Manufacturing method for curved surface touch module

A touch module and manufacturing method technology, applied in the input/output process of data processing, instruments, electrical digital data processing, etc., can solve the problems of long time, damage to plastic materials, high cost of 3D laser cutting equipment, and achieve The effect of reducing production costs, reducing the probability of damage, and improving product reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The invention discloses a manufacturing method of a curved surface touch module, which is beneficial for the curved surface touch module to be introduced into a thermoplastic process to achieve the required product curvature; the curved surface touch module can be applied to display devices, tablet computers, smart phones, etc. Various electronic devices such as mobile phones, notebook computers, desktop computers, TVs, satellite navigation, car displays, aviation displays, or portable DVD players.

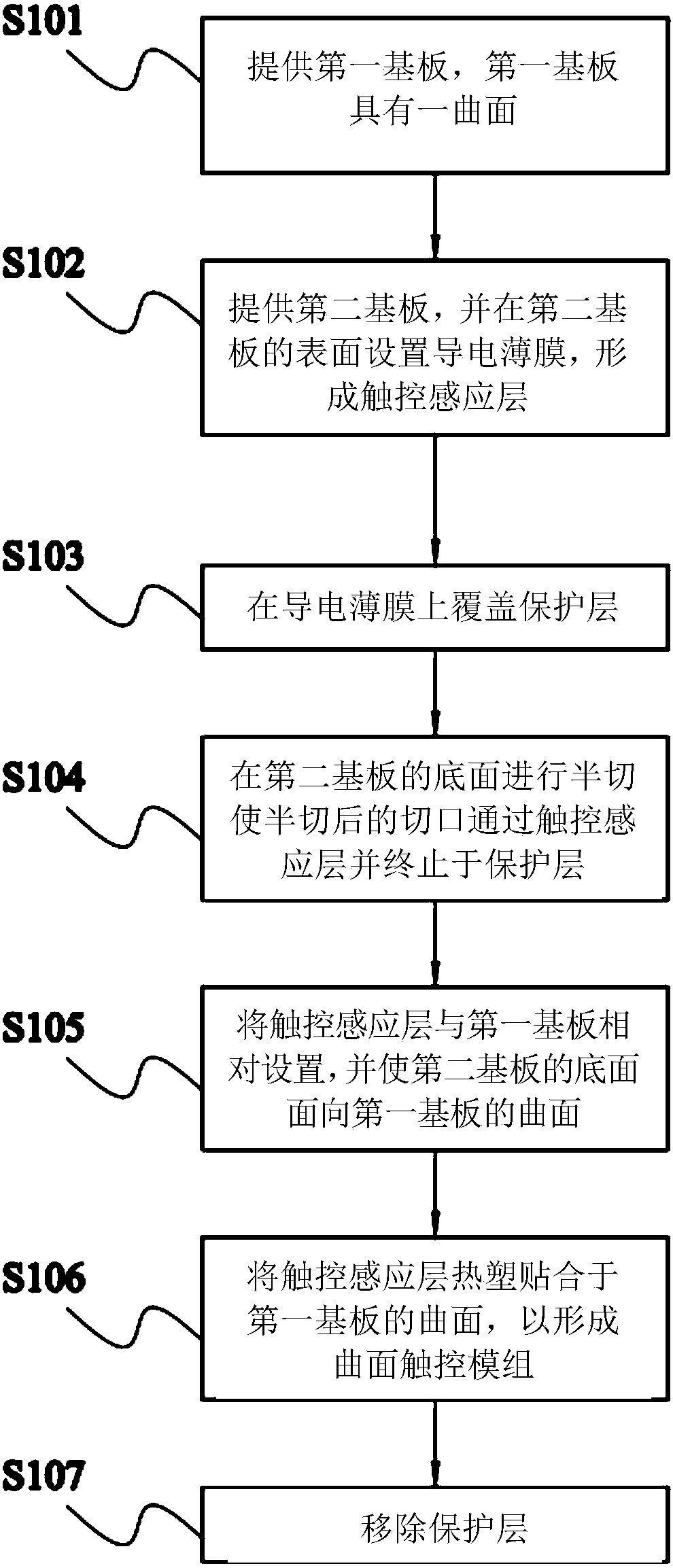

[0034] see figure 1 , which shows the flow chart of the manufacturing method of the curved surface touch module provided by the embodiment of the present invention; at the same time, please refer to Figure 2 to Figure 9 , is a structural cross-sectional view corresponding to each step in the manufacturing method of the curved surface touch module provided by the embodiment of the present invention. This manufacturing method comprises the following steps:

[0035] First, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com