Medium alloy ultrahigh strength and toughness rare earth steel and preparation method thereof

An ultra-high toughness, rare earth technology, applied in the field of medium alloy ultra-high toughness rare earth steel and its preparation, can solve the problems of smelting process output limitation, achieve high hardness, high toughness, and improve the effect of toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

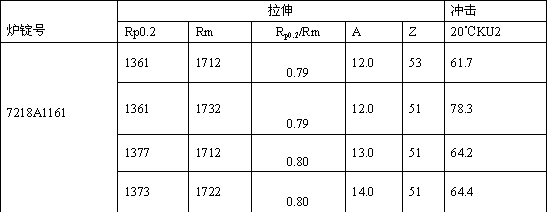

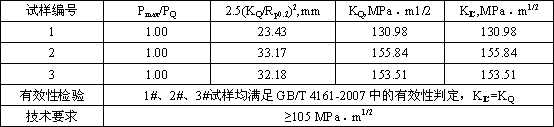

[0018] An ultra-high strength and toughness rare earth steel, comprising the following components in mass fraction: C: 0.26%-0.31%, Mn: 0.50%-0.80%, Si: 1.25%-1.60%, S: ≤0.005%, P: ≤0.010 %, Cr: 3.25%~3.60%, Ni: 0.80%~1.20%, Mo: 0.35%~0.60%, W: 0.40%~1.00%, Nb: 0.02%~0.04%, V: 0.20%~0.40%, La: 0.0045% to 0.006%, Ce: 0.0105% to 0.014%.

[0019] As a preferred embodiment of the present invention, the ultra-high-strength rare earth steel includes the following components in mass fraction: C: 0.28% to 0.29%, Mn: 0.60% to 0.70%, Si: 1.35% to 1.45%, S: ≤0.005 %, P: ≤0.010%, Cr: 3.35%~3.45%, Ni: 0.90%~1.00%, Mo: 0.45%~0.50%, W: 0.60%~0.80%, Nb: 0.02%~0.03%, V: 0.20% to 0.30%, La: 0.005% to 0.006%, Ce: 0.011% to 0.012%.

[0020] The preparation method of ultra-high-strength rare-earth steel provided by the present invention comprises the following steps: electric furnace smelting→LF furnace refining→VD vacuum degassing→argon protection pouring electrode→electrode flame cutting riser...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com