Preparation method of whole-wheat bread with low GI (glycemic index) and high dietary fiber

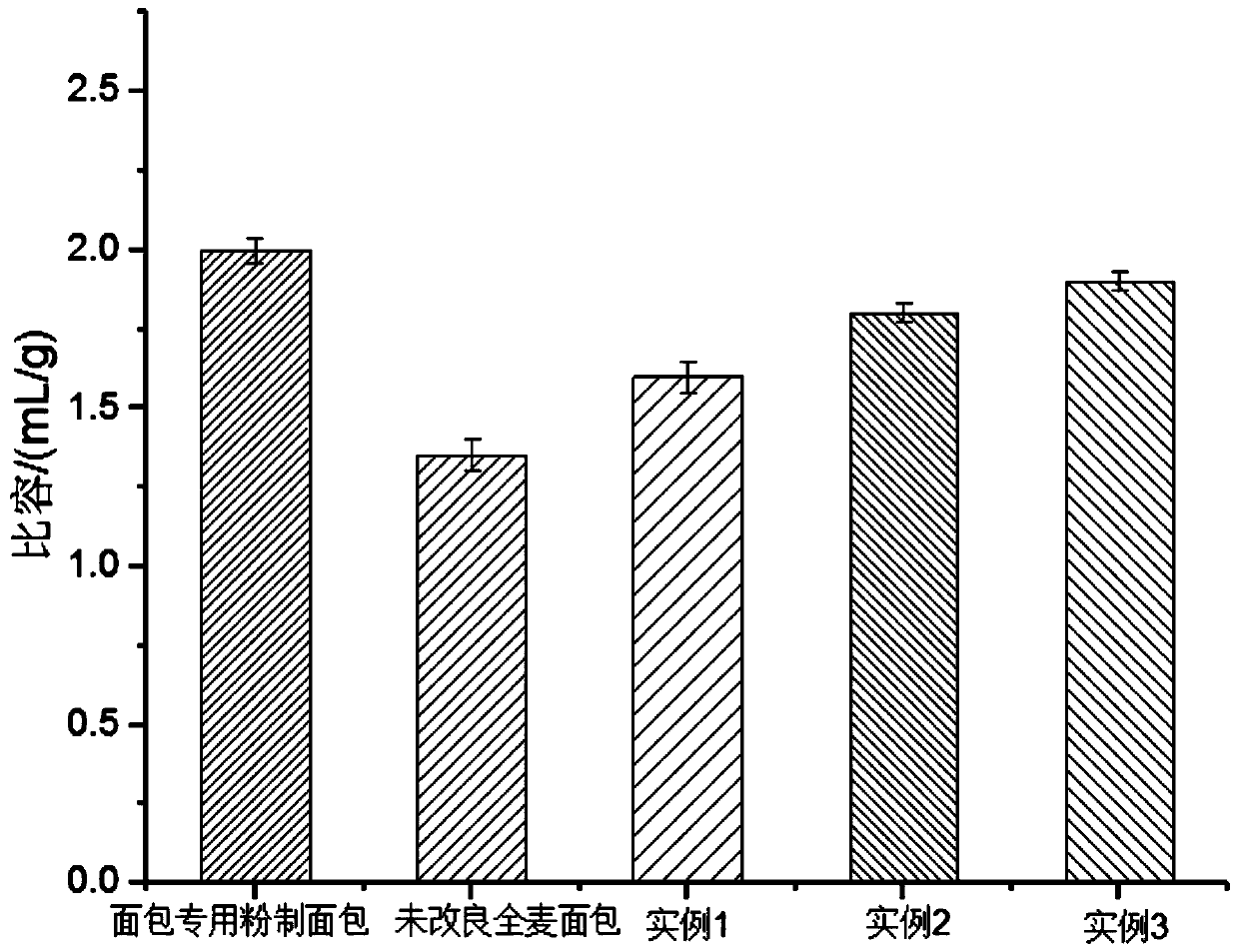

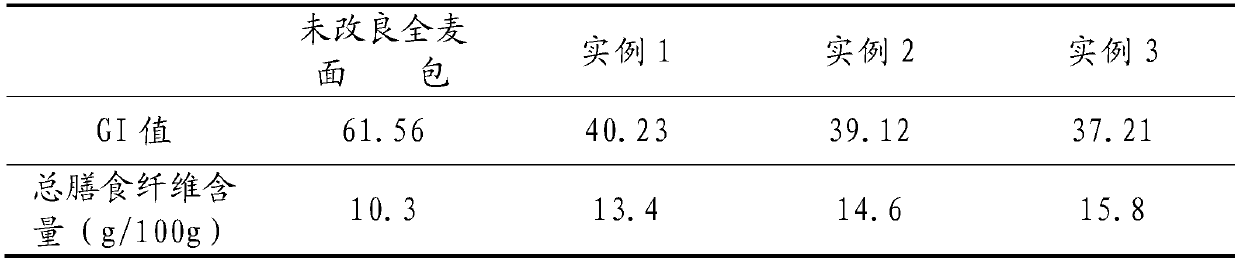

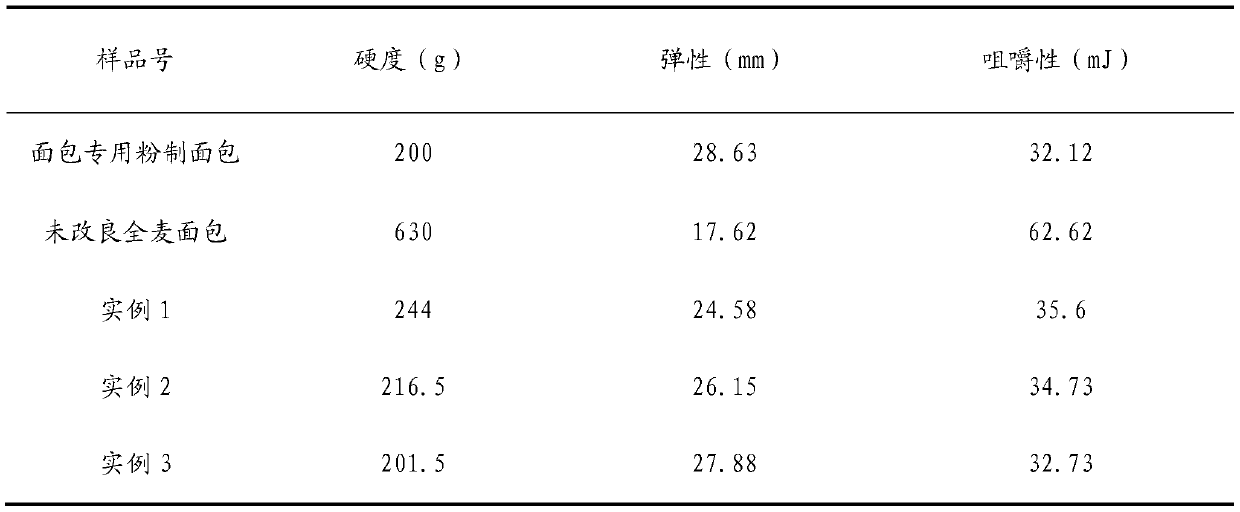

A high-fiber, whole-wheat bread technology, applied in the functions of food ingredients, baked goods, dough preparation, etc., can solve the problems of poor storage stability, high glycemic index, low dietary fiber content, etc., and reduce the hardness , The content of total dietary fiber is increased, and the effect of rich flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Pass the wheat bran through an 80-mesh sieve to remove the flour and bran crumbs in the material, put 10g of wheat bran into a conical flask, add 110mL of clean water, and stir magnetically for 30min. After the magnetic stirring is completed, let it stand for 20min and remove the upper layer For the cleaning solution, dry the wheat bran in a constant temperature drying oven at a temperature of 35° C. so that the moisture content of the wheat bran is 8%. The wheat bran is sent into the twin-screw extruder, and the wheat bran is stabilized by low-temperature extrusion and expansion. The working temperature of each section of the twin-screw extruder is: 25°C in zone I, 35°C in zone II, and 45°C in zone III. ℃, and 55 ℃ of IV zone, rotating speed 150rpm, the moisture of regulating bran is 12%. The extruded and stabilized wheat bran is ultrafinely pulverized and sieved. The wheat bran after 10g superfine pulverization is placed in conical flask and is configured into 10% wh...

Embodiment 2

[0037] Pass the wheat bran through a 90-mesh sieve to remove flour and bran crumbs in the material, put 15g of wheat bran into a conical flask, add 115mL of clean water, and stir magnetically for 35min. For the cleaning solution, place the wheat bran in a constant temperature drying oven to dry at a temperature of 40° C., so that the moisture content of the wheat bran is 9%. The wheat bran is sent into the twin-screw extruder, and the wheat bran is stabilized by low-temperature extrusion and expansion. The working temperature of each section of the twin-screw extruder is: 30°C in zone I, 40°C in zone II, and 50°C in zone III. ℃, and 57 ℃ of IV zone, rotating speed 160rpm, the moisture of regulating bran is 13%. The extruded and stabilized wheat bran is ultrafinely pulverized and sieved. The wheat bran after 15g superfine pulverization is placed in conical flask and is configured into 15% wheat bran mixed liquor, adds 0.7% cellulase, 0.2% xylanase (cellulase, xylanase and tot...

Embodiment 3

[0039] Pass the wheat bran through a 100-mesh sieve to remove flour and bran crumbs in the material, put 20g of wheat bran into a conical flask, add 120mL of clean water, and stir magnetically for 40min. For the cleaning solution, place the wheat bran in a constant temperature drying oven to dry at a temperature of 45° C., so that the moisture content of the wheat bran is 10%. The wheat bran is sent into the twin-screw extruder, and the wheat bran is stabilized by low-temperature extrusion and expansion. The working temperature of each section of the twin-screw extruder is: 35°C in zone I, 45°C in zone II, and 55°C in zone III. ℃, and 60 ℃ of IV zone, rotating speed 170rpm, the moisture of regulating bran is 14%. The extruded and stabilized wheat bran is ultrafinely pulverized and sieved. The wheat bran after 20g superfine pulverization is placed in conical flask and is configured into 20% wheat bran mixed liquor, adds 1% cellulase, 0.3% xylanase (cellulase, xylanase and tot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com