Environmentally-friendly ecologic paper and making method thereof

An environmentally friendly and ecological technology, applied in special paper, paper, papermaking, etc., can solve problems such as unfavorable ecological paper quality requirements, and achieve the effect of loose structure, high water absorption rate, and increased interweaving force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

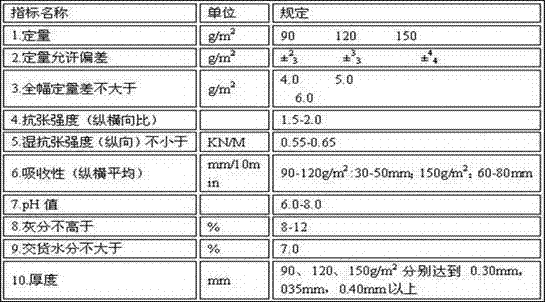

Image

Examples

Embodiment 1

[0031] In order to improve the tensile strength of the finished paper and the water absorption performance of the paper, the beating is to keep the length of the fiber as much as possible, and the fiber bundles can be simply dispersed without damaging the fibers. For the above beating requirements, through several improvements in the processing performance of the beating equipment, the ring gear produced can not only disperse and loosen the pulp fiber bundles, but also keep the beating degree and wet weight of the pulp unchanged.

[0032] The high-frequency deflaking machine produced by the original Shanghai Light Machinery No. The weight decreased by 0.5-1 gram, indicating that it has a certain broom shape, which is not conducive to the quality requirements of ecological paper. After the newly designed and processed beating ring gear is used, there is almost no change in the beating degree and wet weight of the pulp after testing. The fiber bundles are completely disentangled...

Embodiment 2

[0048] The difference between embodiment 2 and embodiment 1 is:

[0049] A kind of environment-friendly ecological paper of the present invention comprises the following components in mass percentage:

[0050] Bleached Softwood Pulp 20%,

[0051] Chemimechanical wood pulp 40%,

[0052] Poplar Machine Wood Flour 30%,

[0053] 10% polyester.

[0054] The thickness of the environment-friendly ecological paper is 42 filaments.

[0055] The preparation method of environment-friendly type ecological paper of the present invention, comprises the steps:

[0056]In step (2), the bleached softwood pulp is put into the high-consistency pulper and then crushed, then enters the second crushing tank, and then enters the softwood pulp tank. The bleached softwood pulp with longer fibers is separately beaten by double disc mills Separation and broomification, enter the needle pulp tank; the degree of percussion of bleached softwood pulp is 25°SR, and the wet weight is controlled at 10g. ...

Embodiment 3

[0061] The difference between embodiment 3 and embodiment 1 is:

[0062] A kind of environment-friendly ecological paper of the present invention comprises the following components in mass percentage:

[0063] Bleached Softwood Pulp 18%,

[0064] Chemimechanical wood pulp 40%,

[0065] Poplar Machine Wood Flour 32%,

[0066] 10% polyester.

[0067] The thickness of the environment-friendly ecological paper is 38 silk.

[0068] The preparation method of environment-friendly type ecological paper of the present invention, comprises the steps:

[0069] In step (2), the bleached softwood pulp is put into the high-consistency pulper and then crushed, then enters the second crushing tank, and then enters the softwood pulp tank. The bleached softwood pulp with longer fibers is separately beaten by double disc mills Separation and broomification, enter the needle pulp tank; the degree of percussion of bleached softwood pulp is 23°SR, and the wet weight is controlled at 8g.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com