Patents

Literature

96results about How to "No investment required" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

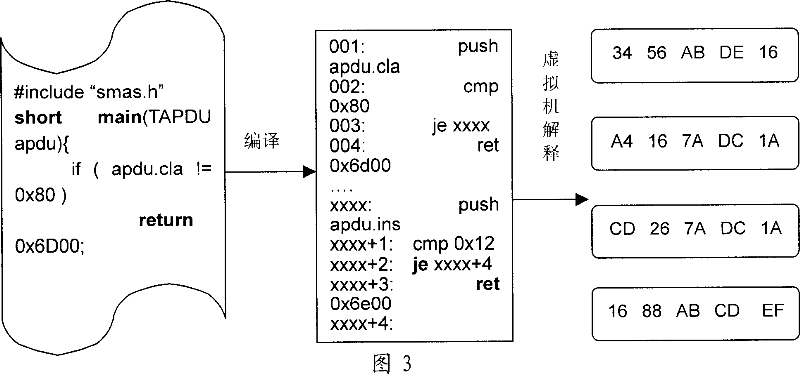

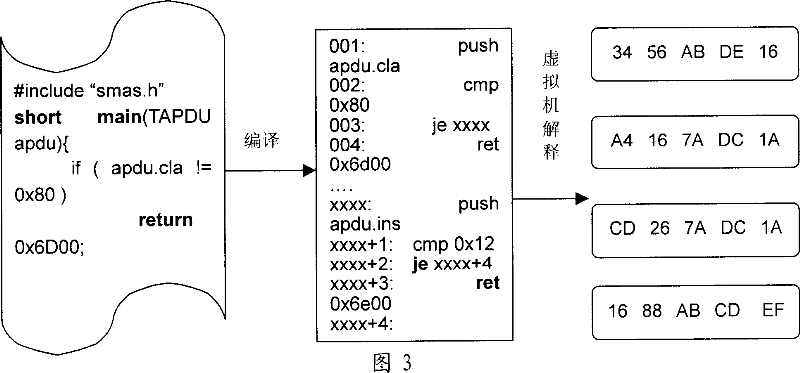

Smart card and method for accessing objects in smart card

ActiveCN101042736AImprove versatilityEasy to createCo-operative working arrangementsSpecific program execution arrangementsControl flowSmart card

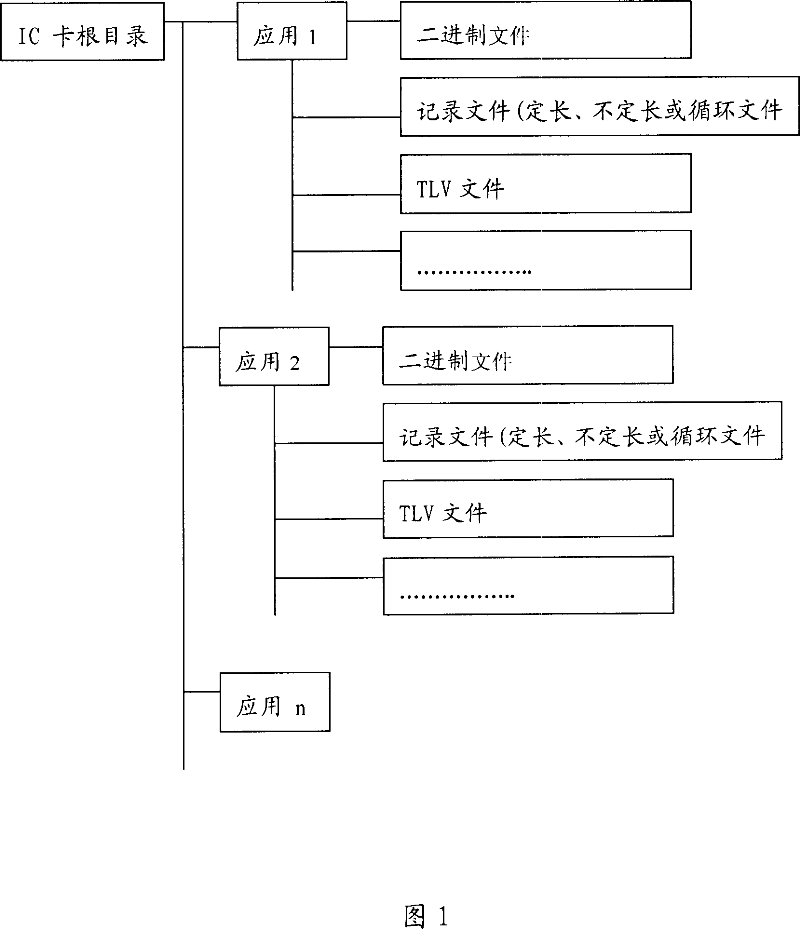

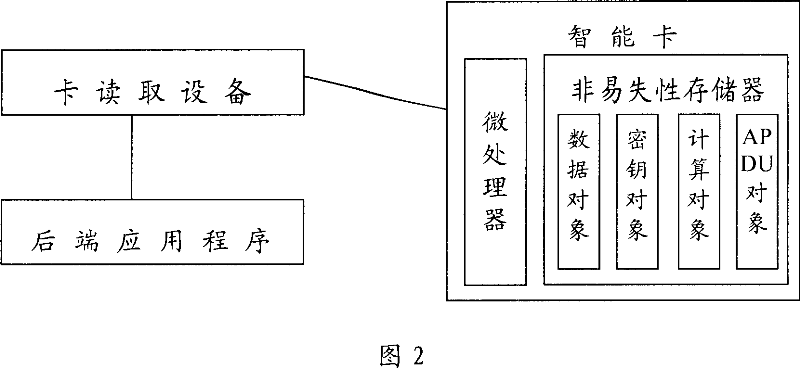

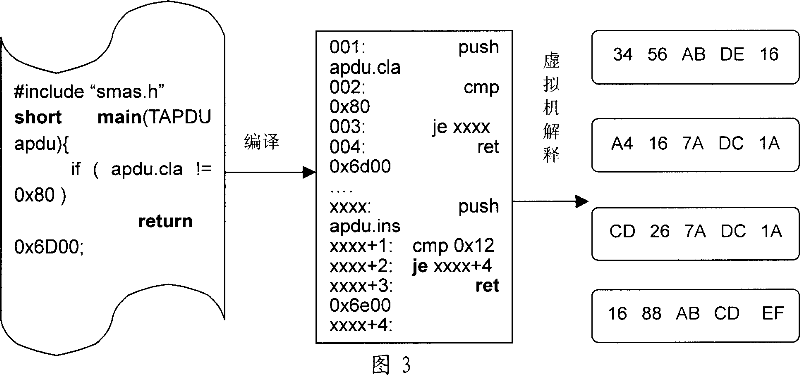

This invention discloses one intelligent card memory subject method by use of capacity device in subject type, which comprises the following steps: testing order parameters and judging its legality and analyzing its detail operation type; analyzing input subject label and judging whether the current application entrance label is same; if yes, then indexing the current entrance; if there is the subject, fulfilling the memory operation flow according to the subject property; due to APDU subject this invention is for each detail application flow.

Owner:CHINA UNIONPAY

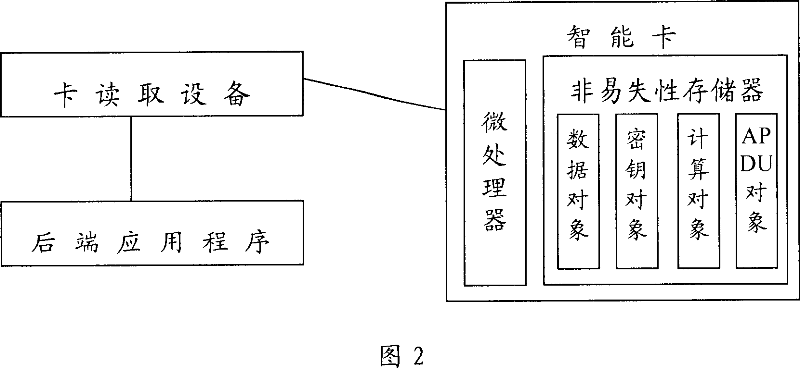

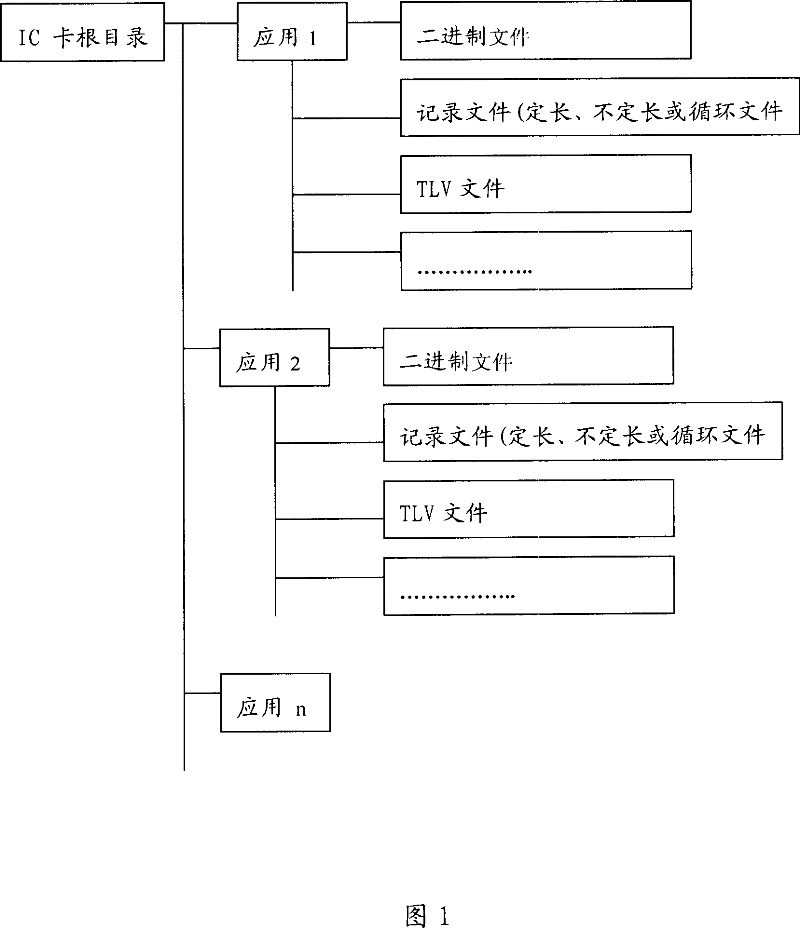

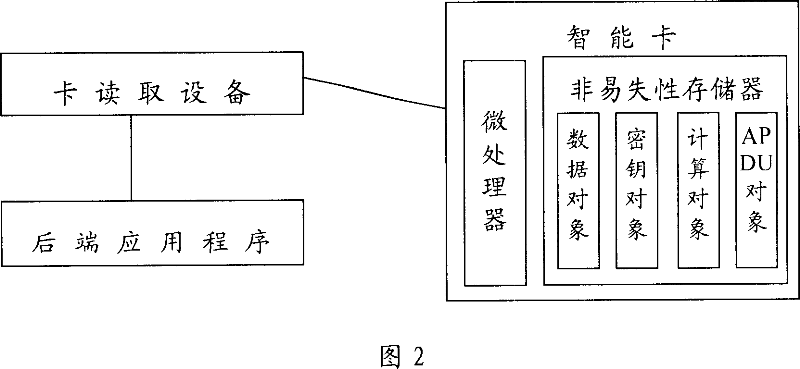

Method for implementing smart card multi-application and data processing apparatus

ActiveCN101042738AImprove versatilityImplement micro-appsCo-operative working arrangementsSpecific program execution arrangementsSmart cardMultiple applications

This invention discloses one method to realize intelligent card multiple application, which comprises the following parts: at least one capacitor to store data on each subject with each one composed of at least one application subject set; operation interface of capacitor to realize common needle subject operation. This invention can use capacitor by intelligent card and subject concept application data to provide common operations for outer process.

Owner:CHINA UNIONPAY

Smart card and method for creating application and insertion objects in smart card

ActiveCN101042737AImprove versatilityImplement micro-appsCo-operative working arrangementsSpecific program execution arrangementsCurrent analysisSmart card

This invention provides one method to establish application to intelligent card composed of capacitor and subject memory data, which comprises the following steps: processing capacitor identifying according to order message data; if it passes, then establishing capacitor into capacitor entrance and analyzing subject label from order message to judge whether the current application entrance label is same; if yes, inserting the current analysis subject into current application entrance list for memory. This invention intelligent card can be suitable for each industries with one common flow.

Owner:CHINA UNIONPAY

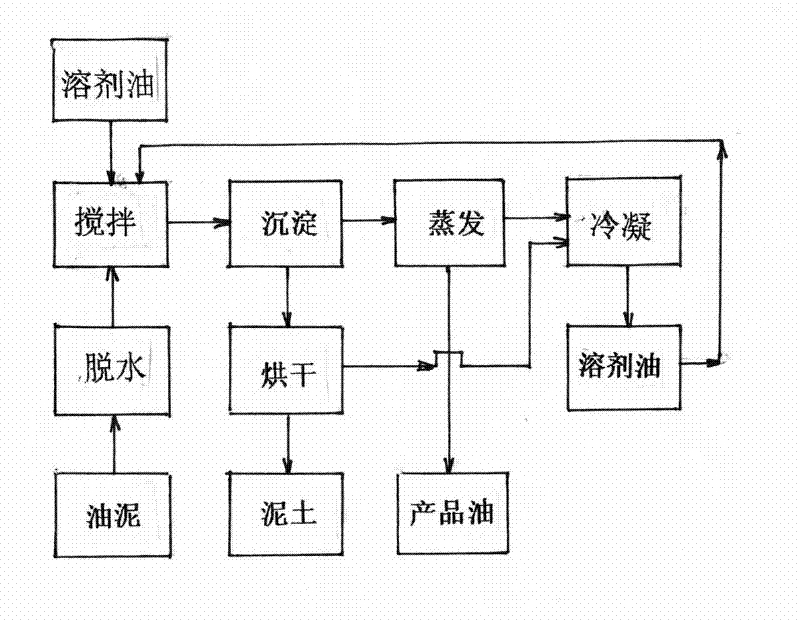

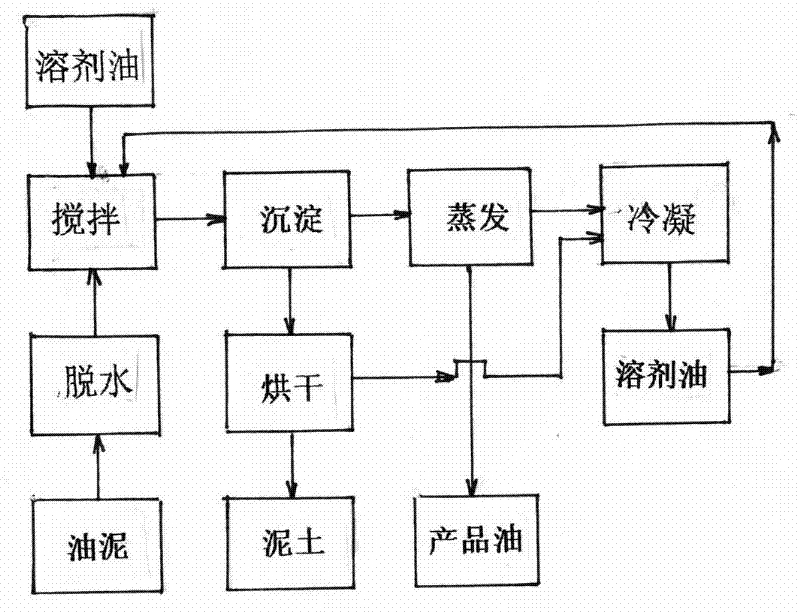

New technology for oil sludge processing

InactiveCN102381821AHigh recovery rateImprove qualityFatty oils/acids recovery from wasteSludge treatment by de-watering/drying/thickeningOil processingFiltration

The invention which belongs to the dangerous waste processing field relates to oil sludge processing and provides a new technology for the oil sludge processing. The technology is mainly characterized in that: after the oil sludge is processed with steps of dehydration, extraction, deposition, evaporation, extraction, pumping filtration, drying and the like, the content of oil in soil is 1% and accords with discharge standards, the total loss of solvent oil is about 1%, the recovery rate of product oil is more than 99%, and no waste gases and no wastewater are discharged. The technology whichhas the advantages of scientific method, mature process, simple equipment and large investment-output benefit and allows great technical problems, environmental protection problems and production safety problems which are difficult to solve for a long time in the dangerous waste processing field to be well solved deserves to be popularized and applied to broad petroleum enterprises, petroleum byproduct enterprises, and plant oil processing and oil product storage and transportation enterprises.

Owner:李廷安

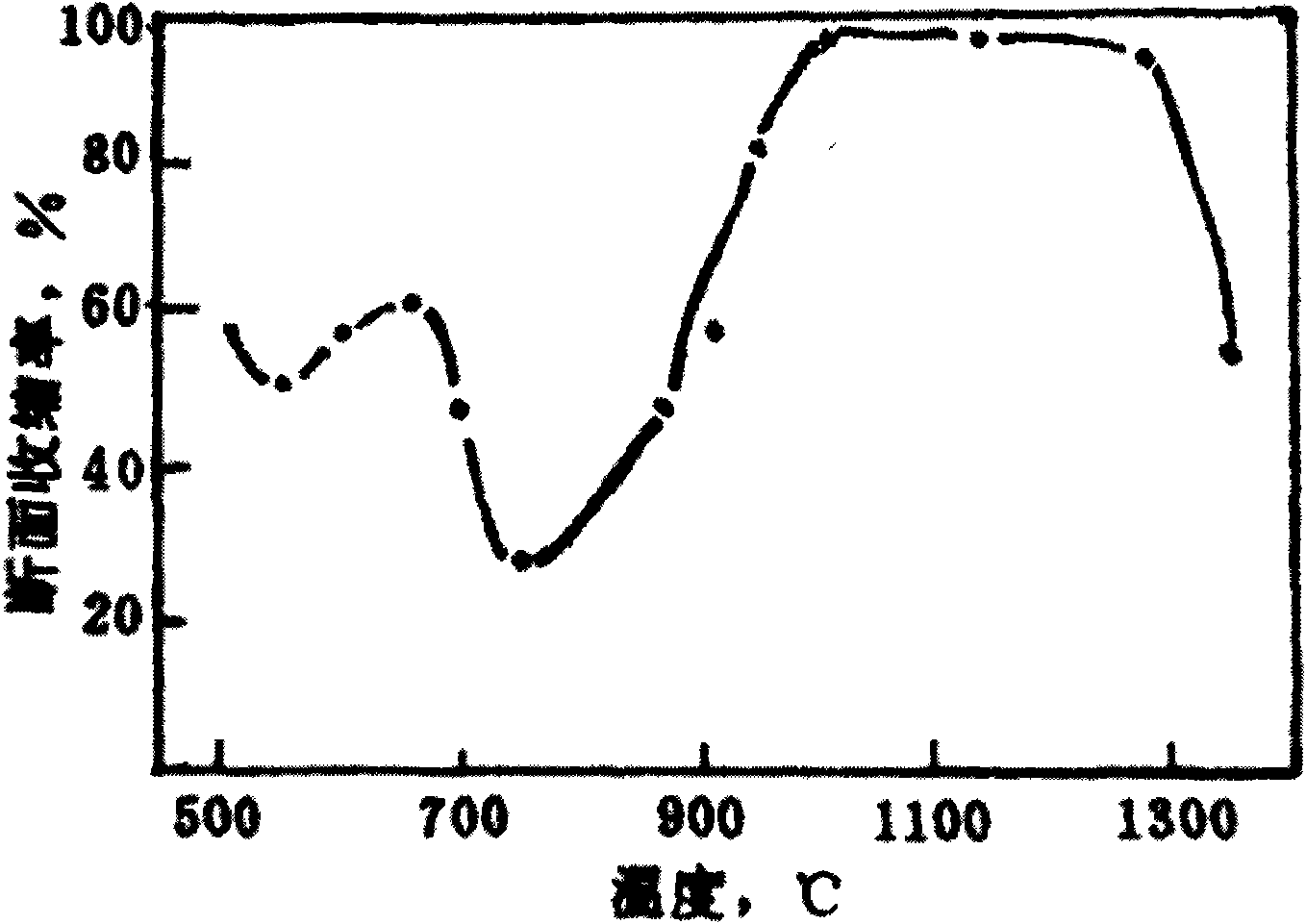

Hot loading method for medium-thick slabs

ActiveCN102861887AAvoid breakingEvenly heatedFurnace typesMetal rolling arrangementsThermodynamicsEngineering

The invention relates to a hot loading method for medium-thick slabs. The method includes: cutting the medium-thick slabs into specific lengths, conveying for rolling, using a traveling vehicle to hang high-temperature slabs to a slow cooling stacking position, placing normal-temperature medium-thick slabs on the high-temperature slabs, stacking in a way that a normal-temperature medium-thick slab is placed between two high-temperature slabs and the topmost piece of each stack is a high-temperature slab for 10-14 hours until each high-temperature slab is cooled to the required uppermost limit of hot loading and each normal-temperature medium-thick slab is preheated to the required lowermost limit of hot loading, and loading the slabs into a heating furnace. Normal-temperature medium-thick slabs are preheated by heat released by high-temperature slabs during slow cooling to reach a surface temperature of more than 400-550 DEG C so as to achieve hot loading. Waste heat of the high-temperature slabs are utilized to the maximum limit and fine energy conservation effect is achieved. A novel method for preheating normal-temperature slabs outside the furnace is created, and fracture of the slabs due to normal-temperature slabs are heated in the heating furnace can be avoided.

Owner:SGIS SONGSHAN CO LTD

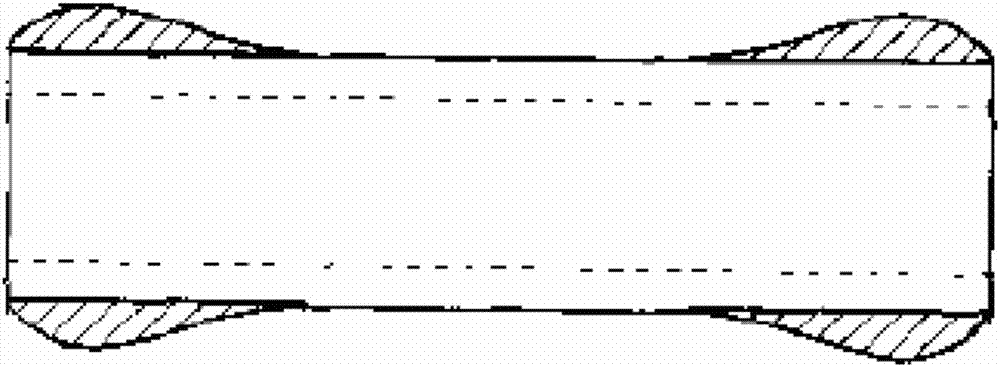

Manufacturing method for reducing edge defects of hot-rolled strip steel

InactiveCN107096795ANo change in processNo change logic controlMetal rolling stand detailsMetal rolling arrangementsProcess systemsStrip steel

The invention relates to a manufacturing method for reducing edge defects of hot-rolled strip steel. The manufacturing method comprises the following steps: carrying out heating control, and heating a slab to 1190-1230 DEG C; setting the width model load, calculating a rough rolling width model according to the thickness and width of the slab and a finished product, and setting the rolling reduction of each pass of a rough rolling vertical roll and a flat roll; carrying out rolling by the rough rolling vertical roll, setting the opening degree of a rough rolling machine E1 and a rough rolling machine E2 according to the model calculation result, and carrying out slab width control; and carrying out rolling on the slab subjected to rolling by the vertical roll through the flat roll, and reducing the thickness of the slab. According to the manufacturing method, process and control optimization are carried out on the basis of existing equipment, so that equipment investment is avoided; the existing process system and logic control are not changed, so that the current production process control is not affected; and adverse effects on other quality indexes such as width control are avoided.

Owner:NINGBO IRON & STEEL

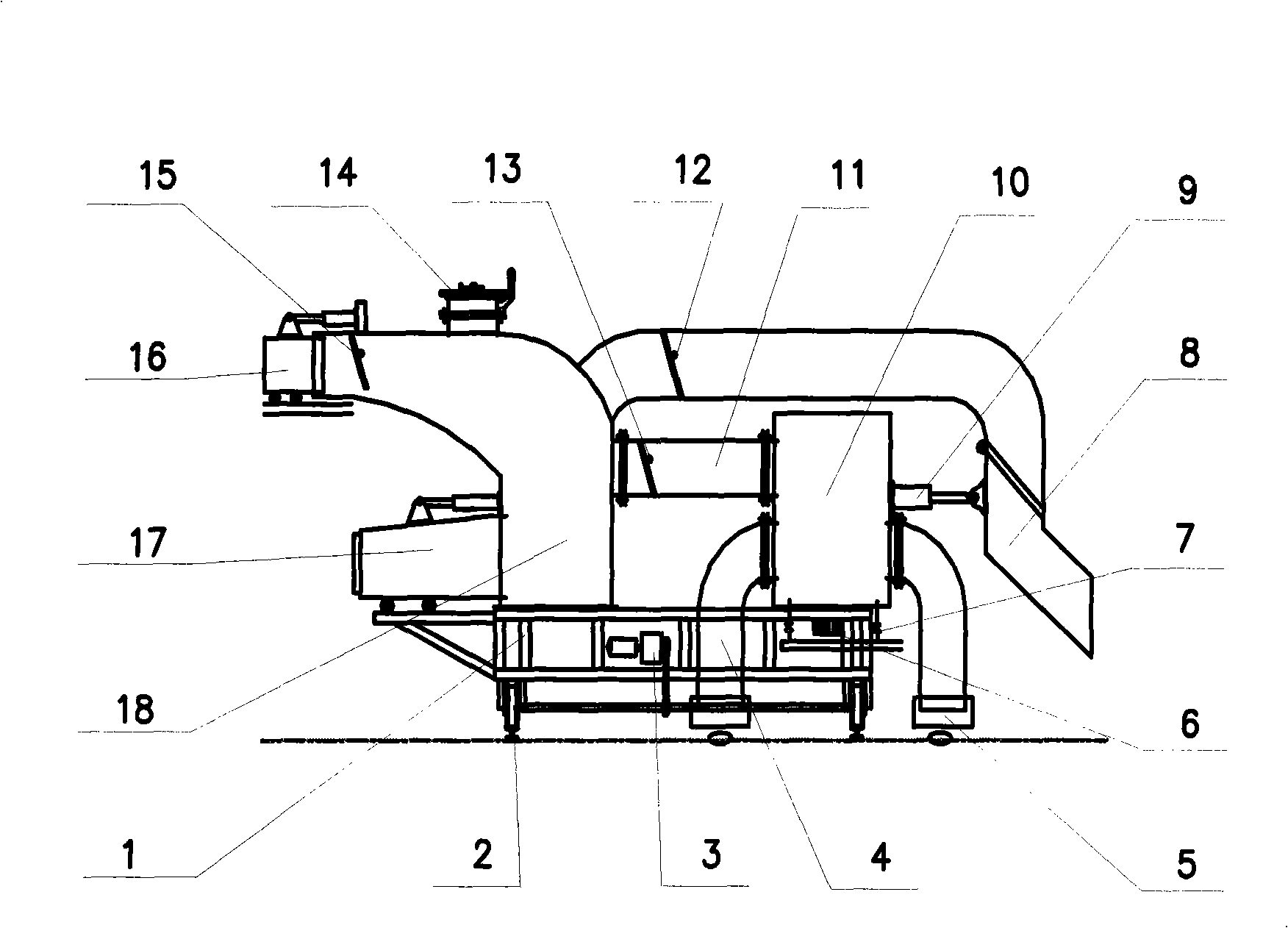

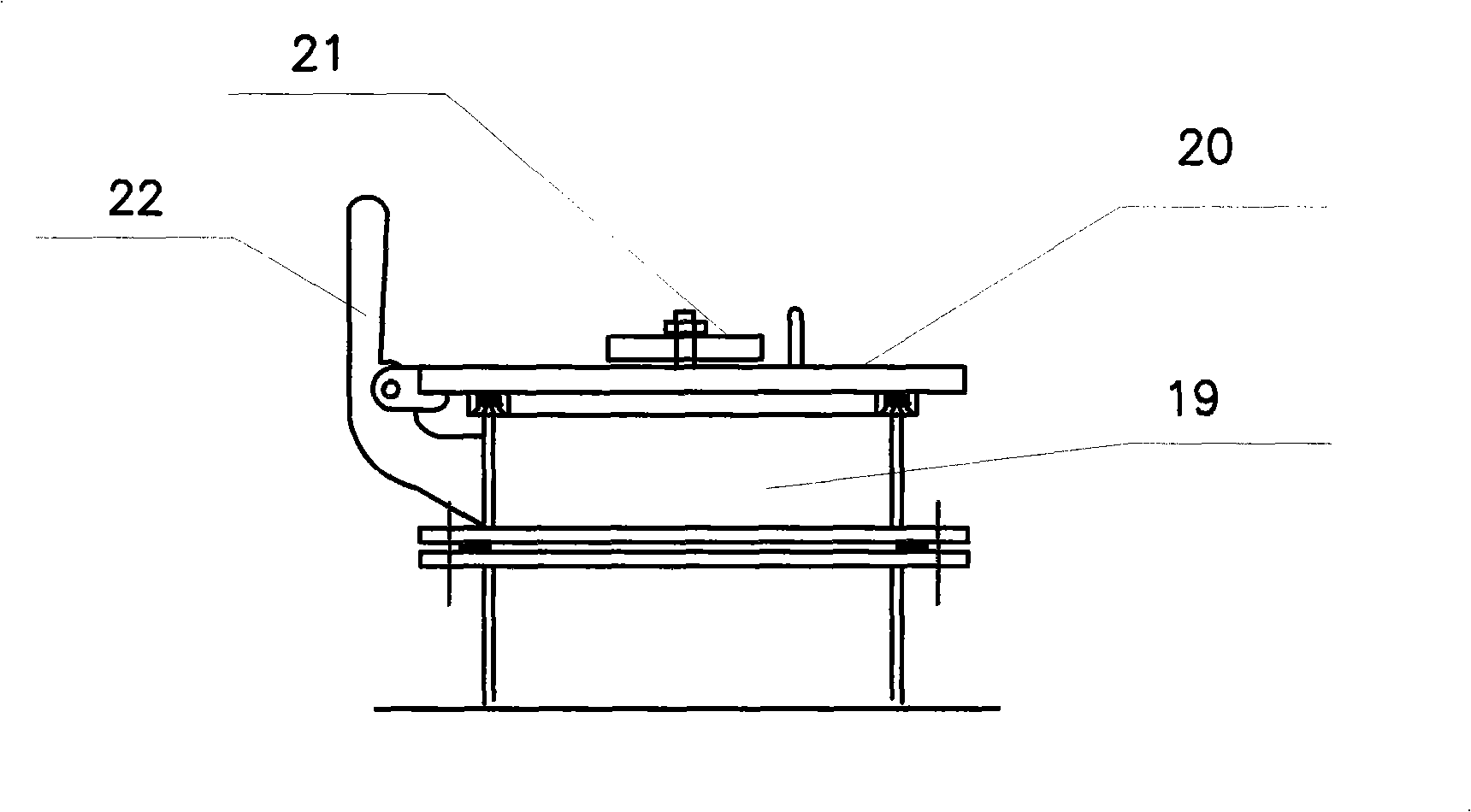

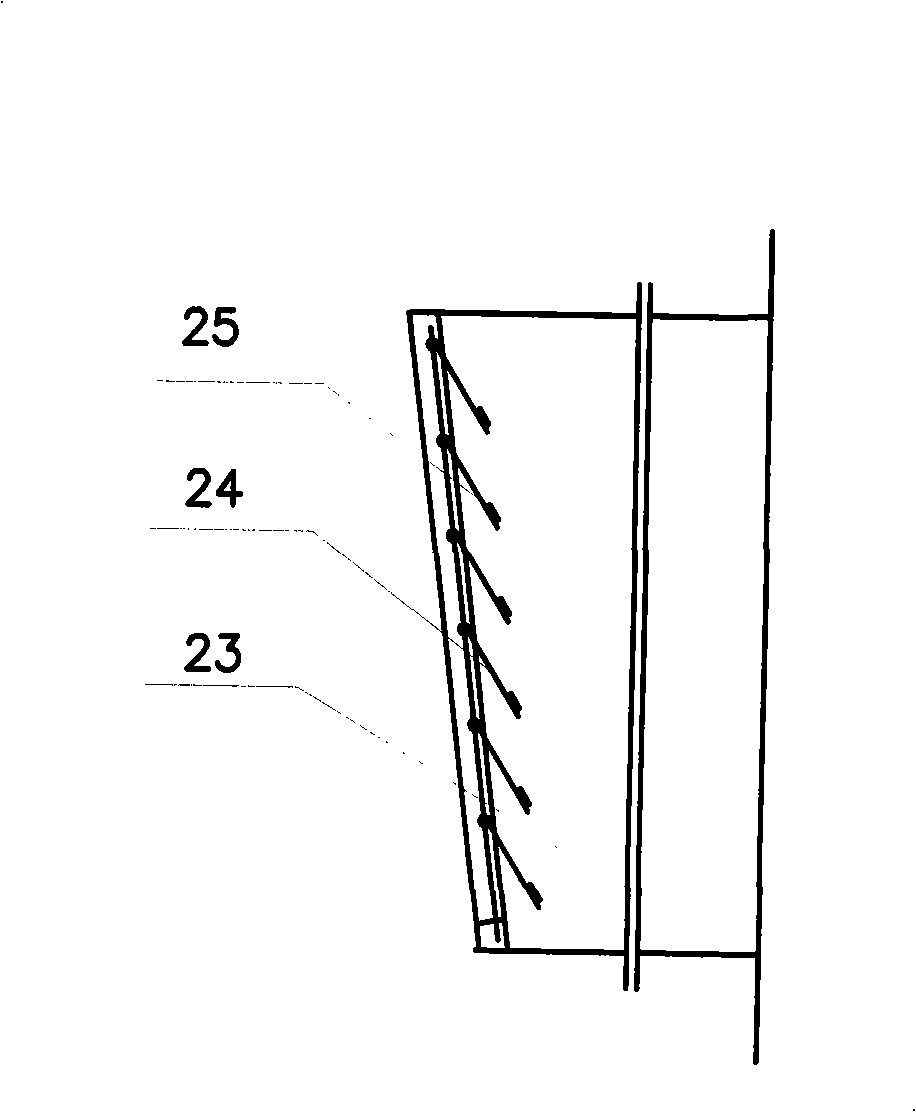

Technique and device for removing dust of coke oven by boiler system

InactiveCN101260304AIncrease capture rateEasy to operateCoke ovensDirt cleaningCombustion chamberCoke oven

The invention relates to a technology and equipment which utilize a boiler system to eliminate fume and dust from a coking oven. A movable dust-collecting vehicle is arranged on the top of the coking oven to collect the fume and dust escaping during the process of coke collecting and coal feeding, and the fume and the dust undergo primary burning in a combustion chamber, the coke foam is separated and then led inside the boiler for sufficient combustion, which not only utilizes the heat energy but also achieves profound dust-elimination and desulfurization for the fume through the configuration facilities of the boiler so as to accomplish the aim of clean discharge. The technology provided by the invention is characterized in simple operation, investment reducing, no occupation of area, and good effect in smoke-removing and dust-elimination, which conforms to national 2nd standard of discharging. The invention can replace the ground dust extract station. In order to implement the fume collection described in the technology, the specific dust-collecting vehicle is designed. The invention is suitable for the factory with an established complete boiler system to carry out the operation of smoke-removing and dust-elimination.

Owner:SHANXI FAXIN GROUP

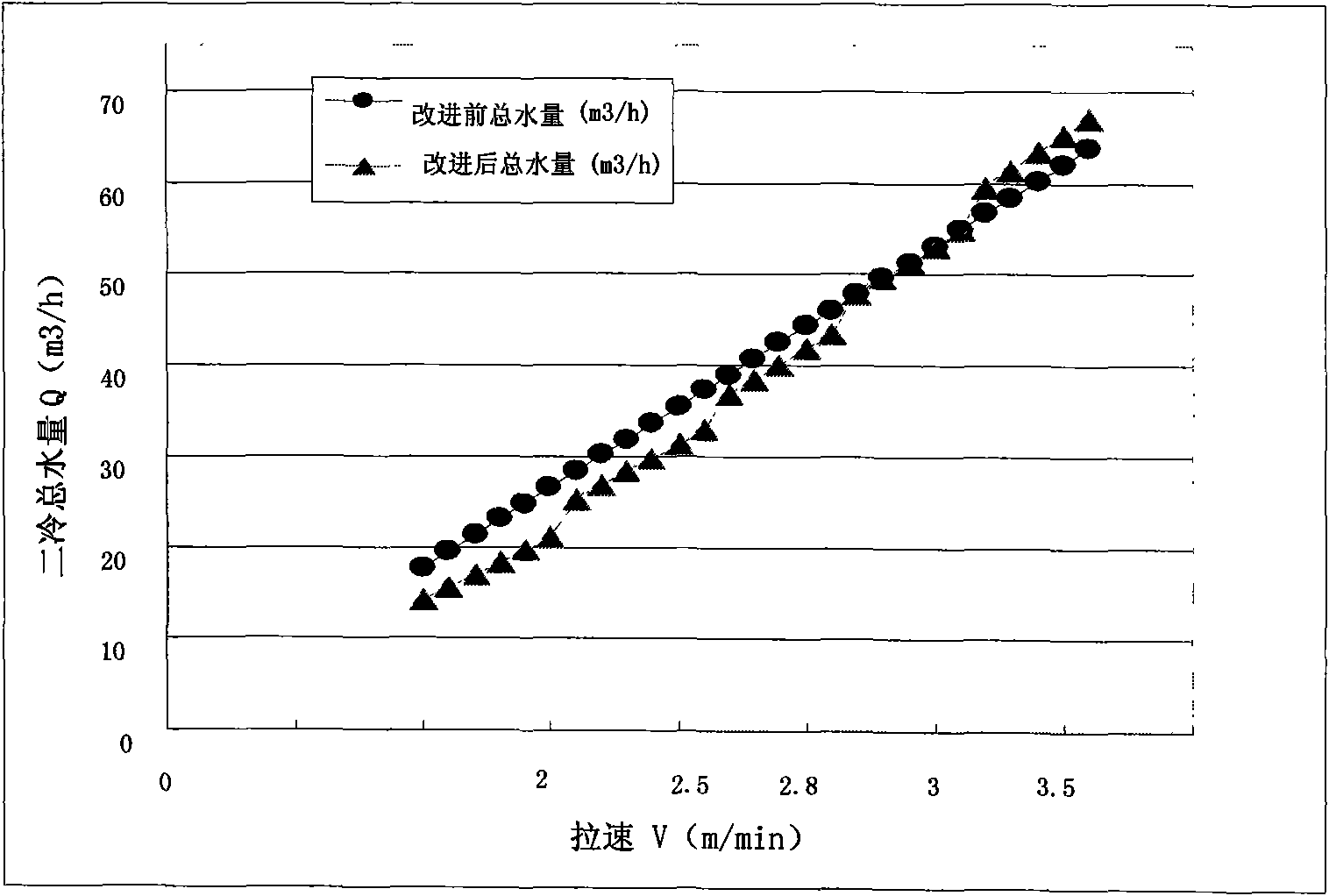

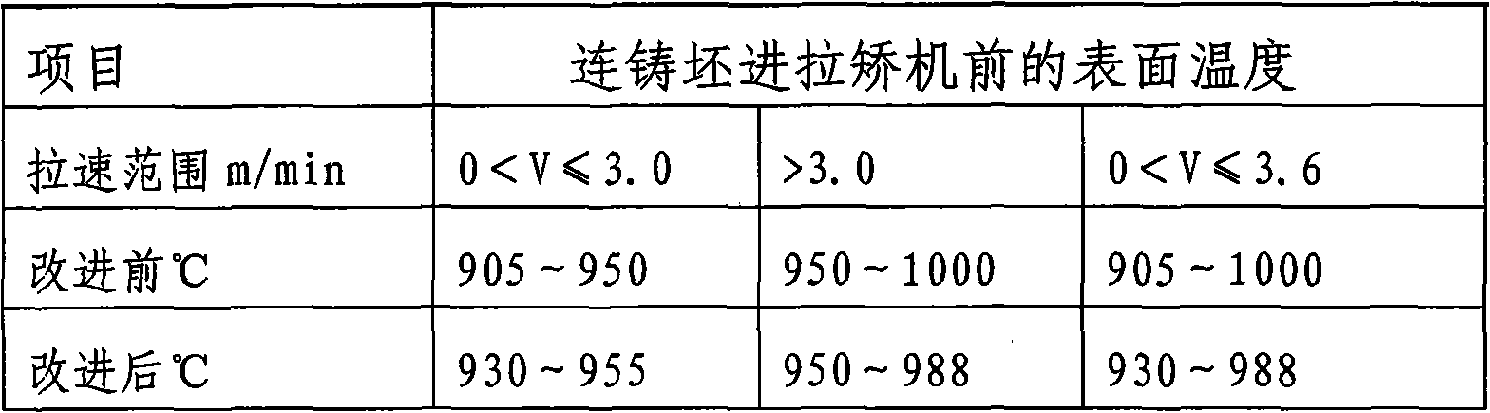

Variable water ratio control method of secondary cooling of billet caster

The invention discloses a variable water ratio control method of the secondary cooling of a billet caster which can reduce the inner crack rate of casting blanks. The control method can realize that the water flow rate delta and the total amount of water Q increase by stages with the increasing of the casting speed V of casting blanks, namely when the casting speed V of casting blanks is 0-2m / min,the water flow rate delta is 1.35-1.39L / kg, the functional relationship between the secondary cooling total amount of water Q and the casting speed V of casting blanks is Q = 13.8-14.3V; when the casting speed V of casting blanks is 2-2.4m / min, the water flow rate delta is 1.58-1.64L / kg, the functional relationship between the secondary cooling total amount of water Q and the casting speed V of casting blanks is Q = 16.2-16.8V; when the casting speed V of casting blanks is 2.4-2.8m / min, the water flow rate delta is 1.67-1.71L / kg, the functional relationship between the secondary cooling totalamount of water Q and the casting speed V of casting blanks is Q = 17.1-17.5V; when the casting speed V of casting blanks is 2.8-3.0m / min, the water flow rate delta is 1.73-1.76L / kg, the functional relationship between the secondary cooling total amount of water Q and the casting speed V of casting blanks is Q = 17.7-18.1V; and when the casting speed V of casting blanks is 3.0-3.6m / min, the waterflow rate delta is 1.8-1.86L / kg, the functional relationship between the secondary cooling total amount of water Q and the casting speed V of casting blanks is Q = 18.5-19.1V.

Owner:XINJIANG BAYI IRON & STEEL

Formaldehyde elimination agent and preparation method thereof

InactiveCN101037576AImprove elimination effectReduce production efficiencyNon-macromolecular adhesive additivesDispersed particle separationStable stateFiber

The invention discloses a formaldehyde eliminating agent and preparing method thereof. Weight proportioning of raw material for the formaldehyde eliminating agent is: 100-300 quotient of formaldehyde, 150-700 quotient of urea, 50-500 quotient of water, 10-80 quotient of accelerant, 0.1-5 quotient of stabilizer, and 1-20 quotient of catalyst. The preparing method includes steps: adding each component into reaction kettle in turn, stirring the mixture at temperature of 20-50 DEG C until equally mixed and whole dissolved, adjusting pH between 7.5-9.0, and stirring until stable. Advantages of the formaldehyde eliminating agent are: preparing cost is low, formaldehyde eliminating effect is evident and permanent when the formaldehyde eliminating agent is used with urea-formaldehyde resin glue or melamine modified urea-formaldehyde resin glue for synthetic plate of incompetent formaldehyde releasing amount and E2 level synthetic plate, making formaldehyde releasing amount of incompetent and E2 level middle / high density fiber board reach to E2 and E1 level separately and observably reducing preparing cost of the middle / high density fiber board without reducing mechanics capability of the synthetic plate.

Owner:EVERFIRST WISEFUND TECH BEIJING

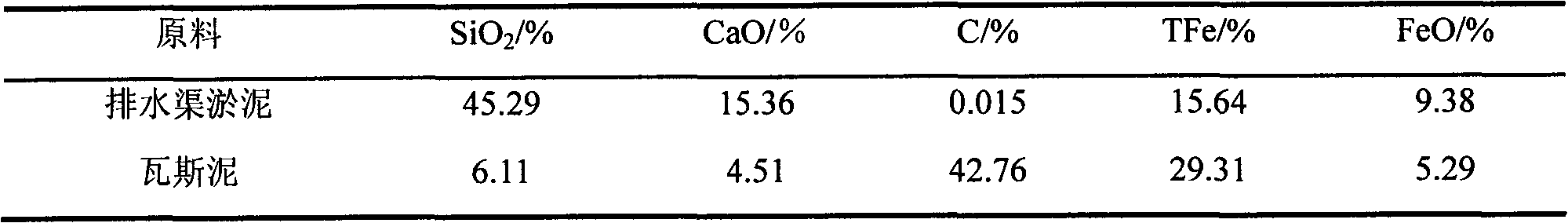

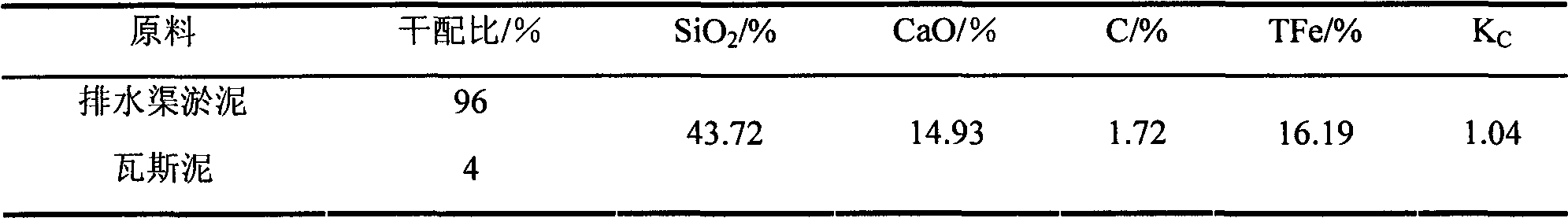

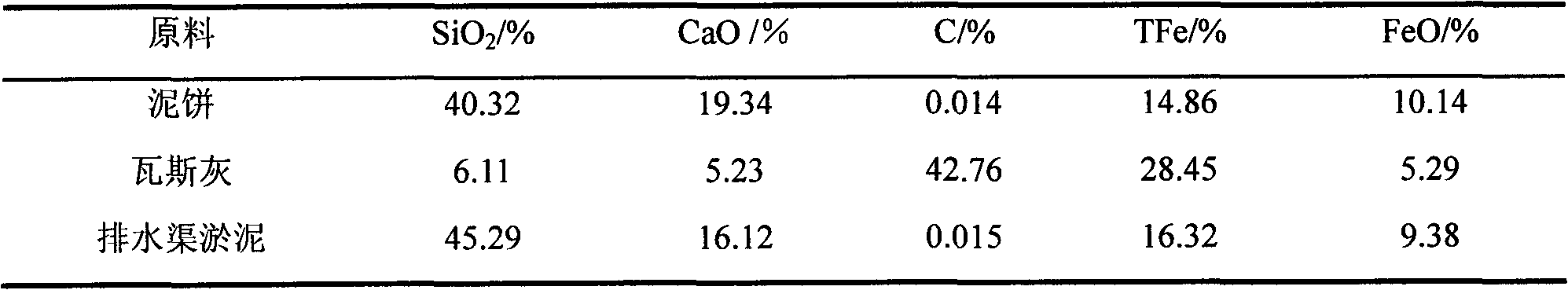

Converter slag modifier and manufacture and using method thereof

ActiveCN102719575AReduce free calcium oxide contentIncrease the scope of applicationManufacturing convertersRecycling and recovery technologiesSludge cakeChemical composition

The invention provides a converter slag modifier using low-iron wastes as raw materials, a manufacture method and a using method thereof. The modifier is a mixture composed of one or several of the following materials: press-filtered sludge cakes through metallurgy waste water treatment, drainage ditch sludge, gas mud and gas ash, and main chemical compositions simultaneously meet the following conditions by weight percentage: 27% to 99.9% of SiO2, 0.01% to 25% of CaO and 0.01% to 50% of TFe. A carbon excess coefficient Kc is 1 to 8. The manufacture method of the converter slag modifier comprises drying, proportioning, mixing, and screening to obtain a finished product. The using method of the converter slag modifier comprises feeding, slagging, slag granulating, etc., thereby making a f-CaO of the converter slag less than or equal to 1.5%, and fulfilling a stable treatment of the converter slag.

Owner:ANGANG STEEL CO LTD

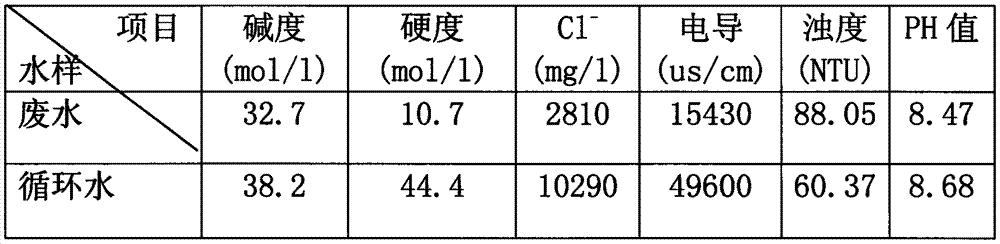

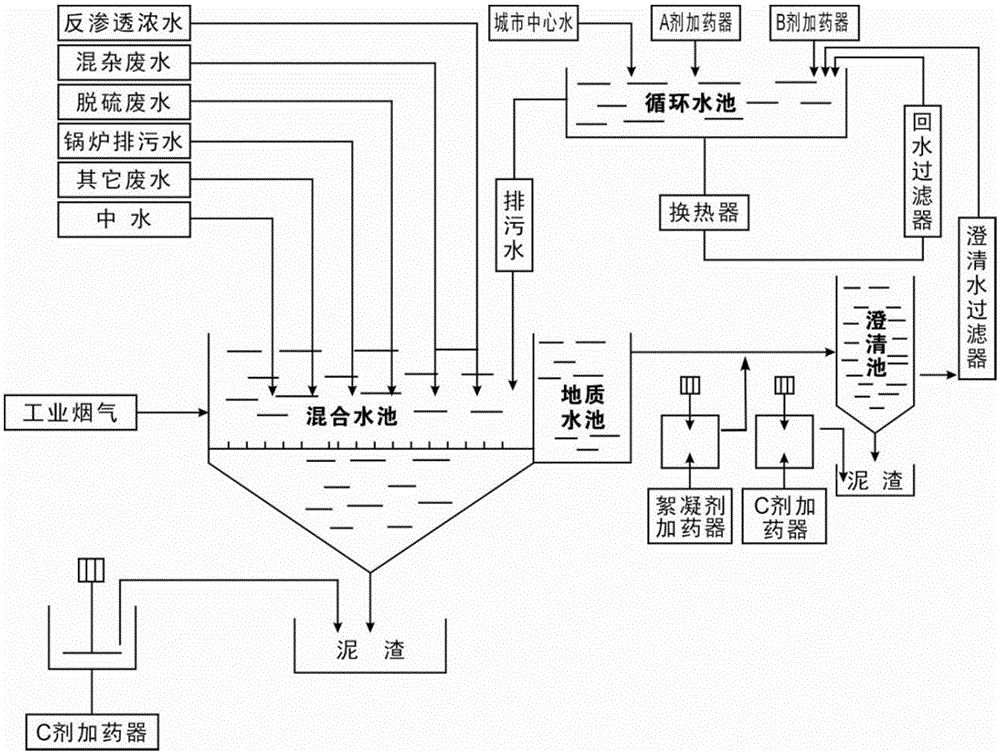

Chemical agent capable of completely recycling power plant wastewater into circulating cooling water and preparation method of chemical agent

InactiveCN104326578ANo investment requiredAchieving zero emissionsSpecific water treatment objectivesTreatment using complexing/solubilising chemicalsSludgeWastewater

The invention discloses a chemical agent capable of completely recycling power plant wastewater into circulating cooling water. The chemical agent is characterized by comprising the following components in percentage by mass: 20-50% of a scale inhibitor, 15-60% of a dispersant, 10-40% of a sludge modifier, 5-10% of a pre-filming agent, 5-10% of a corrosion inhibitor, 5-10% of an anti-settling agent and the balance of water. The chemical agent meets the standard specified by DL / T806-2002 Corrosion Inhibitor for Power Plant Circulating Cooling water. Compared with the prior art, the circulating cooling water is directly injected into a circulating water system with no addition of facilities, no need of investment and no energy consumption, the circulating water system is not scaled or corroded for many years, inorganic solids and sludge formed in the running process can be cleared in the overhaul or pumped by a sludge pump and dried in air for filling pit or paving the road and thus the zero emission of the power plant circulating water system is achieved.

Owner:董升

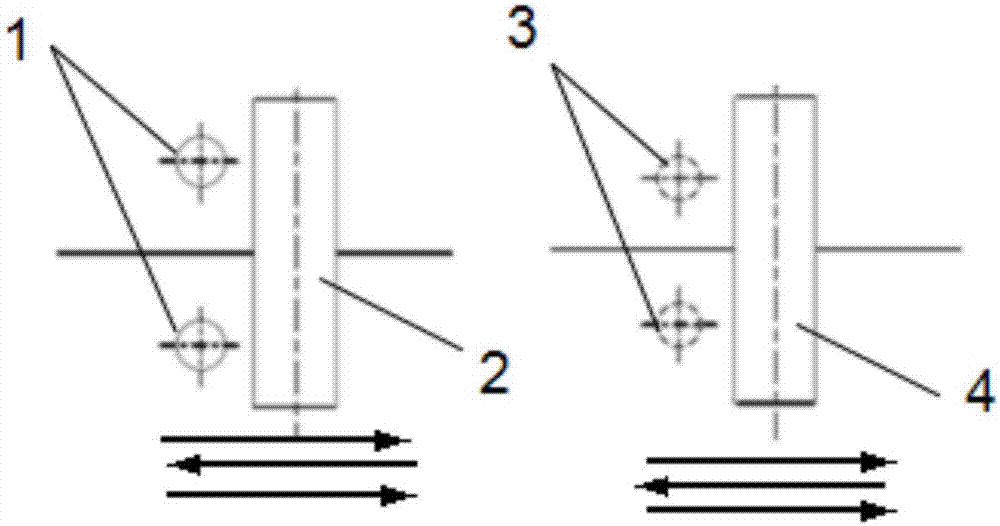

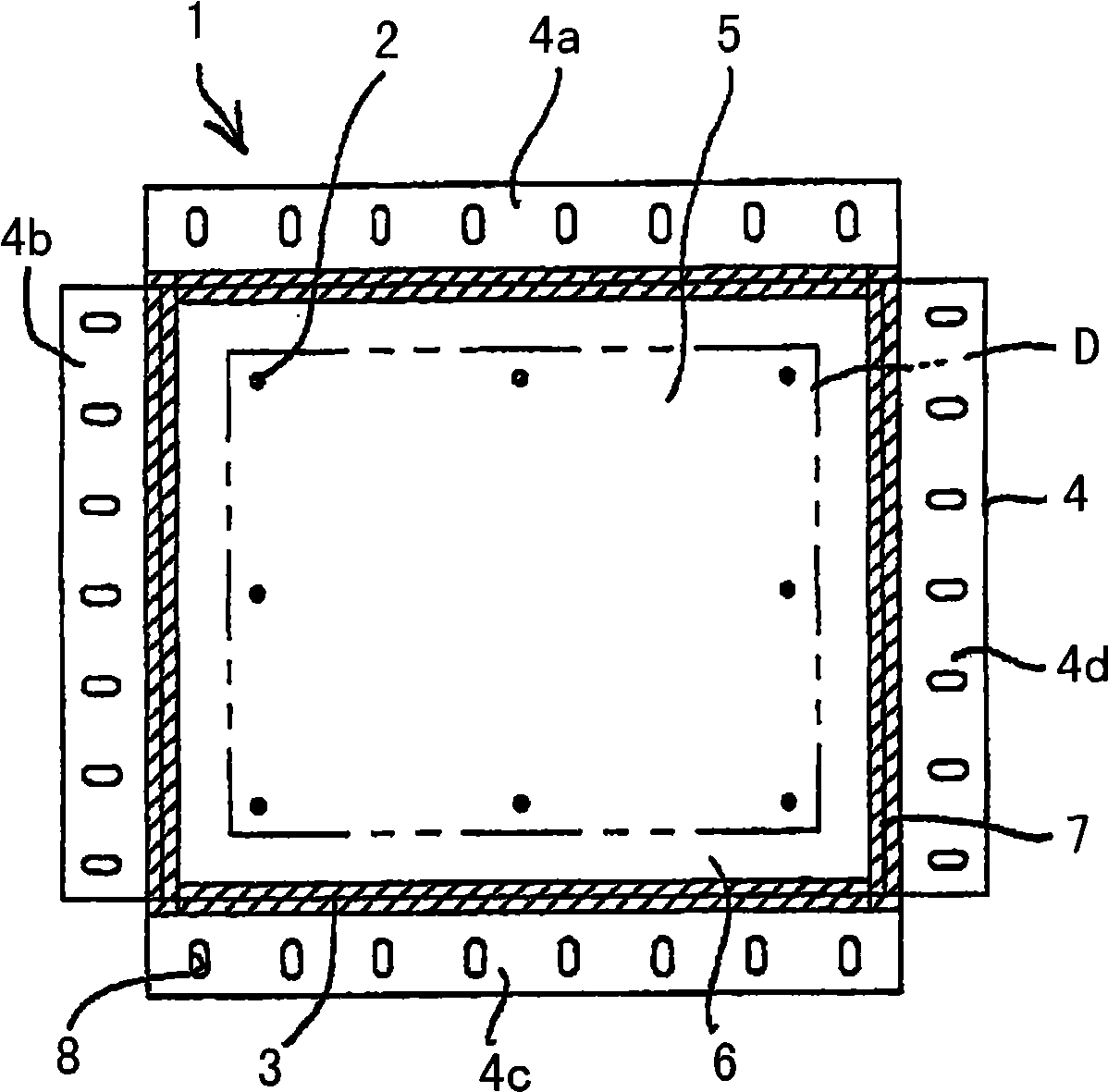

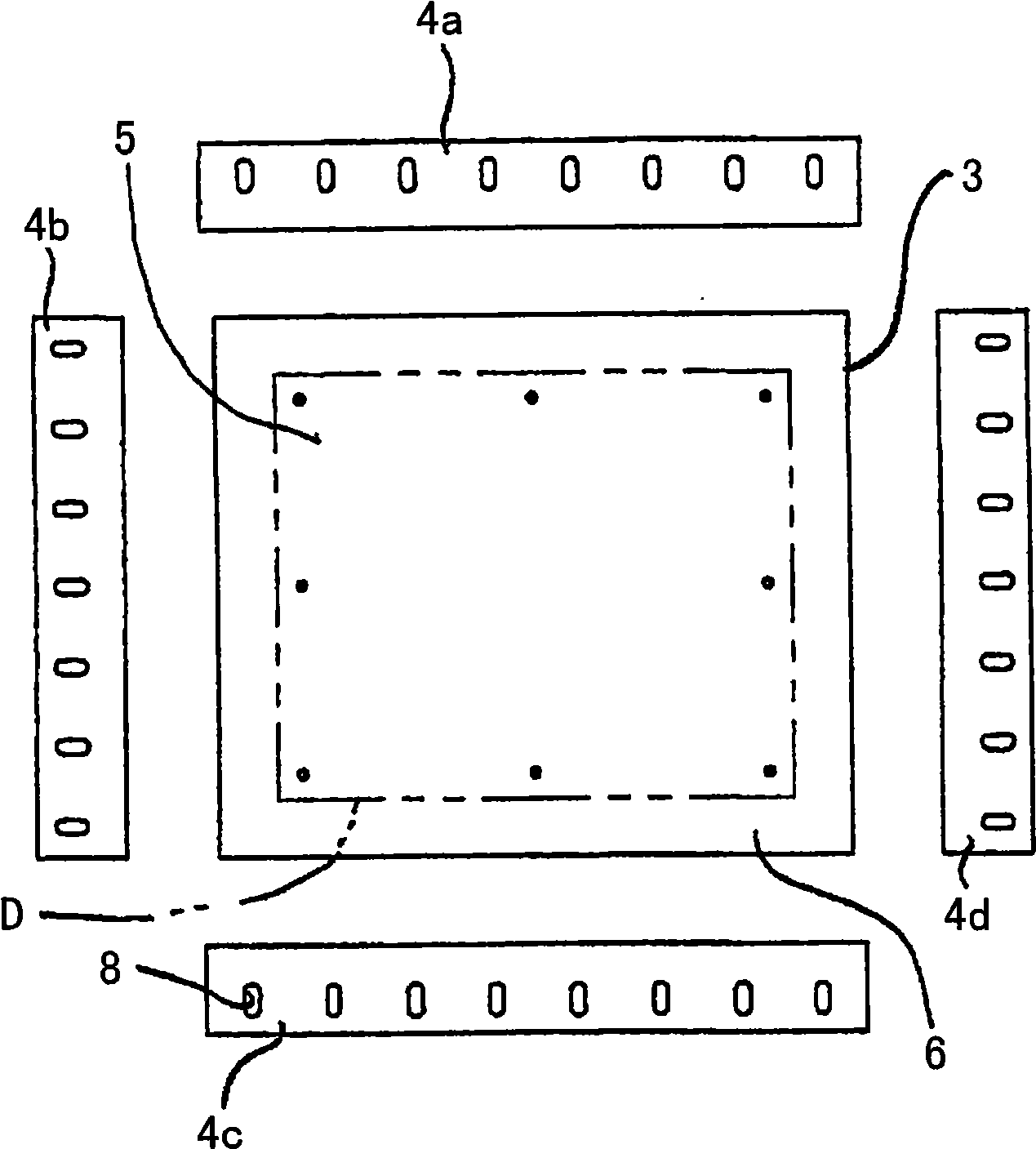

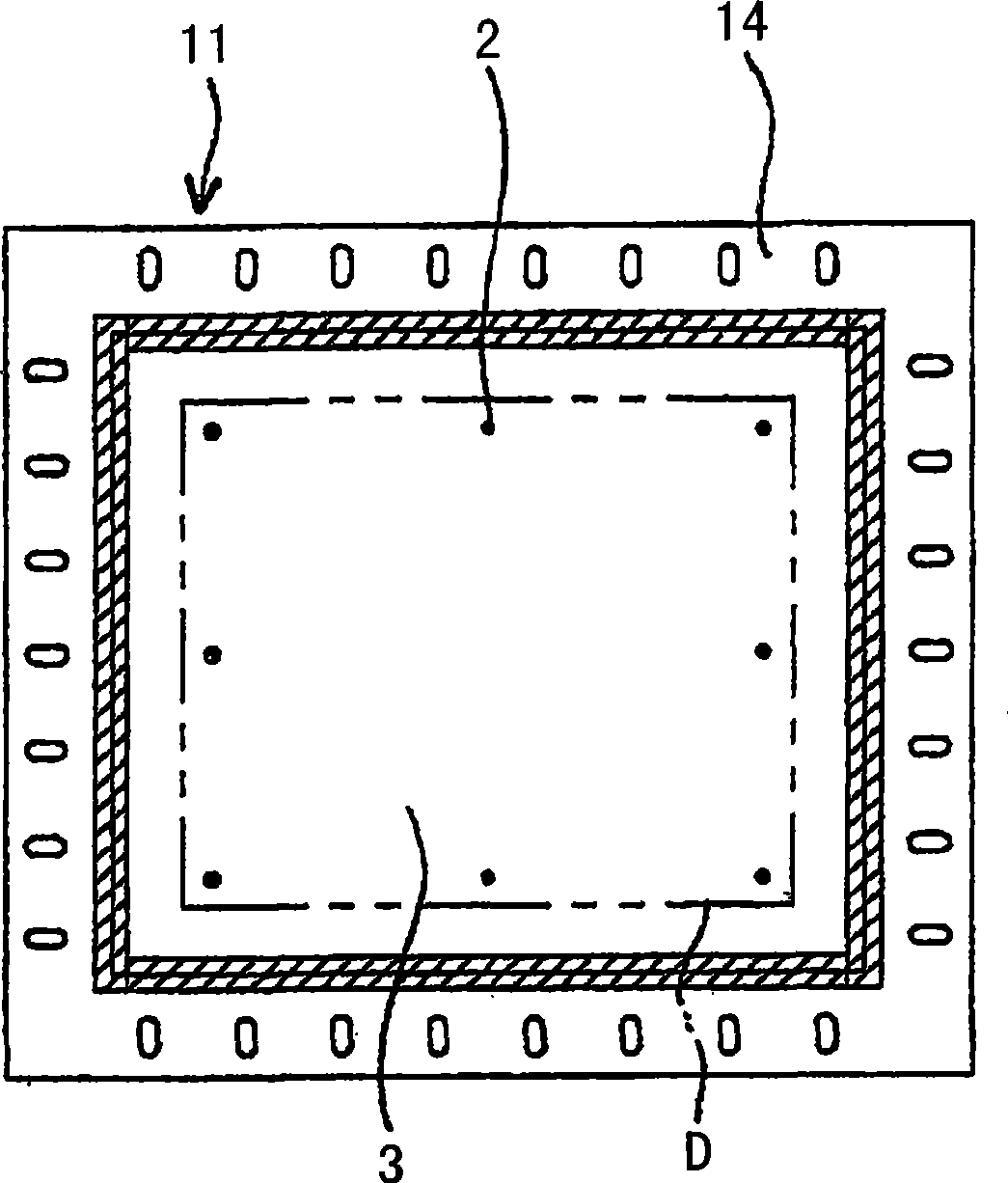

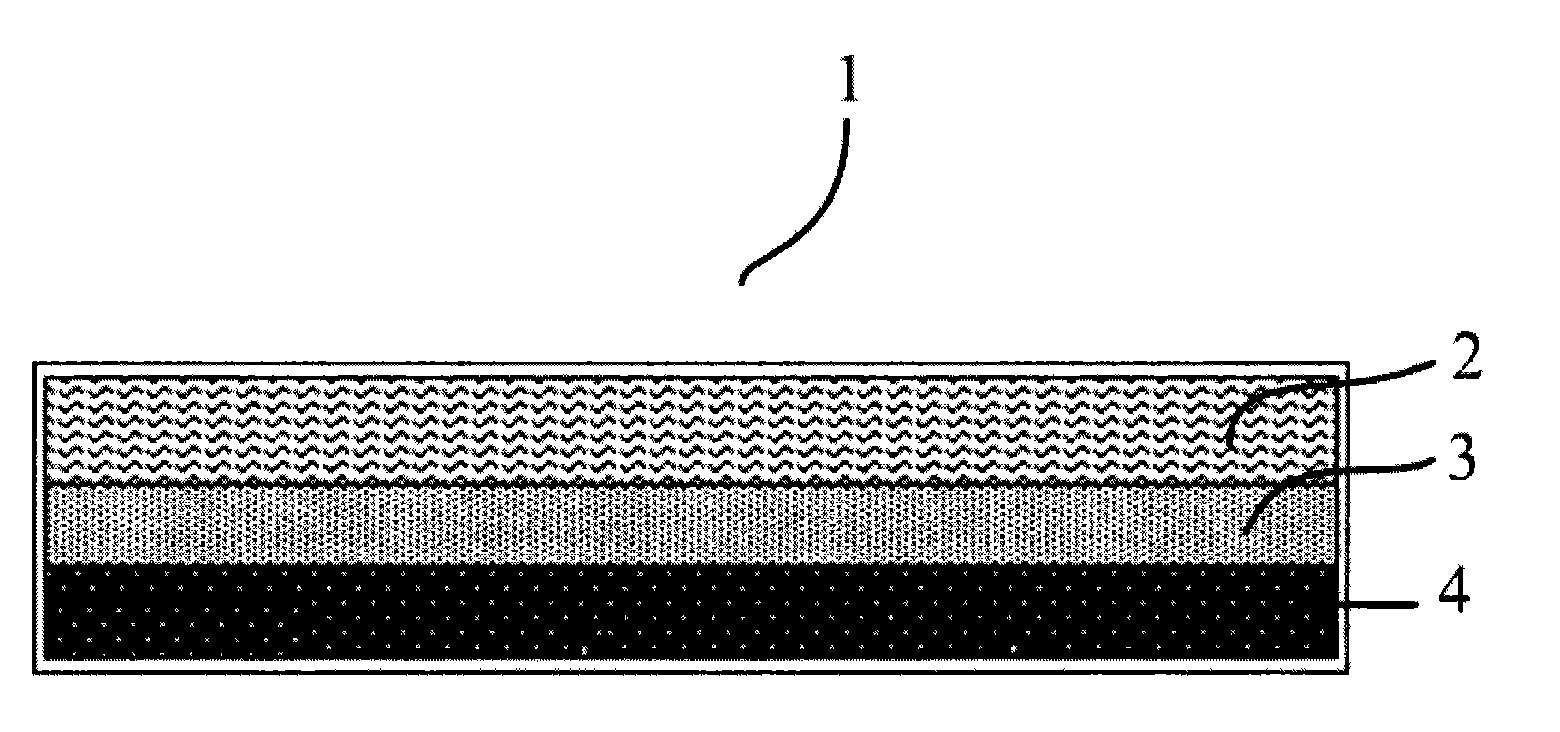

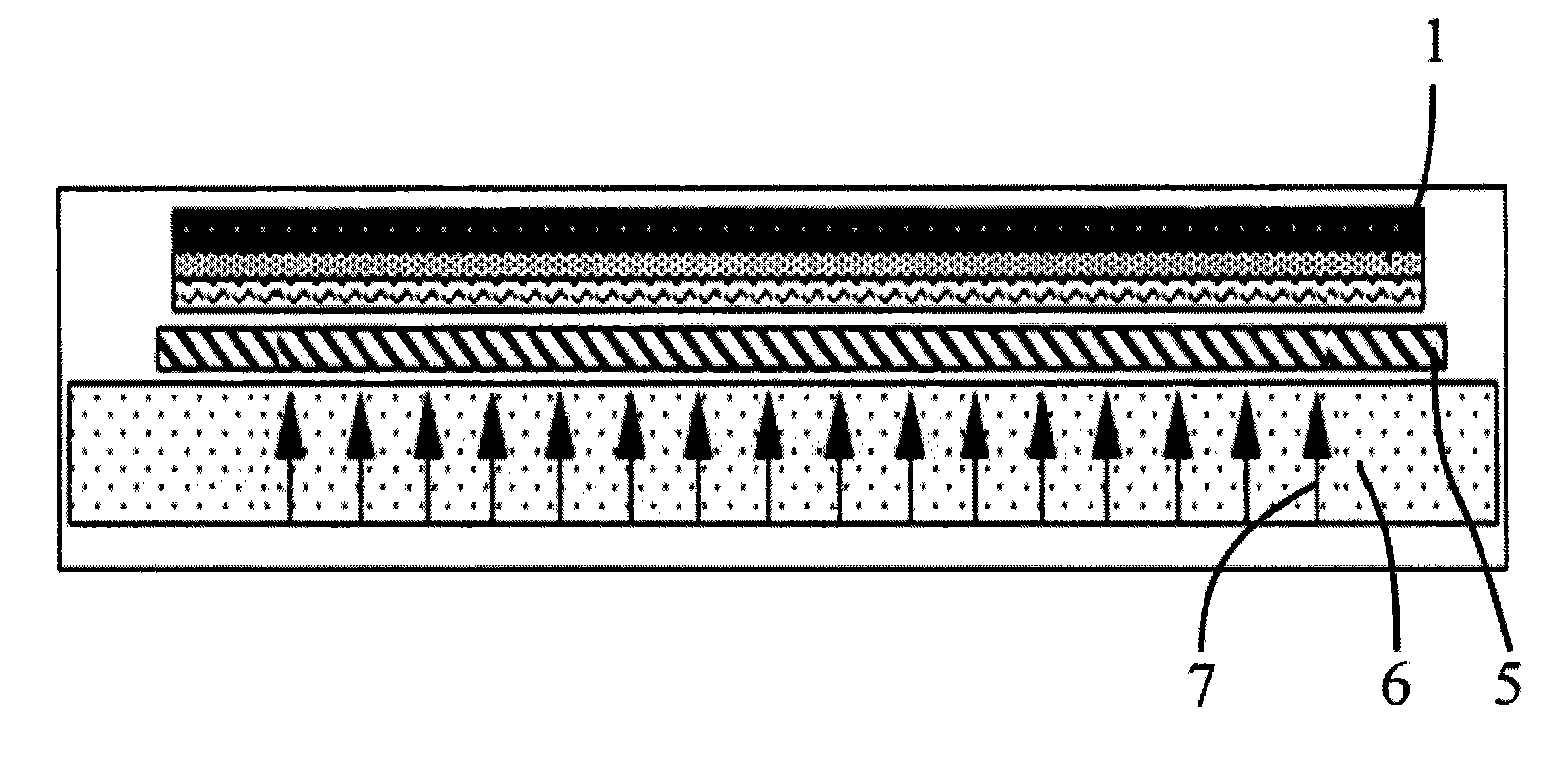

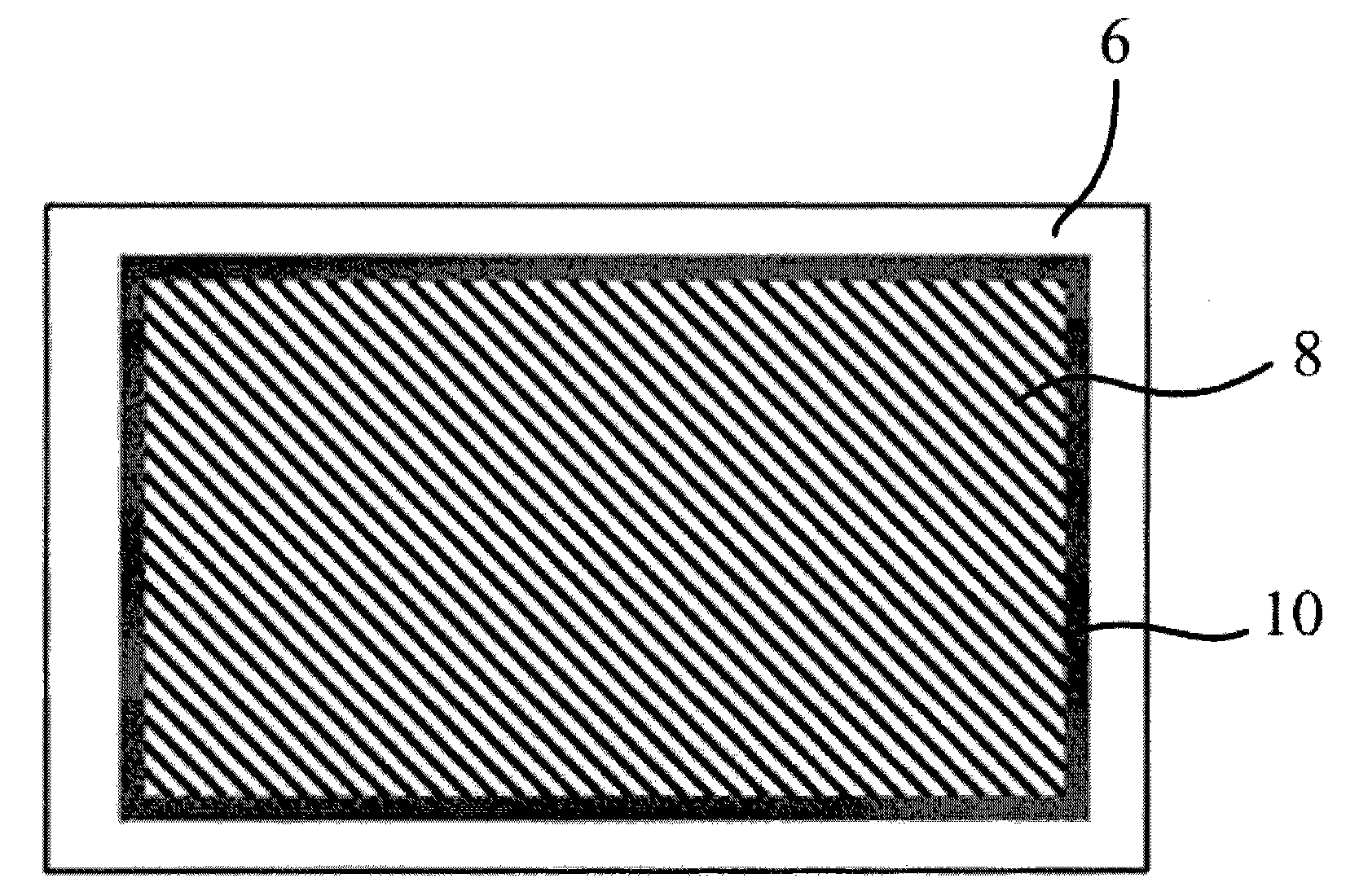

Optical mask for exposure

InactiveCN101482695AReduce partReduce production costPhotomechanical exposure apparatusMicrolithography exposure apparatusEngineeringPhotomask

The invention relates to a photomask, which is formed by dividing the photomask into a central part depicted with patterns and its surrounding force transfer parts, then bonding, so that it can reduce material costs and avoid investment in new facilities. The photomask (1) is divided into a central part(3) including a pattern display area (5), and a force transmission part (4) surrounding the outer peripheral part of the central part (3). The two parts are mutually jionted by the adhesive tape (7). The force transmission part (4) has a jiont part(hole) (8) connected to a force endowing mechanism, for perform elastic deformation to the central part (3).

Owner:SANEI GIKEN

Method for exposing single-sided flexible circuit board

InactiveCN101634809AImprove exposure productivityImprove utilization efficiencyPhotomechanical exposure apparatusPrinted circuit manufactureFlexible circuitsEngineering

The invention discloses a method for exposing a single-sided flexible circuit board, which comprises the following steps: fixing a first film with the film surface facing upwards on a platform surface of an exposure machine; placing a second film with the film surface facing downwards on the first film and aligning the two films; buckling down a mylar film of the exposure machine for the convenience of fixing the second film on the mylar film, and then pulling up the mylar film; contacting a first flexible circuit board and a substrate of a second flexible circuit board, aligning and stacking the first flexible circuit board and the substrate together, and then placing the two on the first film and aligning; and buckling down the mylar film to expose the dry films of the first flexible circuit board and the second flexible circuit board at the same time. The method for exposure production operations improves the exposure production efficiency of the device and promotes the exposure productivity of the exposure machine, and simultaneously the implementation mode is simple without cost input and the consumption of additional charges.

Owner:靖江亚星进出口有限公司

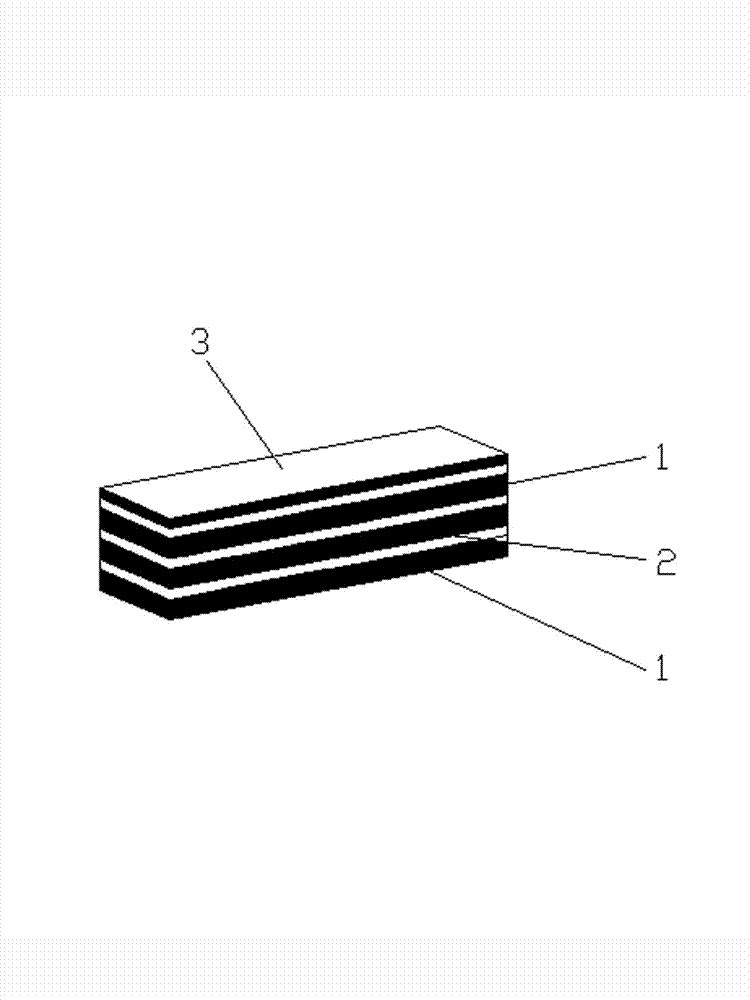

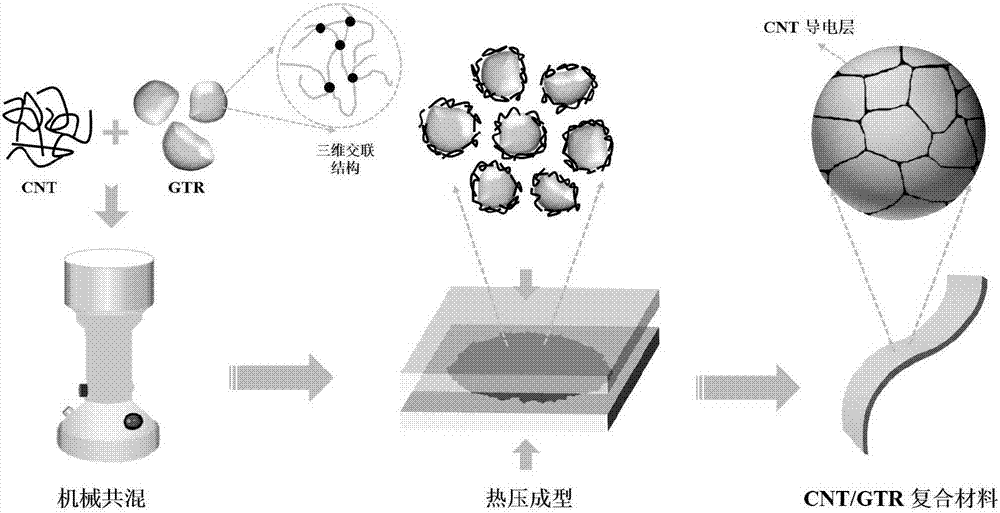

Flexible electromagnetic shielding composite material, preparation method thereof and application

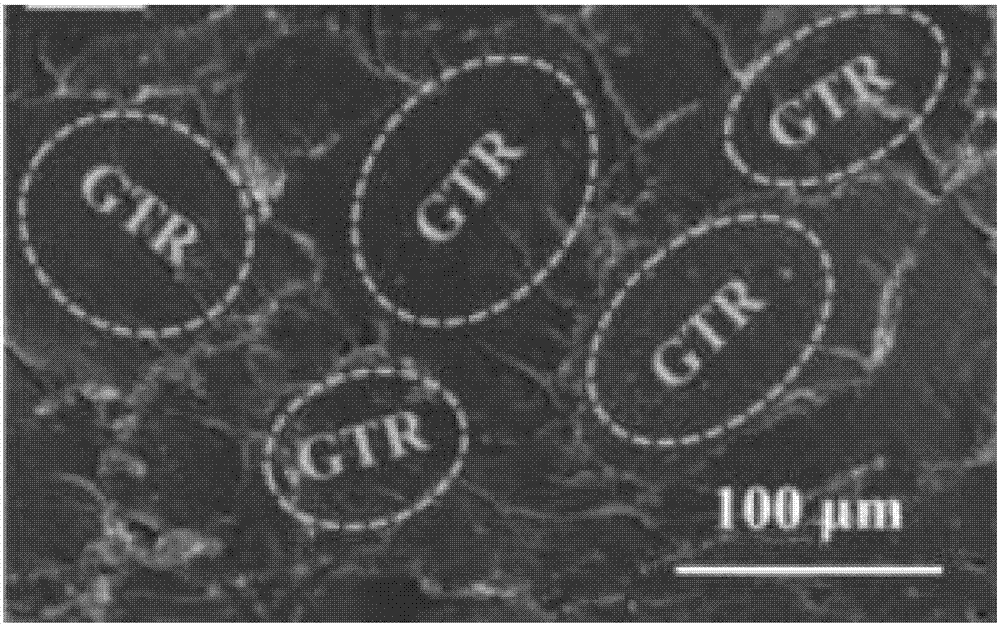

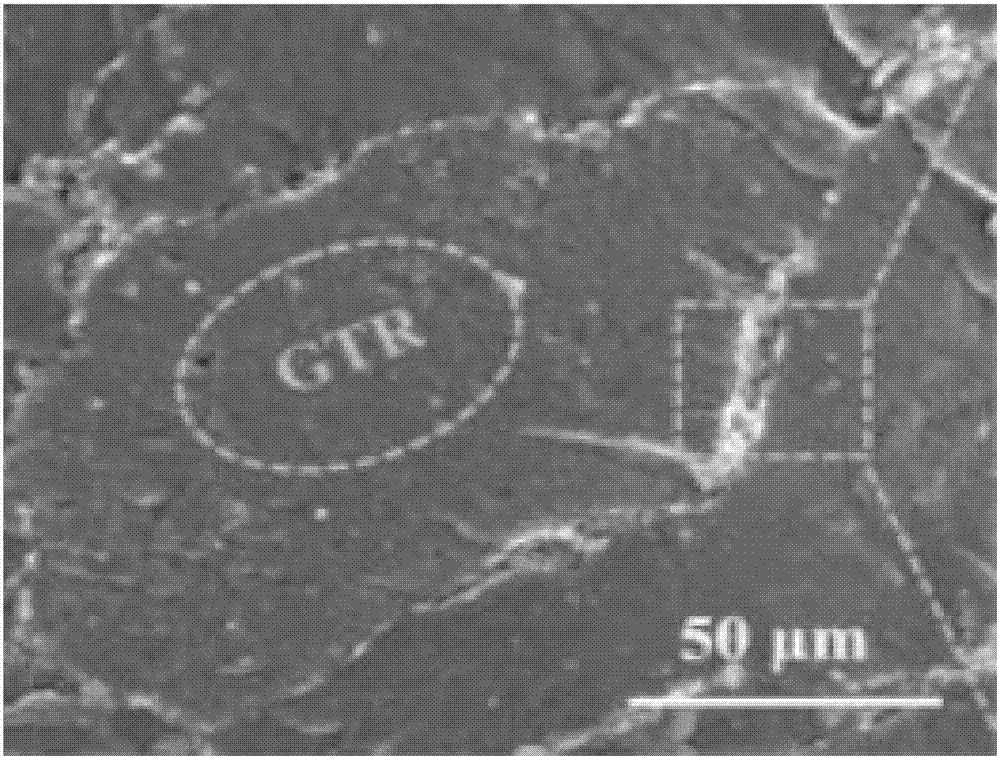

InactiveCN107163333AGood electromagnetic shielding performanceReduce manufacturing costMagnetic/electric field screeningScrapMicrometer

The invention provides a flexible electromagnetic shielding composite material and a preparation method thereof. The method includes the steps: (1) preparing materials in weight percentage: 95-99.9% of scrap rubber powder and 0.1-5% of carbon nano-tubes; (2) drying the carbon nano-tubes, and enabling the moisture of the carbon nano-tubes to be lower than 0.01%; (3) mechanically mixing the dried carbon nano-tubes acquired in the step (2) and the scrap rubber powder at the high temperature at the speed of 24000rpm to obtain composite particles; (4) performing preheating for 5 minutes on the composite particles acquired in the step (3) at the temperature ranging from 150 DEG C to 180 DEG C, performing hot pressing for 10 minutes under the pressure ranging from 10MPa to 50MPa, performing cold pressing to the room temperature under the pressure of 10MPa to obtain flake-like target products. The average diameter of the carbon nano-tubes is 9.5 nanometers, and the average length of the carbon nano-tubes is 1.5 micrometers. The invention further provides an application of the flexible electromagnetic shielding composite material to the field of flexible electron devices. The preparation method is easy to implement, the obtained material has excellent EMI SE (electromagnetic interference shielding effect) and good market application prospect, and scrap rubber can be effectively utilized.

Owner:四川省成都市树德中学

Water quality stabilizer achieving recycling of all industrial waste water and zero pollution discharge and preparation method of water quality stabilizer

ActiveCN105417739ACorrosion does not formAchieving zero emissionsSpecific water treatment objectivesWater contaminantsIndustrial waste waterWater quality

The invention discloses a water quality stabilizer achieving recycling of all industrial waste water and zero pollution discharge and a preparation method of the water quality stabilizer. The water quality stabilizer is prepared from an agent A, an agent B and an agent C. The agent A is prepared from, by mass, 20%-50% of antisludging agent, 15%-60% of dispersing agent, 10%-40% of chelating agent, 5%-10% of stabilizing agent, 0.2-1.2% of synergist, 5%-15% of bactericide and the balance water. The agent B is prepared from, by mass, 20%-50% of phytic acid, 15%-60% of zinc nitrate, 10%-40% of lanthanum nitrate, 5%-10% of nickel nitrate, 5%-10% of 2-hydroxyphosphonoacetic acid, 5%-10% of cobalt nitrate and the balance water. The agent C is prepared from, by mass, 30%-60% of piperazine hexahydrate, 30%-60% of aminoethyl piperazine hexahydrate and the balance water. By means of the water quality stabilizer, a circulating water system cannot scale or be corroded for many years, and zero emission of an industrial circulating water system is achieved.

Owner:河北中创蓝星助剂有限公司

Modified preparation technology for light GMT sheet material

A modified preparation technology for a light GMT sheet material comprises: employing base-free glass fiber and low-melting-point modified polypropylene according to a certain weight ratio as raw materials, employing vacuum infiltration technology, placing base-free glass fiber at the bottom of a mold, then paving polypropylene thick resin blocks on glass fiber, sealing with a vacuum bag, in hot environment, employing vacuum technology to suck resin from top to bottom, wherein the mold comprises an injection system, an exhaust system and a heating system, and is carved with grooves for accelerating resin flow, guaranteeing resin smooth flow, exhausting all gas in the mold cavity and thoroughly infiltrating fiber. The preparation technology is high in efficiency, low in equipment cost and small in energy consumption; the whole preparation technology is free of pollution, small in glass fiber damage and high in raw material utilization rate; and the preparation process is simple.

Owner:合肥杰迈特汽车新材料有限公司

Preparation method of stainless steel surface coating with low temperature insulation

InactiveCN101961709AImprove insulation performanceSimple processPretreated surfacesSpecial surfacesRoom temperatureSilicon dioxide

The invention relates to a preparation method of a stainless steel surface coating with low temperature insulation, comprising the following steps: (1) polishing a common stainless steel substrate by a diamond sandpaper, then performing the ultrasonic cleaning and drying; (2) mixing Si(OC2H5)4, C2H5OH and H2O, adding HCL, and stirring by magnetic force for 3 hours under the room temperature to form a sol; (3) aging the sol for 3 to 14 days under the room temperature to form a silica colloidal solution; and (4) coating the silica colloid by the immersion method to prepare the needed stainless steel substrate. The stainless steel surface coating with low temperature insulation prepared by the method has high bonding strength, so that the stainless steel plate can bear the temperature of 0 to 300 DEG C and has the insulation function. The preparation method has the characteristics of simple operation, simple production process, low production cost and the like.

Owner:DONGHUA UNIV

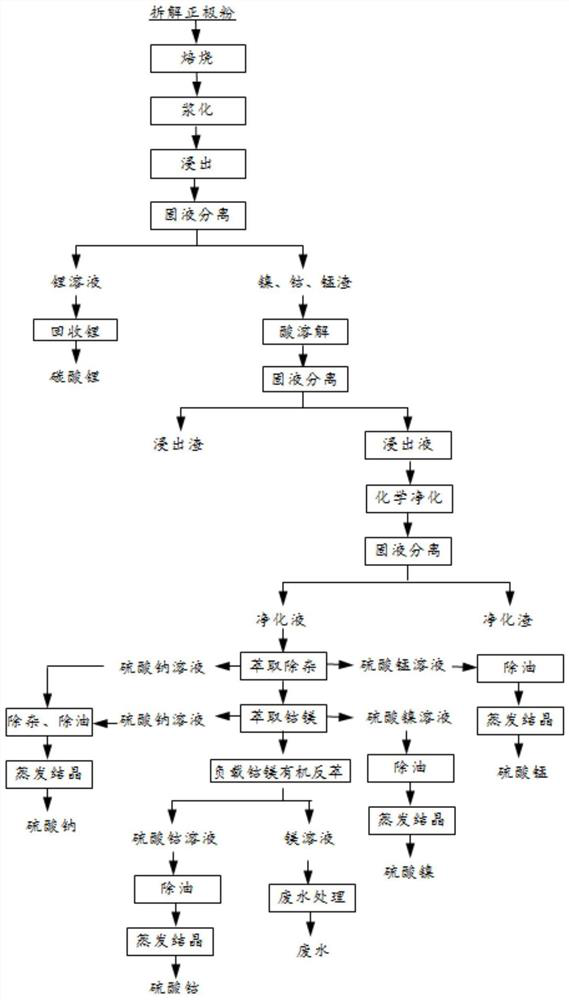

Recovery treatment method for waste power battery powder

PendingCN112375910AImprove leaching rateHigh recovery rateWaste accumulators reclaimingProcess efficiency improvementPower batteryManganese

The invention provides a recovery treatment method for waste power battery powder. According to the treatment method, a dynamic reduction roasting process is adopted for reduction roasting treatment,so that the battery powder is treated more thoroughly, the recovery rate of lithium is increased by about 10%, reduced nickel, cobalt and manganese all are changed from a high valence state to a low valence state more thoroughly, a reducing agent is not consumed basically in the subsequent leaching process, and during nickel recovery, recovery in an extraction mode is not needed. In addition, according to the recovery treatment method, the dynamic reduction process is taken as a starting point, so that lithium recovery is economical and efficient; and the influence on nickel recovery is considered in the cobalt and manganese recovery process, and nickel saponification is adopted, so that the nickel recovery cost is low.

Owner:湖南德景源科技有限公司

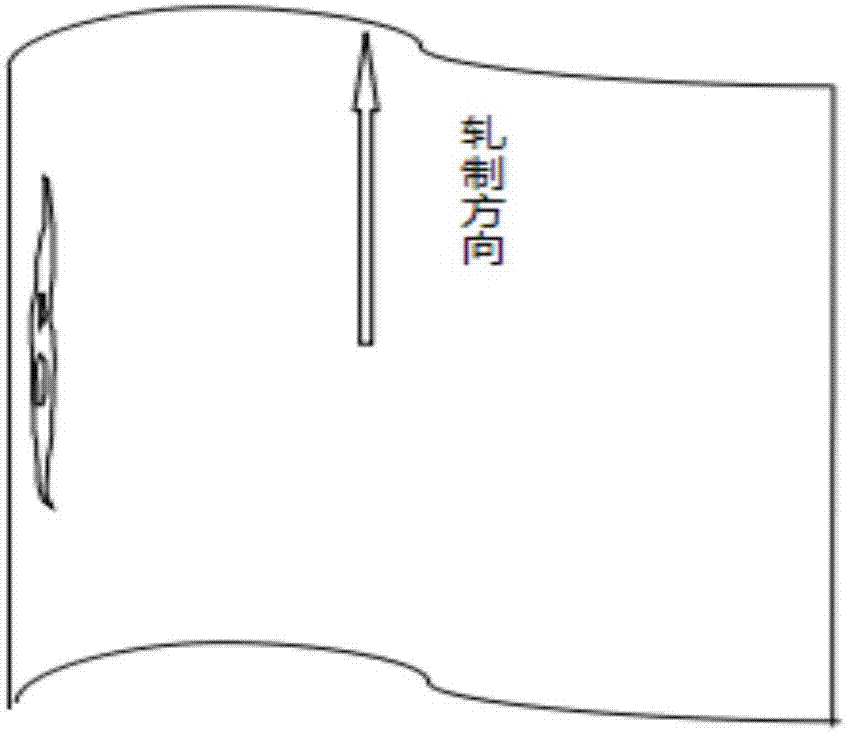

Method for controlling deviation of intermediate billet of coil box

ActiveCN103056168AGuaranteed stable rolling effect in batchesSolve the failure of intermediate volume windingRoll mill control devicesMetal rolling arrangementsEngineeringContinuous rolling

The invention discloses a method for controlling deviation of an intermediate billet of a coil box, and belongs to the technical field of hot-rolled steel. The method includes sequentially feeding the intermediate billet into a bending roll unit via an inlet-side guide plate and an inlet roll unit; bending the intermediate billet to form a strip billet; coiling the strip billet by a forming roll and a first coil carrying roll of a coiling station sequentially to form a strip coil; uncoiling the strip coil by an uncoiling station, and then shifting the strip coil; and flattening the strip coil by a pinch straightening roll, and then feeding the strip coil into a finishing mill group via a front-side guide plate of a flying shear to be rolled. The method has the advantages that problems of coiling failure of an intermediate coil due to deviation of an intermediate billet and uncoiling failure due to a poor coil pattern are effectively solved; and investment is omitted, the method is simple, and is high in applicability and obvious in control effect, a stable batch rolling effect of industrial production is guaranteed, and an effect for obviously improving stable production of the hot continuous rolling coil box is realized.

Owner:BEIJING SHOUGANG CO LTD

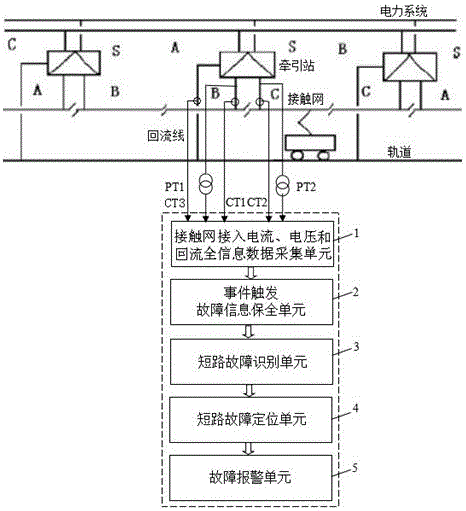

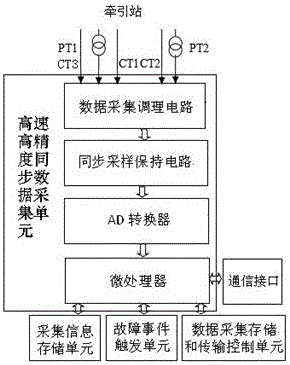

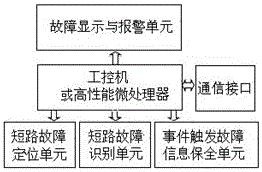

Overhead contact system single-ended traveling wave fault positioning device

ActiveCN105738766AImprove operational reliabilityImprove fault location accuracyFault location by conductor typesEvent triggeredFault occurrence

The present invention discloses an overhead contact system single-ended traveling wave fault positioning device, and relates to an overhead contact system fault positioning technology. The overhead contact system single-ended traveling wave fault positioning device is equipped with an overhead contact system access current, an overhead contact system access voltage, a backflow perfect information data acquisition unit, an event trigger fault information preserving unit, a short circuit fault identification unit, a short circuit fault positioning unit and a fault display and alarm unit. A current transformer and a voltage transformer are accessed in a connection line of a traction station and an overhead contact system, and by real-timely detecting and analyzing the instantaneous waveforms of a current and a voltage, the fault types are identified, and the fault occurrence places are determined. The overhead contact system single-ended traveling wave fault positioning device of the present invention is used for the electrified railway overhead contact system short circuit fault positioning, and has the characteristics of simple structure, high precision and reliability and few investment.

Owner:WUHAN UNIV

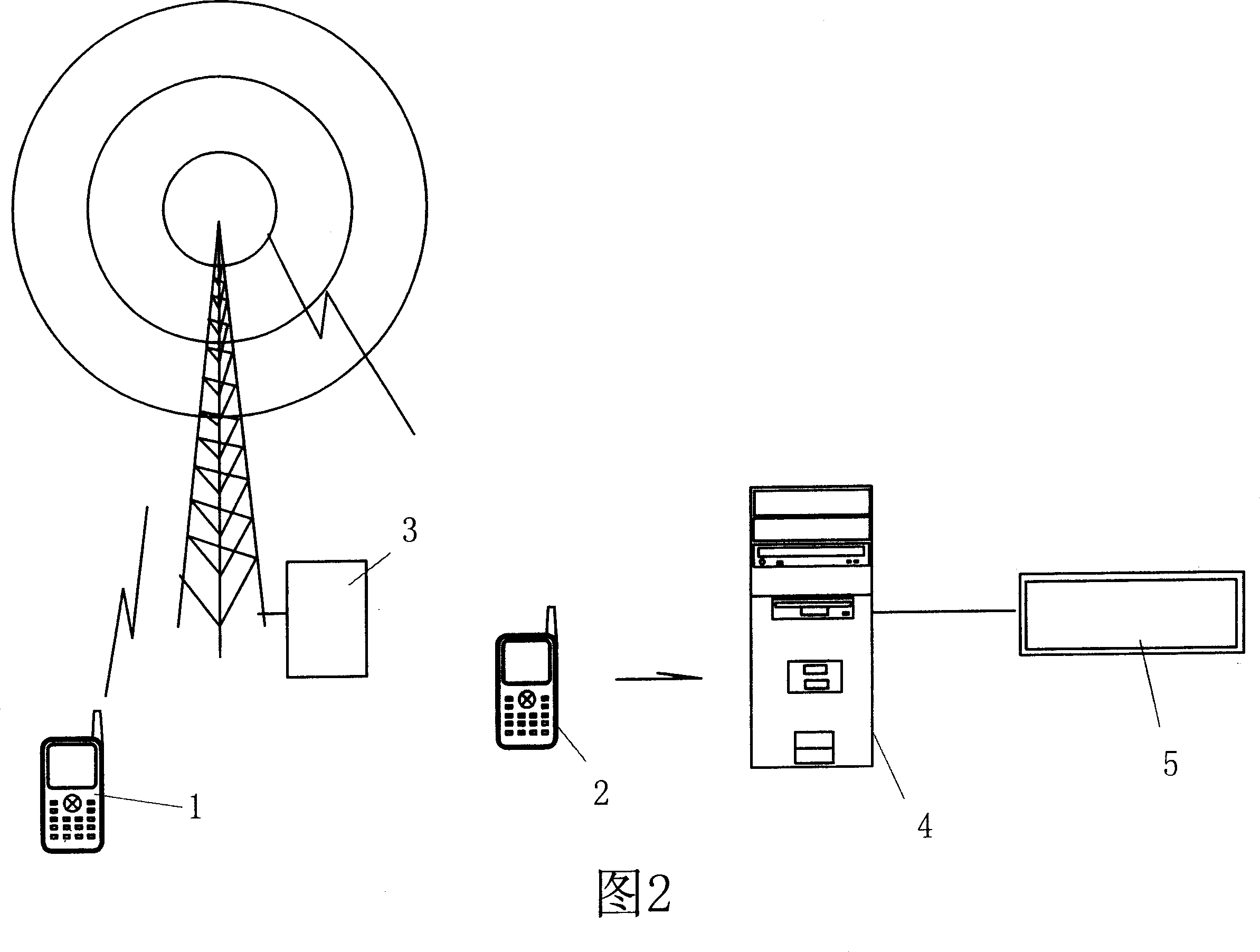

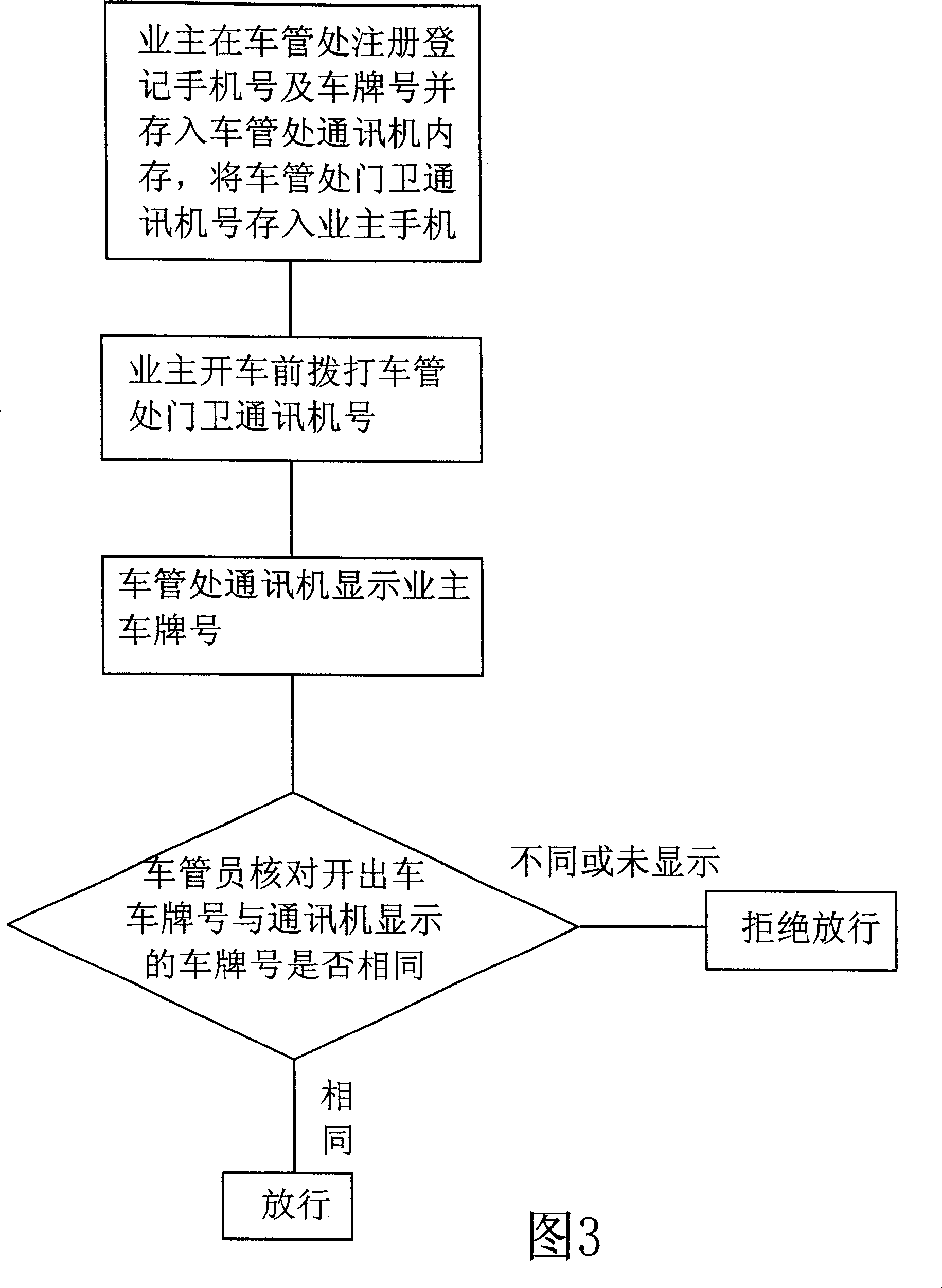

Vehicle theft prevention method and its using device

InactiveCN101055650ANo investment requiredIndestructibleTelephonic communicationChecking apparatusMicrocomputerEngineering

A vehicular theftproof device comprises an owner communication machine, a property warder communication machine, and a communication network for communicating the owner communication machine and a the property warder communication machine, the vehicular theftproof device is characterised in that: the property warder communication machine includes a display screen for caller ID display; a communication number and a vehicle license plate number of the owner communication machine are stored in the property warder communication machine; when the owner dials a communication number of the property warder communication machine, the vehicle license plate number of the owner is displayed on the display screen by the property warder communication machine via the communication network according to a communication number of a caller ID communication machine. The vehicular theftproof device has advantages that: 1, the device is a common communication device or joints a microcomputer, thereby the owner needs no investment; 2, the device has no connection relationship with the vehicle, thereby a theft can not damage; 3, the vehicle license plate number is displayed only by using a special communication machine for the owner, thereby obtaining a strong secrecy.

Owner:王涛

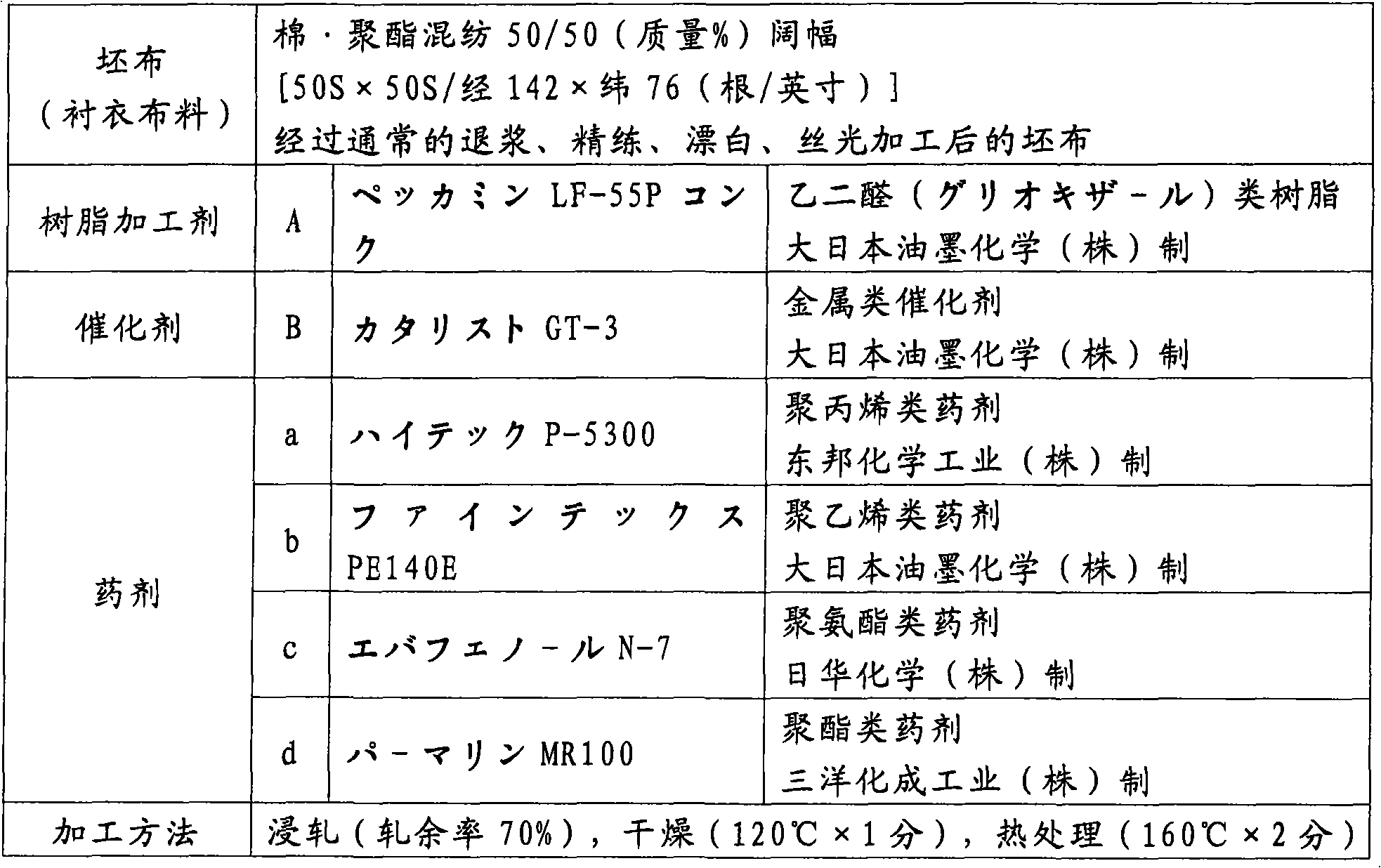

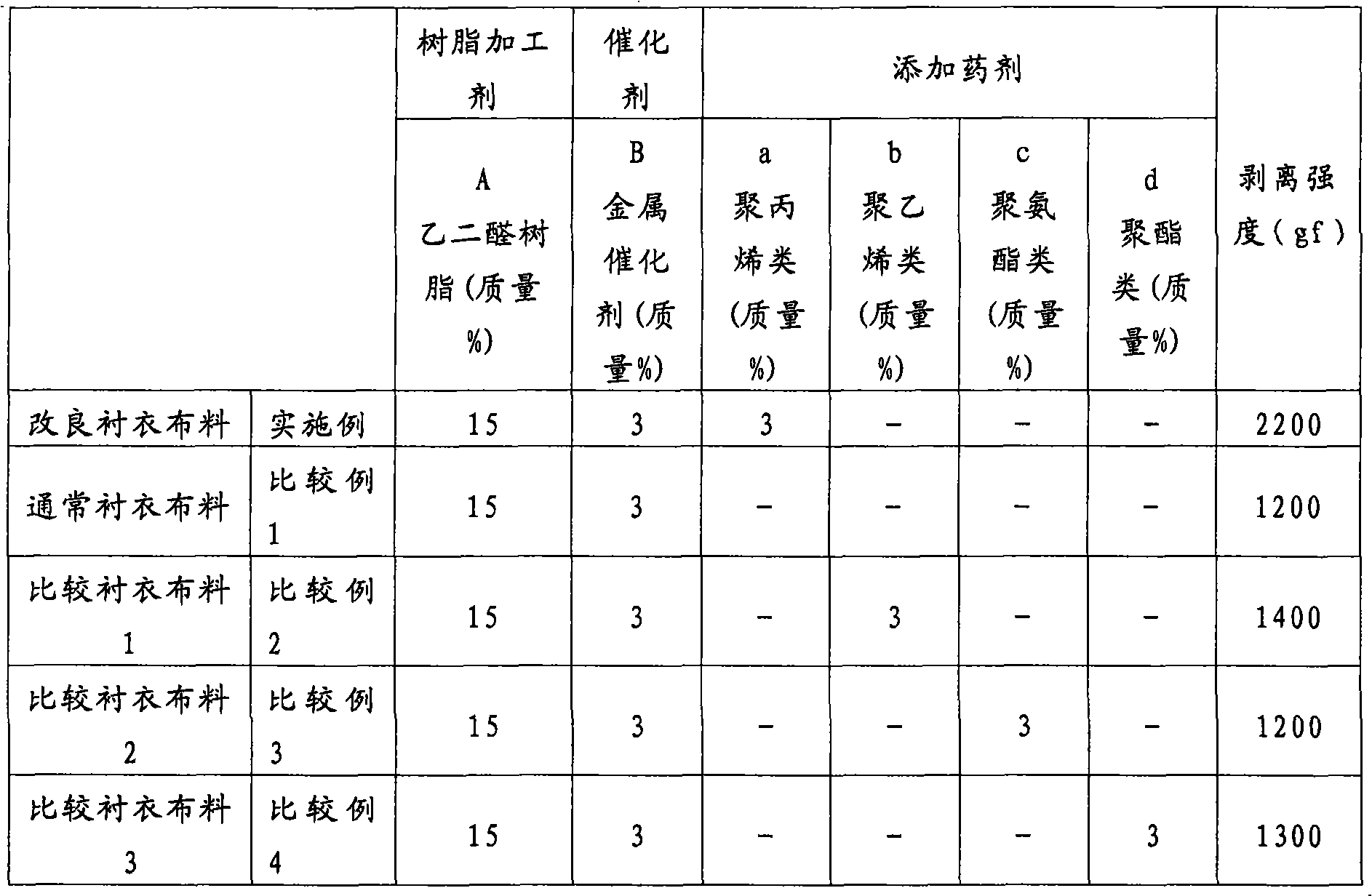

Fibre grey cloth, manufacturing method and fibre grey cloth with lapping cloth forming by bonding lapping cloth on the fibre grey cloth

The invention provides fiber grey cloth attached with given medicine and which is easy to fall off the perspiration and other dirt, has little effusion of the bond, has good contractibility to commercial washing, and has good bonding strength to lapping cloth using common bond, especially the polypropylene bond, a preparing method and the fiber grey cloth stuck with lapping cloth formed by bonding the lapping cloth on the fiber grey cloth. The solving method adopted by the invention is to use a fiber grey cloth attached with medicine having high bonding strength to the lapping cloth; the invention is characterized by attaching a medicine on the fiber grey cloth for bonding the lapping cloth by the bond; the medicine comprises polymer the same with the main component polymer of the bond.

Owner:NISSHINBO IND INC

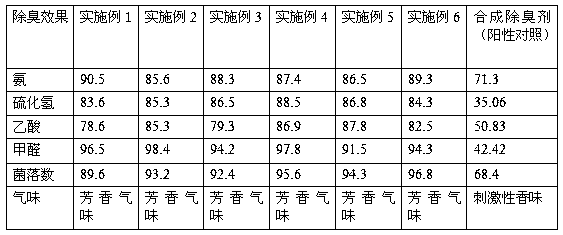

Plant source deodorant and preparation method thereof

The invention discloses a plant source deodorant. Effective constituents of the plant source deodorant consist of a camphor tree extractive, a Mahonia bealei extractive, an oil tea fruit shell extractive and a honeysuckle extractive, and the mass ratio of the camphor tree extractive to the Mahonia bealei extractive to the oil tea fruit shell extractive to the honeysuckle extractive is (1 to 3): (0.1 to 0.2): (0.3 to 0.8): (2 to 4). The pure natural plant extracting solutions are taken as raw materials, and are relatively low in cost, safe, environmentally-friendly, poisonless, harmless and safe to use; foul smell in circulating water in the papermaking production process is effectively removed, secondary pollution to the environment cannot be caused, and the antibacterial effect is obvious.

Owner:INST OF APPLIED CHEM JIANGXI ACAD OF SCI

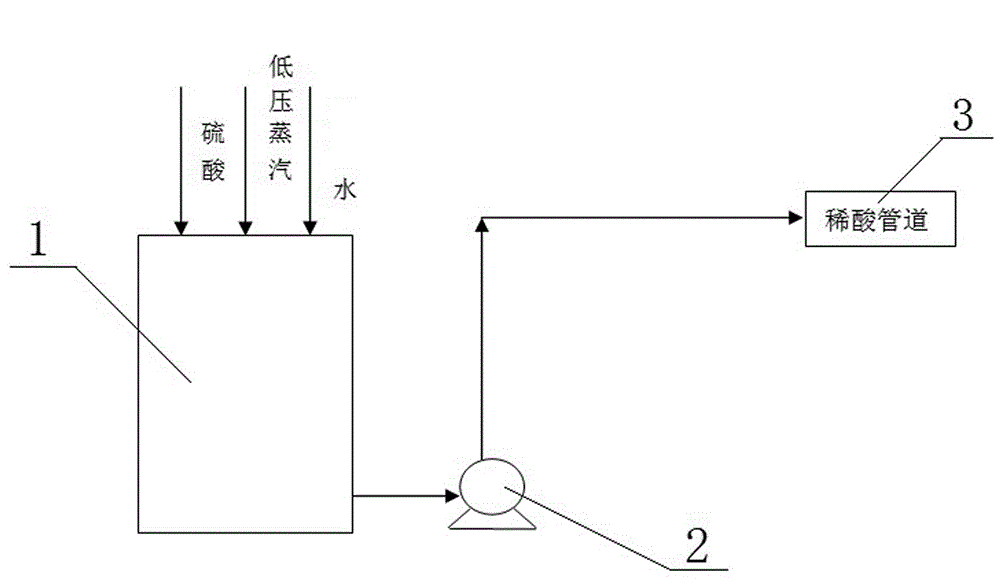

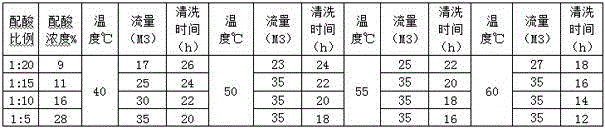

On-line clearing method of dilute acid pipe scales in phosphate ore magnesium-removing and ore-dressing production

InactiveCN104307814ARealize on-line descalingNo investment requiredHollow article cleaningCleaning using liquidsPhosphateTime-Consuming

The invention aims to provide an on-line clearing method of dilute acid pipe scales in phosphate ore magnesium-removing and ore-dressing production and solves the problem in the prior art that the manual cleaning of a dilute acid pipe is time-consuming and labor-consuming in the phosphate ore magnesium-removing and ore-dressing production. The on-line clearing method comprises the following steps: configuring cleaning liquid composed of sulfuric acid and water in a dilute acid configuration tank, wherein the volume ratio of the sulfuric acid to the water is 1:(5-20); then introducing low-pressure steam in the dilute acid configuration tank to heat; conveying the heated cleaning liquid into a dilute acid pipe by using a conveying pump to clean under the situation of no parking. The on-line clearing method has the benefits that the on-line clearing of the scales is realized, no pipe needs to be disassembled, no investment is required, the maneuverability is realized, and no extra equipment needs to be arranged; the scale removal is more obvious, the cleaning is required once a month, and time and labor are saved.

Owner:GANSU WENGFU CHEM

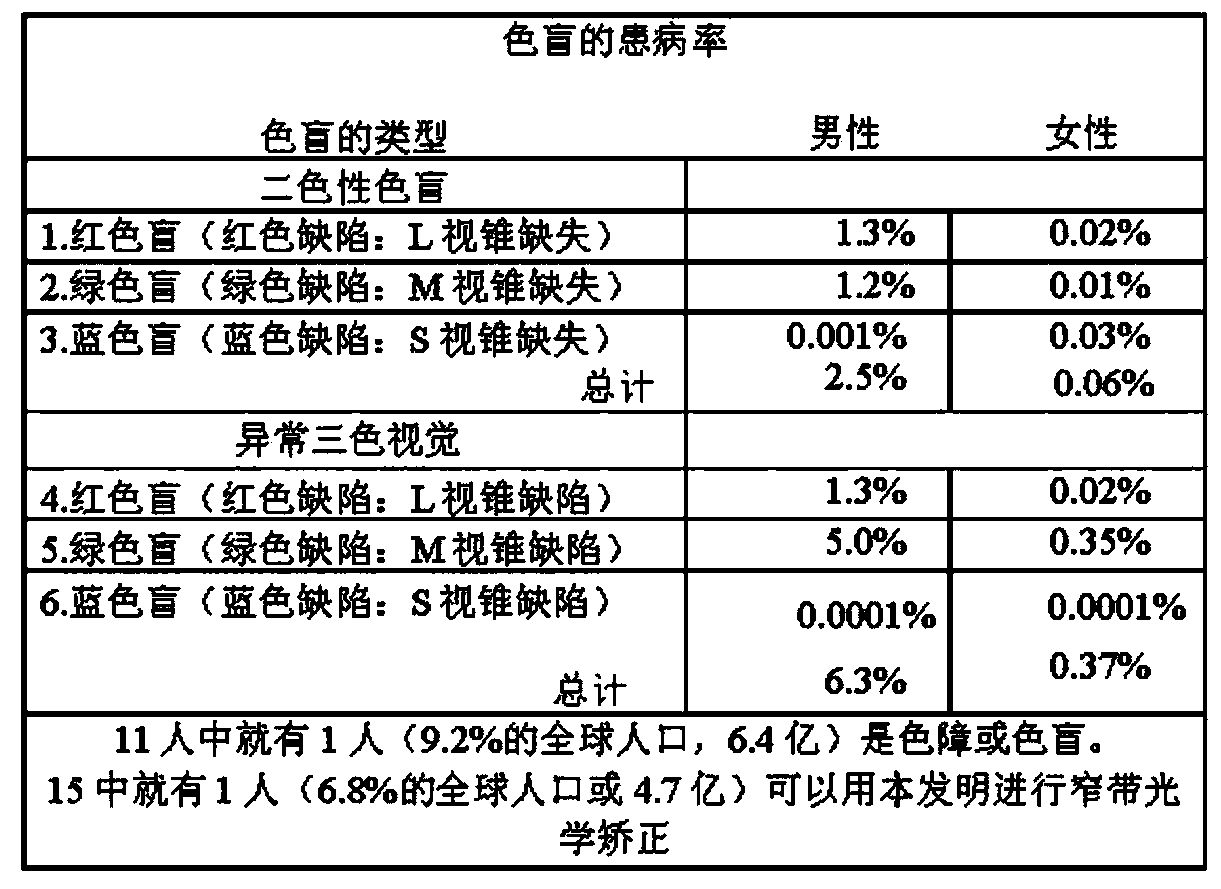

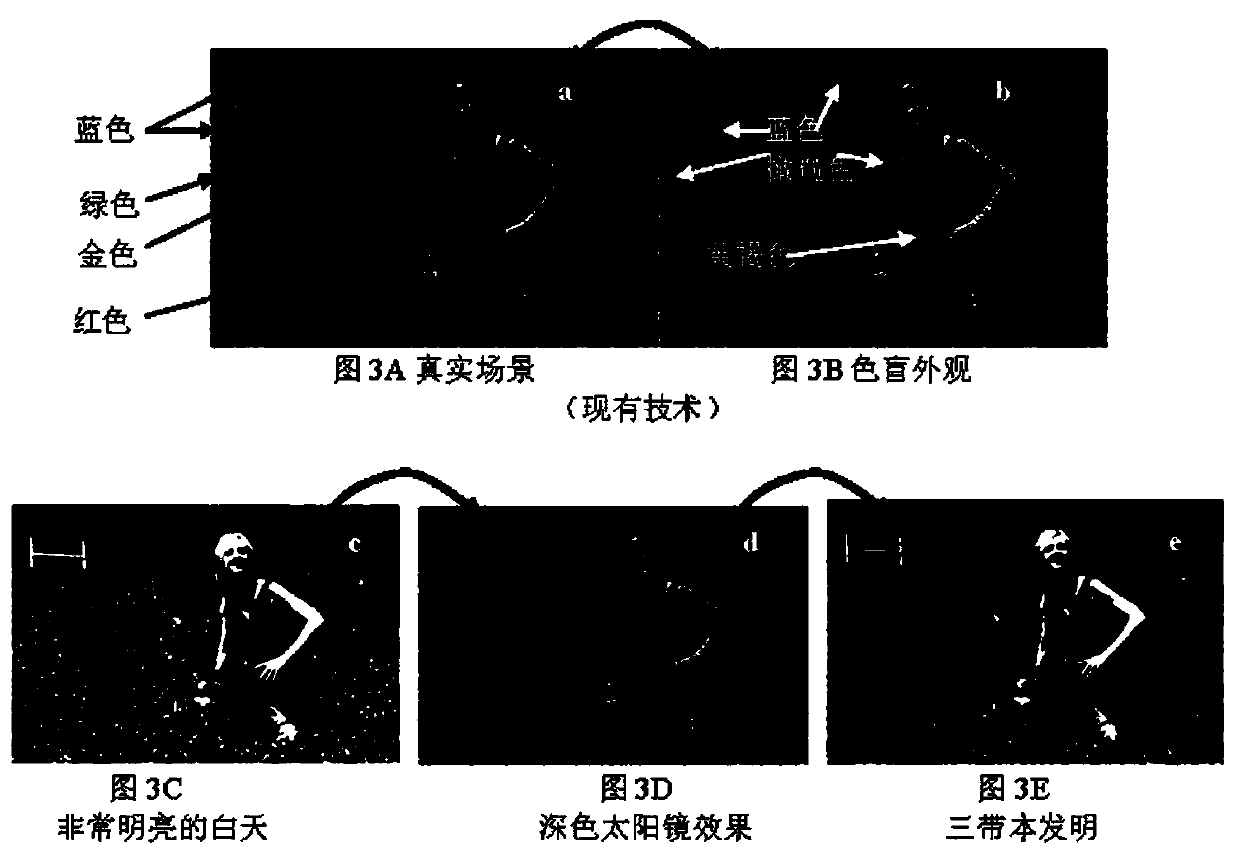

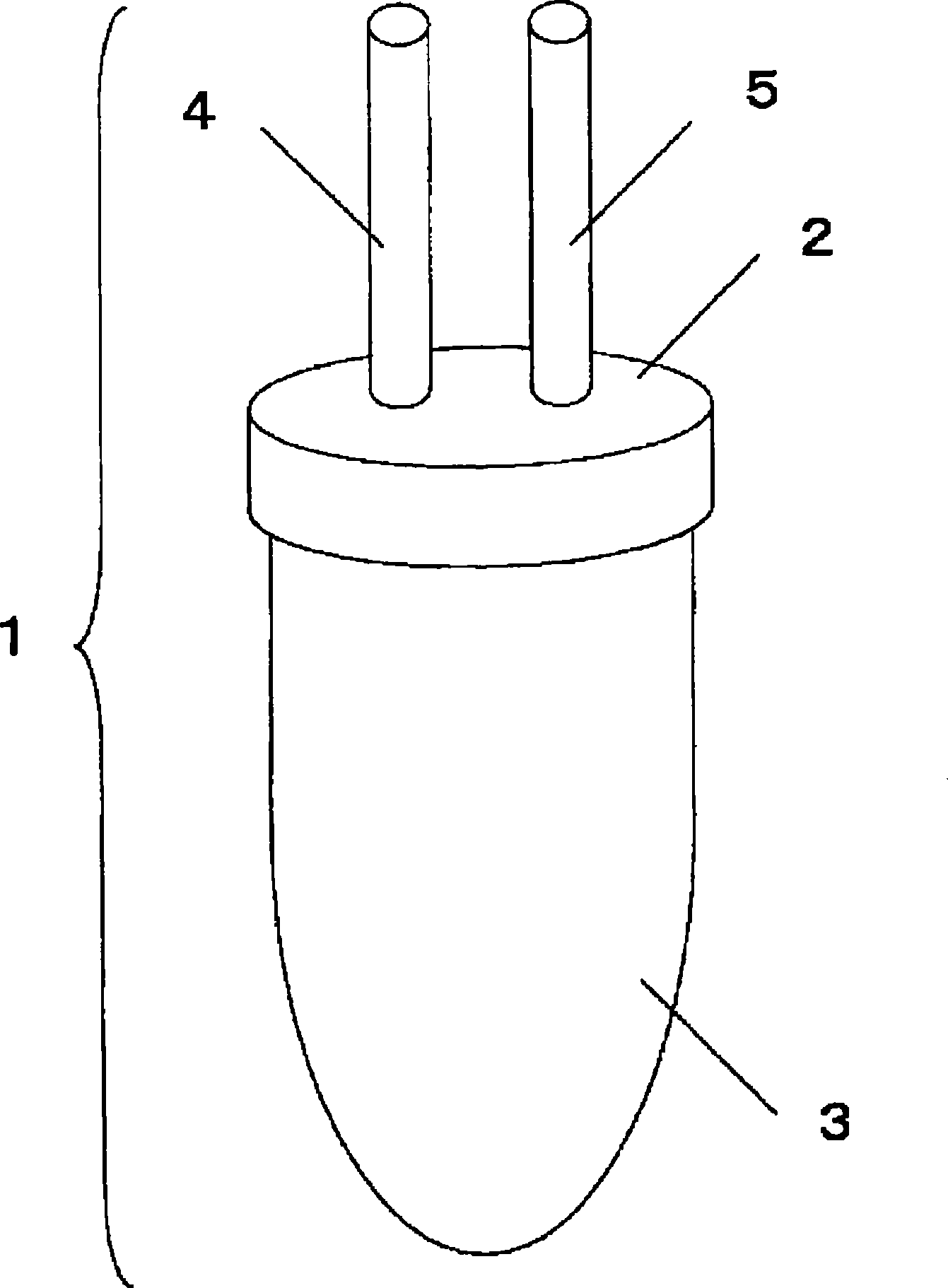

Spectrally sculpted multiple narrowband filtration for improved human vision

PendingCN109791239AChange colorNo investment requiredOptical filtersPolarising elementsColor visionVisual perception

Owner:R S 埃斯

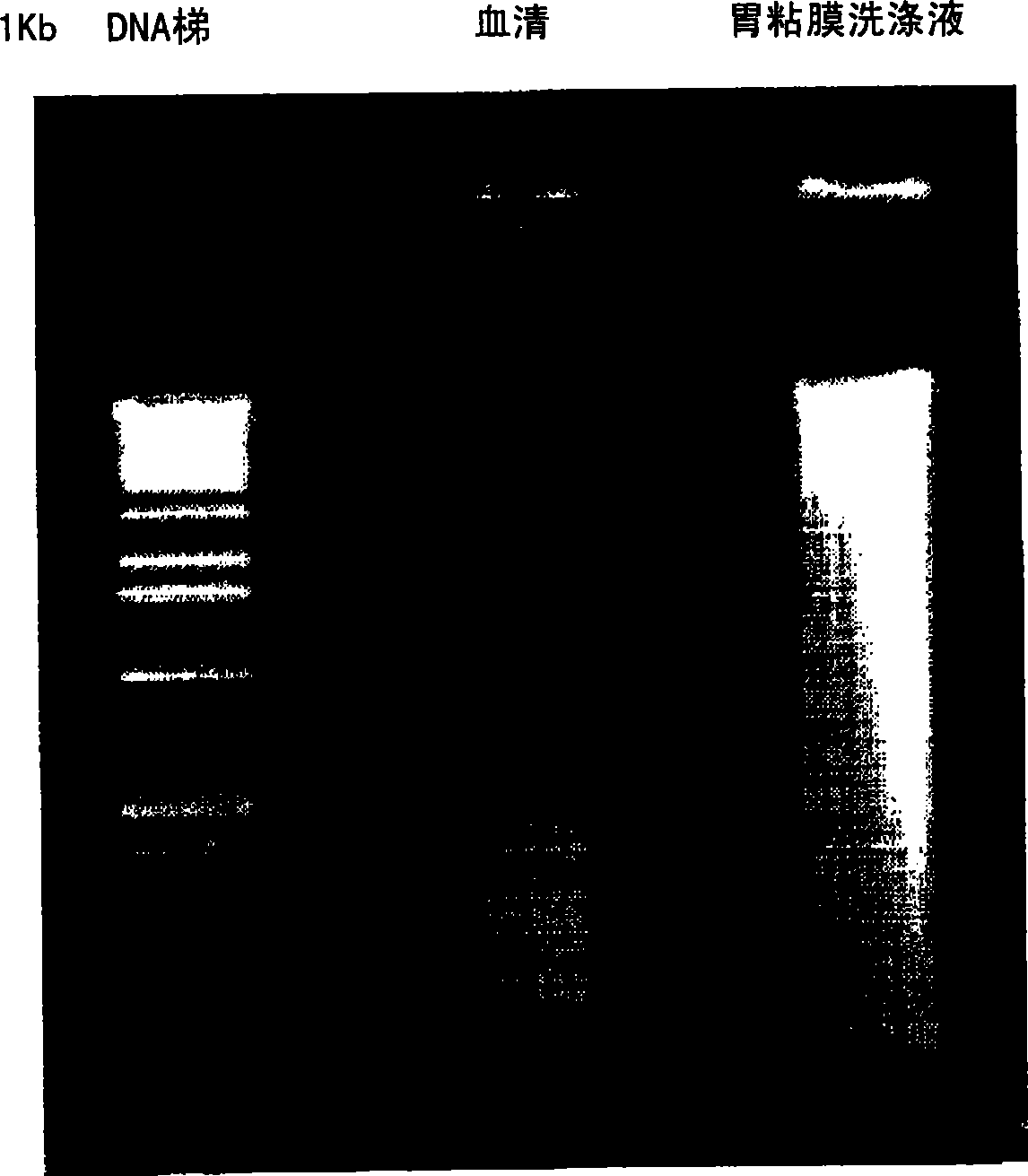

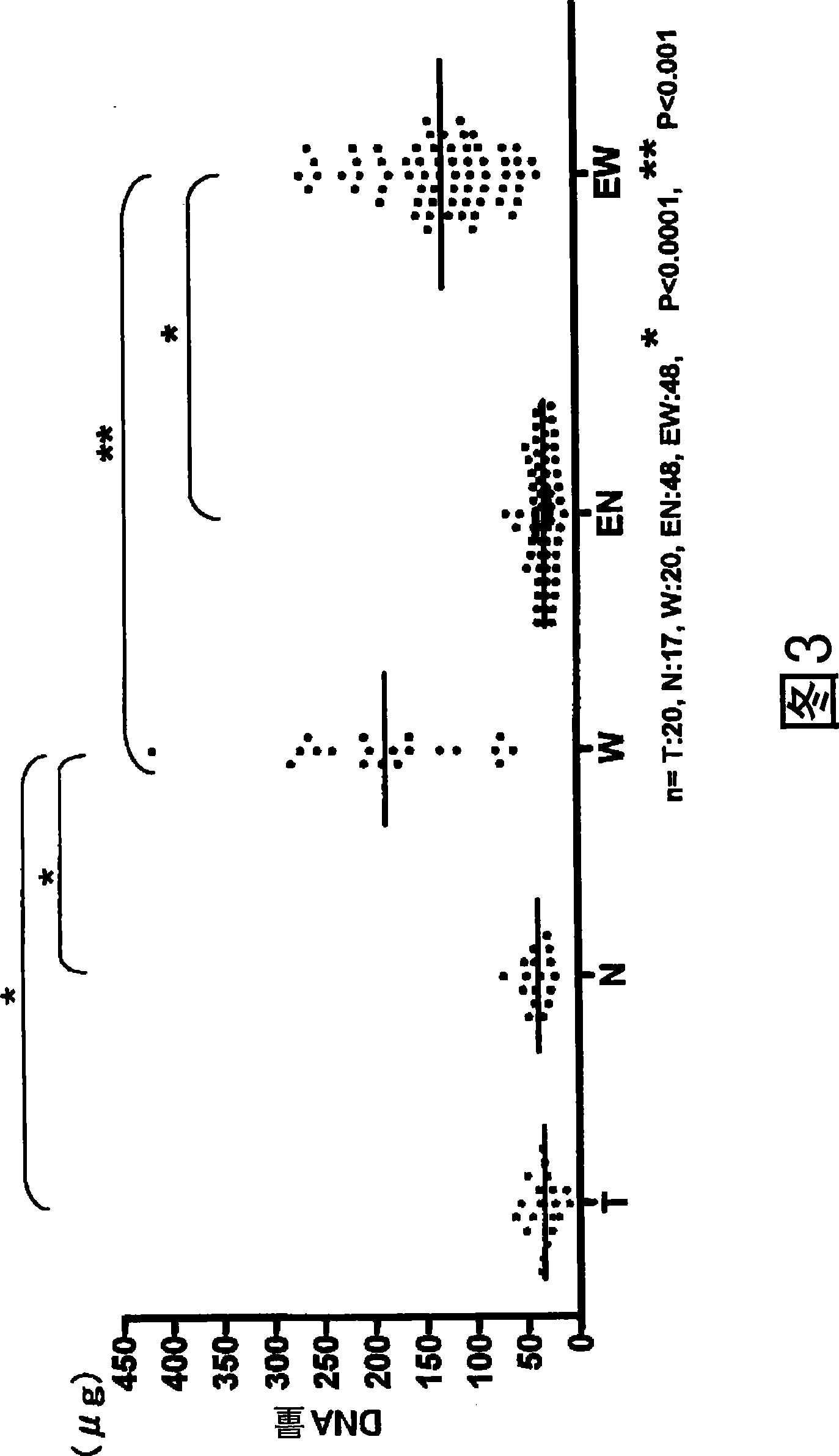

Method for detecting disease-related marker using gastric mucosal lavage fluid

InactiveCN101443462AEasy to collectAvoid pollutionBioreactor/fermenter combinationsBiological substance pretreatmentsDisease causeGastric mucus

Owner:SAPPORO MEDICAL UNIVERSITY +1

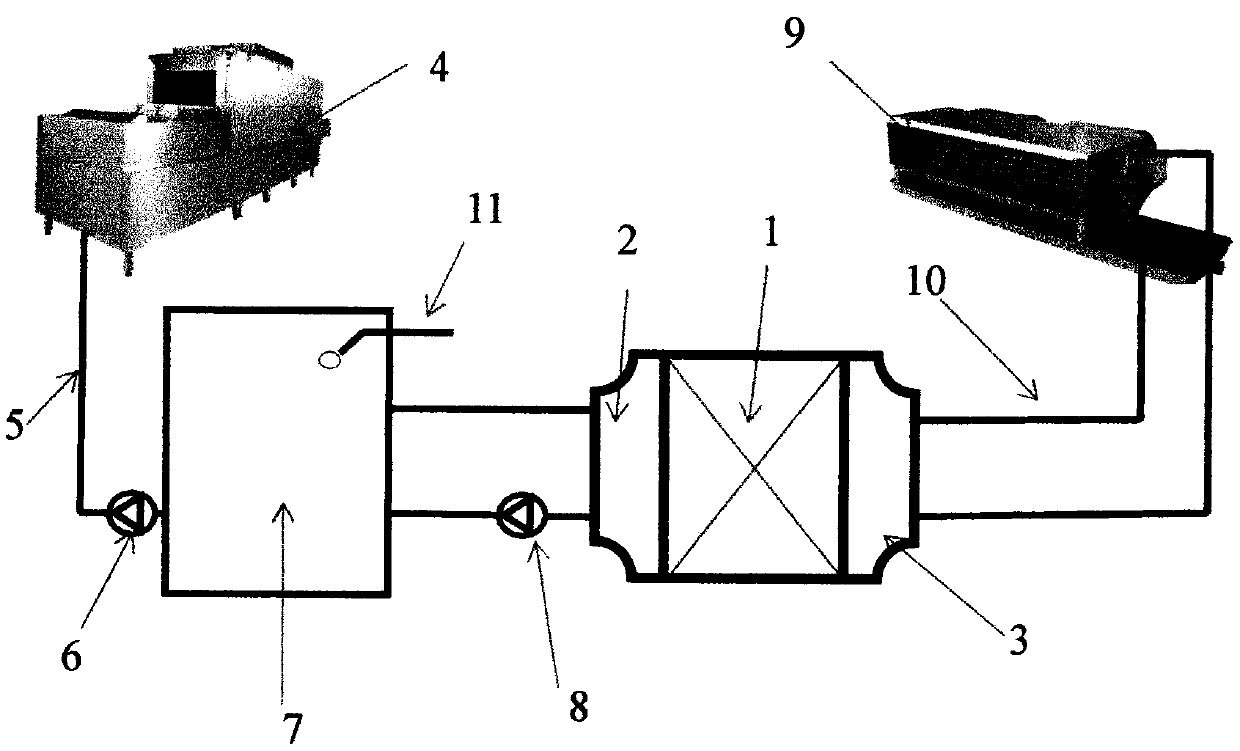

Dish washing machine hot water/dining room air conditioner combined supply heat pump system

InactiveCN110332638AFast room dropReduce the temperatureTableware washing/rinsing machine detailsLighting and heating apparatusCold airThermal energy

The invention relates to the technical field of heat pumps, in particular to a heat pump system for combined supply of a kitchen dish washing machine and a dining room air conditioner. The system canprovide low-cost hot water for the kitchen dish washing machine, cold air or frozen water needed by the air conditioner is supplied to a dining room at the air conditioner season, treated exhaust airof the kitchen is utilized for being supplied to a heat pump in winter, and the energy efficiency of the heat pump is improved. According to the system, the power supply capacity of the dish washing machine is reduced by 60% or above, and the hot water heating cost is reduced by 70% or above compared with electric heating; and meanwhile, the free air conditioner can be achieved in the dining room,the kitchen exhaust air is utilized in winter for heat energy recycling, and meanwhile the energy efficiency of the heat pump is improved.

Owner:苏桐梅

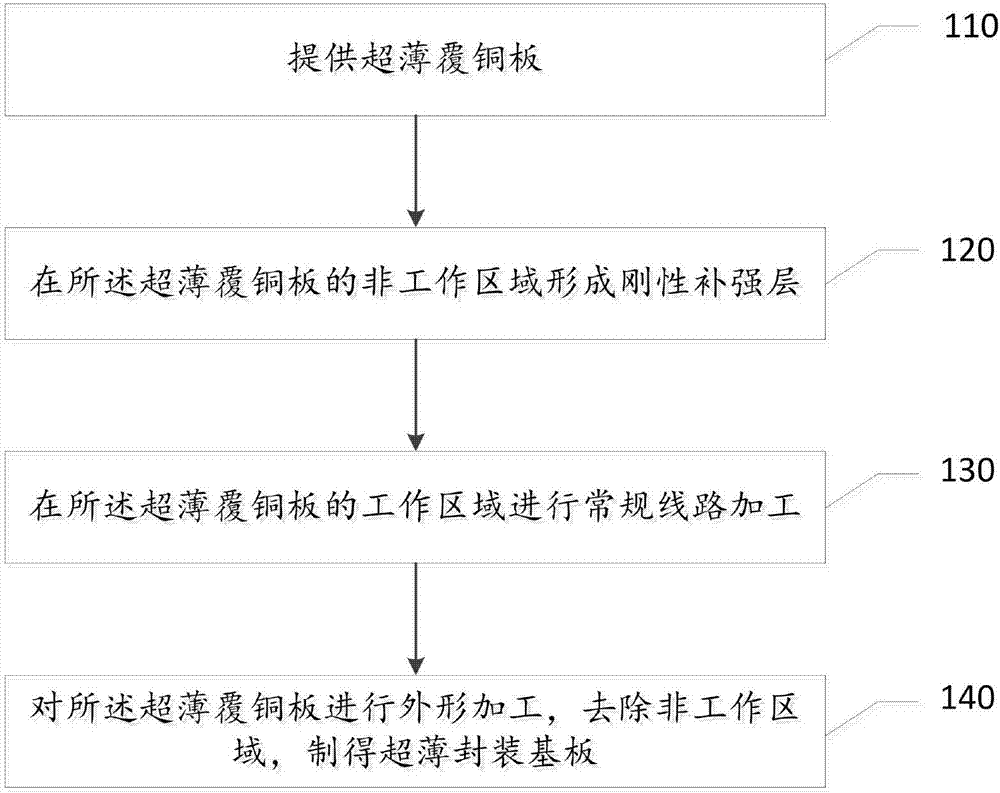

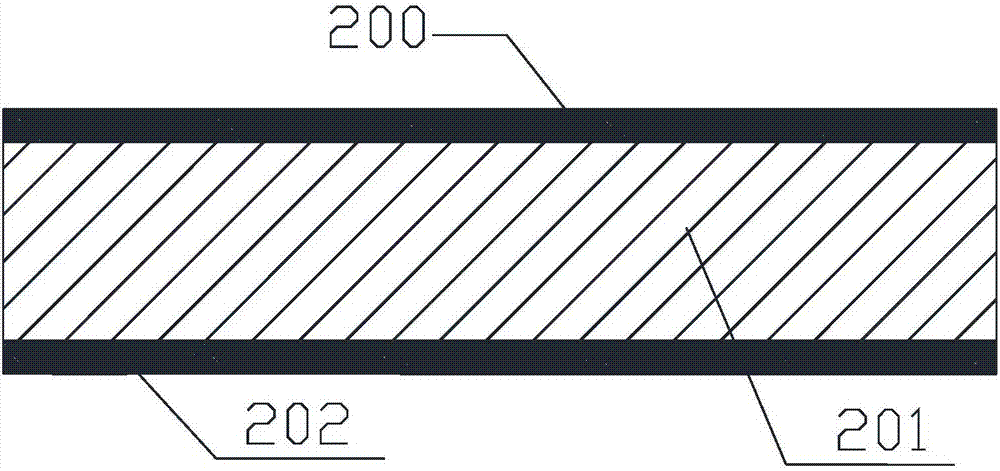

Manufacturing method of ultrathin package substrate and related product

ActiveCN107089641AHigh strengthAvoid deformationDecorative surface effectsSolid-state devicesCopperUltimate tensile strength

The invention discloses a manufacturing method of an ultrathin package substrate and a related product. The manufacturing method can help solve a technical problem that the ultrathin package substrate is low in machinability, each to be injured or damaged in the machining process due to insufficient strength. The method comprises the following steps: providing an ultrathin copper-clad plate; forming a rigid reinforcing layer on a non-working region of the ultrathin copper-clad plate; performing conventional line machining on the working region of the ultrathin copper-clad plate; and performing shape machining on the ultrathin copper-clad plate to remove the non-working region, thereby manufacturing the ultrathin package substrate.

Owner:SHENNAN CIRCUITS

A preparation method for an environmentally-friendly anti-yellowing curing agent with a good adhesive force

ActiveCN103232586AGood resistance to yellowing and weatheringStrong adhesionNon-macromolecular adhesive additivesCoatingsAlcoholPtru catalyst

The present invention relates to a preparation method for an environmentally-friendly anti-yellowing curing agent with a good adhesive force. The preparation method comprises the following steps of: step 1, adding TDI into a solvent for dissolving, and adding a low molecular weight alcohol containing 1-3 hydroxyl groups for a prepolymerization reaction, wherein the low molecular weight alcohol accounts for 20%-35% of the total amount of the alcohol; step 2, after the prepolymerization reaction, adding HDI and the remaining low molecular weight alcohol containing 1-3 hydroxyl groups, and simultaneously adding a silanol for the prepolymerization reaction, wherein the molar ratio of TDI : HDI = 0. 5-1:1, and the molar ratio of the salinol: HDI=0.05-0.2:1; and step 3, after the prepolymerization reaction, adding a trimerization catalyst, continuously detecting contents of NCO (NCO%) and free TDI (TDI%), and when the content of NCO (NCO%) reaches 8.5% and the content of a free monomer is less than 0.5%, adding a polymerization inhibitor to terminate the reaction, and cooling for material unloading. According to the method of the present invention, a trimerization method is used for reducing the content of the free monomer, the process flow is simple, no large investment in equipment is needed, the production cost is low, the product performance fully fulfills the application requirements in the paint field, and is conductive to environmental protection and health; and when the curing agent is used in coatings, the paint film has good adhesive force with the substrate, and the recoating adhesive force is more excellent, and anti-yellowing and anti-weathering performance of the paint film is better.

Owner:SKSHU PAINT

Utilization device for spiral internal air energy

InactiveCN102635443ANo investment requiredEasy to controlGas turbine plantsJet propulsion plantsMechanical energyEngineering

The invention relates to a utilization device for spiral internal air energy, which belongs to the field of renewable energy source and machinery manufacture. The situation that internal air energy is divided into forbidden zones by thermodynamics is a blank by application. Multistage vortex superchargers are respectively connected in series between the compressor of the device and a high-pressure turbine as well as among a high-pressure turbine, a middle-pressure turbine and a low-pressure turbine; the air inlet channel and the air outlet pipeline of each vortex supercharger are respectively provided with a wedge-shaped body regulation device; a high-pressure turbine shaft is in driving connection with a compressor shaft by a ratchet type overrunning clutch; the middle-pressure turbine and the low-pressure turbine shaft are in differential connection by a sleeve type differential coupler and output power by one shaft; under the eddy current field effect, potential flow superposition and the Rafael spray pipe clinical effect action, the vortex supercharger and a vortex exhaust device utilize the internal energy of medium to dynamically compress to lift medium pressure; the conversion of the internal energy to dynamic energy, the dynamic energy to the potential energy and the potential energy to the mechanical energy of the internal medium parts including air is realized to simultaneously produce cold quantity and fresh water. The utilization device is especially suitable for the occasions with refrigeration and fresh water requirement while distributed power generation.

Owner:杜臣

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com