Optical mask for exposure

A photomask, film-like technology, applied in microlithography exposure equipment, originals for photomechanical processing, photolithography process exposure devices, etc. and other problems, to achieve the effect of reducing parts and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

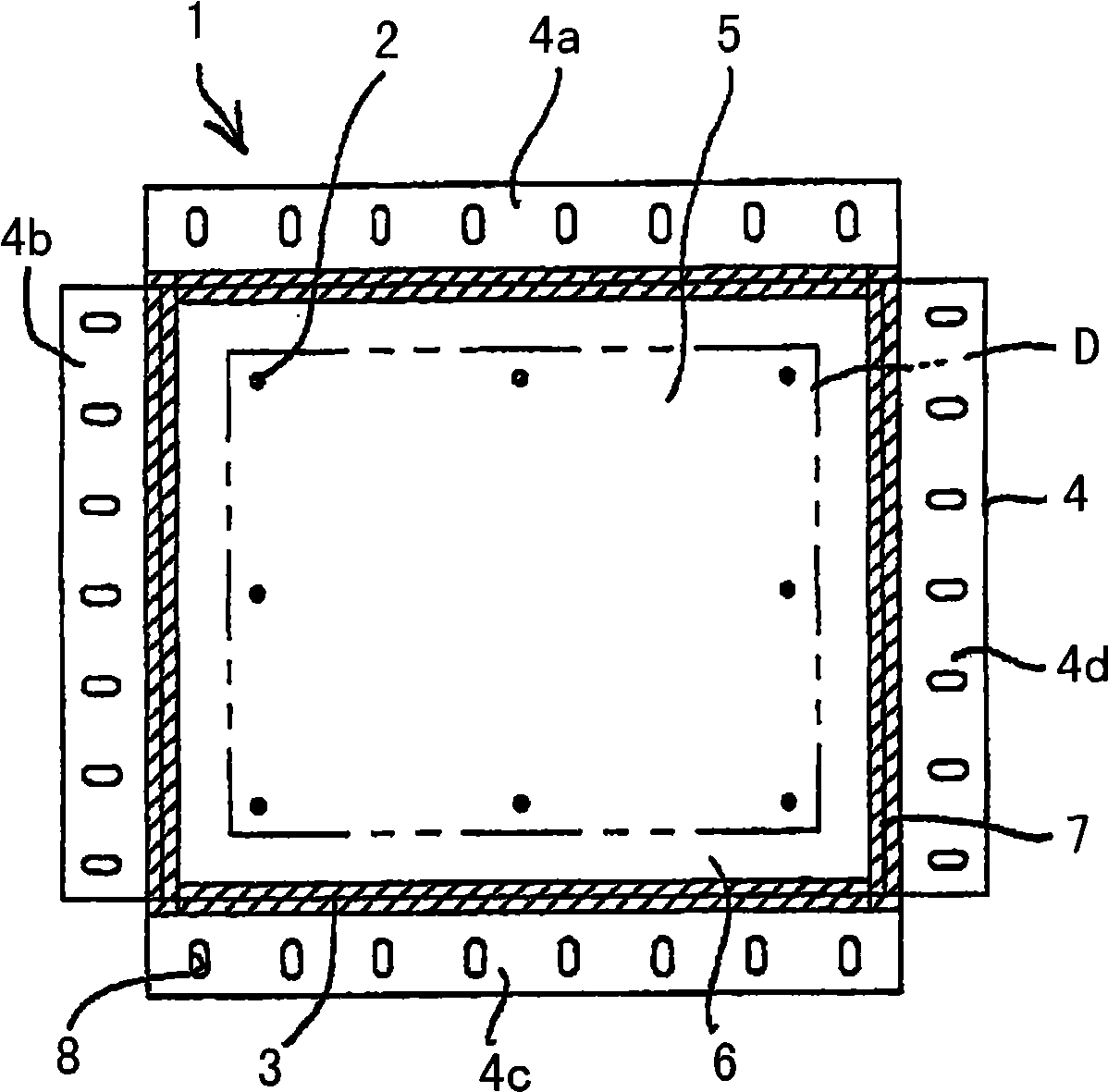

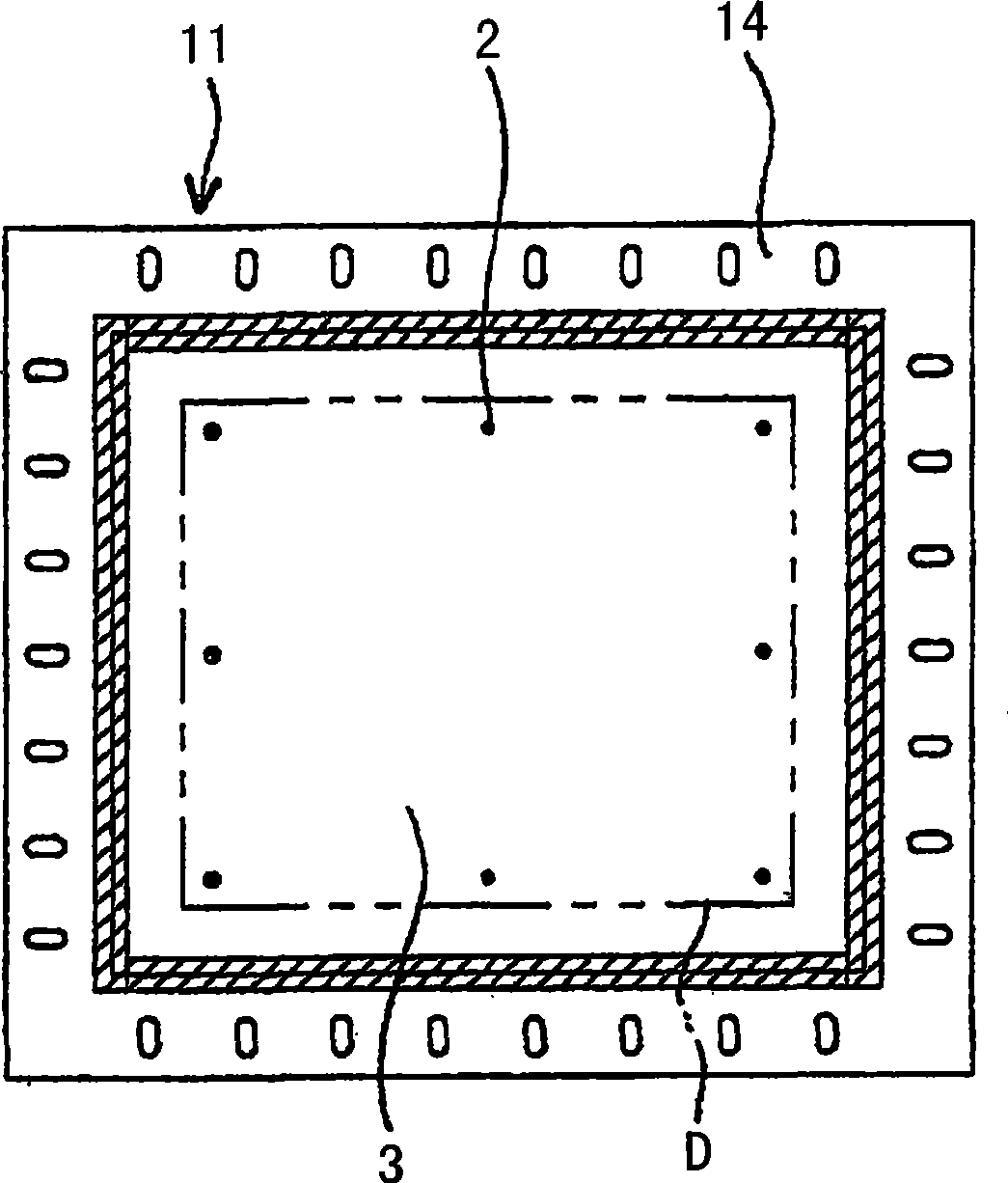

[0041] figure 1 It is a plan view of the photomask 1 according to an embodiment of the present invention. The photomask 1 includes a central part 3 in which a pattern including a plurality of alignment marks 2 is drawn, and a force transmission part 4 which is arranged so as to surround the outer peripheral edge of the central part 3 as a whole. The force transmission part 4 and the central part 3 are made independently.

[0042] The central portion 3 can be divided into an area surrounded by a two-dot chain line D, that is, a pattern display area 5 when a pattern is drawn therein, and an installation area 6 surrounding the area. The central portion 3 is composed of the same or equivalent material as the material forming the existing photomask.

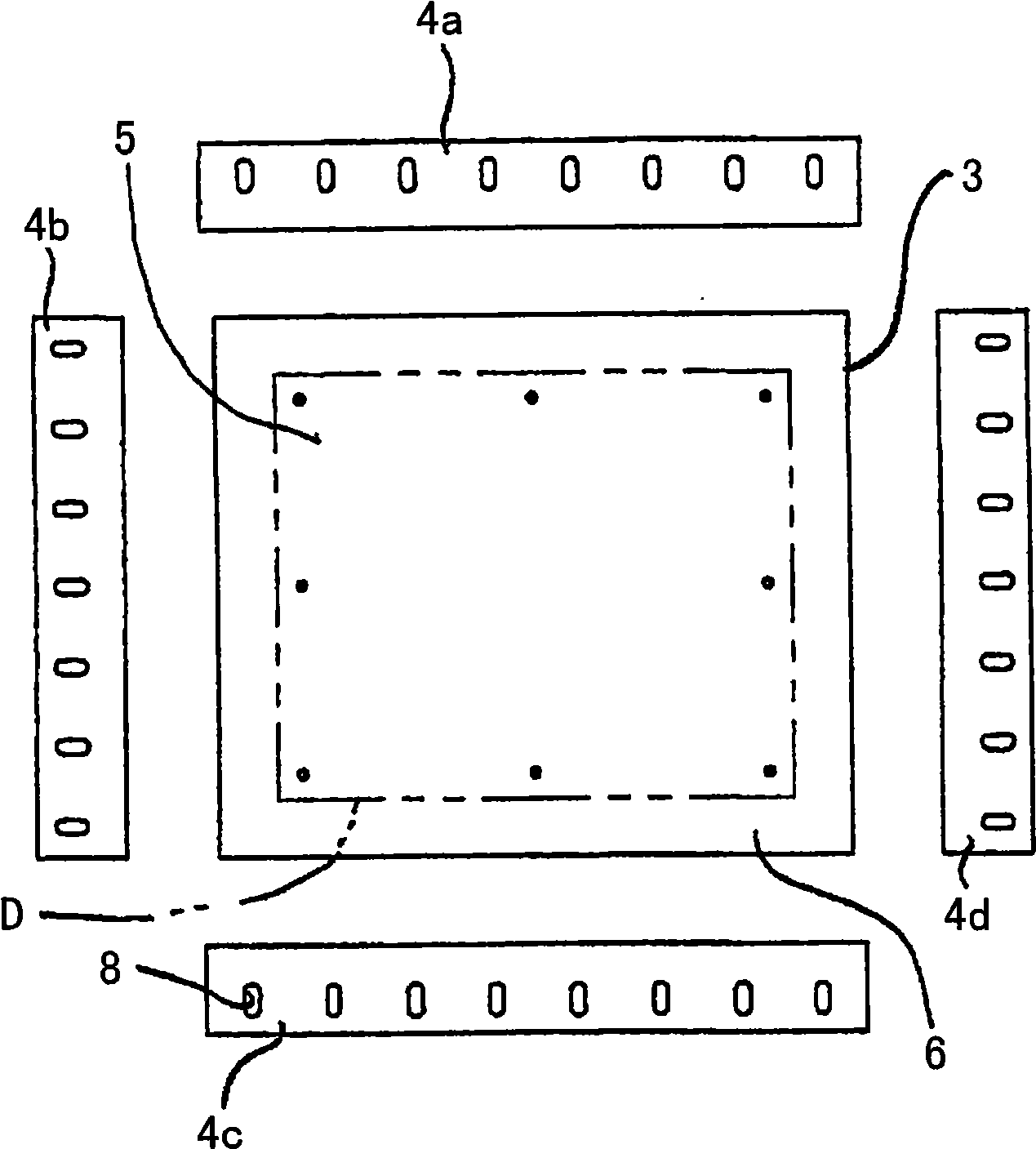

[0043] In this embodiment, as figure 2 As shown, the force transmission part 4 is composed of 4 belt-shaped members 4a-4d independently made on each side of the central part 3. The respective belt-shaped members 4a-4d are joined to each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com