Cylindrical cutter upset-extruding molding method

A forming method and a technology of cylindrical cutters, which are applied to knives, household utensils, kitchen utensils, etc., can solve problems such as polluting the environment, affecting the life of knives, and generating smoke, and achieve the effects of reducing skill requirements, improving the life of knives, and improving precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

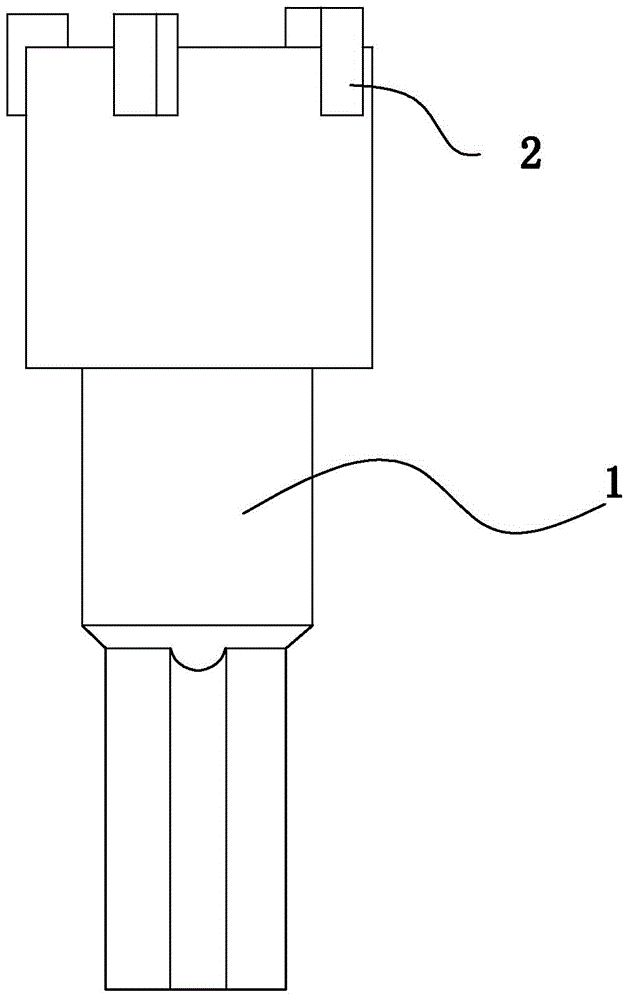

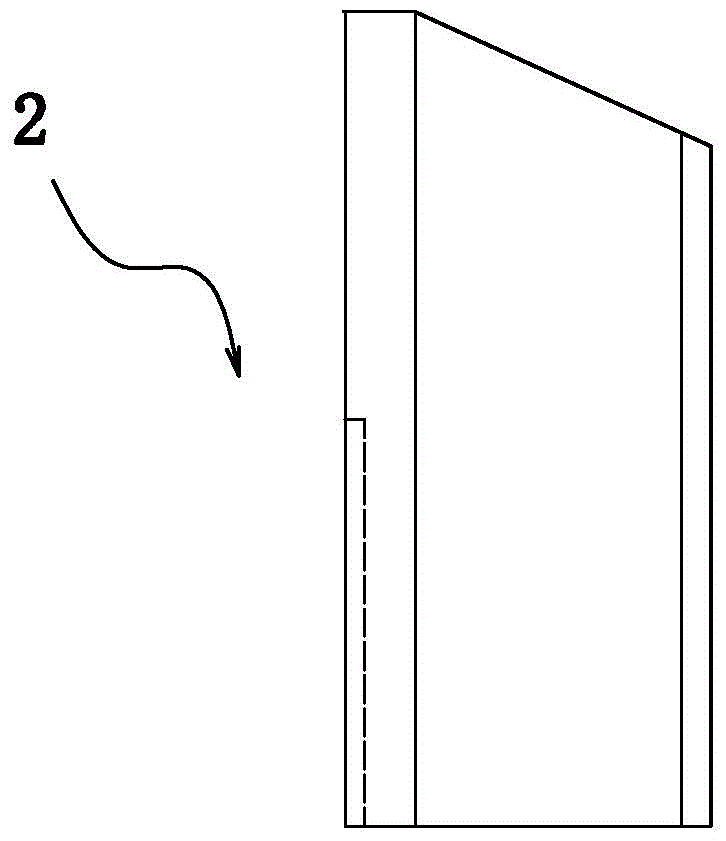

[0033] Such as Figure 1-4 As shown, a method of upsetting and extruding a tubular cutter includes the following steps: preprocessing of the cutter head 2; positioning of the cutter body 1; assembly of the cutter head 2; and upsetting and extrusion forming. The cutter head 2 is a terrace whose bottom diameter is larger than that of the head. The terrace structure is beneficial to control the material flow during upsetting, so that the cutter head and the groove of the cutter body are closely combined and seamlessly connected. The terrace structure can be diversified, see Embodiment 4-8 for details.

[0034] The edge of the head of the cutter head 2 is asymmetrically arranged, and the width of the left edge 22 is smaller than the width of the right edge 23 . At the same time, the length of the left slope 24 is greater than that of the right slope 26, which is conducive to chip removal. This structure reduces the size of the cutter head, about one-sixth of the amount of common...

Embodiment 2

[0036] The difference from Embodiment 1 is that the cutter head 2 has a concave arc-shaped waist 27 at the bottom. The waist is designed for easy positioning between the cutter head and the groove of the cutter body.

Embodiment 3

[0038] Different from Example 1, as Figure 6 As shown, the bottom of the cutter head 2 has an indented portion 28 and a corresponding convex portion 29 . This structure is conducive to positioning, and at the same time, it will not cause damage to the mechanical structure of the cutter head.

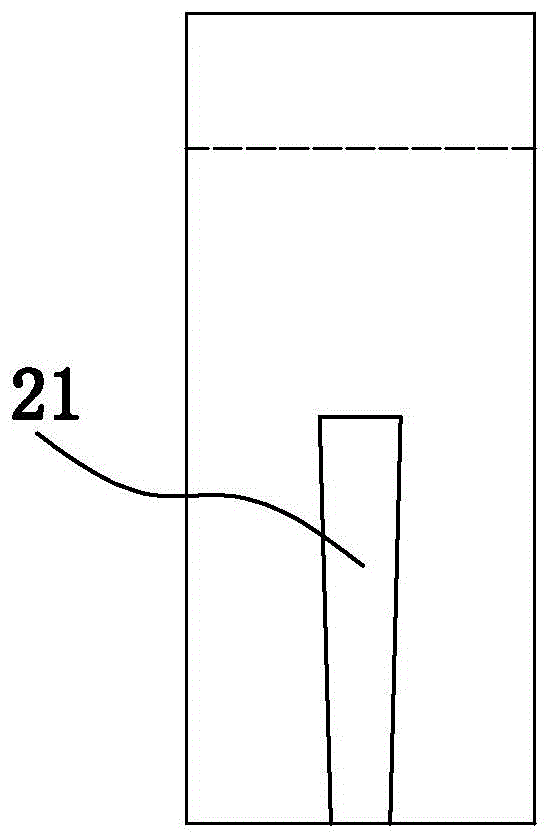

[0039] At least one rectangular groove 21 is opened in the middle of the cutter head.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com