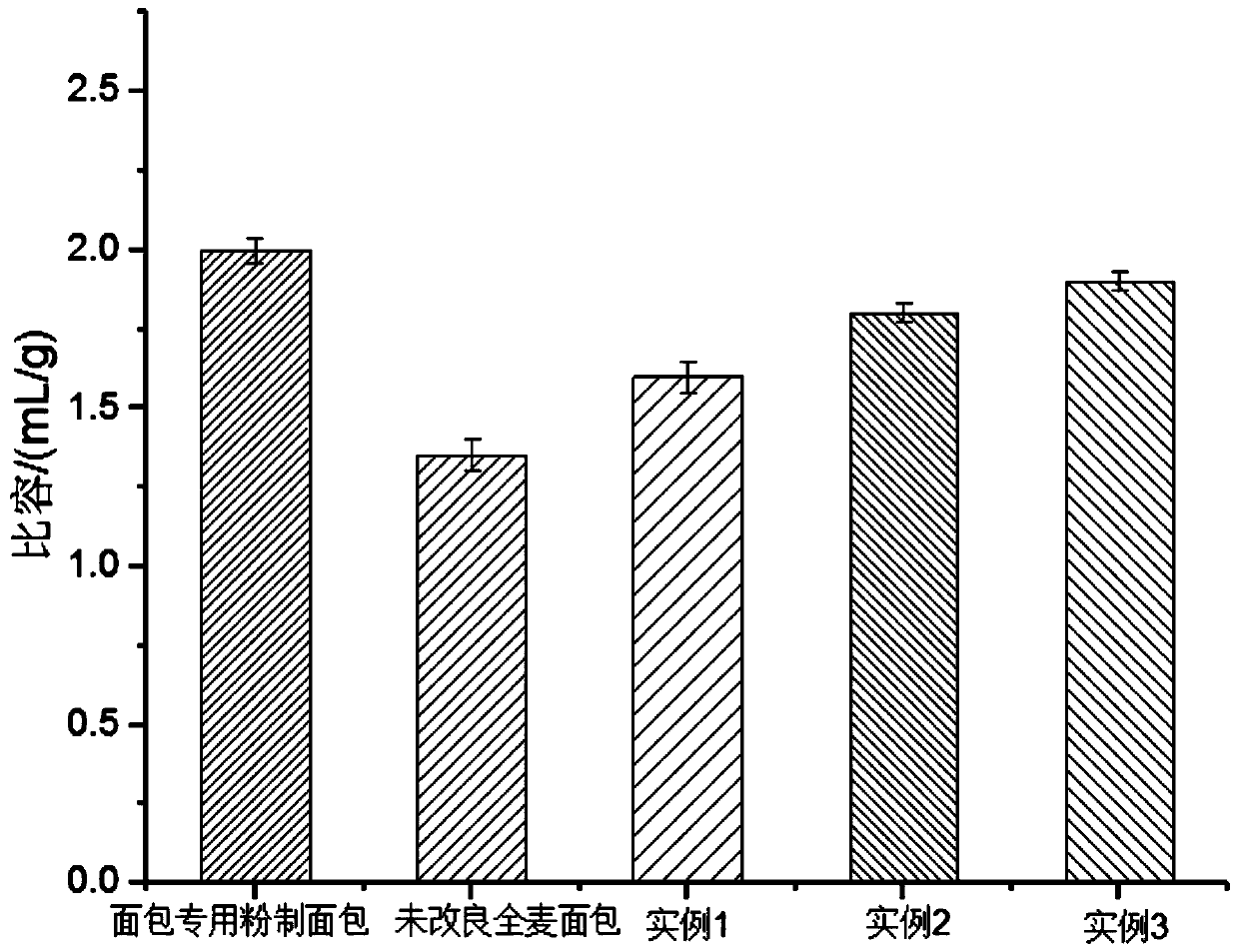

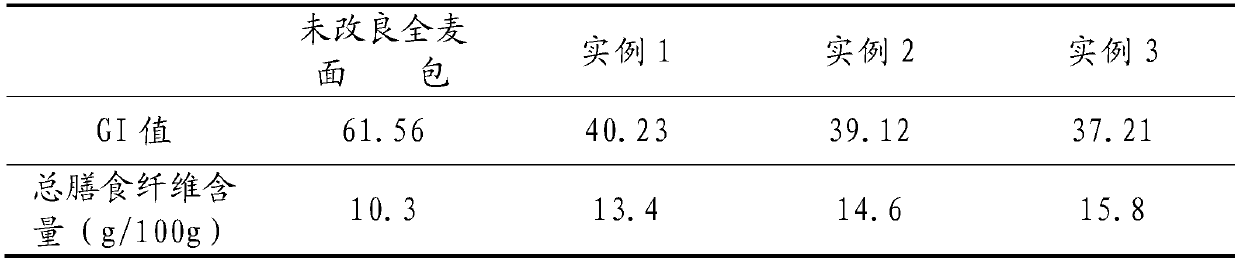

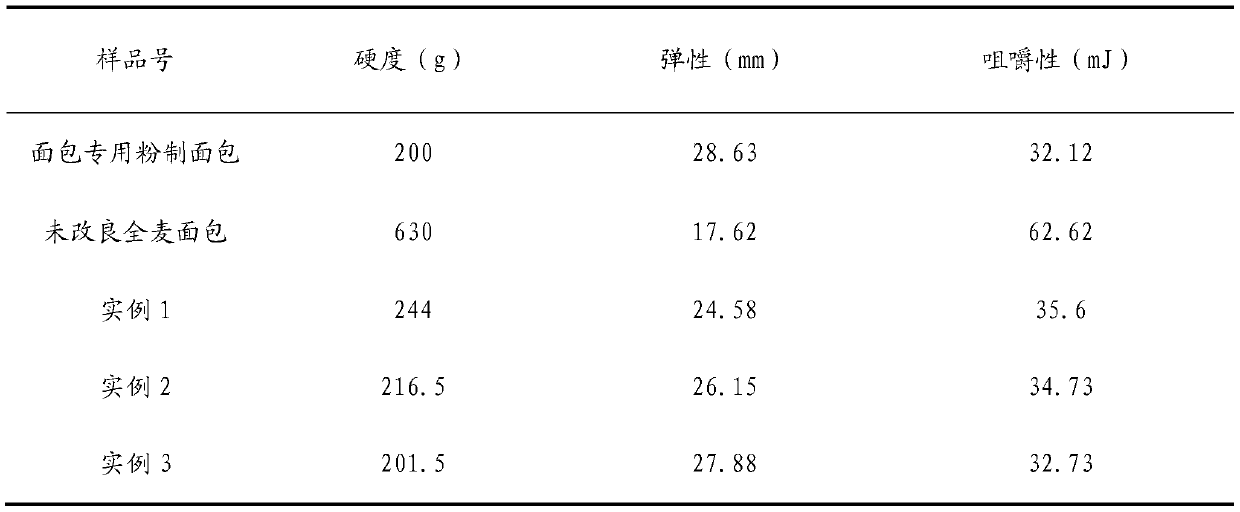

Preparation method of whole-wheat bread with low GI (glycemic index) and high dietary fiber

InactiveCN110050815AReduce production costLow GI valuePre-baking dough treatmentBakery productsSpecific volumeLost Weight

The invention discloses a preparation method of a whole-wheat bread with low GI (glycemic index) and high dietary fiber. Firstly, wheat bran is stabilized after pretreatment, the stabilization of thewheat bran is achieved by an extrusion and complex enzyme technology, and the stabilized wheat bran is ultramicro-porphyrized to obtain stable wheat bran with uniform particle size. Improved whole-wheat flour is obtained by mixing the stabilized wheat bran with bread flour (high gluten flour). The preparation of the whole-wheat bread can be divided into three stages: pre-mixed dough, seed dough and main dough. Compared with traditional whole-wheat bread, the GI value of the whole-wheat bread produced by the technology is decreased by 22.3%, the specific volume is increased by 48%, the hardnessis decreased by 68.01%, the elasticity is increased by 58.22%, and the total dietary fiber content is increased by 53.3%. The whole-wheat bread has the advantages of uniform texture, rich fragrance,crisp taste and strong storage stability. The whole-wheat bread is available for people who need to control blood sugar and lose weight.

Owner:SHENYANG NORMAL UNIV

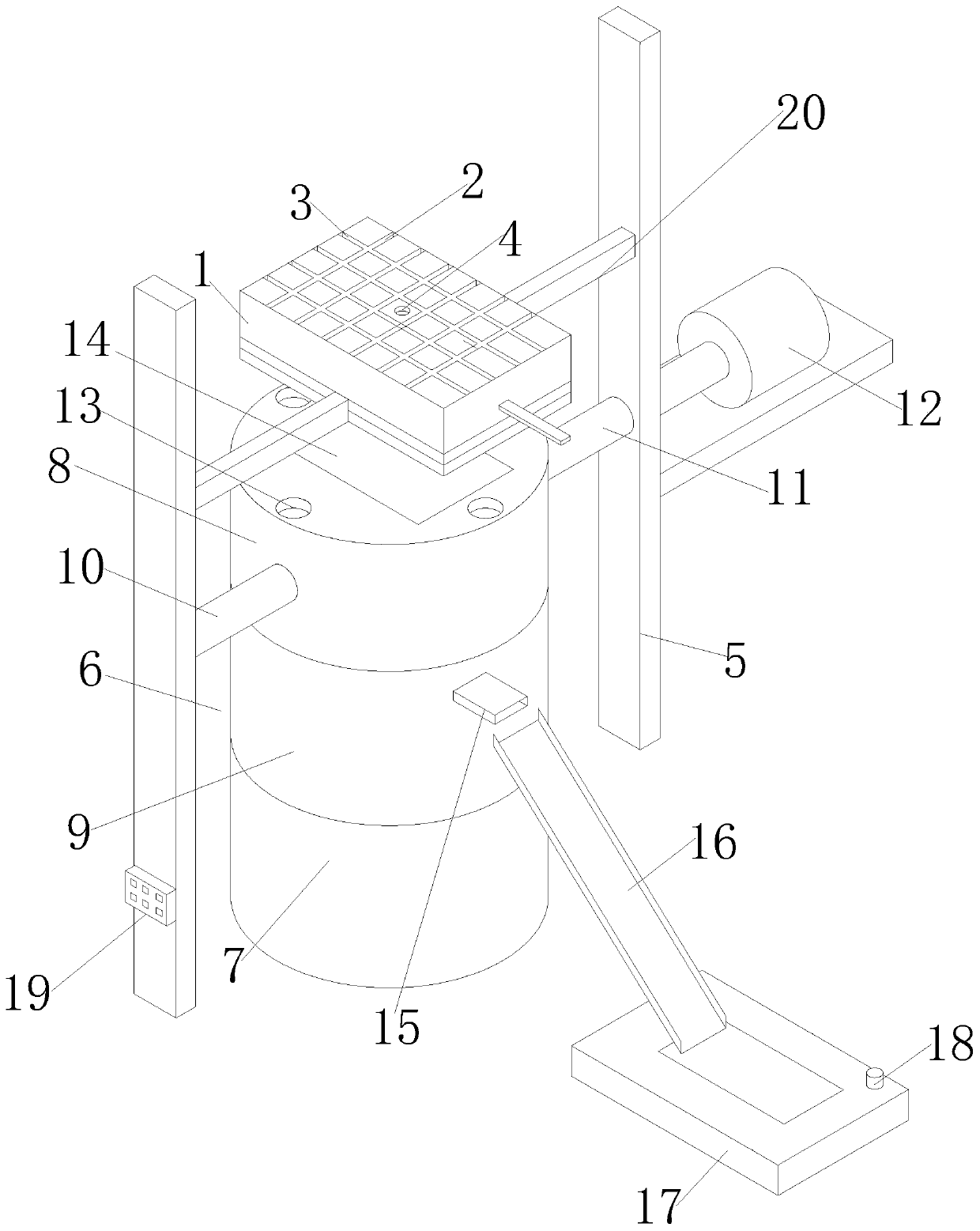

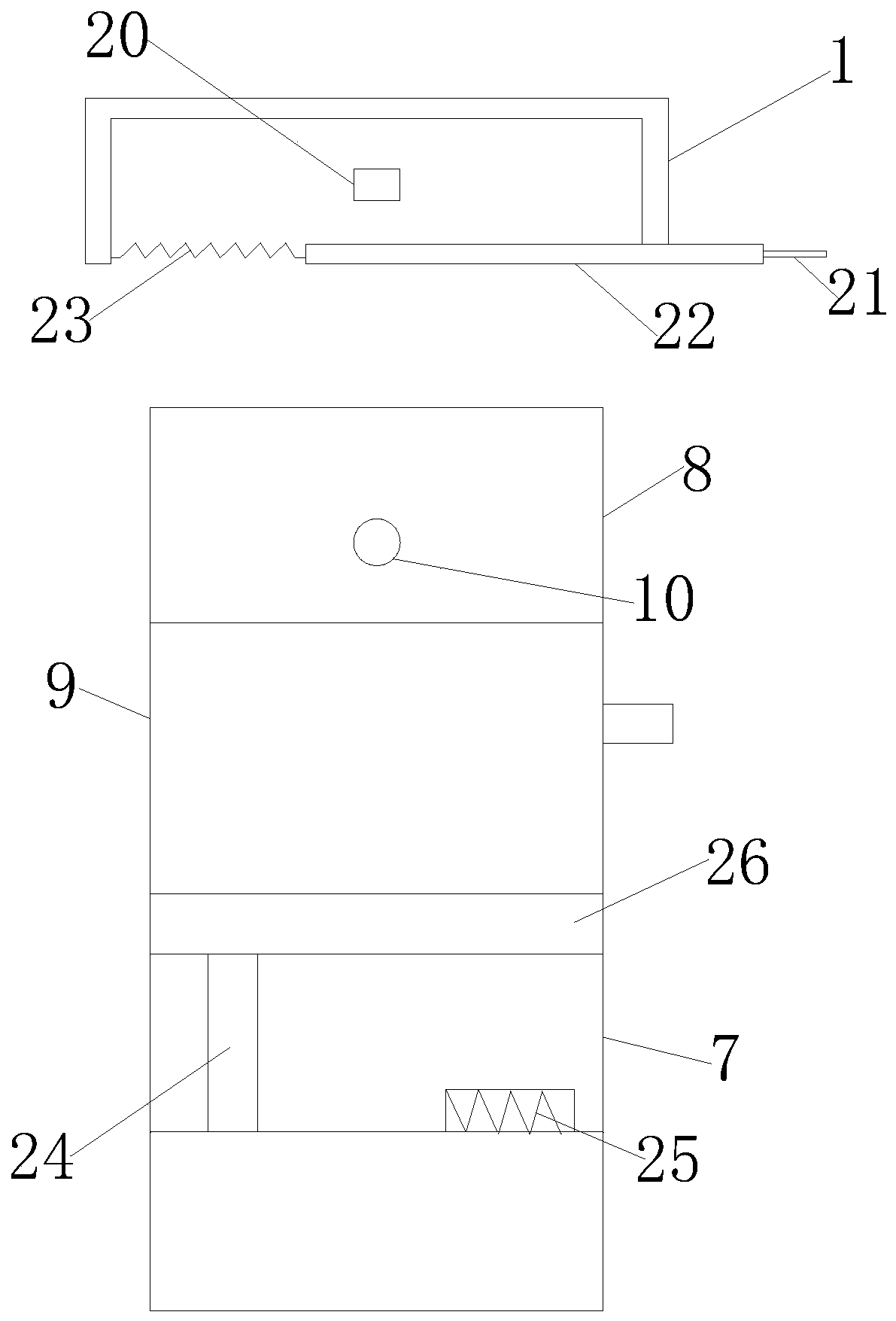

Handmade composite enzyme soap and production device thereof

InactiveCN110194997AHigh economic valueReduce production costSoap detergents with organic compounding agentsCutting soapEnzymeElectric heating

The invention discloses manual composite enzyme soap, sodium soap can be processed into the composite enzyme soap through simple processing in subsequent sodium soap, the economic value can be improved, a production device comprises a cutting box, and the cutting box is connected with a bracket through a cutting box connecting frame. The bottom of the cutting box is of an opening structure. The end surface of the cutting box is provided with a groove. The groove is slidably connected with a bottom plate; one end of the bottom plate passes through the end surface of the cutting box body and isconnected with a stretching rod; a heating cylinder is arranged below the cutting box, a heating plate is arranged inside the heating cylinder, an electric heating wire is arranged on a fixing cylinder, a liquid storage cylinder is arranged above the heating cylinder, two ends of the end surface of the heating cylinder are respectively connected with a left rotating shaft and a right rotating shaft, a liquid outlet is arranged on the end surface of the heating cylinder, a liquid outlet inclined plate is arranged below the liquid outlet, and a mold is arranged at the bottom of the liquid outletinclined plate, so that the manual soap can be completely processed in one step, the manual soap processing procedure is simplified, and the quality of the manual soap is improved.

Owner:六安中达信息科技有限公司

Alcohol biomass clean diesel fuel

The invention relates to an alcohol biomass clean diesel fuel oil, which comprises following materials according to weight percentage: mixed ester 60 to 80%, C9 10 to20%, mixed alcohol 8 to 15%, antioxidizer preservative 1 to 3% and emulsifier 1 to 3%. The alcohol biomass clean diesel fuel oil has the advantages of reducing demand of petrochemical fuel petroleum since main material mixed ester can be extracted from various biomass to substitute petroleum fuel, reducing generation cost and saving resources since mixed ester can be extracted from wastes, facilitating thorough combustion of carbon molecule in fuel and greatly reducing discharge of particle dust since the biomass fuel is the mixture with high oxygen content, and reducing discharge of deleterious wastes and generation of carbon deposition and facilitating thorough combustion of fuel due to the decrease of generation amount of oxynitride caused by slight explosion initiated by water in emulsion liquid with alcohol. The alcohol biomass clean diesel fuel oil can be used for mixed burning with the standard diesel oil with any proportion.

Owner:李国亭

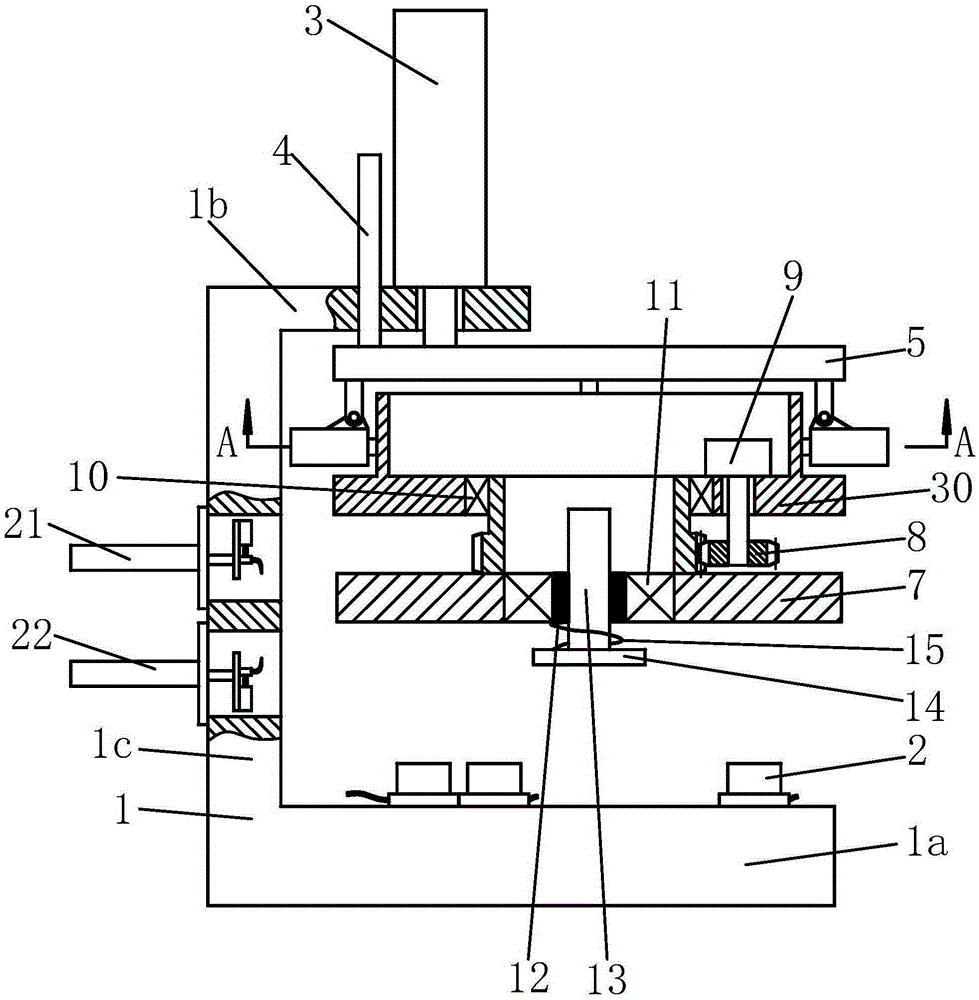

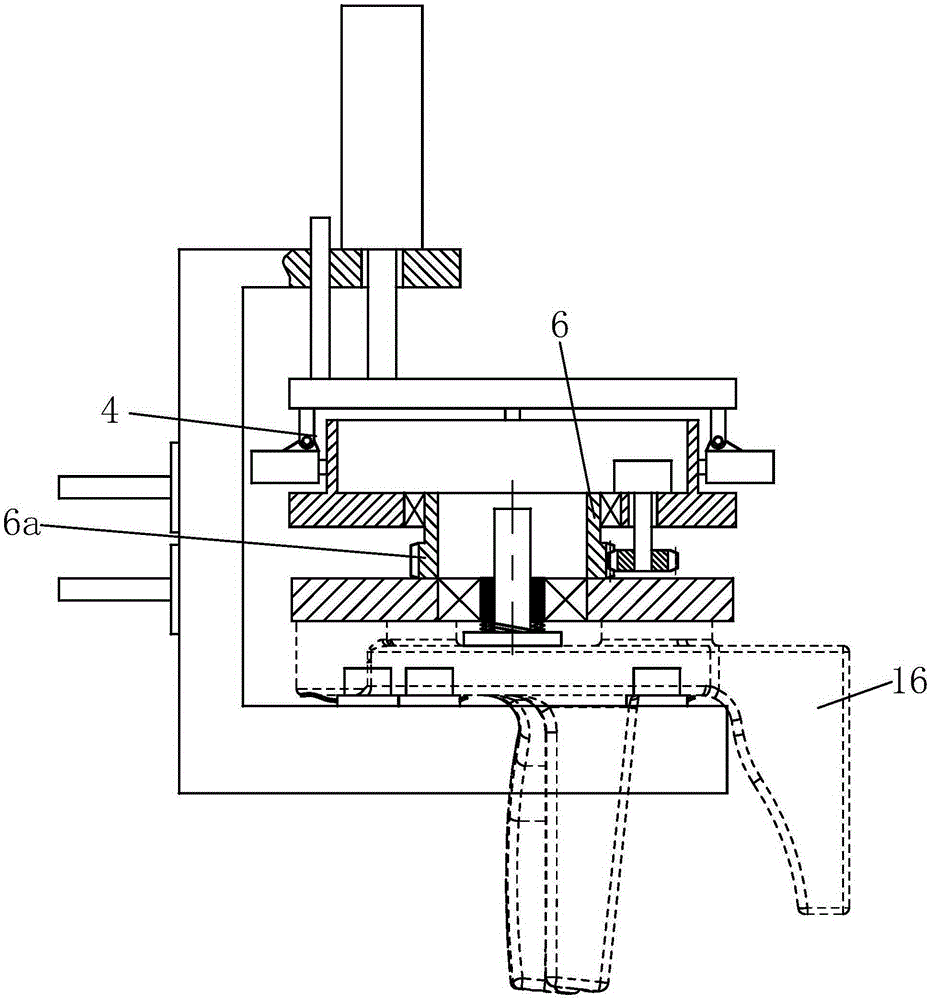

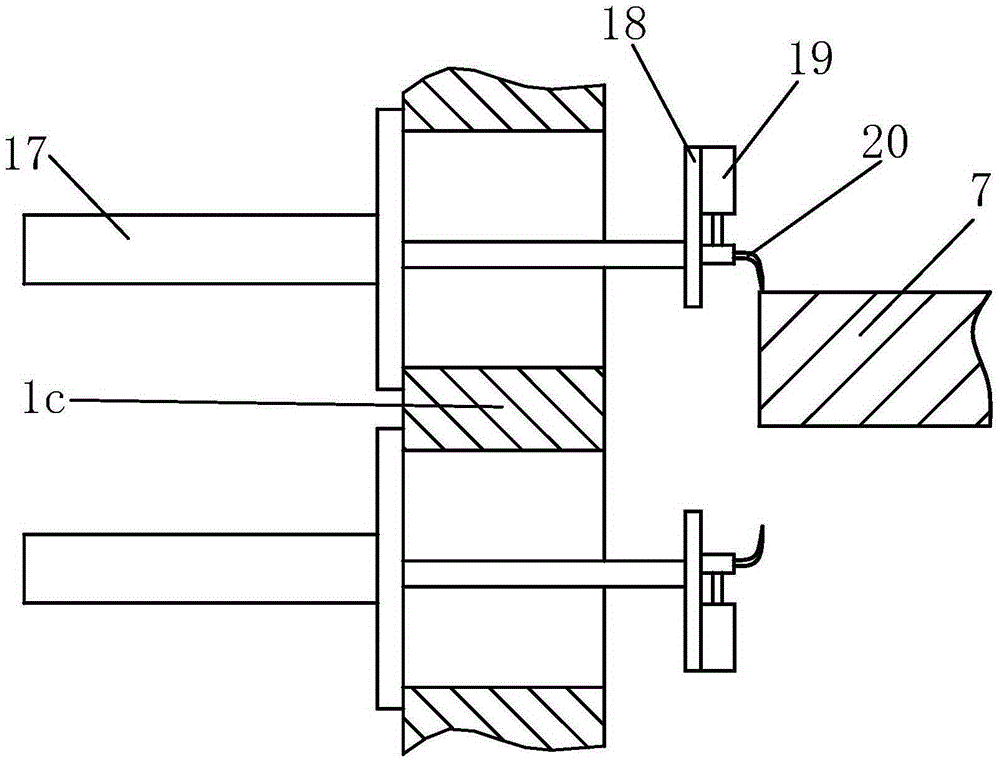

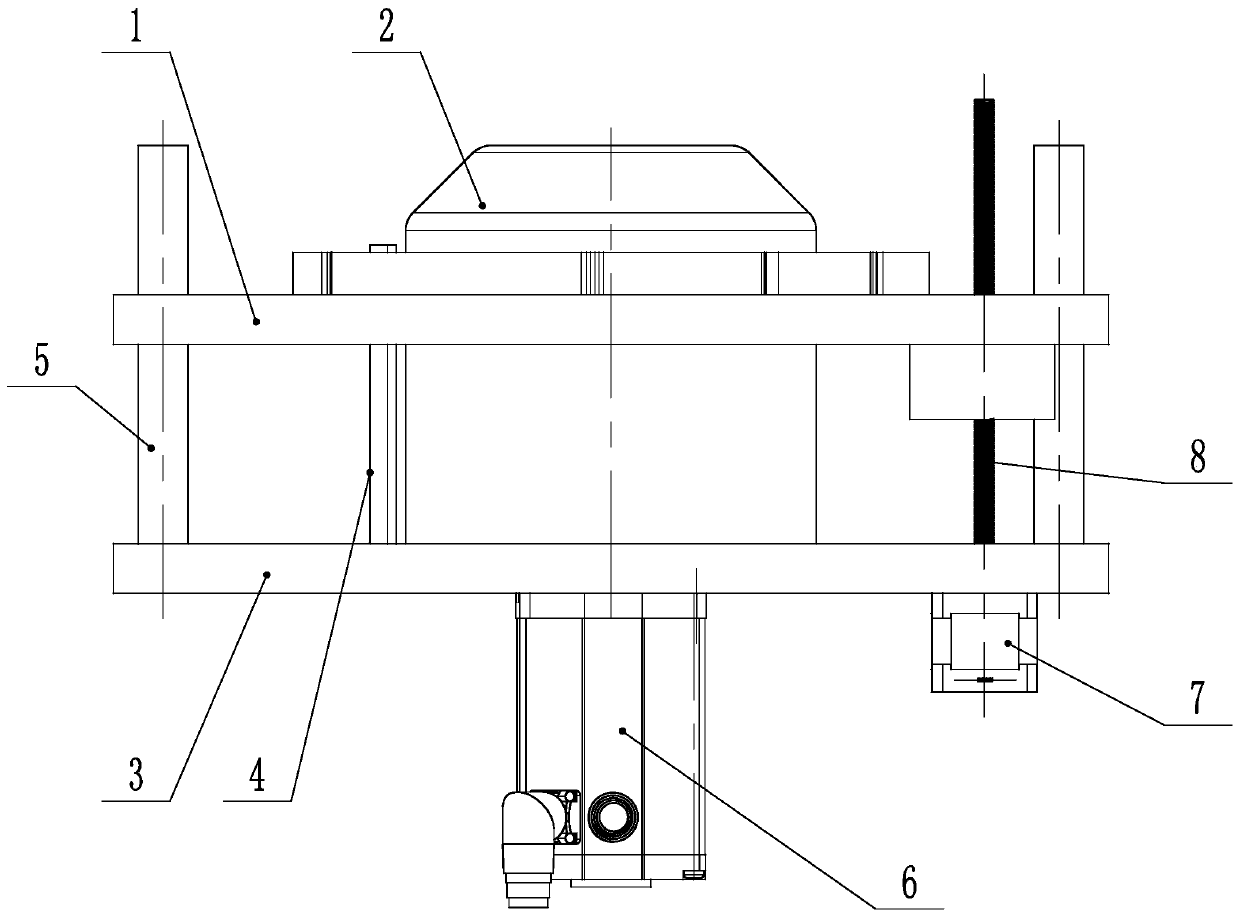

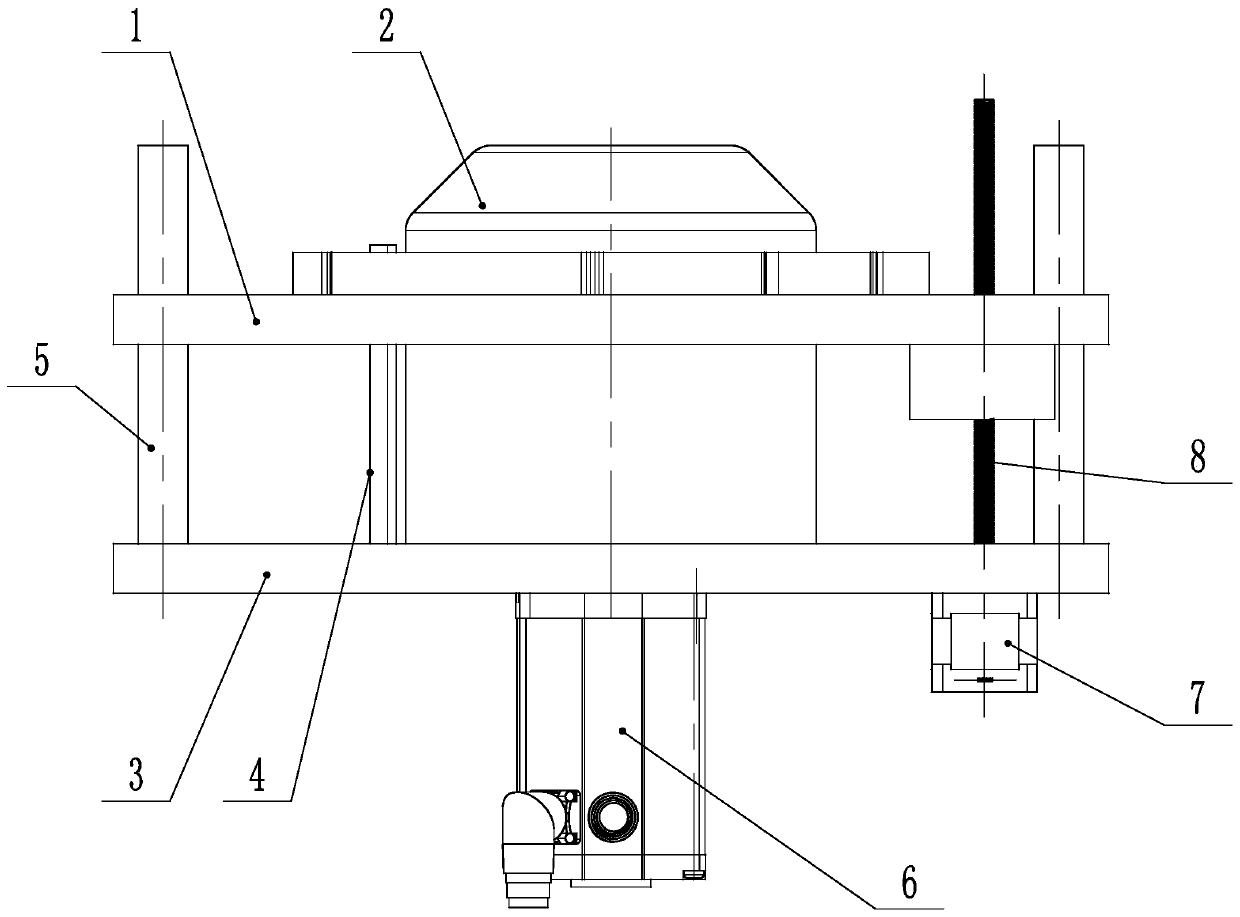

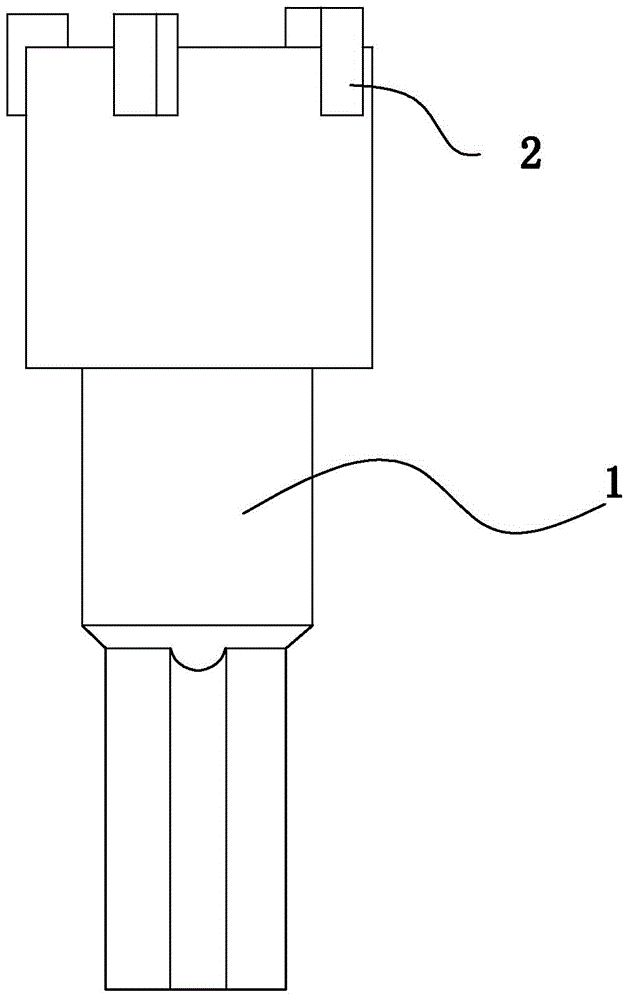

Automatic end surface milling device for automobile flexible shaft brackets

InactiveCN105345107AReasonable structural designReduce production costMilling equipment detailsPositioning apparatusMechanical engineeringEngineering

The invention relates to an automatic end surface milling device for automobile flexible shaft brackets. The automatic end surface milling device comprises a base, a locating device, a lifting regulation device, a milling position regulation device, a rotary milling device, a pressing device and an abrasion detector. The locating device is placed on the upper end surface of a work table, the lifting regulation device is installed on a cross beam, the milling position regulation device is installed in the middle of the lower end of the lifting regulation device, the rotary milling device is installed in the middle of the milling position regulation device, the pressing device is installed in the middle of the lower end of the rotary milling device, the abrasion detector is installed in the middle of a supporting beam, and the lower left part of the rotary milling device is located in the middle of the abrasion detector. The automatic end surface milling device has the advantages of being reasonable in structural design, low in producing and manufacturing cost, convenient to operate, capable of milling the upper end surfaces of the flexible shaft brackets and greatly improving the milling efficiency of the automobile flexible shaft brackets, capable of compensating for abrasion so as to guarantee the machining precision, capable of being regulated according to the automobile flexible shaft brackets of different dimensions, high in flexibility and wide in application range.

Owner:WUHU YINXING AUTO PARTS

Method for producing double-waterproof-groove optical cable cross-connecting box

The invention relates to a communication device and particularly relates to a method for producing a double-waterproof-groove optical cable cross-connecting box. The method comprises the steps of placing a side plate on a specific bending and drawing composite die to bend the U-shaped side plate and draw waterproof grooves on two end faces of the U-shaped side plate in one step; forming waterproof grooves in one side face of a top plate and one side face of a bottom plate in a milling mode respectively; welding the side plate and the top plate together, and welding the side plate and the bottom plate together; placing a box door on a drawing die to form protruding grooves which are matched with shapes of the waterproof grooves of a box body in a drawing mode; spraying waterproof coatings onto an inner cavity of the box body and the inner wall of the box door; performing mechanical strength tests, assembly tests, airtightness tests, combustion performance tests and grounding conductive performance tests on the optical cable cross-connecting box; and performing alcohol solvent resistance tests on the waterproof coating of the inner cavity of the box body. According to the method, the production cost is low, the waterproof effect of products is good, the mechanical performance is high, and the product quality is guaranteed.

Owner:安徽航跃通信设备有限公司

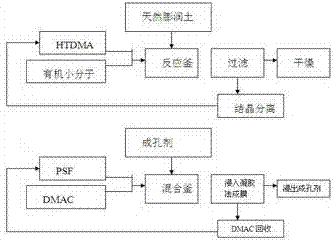

Novel wastewater treatment adsorption material and preparation process thereof

InactiveCN104722272AHigh adsorption capacityReduce production costOther chemical processesWater contaminantsIonHeavy metals

The invention discloses a novel wastewater treatment adsorption material and a preparation process thereof. The process includes bentonite organic modification, bentonite immobilization and continuous treatment of phenolic industrial wastewater. The organic bentonite immobilization method is as below: 1) mixing organic bentonite with quartz sand to improve the permeability of a bed; 2) mixing bentonite with a plastic raw material, and extruding and granulating at high temperature, so as to adsorb heavy metal ions in wastewater; 3) binding organic montmorillonite together by using polyethylene as a binder to obtain get polyethylene immobilized organic montmorillonite for post improving the adsorption capacity. The bentonite organic modification is to establish a microenvironment capable of receiving the organic compounds in the inner space of bentonite and increase the spacing of layers. The invention adopts organic small molecules and long carbon chain cationic surfactant to form a composite column modifier with synergistic effect, and the prepared products can improve the adsorption capacity, reduce the production cost, and continuously adsorb and treat phenolic industrial wastewater.

Owner:XIAN TUOSHI ELECTRONICS TECH

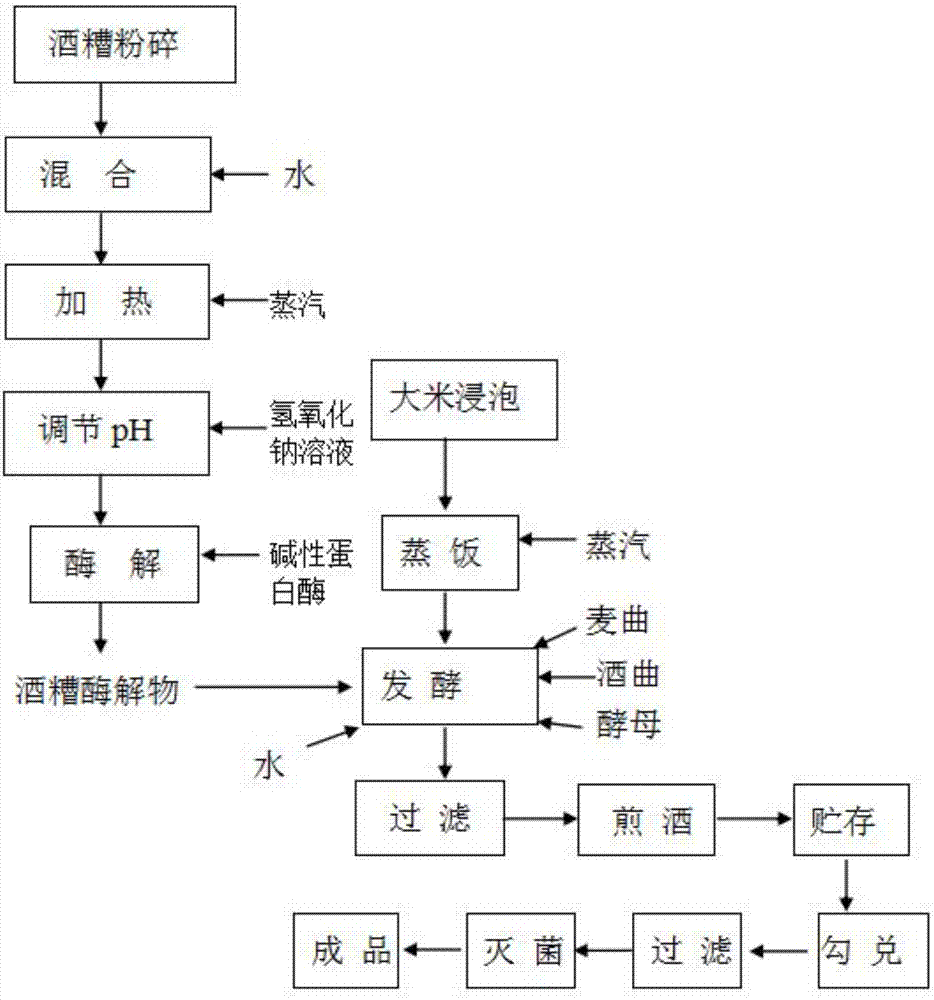

Method for producing cooking wine with high amino acid nitrogen content by using yellow wine stillage

The invention discloses a method for producing cooking wine with high amino acid nitrogen content by using yellow wine stillage. The method at least comprises the following steps of: mixing pretreated stillage with alkaline protease and performing enzymolysis to obtain stillage enzymatic hydrolysate; adding the prepared stillage enzymatic hydrolysate into steamed rice; adding wheat koji, distiller's yeast and active dry yeast; and performing fermentation. According to the method disclosed by the invention, the stillage enzymatic hydrolysate is obtained from the cooking wine stillage by pulverization, heating and protease treatment, the stillage enzymatic hydrolyzate is added into the rice, the fermentation production of the cooking wine is performed, the content of the amino acid nitrogen in the cooking wine is high, and the delicate flavor of the cooking wine is rich; and in addition, when the cooking wine is produced by using the method, resource utilization of the cooking wine stillage can be achieved, the production cost is reduced and the generation of ''waste residues'' in the production process of the cooking wine is reduced.

Owner:安徽海神黄酒集团有限公司

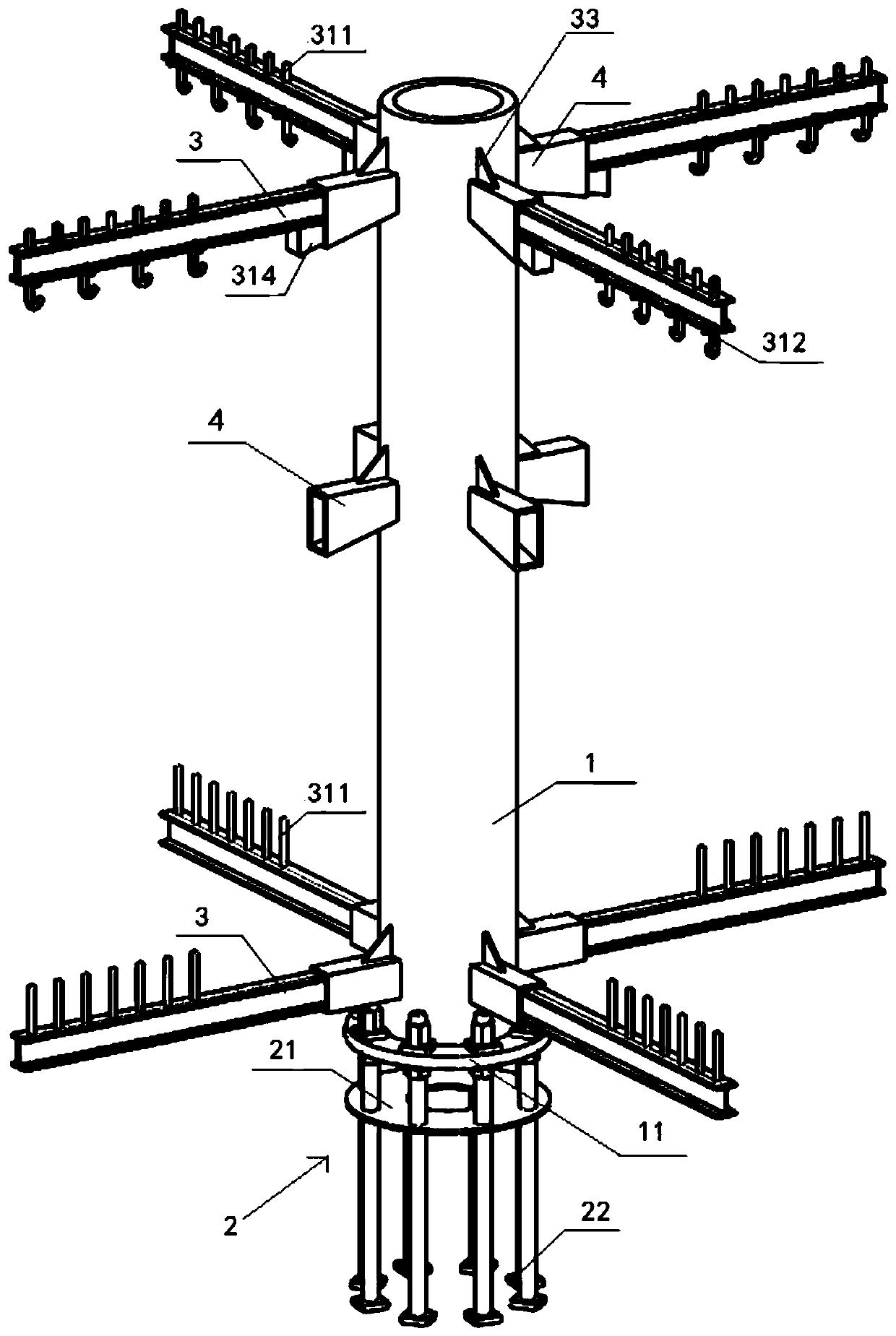

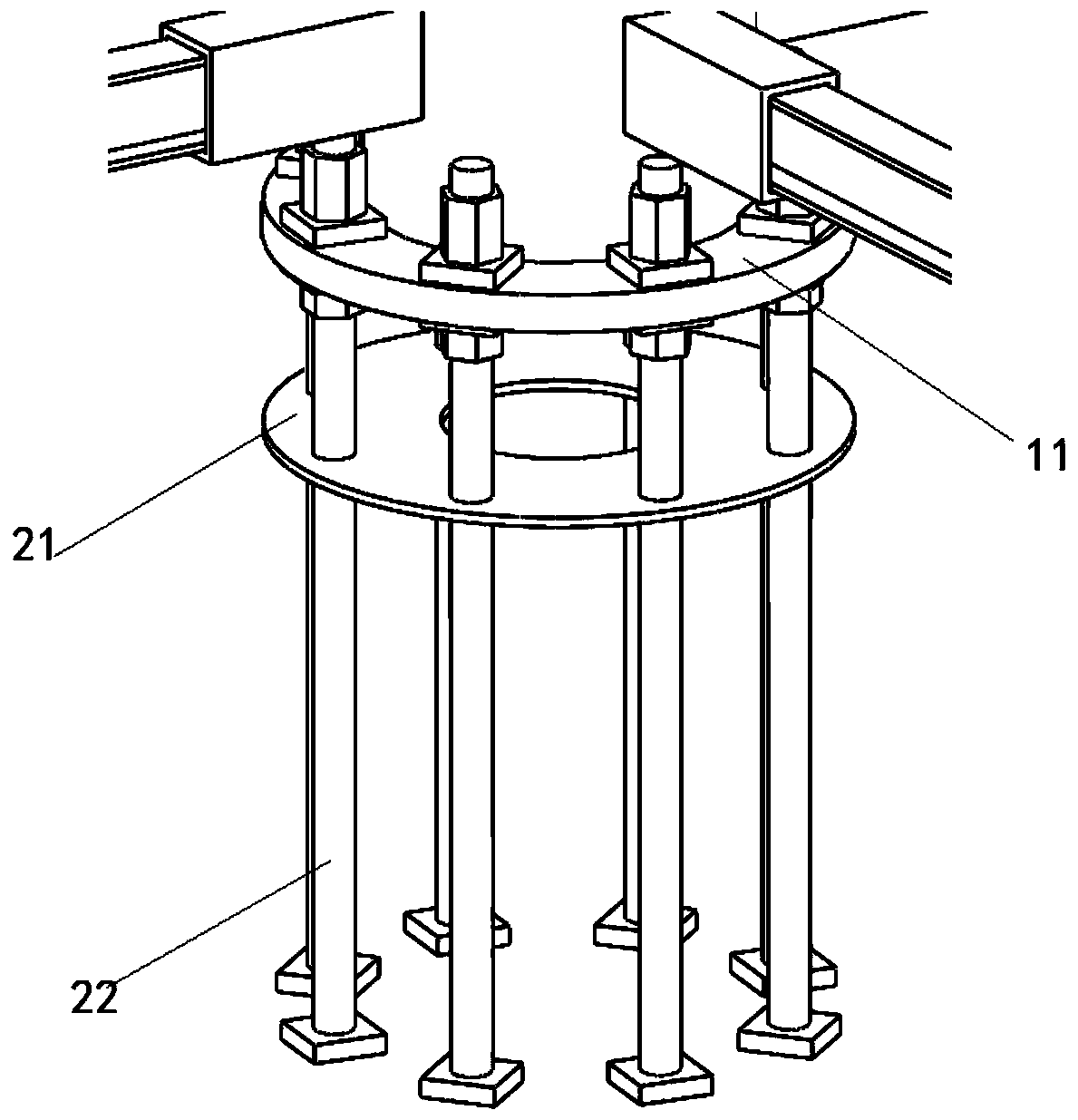

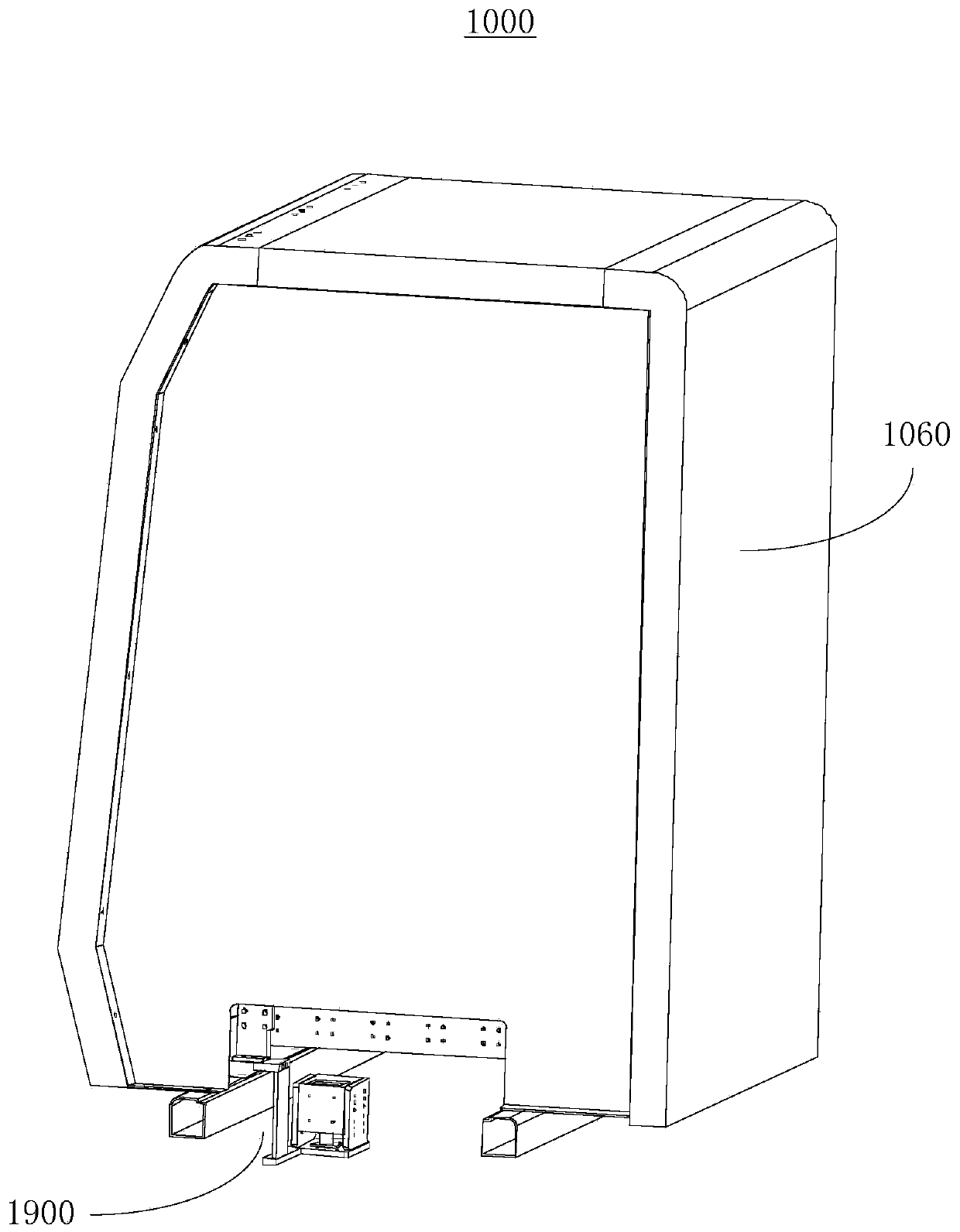

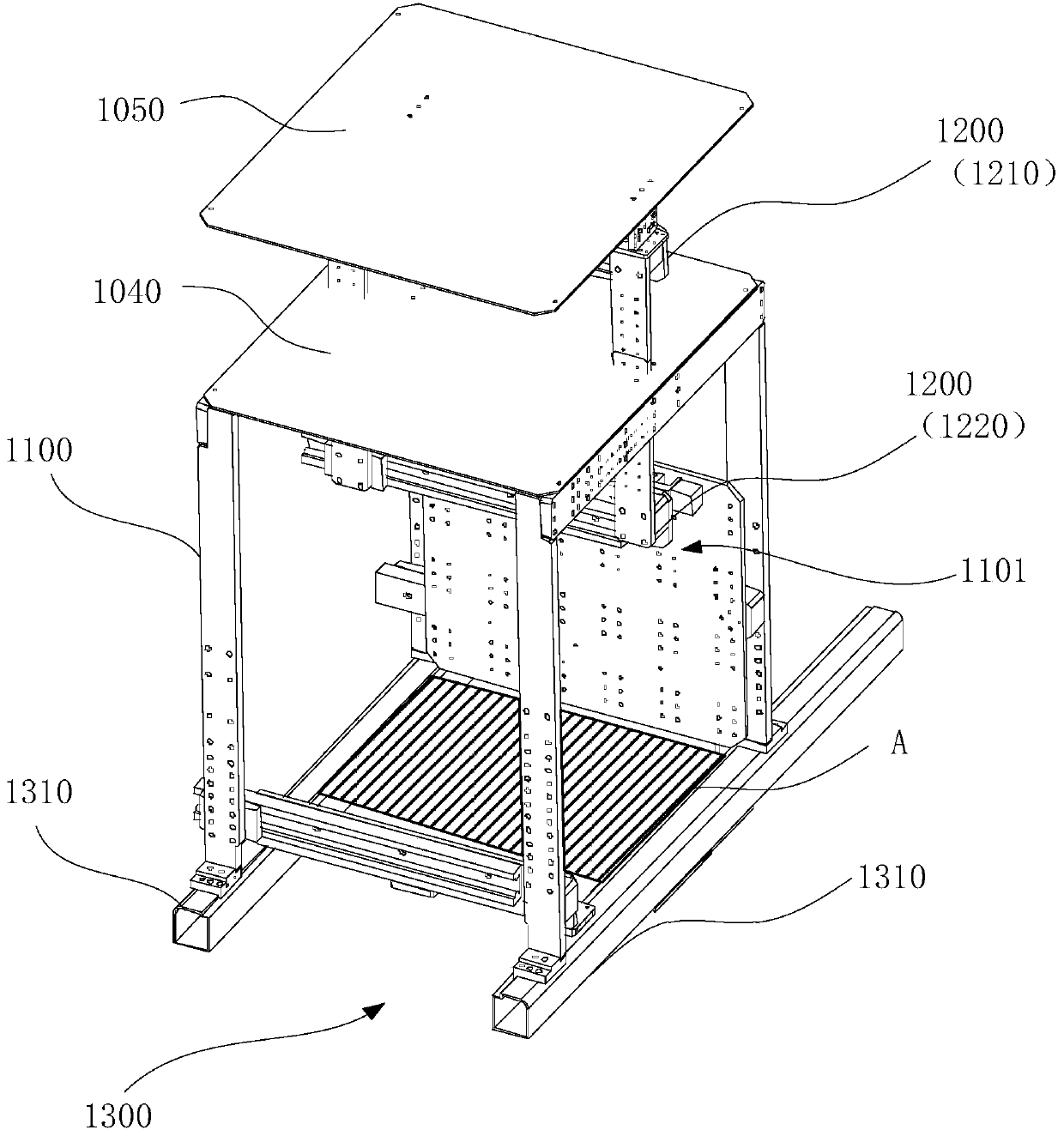

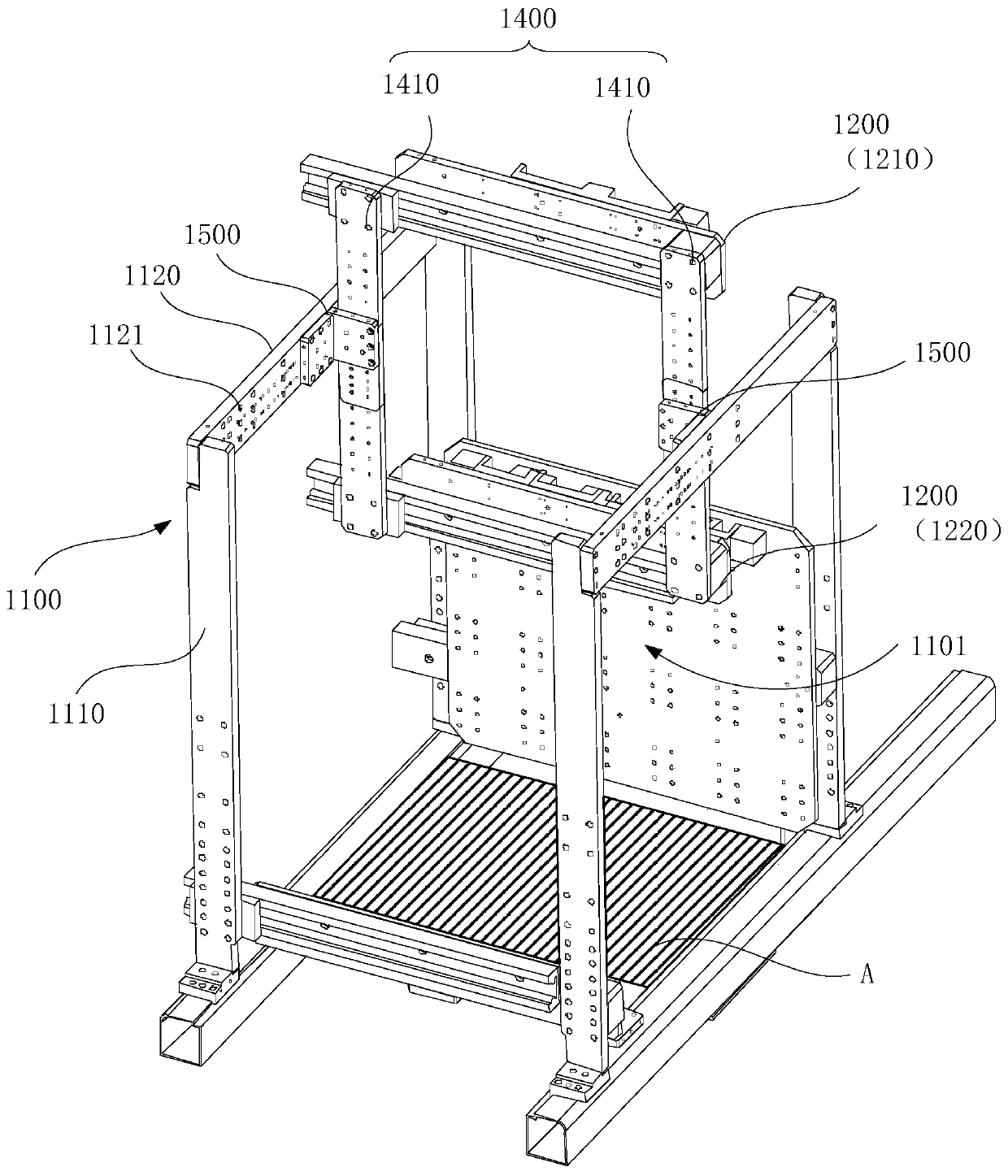

Manufacturing and shaping method for large-cross-sectional steel column outer ring beam reinforcement cage and mold frame

ActiveCN110821183AIncrease productivityReduce production costWire networkBuilding reinforcementsRebarSteel columns

The invention provides a manufacturing and shaping method for a large-cross-sectional steel column outer ring beam reinforcement cage and a mold frame. The manufacturing and shaping method for the large-cross-sectional steel column outer ring beam reinforcement cage comprises a vertical column, a plurality of positioning sleeve assembly, a balance beam assembly and a column base connecting piece,a bottom plate is connected with the bottom of the vertical column, the positioning sleeve assemblies are connected with the side wall of the vertical column and distributed on the vertical column inthe height direction, the first end of the balance beam assembly is detachably mounted on the positioning sleeve assemblies, the balance beam assembly is distributed along the vertical column in the radial direction, a sliding rail is arranged on the lower side of the second end of the balance beam assembly, a plurality of hooks used for hooking steel bars of the ring beam reinforcement cage are slidably arranged on the sliding rail, and the column base connecting piece is connected to the lower side of the bottom plate. The invention further provides a method for manufacturing the reinforcement cage by using the manufacturing and shaping mold frame for the large-cross-sectional steel column outer ring beam reinforcement cage.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

Formaldehyde-free environment-friendly glue

InactiveCN107541161AReduce investment in anti-virus production equipmentReduce production costMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesEmulsionChemistry

The invention discloses a formaldehyde-free environment-friendly glue. The glue is prepared from, by weight, 50-90 parts of vinyl acetate emulsion, 25-40 parts of salicylic acid, 10-15 parts of acaciagum, 20-40 parts of protein adhesive, 8-20 parts of silicon dioxide, 5-20 parts of hide glue, 6-10 parts of bone glue, 2-50 parts of starch, 1-3 parts of carbonic acid, 1-3 parts of polyvinyl alcohol, 0.5-1 part of polyacrylamide, 0.5-1.5 parts of hydrogen peroxide, 0.3-0.5 part of ethylene glycol, 1-4 parts of ethyl alcohol, 0.05-0.1 part of sodium stearate, 2-8 parts of sucrose, 5-9 parts of dispersing agent and 1-5 parts of water.

Owner:王莉

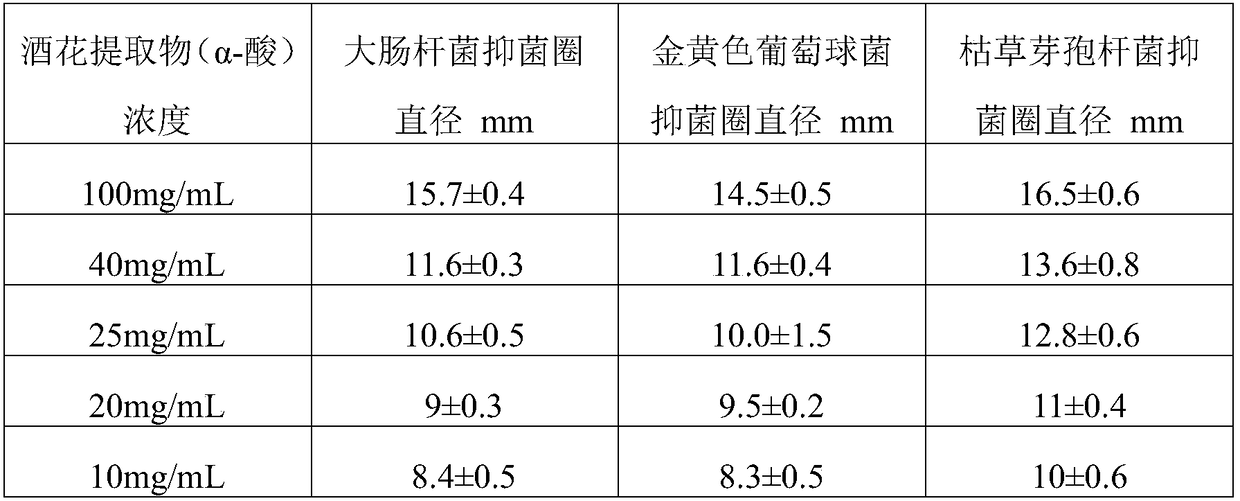

Hop product applied to feed additives by replacing antibiotics

InactiveCN109329595APrevent mildewImprove immunityFood preservationAnimal feeding stuffBiotechnologyMildew

The invention relates to a hop product applied to feed additives by replacing antibiotics. The method adds the hop product as additive into a feed, and the hop product is independently used as an additive or in combination with other additives, wherein the mass ratio of hop product to the feed is 1:(50-100). The method uses the hop product to replace antibiotics, and the hop product is used as a feed additive to be applied to the feed, has mildew-proof and corrosion-proof effects on the feed, and can be used as an antibiotic to enhance the immunity of animal organisms, to promote intestinal digestion, to improve intestinal flora, to reduce diarrhea rate, to avoid feed mildewing, to reduce unnecessary loss, to achieve the bacteriostatic effect, and to effectively replace antibiotics.

Owner:QILU UNIV OF TECH

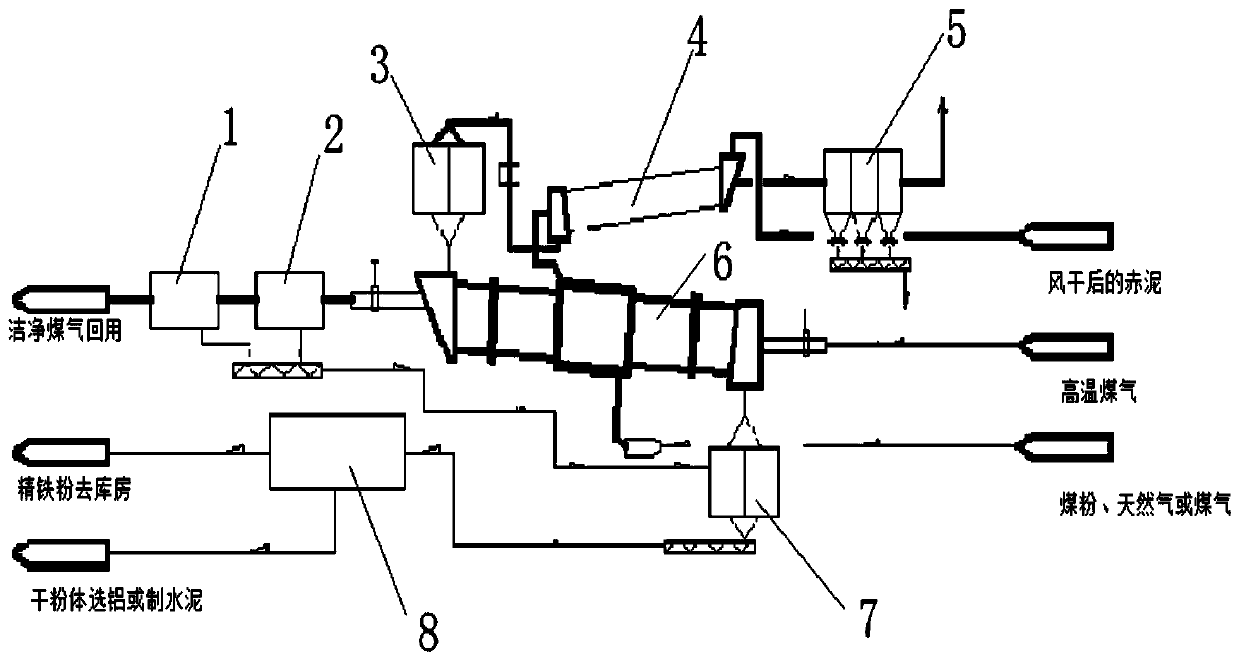

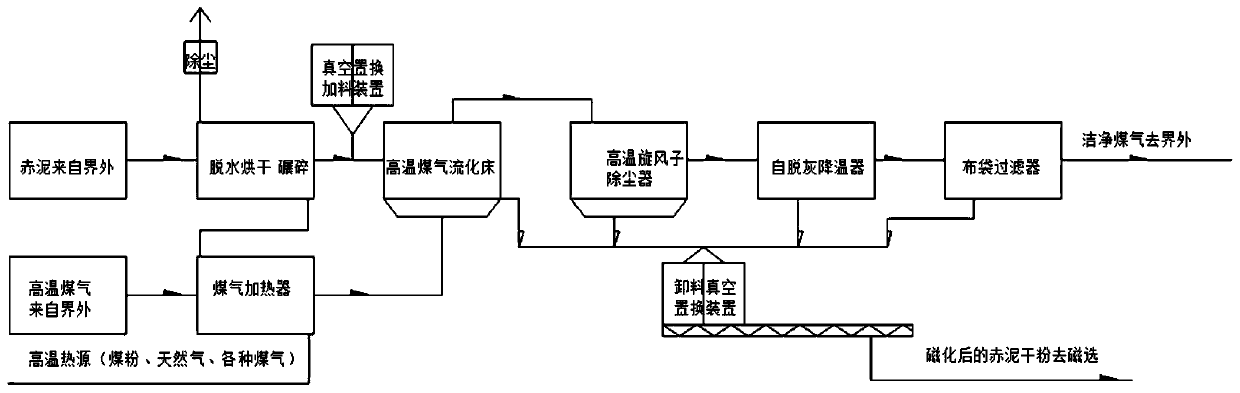

Comprehensive treatment method and system for red mud resource utilization

PendingCN111320213ALow costReduce production costFerroso-ferric oxidesCement productionChemistryIndustrial waste

The invention provides a comprehensive treatment method and system for red mud resource utilization, and belongs to the technical field of industrial waste residue resource utilization. According to the method, dried and heated red mud is directly and fully contacted with reducing gas and reacts with reducing gas; ferric oxide in the red mud is reduced into ferroferric oxide, ferroferric oxide isrecovered through magnetic separation, the remaining dry red mud can be directly processed to prepare cement or used for further separation of other metals, the technological process is simple and convenient, and the method has a good practical application value, especially large-scale industrialization value and industrialization application value.

Owner:彭思尧

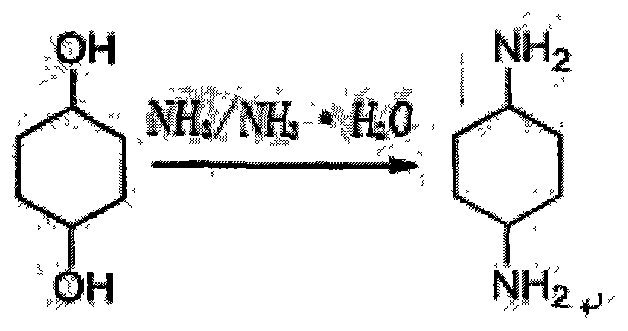

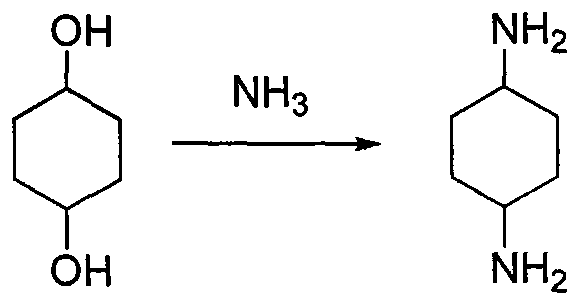

Method for preparing 1,4-diaminocyclohexane

InactiveCN105001095AImprove securityAvoid hydrogenOrganic compound preparationAmino compound preparationReaction temperatureHigh pressure

The invention discloses a method for preparing 1,4-diaminocyclohexane. The method comprises the following steps that 1,4-cyclohexanediol and liquid ammonia or 25% ammonium water are added into a high-pressure reactor to be reacted for 12 h at 10-15 MPa, the reaction temperature is 220 DEG C-250 DEG C, and the target product 1,4-diaminocyclohexane is obtained. The preparation method is short in technology process, low in production cost and high in production security, the product conversion rate is above 95 percent, and the finished product yield is about 93 percent.

Owner:陈爱华

Electroluminescence sheet and luminous writing board using electroluminescence sheet

InactiveCN108674060AReduce production costImprove cooling effectBoard cleaning devicesWriting boardsElectric heatingHandwriting

The invention discloses an electroluminescence sheet and a luminous writing board using the electroluminescence sheet. The electroluminescence sheet comprises a first body, a base material layer and aheat dissipation base, wherein the first body is arranged at the upper end of the base material layer and is in bonding fit with the upper end of the base material layer, and the first body and the base material layer are inserted into the heat dissipation base matched with the first body and the base material layer. The luminous writing board comprises a second body matched with the electroluminescent sheet in an inserted mode. A writing board body matched with the electroluminescent sheet for use is arranged on the second body. A cleaning device used for automatically removing handwriting on the writing board body is arranged on the left side of the writing board body. A thermocouple capable of achieving heating and refrigeration and an electric heating and refrigeration piece are arranged on the other side, matched with the electroluminescence sheet in an inserted mode, of the second body. According to the electroluminescence sheet and the luminous writing board using the electroluminescence sheet, the handwriting on the writing board body can be automatically removed; and heating and refrigerating functions are achieved so that hands can be warmed in winter and can be cooled in summer.

Owner:温州中祥光电科技发展有限公司

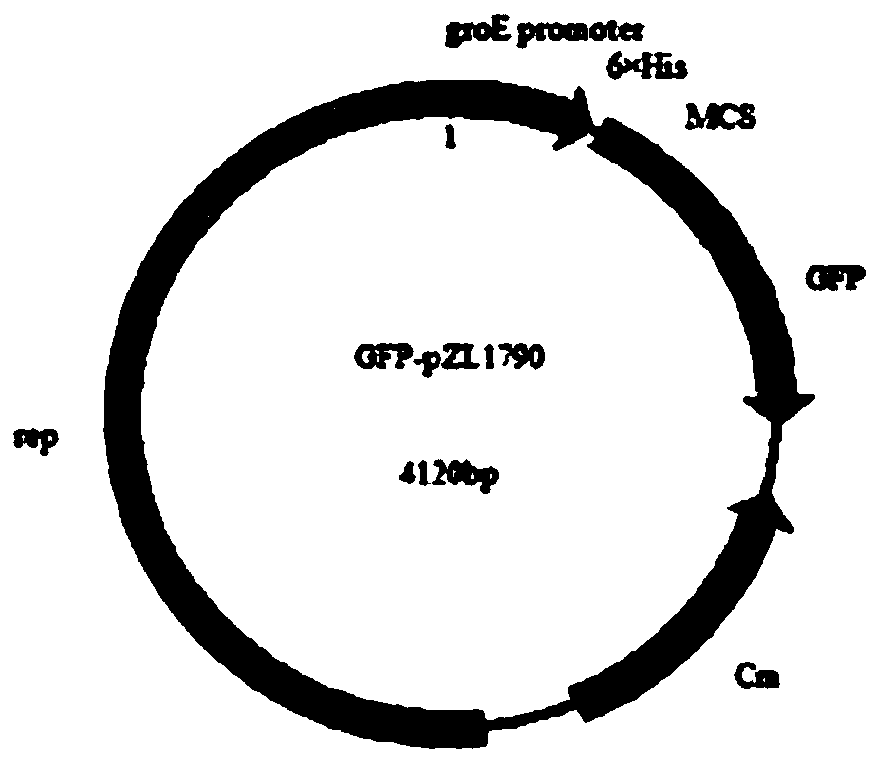

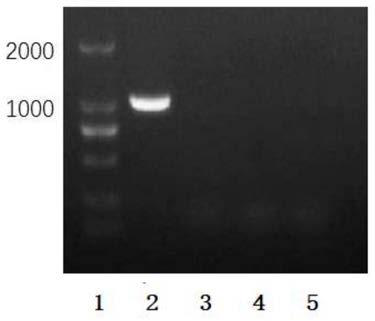

Rough-type brucella with recombinant O-type foot and mouth disease virus VP1 gene and vaccine production method of brucella

InactiveCN110004100AGood immune protectionLow costAntibacterial agentsBacterial antigen ingredientsSaccharumVaccine Production

The invention relates to a strain of rough-type brucella with a recombinant O-type foot and mouth disease virus (FMDV) VP1 gene and a vaccine production method of the brucella. With a rough-type cattle-species brucella low virulent strain RA343 as a parent strain and a saccharose suicide plasmid as a carrier, the O-type foot and mouth disease virus VP1 gene with a specific promoter sequence is inserted in a brucella genome without any trace through codon optimization, and the recombinant brucella RA343-VP1-FMDV-O strain which can efficiently express an FMDV VP1 gene form is successfully established. The vaccine strain reserves the rough-type characteristic of the original parent strain RA343 and has good immune protection performance on brucellosis, after the recombinant bacterium is usedfor immunizing an animal, a targeted FMDVVP1 antibody can be generated, and accordingly FMD immune protection is achieved. The recombinant vaccine strain is developed into a novel vaccine with a heat-resident protection characteristic according to a specific technology, and after the animal is immunized, the dual immune protection on the brucellosis and the foot and mouth disease can be achieved at the same time.

Owner:CHINA INST OF VETERINARY DRUG CONTROL

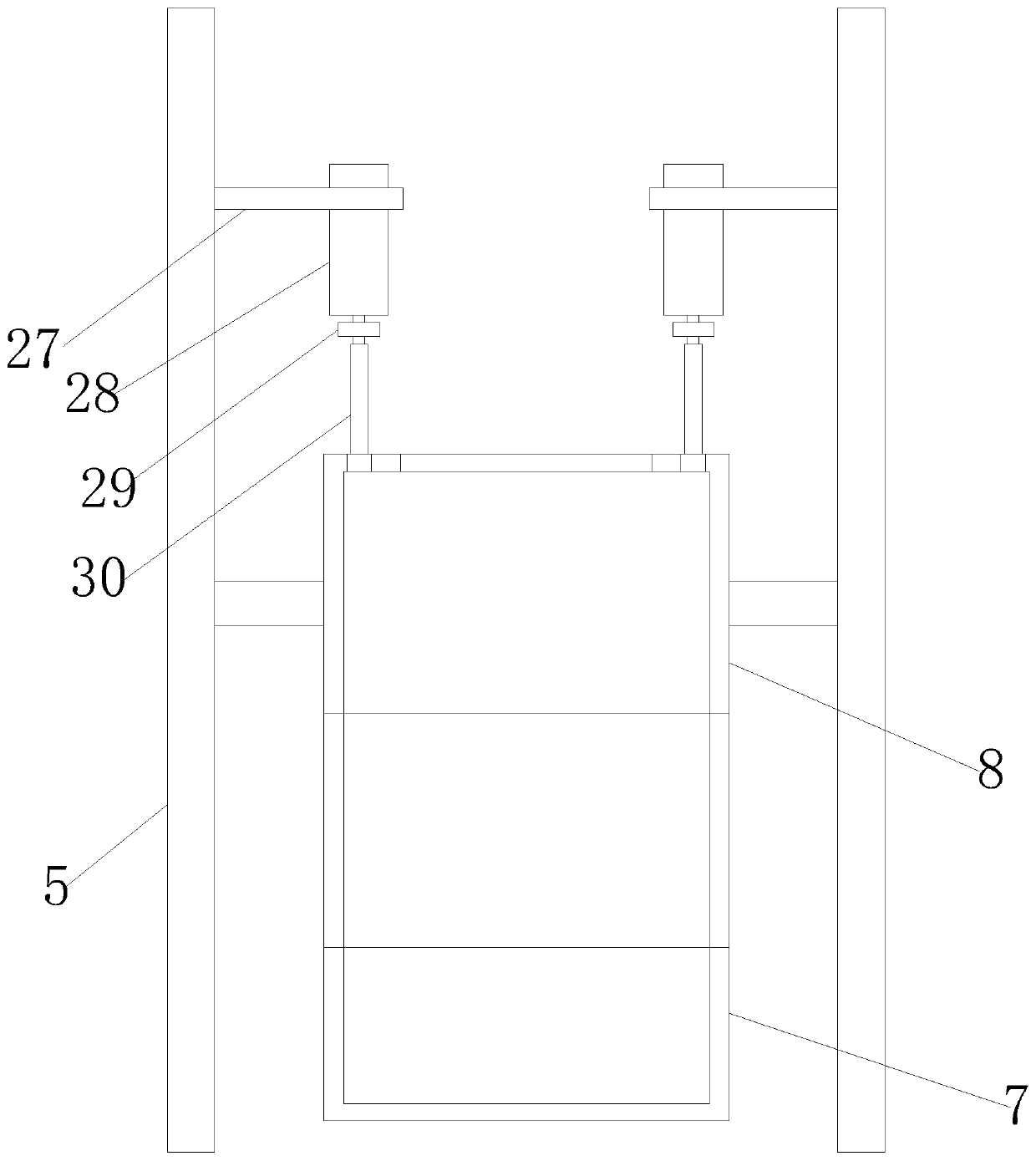

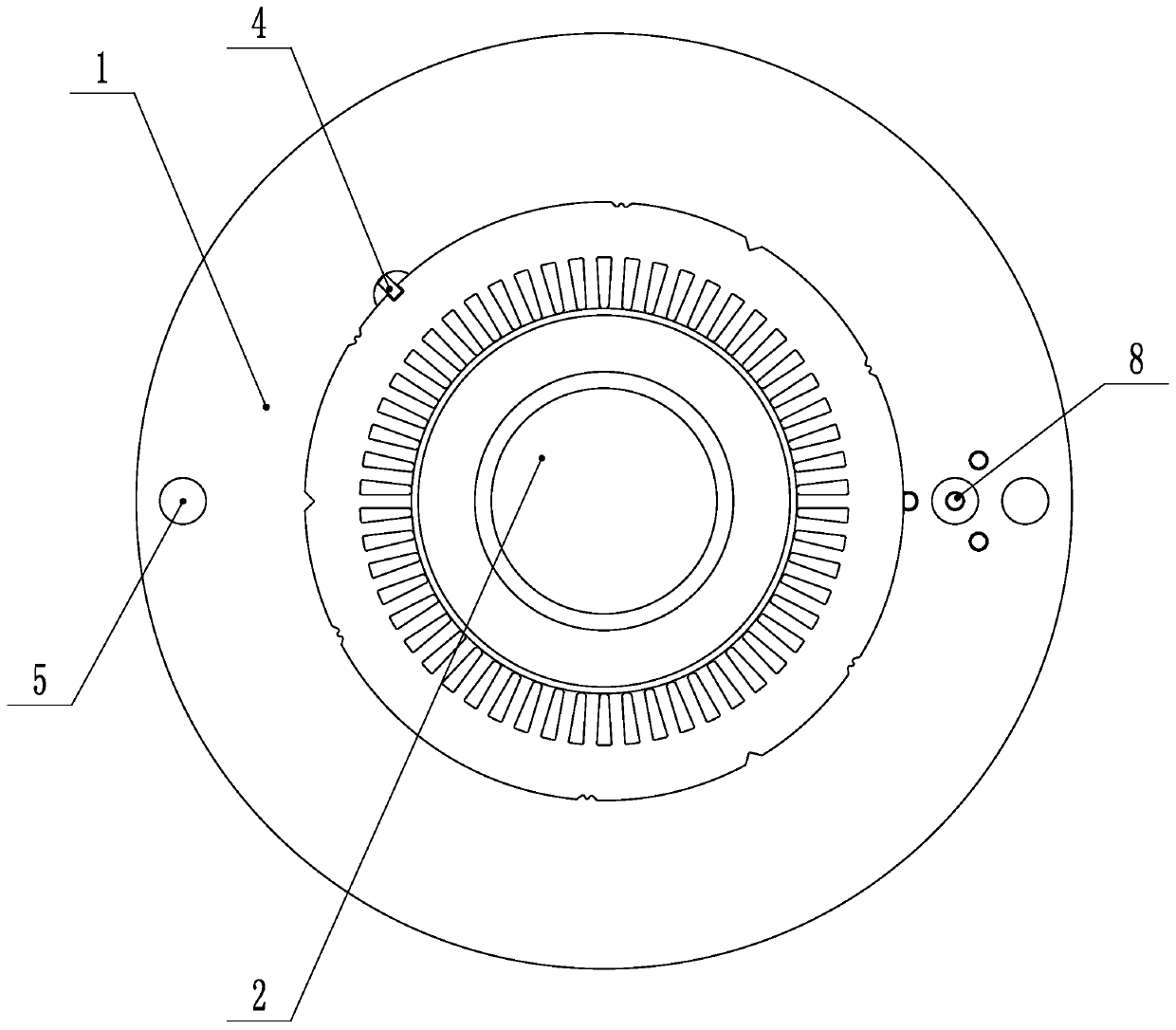

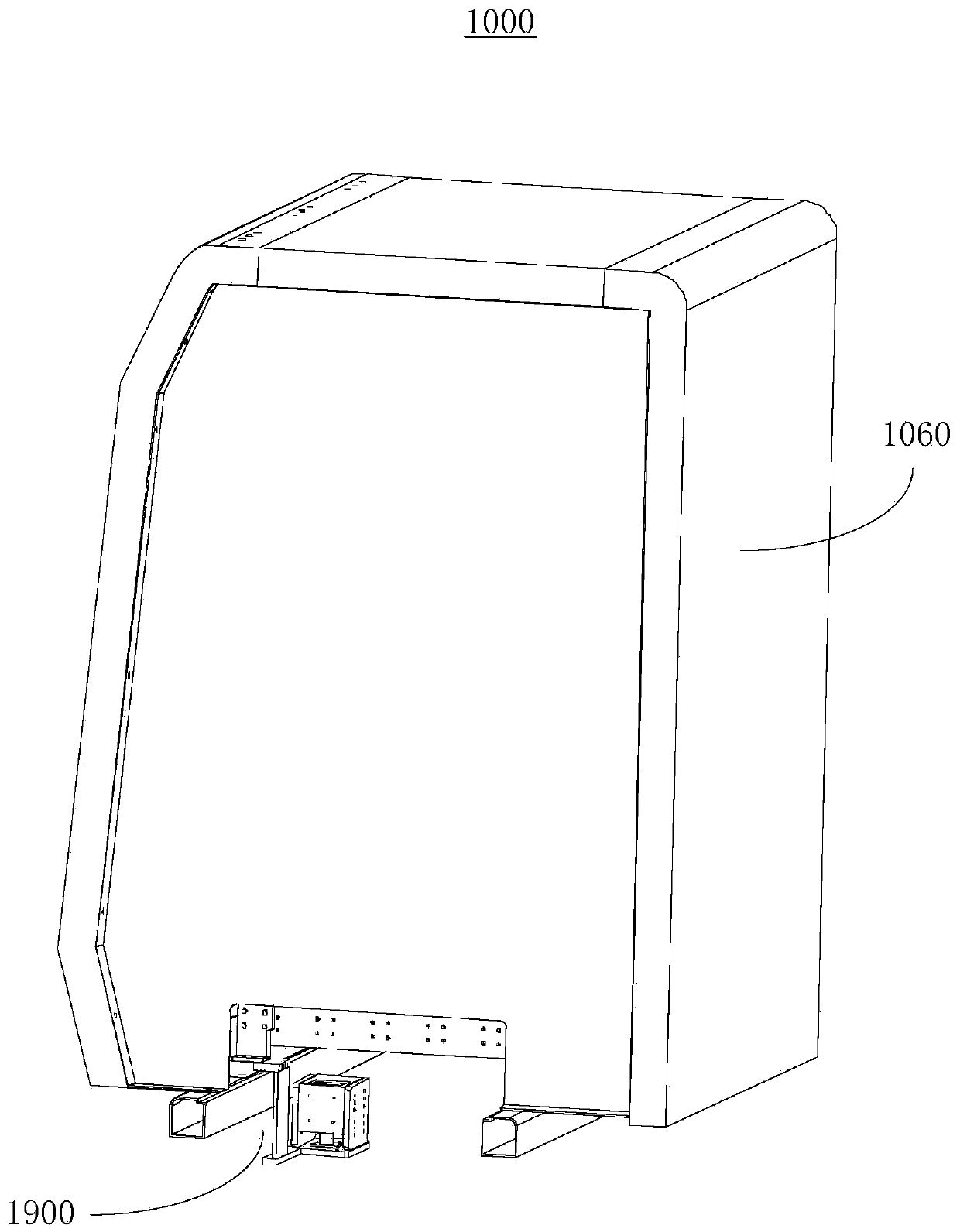

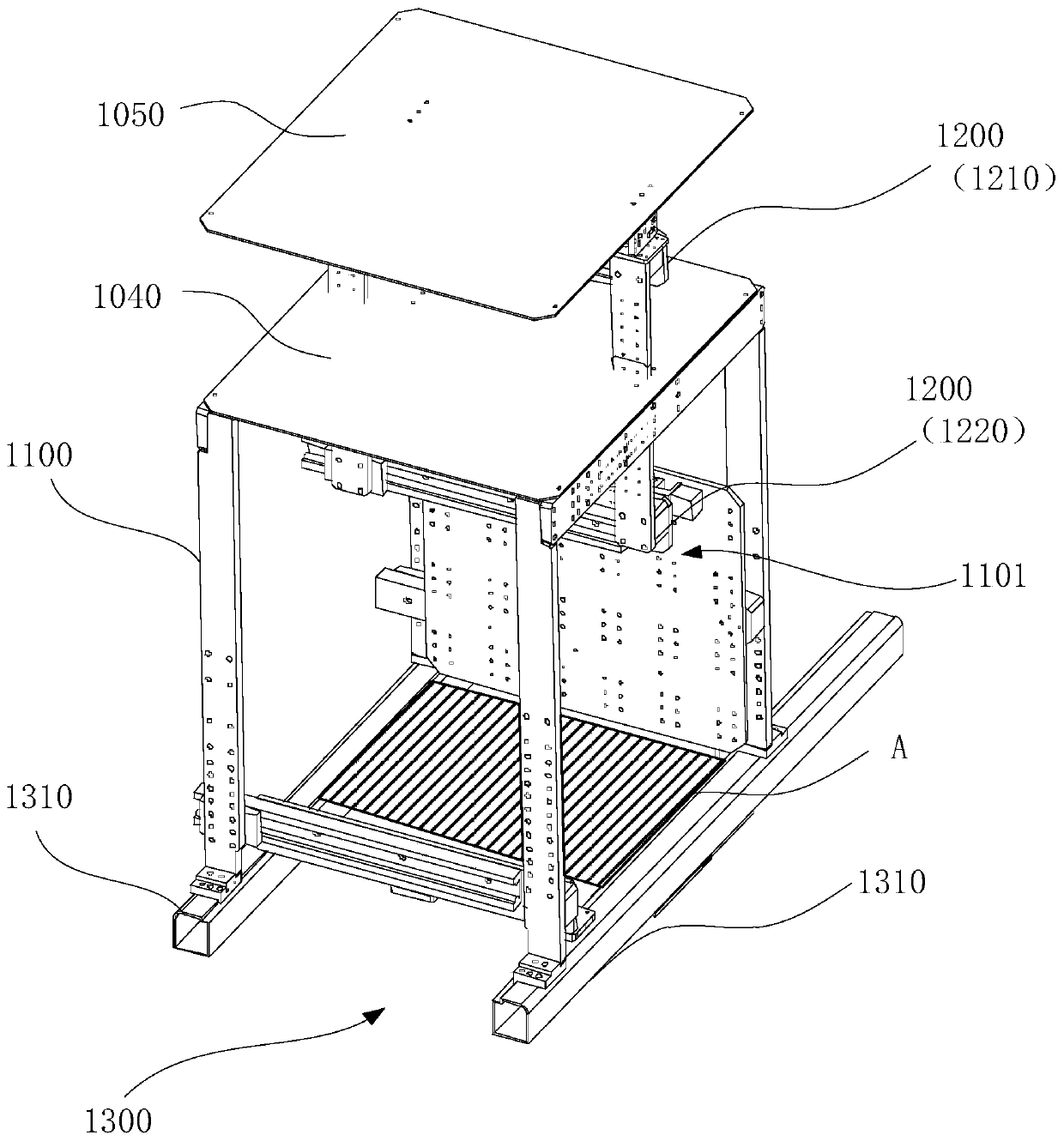

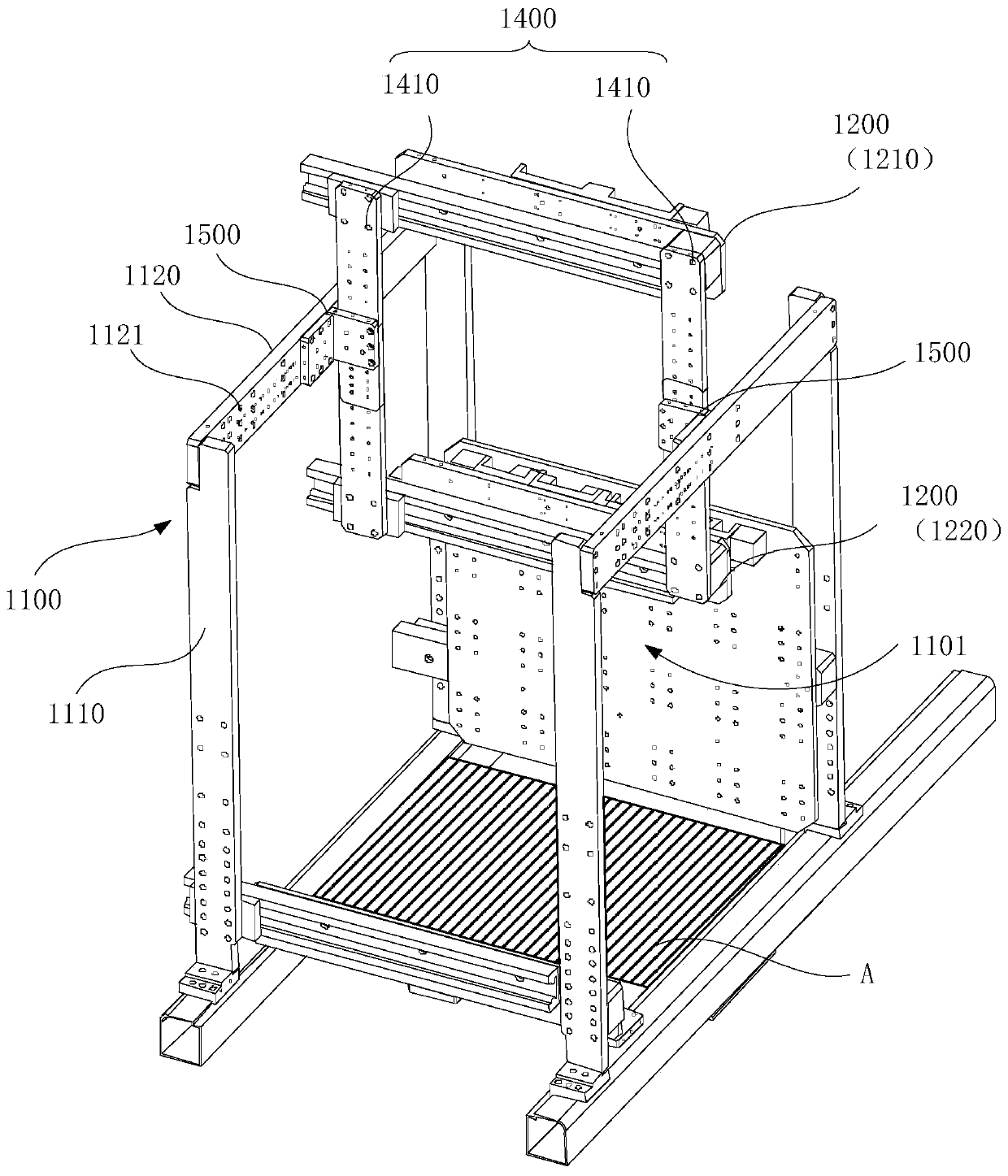

Slow-descending type automatic sheet sorting machine

PendingCN110011490AImprove film processing efficiencyReduce production costManufacturing stator/rotor bodiesStatorEngineering

The invention discloses a slow-descending type automatic sheet sorting machine, and relates to the field of motor part processing process equipment. For a long time, the stator punching sheets with thin thickness and larger diameters are mostly manually sorted, so that the labor intensity is high and the efficiency is low. The slow-descending type automatic sheet sorting machine comprises a mounting plate, guide pillars and a first servo motor which are fixed on the mounting plate, a mandrel connected with an output shaft at the upper end of the first servo motor, a supporting plate capable ofsliding up and down along the guide pillars, and a second servo motor arranged at the lower end of the mounting plate, wherein the output shaft at the upper end of the second servo motor is connectedwith the supporting plate through a screw rod pair, and the mandrel is driven to rotate by the first servo motor. When the sheets are sorted, the stator punching sheets are placed in alignment with the mandrel, the mandrel is driven by the first servo motor to drive the punching sheets to rotate, when the punching sheet positioning notches are aligned with the positioning keys, the punching sheets fall off, and the supporting plate is descended by the thickness of one punching sheet under the effect of the screw rod pair driven by the second servo motor. The automatic sheet sorting of the stator punching sheets with the thin thickness and the large diameters can be rapidly achieved, and the sheet sorting efficiency is improved.

Owner:WOLONG ELECTRIC GRP CO LTD

Cement fiber foam board

The invention discloses a cement fiber foam board. The cement fiber foam board is characterized by comprising the following components in parts by weight: 50 to 60 parts of straw fibers, 20 to 25 parts of silicon-aluminum sol, 14 to 18 parts of a binder, 10 to 12 parts of propyl p-hydroxybenzoate, 6 to 10 parts of hydrotalcite, 12 to 15 parts of barium silicate, 10 to 14 parts of perlite powder, 30 to 40 parts of cement, 0.2 to 0.3 part of a water retention agent, 0.3 to 0.5 part of a waterproof agent, 4 to 6 parts of a flocculating agent, 10 to 12 parts of polyvinyl acetate, 1.5 to 2 parts ofcalcium stearate, 0.6 to 1 part of lauryl sodium sulfate, and 30 to 40 parts of water. The straw fibers prepared from crop waste straws are used as a raw material and mixed with cement to be foamed,and the mixture is made into the cement fiber foam board by virtue of a mold, so that the product is energy-saving, environmentally friendly, and low in production cost; the product can prevent fire and insulate the heat, and can meet the building thermal insulation requirement; and the product is light in weight, and convenient to install.

Owner:ANHUI JIHONG ENVIRONMENTAL PROTECTION TECH CO LTD

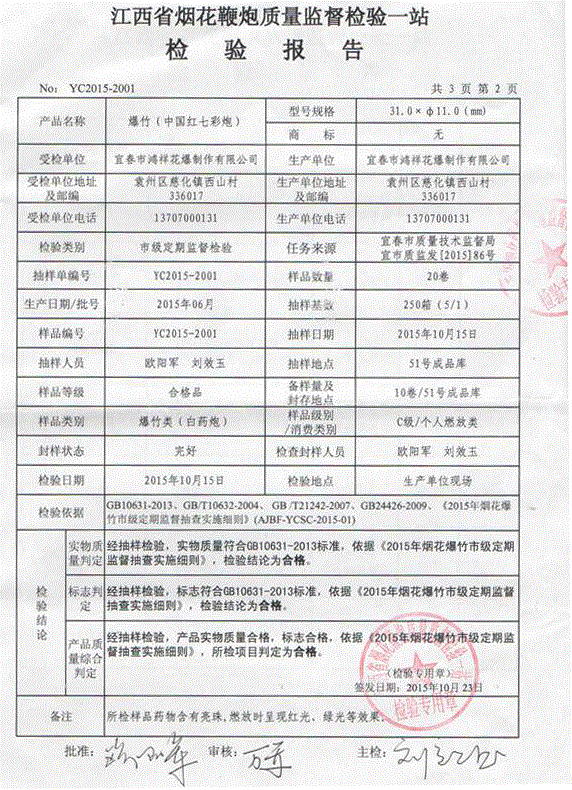

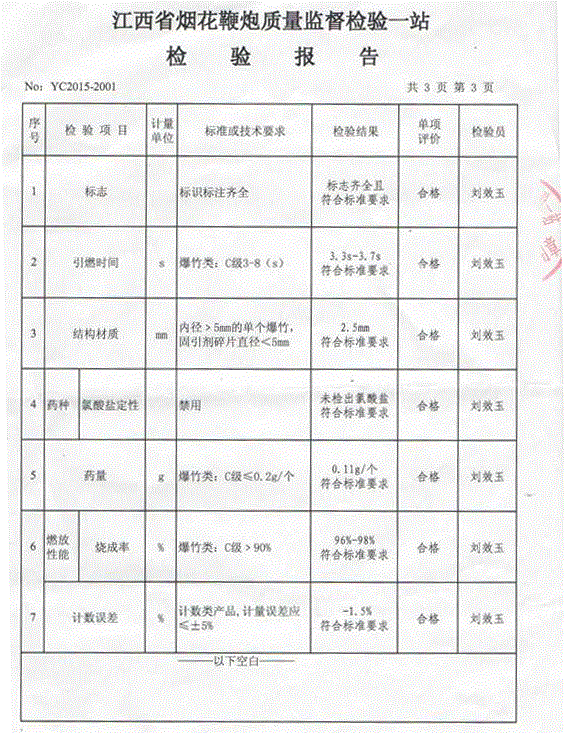

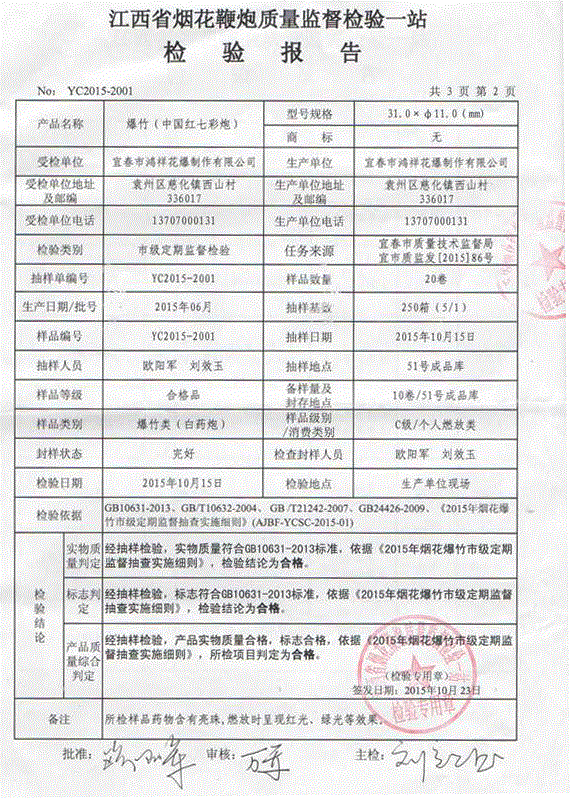

Fragrant fireworks

The invention discloses a kind of fragrant fireworks and firecrackers. The technical scheme of Yixiang fireworks and firecrackers includes explosive powder, which includes raw materials of the following mass components: 40%-55% of potassium perchlorate, 20%-30% of metal powder, 5%-15% of bright pearls, perlite powder 10‑15%, Chinese herbal medicine 5%‑15%. The fragrance-filled fireworks not only have the same effect as fireworks, but also have the traditional use and safety of firecrackers on the ground. At the same time as the atmosphere of the scene or the festive atmosphere, it can also give people a pleasant enjoyment of fragrance.

Owner:张京

Fiber preform forming method of ceramic matrix composite longitudinal corrugated heat insulation screen

ActiveCN114055865AReduce fiber damageReduce production costContinuous combustion chamberLaminationChemical vapor infiltrationCeramic matrix composite

The invention discloses a method for forming a fiber preform of a ceramic matrix composite longitudinal corrugated heat shield, which comprises the following steps of: preparing an inner mold and an outer mold of a heat shield mold, winding single-layer unidirectional fiber cloth on the inner mold for one circle and fixing, replacing fiber bundles and hot melt adhesive lines in situ, and repeating the operations to obtain the fiber preform; and finally, clamping the fiber preform between the inner mold and the outer mold, and sewing the inner mold, the fiber preform and the outer mold into a whole by using a sewing line, thereby completing the forming of the fiber preform. According to the invention, the fiber damage in the fiber preform forming process can be greatly reduced. According to the method, the mold attaching rate of the prefabricated body can be remarkably improved, meanwhile, the production cost can be remarkably reduced, and the preparation period is shortened. In addition, the prepared fiber preform can be subjected to a subsequent densification process of a ceramic matrix by adopting a chemical vapor infiltration method, a resin infiltration cracking method or a melt infiltration method, so that the process adaptability is better.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Circuit board detection device

PendingCN111007011AReduce production costMeet testing needsMaterial analysis by optical meansEmbedded systemLight source

The invention discloses a circuit board detection device, and the device comprises a detection support which is detachably disposed on a transportation path of a circuit board, and a space region defined by the detection support is provided with an imaging part; and a light source installation assembly which is connected with the detection support and erected on the transportation path, the lightsource installation assembly is used for detachably installing light sources, the light source installation assembly is provided with a plurality of first installation parts, and different light sources are connected with the light source installation assembly through the matched first installation parts. The circuit board detection device provided by the invention can save the production cost.

Owner:GUANGDONG MIDEA WHITE GOODS TECH INNOVATION CENT CO LTD +1

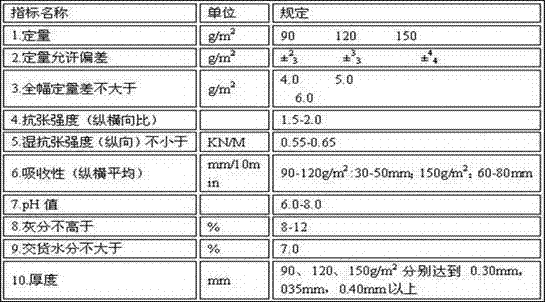

Environmentally-friendly ecologic paper and making method thereof

InactiveCN107268335ALoose structureImprove water absorptionVegetable material additionPaper/cardboardFiberPolyester

The invention discloses an environmentally-friendly ecologic paper and a making method thereof. The environmentally-friendly ecologic paper comprises, by mass, 15-20% of bleached softwood pulp, 40% of chemi-mechanical wood pulp, 30-35% of poplar wood powder and 10% of polyester fibers. The finished paper has the advantages of loose structure, high water absorption rate, great reduction of the production cost, high surface flatness (smooth paper surface), increase of the interweaving force among fibers, improvement of the bonding force of the fibers, and enhanced tensile strength.

Owner:杭州先进特种纸业有限公司

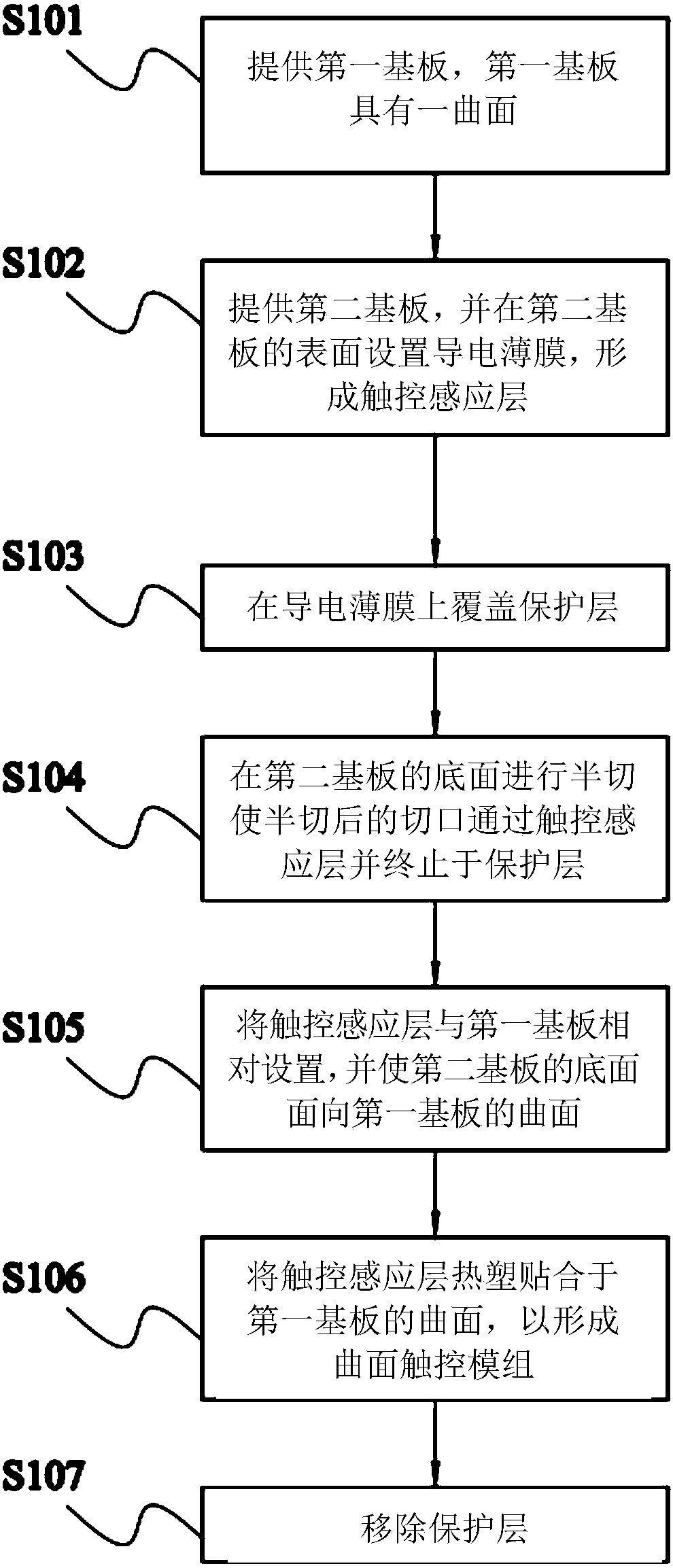

Manufacturing method for curved surface touch module

ActiveCN108459769AReduce production costReduce chance of damageInput/output processes for data processingQuality controlEngineering

The invention discloses a manufacturing method for a curved surface touch module. An existing curved surface touch product needs to be trimmed again after a thermoplastic lamination process, so that product quality control management is difficult; a protective layer is used for avoiding damage of a conductive film in a thermoplastic process, and meanwhile, the protective layer is taken as a bearing film; a touch sensing layer is semi-cut, so that after the thermoplastic lamination process, the protective layer only needs to be removed, and the trimming action does not need to be performed again; and therefore, the process yield can be effectively increased, and the production cost is reduced.

Owner:INTERFACE TECH CHENGDU CO LTD +2

Cylindrical cutter upset-extruding molding method

The invention relates to a cylindrical cutter upset-extruding molding method. Extruding is utilized to replace brazing, or a cemented cutter is adopted. A press machine is adopted to compress a cutter body to enable the cutter body to have radial and axial plastic deformation. Mechanical biting force is utilized to achieve connection of the cutter body and a hard alloy cutter bit to achieve the advantages of simple process method, high accuracy, high production speed, low labor intensity, no pollution in the manufacturing process and the like.

Owner:许自清

Circuit board detection device

PendingCN110987809AReduce production costMeet testing needsMaterial analysis by optical meansEmbedded systemImaging equipment

The invention discloses a circuit board detection device, which comprises a detection support, at least two imaging mounting assemblies and a controller, wherein the detection support is detachably disposed on a transportation path of a circuit board, and a space region defined by the detection support is provided with an imaging position; the at least two imaging mounting assemblies are respectively used for mounting different numbers of imaging devices, the at least two imaging mounting assemblies are arranged on the detection support in a position-adjustable manner, and each imaging mounting assembly can be adjusted to the imaging position; and the controller is used for controlling the imaging devices installed on the imaging mounting assembly located at the imaging position to image the circuit board located on the transportation path. The circuit board detection device provided by the invention can save the production cost.

Owner:GUANGDONG MIDEA WHITE GOODS TECH INNOVATION CENT CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com