Flexible electromagnetic shielding composite material, preparation method thereof and application

A technology of electromagnetic shielding and composite materials, applied in the direction of magnetic/electric field shielding, electrical components, etc., can solve problems such as poor flexibility, and achieve the effects of easy mastery of the process, low production cost, and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The main raw materials are composed as follows in parts by weight: GTR 99.9%; CNT 0.1%.

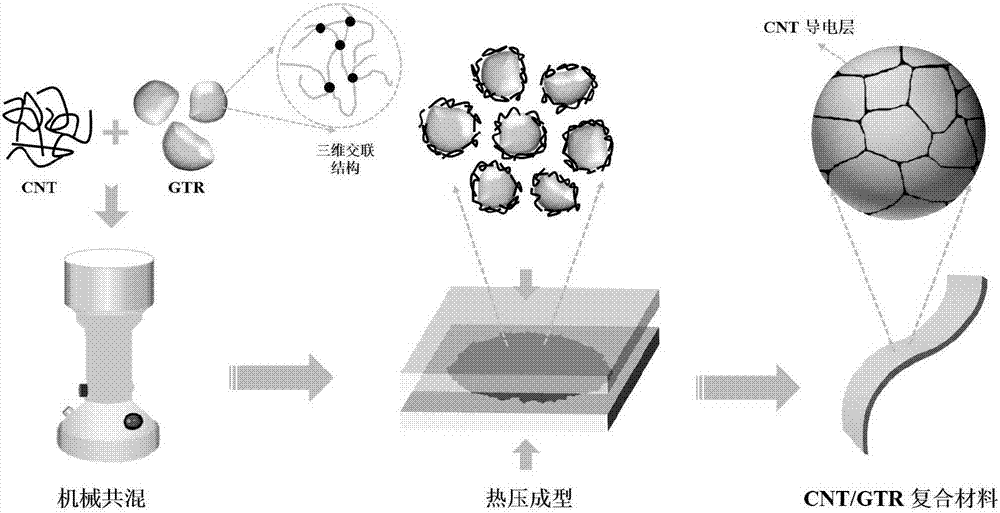

[0034] The process steps adopt:

[0035] (1) Drying of raw materials: drying the CNTs in an oven at a constant temperature of 80°C until the water weight content is lower than 0.01%;

[0036] (2) Preparation of CNT / GTR composite particles: Mix the dried CNT and GTR in (1) by high-speed machinery to obtain CNT / GTR conductive composite particles. The mixing rate and time are 24,000rpm and 2min, respectively;

[0037] (3) Compression molding: Preheat the CNT / GTR composite particles prepared in step (2) at 170° C. for 5 minutes, then hot press at 50 MPa for 10 minutes, and finally cool to room temperature to obtain the target product in sheet form.

Embodiment 2

[0039] Others are the same as in Example 1, the ratio of raw materials is GTR 99.2%; CNT 0.2%;

Embodiment 3

[0041] Others are the same as in Example 1, the ratio of raw materials is GTR 99.7%; CNT 0.3%;

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com